A cold dyeing direct printing process suitable for cotton fabric reactive dye printing

A reactive dye, cold dyeing and direct printing technology, applied in dyeing method, textile and papermaking, fiber processing and other directions, can solve the problems of indistinct pattern outline of printed fabrics, easily stained white ground, etc. Short steaming time and the effect of saving steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Fabric: cotton gauze 21*21 108*58 47 / 63 / 67

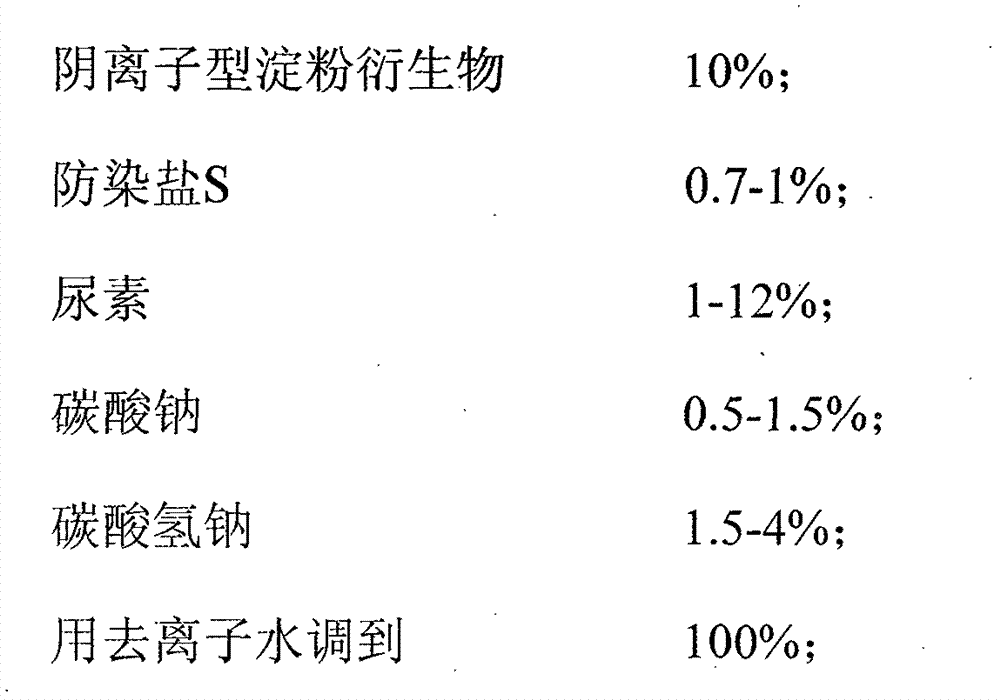

[0027] The content of each component of the pretreatment liquid formulation of the cold dyeing direct printing process by weight percentage is:

[0028] Anionic starch derivatives 10%;

[0029] Anti-staining salt S 0.7%;

[0030] Urea 8%;

[0032] Sodium bicarbonate 1.5%;

[0033] Adjust to 100% with deionized water.

[0034] Wherein the anionic starch derivative is selected from anionic carboxyl starch sodium. The purity of anionic starch derivatives, anti-staining salt S, urea, sodium carbonate and sodium bicarbonate is above industrial purity, including industrial purity.

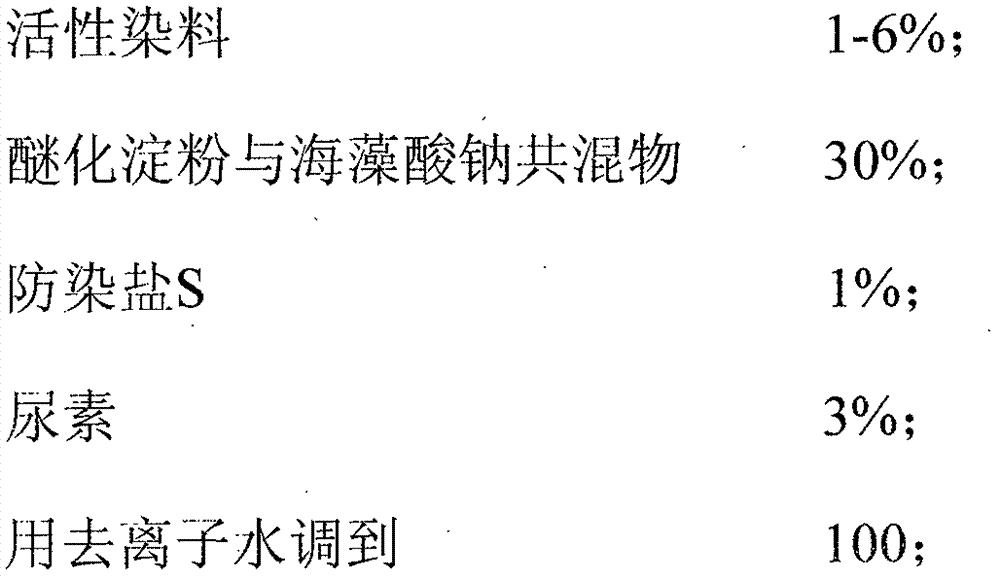

[0035] The content of each component of the color paste formula of the cold dyeing direct printing process by weight percentage is:

[0036] K type reactive dye 1-6%;

[0037] Blend of etherified starch and sodium alginate 30%;

[0038] Anti-staining salt S 1%;

[0039] Urea 3%;

[0040] Adjust to 100% with dei...

Embodiment 2

[0046] Fabric: cotton poplin 40*40 133*72 63 / 67

[0047] The content of each component of the pretreatment liquid formulation of the cold dyeing direct printing process by weight percentage is:

[0048] Anionic starch derivatives 10%;

[0049] Anti-staining salt S 1%;

[0050] Urea 1%;

[0052] Sodium bicarbonate 4%;

[0053] Adjust to 100% with deionized water.

[0054] Wherein the anionic starch derivative is selected from anionic carboxyl starch sodium. The purity of anionic starch derivatives, anti-staining salt S, urea, sodium carbonate and sodium bicarbonate is above industrial purity, including industrial purity.

[0055] The color paste of the cold dyeing direct printing process uses M-type reactive dyes, and the content of each component and the preparation method are the same as the method described in the above-mentioned embodiment 1.

[0056] Cold dyeing direct printing process: cotton poplin is firstly padded with pre-treatme...

Embodiment 3

[0058] Fabric: cotton plain cloth 30*30 68*68 65

[0059] The content of each component of the pretreatment liquid formulation of the cold dyeing direct printing process by weight percentage is:

[0060] Anionic starch derivatives 10%;

[0061]Anti-staining salt S 0.8%;

[0062] Urea 12%;

[0063] Sodium carbonate 1%;

[0064] Sodium bicarbonate 3%;

[0065] Adjust to 100% with deionized water.

[0066] Wherein the anionic starch derivative is selected from anionic carboxyl starch sodium. The purity of anionic starch derivatives, anti-staining salt S, urea, sodium carbonate and sodium bicarbonate is above industrial purity, including industrial purity.

[0067] The color paste of the cold dyeing direct printing process uses PF type reactive dyes, and the content of each component and the preparation method are the same as the method described in the above-mentioned embodiment 1.

[0068] Cold dyeing direct printing process: cotton plain cloth is firstly padded with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com