Patents

Literature

34results about How to "Raise the degradation temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC foaming wood plastic composite material

The invention discloses a PVC foaming wood plastic composite material which is produced by processing the raw materials based on the parts by weight: 100 parts of polyvinyl chloride (PVC), 40-50 parts of lignified plant fiber, 10-20 parts of active light calcium, 3-6 parts of calcium zinc complex stabilizer, 1-3 parts of compound-type foaming agent, 0.5-1.5 parts of lubricating agent OPE wax, 0.5-1 part of compound lubricating agent and 3-8 parts of foaming conditioning agent; the raw materials are evenly mixed by a mixing machine and then are directly put into a screw extruder to be extruded and molded at the temperature of 160-170 DEG C. The PVC foaming wood plastic composite material is added with full dose of heat stabilizer in the process of blending and processing, so that the degradation temperature of plastics can be increased, thermal degradation of the plastics and carbonization of wood powder in the process of mixing and forming can be prevented, and the operation of extruding and molding can be completed in one step, thus greatly simplifying the production technique and reducing the production cost.

Owner:石河子市森力新材料科技有限公司

Nanometer composite materials with soya protein and montmorillonite, its production and use

A soy protein / montmorillonite nanometer composite material, its production and use are disclosed. The material consists of montmorillonite 1~24wt% and soy protein 76~99wt%. The process is carried out by dispersing montmorillonite and soy protein in water proportionally, agitating the two soliquoids while blending, drying to obtain soy protein / montmorillonite nanometer composite, adding into glycerine, mixing by extruder and hot pressing to obtain plastic sheet material. It is simple, has excellent mechanical, thermal, ultraviolet absorbing performances and no environmental pollution. It can be used for optical selectivity and biological degradable material.

Owner:WUHAN UNIV

Low-odor environmentally-friendly polyvinyl chloride (PVC) composite material

ActiveCN107286512AThe amount of volatile gas is reducedHigh strengthPolyvinyl chlorideFire retardant

The invention relates to the field of polymer materials, and specifically relates to a low-odor environmentally-friendly polyvinyl chloride (PVC) composite material. The composite material at least comprises the following components in parts by weight: 80 to 110 parts of polyvinyl chloride resin, 4 to 12 parts of chlorinated polyethylene, 8 to 20 parts of butyl etherified urea-formaldehyde resin, 15 to 40 parts of plasticizer, 4 to 10 parts of benzhydrazide derivatives, 0.1 to 0.8 part of lubricant, 0.5 to 3 parts of fire retardant, 1 to 3 parts of vermiculite powder, and 1 to 3 parts of montmorillonite; wherein the weight-average molecular weight of the polyvinyl chloride resin is in a range of 60000 to 120000, the plasticizer is a citrate plasticizer, and the lubricant is a fatty acid or metal soap lubricant.

Owner:浙江天原医用材料有限公司

Production method of 5 type PVC (poly vinyl chloride) resin foamed wood plastic composite

The invention relates to a production method of a 5 type PVC (poly vinyl chloride) resin foamed wood plastic composite. The comprises the following raw materials in parts by weight: 100 parts of 5 type PVC resin, 40-85 parts of wood fibers, 4-5 parts of a stabilizer, 0.2-1 part of a foaming agent, 4-5 parts of a foaming regulating agent, 2-3 parts of a modifier, 0.2-0.3 part of a lubricating agent and 20 parts of light calcium carbonate. The preparation method comprises the following steps of: (1) mixing the raw materials, namely stirring and mixing the raw materials by adopting a 800 / 2500 type mixer; and (2) carrying out extrusion moulding, namely feeding the uniformly mixed material in the step (1) into a 65 type double-screw wood plastic moulding machine to be extruded and moulded. The production method has the advantages that the raw material ratio is reasonable, a dustfree compound stabilizer is added to increase a plastic degradation temperature and prevent materials from carbonization in a production process, extrusion moulding can be carried out by adopting a one-step method of the double-screw extruder, and foaming ratio, surface hardness and glossiness of the 5 type PVC resin foamed wood plastic composite product are consistent with those of SG-7 and SG-8 type PVC products.

Owner:JIUJIANG SALT LAKE NEW MATERIALS CO LTD

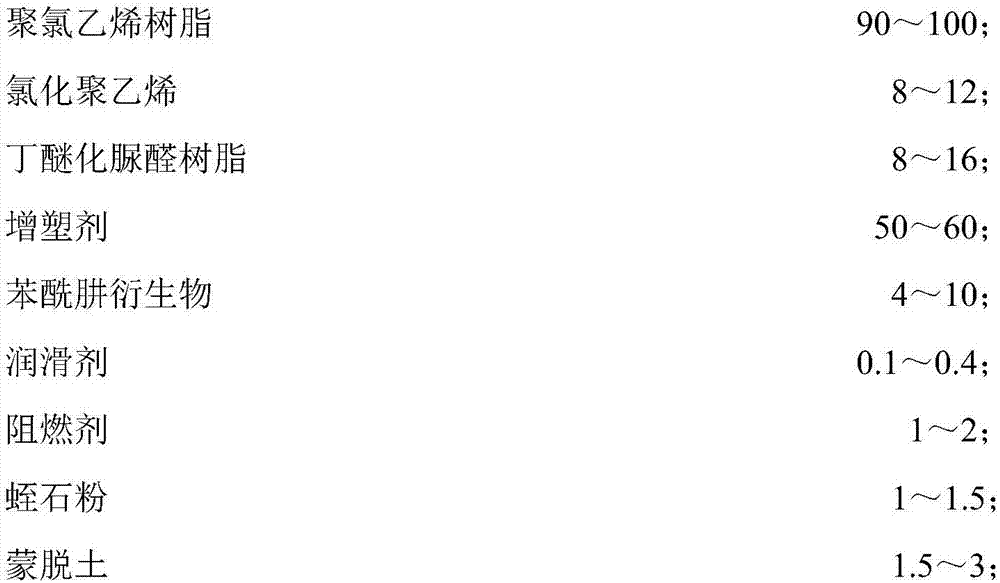

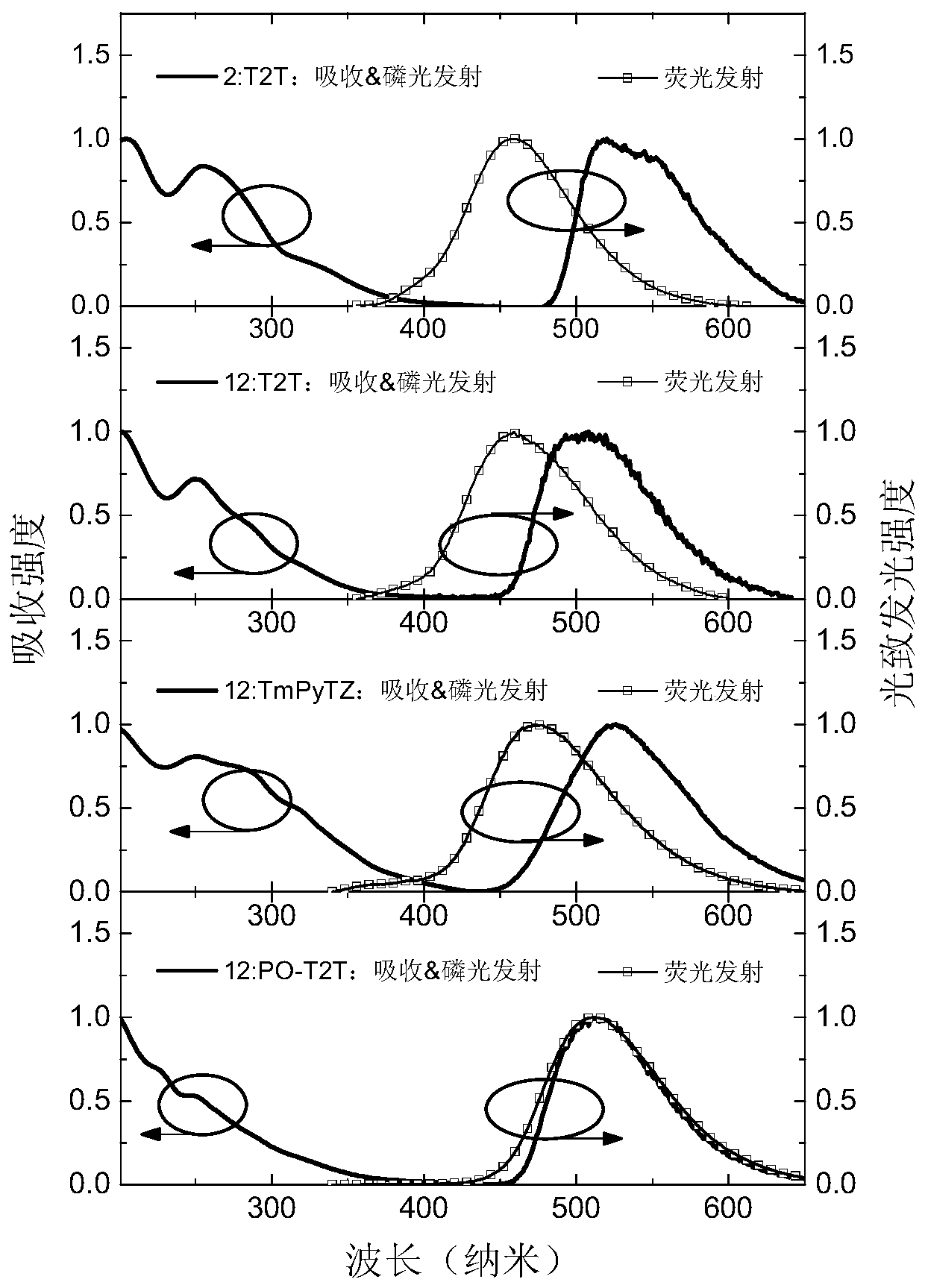

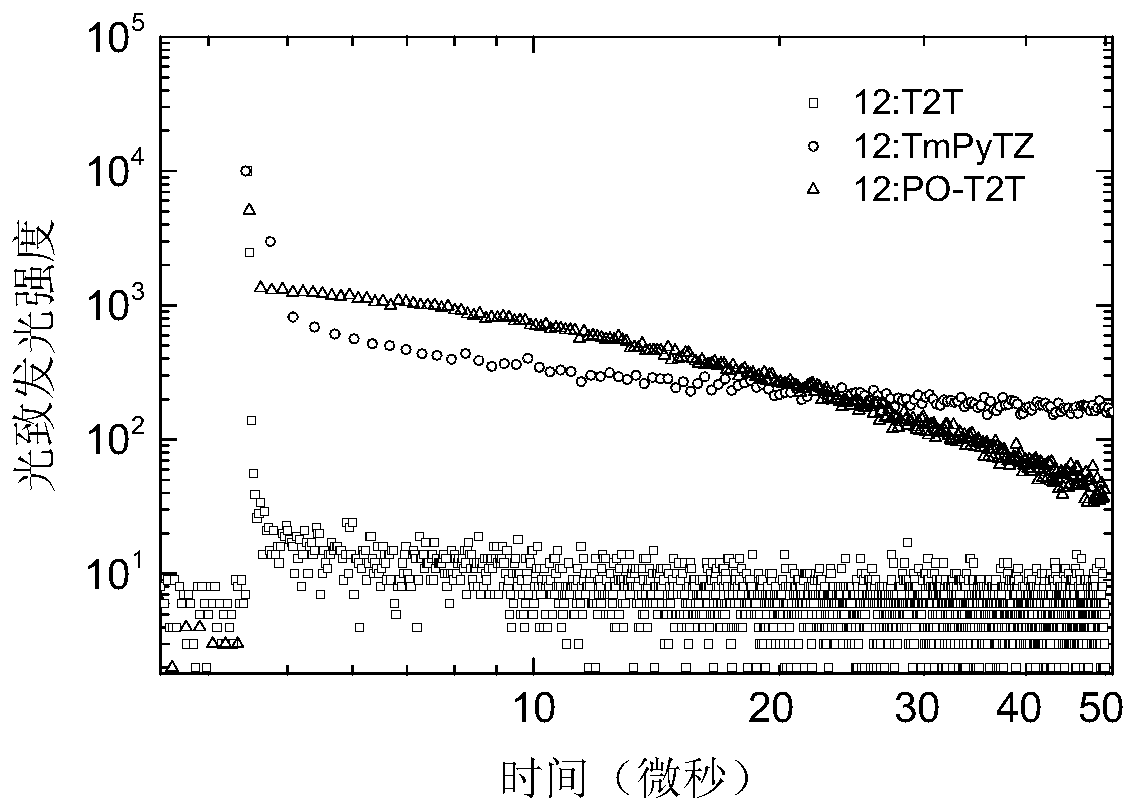

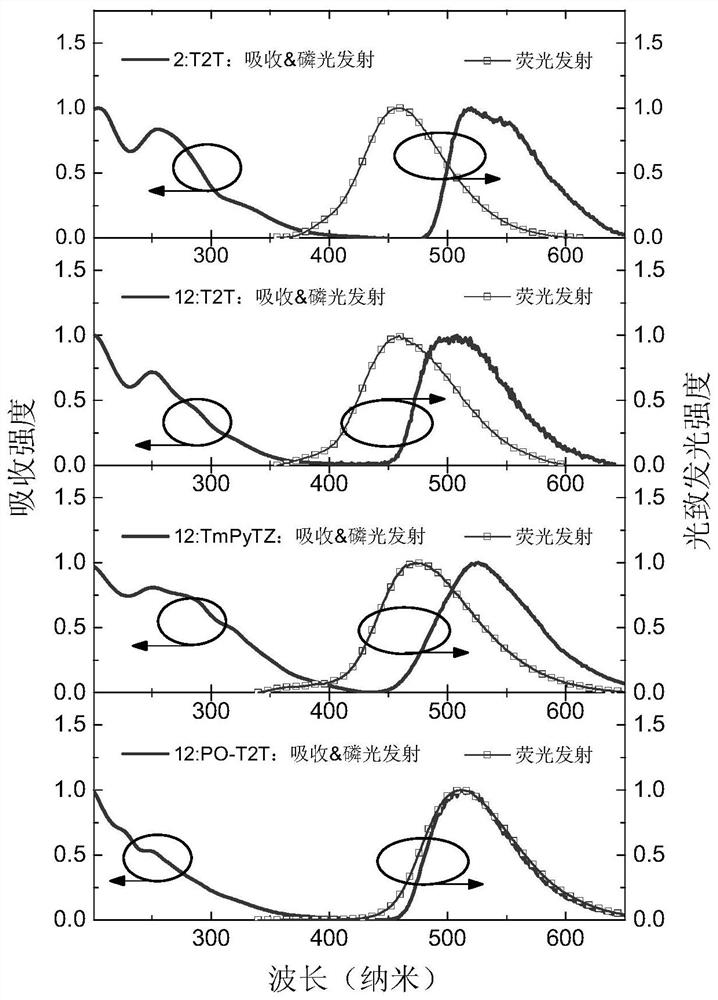

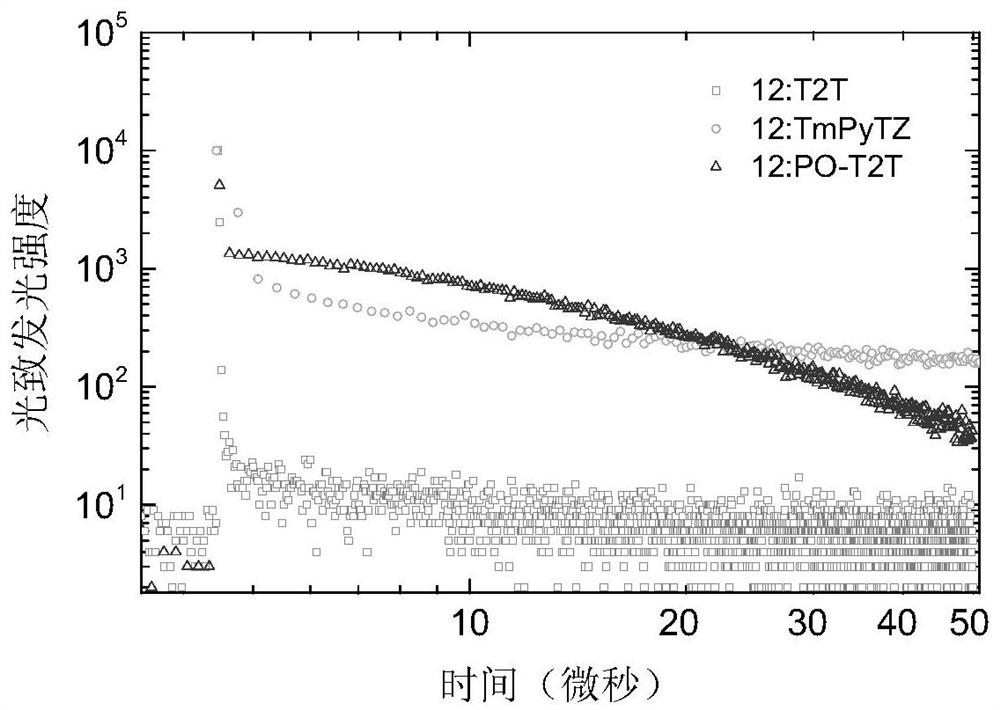

Non-aromatic amine small molecule photoelectric material and preparation and application thereof

