Patents

Literature

84results about How to "Avoid charring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC foaming wood plastic composite material

The invention discloses a PVC foaming wood plastic composite material which is produced by processing the raw materials based on the parts by weight: 100 parts of polyvinyl chloride (PVC), 40-50 parts of lignified plant fiber, 10-20 parts of active light calcium, 3-6 parts of calcium zinc complex stabilizer, 1-3 parts of compound-type foaming agent, 0.5-1.5 parts of lubricating agent OPE wax, 0.5-1 part of compound lubricating agent and 3-8 parts of foaming conditioning agent; the raw materials are evenly mixed by a mixing machine and then are directly put into a screw extruder to be extruded and molded at the temperature of 160-170 DEG C. The PVC foaming wood plastic composite material is added with full dose of heat stabilizer in the process of blending and processing, so that the degradation temperature of plastics can be increased, thermal degradation of the plastics and carbonization of wood powder in the process of mixing and forming can be prevented, and the operation of extruding and molding can be completed in one step, thus greatly simplifying the production technique and reducing the production cost.

Owner:石河子市森力新材料科技有限公司

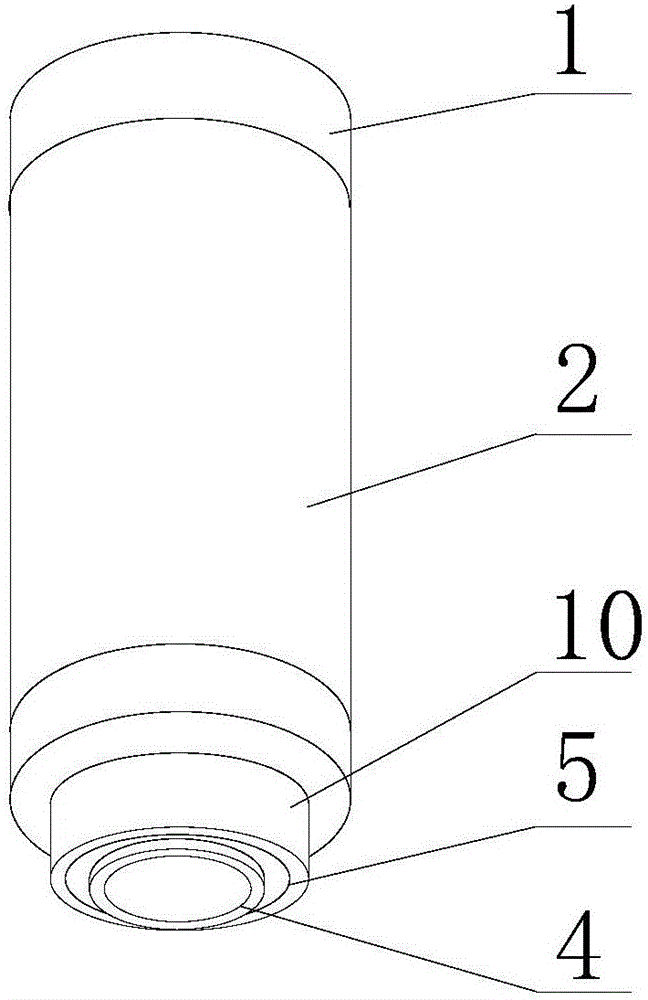

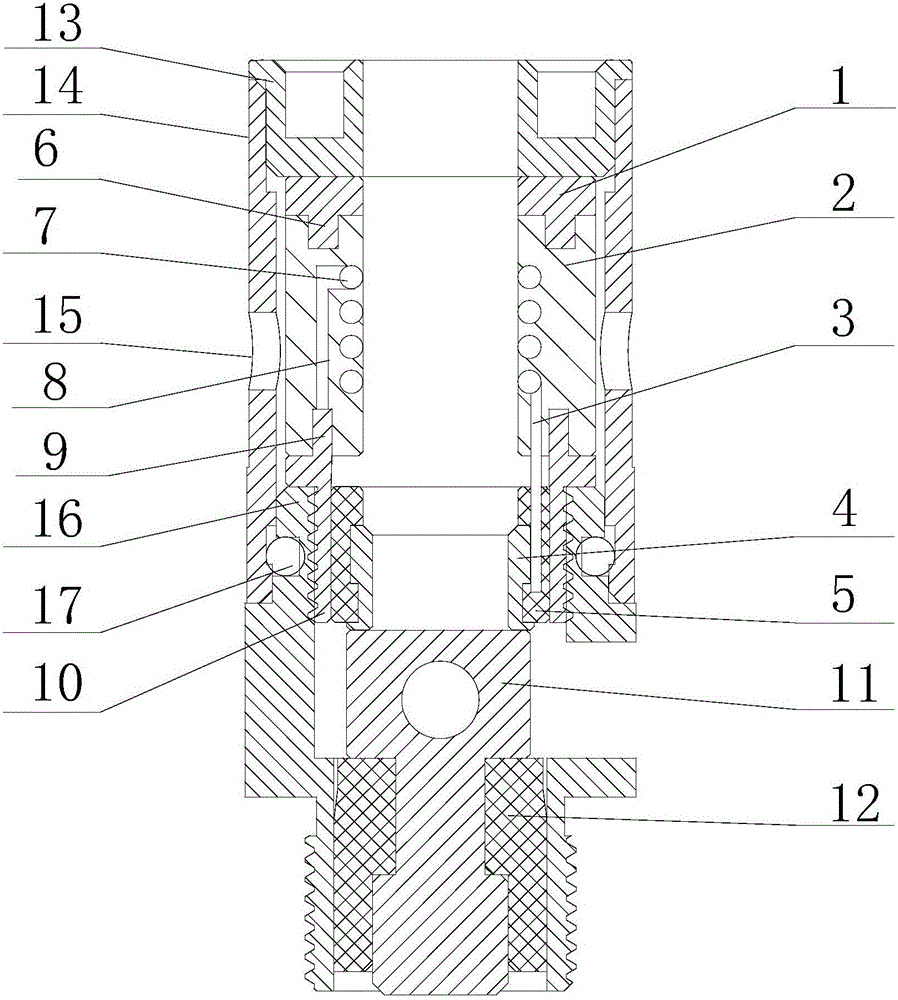

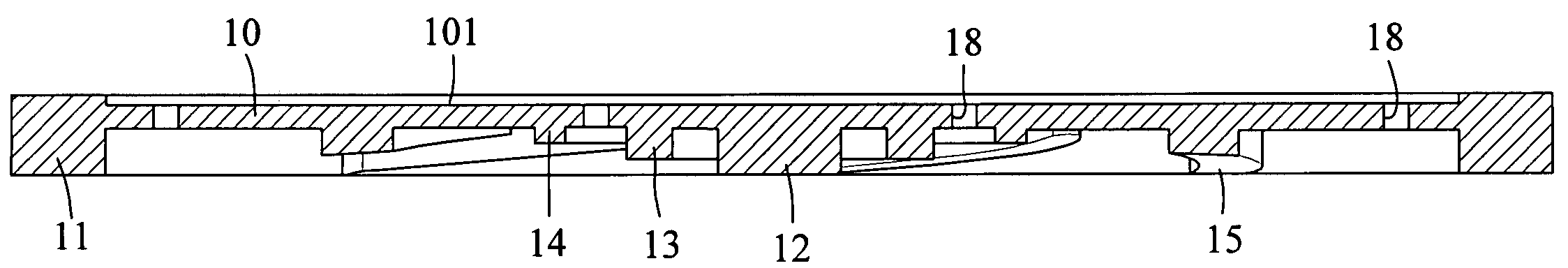

Ceramic composite electronic cigarette heating pipe and electronic cigarette atomizing core employing same

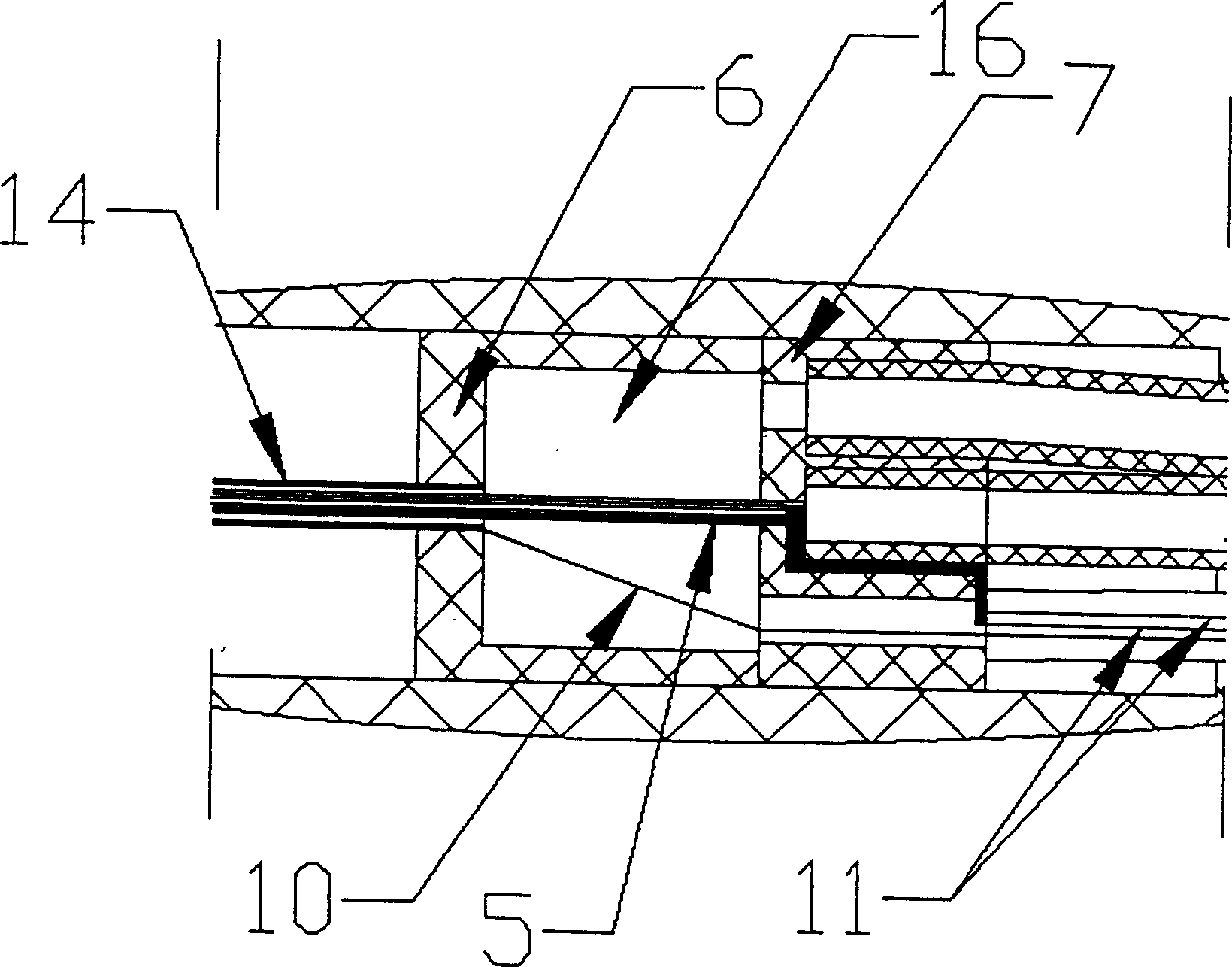

The invention discloses a ceramic composite electronic cigarette heating pipe which comprises an electric heating wire and a micro-porous ceramic pipe; a main body part of the electric heating wire is pre-embedded in the pipe wall of the micro-porous ceramic pipe; the electric heating wire is led out of the outside of the micro-porous ceramic pipe through connecting pins. A compact connecting piece is arranged at each of the upper and lower ends of the micro-porous ceramic pipe. The two connecting pins of the electric heating wire are lead out from the lower end of the micro-porous ceramic pipe; the compact connecting piece at the lower end is a metal connecting ring; a connecting pile protruding into the pipe wall of the micro-porous ceramic pipe is arranged on the upper side of the metal connecting ring. A double-electrode conductive connecting ring consists of an inner ring electrode and an outer ring electrode and is arranged on the lower side of the metal connecting ring; the outer ring electrode is electrically connected or integrally formed with the metal connecting ring; an insulating ring is arranged between the outer ring electrode and the inner ring electrode. The inner ring electrode and the outer ring electrode of the double-electrode connecting ring are respectively electrically connected with the two connecting pins of the electrical heating wire. When the heating pipe disclosed by the invention is in use, the double-electrode conductive connecting ring and a double-electrode conductive connecting column of an atomizing core are designed to be in threaded connection for realization.

