Power battery temperature detection structure

A power battery, temperature sensor technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of inconsistent bonding positions, inconvenient operation and replacement, reduced production efficiency, etc., to achieve installation adaptability and versatility Good, convenient and quick installation and disassembly, accurate and reliable temperature detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

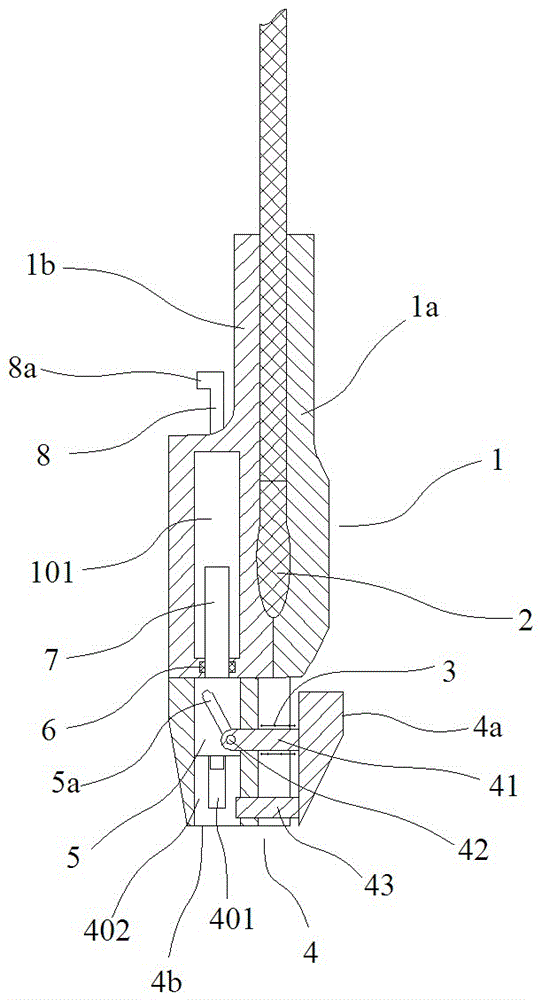

[0018] Such as figure 1 In the shown embodiment, a power battery temperature detection structure includes a body 1, a temperature sensor 2 and a guide positioning body 4, wherein the body includes a heat-conducting silica gel block 1a and an ordinary silica gel block 1b, and the heat-conducting silica gel block is made of heat-conducting silica gel , has the ability to transfer heat quickly, and the ordinary silica gel block is made of ordinary silica gel, which has a certain structural strength and softness. The temperature sensor is vertically arranged between the heat-conducting silica gel block and the ordinary silica gel block, the wires of the temperature sensor lead upwards, and the heat-conducting silica gel block and the ordinary silica gel block are bonded to ensure that the position of the temperature sensor is fixed and does not mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com