Ultraviolet curing adhesive with high temperature resistance and preparation method thereof

A technology of ultraviolet light and curing glue, which is applied in the direction of non-macromolecular organic compound adhesives, adhesives, adhesive additives, etc., can solve the problems of inability to maintain adhesive performance, easy to fall off, etc., and achieve high cross-linking degree and increase High temperature resistance, the effect of excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

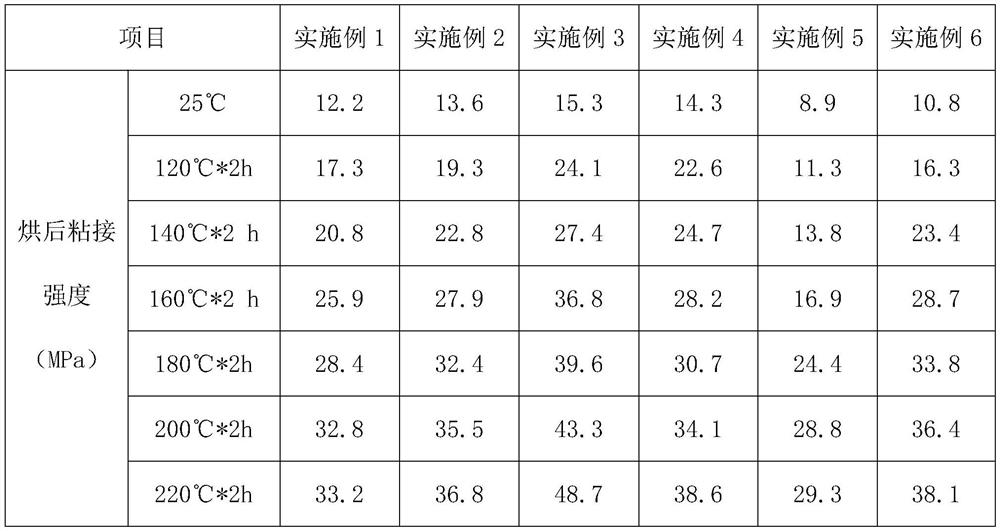

Examples

Embodiment 1

[0026] A UV-curable adhesive with high temperature resistance in this embodiment, the raw material includes the following components and contents: 70 parts of acrylate prepolymer, which contains 60% hydroxyl silicone modified acrylate and 40% acrylate Methacrylate type liquid isoprene rubber (UC102); 10 parts of active monomer LA (lauryl acrylate); 3 parts of photoinitiator 184 (1-hydroxycyclohexyl benzophenone); silane coupling agent KH5701 parts ; Antioxidant 10100.5 parts.

[0027] The UV-curable adhesive with high temperature resistance described in Preparation Example 1 is:

[0028] Add the acrylate prepolymer, active monomer, photoinitiator and auxiliary agent into the double planetary power mixing kettle according to the weight ratio, stir and disperse for 2.5h at the stirring speed of 500r / min, and then stir and disperse at the speed of 5000r / min. Centrifugal defoaming under the same centrifugal conditions to obtain UV-curable adhesive, which can be sealed and package...

Embodiment 2

[0030] A UV-curable adhesive with high temperature resistance in this embodiment, the raw material includes the following components and contents: 70 parts of acrylate prepolymer, which contains 60% aminoorganosilicon modified acrylate and 40% Methacrylate type liquid isoprene rubber (UC102); 10 parts of active monomer LA (lauryl acrylate); 3 parts of photoinitiator 184 (1-hydroxycyclohexyl benzophenone); silane coupling agent KH5701 parts ; Antioxidant 10100.5 parts.

[0031] The UV-curable adhesive with high temperature resistance described in Preparation Example 2 is:

[0032] Add the acrylate prepolymer, active monomer, photoinitiator and auxiliary agent into the double planetary power mixing kettle according to the weight ratio, stir and disperse for 2.5h at the stirring speed of 500r / min, and then stir and disperse at the speed of 5000r / min. Centrifugal defoaming under the same centrifugal conditions to obtain UV-curable adhesive, which can be sealed and packaged.

Embodiment 3

[0034] The raw material of the UV-curable adhesive with high temperature resistance in this embodiment includes the following components and contents: 70 parts of acrylate prepolymer, which contains 60% alkoxy silicone modified acrylate and 40% methacrylate type liquid isoprene rubber (UC102); 10 parts of active monomer LA (lauryl acrylate); 3 parts of photoinitiator 184 (1-hydroxycyclohexyl benzophenone); silane coupling agent KH5701 parts; antioxidant 10100.5 parts.

[0035] The UV-curable adhesive with high temperature resistance described in Preparation Example 3 is:

[0036] Add the acrylate prepolymer, active monomer, photoinitiator and auxiliary agent into the double planetary power mixing kettle according to the weight ratio, stir and disperse for 2.5h at the stirring speed of 500r / min, and then stir and disperse at the speed of 5000r / min. Centrifugal defoaming under the same centrifugal conditions to obtain UV-curable adhesive, which can be sealed and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com