Owner:INNOKIN TECH

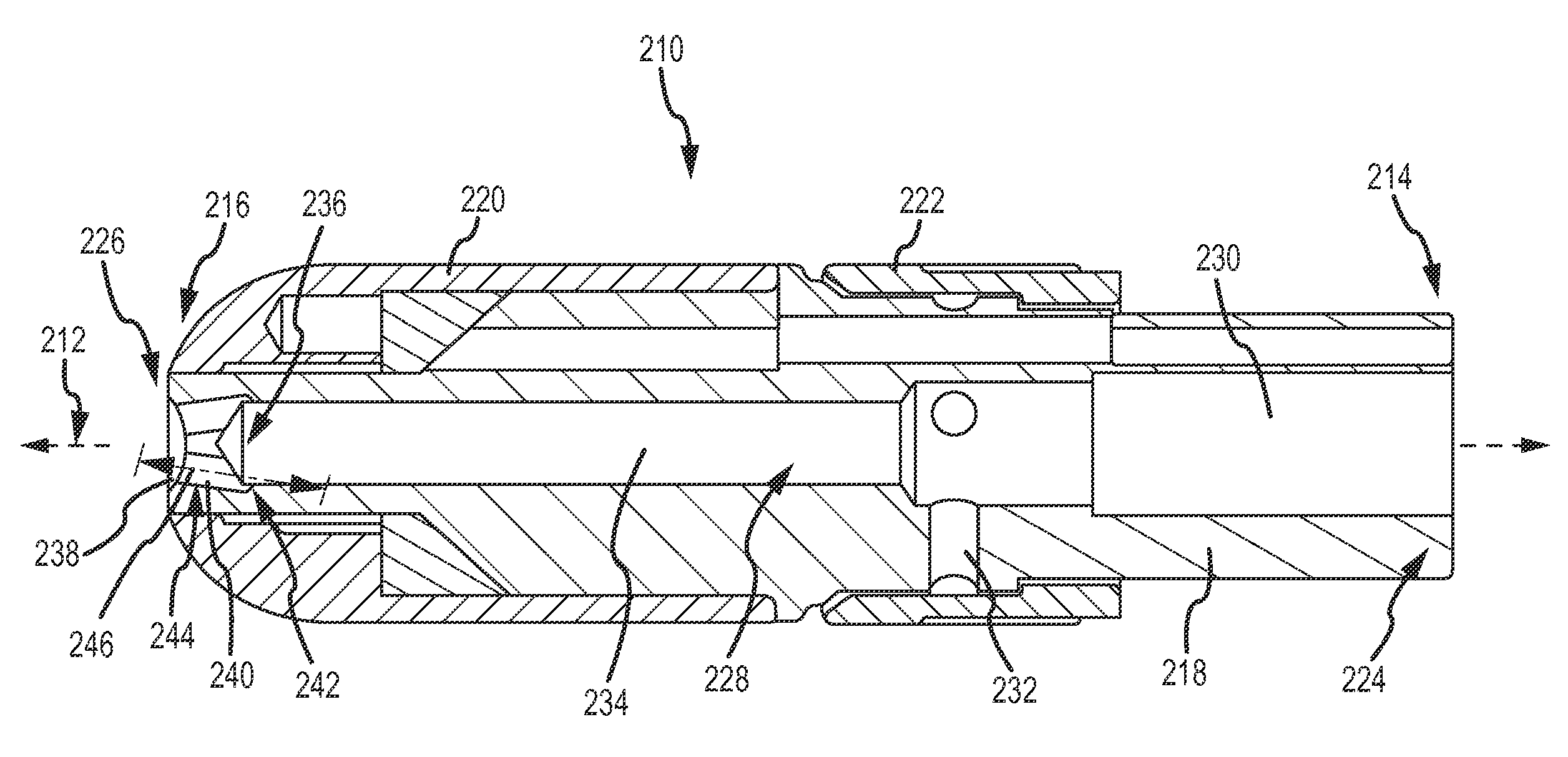

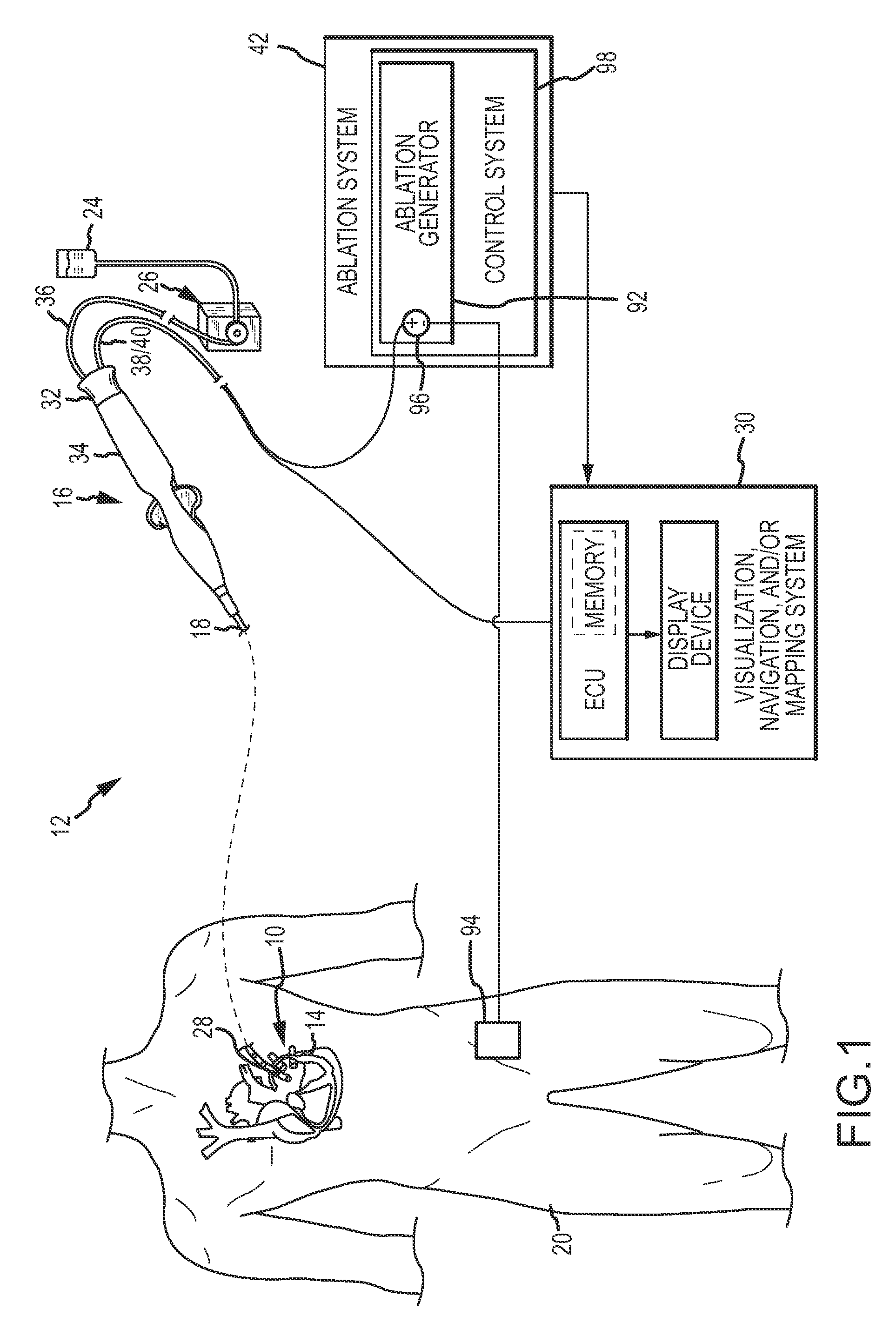

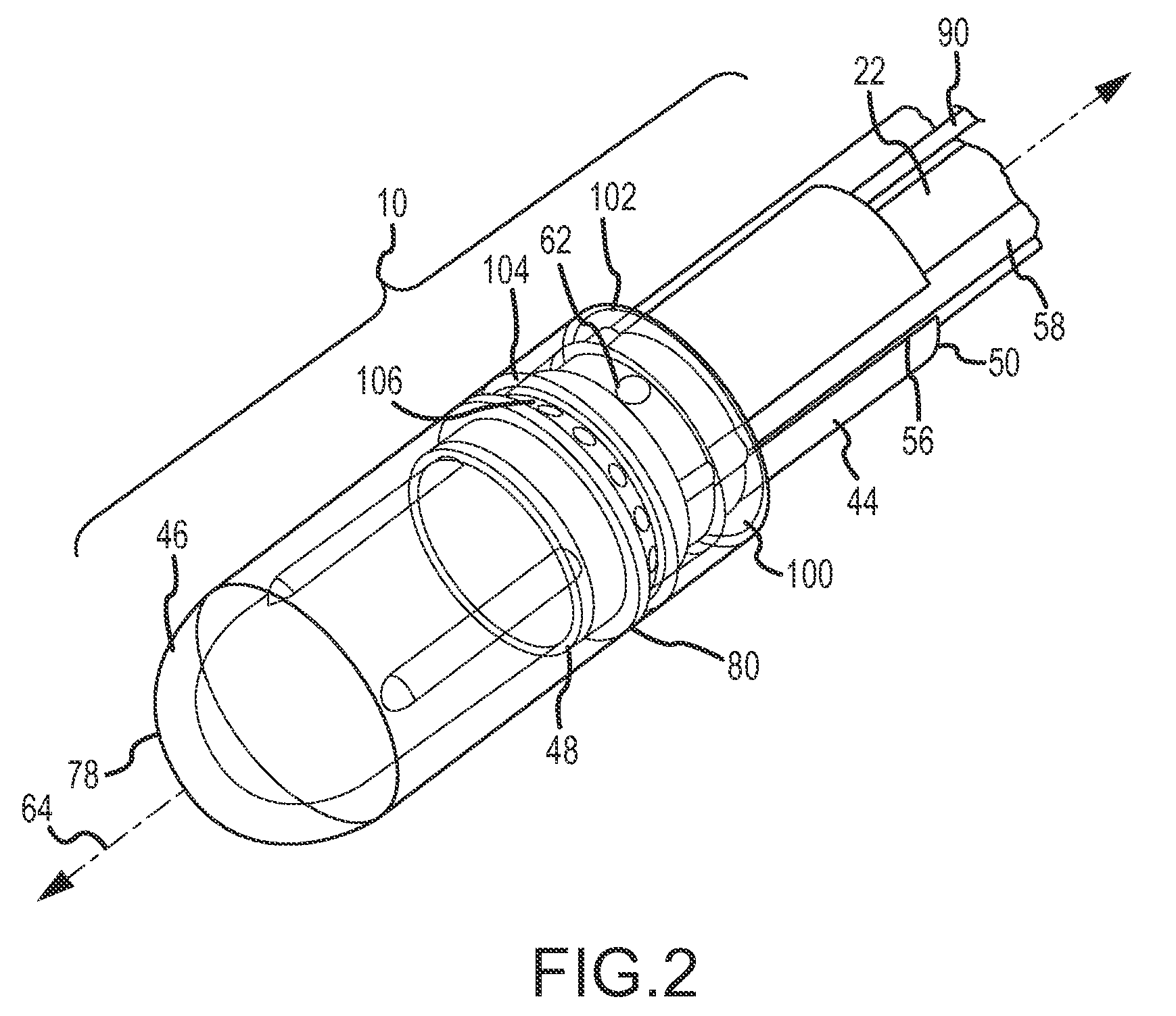

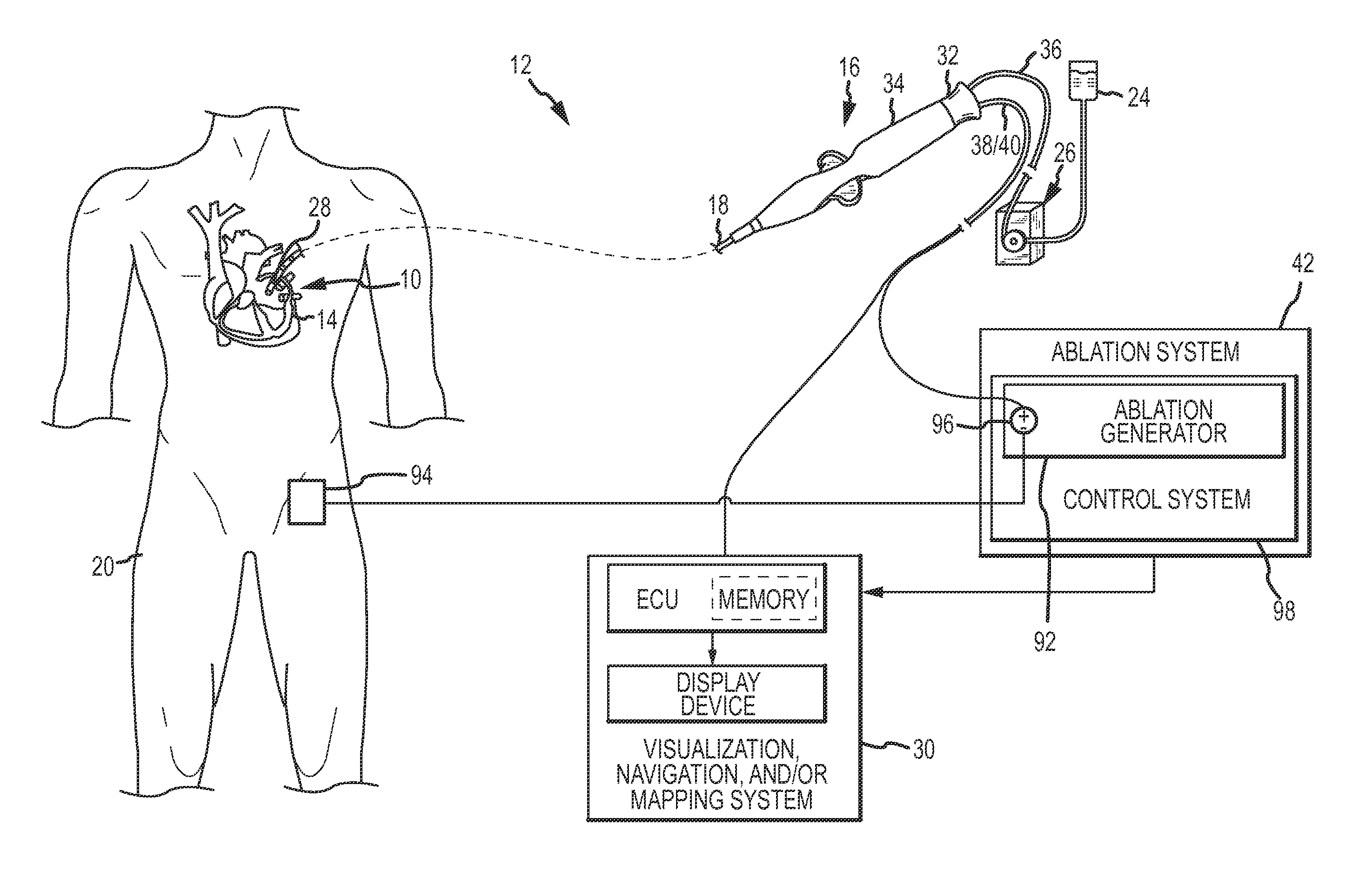

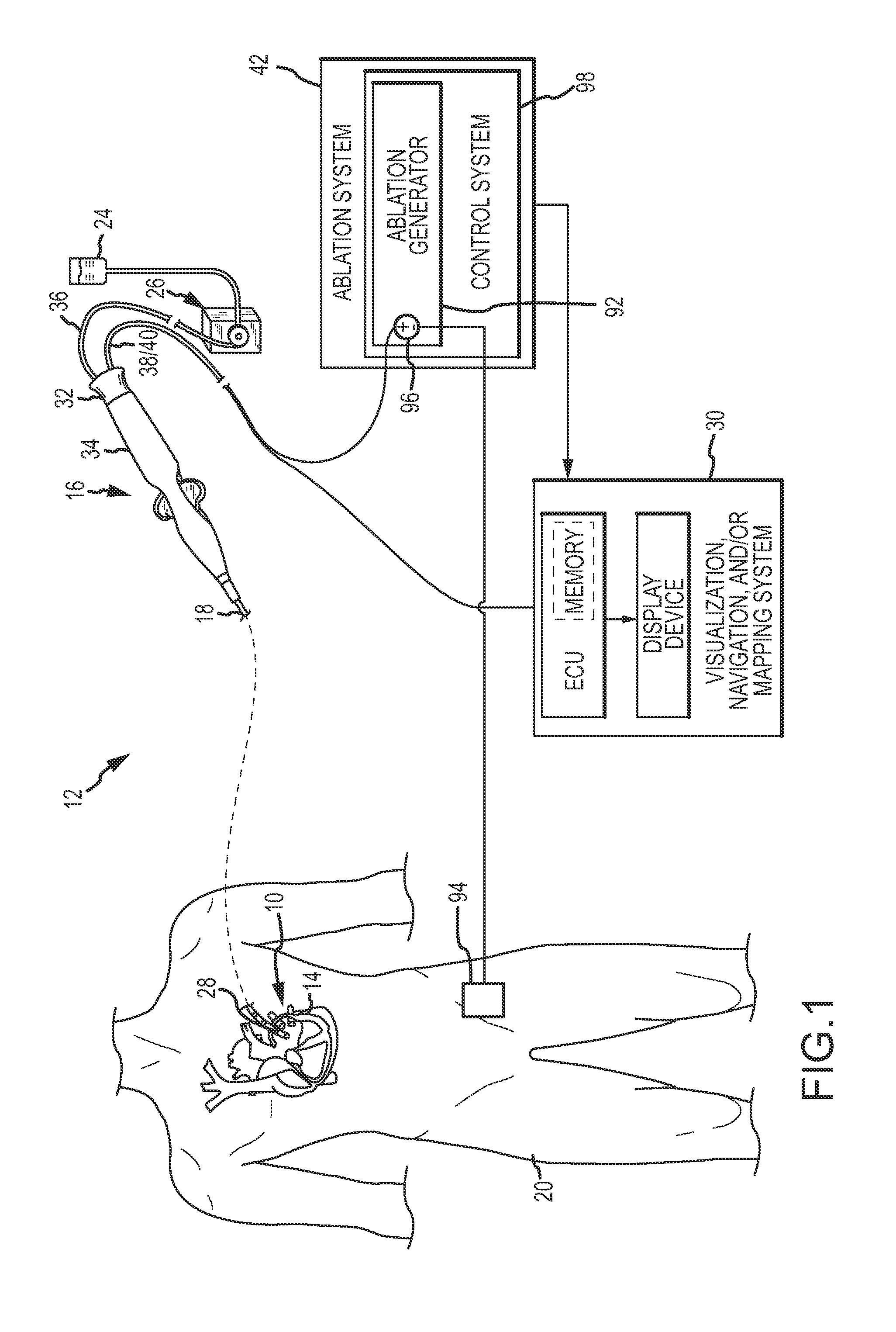

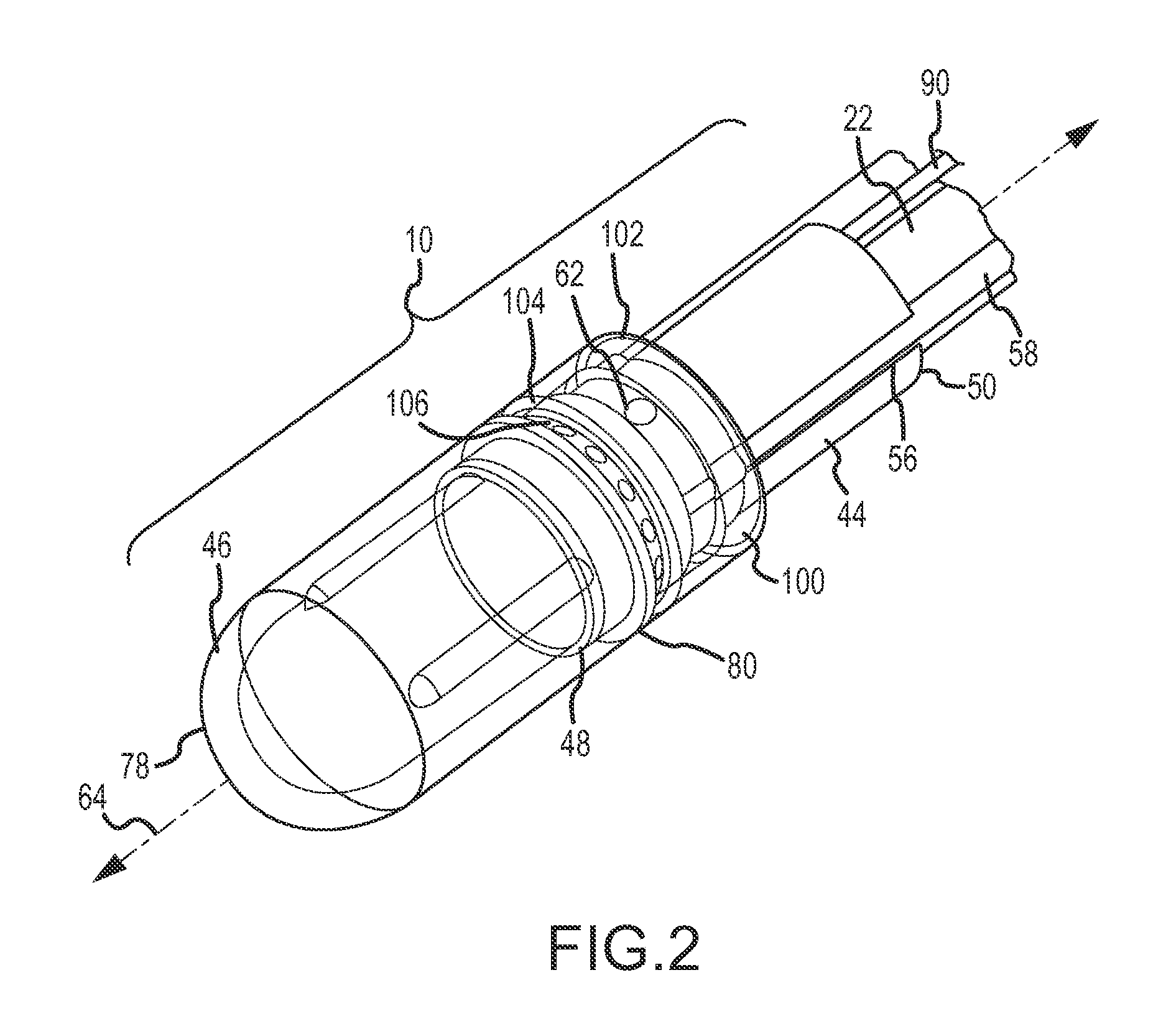

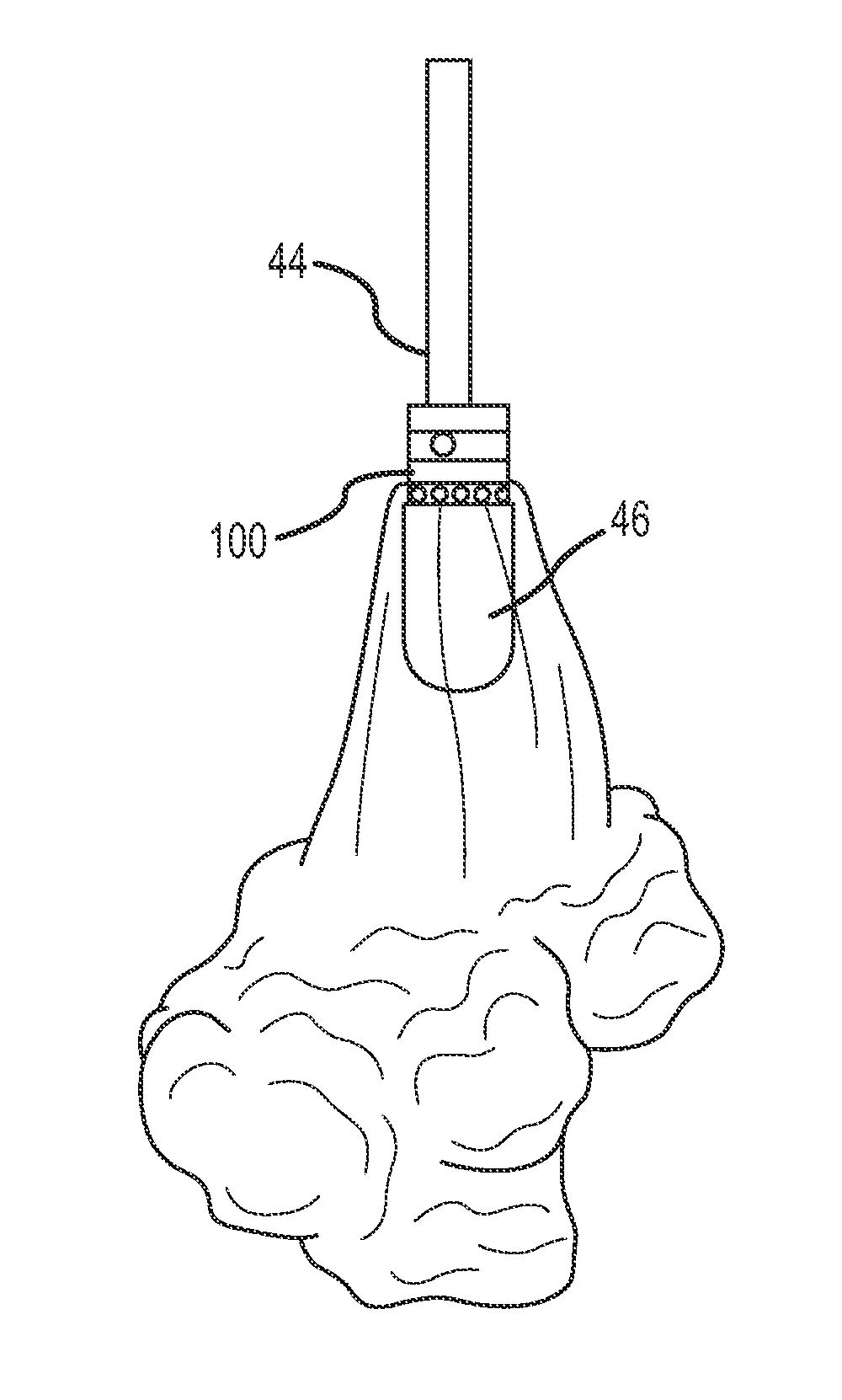

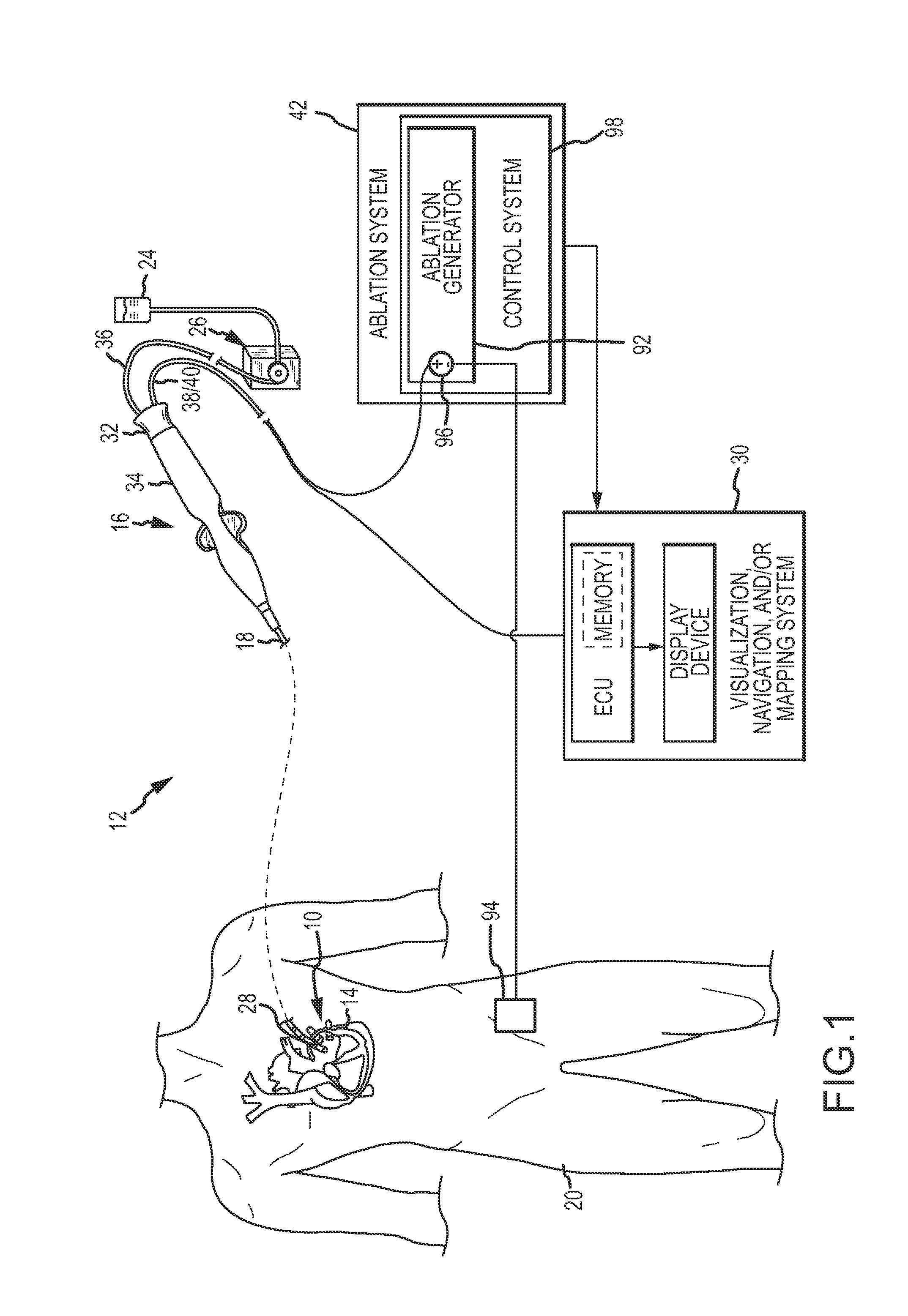

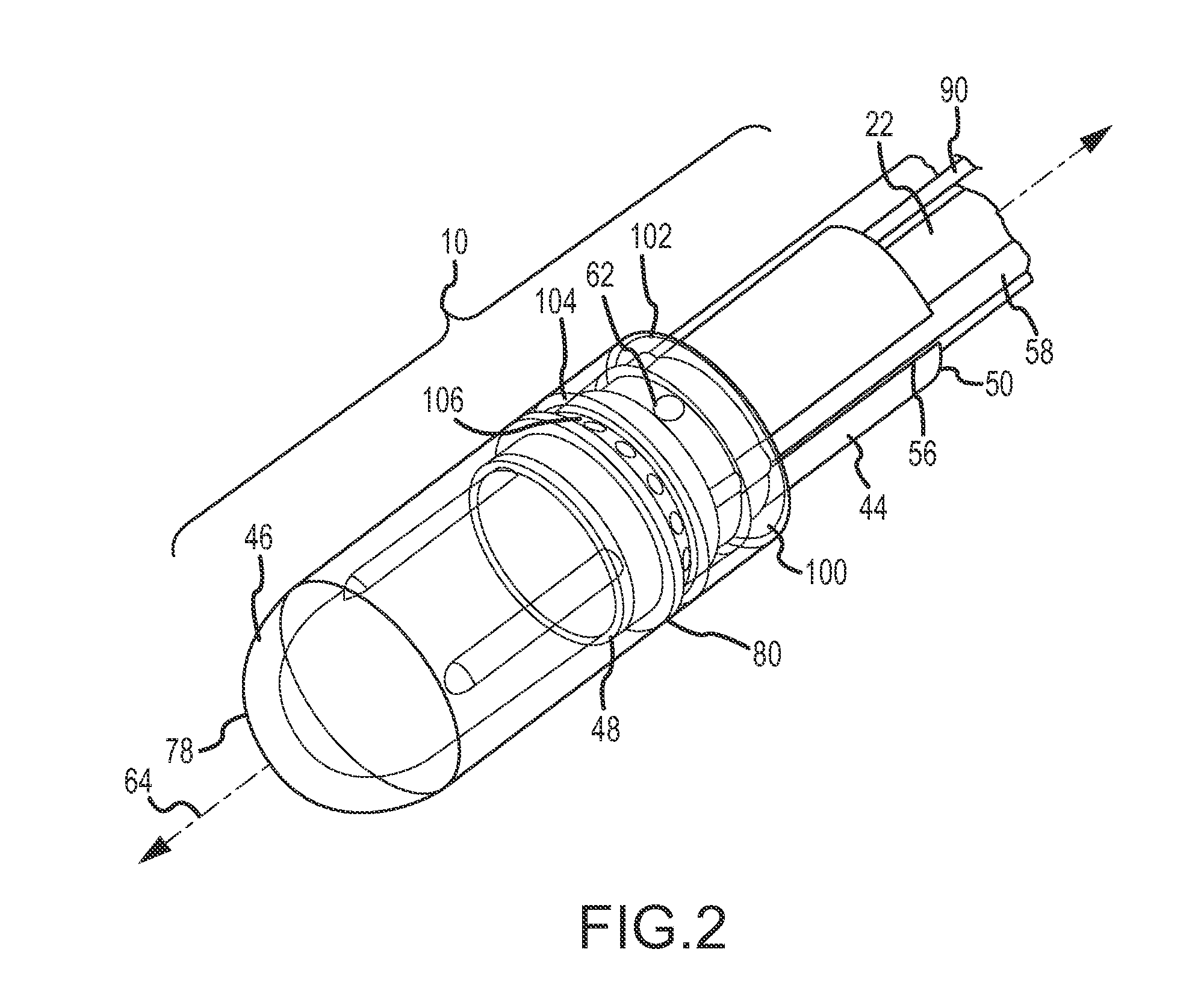

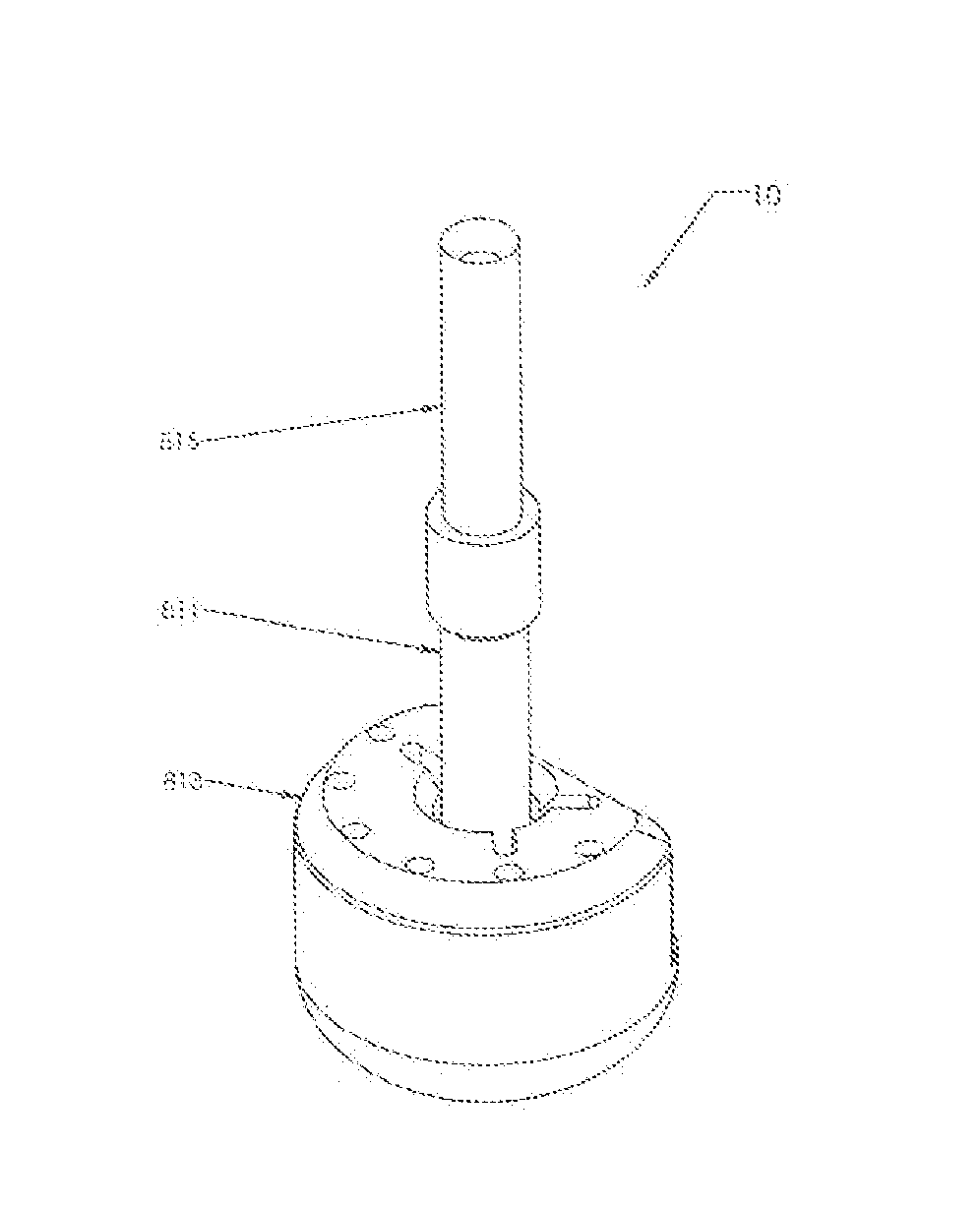

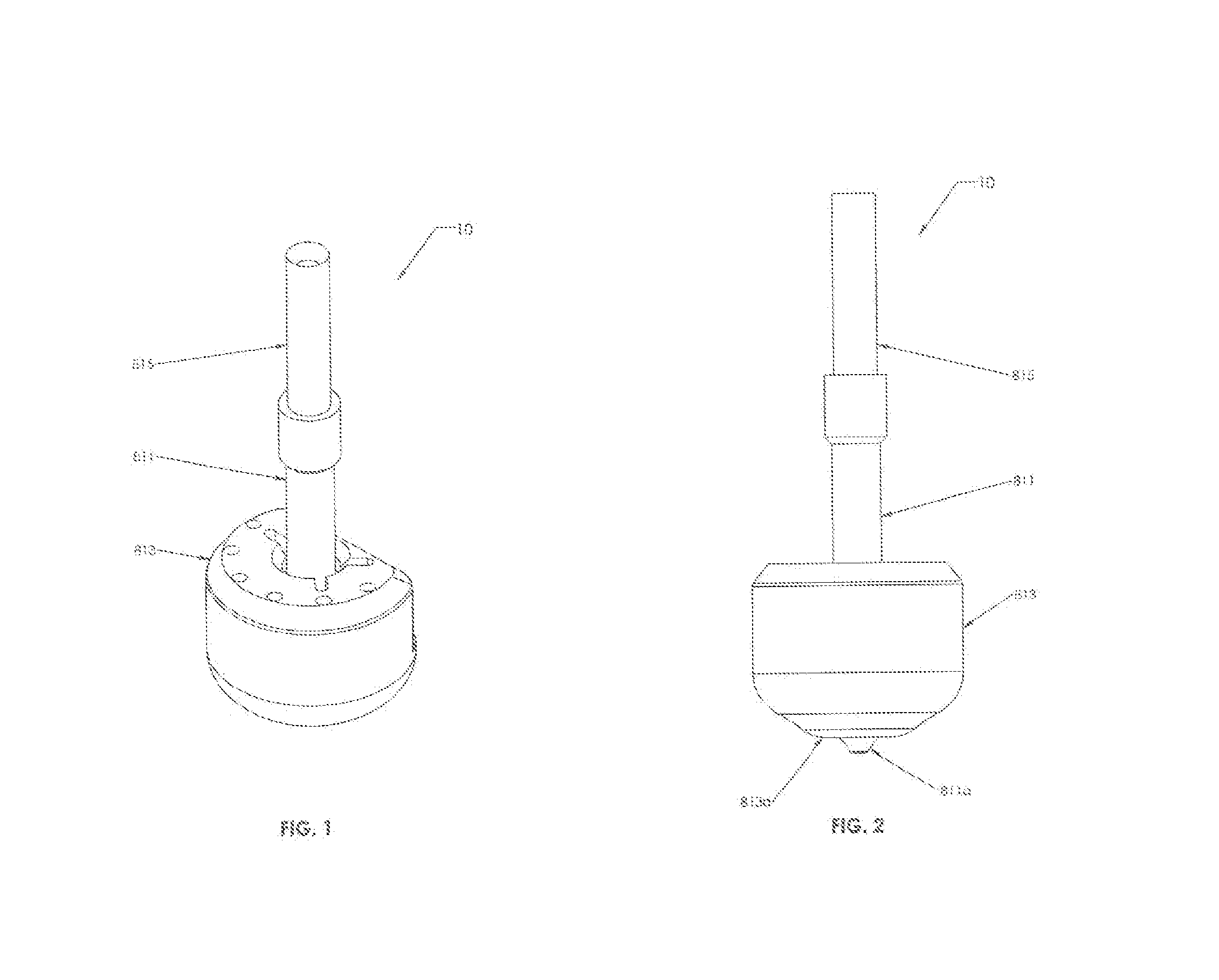

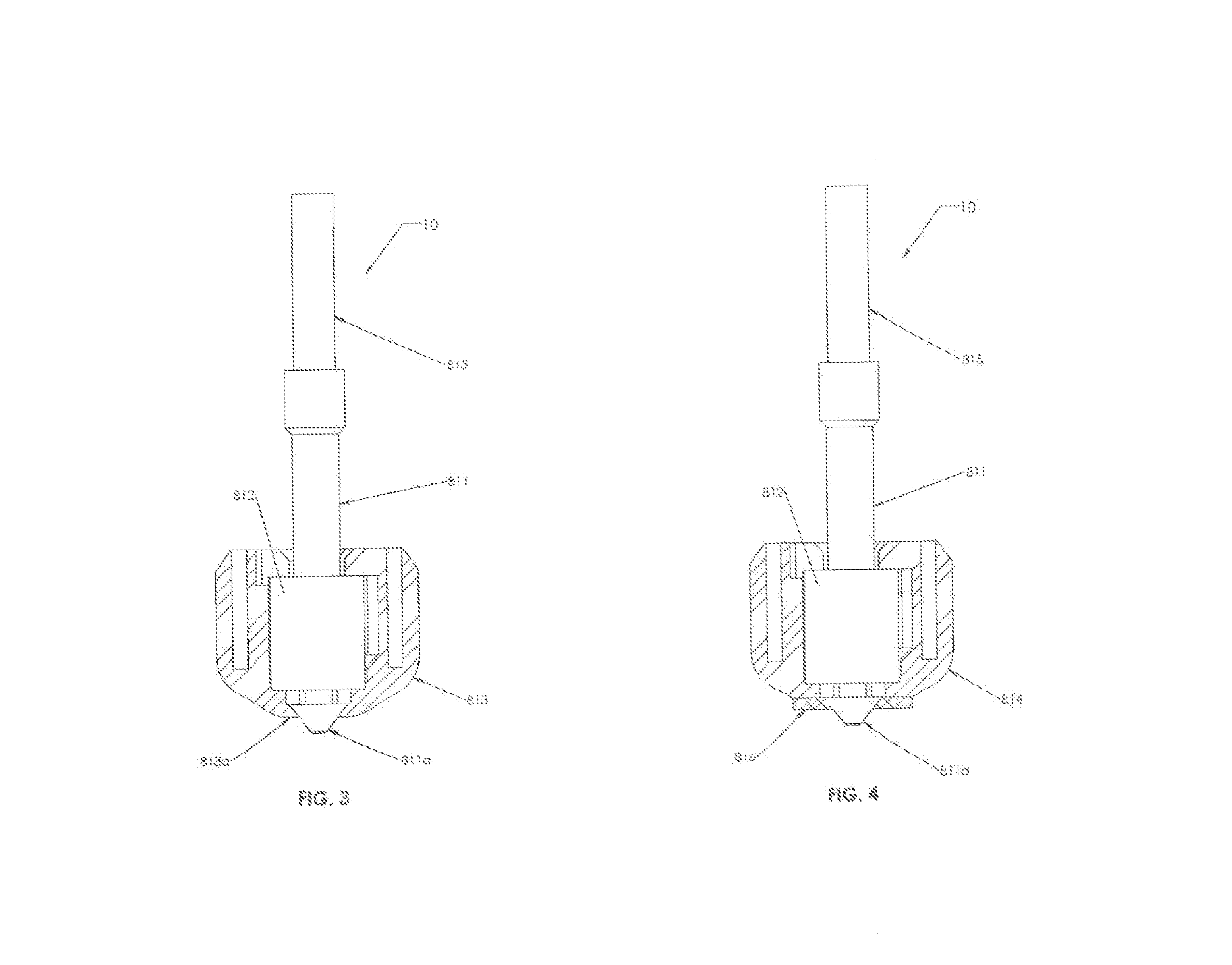

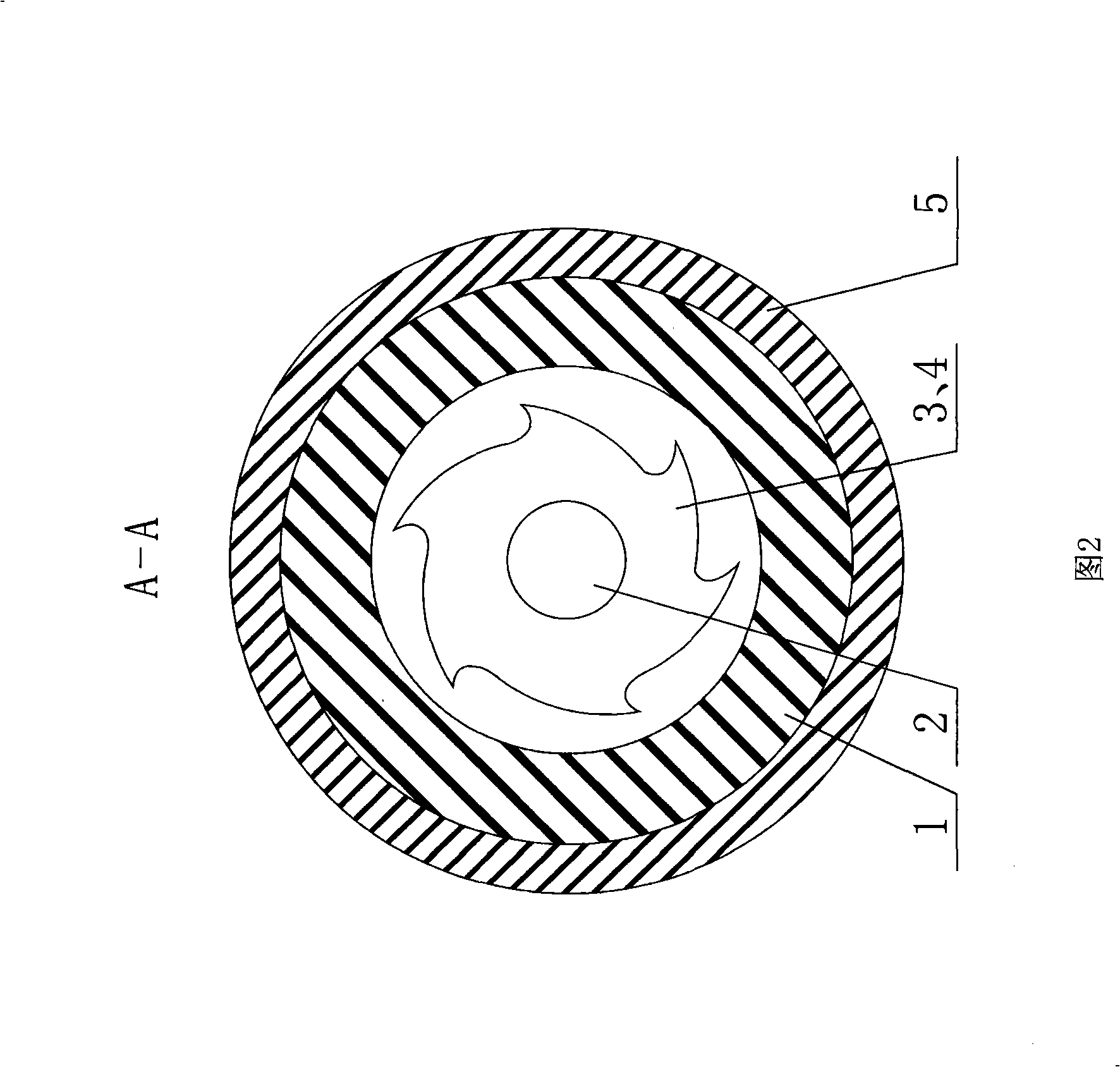

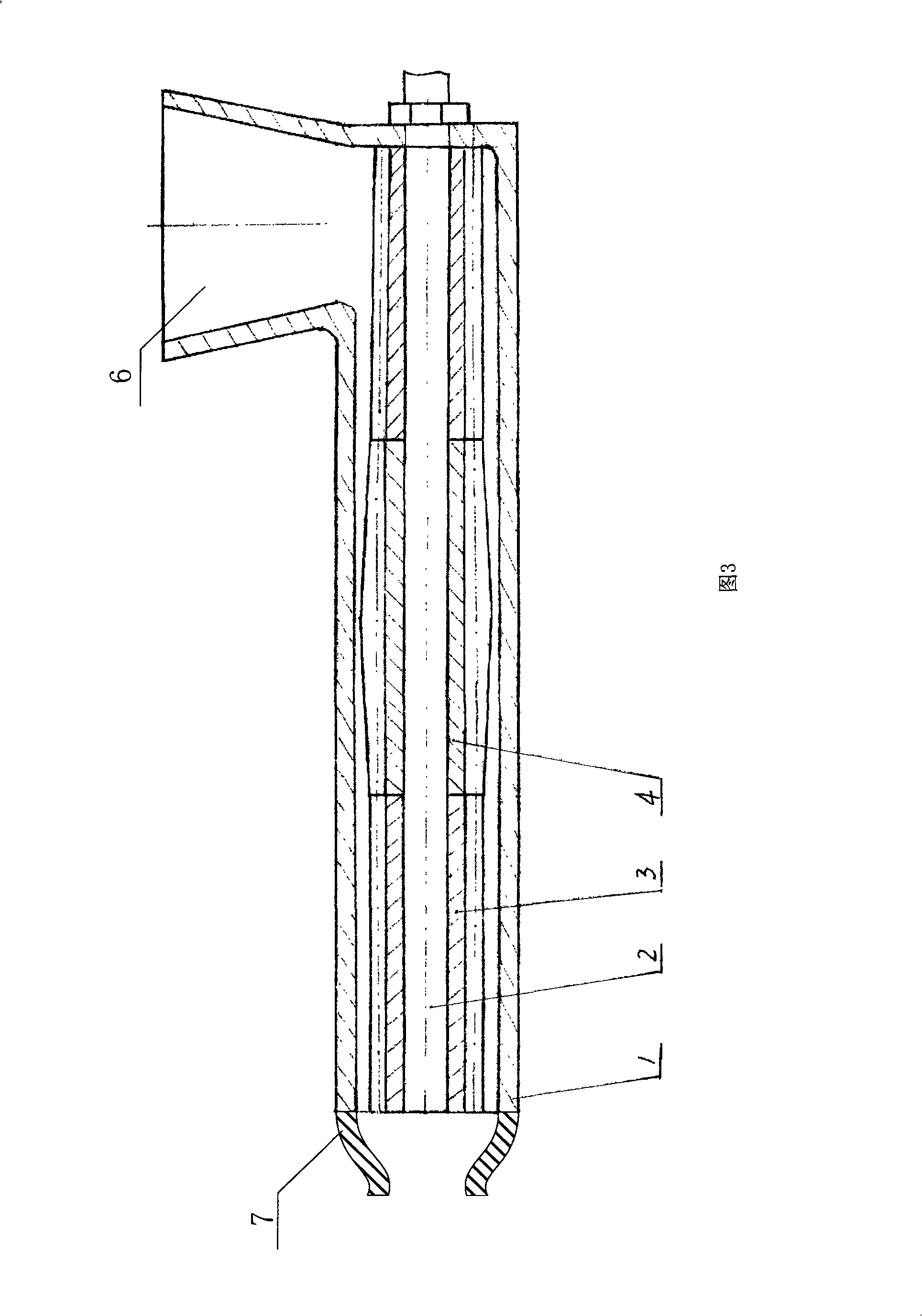

Irrigant distribution system for electrodes

ActiveUS9066725B2Improved temperature correlationReduce formationSurgical instruments for heatingCoatingsDistribution systemBiomedical engineering

An ablation electrode assembly is provided with improved irrigation cooling of the assembly and ablation site. The assembly includes a proximal end configured to be coupled to a catheter shaft and a distal end configured to deliver ablation energy to tissue. The assembly further includes a fluid manifold extending from the proximal end to the distal end and configured to fluidly communicate with a fluid lumen in the catheter shaft. The fluid manifold defines an axial passageway centered about a longitudinal axis extending in the longitudinal direction of the assembly. The axial passageway has a distal end terminating prior to the distal end of the electrode assembly. The assembly further includes means for creating turbulence in fluid exiting the first axial passageway.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Irrigant distribution system for electrodes

ActiveUS20140163548A1Promote dilution and movementImproved temperature correlationSurgical instruments for heatingCoatingsDistribution systemIrrigation

An ablation electrode assembly is provided with improved irrigation cooling of the assembly and ablation site. The assembly includes a proximal end configured to be coupled to a catheter shaft and a distal end configured to deliver ablation energy to tissue. The assembly further includes a fluid manifold extending from the proximal end to the distal end and configured to fluidly communicate with a fluid lumen in the catheter shaft. The fluid manifold defines an axial passageway centered about a longitudinal axis extending in the longitudinal direction of the assembly. The axial passageway has a distal end terminating prior to the distal end of the electrode assembly. The assembly further includes means for creating turbulence in fluid exiting the first axial passageway.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

