Patents

Literature

63 results about "Poly-3-hydroxybutyrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroxybutyrate and poly-hydroxybutyrate as components of animal feed or feed additives

ActiveUS20100093860A1Optimized formulaSmall particlesAntibacterial agentsBiocideEscherichia coliFood additive

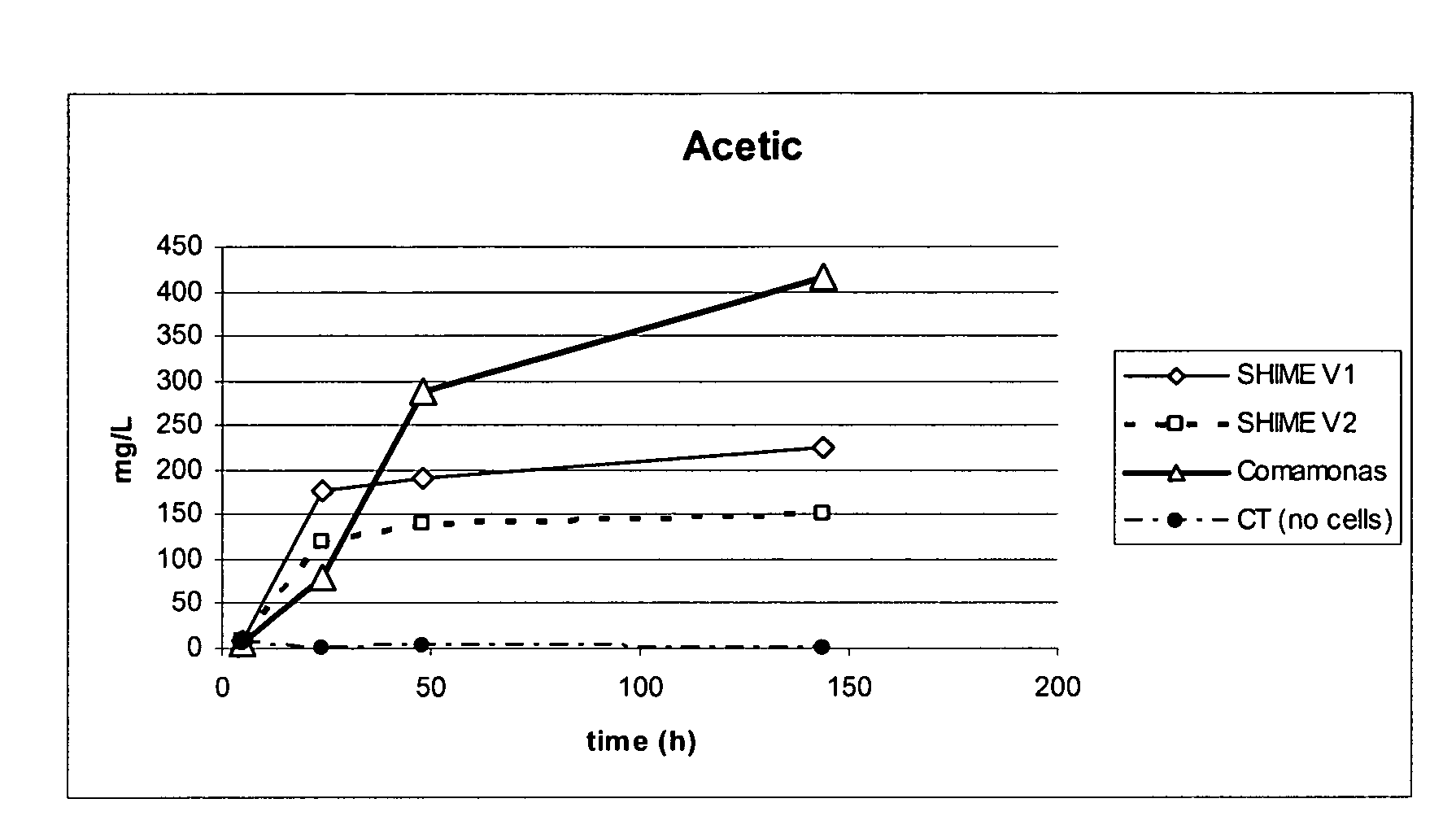

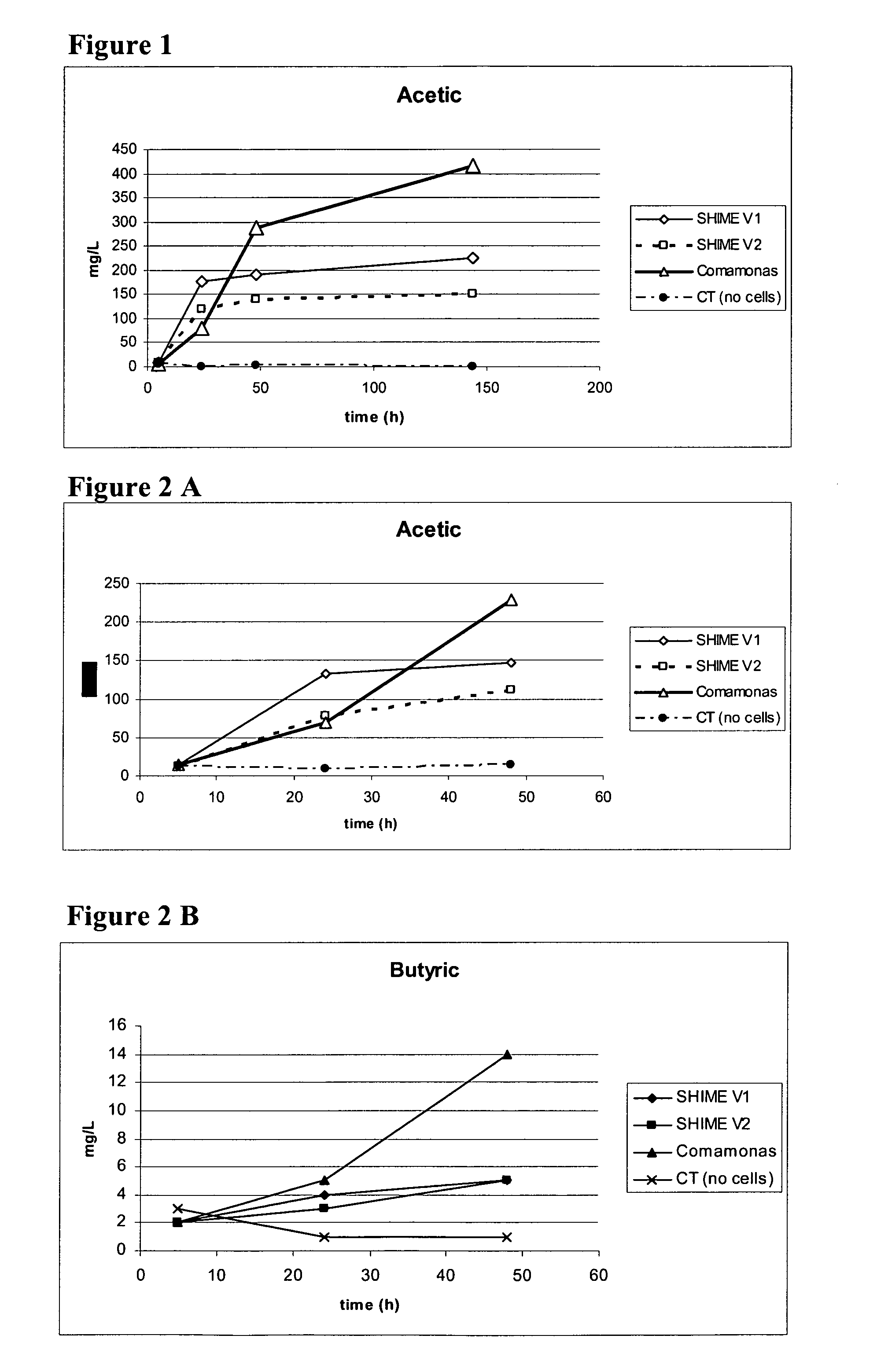

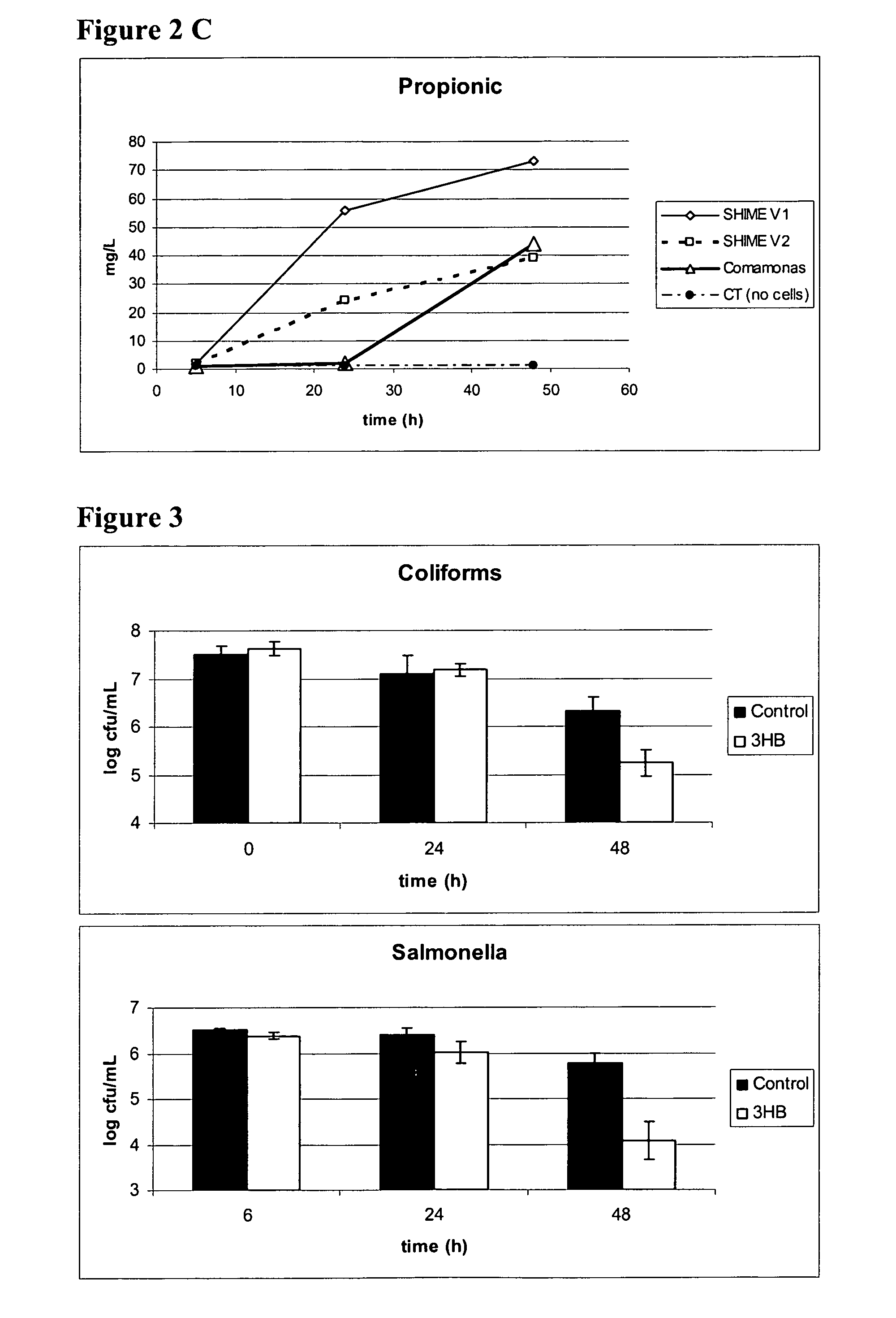

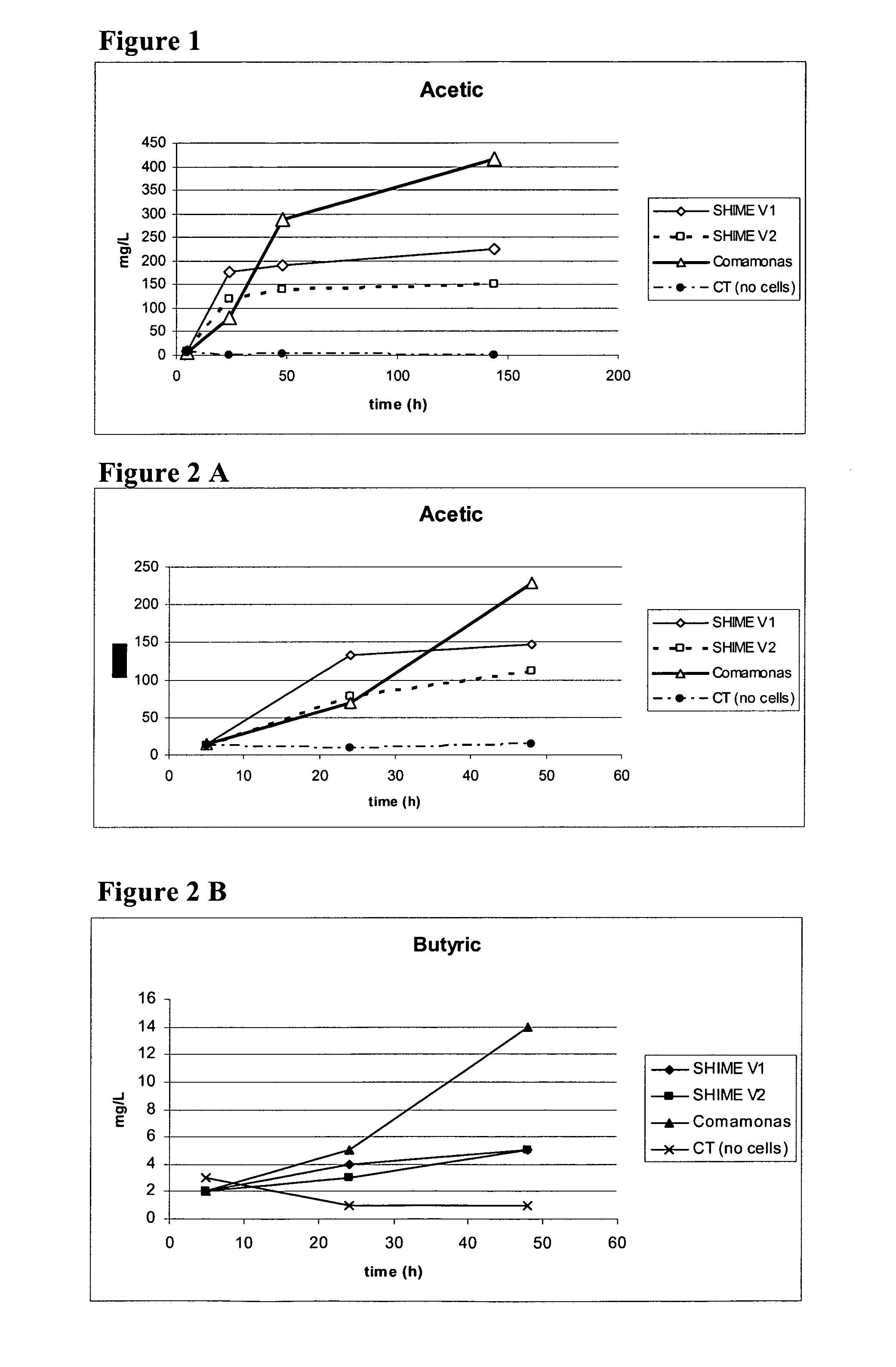

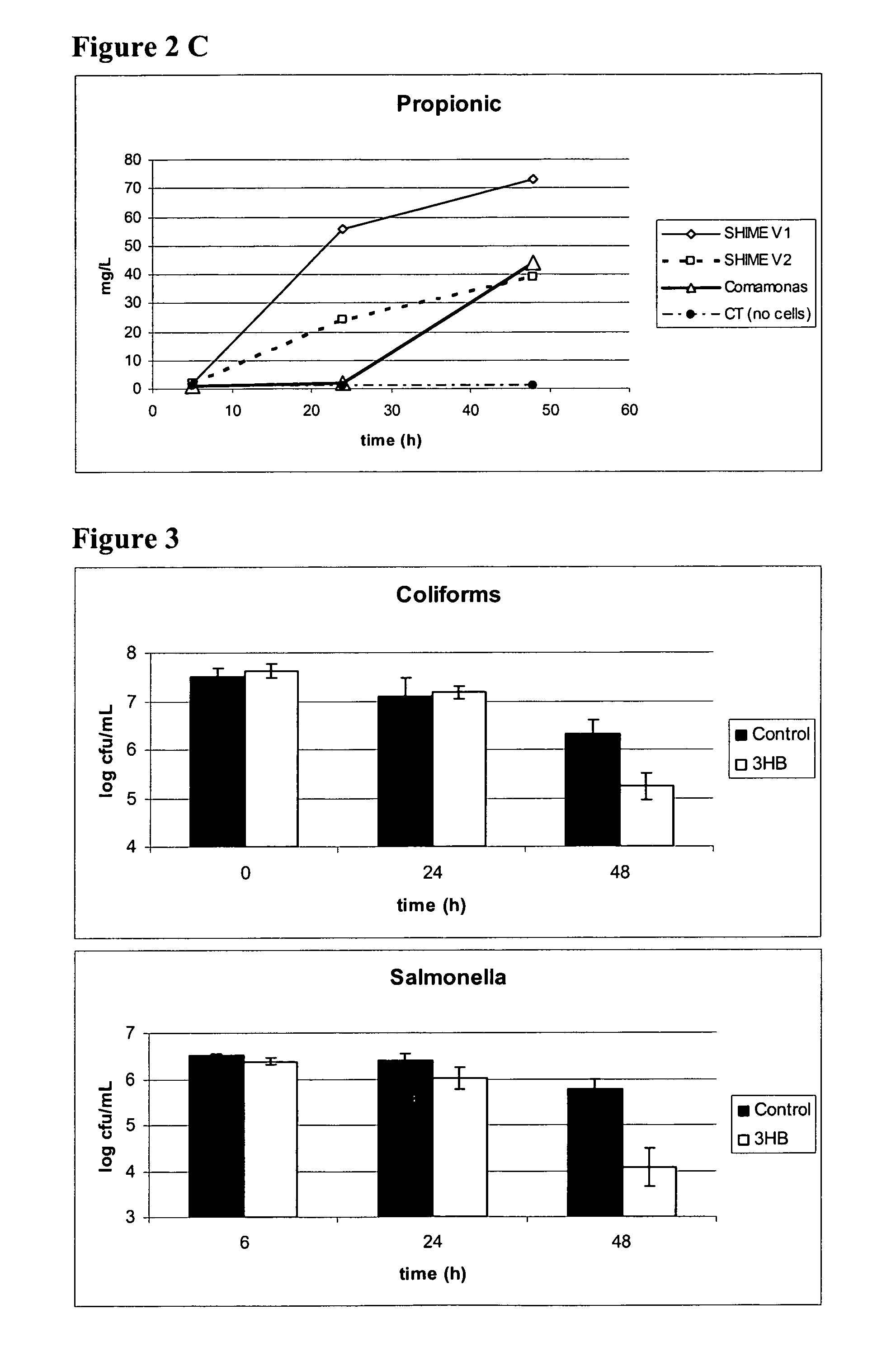

This invention relates to the use of hydroxybutyrate and poly hydroxybutyrate as components of animal feed or feed additives, as well as to compositions, feed additives and feed containing them. The inventors surprisingly found that hydroxybutyrate and poly-hydroxybutyrate, preferably 3-hydroxybutyrate and poly-3-hydroxybutyrate, have a great potential for use in animal feed for modulation of the gut flora. More precisely, it has been found that poly-3-hydroxybutyrate or a microbial strain capable for producing poly-3-hydroxybutyrate can be used as a potential growth promoter or gut flora modulator by releasing SCFA, preferably 3-hydroxy butyric acid, in the gut micro flora. Further, the inventors found that 3-hydroxybutyrate and poly-3-hydroxybutyrate have a great potential for suppressing or inhibiting pathogenic bacteria in the gastro intestinal tract, e.g. have a antimicrobial activity against strains of Vibrio, E. coli and Salmonella.