ActiveCN109776490AEffective control of dihedral angleRegulating Molecular WeightOrganic chemistrySolid-state devicesQuantum yieldStructural formula

Owner:SOUTH CHINA UNIV OF TECH

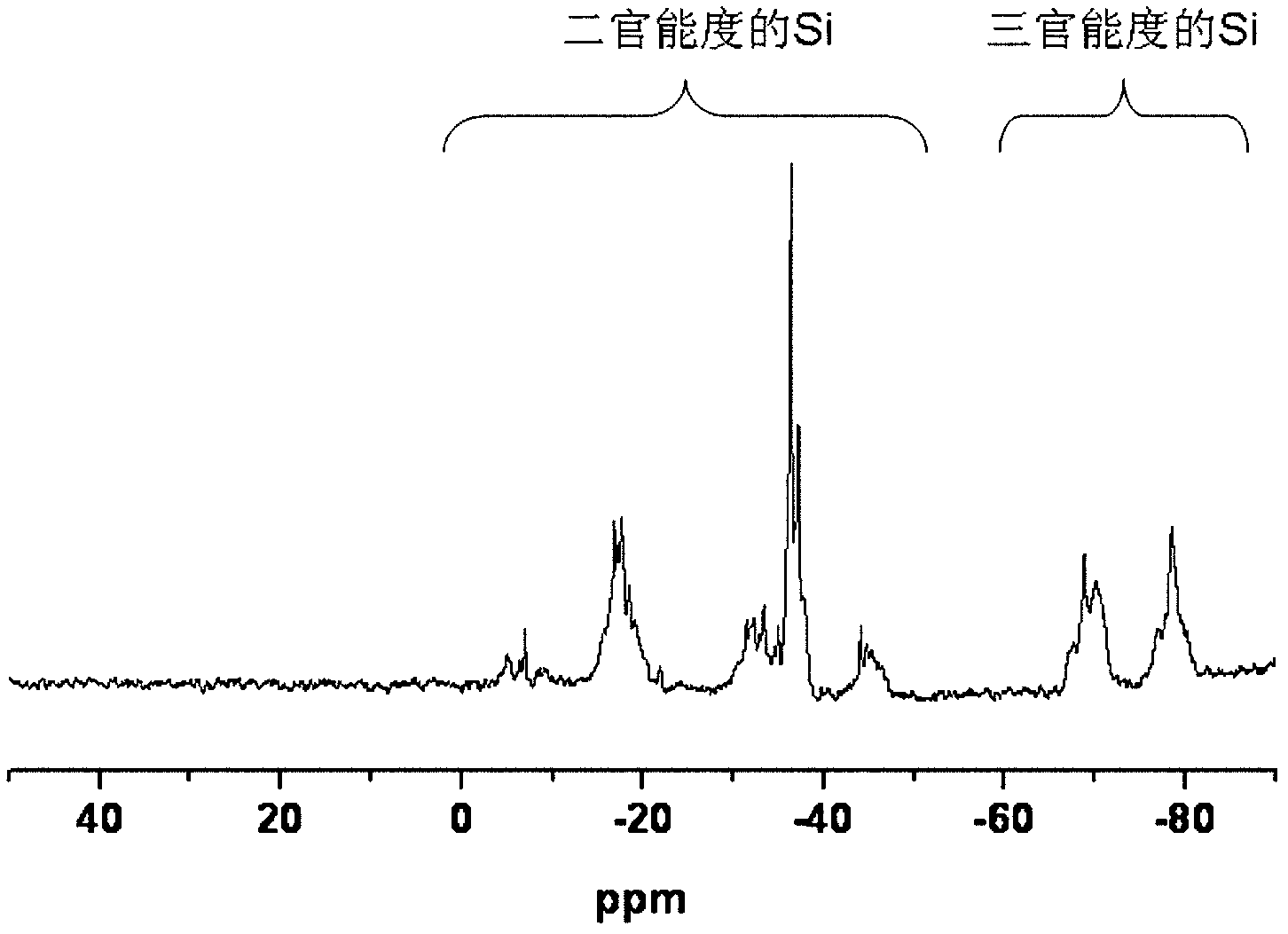

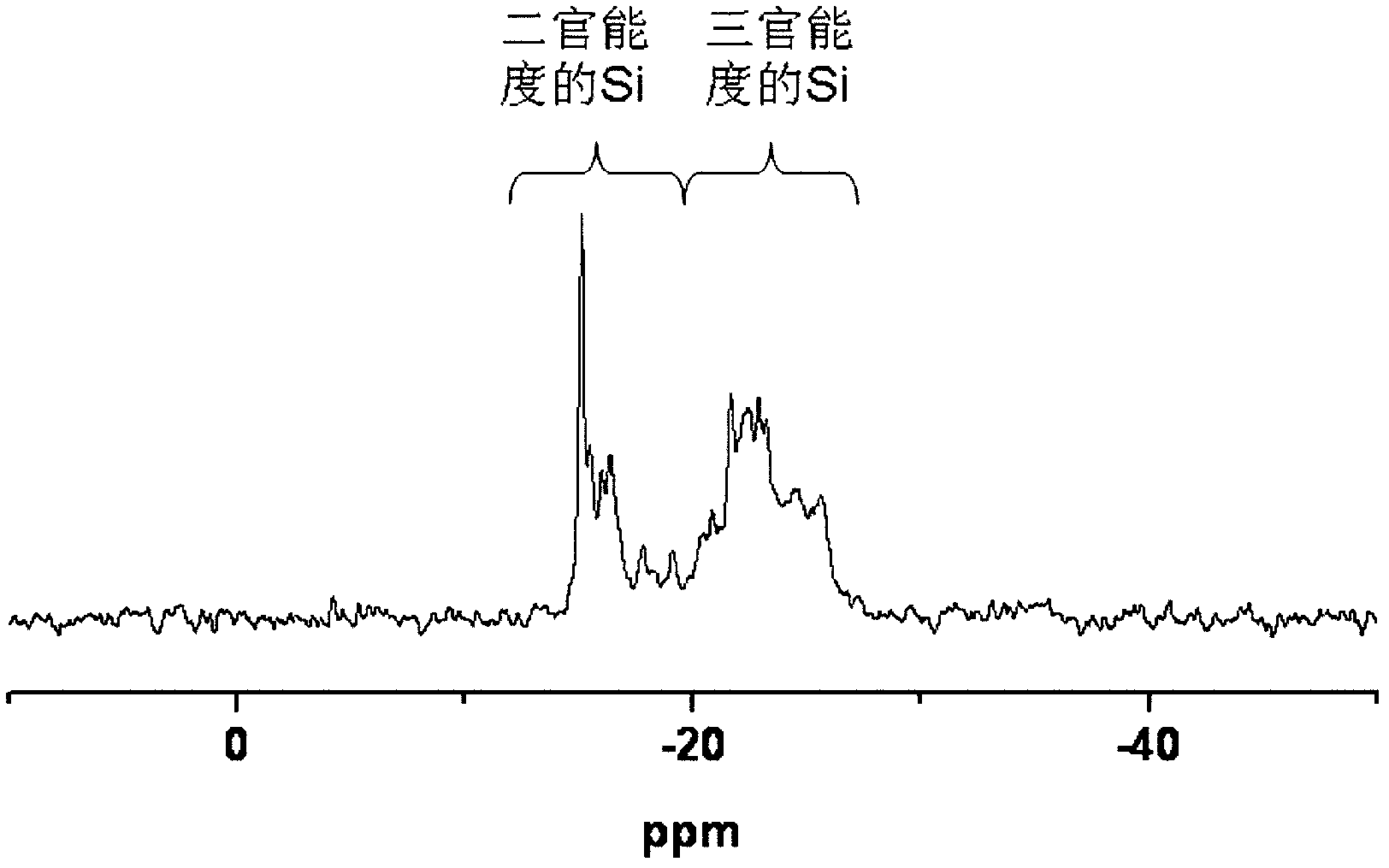

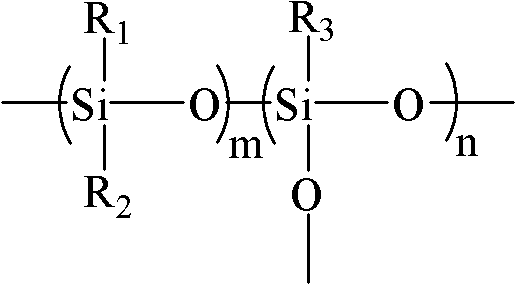

Room temperature curing ultrahigh temperature-resistant adhesive, liquid silicon resin dedicated for the room temperature curing ultrahigh temperature-resistant adhesive and their preparation methods

ActiveCN102627769ARaise the degradation temperatureGood temperature resistanceNon-macromolecular adhesive additivesSolventLap joint

The invention discloses a room temperature curing ultrahigh temperature-resistant adhesive, a liquid silicon resin dedicated for the room temperature curing ultrahigh temperature-resistant adhesive and their preparation methods. The preparation method of the liquid silicon resin comprises the following steps of dissolving organic chlorosilanes in one or more organic solvents, dropwisely adding the mixture obtained by the previous step into a mixture of water and one or more organic solvents, stirring at a temperature of 40 to 100 DEG C for 5 to 40 hours, separating out an organic phase, washing the organic phase by distilled water so that a pH value is 7, drying, filtering, and carrying out solvent removal to obtain the liquid silicon resin which is transparent. The liquid silicon resin as an adhesive base, a silicon-nitrogen polymer as a curing agent and a certain amount of a composite filling material are prepared into the room temperature curing ultrahigh temperature-resistant adhesive. After room temperature curing for 3 days, the room temperature curing ultrahigh temperature-resistant adhesive has single-lap joint shearing strength of 5.63Mpa to stainless steel. After aging at a temperature of 1000 DEG C for 20 minutes, the room temperature curing ultrahigh temperature-resistant adhesive retains shearing strength of 2.16Mpa. After room temperature curing, the room temperature curing ultrahigh temperature-resistant adhesive has the maximum shearing strength of 2.41Mpa at a temperature of 800 DEG C.

Owner:INST OF CHEM CHINESE ACAD OF SCI

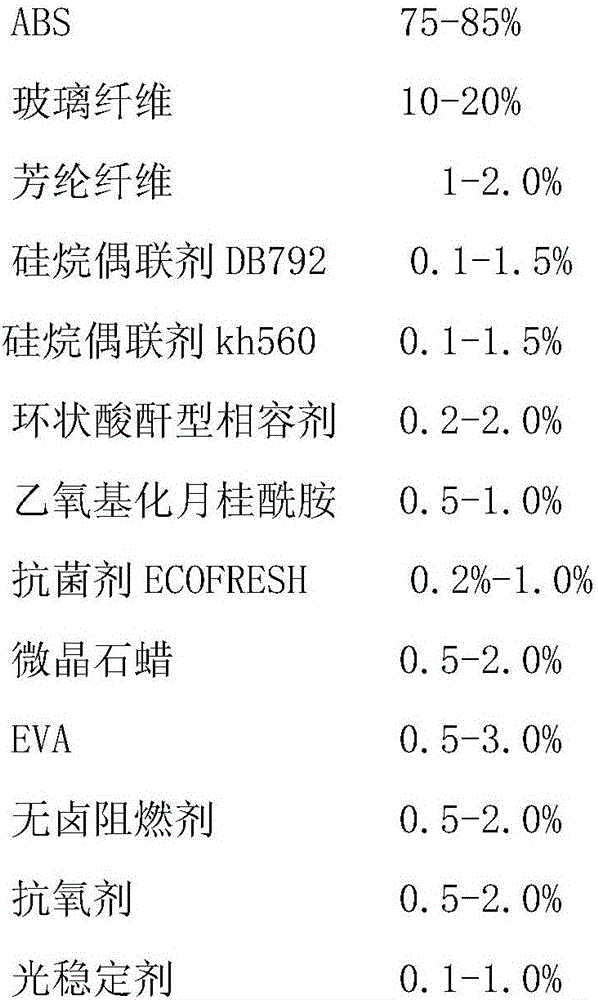

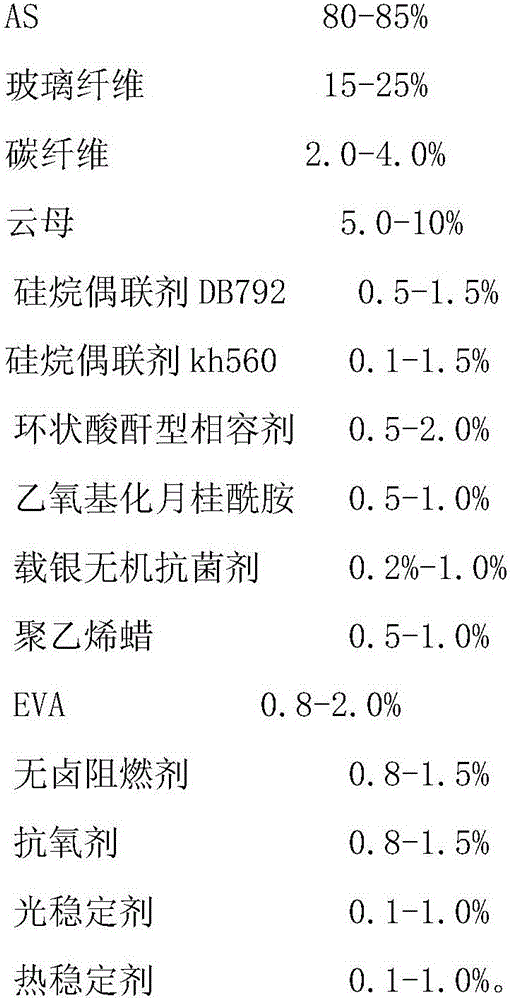

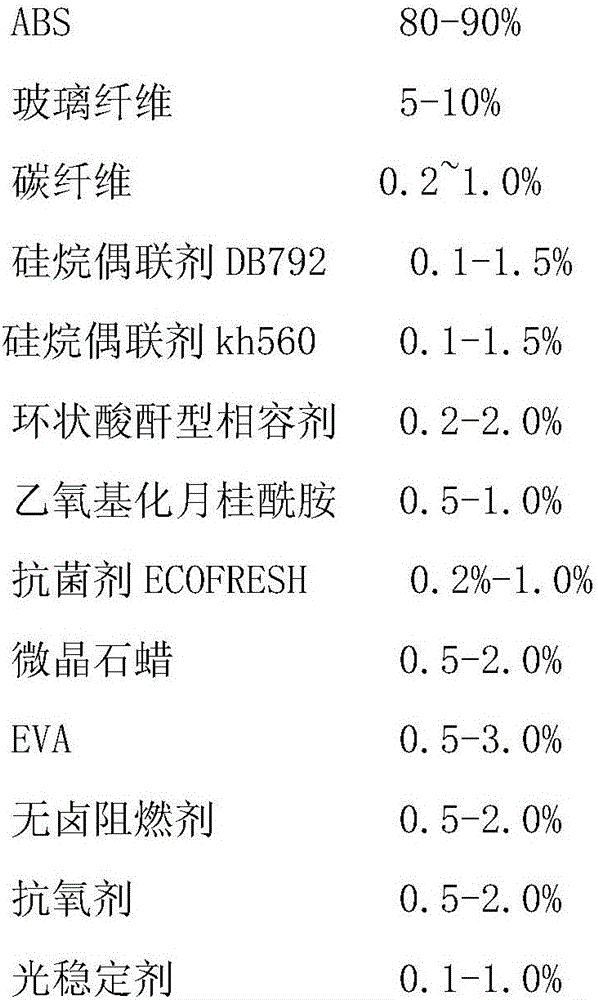

Centrifuging fan blade and preparation method thereof

InactiveCN106700401AImprove heat resistanceGood chemical resistanceMicrocrystalline waxPlastic materials