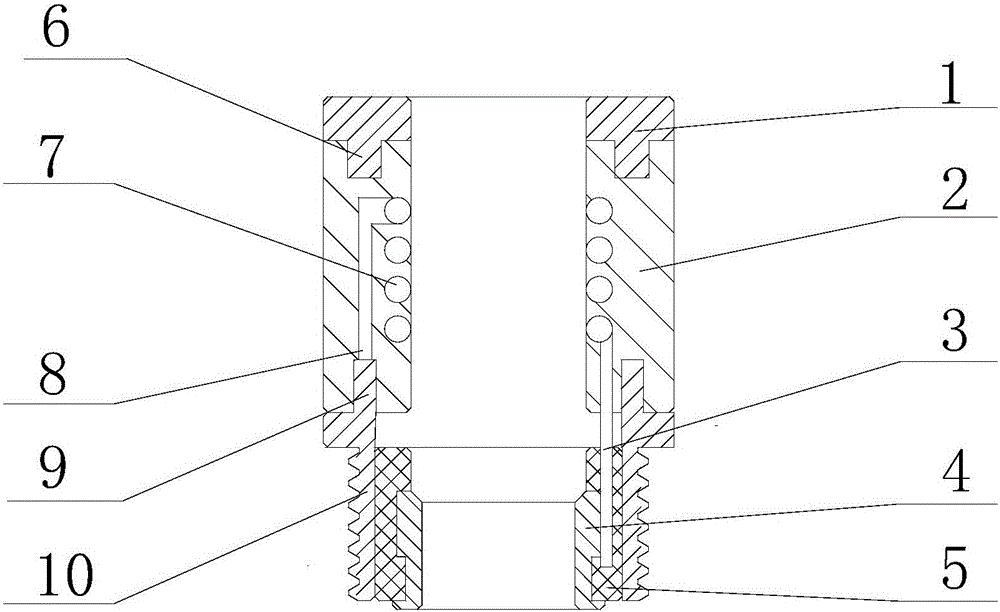

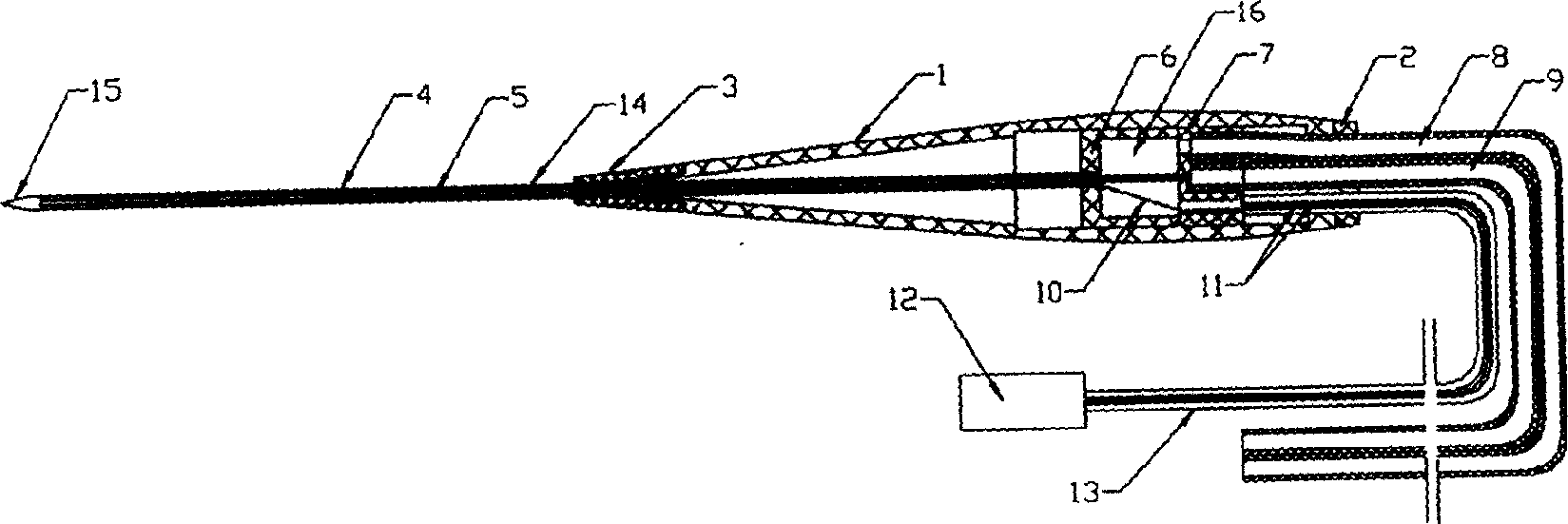

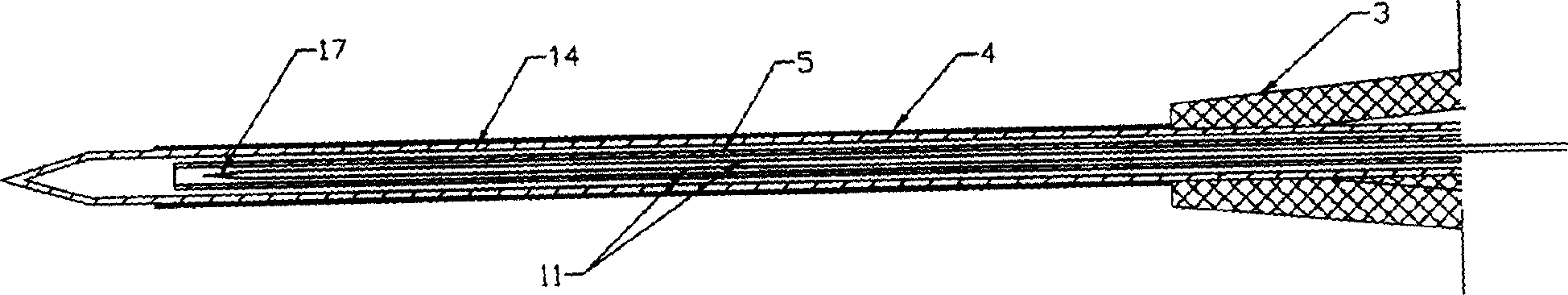

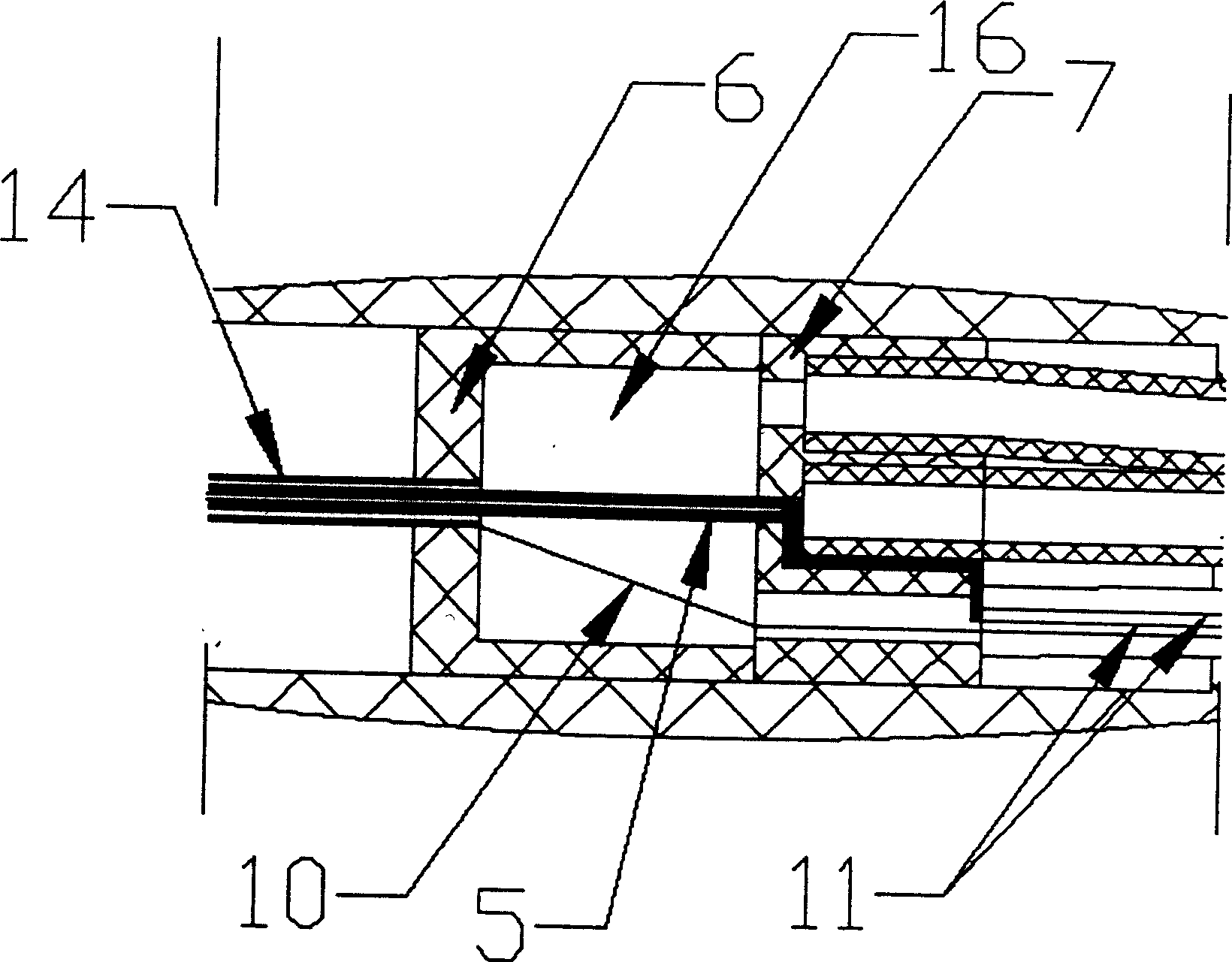

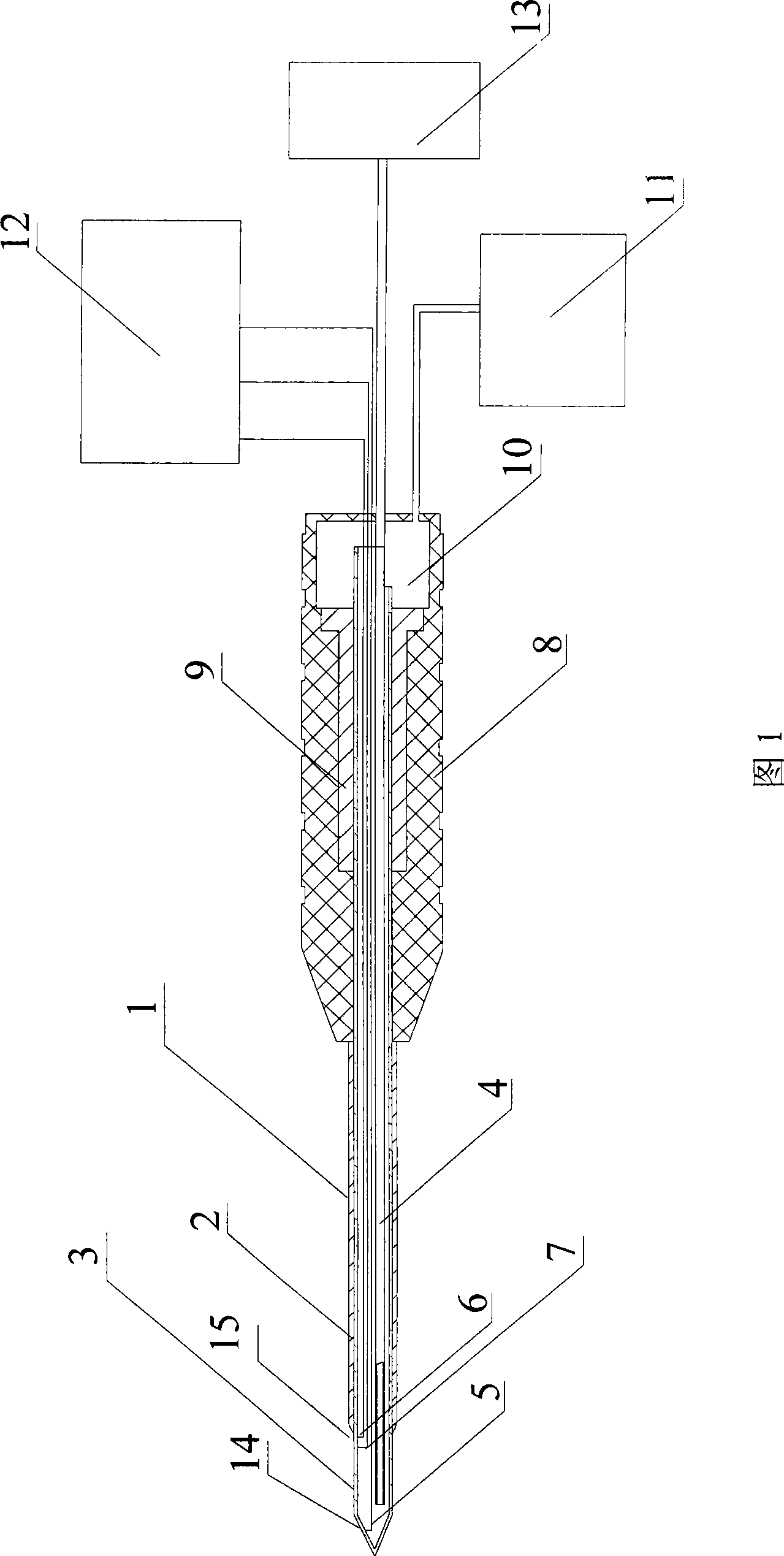

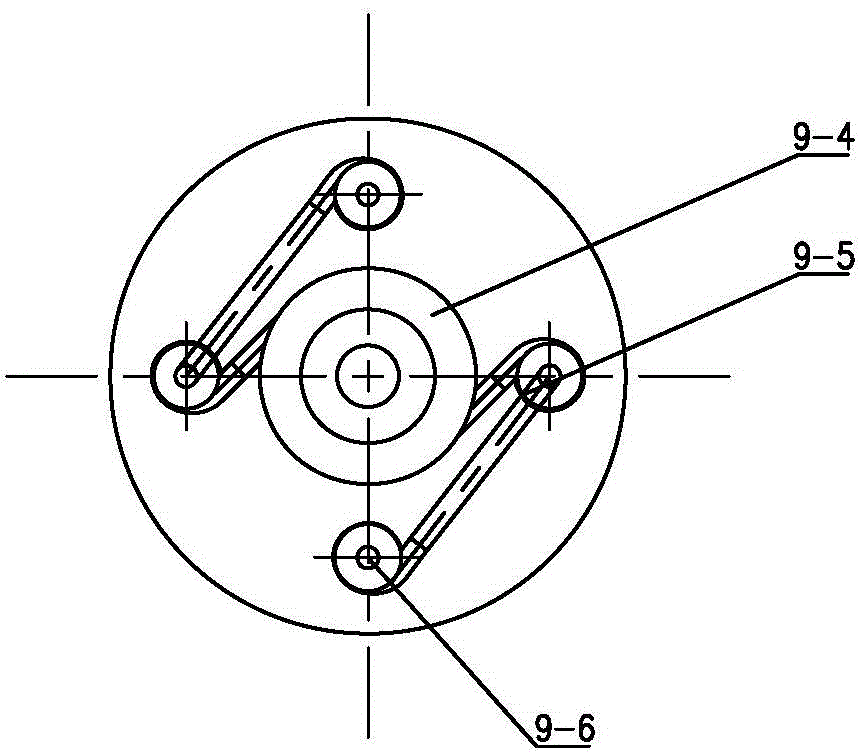

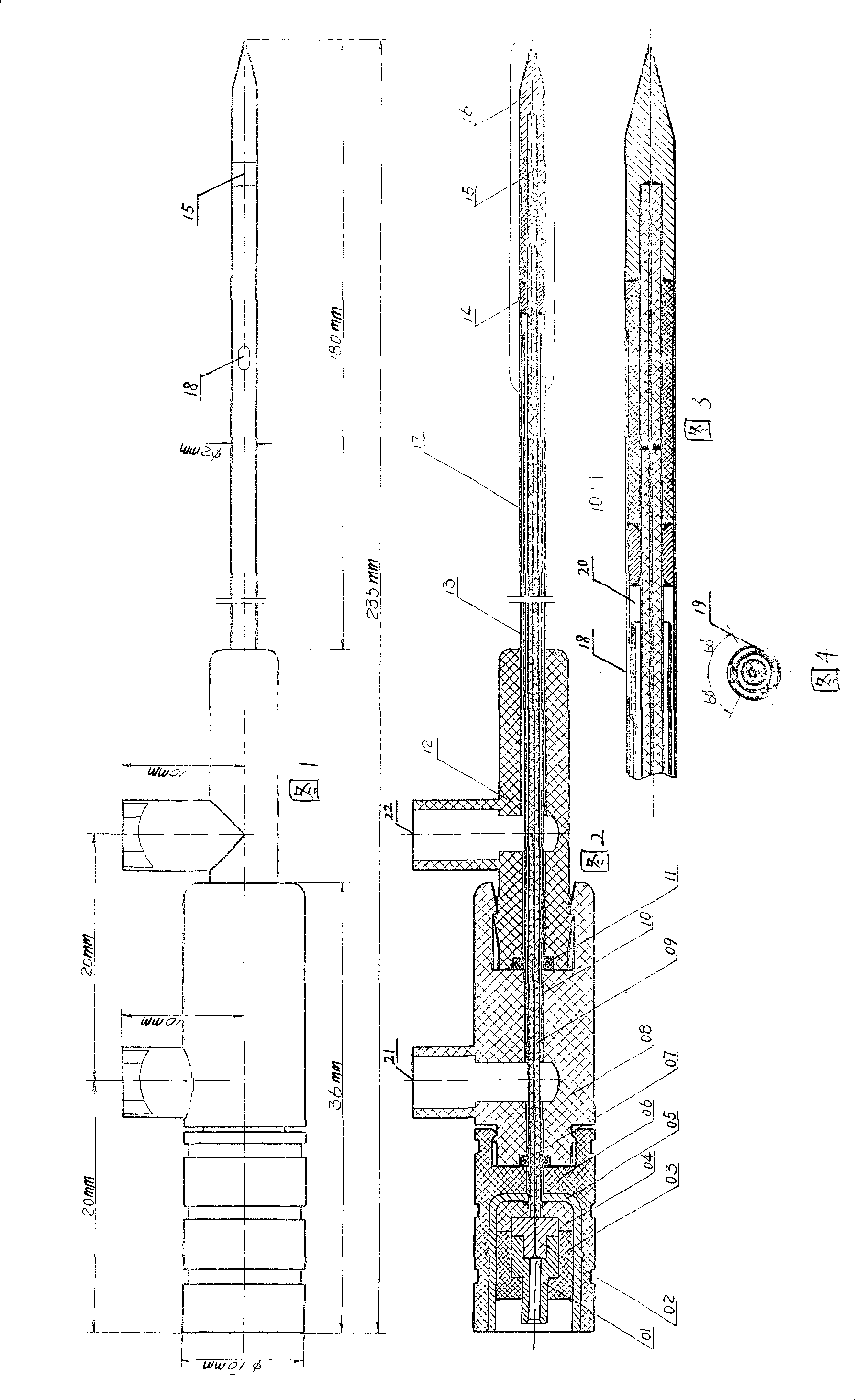

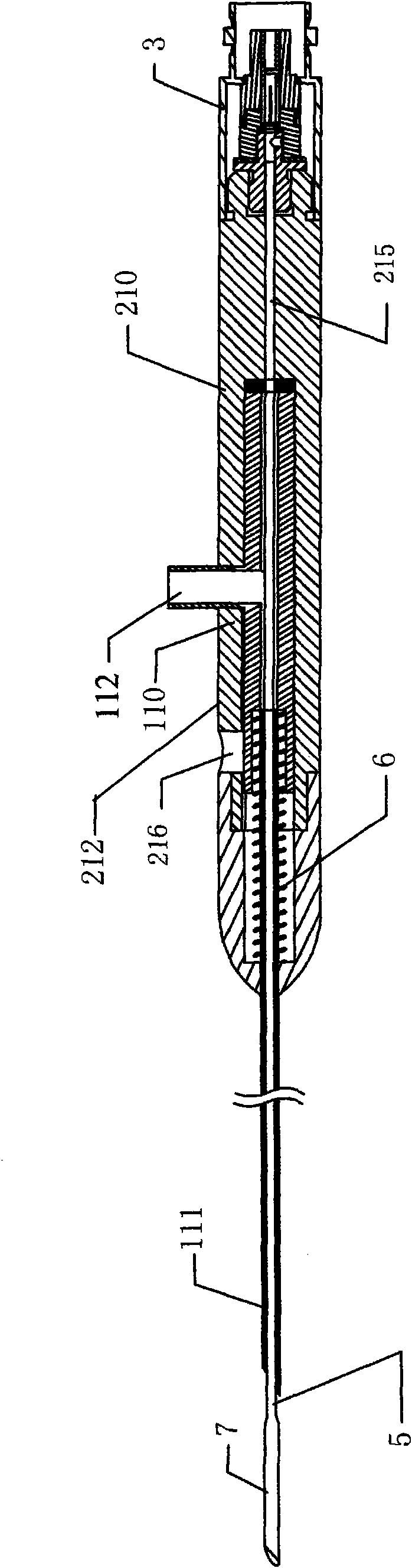

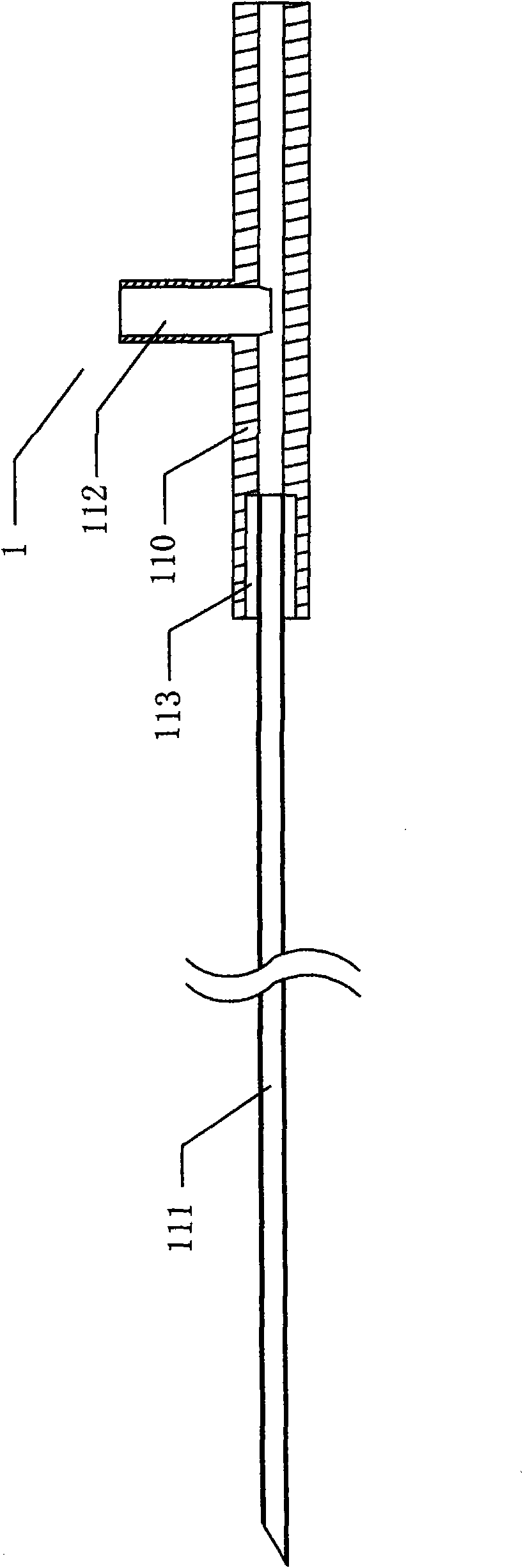

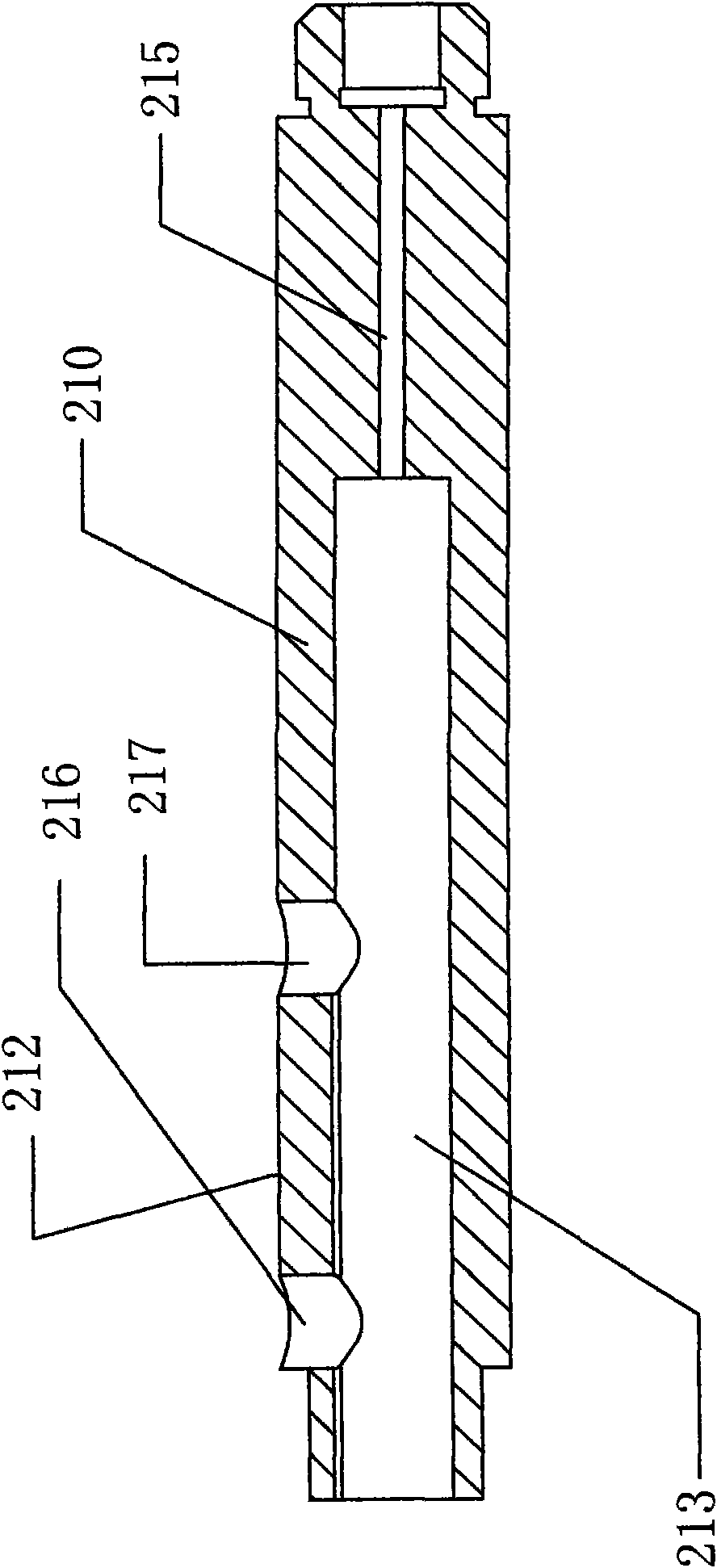

Single needle water cooling type radio frequency ablation electrode

InactiveCN1554314AReliable cauterizationAccurate insertionSurgical instruments for heatingRf ablationRadio frequency

The single needle water cooling type RF ablation electrode has support frame inside handle matching and inserting into the water storing frame, middle cavity to form cooling water return pool, electrode needle with insulating material coated and scaled front section, bare tip and back section inserted inside the handle and connected to RF wire, built-in water guiding steel pipe, and temperature metering thermocouple inserted into the electrode needle in the coaxial position. The water inlet hose is connected to the built-in water guide steel pipe, water outlet hose connected to the cooling water return pool, and the RF wire and the thermocouple constitute the connecting cable connected to the system unit of the RF ablation system for signal transmission. The cooling water circulates in the system. The present invention has novel structure, great and controllable ablation range and high safety and reliability.

