Eco-friendly livestock carcass disposal facility and burial disposal method

A technology for livestock and poultry carcasses and treatment equipment, which is applied in the direction of solid waste removal, bacteria, protection devices, etc. It can solve problems such as difficult to achieve batch processing, soil and groundwater pollution, and odor emission, so as to improve land utilization rate and sterilization effect Significant, effect of preventing external diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0105] Preparation Example 1 of a microbial preparation that can be used in the present invention is as follows: Microorganisms are inoculated on a culture medium and cultured. The medium consists of tryptone, yeast extract, glucose, sodium chloride (NaCl), dipotassium hydrogen phosphate (K 2 HPO 4) mixed uniformly with water. After the microorganisms are inoculated on the culture medium, culture is carried out at 30-40° C. for 1-3 days to obtain a culture solution. Next, the medium is mixed with the carrier. After the culture medium is absorbed by the carrier, the microorganisms are also fixed on the carrier. At this time, the preferred weight ratio of the culture solution to the carrier is 1:10-50, without limitation. Finally, the prepared microbial preparation is mixed with the livestock and poultry carcasses and put into the livestock and poultry degradation layer.

[0106] The livestock and poultry degradable layer of the present invention also includes oxygen nano-b...

Embodiment 1

[0116] After burying the livestock and poultry carcasses, it was confirmed that the aerobic thermophilic microorganisms had been activated by the oxygen nanobubble water and the temperature had risen.