The invention relates to a fan blade and a preparation method of the fan blade. The centrifuging fan blade is prepared through injection moulding from the following materials by mass percent: 75-85% of ABS, 10-20% of glass fiber, 1.0-2.0% of aramid fiber, 0.1-1.5% of a silane coupling agent DB792, 0.1-1.5% of a silane coupling agent kh560, 0.2-2.0% of a cyclic anhydride type compatilizer, 0.5-1.0% of ethyoxyl lauramide, 0.2%-1.0% of antibacterial agent ECOFRESH, 0.5-2.0% of microcrystalline wax, 0.5-3.0% of EVA, 0.5-2.0% of a halogen-free flame retardant, 0.5-2.0% of antioxygen, 0.1-1.0% of a light stabilizer, and 0.1-1.0% of a heat stabilizer. The centrifuging fan blade has the higher performances of heat resistance, resistance to chemical attack, ageing resistance, mildew prevention, protection from ultraviolet rays and the like, is high in density and hardness and small in size deformation, and improves the tensile strength of a plastic material.

Owner:安徽朗迪叶轮机械有限公司

Modified polypropylene plastic

The invention discloses a modified polypropylene plastic, which comprises the following raw materials in parts by weight: 80-150 parts of PP, 3-12 parts of POE, 1-9 parts of grafted EVA, 1-5 parts ofa mixture of silicone powder and PE wax, 5-30 parts of calcium carbonate and 2-15 parts of a flame retardant. The modified polypropylene plastic is prepared by adding the silicone powder, so that themechanical property of the polypropylene plastic is improved, and the toughness of the polypropylene plastic is improved; the silicone powder and the PE wax are compounded to achieve a synergistic effect, so that the mechanical property of the polypropylene plastic is further improved.

Owner:ZHEJIANG XINDING PLASTIC

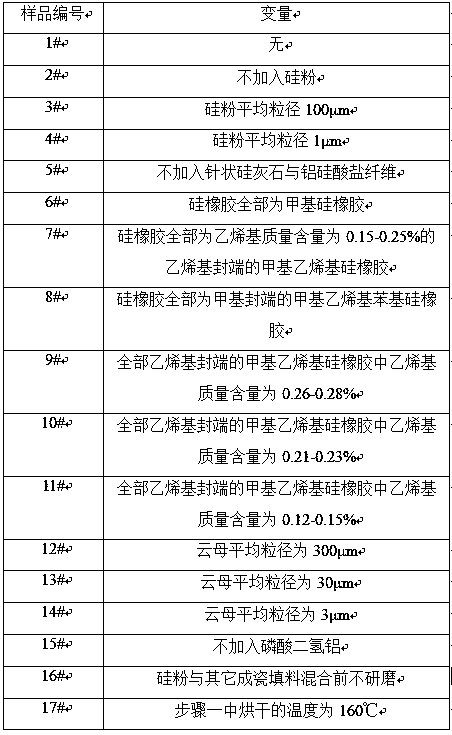

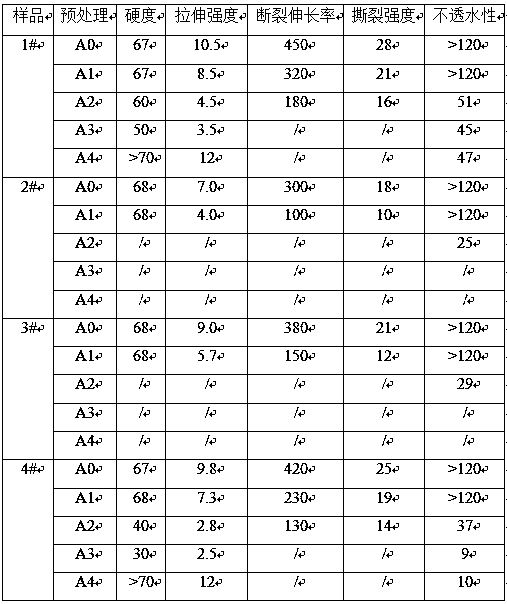

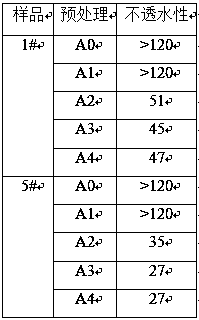

Waterproof ceramicized silicon rubber material and preparation method and application thereof

InactiveCN108948744ADenseImprove waterproof performanceApparatus for joining/termination cablesCable glandPolymer science

The invention discloses a waterproof ceramicized silicon rubber material comprising a ceramic-forming filler, silicone rubber, silicone oil, boron oxide, a coupling agent and a vulcanizing agent; andthe ceramic-forming filler comprises silicon powder, mica and silicon dioxide. A preparation method comprises the following steps: (1) grinding the silicon powder, mixedly grinding the silicon powderand other ceramic-forming filler components, and drying to obtain the pretreated ceramic-forming filler; (2) blending all components excluding the ceramic-forming filler and the vulcanizing agent, mixing and performing mixing under vacuum to obtain organosilicone rubber compound; (3) mixing the pretreated ceramic-forming filler with the organosilicone rubber compound; and (4) adding the vulcanizing agent for mixing. The waterproof ceramicized silicone rubber has good mechanical properties at normal temperature, and has a low ceramic-forming temperature to avoid cracking at ambient temperatureof 300 to 400 DEG C, so that a ceramic body transformed after ceramic-forming has a dense structure and good waterproof performance. The waterproof ceramicized silicon rubber material can be used in acable gland with a refractory layer made of the waterproof ceramicized silicon rubber material, and the cable gland is mechanically stable and still has water resistant at high temperature.

Owner:BEISIT ELECTRIC TECH HANGZHOU CO LTD

Ultraviolet curing adhesive with high temperature resistance and preparation method thereof

PendingCN114854312AGood adhesionImprove high temperature resistanceNon-macromolecular adhesive additivesChemical industryMethacrylatePolymer science

The invention discloses an ultraviolet curing adhesive with high temperature resistance and a preparation method of the ultraviolet curing adhesive, and belongs to the technical field of preparation of photocuring materials. The technical problems that an existing ultraviolet curing adhesive cannot keep the adhesive performance under the high-temperature condition and is prone to falling off in the production process are solved. The ultraviolet curing adhesive comprises an acrylate prepolymer, an active monomer, a photoinitiator and an auxiliary agent. Wherein the acrylic acid prepolymer is a mixture of organic silicon modified acrylate and methacrylate type liquid isoprene rubber. According to the invention, a manner of modifying acrylate is adopted, a group structure with high temperature resistance is introduced into an acrylate prepolymer, and the modified acrylate and methacrylate isoprene are blended according to a certain proportion, so that the prepolymer with excellent high temperature resistance is prepared; by optimizing the formula, the ultraviolet curing adhesive which can still keep good adhesive performance in a high-temperature environment is obtained.