Owner:UNIV GENT

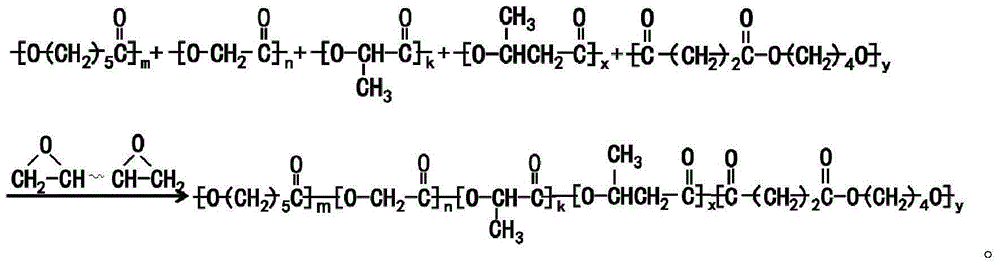

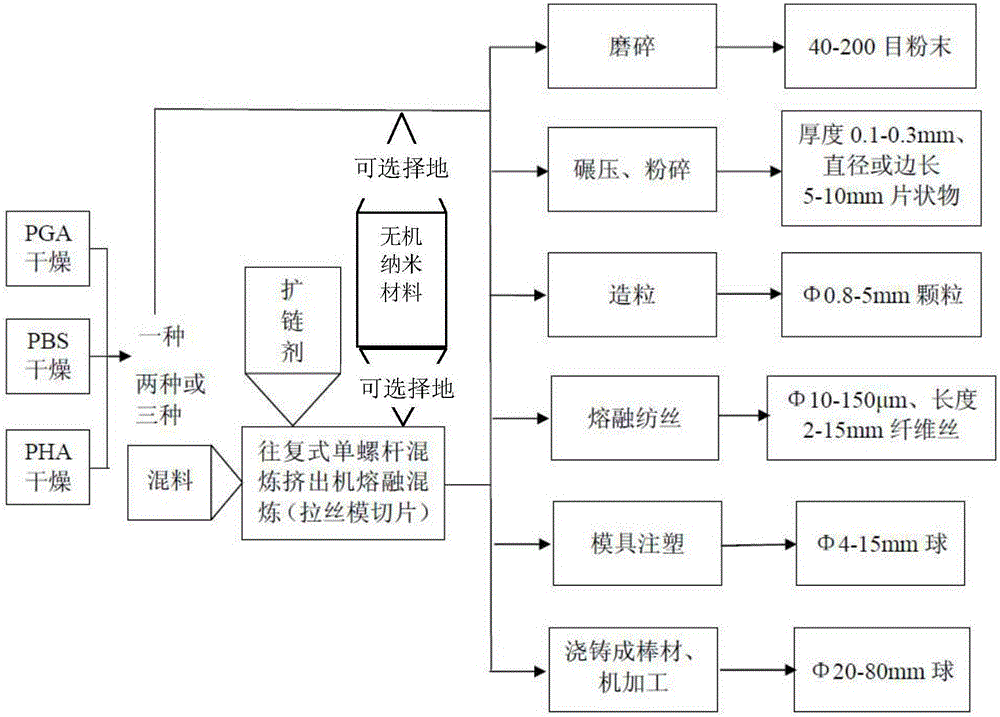

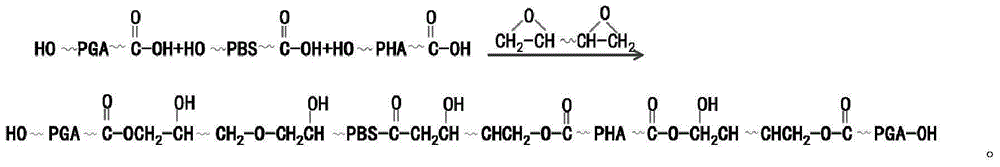

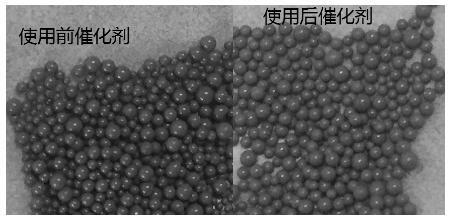

Degradable material for oil and gas field operation and preparation method thereof

