Process and equipment for preprocessing cellulosic ethanol raw material

A cellulosic ethanol and pretreatment technology, which is applied in the field of cellulosic ethanol raw material pretreatment process and equipment, can solve the problems affecting the yield of cellulosic ethanol, cost pollution load and equipment investment, etc., so as to reduce pollution load, production cost and high yield. , good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

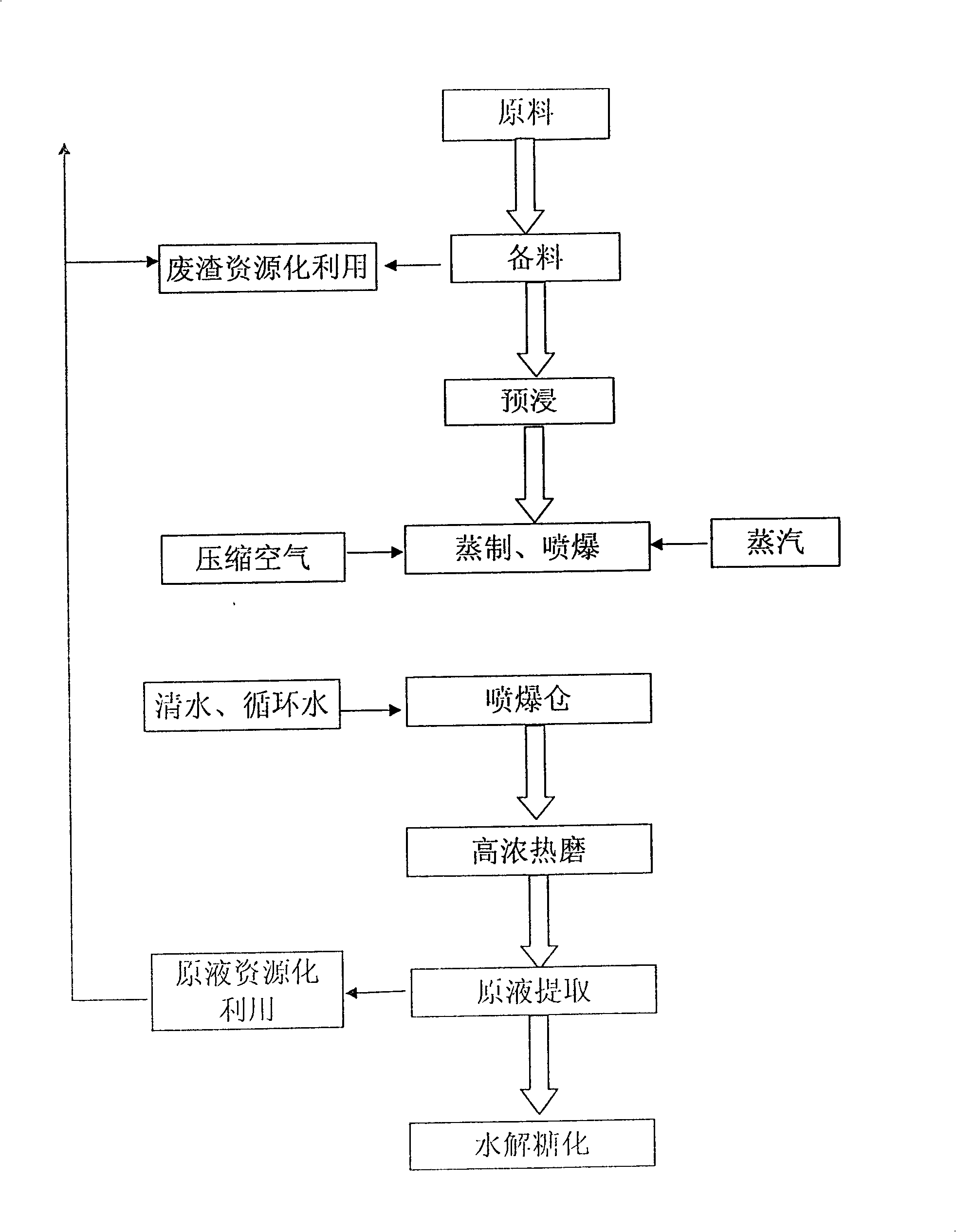

[0020] Example 1: Pretreatment process of cellulosic ethanol using wheat straw as raw material

[0021] 250 kg of wheat straw, cut into 3-5 cm long, remove the soil, wheat leaves, wheat husks, wheat awns, etc. According to the weight ratio of raw material to pretreatment waste liquid or circulating water of 1:0.8-1.5, wetting is carried out and then placed in a pyrolysis tank. Introduce saturated or supersaturated steam to raise the temperature inside the tank to 145-180 degrees. After steaming for 4 to 10 minutes, pass compressed air to 1.3 to 2.0mpa, open the spray valve of the pyrolysis tank to spray and explode, and the obtained material has a pH of 5.0 to 6.5 (water can be added to the concentration required by the process), and the conveying device reaches high-concentration heat. After grinding, enter the original liquid extraction device, extract the original liquid amount of 1.5 ~ 3M 3 / t. The material enters hydrolysis and saccharification, and the raw liquid is u...

Embodiment 2

[0022] Embodiment 2: The pretreatment process of cellulosic ethanol using rubber seed husk as raw material.

[0023] 250 kg of rubber seed shells, after crushing, remove dust, grease and other sundries. According to the weight ratio of raw material to pretreatment waste liquid or circulating water of 1:0.6-1.5, it is soaked and placed in a pyrolysis tank. Introduce saturated or supersaturated steam to raise the temperature inside the tank to 150-200 degrees. After steaming for 4-10 minutes, pass compressed air to 1.5-2.5mpa, and open the spray valve of the pyrolysis tank to blast. The obtained material has a pH of 5.0-6.5 (water can be added to the concentration required by the process), and after being conveyed to the high-concentration hot mill, it enters the raw liquid extraction device, and the extracted raw liquid is 1.5-3M 3 / t, the obtained material enters hydrolysis and saccharification, and the extracted raw liquid is used for resource utilization such as presoaking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com