Owner:长春艾德斯新材料有限公司

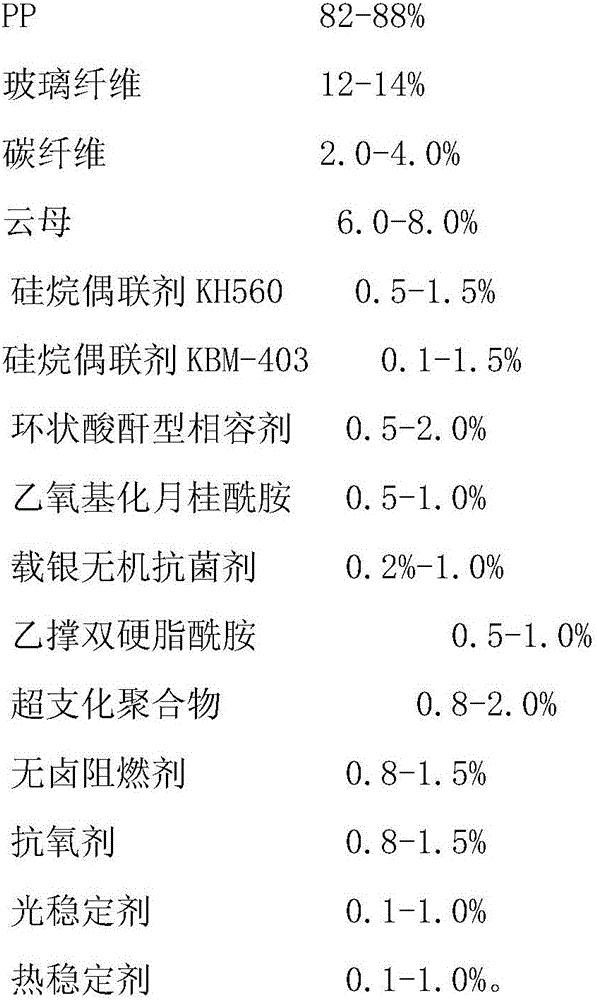

Centrifugal fan blade and preparation method thereof

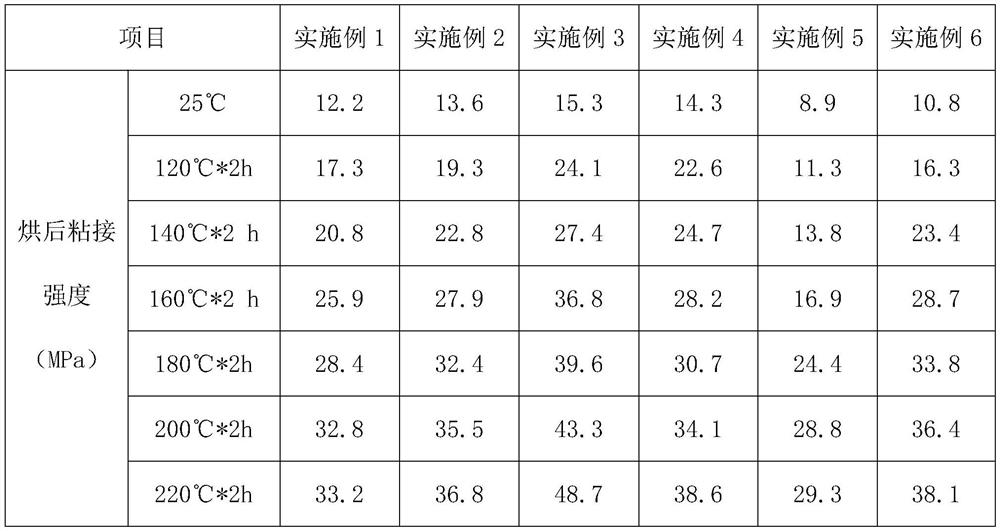

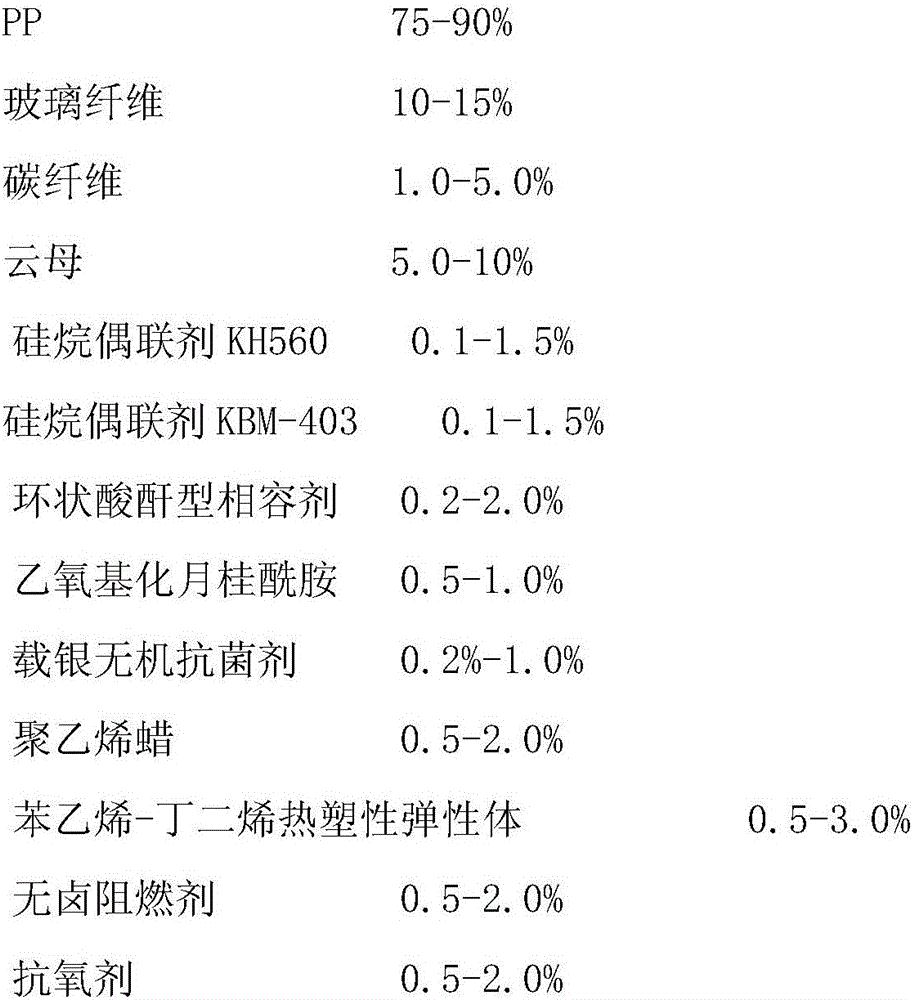

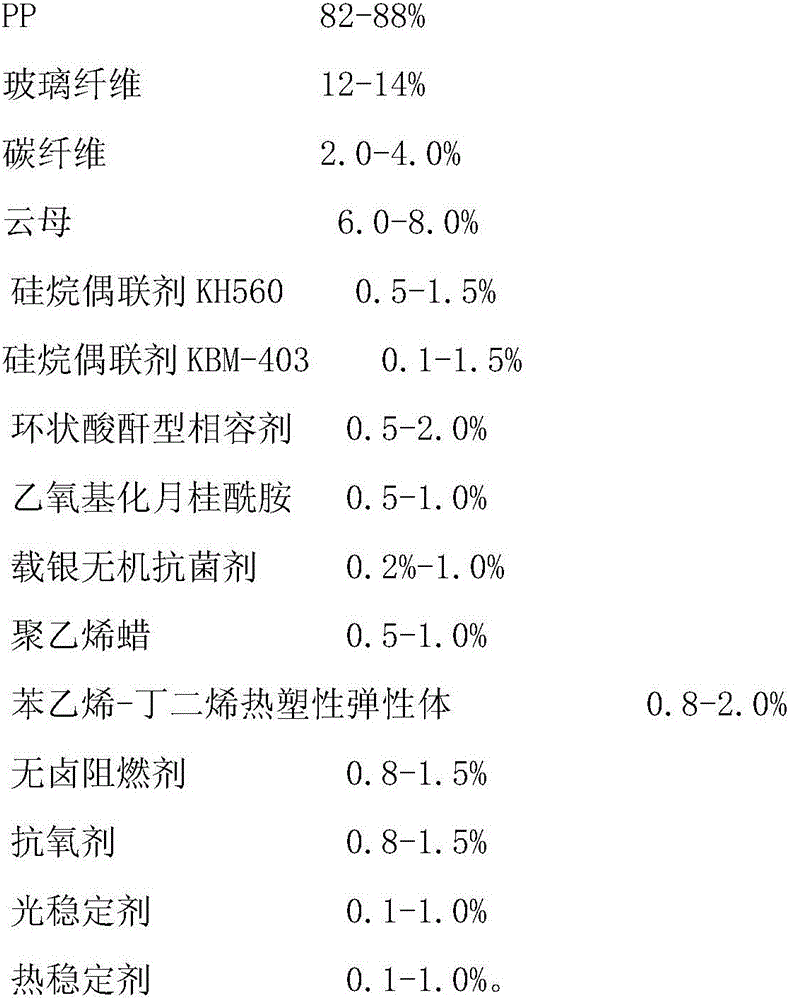

The invention relates to a fan blade and a preparation method thereof. A centrifugal fan blade is prepared the following materials in percentage by mass through injection molding: 75 to 90 percent of PP (Poly Propylene), 10 to 15 percent of fiberglass, 1.0 to 5.0 percent of carbon fiber, 5.0 to 10 percent of mica, 0.1 to 1.5 percent of silane coupling agent KH560, 0.1 to 1.5 percent of silane coupling agent KBM-403, 0.2 to 2.0 percent of cyclo-anhydride compatilizer, 0.5 to 1.0 percent of ethoxyl lauramide, 0.2 to 1.0 percent of silver-loaded inorganic anti-bacterial agent, 0.5 to 2.0 percent of polyethylene wax, 0.5 to 3.0 percent of styrene-butadiene thermoplastic elastomer, 0.5 to 2.0 percent of halogen-free flame retardant, 0.5 to 2.0 percent of antioxidant, 0.1 to 1.0 percent of light stabilizer and 0.1 to 1.0 percent of thermal stabilizer. The centrifugal fan blade disclosed by the invention has higher properties of heat resistance, chemical corrosion resistance, aging resistance, mildew prevention, ultraviolet irradiation prevention and the like, the density is high, the hardness is high, the size deformation is small, and the tensile strength of a plastic material is increased.

Owner:安徽朗迪叶轮机械有限公司

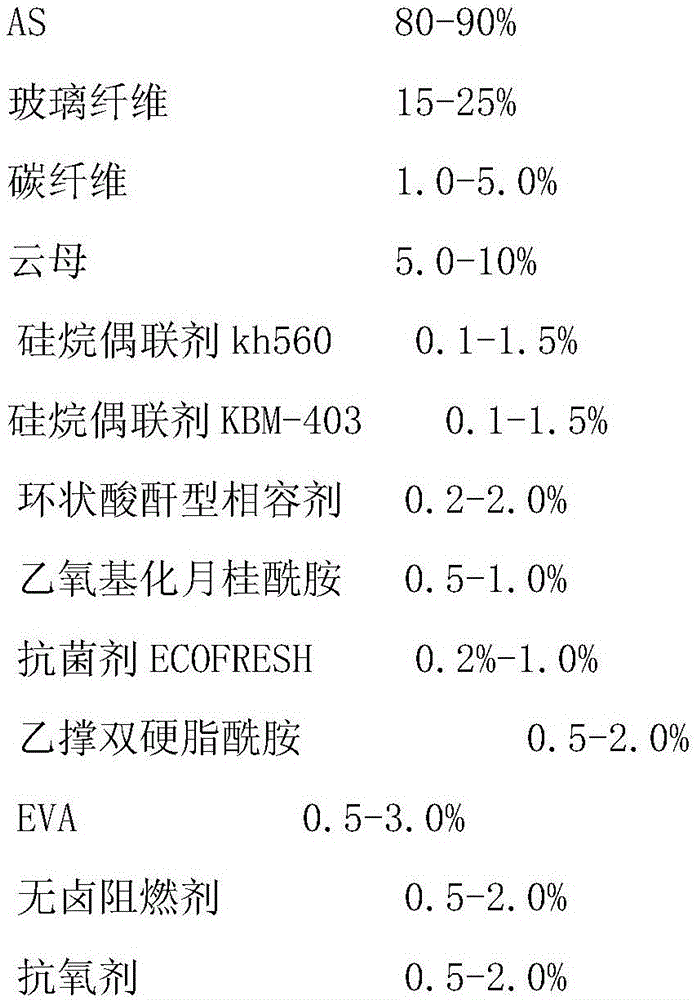

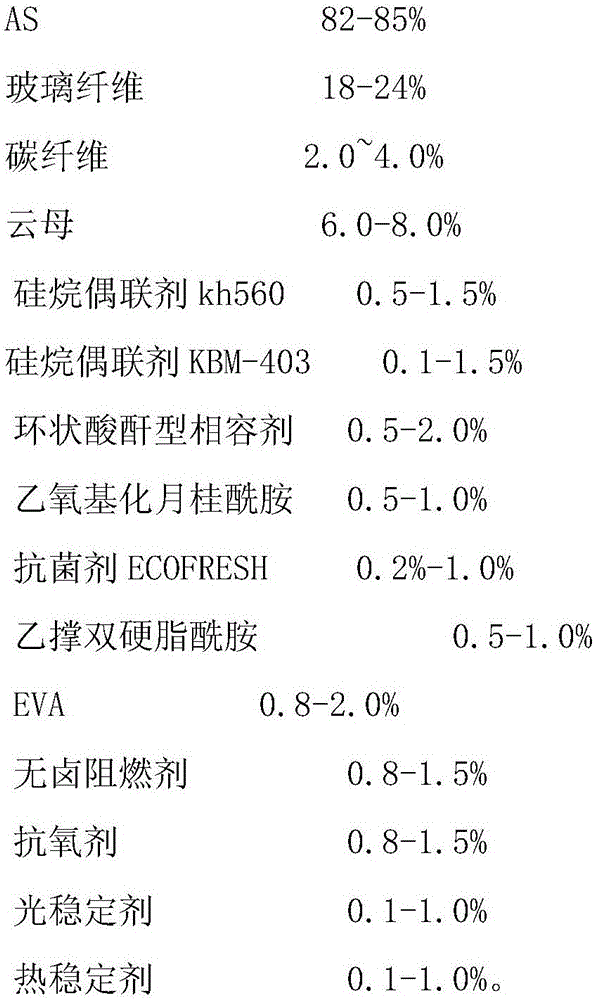

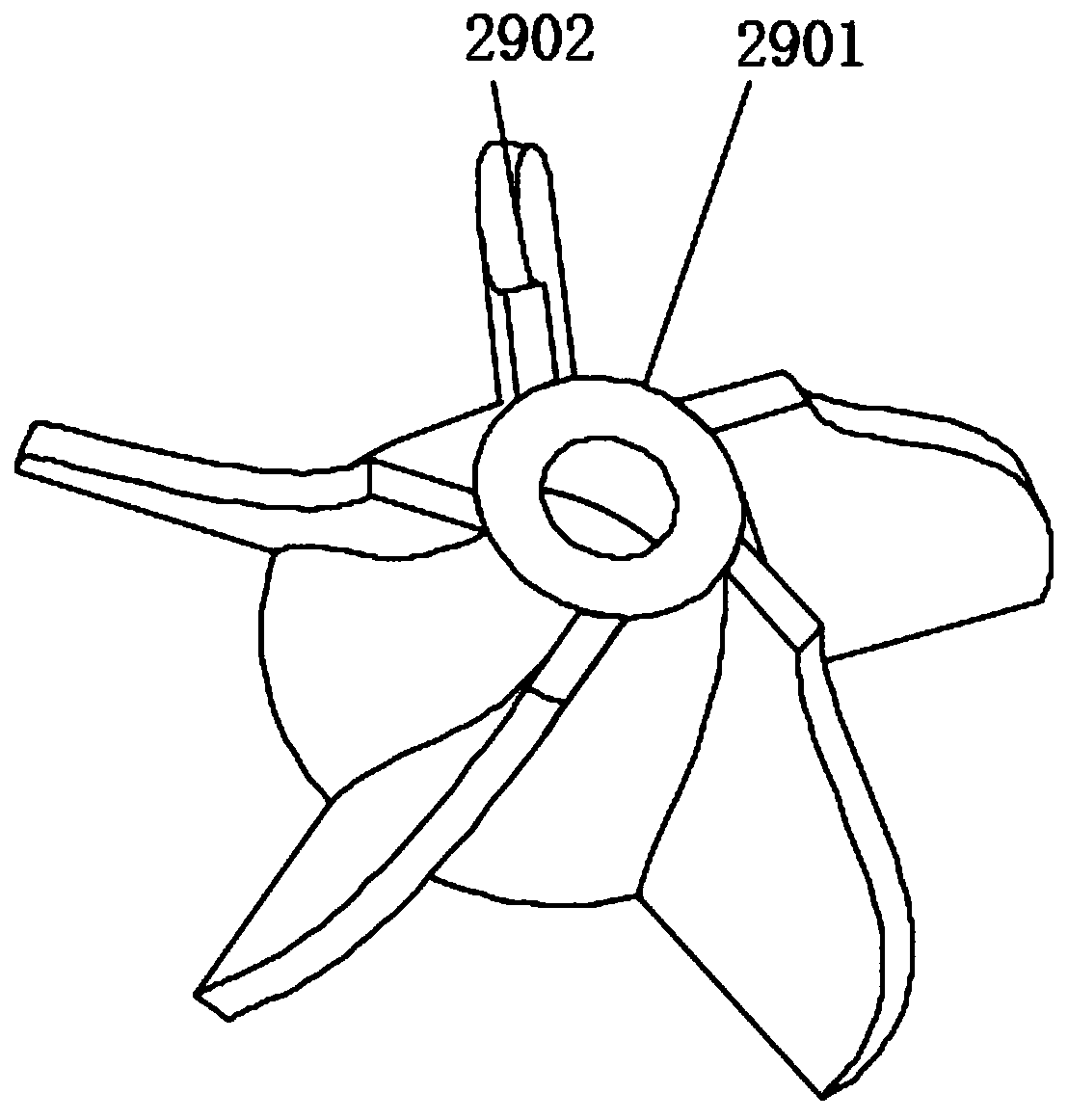

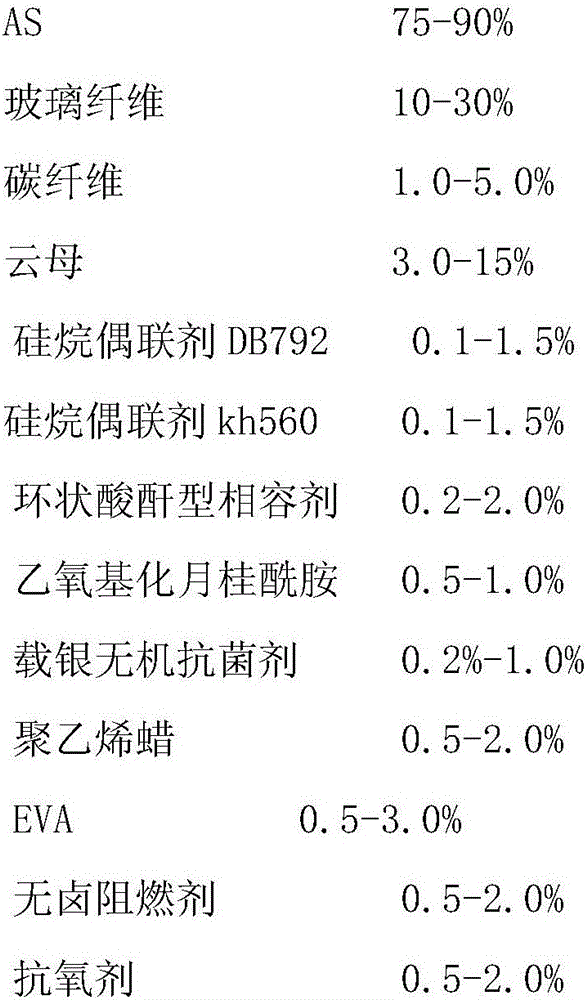

Axial impeller and preparation method thereof

The invention relates to a fan blade and a preparation method thereof. An axial impeller is prepared from the following materials in percentage by mass through injection molding: 75 to 90 ppercent of AS (Acrylonitrile-Styrene), 15 to 20 percent of glass fiber, 1.0 to 5.0 percent of carbon fiber, 5.0 to 15 percent of mica, 0.1 to 1.5 percent of silane coupling agent kh 560, 0.1 to 1.5 percent of silane coupling agent KBM 403, 0.2 to 2.0 percent of cyclo-anhydride type compatilizer, 0.5 to 1.0 percent of ethoxylated lauramide, 0.2 to 1.0 percent of antibacterial agent ECOFRESH, 0.5 to 2.0 percent of microcrystalline paraffin, 0.5 to 3.0 percent of EVA (Ethylene-Vinyl Acetate), 0.5 to 2.0 percent of halogen-free flame retardant, 0.5 to 2.0 percent of antioxidant, 0.1 to 1.0 percent of light stabilizer and 0.1 to 1.0 percent of thermal stabilizer. The axial impeller disclosed by the invention has higher properties of heat resistance, chemical corrosion resistance, aging resistance, mildew resistance, ultraviolet radiation resistance and the like, the density is high, the hardness is high, the size deformation is small, and the tensile strength of a plastic material is increased.