Owner:SHANGHAI JIAO TONG UNIV

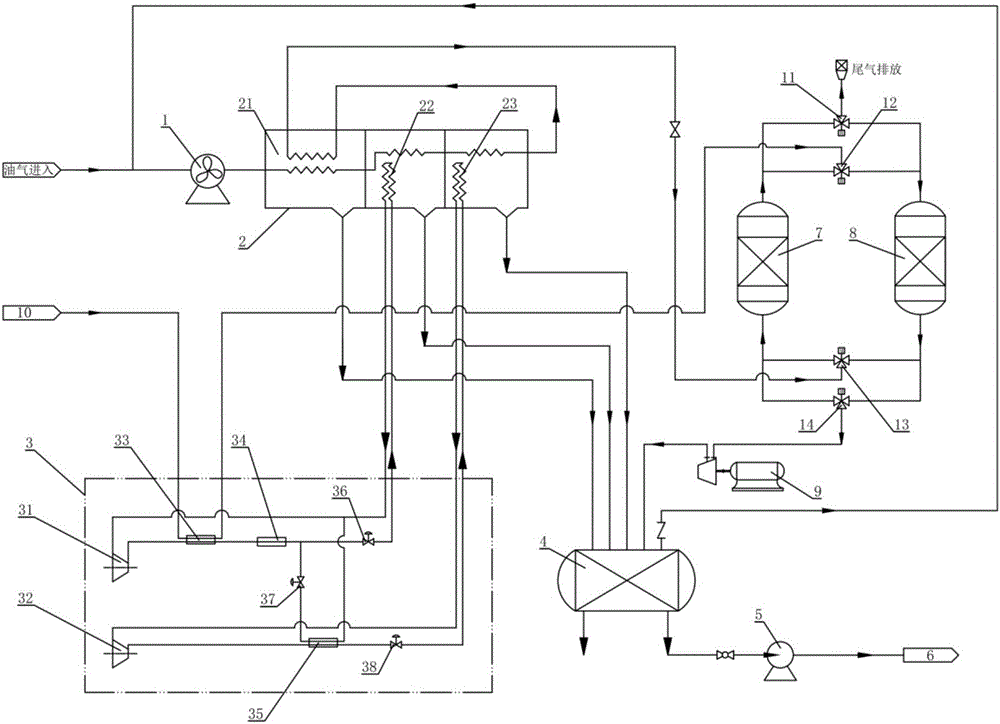

Oil gas recovery device and method

InactiveCN106166399AReduce energy consumptionEliminate potential safety hazardsGas treatmentMultiple-effect/fractional condensationAutomatic controlDesorption

The invention relates to an oil gas recovery device, comprising an anti-exposure centrifugal fan, a cold box, a refrigeration unit, a liquid storage tank, a liquid return pump, an oil storage tank, a first adsorption tank, a second adsorption tank, a vacuum pump, a nitrogen making unit, and Including the PLC automatic control system; the oil and gas are first transported into the cold box by the anti-exposure centrifugal fan, and the liquid oil condensed by the pre-cooling part, the first-level condensing part and the second-level condensing part of the cold box is sent to the liquid storage tank, and then returned to the storage tank. The liquid pump is sent to the oil storage tank for recovery; the oil and gas from the secondary condensing part are sent to the first adsorption tank after the heat is raised by the pre-cooling part, and the first adsorption tank and the second adsorption tank are cycled for adsorption and desorption. When the first adsorption tank or the second adsorption tank enters the desorption stage, the vacuum pump is turned on, and when the vacuum degree of the adsorption tank reaches the set value, the hot nitrogen gas is turned on to desorb the oil and gas with the hot nitrogen gas. By utilizing the advantages of the condensation method and the adsorption method to optimize the combination, the purpose of reducing energy consumption and eliminating potential safety hazards is achieved.

Owner:QUANZHOU TIANLONG ENVIRONMENTAL ENG

Colored STUCCO wall decoration mortar and construction process thereof

The invention discloses colored STUCCO wall decoration mortar, relating to the field of building interior and exterior wall decoration and protection. The colored STUCCO wall decoration mortar comprises the components of: silicate cement, aluminate cement, anhydrite, quartz sand, re-dispersible latex powder, lignocellulose, cellulose ether, a moisture repellent and ferric oxide series pigments. The invention also discloses a construction process of the colored STUCCO wall decoration mortar, which comprises the following steps of: cleaning the wall base surface; leveling the wall base surface by using interface mortar; preparing the colored STUCCO wall decoration mortar; flatly spreading the colored STUCCO wall decoration mortar on the leveled interface mortar; and coating a protective paint. The invention aims at providing the colored STUCCO wall decoration mortar and the construction process thereof. Colored fair-faced concrete layers can be simply and conveniently constructed on different base surfaces by using the colored STUCCO wall decoration mortar, and no high-alkaline environment can be caused by the concrete pouring process to damage cement color.

Owner:SHENZHEN SIMON BUILDING MATERIAL

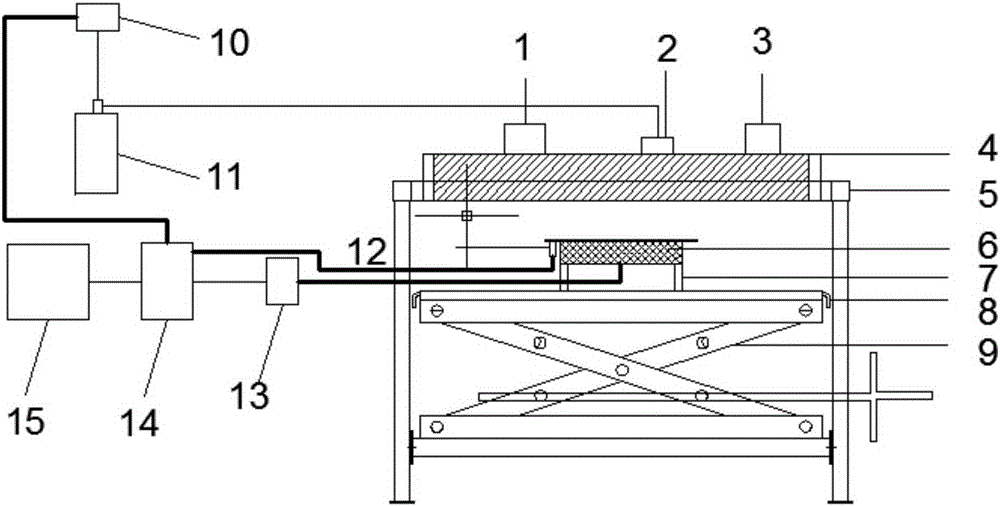

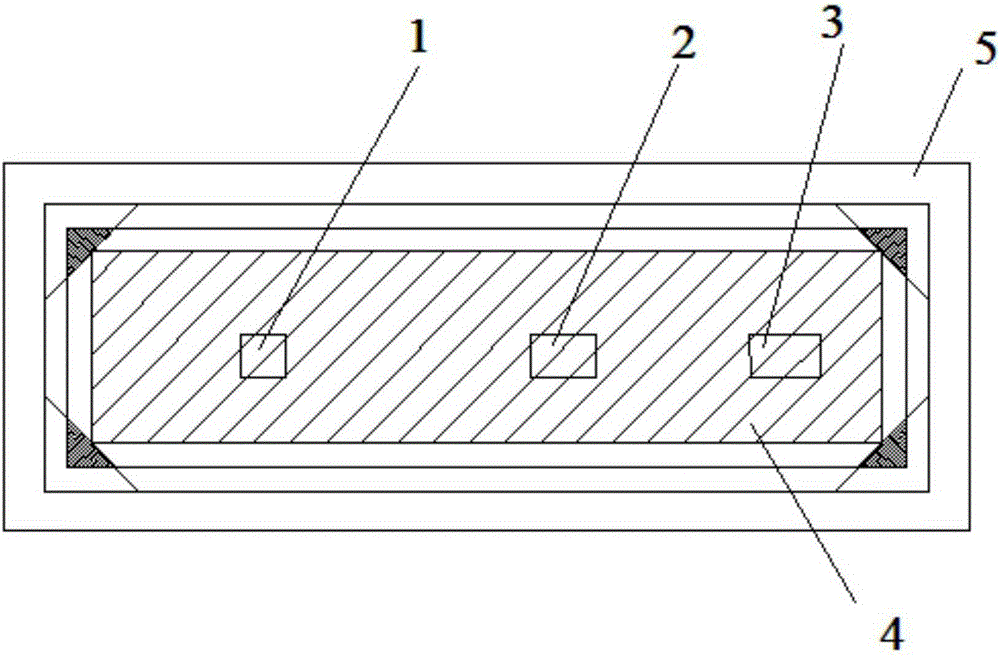

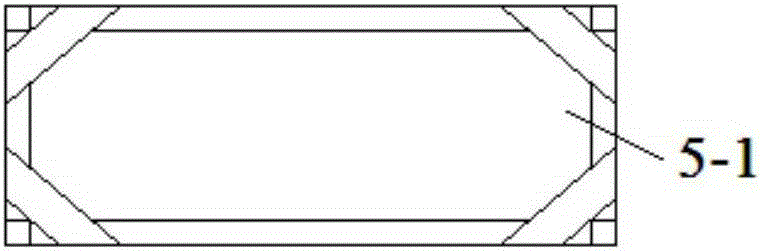

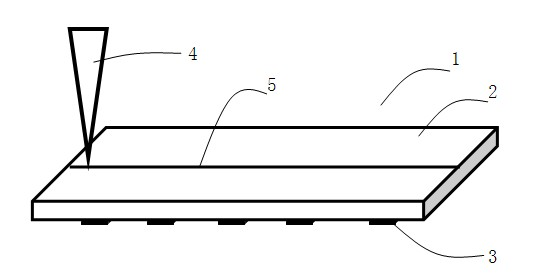

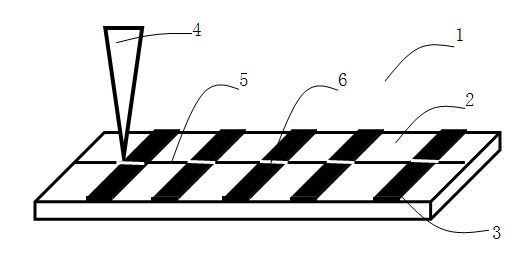

Infrared heating testing device and testing method for bituminous pavement

InactiveCN105319238AImprove heating efficiencyMeet the requirements of hot-in-place regenerationMaterial heat developmentInfraredData acquisition

The invention discloses an infrared heating testing device and testing method for bituminous pavement, and aims to enable the measured test data conclusion to play a theoretical guiding function on practice, and further enable the accuracy to be high, the simulation performance to be high and operation to be simple; the infrared heating testing device comprises a test bed framework, wherein an infrared ray generation device is arranged on the test bed framework; the infrared ray generation device is connected with an infrared ray generation controller, a liquefied petroleum gas inlet control valve and a variable-frequency air blower; the liquefied petroleum gas inlet control valve is connected to a liquefied petroleum gas source; the variable-frequency air blower is connected with an air source; a test block tray used for placement of a pitch test block is arranged at the lower end of the infrared ray generation device; an infrared radiation flow sensor capable of collecting the infrared ray radiation quantity of the infrared ray generation device is arranged on the test block tray; a plurality of temperature sensors are arranged in the pitch test block during testing; the infrared radiation flow sensor and the temperature sensors are all connected to a data acquisition instrument; the data acquisition instrument is connected to a computer capable of displaying test data.

Owner:CHANGAN UNIV

Radiofrequency ablation electrode with homogeneous surface temperature

InactiveCN101411645AUniform temperatureReal-time measurement of temperatureSurgical instruments for heatingRf ablationCarbonization

The invention provides a radio-frequency ablation electrode with uniform surface temperature, which comprises a radio-frequency needle, a control collector, a gas container, an exhaust cavity and a gas receiving vessel, wherein the surface of the radio-frequency needle is coated with an insulating layer, and a needle point is exposed; the radio-frequency needle is hollow, and a gas conveying pipe, a temperature sensor and a radio-frequency wire are arranged inside the radio-frequency needle; both ends of the temperature sensor and the radio-frequency wire are connected with the tip of the radio-frequency needle and the control collector respectively; the gas conveying pipe is connected with the gas container; and gas is filled into the gas container which has certain initial pressure. By adoption of the arrangement, uniform surface temperature of the needle point can be realized by utilization of heat exchange between the gas and the needle point, so as to prevent carbonization, thereby the radio-frequency ablation electrode can be widely applied to pathological tissues.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

Method for cutting golden finger of flexible circuit board by ultraviolet laser

ActiveCN102179632AImprove cut qualityAvoid heat damageWelding/soldering/cutting articlesMetal working apparatusFlexible circuitsHigh energy

The invention discloses a method for cutting a golden finger of a flexible circuit board by ultraviolet laser. Ultraviolet pulse laser with 16-29j / cm2 of low-energy density and 60-90kHz of high repetition frequency is adopted to cut and process PI (polyimide) substrate at 100-400mm / s scanning speed, then ultraviolet pulse laser with 113-226j / cm2 of high-energy density and 20-30kHz of low repetition frequency is adopted to cut and process copper foil material at 50-200mm / s scanning speed, and the ultraviolet pulse laser is closed when no copper foil material exists, until the copper foil material is penetrated in a cutting manner, so as to carry out FPC (flexible circuit board) golden finger cutting and processing procedures. In the method, the method that the ultraviolet pulse laser with high-energy density and low repetition frequency only cuts the copper foil material and the method that the ultraviolet pulse laser with low-energy density and high repetition frequency only cuts the PI substrate are combined to cut the substrate of the FPC, so that heat damage, carbonization and chippings at the cutting edge of PI can be effectively avoided, the cutting quality of the golden finger is improved and the problems in the prior art are solved.

Owner:武汉飞能达激光技术有限公司

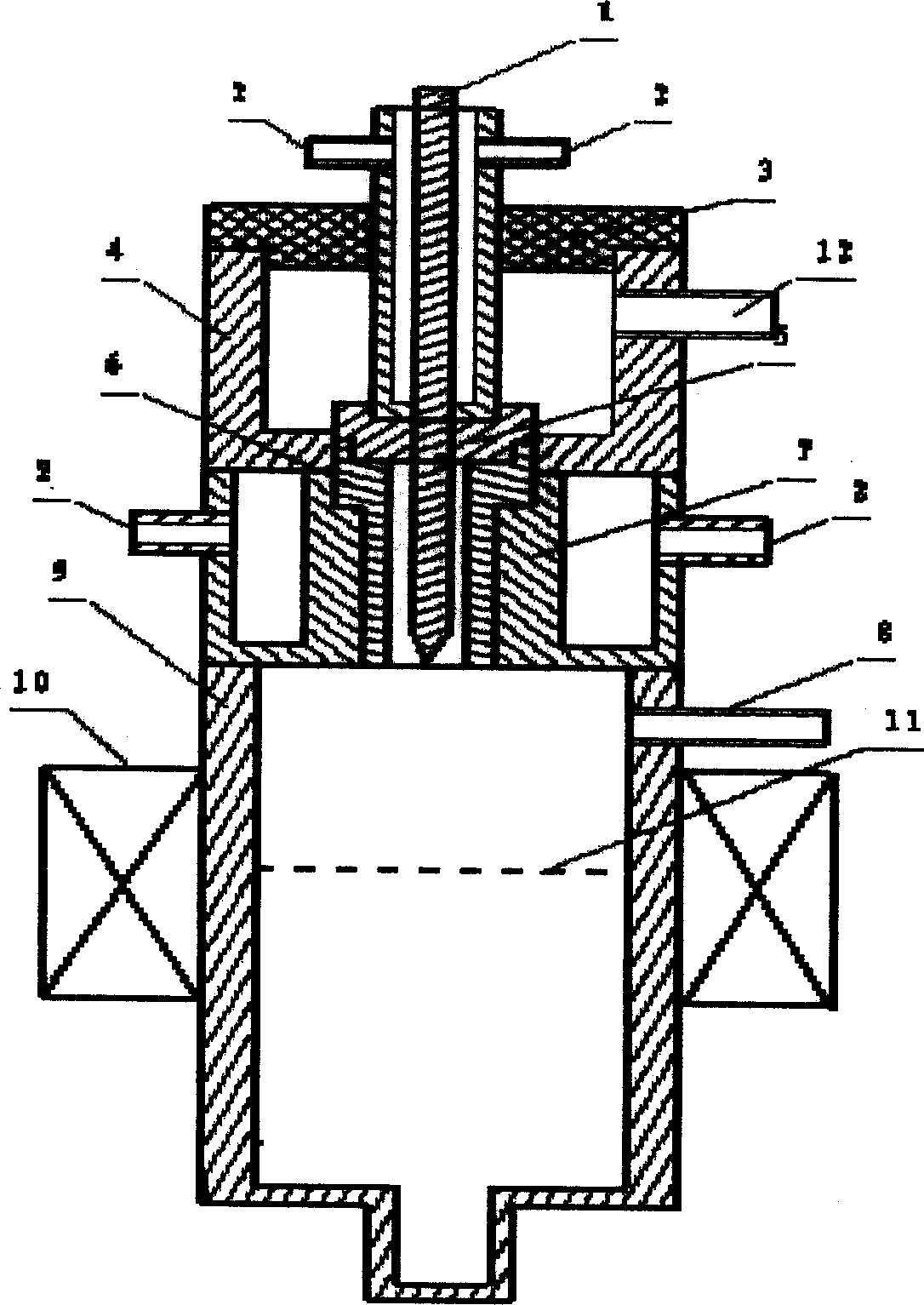

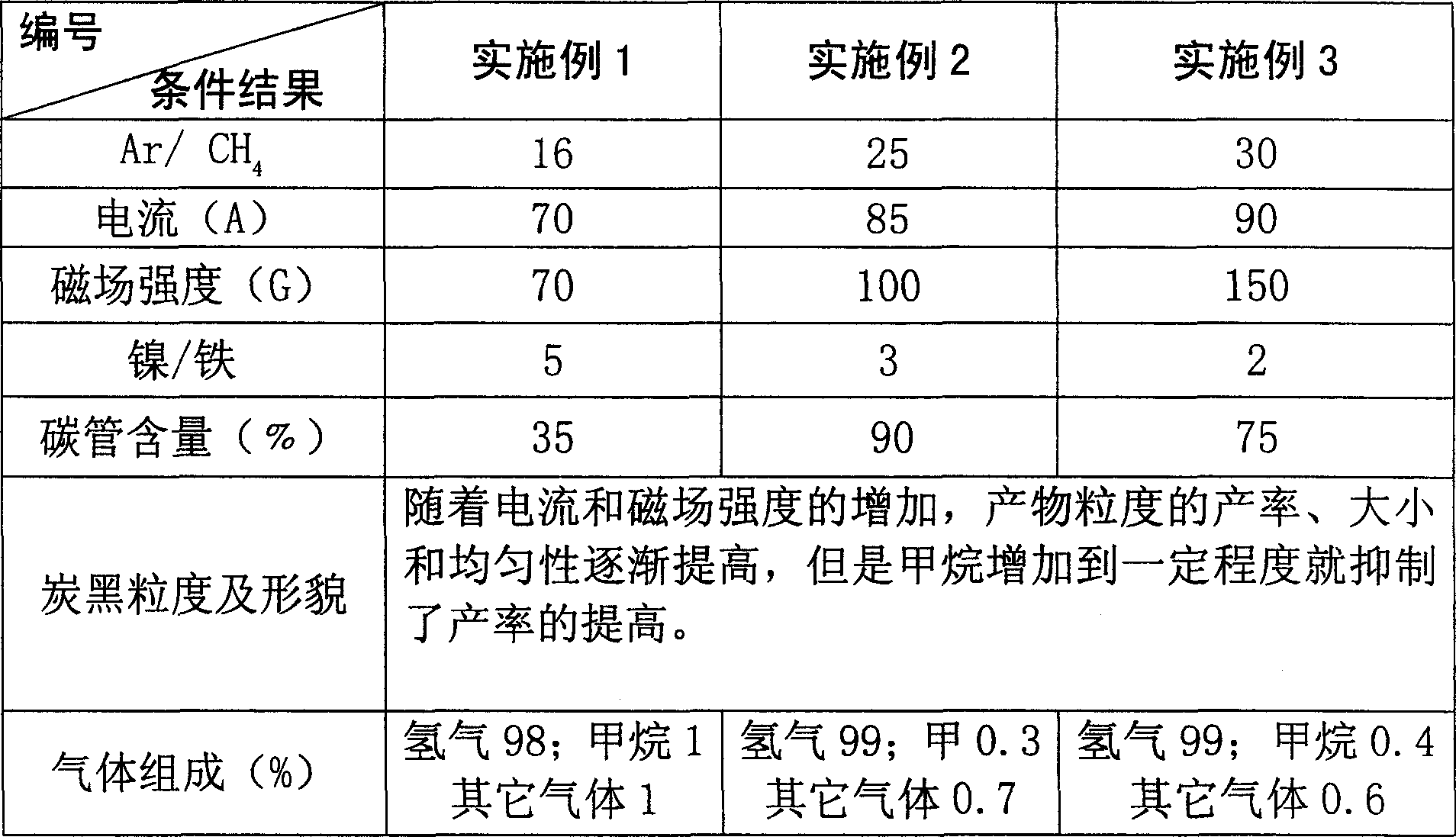

Technology and equipment for preparing magnetic carbon nanometer tube by plasma

InactiveCN1547225AWell mixedEasy to mix well with hydrocarbon cracking productsInductances/transformers/magnets manufacturePlasma techniquePlasma generatorCarbon nanotube

The invention is a technology for using plasma to produce the magnetic carbon nano pipe. The argon is blown into the plasma generator, there forms the plasma efflux under the effect of the current; the methane is blended with the plasma in condition without oxygen, it is ionized and decomposed into nano grade active carbon particles, and enters the reactor whose magnetism intensity if 70-200G, and uses the nickel sieve carrying load iron powder or ferric oxide powder to generate the magnetic carbon nano pipe. The structure is simple, the device is cheap, and it can avoid the structure deficiencies.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

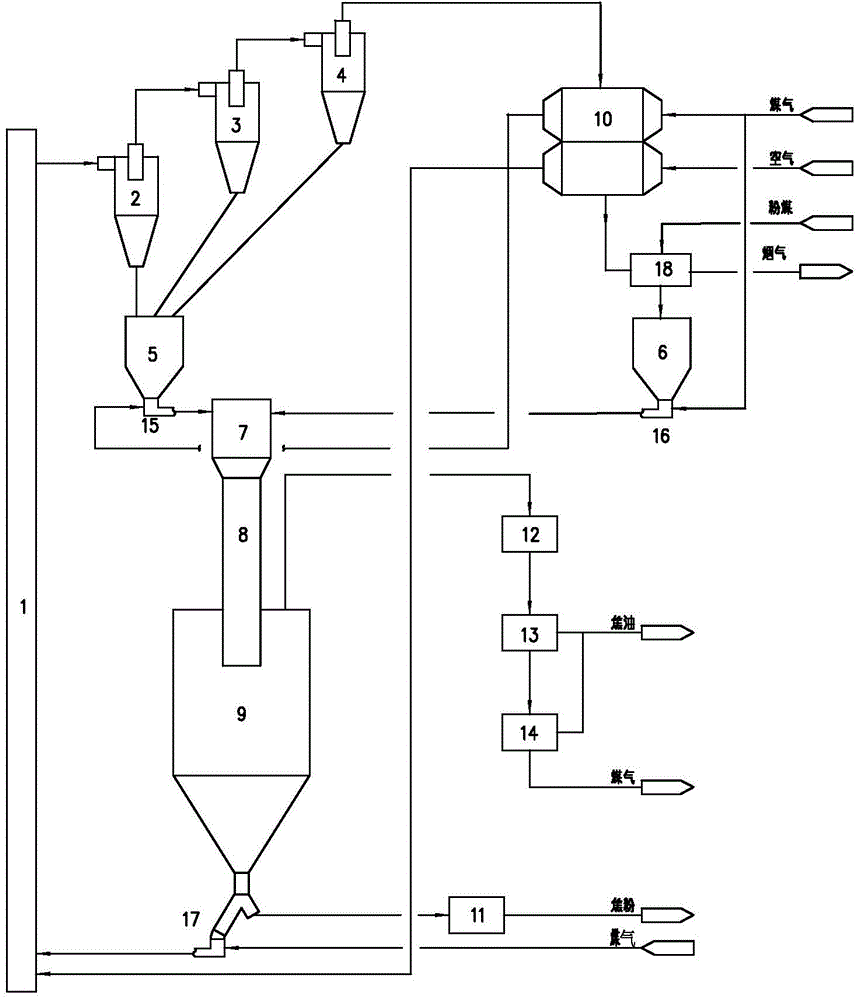

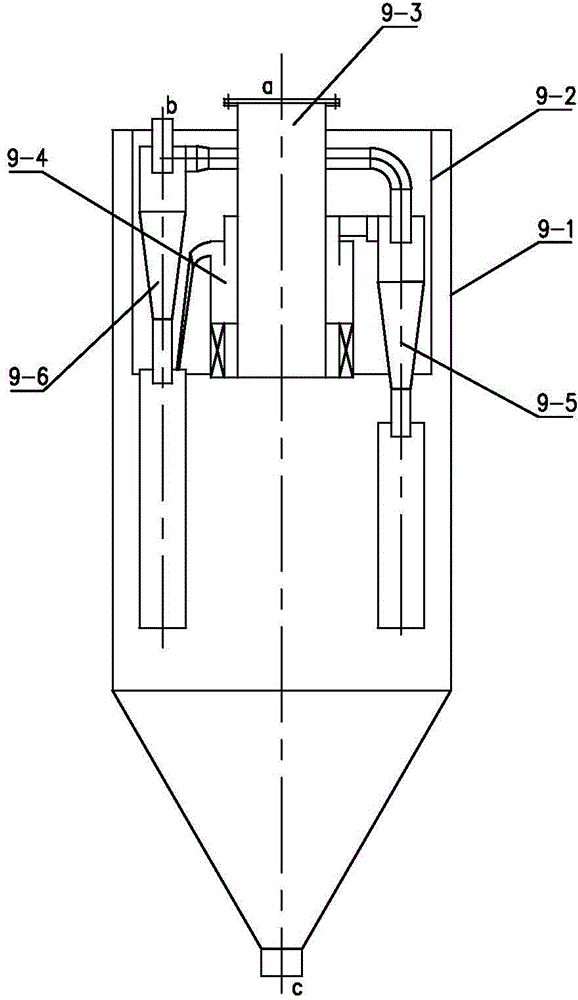

Down-flow gas semi-coke activated pulverized coal pyrolysis system and method

ActiveCN104449774AImprove pyrolysis efficiencyImprove dust removal efficiencyDirect heating destructive distillationGasification processes detailsCycloneFlue gas

The invention relates to a down-flow gas semi-coke activated pulverized coal pyrolysis system and method. The system is characterized in that a high-temperature flue gas heat exchanger is communicated with a second L-shaped valve, a first L-shaped valve, a vertical mill and an upward heating riser; the vertical mill is communicated with a dry pulverized coal surge bin; a cyclone mixer is communicated with a high-temperature semi-coke surge bin, the high-temperature flue gas heat exchanger, the dry pulverized coal surge bin and a downer reaction pipe; the downer reaction pipe is communicated with an oil-gas cyclone dust collector; the oil-gas cyclone dust collector is communicated with a semi-coke cooler and the upward heating riser; the upward heating riser is communicated with a primary cyclone dust collector; the primary cyclone dust collector is communicated with a secondary cyclone dust collector; the secondary cyclone dust collector is communicated with a ternary cyclone dust collector; the ternary cyclone dust collector is communicated with the high-temperature flue gas heat exchanger; and the primary cyclone dust collector, the secondary cyclone dust collector and the ternary cyclone dust collector are communicated with the high-temperature semi-coke surge bin. The system and the method can be used for improving the yield of coal tar and reducing the consumption of energy, the dust collectors discharge materials smoothly, and subsequent fine dust removal is carried out stably.

