Process technological process of plants stalk

A plant straw and processing technology, which is applied in animal feed, animal feed, food processing, etc., can solve environmental pollution and other problems, achieve the effects of reducing costs, improving environmental pollution problems, and major social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 Get 10kg of wheat straw, first remove the impurities therein with a dedusting device, then pulverize it with a pulverizer, and pulverize it into a powder of 1 to 5 mm, add 0.08 kg of sodium carboxymethyl cellulose to the straw powder, that is, a small 0.8% of the weight of wheat straw, stir evenly, send the stirred mixture into a plant straw expansion press, the temperature reaches 120°C, the reaction time is 40s, and the material is ejected instantly to form a granular product.

Embodiment 2

[0022] Example 2 Take 30kg of corn stalks, remove the impurities therein with a dedusting device, then pulverize them with a pulverizer to a powder of 1-3 mm, add 0.3 kg of sodium carboxymethyl cellulose to the straw powder, that is, corn stalks 1.0% of the straw weight, stir evenly, send the stirred mixture into the plant straw expansion press, the temperature reaches 150°C, the reaction time is 30s, and the material is ejected instantly to form a sheet product.

Embodiment 3

[0023] Example 3 Take 60kg of the mixed material of rape stalks and bean stalks, remove the impurities therein with dust removal equipment, then pulverize them with a pulverizer, and pulverize them into powders of 1-3mm, and add 0.9kg of carboxymethyl Sodium cellulose, which is 1.5% of the weight of rape straw and soybean straw, is stirred evenly, and the mixed material is sent to the plant straw expansion press, the temperature reaches 180°C, the reaction time is 20s, and the material is ejected instantly to form a sheet shaped products.