Owner:武汉朗迪叶轮机械有限公司

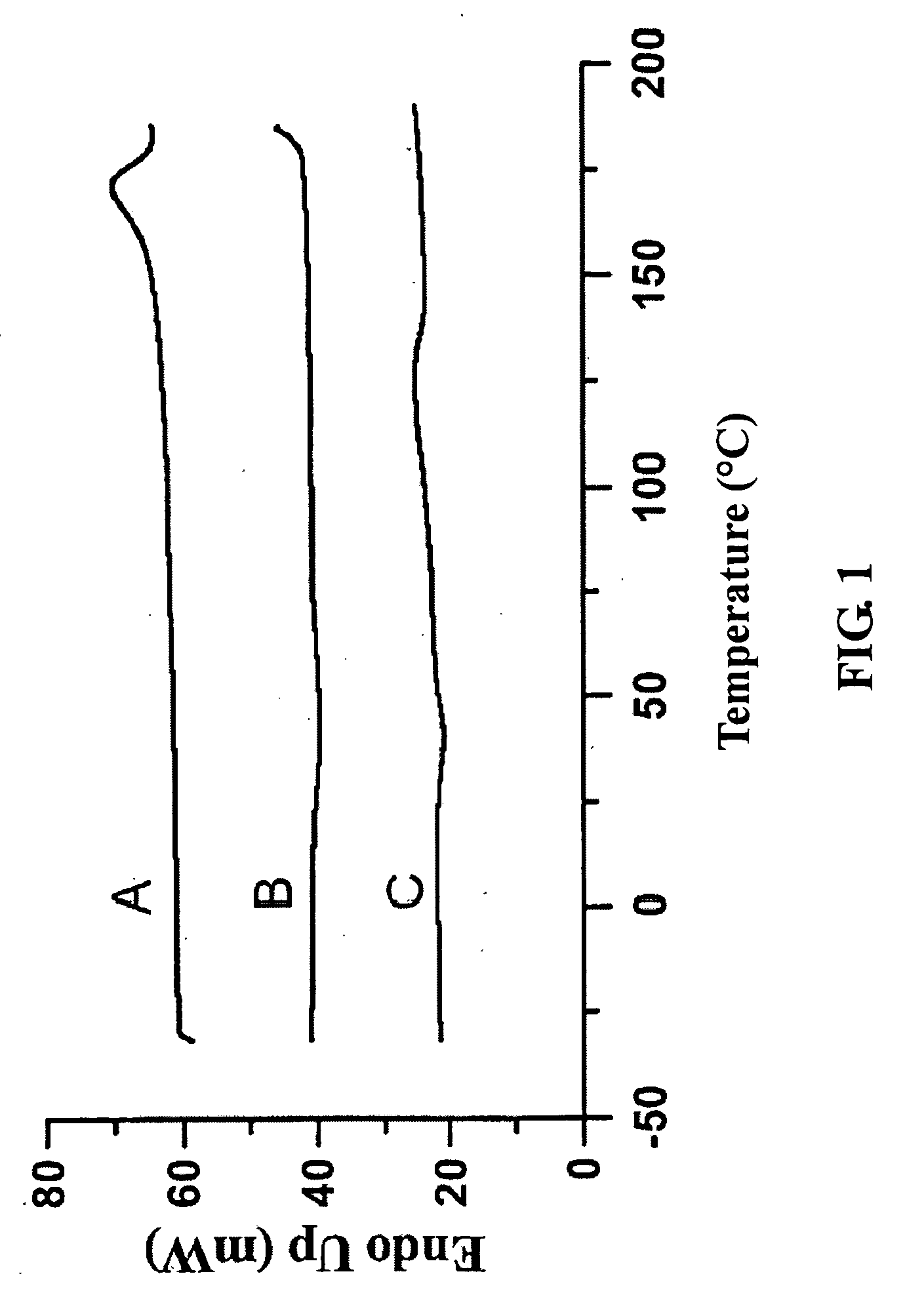

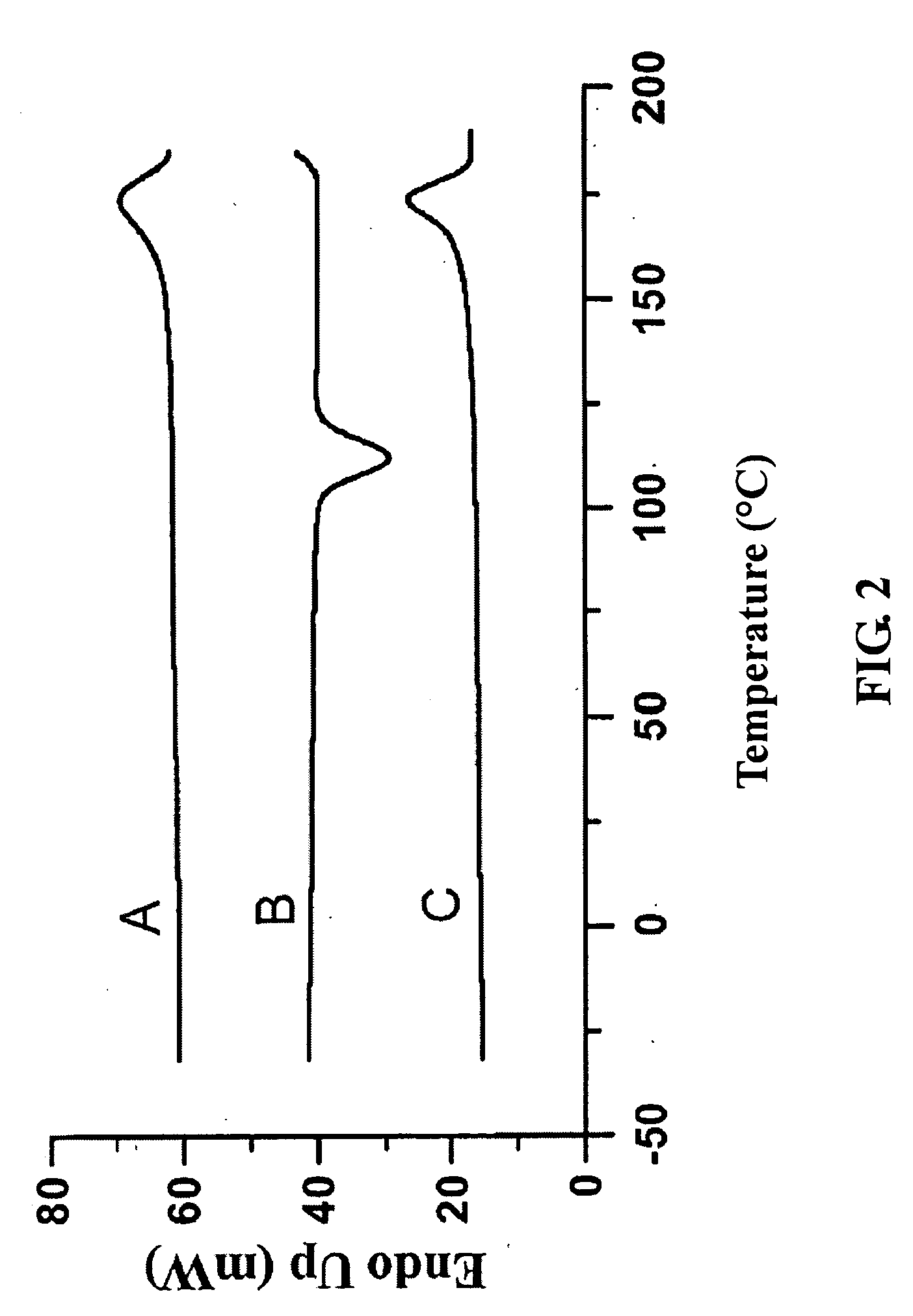

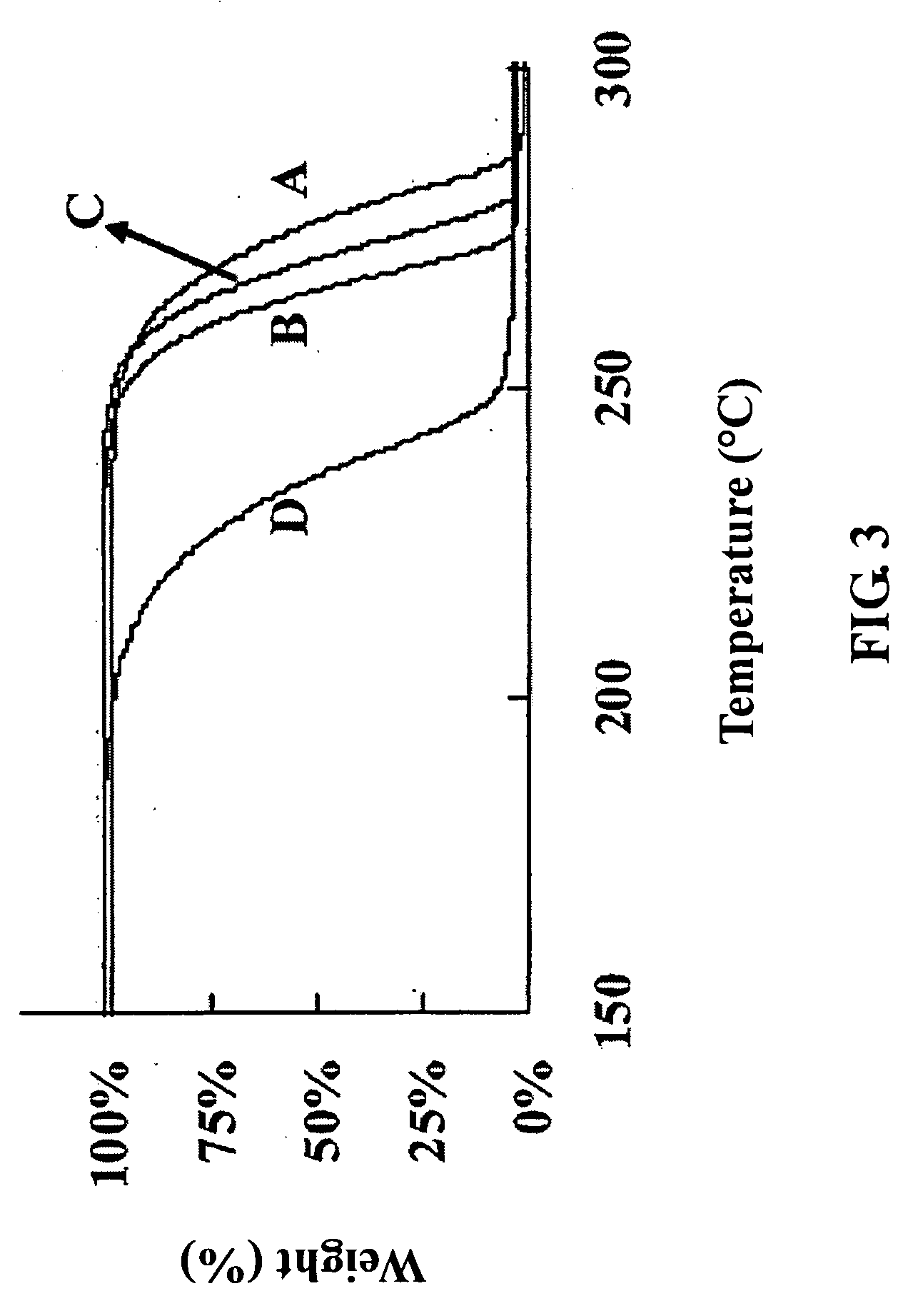

Method of improving thermal stability of poly-3-hydroxybutyrate

InactiveUS20080293894A1Improve thermal stabilityReduced thermal stabilityPoly-3-hydroxybutyrateThermal stability

The present invention discloses a method of improving the thermal stability of poly-3-hydroxybutyrate (PHB). The thermal stability of PHB was improved by grafting maleic anhydride (MA) onto the PHB through various processes. It has been proved that purified grafted PHB had a higher degradation temperature, a better thermal stability than the pristine PHB, and was not easy to decrease molecular weight by heat treatment. At the same time, the crystallization rate, the melting temperature and crystallinity were all increased. The MA was effectively grafted onto PHB by processes of solution grafting, melt grafting, mechanical grafting methods and so on. The grafting degree of MA was changed with the increasing amounts of the initiator and MA. The degradation temperature of the PHB was significantly increased by MA grafting because the degradation was blocked in the formation of six-member ring by the steric hindrance of the grafted MA. The PHB grafted with the mechanical grafting method was not easy to generate scission degradation during reaction, and showed the best thermal stability and forming ability. The initial degradation temperature of PHB was increased at least 50° C.

Owner:YUAN ZE UNIV

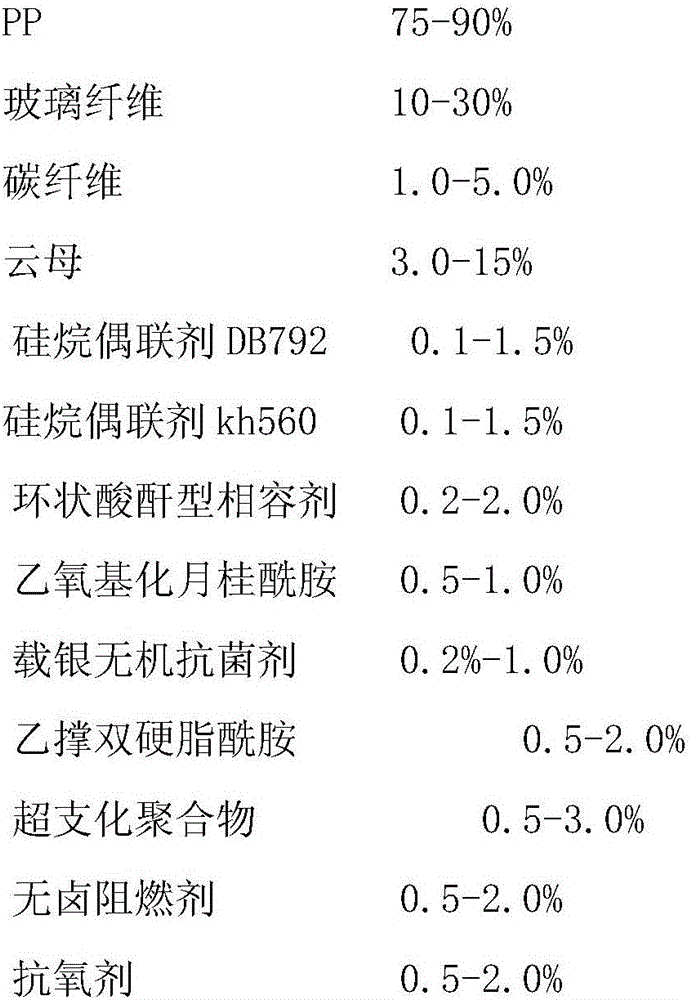

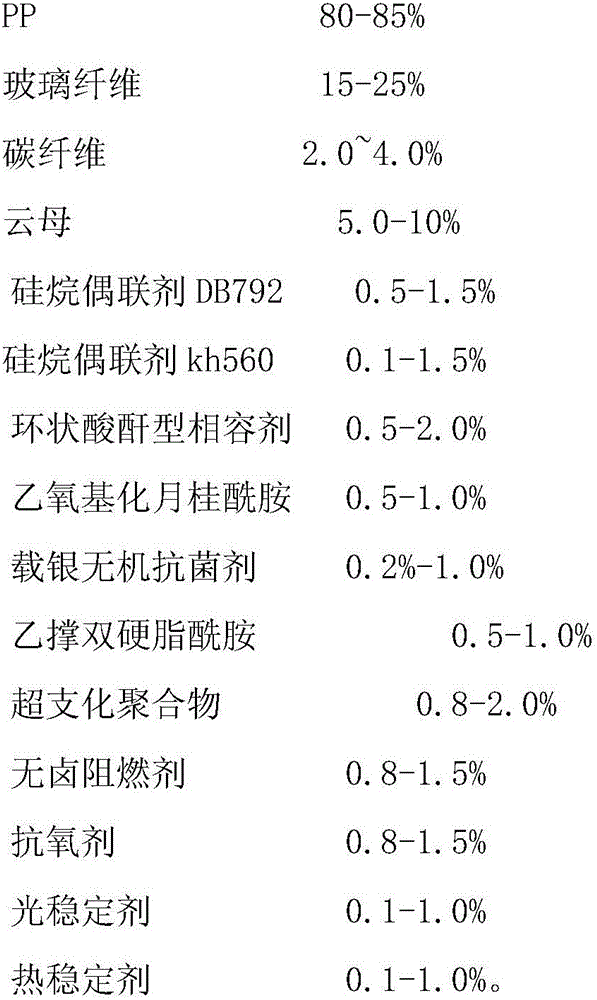

Mixed flow fan blade and preparation method thereof

The invention relates to a mixed flow fan blade and a preparation method thereof. The fan blade is produced by injection moulding of the following materials which comprise, by mass percentage, 75-90% of PP, 10-30% of glass fiber, 1.0-5.0% of carbon fiber, 3.0-15% of mica, 0.1-1.5% of silane coupling agent DB792, 0.1-1.5% of silane coupling agent kh560, 0.2-2.0% of cyclic anhydride type compatibilizer, 0.5-1.0% of ethoxylated lauryl amide, 0.2-1.0% of silver loaded inorganic antibacterial agent, 0.5-2.0% of microcrystalline wax, 0.5-3.0% of hyperbranched polymer, 0.5-2.0% of halogen-free flame retardant agent, 0.5-2.0% of anti-oxidant, 0.1-1.0% of light stabilizer and 0.1-1.0% of heat stabilizer. The mixed flow fan blade has high heat-resistant, anti-chemical-corrosion, anti-aging, mouldproof, ultraviolet-radiation-proof properties and the like, and is high in density and hardness, and small in size deformation. The preparation method of the mixed flow fan blade enhances the tensile strength of a plastic material.