Owner:王树宽

Irrigant distribution system for electrodes

ActiveUS20150327925A1Improved temperature correlationReduce formationSurgical instruments for heatingCoatingsDistribution systemCatheter

An ablation electrode assembly is provided with improved irrigation cooling of the assembly and ablation site. The assembly includes a proximal end configured to be coupled to a catheter shaft and a distal end configured to deliver ablation energy to tissue. The assembly further includes a fluid manifold extending from the proximal end to the distal end and configured to fluidly communicate with a fluid lumen in the catheter shaft. The fluid manifold defines an axial passageway centered about a longitudinal axis extending in the longitudinal direction of the assembly. The axial passageway has a distal end terminating prior to the distal end of the electrode assembly. The assembly further includes means for creating turbulence in fluid exiting the first axial passageway.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

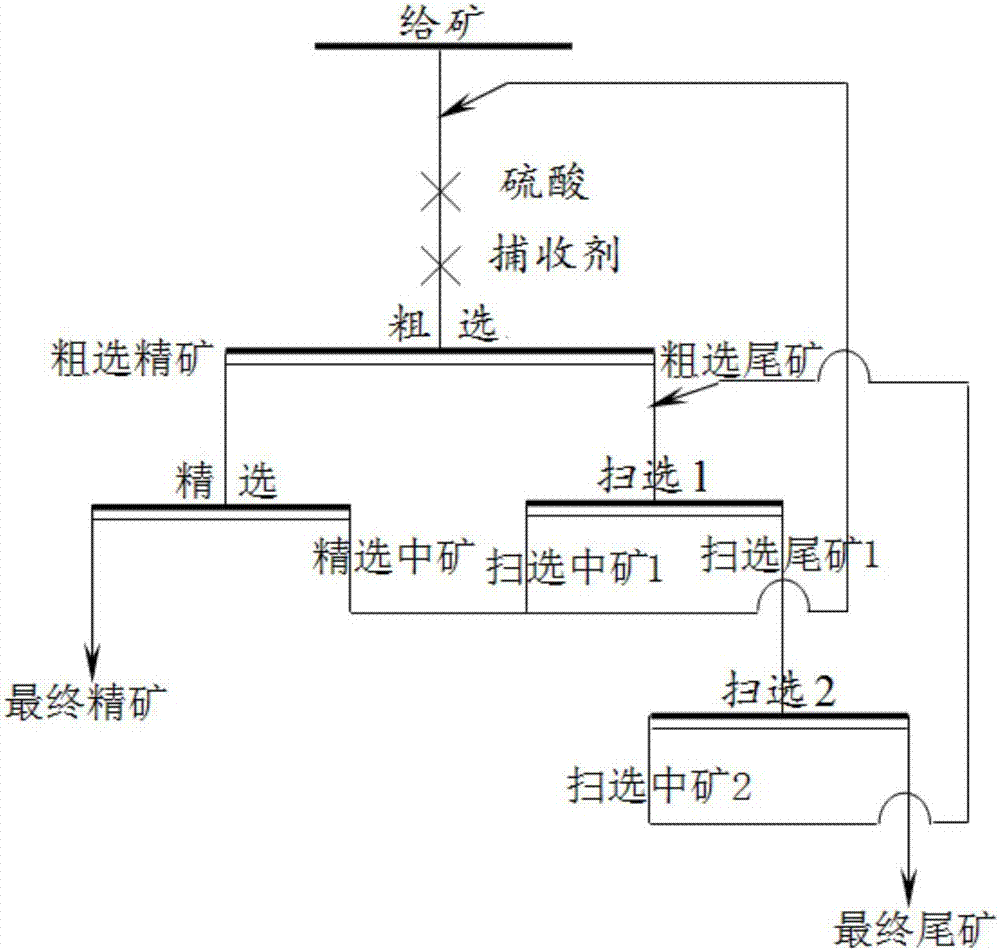

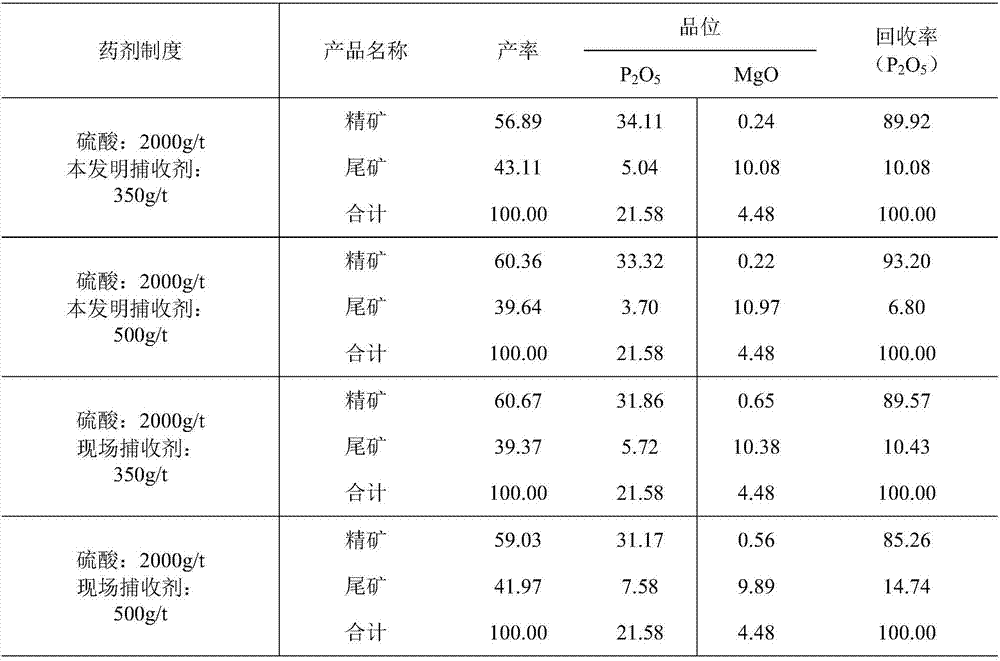

Collophanite reverse flotation collector and preparation method and application method thereof

ActiveCN106944263AGood mud resistanceThe flotation index is stableFlotationHigh phosphateOrganic layer

The invention discloses a collophanite reverse flotation collector and a preparation method and an application method thereof, and belongs to the technical field of solid mineral resource separation. Vacuum five-line phenol extract oil, a diluent, fuming sulphuric acid, sodium hydroxide and the like are used as raw materials, after raw oil and the diluent are mixed according to a certain mass percent, the fuming sulphuric acid is fed into a reaction still for sulfonation, stirring and washing are conducted after a sulfonation reaction is completed, still standing is conducted for layering, an organic layer is taken for primary saponification in a saponification reaction still, and sulphonate is obtained; and the obtained sulphonate and soy acid are compounded into a mixture according to a certain mass percent, the mixture is subjected to secondary saponification, and the anionic high-calcium (high-magnesium) collophanite reverse flotation collector is obtained. The collector is simple in preparation process, high in adaptability (such as the temperature and the ore pulp pH), good in mud resistance, high and stable in flotation index, low in cost and free of toxicity; and when the collector is applied to high-calcium (high-magnesium) collophanite flotation, the high-phosphate concentrate grade (P2O5) can be remarkably improved, the recovery rate of high-phosphate concentrate can be remarkably increased, and the impurity content of the concentrate is lowered.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

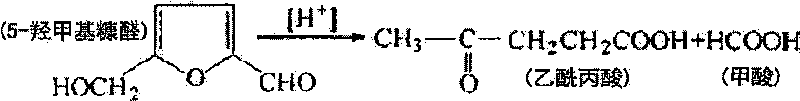

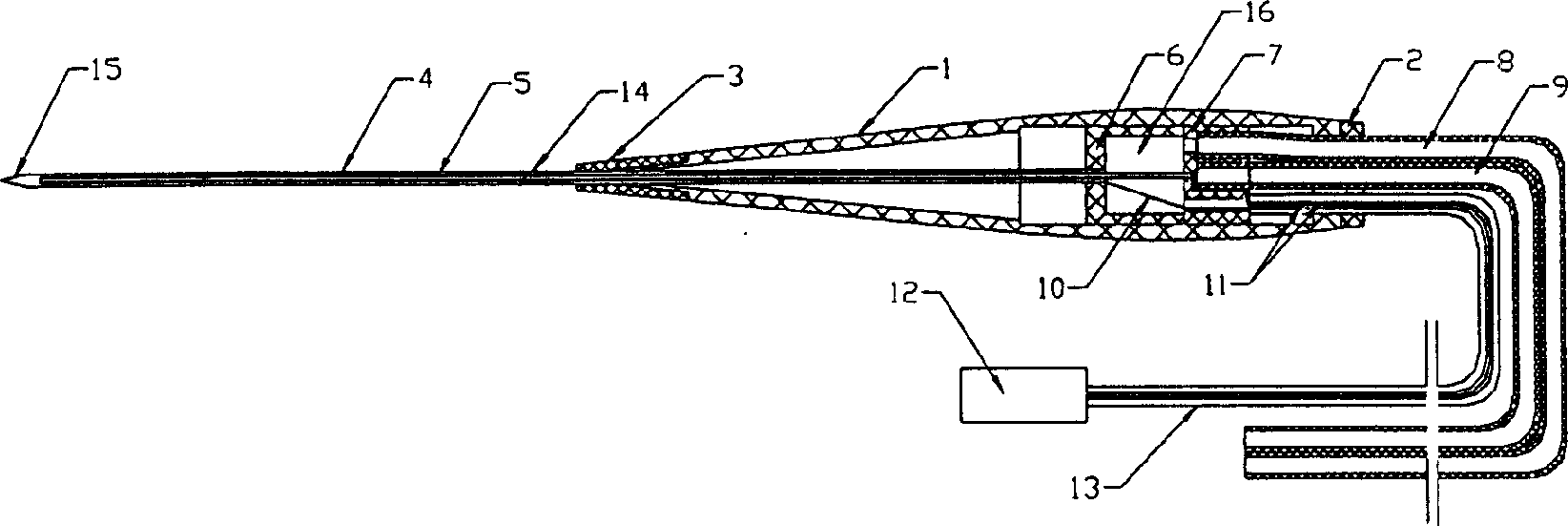

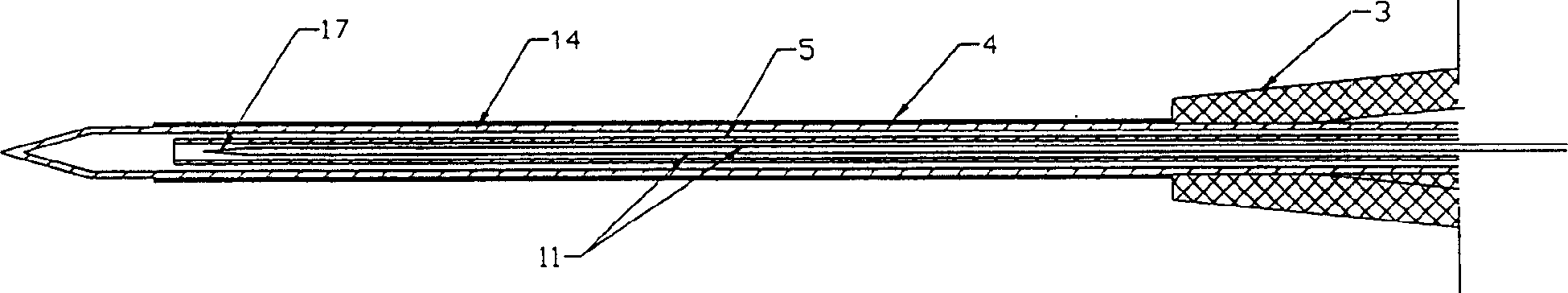

Microwave ablation water knife

ActiveCN101224136AAvoid stickingAvoid charringSurgical needlesSurgical instruments for irrigation of substancesHuman tumorExternal catheter

The invention relates to a microwave ablation water jet scalpel for the minimally invasive ablation of human tumors, which aims at solving the problems of surrounding carbonization of a scalpel head and smaller ablation area of the existing microwave scalpel in operation, as well as the scald of the skin and other tissues by the shaft temperature caused by the standing wave of the microwave, the invention is composed of three parts: an external duct system which is composed of a mold frame with a water injection hole and an external duct, an internal duct system which is composed of the mold frame with a water outlet hole and an internal duct and a microwave scalpel head system which is composed of a microwave electrode interface mold frame and a microwave scalpel head connected by a microwave guide wire and an insulation pipe; as the invention adopts the structure, when the external duct and the internal duct have displacement, part of physiological saline is injected in the tissues; the injected physiological saline in the tissues at the same time of the microwave work of the invention can generate the functions of moisturization, penetration and thermal conductivity, thereby preventing carbonization, avoiding the tissue adhesion and expanding the ablation volume. At the same time, the invention can be combined with chemotherapy drugs for carrying out targeted therapy. A circulating cavity which is formed by the internal and external ducts at the same time of water injection can freely control the pipe wall temperature of the microwave scalpel and avoid the pipe wall from scalding the tissues.

Owner:盛林 +1

Method for determining dissolved quantity of lignin

InactiveCN104089912AAvoid charringColor/spectral properties measurementsFiltrationPhysical chemistry

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU

Nozzle cover coating

InactiveUS20160236413A1Avoid stickingAvoid charringProgramme controlAdditive manufacturing apparatusEngineeringSilicone

A nozzle and cover for use in 3D printing, including a nozzle body having a relatively flattened end; a nozzle tip protruding a small distance from the flattened end; a disk of material surrounding the nozzle tip, the disk being in contact with the flattened end; and wherein the disk of material prevents sticking of plastic and thereby prevents charring. The device further includes providing the disk of material being composed of PTFE or silicone.

Owner:ARMANI MICHAEL DANIEL +1

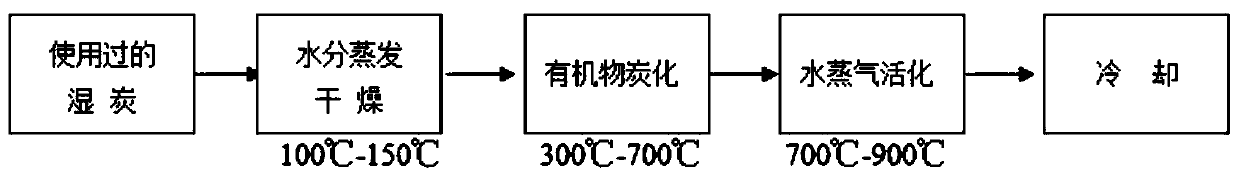

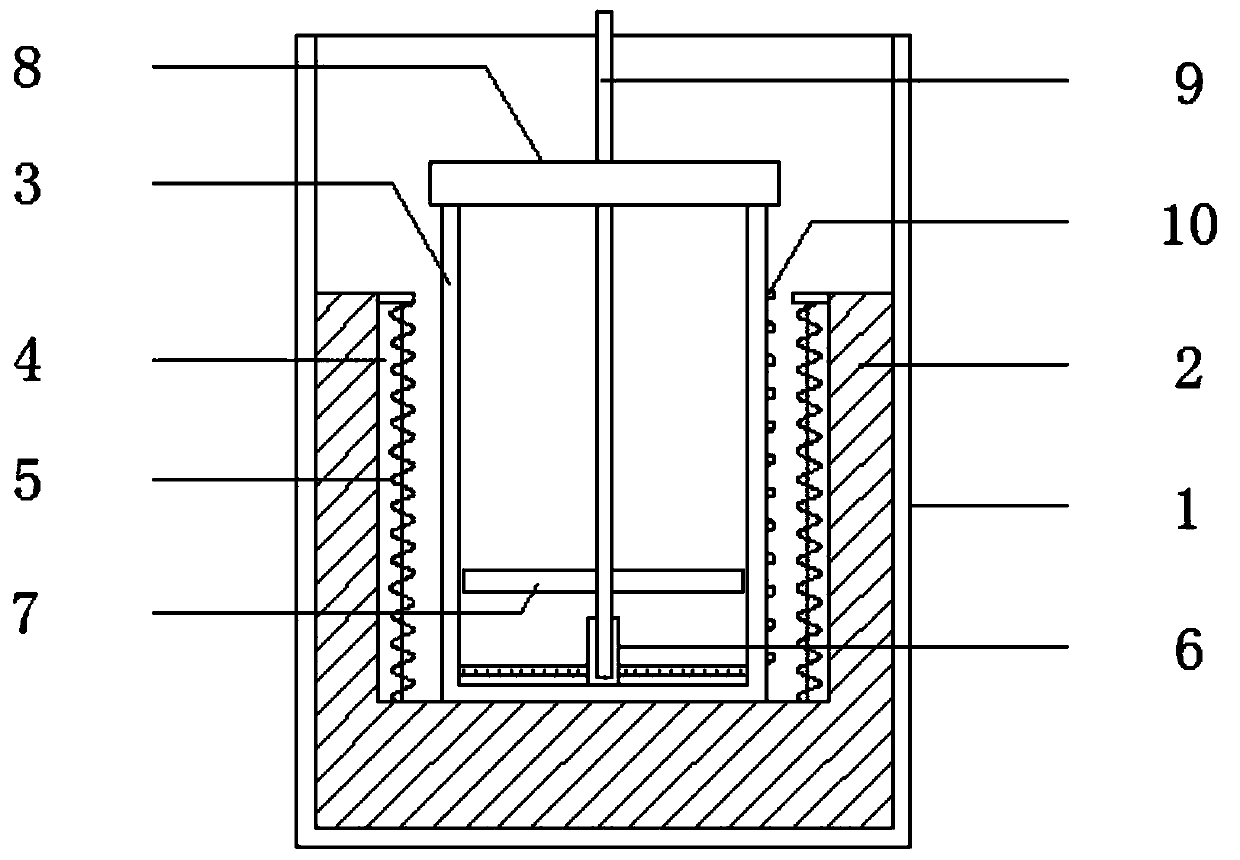

Thermal regeneration and reutilization method for waste active carbon

InactiveCN110394168AReduce overflowReduces powder carry-offOther chemical processesCarbon compoundsActivated carbonCarbonization

The invention relates to the technical field of reutilization of active carbon, specifically to a thermal regeneration and reutilization method for waste active carbon. The method comprises the following steps: 1) drying: a step of heating used wet carbon to 100 to 150 DEG C, and carrying out heating for 2 to 3 hours at a constant temperature in a range of 100 to 150 DEG C; 2) carbonization: a step of heating dried active carbon to 300 to 700 DEG C in a certain period of time, and maintaining the temperature for 6 hours; 3) activation: a step of heating carbonized active carbon to 850 to 855 DEG C, controlling a certain heating rate, and after heating is completed, maintaining the temperature for 2 to 3 hours; and 4) cooling: a step of quenching activated active carbon to a certain temperature. The invention discloses the thermal regeneration and reutilization method for the waste active carbon. The method provided by the invention effectively compensates for the defect of high regeneration volume loss rate of the active carbon in a conventional active carbon regeneration technology.

Owner:上海政宝环保科技有限公司

Production method of refined cotton

InactiveCN102321926AAvoid charringImprove qualityFibre treatment to obtain bast fibreAcid waterCarbonization

The invention belongs to the technical field of refined cotton production, and particularly relates to a production method of refined cotton; the invention can not only improve the quality of refined cotton products, but also reduce water and steam consumption, and can reduce acid water discharge. The method particularly comprises the following steps of: 1) boiling of cotton linter; 2) washing, wherein nitrocellulose acidic waste water is used for washing, and washing is performed till the pH of the cotton material is 6.5-7.5; 3) bleaching, wherein a sodium hypochlorite solution is used for bleaching; 4) acidification, wherein nitrocellulose acidic waste water is added during acidification to control the pH to be 1-5; 5) cold washing, wherein cold washing is performed with water. The nitrocellulose acidic waste water has a total acidity of 5-15 g / l, and comprises the following main components by weight: 0.003%-0.023% of sulfuric acid, 0.006%-0.018% of nitric acid, and the balance of water and impurities. The beneficial effect of the invention is that nitrocellulose acid water needing to be discharged is used to substitute concentrated sulfuric acid during the refined cotton production process, which avoids the carbonization of refined cotton by concentrated sulfuric acid, improves the quality of refined cotton, reduces water and consumption, reduces the discharge of nitrocellulose acid water, and saves the cost for nitrocellulose acid water treatment.

