Thermal regeneration and reutilization method for waste active carbon

A technology of activated carbon and thermal regeneration, which is applied in the direction of chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problem of high volume loss rate of activated carbon regeneration, and achieve the effect of reducing gas overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

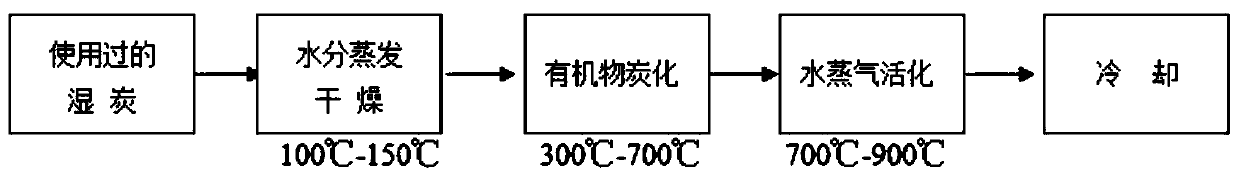

[0029] A thermal regeneration and reuse method of spent activated carbon, the method comprises the following steps:

[0030] 1) Drying: Heat the used wet charcoal to 100°C, and heat it at a constant temperature within this temperature range for 3 hours;

[0031] 2) Carbonization: heat the dried activated carbon to 700°C within 4 hours and keep it for 6 hours;

[0032] 3) Activation: heat the carbonized activated carbon to 850°C, control the heating rate to 15°C / min, and keep it for 3 hours after the heating is completed;

[0033] 4) Cooling: The activated carbon after the activation treatment is rapidly cooled to 25°C.

Embodiment 2

[0035] A thermal regeneration and reuse method of spent activated carbon, the method comprises the following steps:

[0036] 1) Drying: Heat the used wet charcoal to 150°C, and heat it at a constant temperature within this temperature range for 2 hours;

[0037] 2) Carbonization: heat the dried activated carbon to 300°C within 6 hours and keep it for 6 hours;

[0038] 3) Activation: heat the carbonized activated carbon to 855°C, control the heating rate to 15°C / min, and keep it for 2 hours after the heating is completed;

[0039] 4) Cooling: The activated carbon after the activation treatment is rapidly cooled to 28°C.

Embodiment 3

[0041] A thermal regeneration and reuse method of spent activated carbon, the method comprises the following steps:

[0042] 1) Drying: Heat the used wet charcoal to 100°C, and heat it at a constant temperature within this temperature range for 2 hours;

[0043] 2) Carbonization: heat the dried activated carbon to 700°C within 6 hours and keep it for 6 hours;

[0044] 3) Activation: heat the carbonized activated carbon to 850°C, control the heating rate to 15°C / min, and keep it for 2 hours after the heating is completed;

[0045] 4) Cooling: The activated carbon after the activation treatment is rapidly cooled to 28°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com