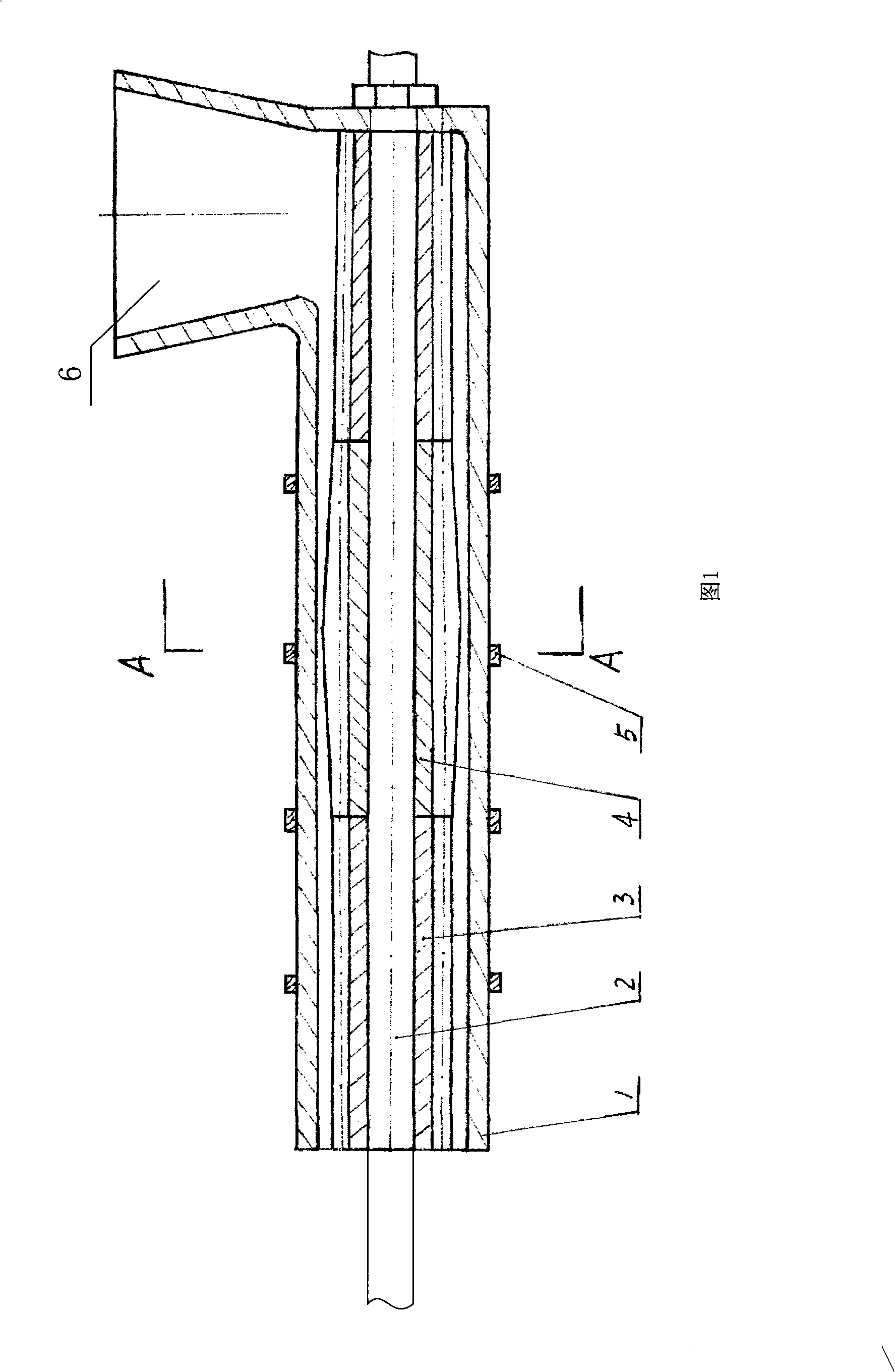

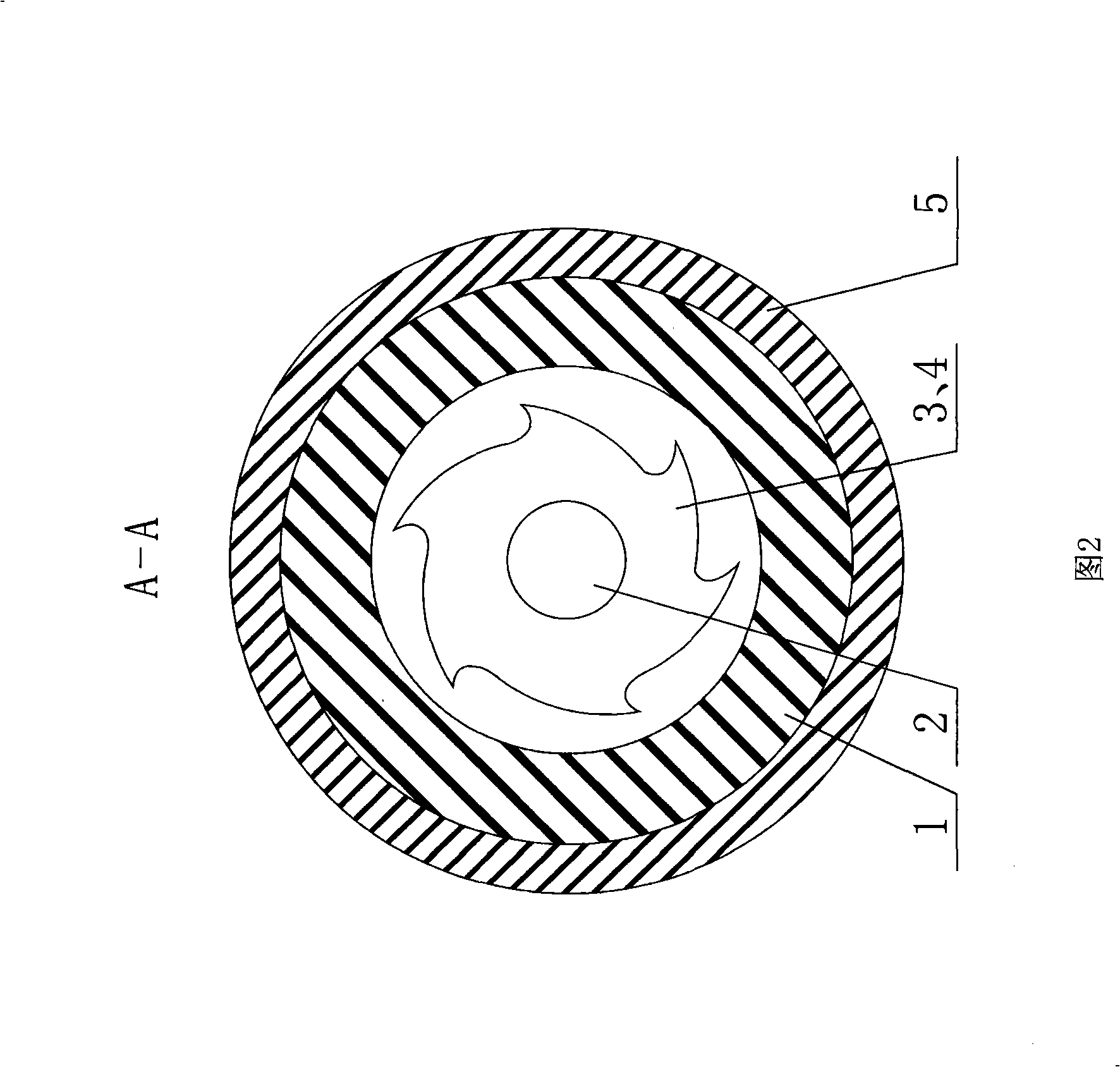

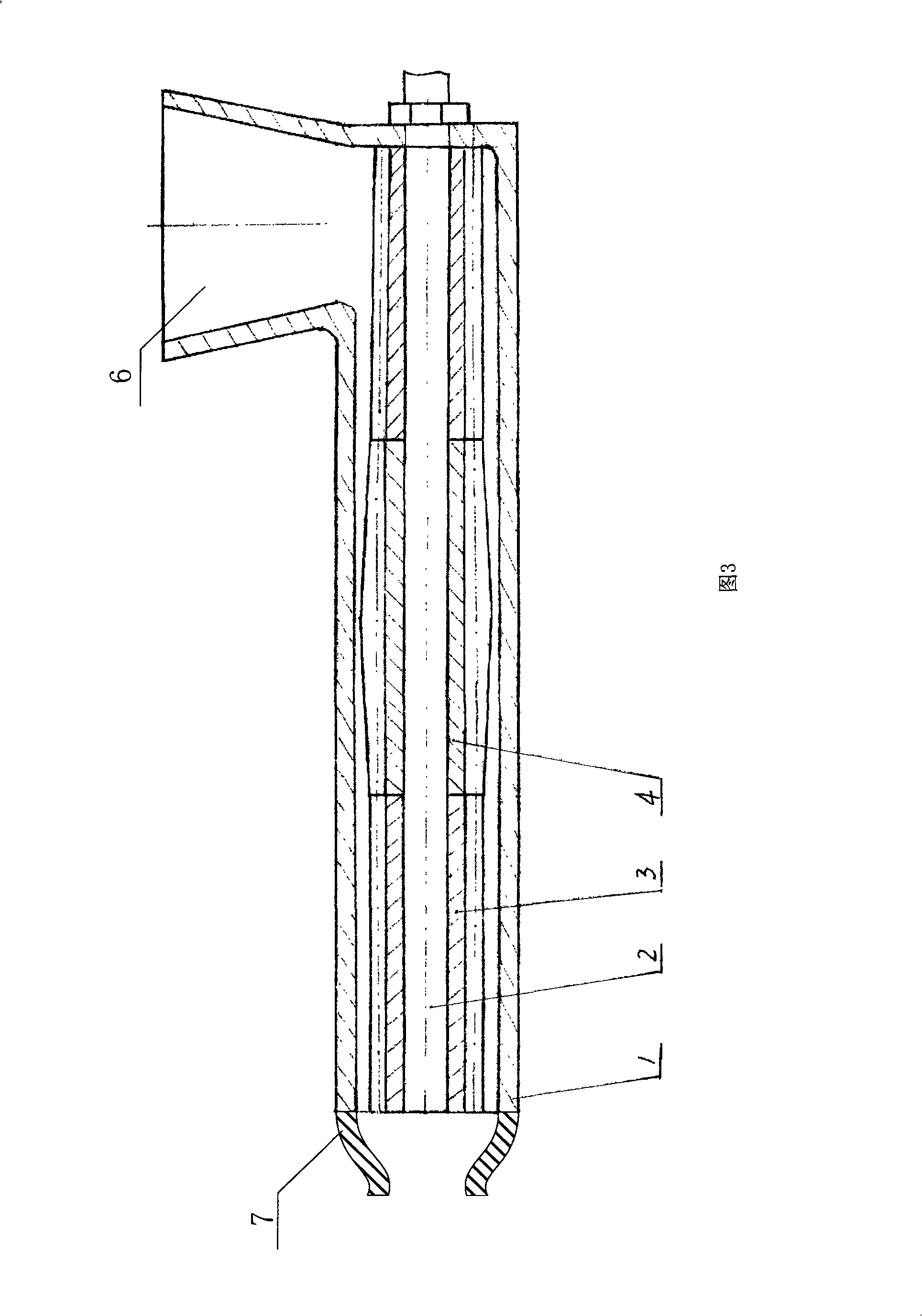

[0024] As shown in Figures 1 and 2, the plant straw expansion press is composed of a shell 1, a spiral sleeve, and an electric heater 5. There is a funnel-shaped feed inlet 6 at the upper end of the shell 1, and the inside of the shell 1 is along the A number of spiral sleeves are arranged in the axial direction, and the adjacent spiral sleeves A 3 and B 4 are connected as a whole through keys. The spiral sleeves are set on the main shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com