Owner:SICHUAN NITROCELLULOSE CORP

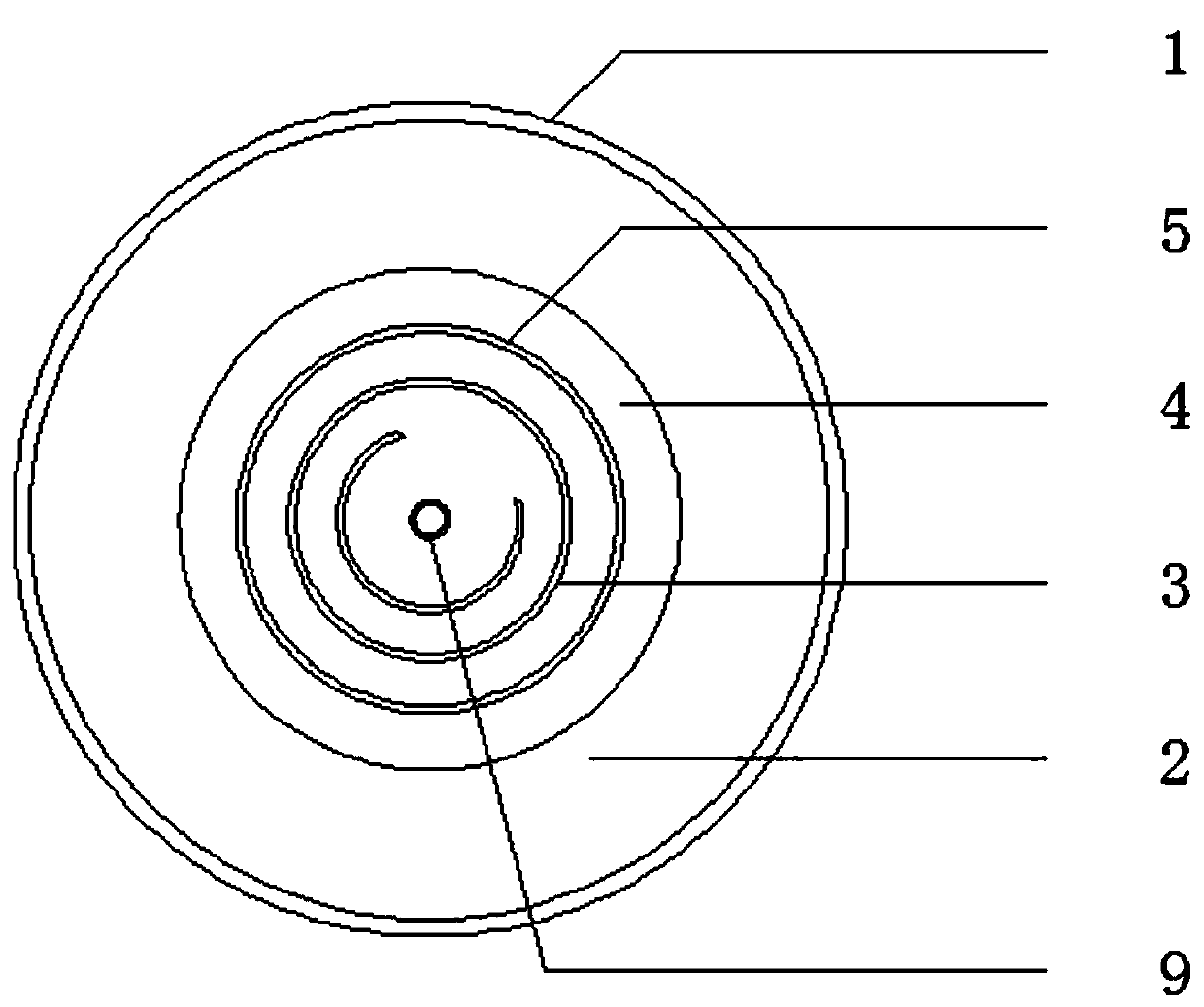

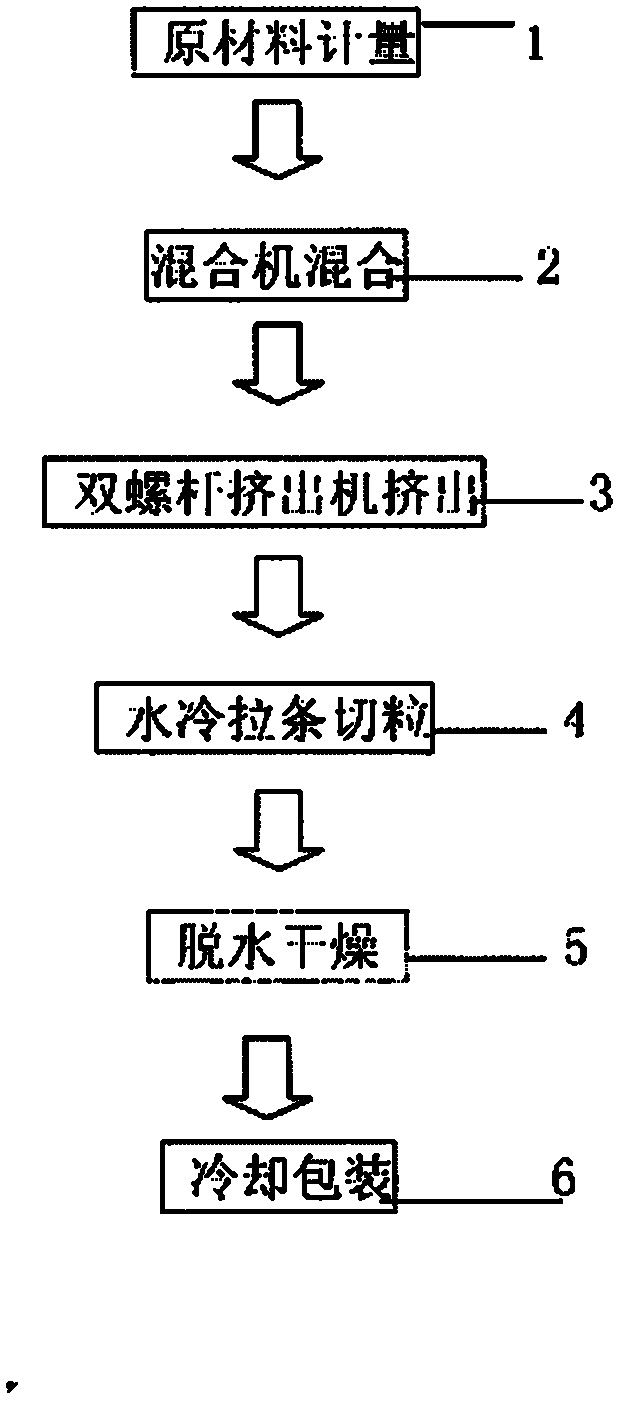

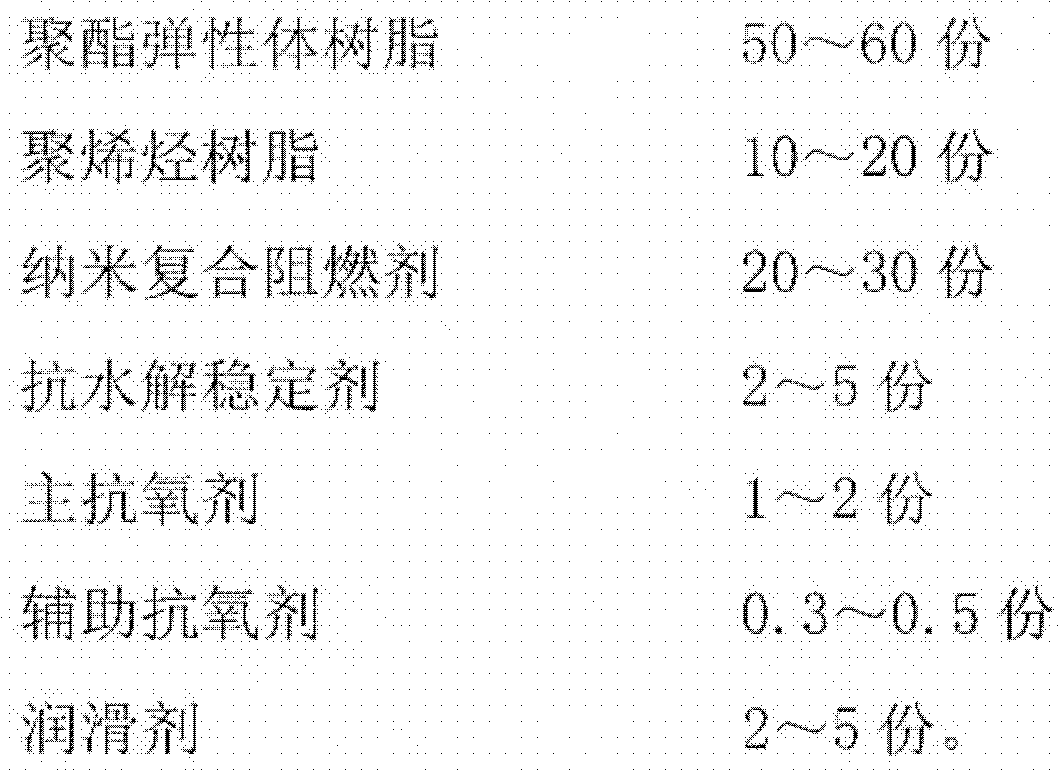

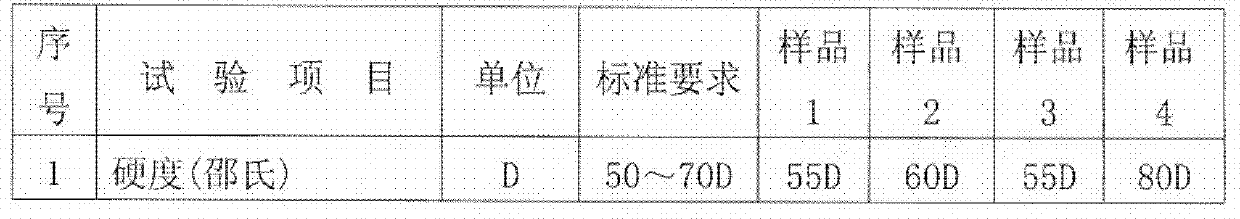

Low-smoke, halogen-free and flame-retardant polyester elastomer thin-wall insulating material and preparation method thereof

The invention discloses a low-smoke, halogen-free and flame-retardant polyester elastomer thin-wall insulating material and a preparation method thereof. The insulating material mainly comprises the following components in parts by weight: 60-80 parts of polyester elastomer, 20-30 parts of nanocomposite flame retardant, 2-5 parts of anti-hydrolysis stabilizer, 1-2 parts of main antioxidant, 0.3-0.5 part of auxiliary antioxidant and 2-5 parts of lubricant. The method comprises the following steps of: uniformly mixing each component of the low-smoke, halogen-free and flame-retardant polyester elastomer thin-wall insulating material in a mixer at the temperature of 125 DEG C; and extruding and pelletizing in a double screw extruder. According to the insulating material, degradation and carbonization of acids are prevented, degradation and brittleness of the polyester elastomer in a high-heat and moist heat environment are eliminated by using the amine anti-hydrolysis stabilizer, long-term aging performance is ensured by using the special high-temperature-resistant antioxidant, the insulating performance is improved by blending polyolefin resin, and smooth and fine product appearance are ensured by using the special lubricant.

Owner:天津市普立泰高分子科技有限公司

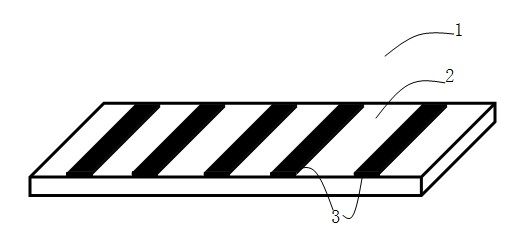

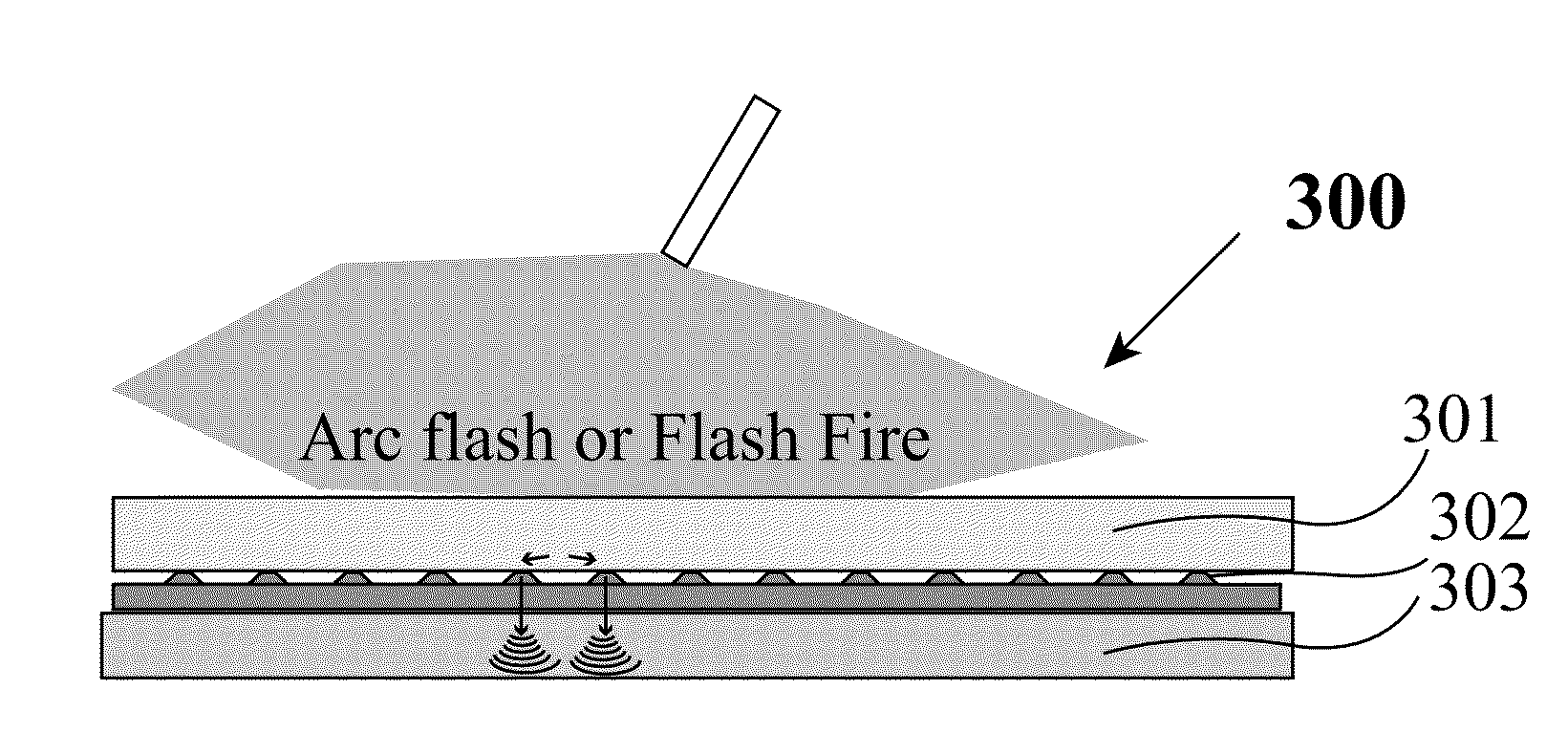

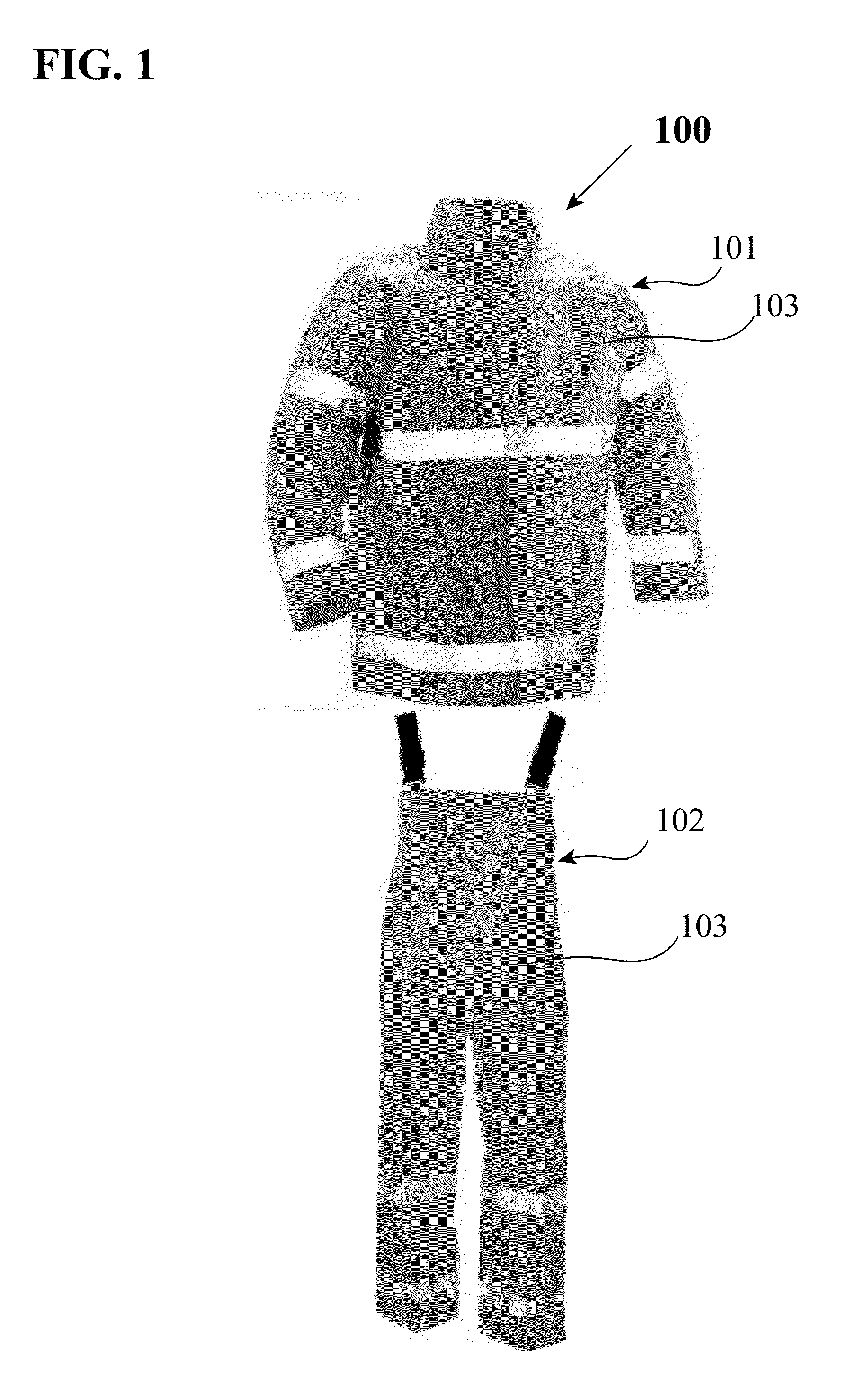

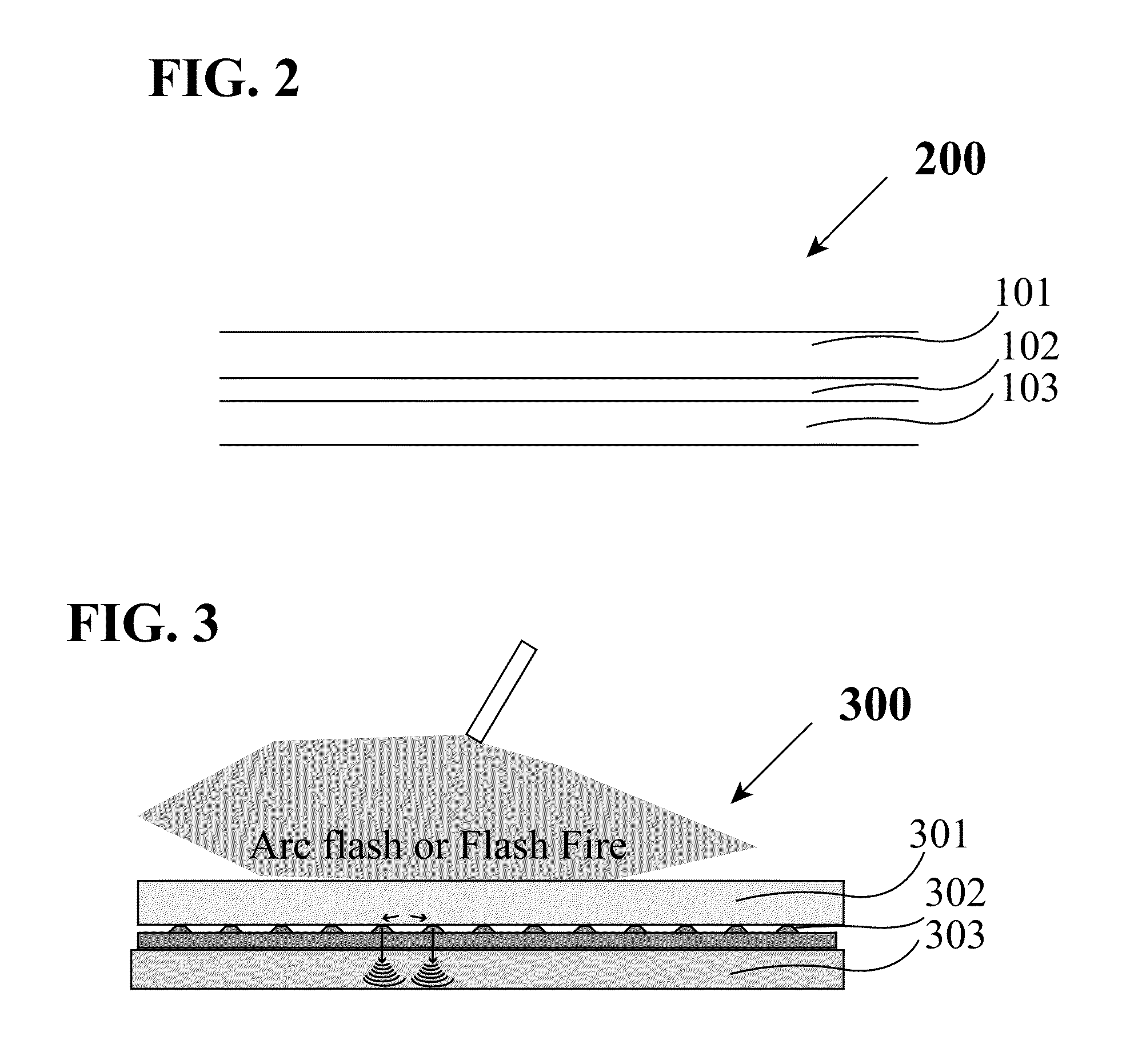

Flexible lightweight arc flash and flash fire resistant polyvinylchloride fabric and garments and methods therefor

ActiveUS20160039170A1Prevent saggingAvoid charringSynthetic resin layered productsClothingsArc flashResist

A light weight flexible flame, arc flash and flash fire resistant fabric for protective garments is made from a flexible polyvinylchloride sheet having phthalate or phthalate free plasticizers coated with well defined parallel lines or grids of adhesive layer. The adhesive coated polyvinylchloride sheet contacts a non-woven meta-aramid fiber liner and is heated to produce a bond between the polyvinylchloride sheet and the liner. Both polyvinylchloride sheet and meta-aramid non-woven liner resist heat. When heat from arc flash or flash fire is applied, the heat is conducted away at local contacting regions of the adhesive with the polyvinylchloride sheet to the liner whereby the temperature of the polyvinylchloride is locally reduced preventing sagging, charring or burning of the space between adhesive contacting regions. This structure produces mechanically strong lightweight arc flash and flash fire resistant fabric suited for producing garments that meet all ASTM specifications for fireproof garments.

