A kind of Rehmannia glutinosa processing technology

A yellow processing and crafting technology, applied in the new field of Rehmannia glutinosa processing technology, can solve the problems of long steaming time, high defective rate, difficult to satisfy moisture and verbascoside content, etc., and achieves short steaming time and high qualification rate. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

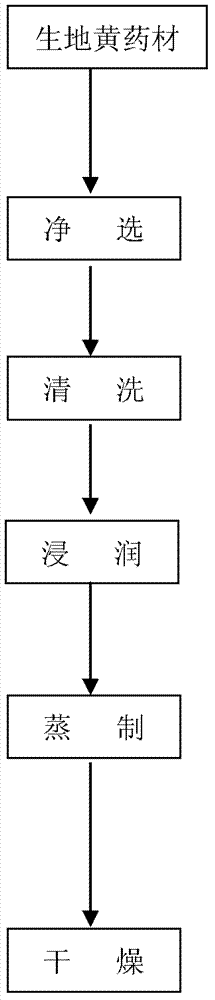

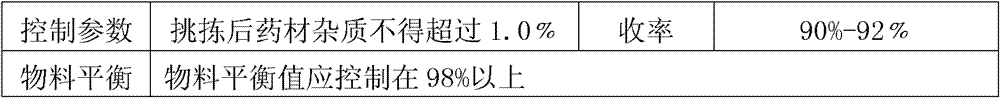

Method used

Image

Examples

experiment example 1

[0094] An investigation report on the production process and product quality of rehmannia glutinosa as an experimental example

[0095] 1. Purpose of inspection:

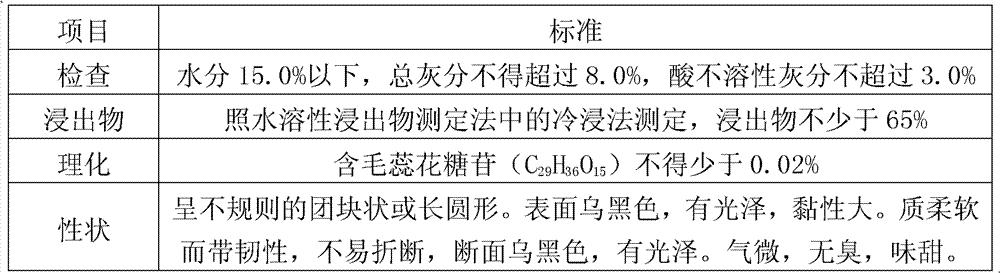

[0096] In view of the 2010 edition of the Pharmacopoeia, the water content of rehmannia glutinosa should not exceed 15.0%, and the production process and quality of rehmannia glutinosa were inspected.

[0097] 2. Study plan

[0098] 1. Statistics of the corresponding data of processed mature Rehmannia glutinosa in Shangluo history---moisture content and content, so as to clarify the corresponding relationship between content loss and moisture reduction in the process of processing;

[0099] 2. Track the production process of a batch of Rehmannia glutinosa, take samples in the middle, investigate the content changes in each production process, determine the key processes that affect the content of verbascoside, and provide data support for optimizing the processing process and reducing content loss during processing...

experiment example 2

[0115] Experimental Example 2: Experiment on the change of verbascoside in Rehmannia glutinosa under different steaming times.

[0116] 1. Objective: To determine the effective steaming time period of Rehmannia glutinosa according to the change rule of verbascoside under different steaming time.

[0117] 2. Method steps: ①Clean selection and cleaning: clean the Rehmannia glutinosa until there is no sand, stones, clods and impurities, and then clean until the surface is free of dust and mud sand; ②Infiltration: Pour the rehmannia glutinosa into the moistening medicine pool, and gradually add the prepared auxiliary materials , constantly turning until the auxiliary materials are completely immersed in the medicinal materials; ③ steaming: put the moistened rehmannia glutinosa into the steamed medicine basket, the thickness not exceeding 15cm, put it into a horizontal sterilizer, control the pressure at 0.12mpa ~ 0.15mpa, every Open the trap to drain water once in half an hour, an...

experiment example 3

[0136] Experimental Example 3: Experiment on the influence of different packing methods on the content of steamed Rehmannia glutinosa.

[0137] 1. Purpose: To explore a better way of dressing according to the difference in steam penetration and juice loss under different dressing conditions.

[0138] 2. Method steps:

[0139] ① The conditions of net selection, cleaning, infiltration and steaming are the same as those of Test 2, and the steaming time is 3 hours;

[0140] ②Method one bag method: Put the moistened rehmannia glutinosa into a woven bag and spread it on a stainless steel plate (with holes), the thickness not exceeding 15cm, put it into a horizontal sterilizer for steaming;

[0141] Method two tray loading method: evenly spread the moistened rehmannia glutinosa on a stainless steel tray (with holes), the thickness not exceeding 15cm, put it into a horizontal sterilizer for steaming;

[0142] Method 3 Frame loading method: put the moistened rehmannia glutinosa direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com