Oil gas recovery device and method

A recovery device and recovery method technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of large residual organic matter in adsorbent, low concentration of organic matter in desorbed gas, low condensation recovery efficiency, etc., and achieve good results. Desorption effect, elimination of potential safety hazards, reduction of operating costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the present invention is not limited.

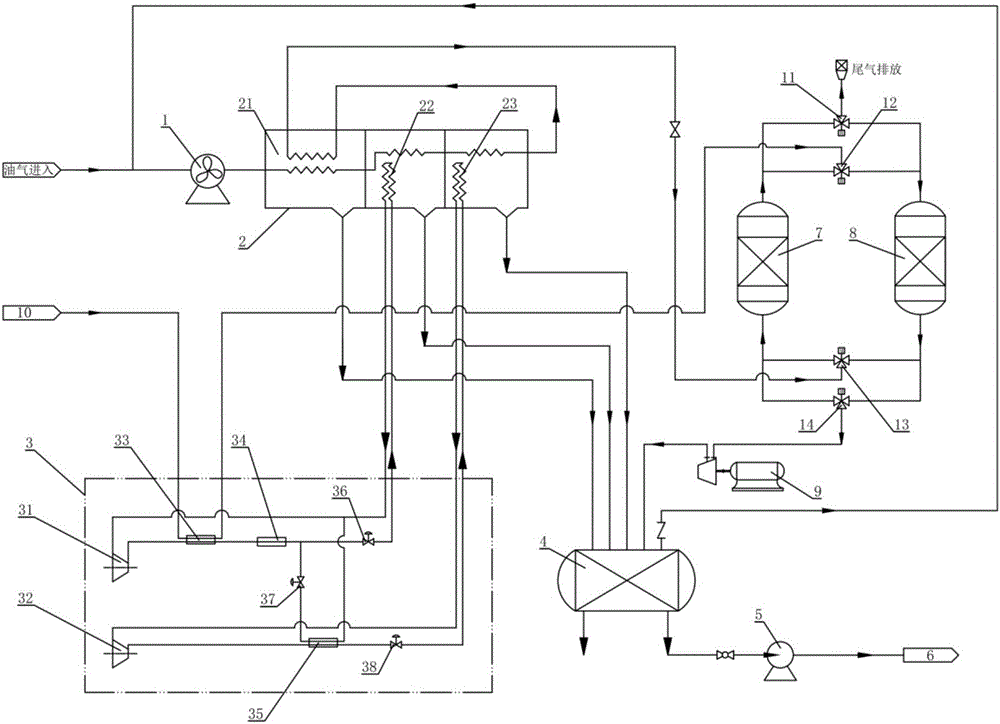

[0022] An oil gas recovery device, comprising an anti-exposure centrifugal fan 1, a cold box 2, a refrigeration unit 3, a liquid storage tank 4, a liquid return pump 5, an oil storage tank 6, a first adsorption tank 7, a second adsorption tank 8, and a vacuum pump 9 , nitrogen generating unit 10, also includes PLC automatic control system; VOCs oil gas is first transported into cold box 2 by anti-exposure centrifugal fan 1, and said cold box 2 includes precooling part 21, primary condensing part 22, secondary condensing part 23 , wherein the secondary condensing part 23 is connected to the precooling part 21, so that the cooling capacity of the precooling part 21 comes from the oil and gas from the secondary condensing part 23, and the primary condensing part 22 and the secondary condensing part 23 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com