Owner:TINGLEY RUBBER CORP

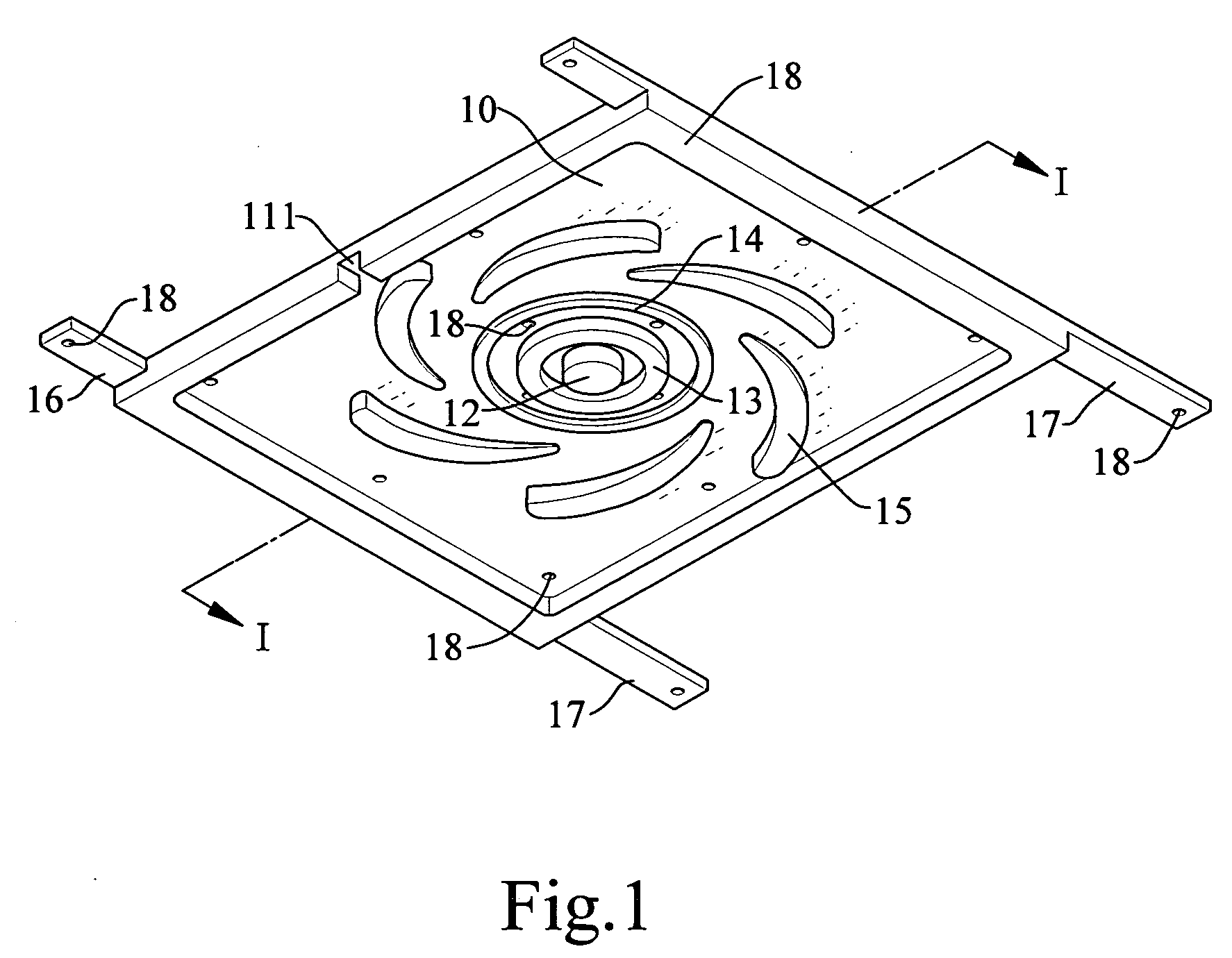

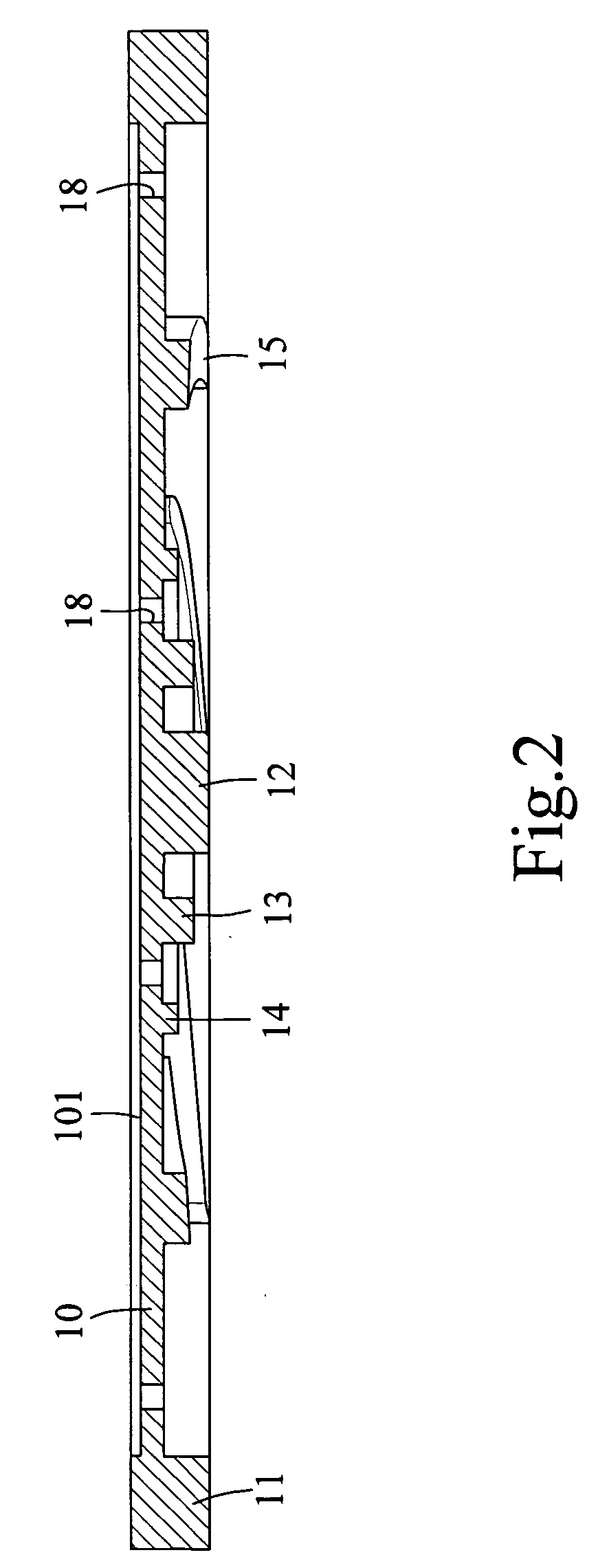

Flat-top grill heating means

InactiveUS20100116149A1Improve thermal efficiencyHeating evenlyFrying pansHeat conductingEngineering

A flat-top grill heating means includes a base plate, a convex edge is formed on the bottom side of the base plate along the periphery of which; a convex central block is set in the centre of the area enclosed by said convex edge; a plurality convex heat conducting rings are disposed around said central block on the bottom of said base plate; and a plurality convex heat conducting ribs are disposed around said heat conducting rings; when using the present invention, the base plate is secured to the iron plate of a teppanyaki grill with screws, a gas burner is placed under the bottom of the central block, with installation of central block, heat conducting rings and ribs, heat can be conducted uniformly to the iron plate preventing overheating and charring the center of the iron plate; space enclosed by convex edge can accumulate the hot air, increasing efficacy of heating.

Owner:LAI JUN QING

Water injected microwave antenna

InactiveCN102138825ATemperature controlInhibit sheddingSurgical instrument detailsMicrowaveEngineering

The invention relates to a water injected microwave antenna. An outer pipe assembly is communicated with an inner pipe assembly; the antenna penetrates through the inner parts of the inner pipe assembly and the outer pipe assembly; the tail end of the antenna is fixed at the inner part of a socket; an inner core of the antenna is also arranged at the front end of the antenna; the outer pipe assembly comprises an outer pipe frame, an outer pipe and a water injection hole; a sliding groove, a movable passageway of the outer pipe frame, and an antenna passageway are arranged on the inner pipe frame in the inner pipe assembly; the sliding groove is arranged on the outer wall of an inner pipe frame; the movable passageway of the outer pipe frame is arranged at the inner part of the inner pipe frame; the outer pipe frame is arranged in the movable passageway of the outer pipe frame; a front plug is installed at the front end of the inner pipe frame; a linking component is arranged in the front plug; and the outer pipe assembly displaces at the outer side of the antenna through the linking component and the inner pipe assembly so as to control the inner core of the antenna to stretch outof the outer pipe or hide at the inner part of the outer pipe. In the invention, the inner core of the antenna can be prevented from falling due to the adhesion between the inner core and skin or tissue after the inner core is heated, and the wall of the outer pipe can also be prevented from scalding the skin of a patient when the microwave antenna is in operation.

Owner:常承忠 +1

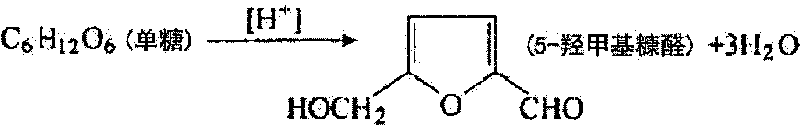

Acid-adjusting hydrolysis process for preparing levulinic acid

InactiveCN101691326AWide variety of sourcesSufficient quantityOrganic compound preparationCarboxylic compound preparationRice strawSlag

The invention relates to an acid-adjusting hydrolysis process for preparing levulinic acid. The raw materials are ground, sieved and combined, and the concentration of the catalyst of sulfuric acid is adjusted to reduce the initial concentration of the reacted acid, thus the reaction can be carried out more moderate and environmental-friendly, and more importantly, the yield of the levulinic acid prepared with the acid-adjusting hydrolysis process can be greatly improved by 57.95 percent on average. In the invention, the waste agricultural crops such as the core straw, the rice straw and the rice husk which has the lowest utilization ratio are combined, thus the content of the cellulose in the raw materials are improved, and the carbonization to the rice husk from the acid is reduced. The cellulose can be thoroughly hydrolyzed in the reaction process through adjusting the concentration of the sulfuric acid in the reaction process, while the slag from other similar hydrolysis reaction contains part of the cellulose which is not hydrolyzed in the current time. The invention can avoid the raw material carbonization and the equipment damage which are resulted from the over high concentration of the acid.

Owner:HEILONGJIANG ACAD OF SCI INST OF NATURAL RESOURCES

Process technological process of plants stalk

InactiveCN101253928AAvoid charringImprove conversion rateFood processingAnimal feeding stuffBiotechnologyCellulose

The invention discloses a method for treating and processing plant straws, and comprises the steps of removing impurities in the plant straws by using dust removing equipment; pulverizing the plant straws free of impurities into powder feed of 1-5mm by using a pulverizer; adding sodium carboxymethyl cellulose (0.1%-2.0% of the plant straw by weight) to the powder feed; blending; feeding the blended mixture into a turgor machine for hydrolytic treatment with reaction time of 10s -60s at the temperature of 100 DEG C- 200 DEG C; and fabricating granular, strip-shaped and flake-like products after the treated mixture sprays momentarily. The products can be used as paper making raw ingredients or livestock feed. The method is environment-friendly, and can convert the plant straws into oligosaccharides with conversion rate of 98%, thereby being favorable to digestive absorption by poultry of livestock.

Owner:洛阳义天科技开发有限公司

Single needle water-cooling type radio frequency ablation electrode

InactiveCN1263431CAccurate insertionSafe insertionElectrotherapySurgical instruments for heatingRf ablationEngineering

The single needle water cooling type RF ablation electrode has support frame inside handle matching and inserting into the water storing frame, middle cavity to form cooling water return pool, electrode needle with insulating material coated and scaled front section, bare tip and back section inserted inside the handle and connected to RF wire, built-in water guiding steel pipe, and temperature metering thermocouple inserted into the electrode needle in the coaxial position. The water inlet hose is connected to the built-in water guide steel pipe, water outlet hose connected to the cooling water return pool, and the RF wire and the thermocouple constitute the connecting cable connected to the system unit of the RF ablation system for signal transmission. The cooling water circulates in the system. The present invention has novel structure, great and controllable ablation range and high safety and reliability.

Owner:SHANGHAI JIAO TONG UNIV

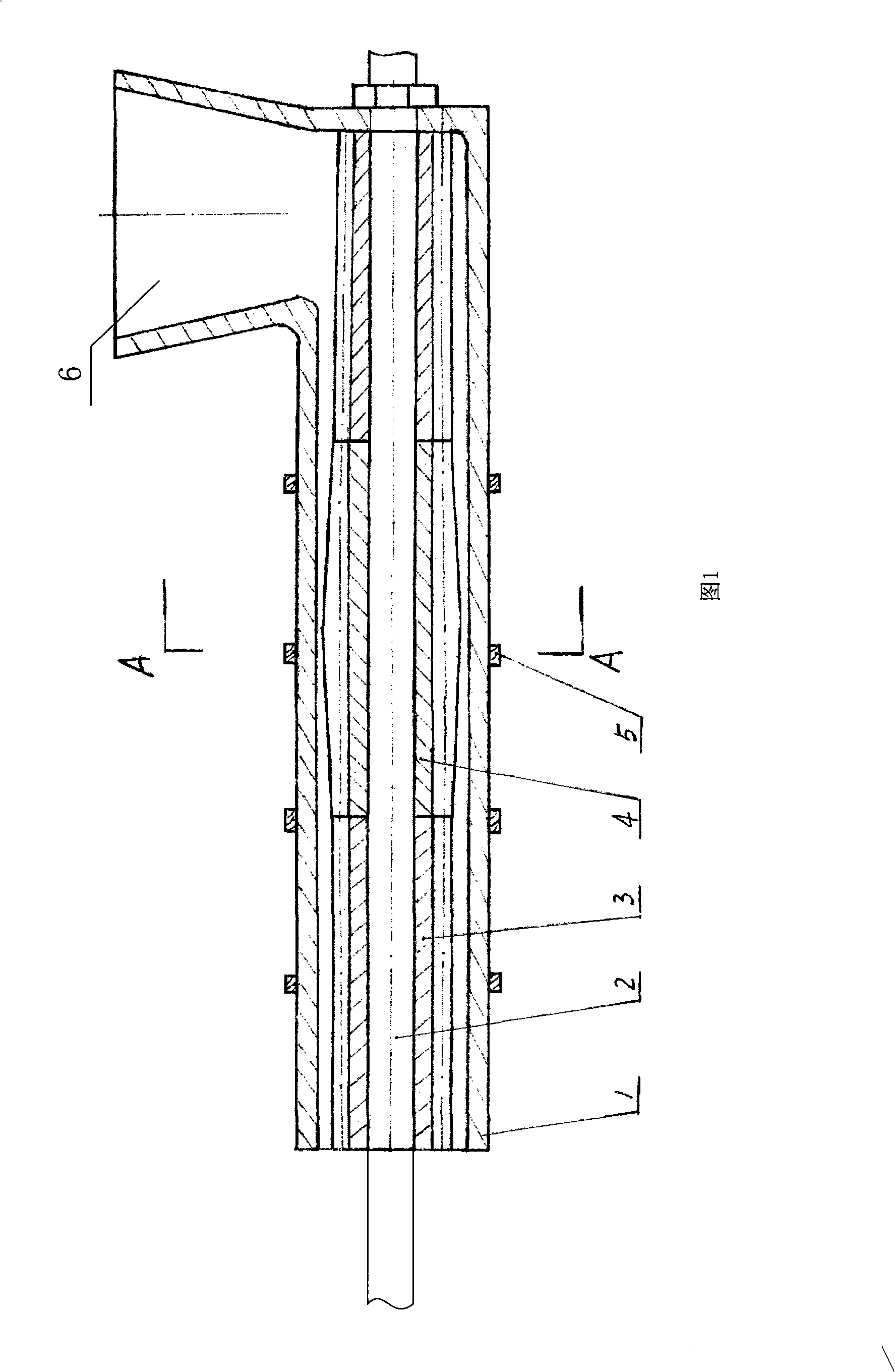

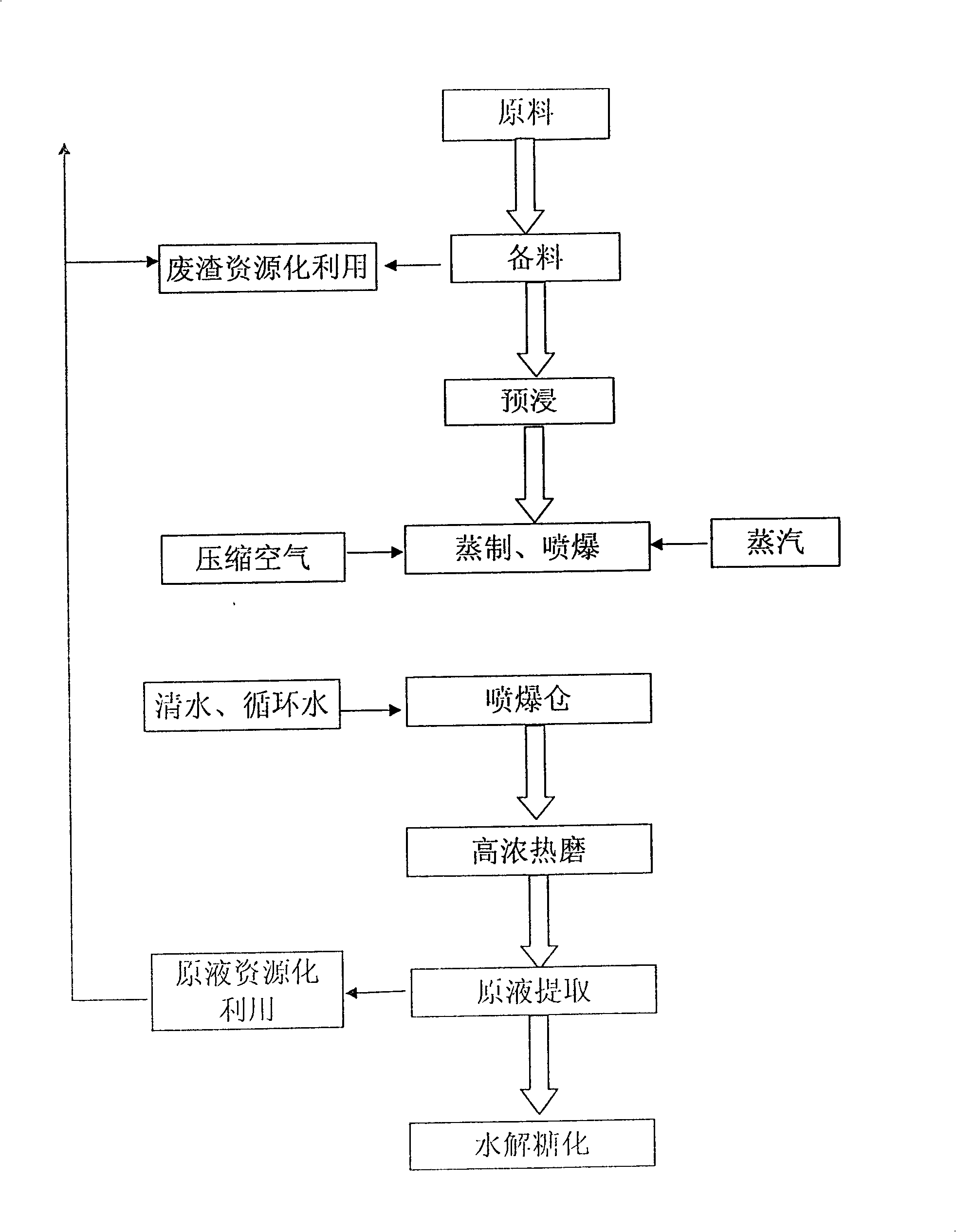

Process and equipment for preprocessing cellulosic ethanol raw material

InactiveCN101514348AShort steaming timeHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsFiberLiquid waste

The invention provides a process and equipment for preprocessing a cellulosic ethanol raw material, which is a raw material preprocessing process for producing cellulosic ethanol by straw biomass raw materials, such as wheat straw hood, cornstalk, and the like, and shell biomass raw materials, such as rubber seed shell, palm shell, and the like. In the raw material preprocessing process, steam and compressed air are adopted; and chemical medicines and auxiliary agents are not used during steaming, the temperature is low and the time is short, so the process can effectively prevent fiber from degrading and charring, improve the yield and the separation effect by high consistency hot grinding, and reduce the pollution load. Meanwhile, the production cost and the equipment investment can be reduced, and no waste liquor drainage in the whole preprocessing process can be realized.

Owner:上海天之冠可再生能源有限公司

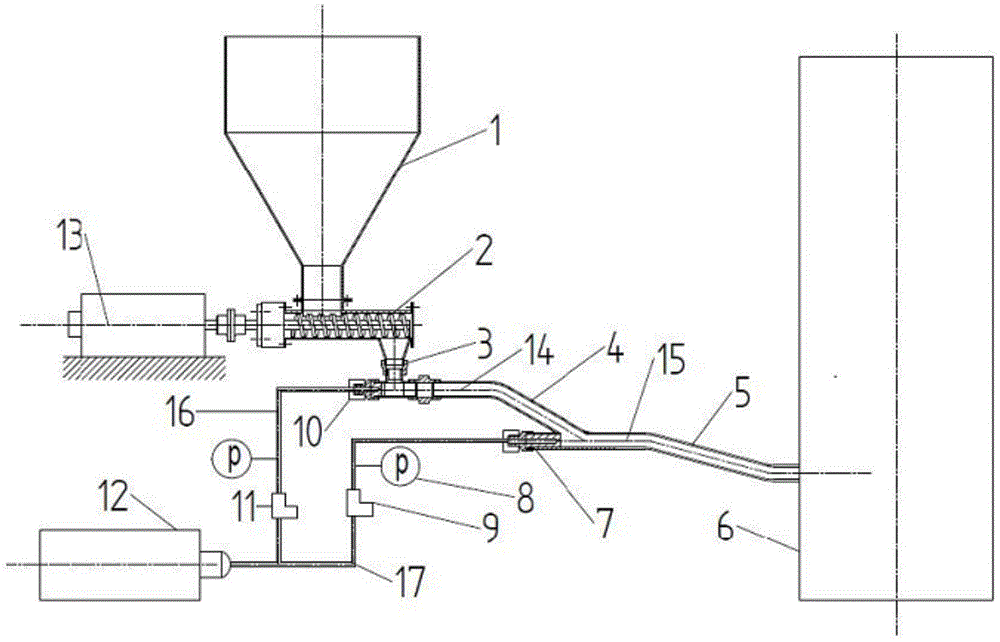

Spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis

InactiveCN104877694AAdjust feed amountPrevent blowbackBiofuelsLiquid hydrocarbon mixture productionSolenoid valveGas cylinder

The invention relates to a spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis and belongs to the technical field of biomass pyrolysis. The feeder comprises a spiral feeding device, inclined delivery pipes, solenoid valves and nozzles. The discharge port of the spiral feeding device is connected to an upper horizontal delivery pipe and the inclined delivery pipe through a transition joint and is connected to a lower horizontal delivery pipe and the inclined delivery pipe, gas of a gas bottle is sprayed through the nozzles, the nozzles are capable of adjusting the feeding amount and preventing reverse spraying, the feeding process is controllable and safe, and the reliability of the producing process is improved. The feeding port advanced charring and plugging problems can be solved, the process requirements of fast biomass pyrolysis can be met, the pyrolysis equipment producing and maintaining time can be shortened, the pyrolysis oil producing efficiency is improved, the maintaining cost is reduced effectively, and the technology guaranteeing effect can be achieved for large-scale pyrolysis production development.

Owner:BEIJING FORESTRY UNIVERSITY

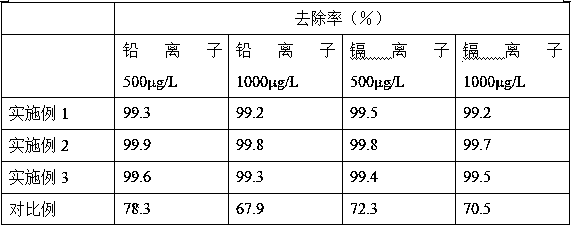

Preparation method of metal ion adsorbent

InactiveCN109126738AHigh porosityImprove adsorption capacityOther chemical processesWater contaminantsCross-linkSorbent

The invention relates to a preparation method of a metal ion adsorbent and belongs to the technical field of adsorbents. According to the preparation method, bamboo is adopted as a carrier, pores in the bamboo are increased through a steam blasting method, an internal structure of the bamboo is destroyed, the adsorption performance is improved, and then the bamboo is put into a carbonization furnace for pre-carbonization; complete carbonization of the interior of the bamboo is avoided through pre-carbonization, internal materials of the bamboo are partially decomposed or degraded, the adsorption and binding capability is improved, and then composite glue and sea mud are added; active substances in the sea mud can be well combined with the composite glue to achieve wrapping of pre-carbonized particles, metal substances in the sea mud are utilized to promote cross-linking in the composite glue for improving the adsorption performance, the composite glue is cross-linked with acrylic acidunder the action of sodium hydroxide, and under the action of N,N-dimethyl amide and sodium hydrosulfide, sulfydryl is added to the surface of the adsorbent, so that the adsorption performance for metal ions is improved.

Owner:张剑

Preparation technology of MC nylon active material

InactiveCN1718610ARealize industrial preparationRealize streamlined productionCarboxylic acid amide separation/purificationNylon materialEngineering

A process for preparing active nylon MC includes such steps as fusing the nylon monomer, loading in reactor, dewatering, adding catalyst, dewatering, examining specimen, loading in transfer container, proportionally loading in stirrer, adding cocatalyst and stirring.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com