Owner:中山市朗迪电器有限公司

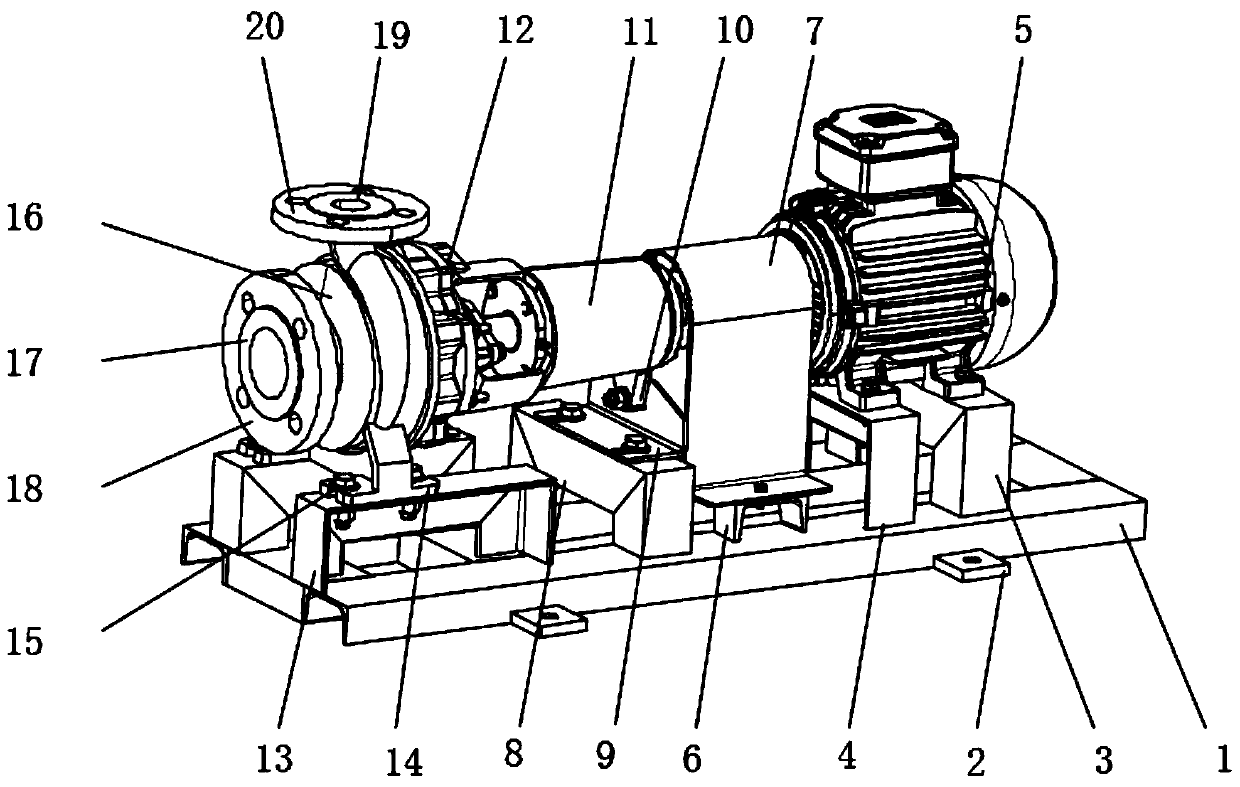

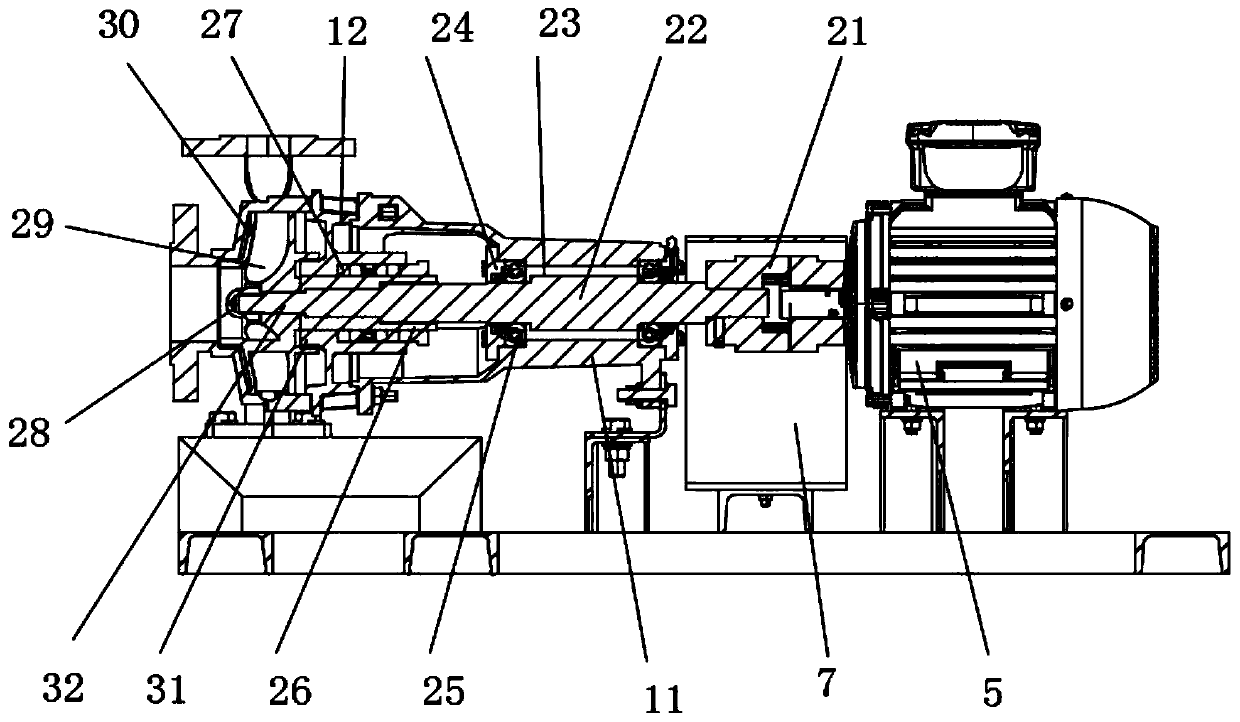

Mechanical seal chemical pump and using method thereof

PendingCN111520334AHeat resistantImprove heat resistancePump componentsPump installationsImpellerSuction force

The invention discloses a mechanical seal chemical pump and a using method thereof. The mechanical seal chemical pump comprises a mounting base, two fixing bolt plates are fixedly mounted on each of the front surface and the rear surface of the mounting base, a first supporting frame is fixedly mounted at the position, close to one end, of the upper surface of the mounting base, a second supporting frame is fixedly mounted at the position, close to one side of the first supporting frame, of the upper surface of the mounting base, driving motors are fixedly mounted at the upper ends of the first supporting frame and the second supporting frame, and a third supporting frame is fixedly mounted at the side, close to the second supporting frame, of the upper surface of the mounting base. An impeller has the advantages of high heat resistance, chemical corrosion resistance, aging resistance, mildew resistance, ultraviolet radiation resistance, high density, high hardness and small size deformation, the tensile strength of the plastic material is increased, the durability of the impeller is improved, the service life of a chemical pump is prolonged, a pump cover, a first cylinder and a second cylinder are mechanically sealed, and the sealing performance and the suction force of the chemical pump are improved.

Owner:ANHUI NANFANG CHEM PUMP IND

Nanometer composite materials with soya protein and montmorillonite, its production and use

Owner:WUHAN UNIV

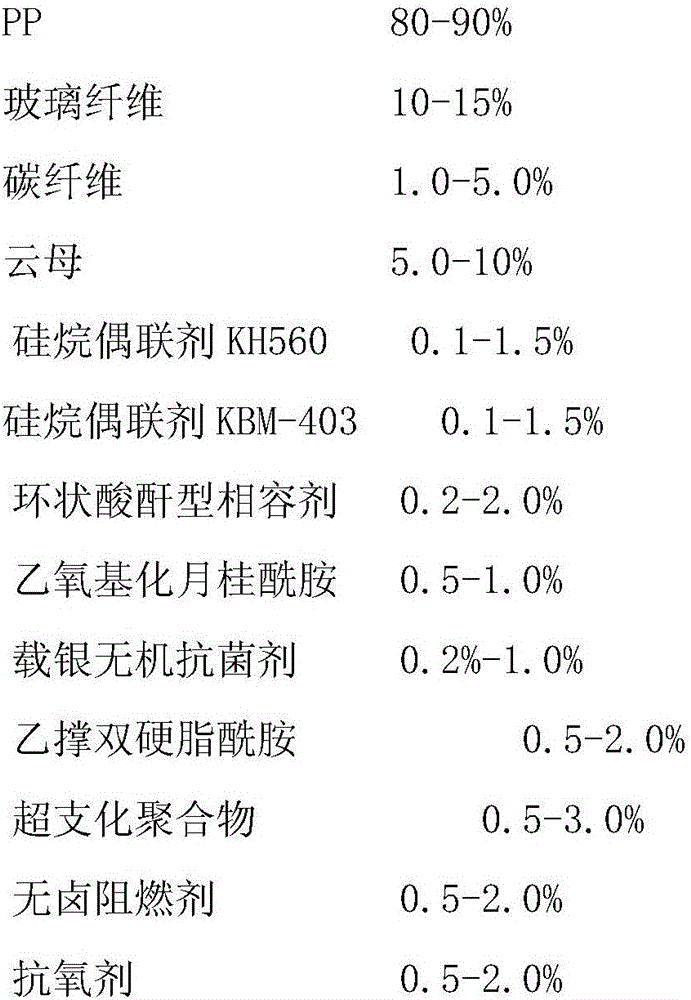

Cross-flow fan blade and preparation method thereof

The invention relates to a cross-flow fan blade and a preparation method thereof. The cross-flow fan blade is formed by injection moulding of the following materials in percentage by mass: 80-90% of PP, 10-15% of glass fiber, 1.0-5.0% of carbon fiber, 5.0-10% of mica, 0.1-1.5% of a silane coupling agent KH560, 0.1-1.5% of a silane coupling agent KBM-403, 0.2-2.0% of cyclic anhydride type compatilizer, 0.5-1.0% of ethoxylated lauramide, 0.2-1.0% of a silver-loaded inorganic antibacterial agent, 0.5-2.0% of a microcrystalline wax, 0.5-3.0% of hyperbranched polymer, 0.5-2.0% of a halogen-free flame retardant, 0.5-2.0% of an antioxidant, 0.1-1.0% of a light stabilizer and 0.1-1.0% of a heat stabilizer. The cross-flow fan blade has relatively high heat resistance, chemical corrosion resistance, aging resistance and mildew prevention, is high in density and hardness and small in size deformation, and the tensile strength of the plastic material is increased.

Owner:安徽朗迪叶轮机械有限公司

Filter screen panel for air conditioner and preparation method of filter screen panel

The invention relates to the field of accessories of air conditioning equipment. A filter screen panel for an air conditioner is prepared through injection moulding from the following materials by mass percent: 70-90% of ABS, 10-30% of glass fiber, 1.0-5.0% of carbon fiber, 0.1-1.5% of silane coupling agent DB792, 0.1-1.5% of silane coupling agent kh560, 0.2-2.0% of cyclic anhydride type compatilizer, 0.5-1.0% of ethyoxyl lauramide, 0.2%-1.0% of an antibacterial agent ECOFRESH, 0.5-2.0% of microcrystalline wax, 0.5-3.0% of EVA, 0.5-2.0% of halogen-free flame retardant, 0.5-2.0% of an antioxygen, 0.1-1.0% of a light stabilizer, and 0.1-1.0% of a heat stabilizer. The filter screen panel for the air conditioner has the higher performances of heat resistance, resistance to chemical attack, ageing resistance, mildew prevention, protection from ultraviolet rays and the like, is high in density and hardness and small in size deformation, and improves the tensile strength of a plastic material.

Owner:NINGBO LANGDI IMPELLER MACHINERY

A kind of non-aromatic amine small molecule optoelectronic material and its preparation and application

ActiveCN109776490BEffective control of dihedral angleRegulating Molecular WeightOrganic chemistrySolid-state devicesQuantum yieldElectron hole

Owner:SOUTH CHINA UNIV OF TECH

Cross-flow fan and preparing method thereof

The invention relates to a fan and a preparing method thereof. A cross-flow fan is prepared from, by mass, 75-90% of AS, 10-30% of glass fiber, 1.0-5.0% of carbon fiber, 3.0-15% of mica, 0.1-1.5% of silane coupling agent DB 792, 0.1-1.5% of silane coupling agent kh 560, 0.2-2.0% of cyclic anhydride type compatilizer, 0.5-1.0% of ethoxylated lauramide, 0.2-1.0% of silver-loaded inorganic antibacterial agent, 0.5-2.0% of polyethylene wax, 0.5-3.0% of EVA, 0.5-2.0% of halogen-free flame retardant, 0.5-2.0% of antioxidant, 0.1-1.0% of light stabilizer and 0.1-1.0% of heat stabilizer through injection molding. The cross-flow fan has high heat resistance, chemical corrosion resistance, ageing resistance, mouldproof performance and ultraviolet radiation performance, is high in density and hardness and small in size distortion and improves tensile strength of a plastic material.

