Low-odor environmentally-friendly polyvinyl chloride (PVC) composite material

A composite material and polyvinyl chloride technology, applied in the field of polymer materials, can solve the problems of decreased plasticizer content, poor processability, crystal decomposition, etc., and achieve the effects of reducing the amount of volatile gas, improving dimensional stability, and increasing degradation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of described butylated urea formaldehyde resin comprises the steps:

[0051] Take 370 parts by weight of formaldehyde (37% aqueous solution) and hexamethylenetetramine (CAS No. 100970), put it into a 1L three-necked flask, stir for 30min to 1.5 hours, then raise the temperature to 98°C, reflux for 30min, and then add 80 wt. Parts of n-butanol keep the temperature at 85°C to 90°C, add 3 parts by weight of phthalic anhydride (CAS No. 85449), and continue the reaction at this temperature for 90 minutes. Then adjust the pH to 7.5-8.0 with 30% sodium hydroxide aqueous solution, add 15 parts by weight of thiourea (CAS No. 62566), continue stirring for 15 minutes, and then stop heating to obtain butylated urea-formaldehyde resin.

[0052] plasticizer

[0053] Plasticizers in the present invention are not particularly limited, and phthalates, fatty acid esters, phosphoric acid esters, epoxy esters, polyesters and trimellitates, chlorine-containing Pla...

Embodiment 1

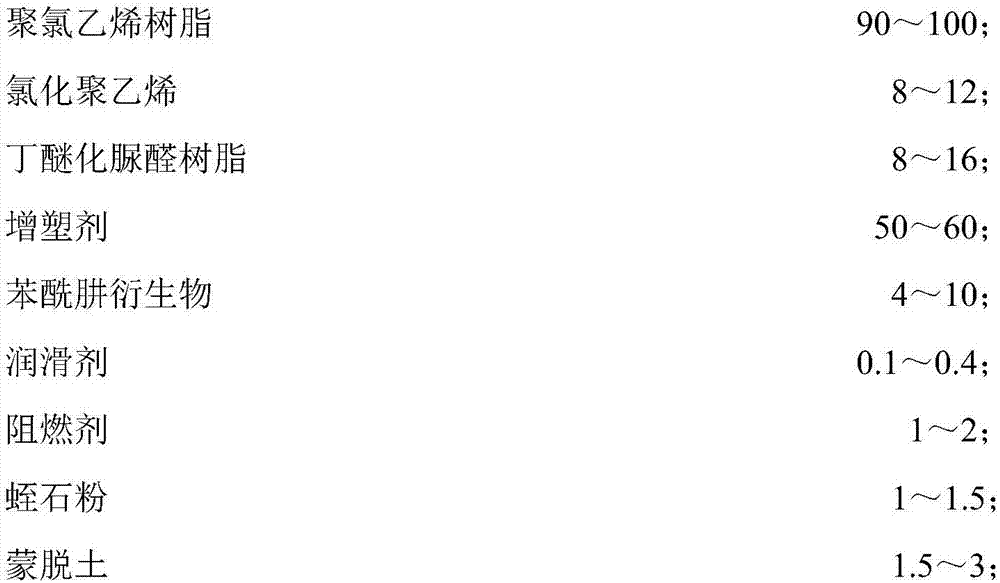

[0121] Embodiment 1 provides a low-odor environment-friendly polyvinyl chloride composite material, which at least includes the following components in parts by weight:

[0122]

[0123] The polyvinyl chloride resin is PVC-SG3, which is purchased from Jiangsu North Chlor-Alkali Group Co., Ltd.; the chlorinated polyethylene is purchased from Shijiazhuang Shunyi Chemical Co., Ltd., and the brand is SY-6; the plasticizer is acetylcitric acid Tributyl ester; the phenylhydrazide derivative is phenylhydrazide; the lubricant is a mixture of calcium stearate and zinc stearate, in parts by weight, the ratio is 1:1; the flame retardant is The mixture of antimony trioxide and zinc borate, in parts by weight, has a ratio of 3:2; the montmorillonite is purchased from Sinopharm Chemical Reagent, and the brand name is XW13189301--montmorillonite K10.

[0124] The preparation method of described butylated urea formaldehyde resin comprises the steps:

[0125] Take 370 parts by weight of fo...

Embodiment 2

[0129] Embodiment 2 provides a low-odor environment-friendly polyvinyl chloride composite material, which at least includes the following components in parts by weight:

[0130]

[0131] The polyvinyl chloride resin is PVC-SG3, which is purchased from Jiangsu North Chlor-Alkali Group Co., Ltd.; the chlorinated polyethylene is purchased from Shijiazhuang Shunyi Chemical Co., Ltd., and the brand is SY-6; the plasticizer is acetylcitric acid Tributyl ester; the phenylhydrazide derivative is phenylhydrazide; the lubricant is a mixture of calcium stearate and zinc stearate, in parts by weight, the ratio is 1:1; the flame retardant is The mixture of antimony trioxide and zinc borate, in parts by weight, has a ratio of 3:2; the montmorillonite is purchased from Sinopharm Chemical Reagent, and the brand name is XW13189301--montmorillonite K10.

[0132] The preparation method of described butylated urea formaldehyde resin comprises the steps:

[0133]Take 370 parts by weight of for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com