Online temperature detection device

A detection device and temperature detector technology, applied in the direction of measuring devices, thermometers, thermometers, etc., can solve the problems of the influence of finished product performance, great influence of finished product performance, large temperature error of sintered body, etc., and achieve convenient installation and disassembly, temperature Detecting Accurate and Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited thereby.

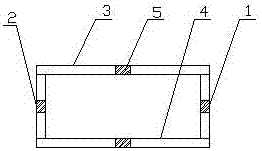

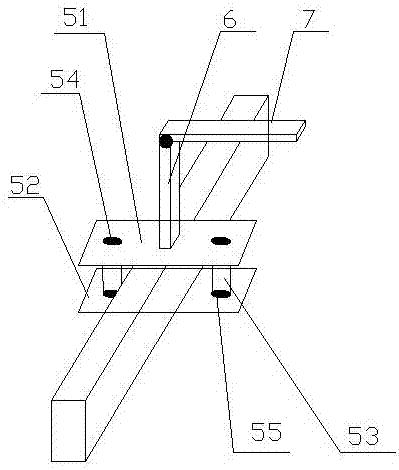

[0017] A temperature online detection device, such as Figure 1-2 As shown, including the kiln car entering and leaving the kiln, the outer frame of the front outer frame 1, rear outer frame 2, left outer frame 3, and right outer frame 4 of the kiln car is provided with a fixing seat 5, and the fixing seat includes an upper The fixed plate 51 and the lower fixed plate 52, the upper fixed plate 51 is provided with two first through holes 54 near the two ends, and the lower fixed plate is provided with a second through hole 55 adapted to the first through hole 54 , the upper fixing plate 51 and the lower fixing plate 52 are respectively located on the upper and lower sides of the same outer frame, the two first through holes 54 are respectively located on the left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com