Owner:广东朗迪格林特电器有限公司

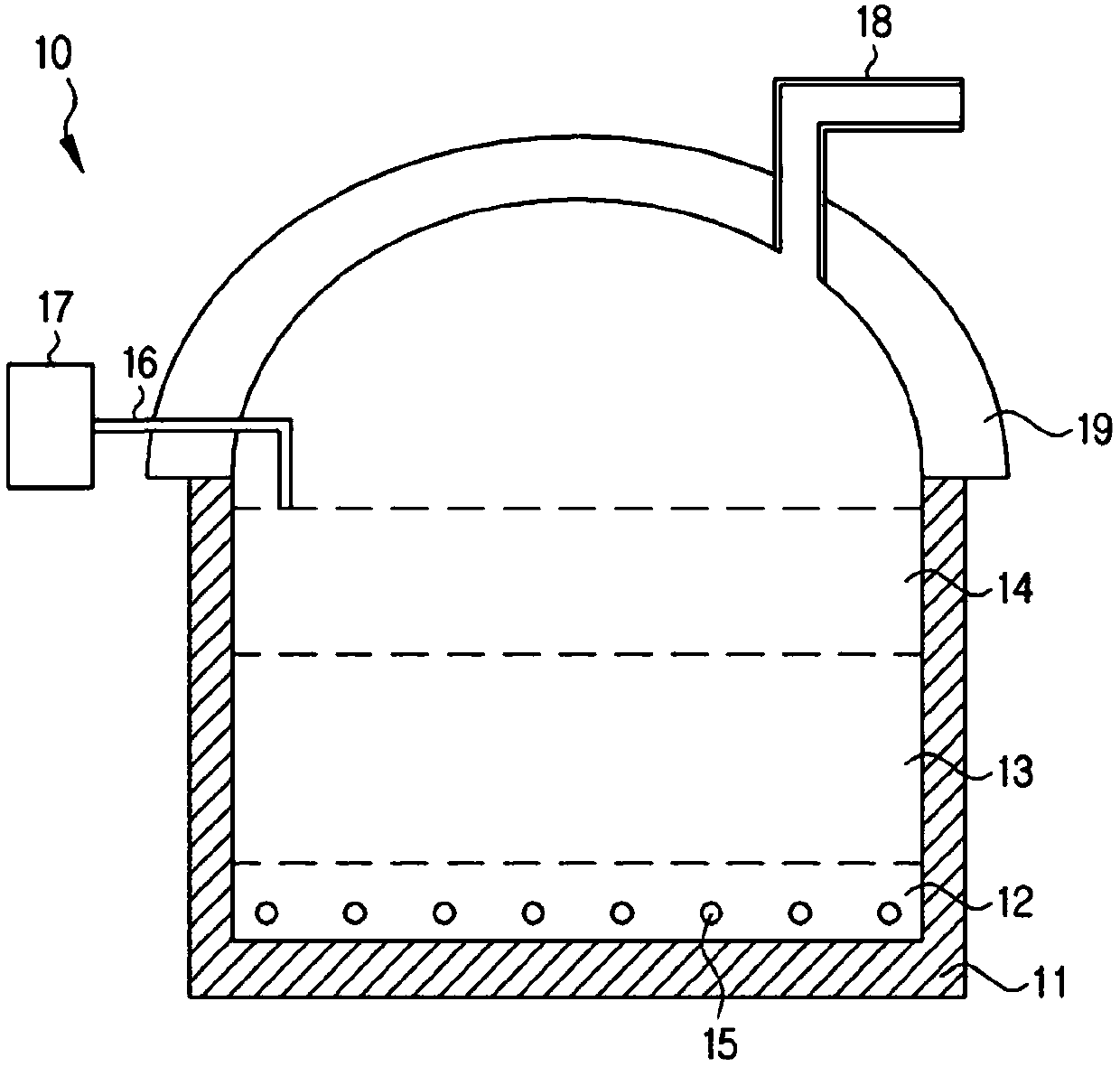

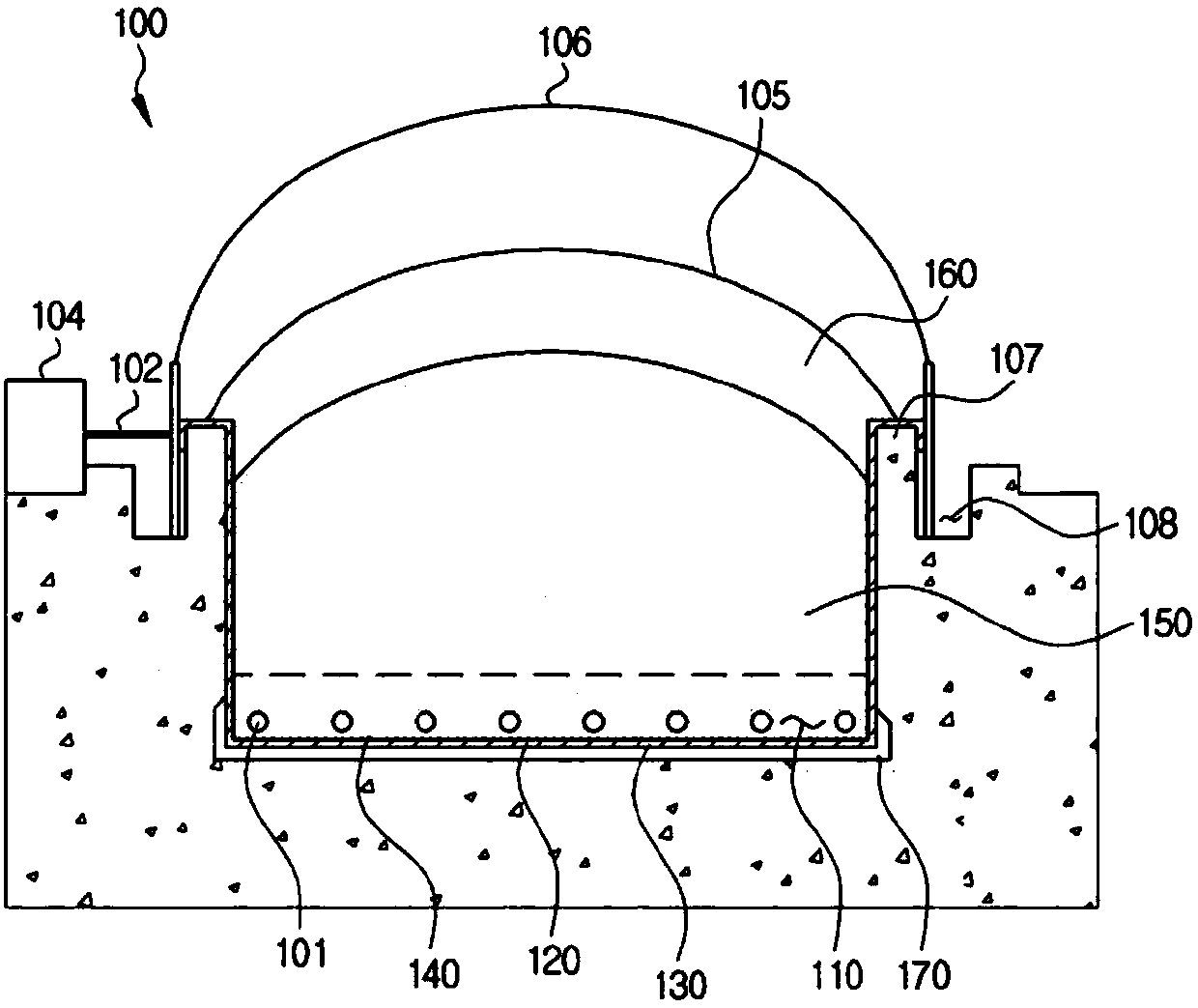

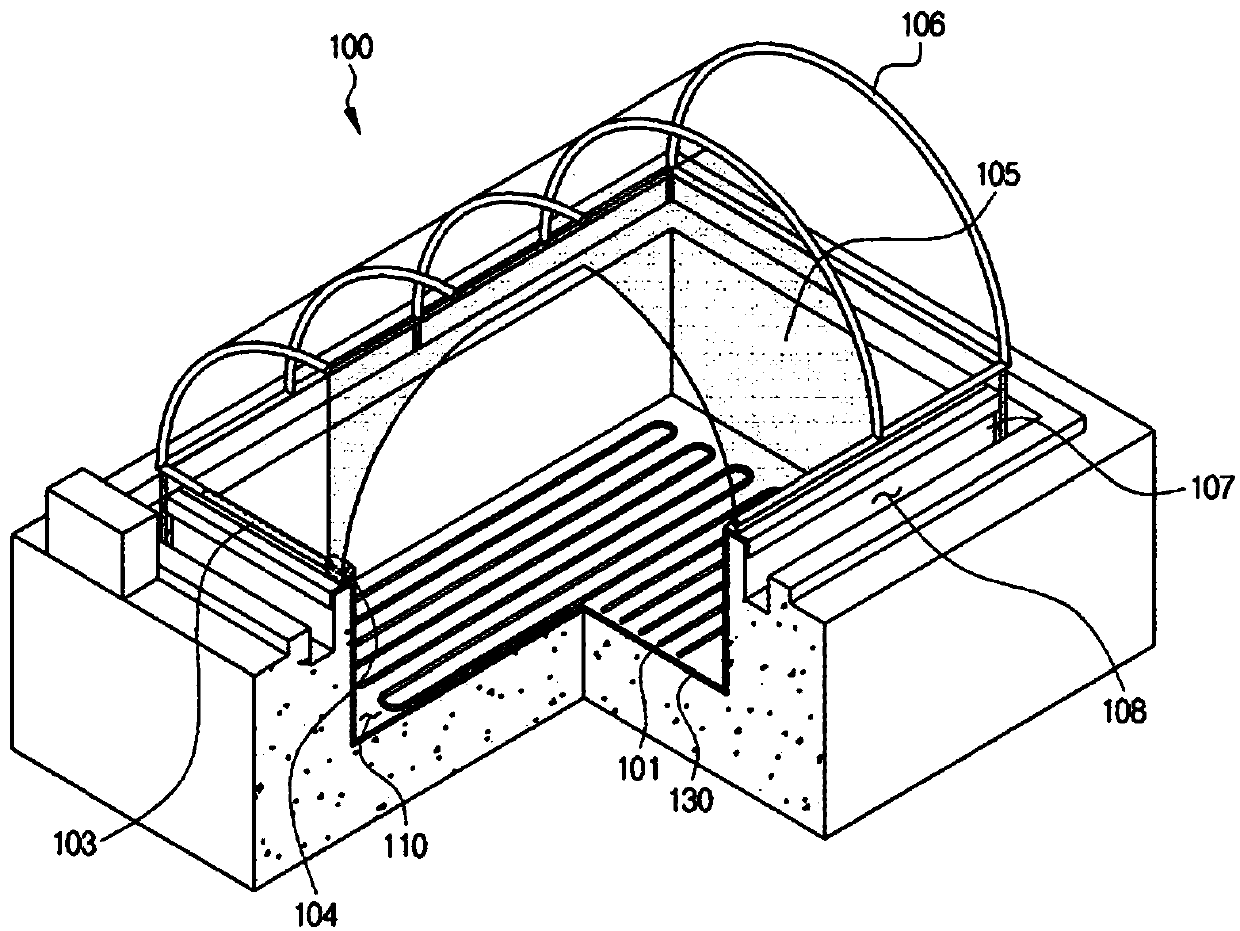

Eco-friendly livestock carcass disposal facility and burial disposal method

InactiveCN107921490AImprove degradation efficiencyRaise the degradation temperatureBacteriaSolid waste disposalDecompositionEngineering

The present invention relates to a livestock carcass disposal facility using aerobic thermophilic microorganisms and a burial disposal method. The present invention relates to a livestock carcass disposal facility and a burial disposal method, wherein the nano-bubble oxygen water is used when livestock carcasses are disposed of, and thus the air supply from the outside is not required at the initial time of carcass decomposition, thereby preventing the release of various animal pathogenic bacteria remaining in the livestock carcasses, especially, avian influenza, and viruses causing foot-and-mouth disease, into the air, and does not only suppress the generation of leachate and odor derived from the livestock carcasses but can also reduce the management period and maximize the land availability through economical and prompt decomposition.

Owner:微巨营农组合法人

Axial flow fan blade and preparation method thereof

The invention relates to a fan blade and a preparation method thereof. An axial flow fan blade is prepared by, by mass, 80-90% of AS, 10-15% of glass fibers, 5.0-10.0% of carbon fibers, 0.1-1.5% of silane coupling agent DB792, 0.1-1.5% of silane coupling agent KBM-403, 0.2-2.0% of cyclic anhydride compatibilizer, 0.5-1.0% of ethoxylated lauramide, 0.2-1.0% of silver-loaded inorganic antibacterial agent, 0.5-2.0% of butyl stearate, 0.5-3.0% of ethylene-vinyl acetate copolymer, 0.5-2.0% of halogen-free flame retardant, 0.5-2.0% of antioxidant, 0.1-1.0% of light stabilizer and 0.1-1.0% of heat stabilizer in an injection molding mode. The axial flow fan blade has high heat resistance, chemical corrosion resistance, aging resistance, mould resistance, ultraviolet radiation resistance and other performance, and is high in density and hardness and small in size deformation, and the tensile strength of a plastic material is improved.

Owner:NINGBO LANGDI IMPELLER MACHINERY

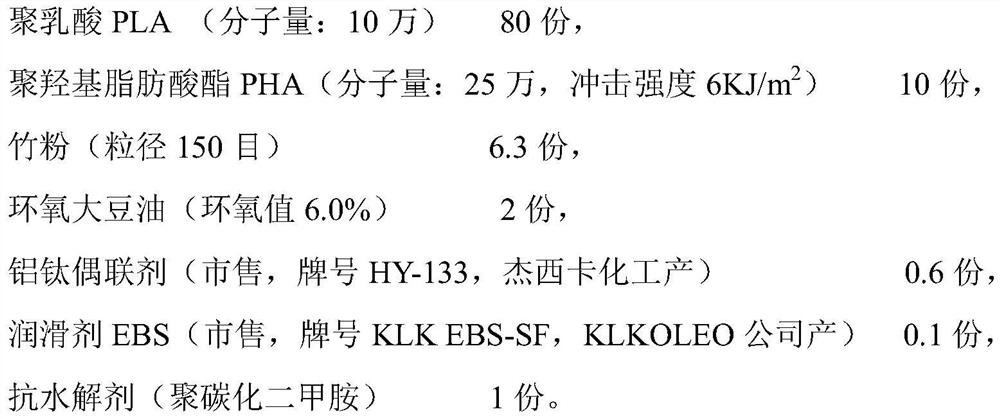

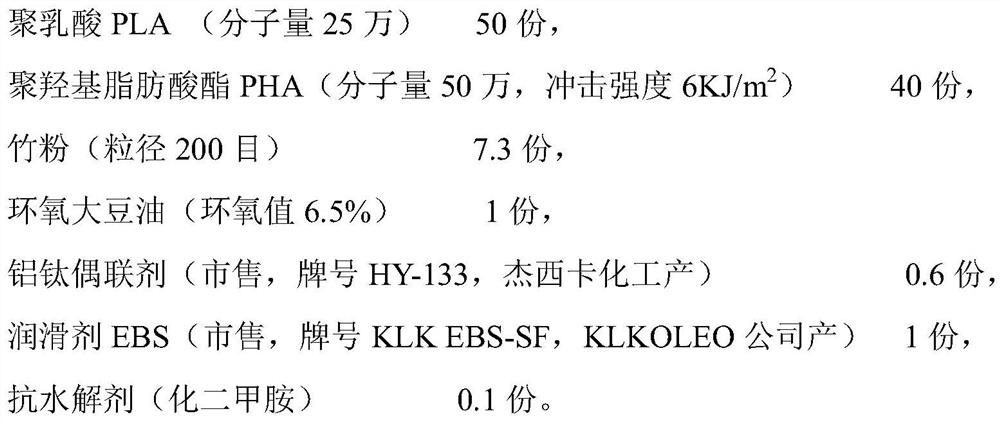

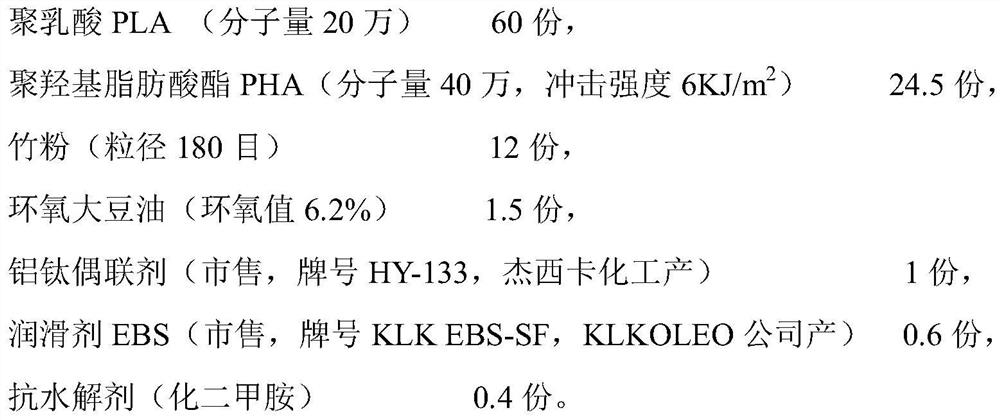

A kind of biodegradable straw and preparation method thereof

Owner:NANJING PRIDE PLASTIC TECH

Production method of type 5 pvc resin foamed wood-plastic material

Owner:JIUJIANG SALT LAKE NEW MATERIALS CO LTD

Composite lead salt thermally-stable anti-degradation auxiliary agent as well as preparation method and application thereof

The invention belongs to the technical field of plastic processing, in particular relates to a composite lead salt thermally-stable anti-degradation auxiliary agent as well as a preparation method andapplication thereof. The composite lead salt thermally-stable anti-degradation auxiliary agent provided by the invention comprises the following raw material components by mass percentage: 35-60% ofbasic lead salt, 0-10% of an acid binding agent, 10-20% of a lubricant, 0-2% of titanium dioxide, 5-18% of fly ash and 10-40% of calcium carbonate. Results of embodiments show that the composite leadsalt thermally-stable anti-degradation auxiliary agent provided by the invention has outstanding thermal stability performance, can effectively improve the degradation temperature of polyvinyl chloride, and has high initial whiteness and good long-term stability.