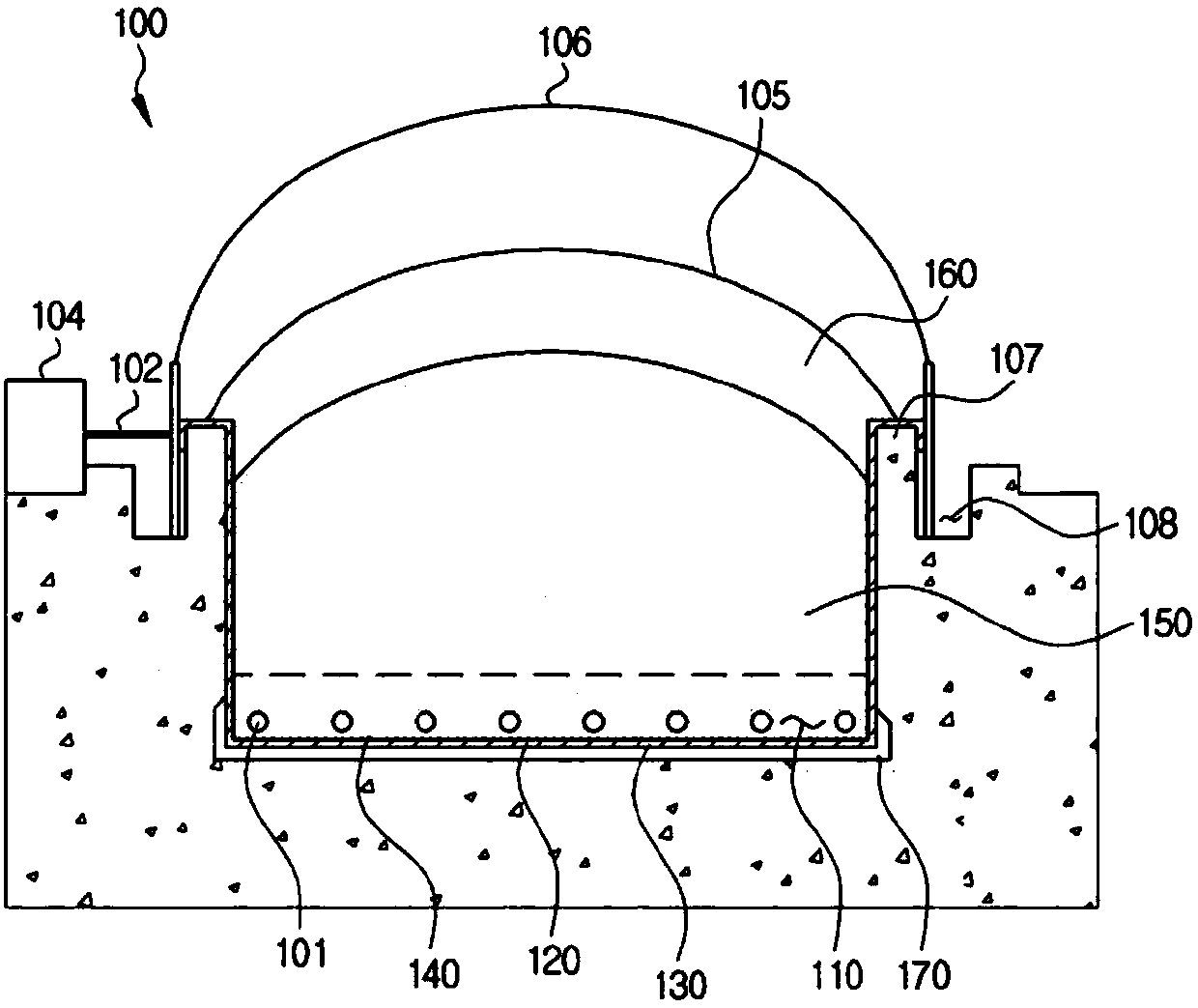

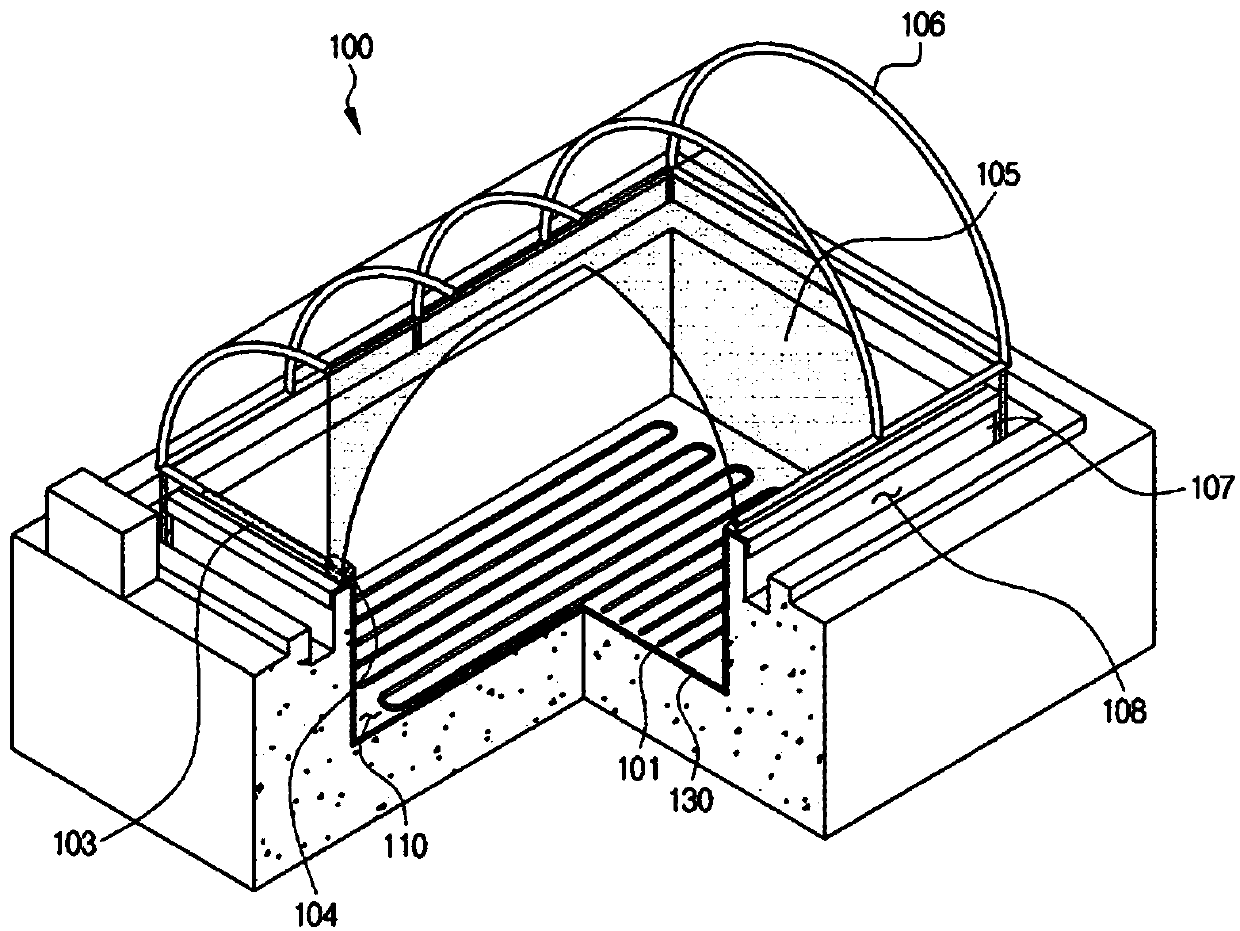

[0117] With 10kg (5kg×2) of chicken carcasses, 3kg of coarse bran, litter, sawdust, fallen leaves, hay and fully cooked compost mixture of coarse bran, 0.48kg of oxygen nano-bubble water and microbial preparations (natural love (company name), MICRO MAX Agricultural Association, Inc.) for mixing. The mixing ratio of the microbial agent and the chaff mixture was 1:36, and no oxygen was supplied from the outside within 48 hours.

[0118] Normal water was used instead of oxygen nanobubble water for mixing, and the outside air was delivered by a ring blower from the beginning as a control group. The temperature was measured after 24 hours and 48 hours respectively, and the degree of activity of the aerobic thermophilic microorganisms was confirmed. The temperature measurement res...

Embodiment 2

[0120] To observe the degradation degree of livestock and poultry carcasses using oxygen nanobubble water. Microbial preparations (Natural Love (company name), MICRO MAX Agricultural Associates, Inc.) were mixed with a mixture of chaff, litter, sawdust, litter, hay and fully cooked compost, and oxygen in experimental landfill boxes that could be observed from the outside. Nanobubble water mixed well. The mixing ratio of microbial agent and coarse bran mixture is 1:36, and it is covered on the bottom of the box to form an active layer. Then, 10 kg of chicken carcasses, 0.48 kg of oxygen nano-bubble water, and microbial preparations were mixed evenly. The mixing ratio of microbial preparations and coarse bran mixture was 1:36, and covered on the active layer to form a corpse degradation layer. Then, the mixture of microbial preparation and coarse bran was mixed at a ratio of 1:36, and covered on the corpse degradation layer to form a deodorizing embedding layer. When using oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com