Owner:内蒙古佳运通智能环保新材料有限公司

A kind of composite lead salt heat-stable anti-degradation additive and its preparation method and application

The invention belongs to the technical field of plastic processing, and in particular relates to a composite lead salt heat-stable anti-degradation additive and its preparation method and application. The composite lead salt heat-stable anti-degradation aid provided by the invention comprises the following raw material components in mass percent: 35-60% of basic lead salt, 0-10% of acid-binding agent, 10-20% of lubricant, and 0% of titanium dioxide. ~2%, fly ash 5~18%, calcium carbonate 10~40%. The results of the examples show that the composite lead salt heat-stable anti-degradation additive provided by the present invention has outstanding performance in heat stability, can effectively increase the degradation temperature of polyvinyl chloride, and has high initial whiteness and good long-term stability.

Owner:内蒙古佳运通智能环保新材料有限公司

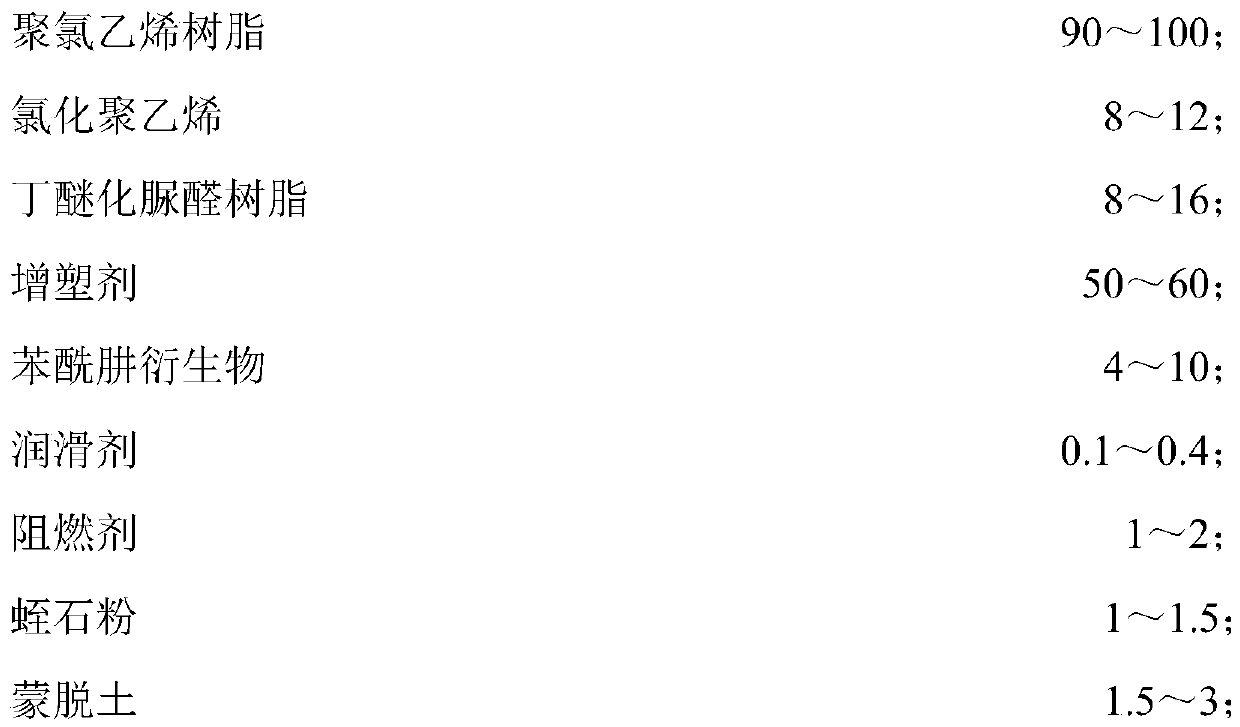

Low-odor environment-friendly polyvinyl chloride composite material

The invention relates to the field of polymer materials, and specifically relates to a low-odor environmentally-friendly polyvinyl chloride (PVC) composite material. The composite material at least comprises the following components in parts by weight: 80 to 110 parts of polyvinyl chloride resin, 4 to 12 parts of chlorinated polyethylene, 8 to 20 parts of butyl etherified urea-formaldehyde resin, 15 to 40 parts of plasticizer, 4 to 10 parts of benzhydrazide derivatives, 0.1 to 0.8 part of lubricant, 0.5 to 3 parts of fire retardant, 1 to 3 parts of vermiculite powder, and 1 to 3 parts of montmorillonite; wherein the weight-average molecular weight of the polyvinyl chloride resin is in a range of 60000 to 120000, the plasticizer is a citrate plasticizer, and the lubricant is a fatty acid or metal soap lubricant.

Owner:浙江天原医用材料有限公司

PVC foaming wood plastic composite material

The invention discloses a PVC foaming wood plastic composite material which is produced by processing the raw materials based on the parts by weight: 100 parts of polyvinyl chloride (PVC), 40-50 parts of lignified plant fiber, 10-20 parts of active light calcium, 3-6 parts of calcium zinc complex stabilizer, 1-3 parts of compound-type foaming agent, 0.5-1.5 parts of lubricating agent OPE wax, 0.5-1 part of compound lubricating agent and 3-8 parts of foaming conditioning agent; the raw materials are evenly mixed by a mixing machine and then are directly put into a screw extruder to be extruded and molded at the temperature of 160-170 DEG C. The PVC foaming wood plastic composite material is added with full dose of heat stabilizer in the process of blending and processing, so that the degradation temperature of plastics can be increased, thermal degradation of the plastics and carbonization of wood powder in the process of mixing and forming can be prevented, and the operation of extruding and molding can be completed in one step, thus greatly simplifying the production technique and reducing the production cost.

Owner:石河子市森力新材料科技有限公司

Cross-flow fan and preparation method thereof

The invention relates to a fan and a preparation method thereof. A cross-flow fan is injection moulded from the following materials in percentage by mass: 80-90% of ABS, 5-15% of glass fiber, 0.2-1.0% of carbon fiber, 0.1-1.5% of silane coupling agent DB792, 0.1-1.5% of silane coupling agent kh560, 0.2-2.0% of cyclic acid anhydride type compatilizer, 0.5-1.0% of ethoxylated lauramide, 0.2-1.0% of antibacterial agent ECOFRESH, 0.5-2.0% of microcrystalline wax, 0.5-3.0% of EVA, 0.5-2.0% of halogen-free flame retardant, 0.5-2.0% of antioxidant, 0.1-1.0% of light stabilizer and 0.1-2.0% of heat stabilizer. The oblique-blade cross-flow fan has relatively high properties in heat resistance, chemical corrosion resistance, aging resistance, mould prevention, ultraviolet radiation prevention and the like and high density and hardness and little size distortion and enhances the tensile strength of a plastic material. Meanwhile, the oblique-blade cross-flow fan also has static resistance, antibacterial property and flame retardation and enhances the aging property and thermal decomposition property.

Owner:武汉朗迪叶轮机械有限公司

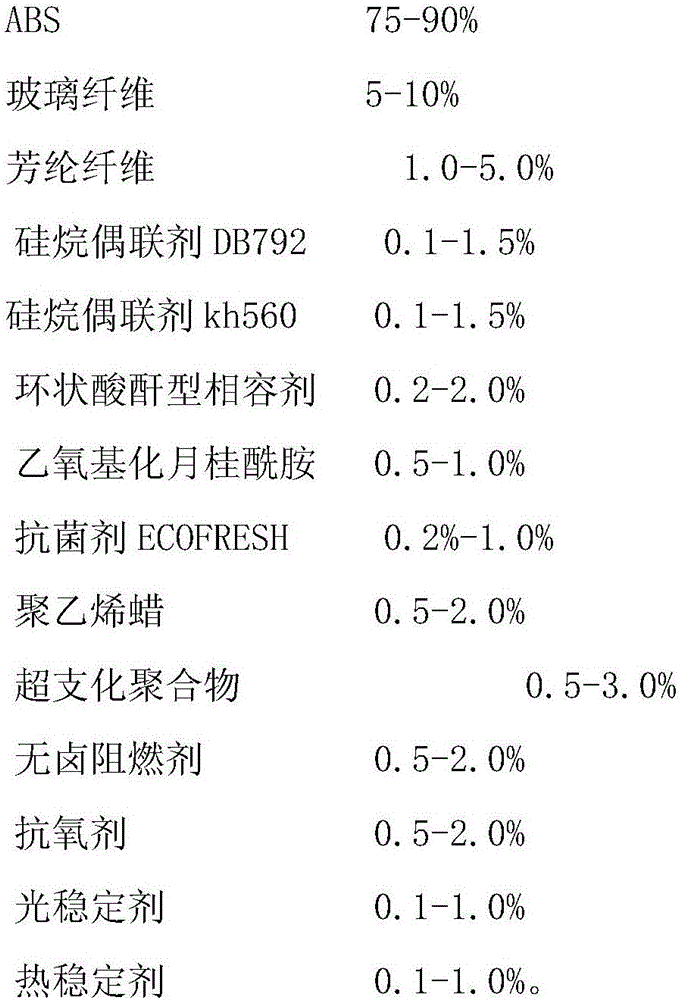

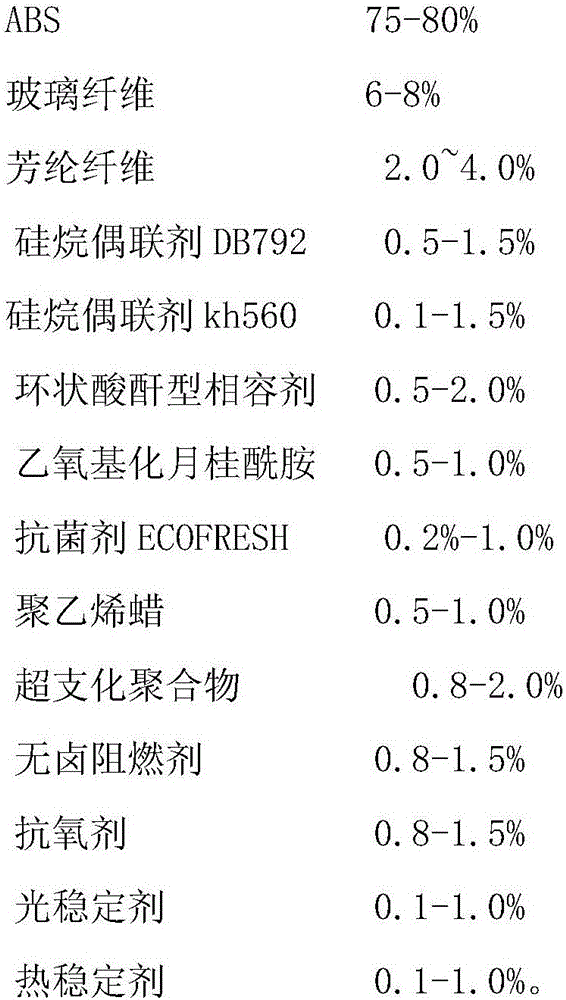

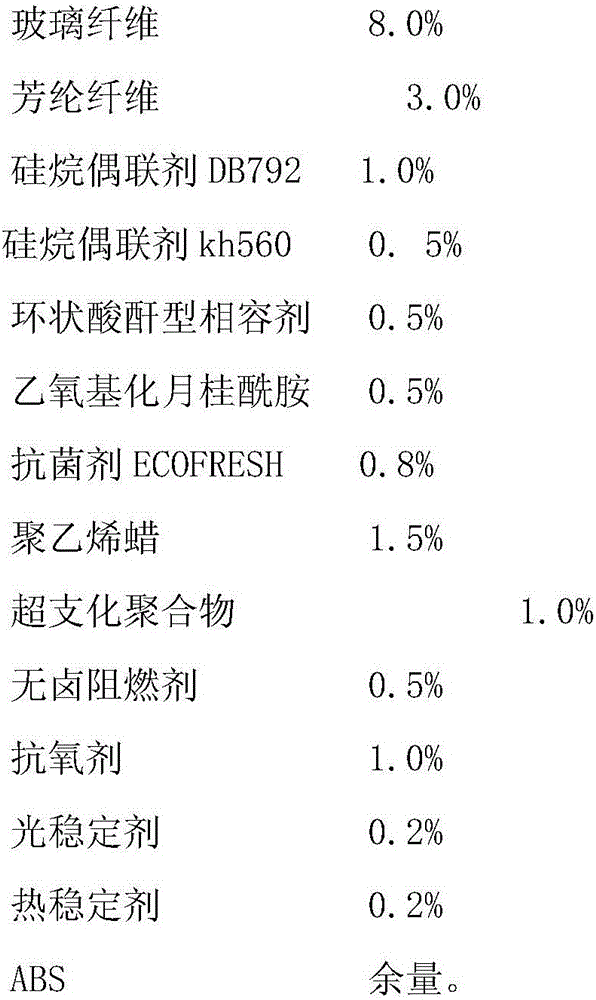

Oblique flow fan blade and preparation method thereof

The invention relates to a fan blade and a preparation method. An oblique flow fan blade is prepared by injecting and molding the following materials in percentage by mass: 75-90 percent of ABS, 5-10 percent of glass fibers, 1.0-5.0 percent of aramid fibers, 0.1-1.5 percent of saline coupler DB792, 0.2-2.0 percent of cyclic anhydride compatilizer, 0.5-1.0 percent of ethoxy lauramide, 0.2-1.0 percent of an antibacterial agent ECOFRESH, 0.5-2.0 percent of polyethylene wax, 0.5-3.0 percent of hyperbranched polymer, 0.5-2.0 percent of halogen-free flame retardant, 0.5-2.0 percent of antioxidant, 0.1-1.0 percent of light stabilizer and 0.1-1.0 percent of thermal stabilizer. The oblique flow fan blade has relatively high performances of heat resistance, chemical corrosion resistance, aging resistance, mildew prevention, ultraviolet radiation resistance and the like, has high density, high hardness and small size deformation, and can be used for improving the tensile strength of plastic materials. Furthermore, the oblique flow fan blade has anti-static and antibacterial performances and flame retarding performance, and the aging performance and thermal decomposition performance can be improved.

Owner:武汉朗迪叶轮机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com