InactiveCN105295321ALess intrusiveReduce harmFluid removalDrilling compositionAcid fracturingPoly-3-hydroxybutyrate

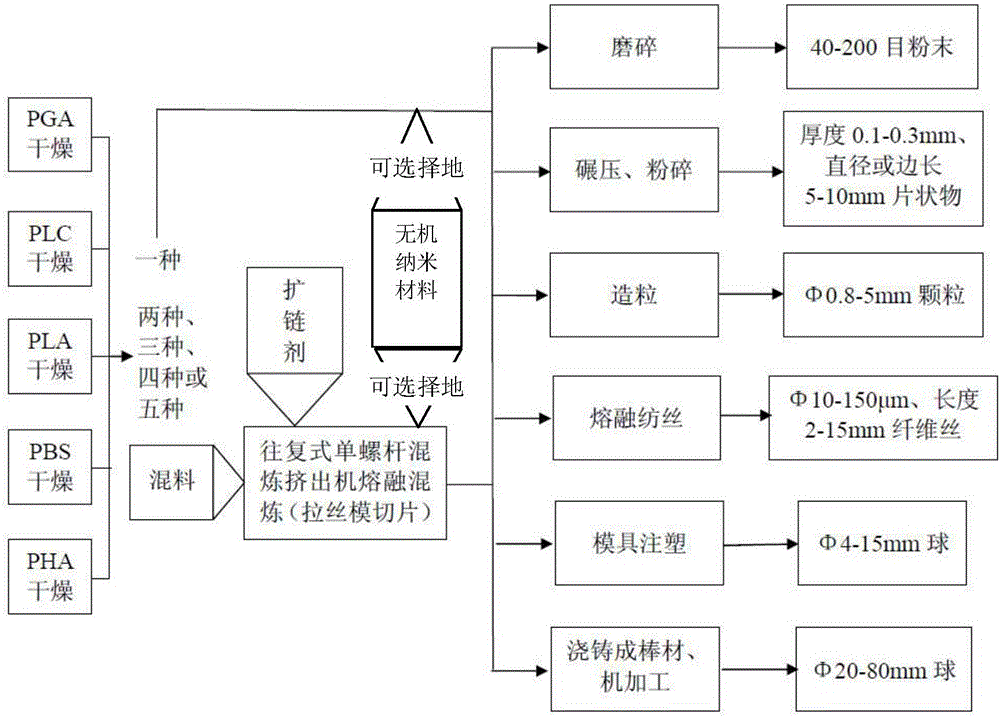

The invention provides a degradable material for oil and gas field operation and a preparation method thereof. The preparation method of the degradable material for oil and gas field operation comprises the step of carrying out melting mixing reaction on two, three, four, or five polymers of polyglycolic acid, polycaprolactone, polylactic acid, poly butylene succinate and poly-3-hydroxybutyrate and a chain extender, so as to obtain resin alloy, namely, the degradable material for oil and gas field operation. The degradable material for oil and gas field operation can be prepared into shapes such as pieces, powder, particles and balls, or can be prepared from one of polyglycolic acid, polycaprolactone, polylactic acid, poly butylenes succinate and poly-3-hydroxybutyrate into shapes such as pieces, powder, particles and balls through the method, is used for temporary plug and filtration reduction for protecting a reservoir, and temporarily plugging shot holes, constructed layer sections, and the like during various operation (drilling, well completion, well repair and acid fracturing) in the oil and gas field, and has the advantages of being completely degradable and harmless to the stratum.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

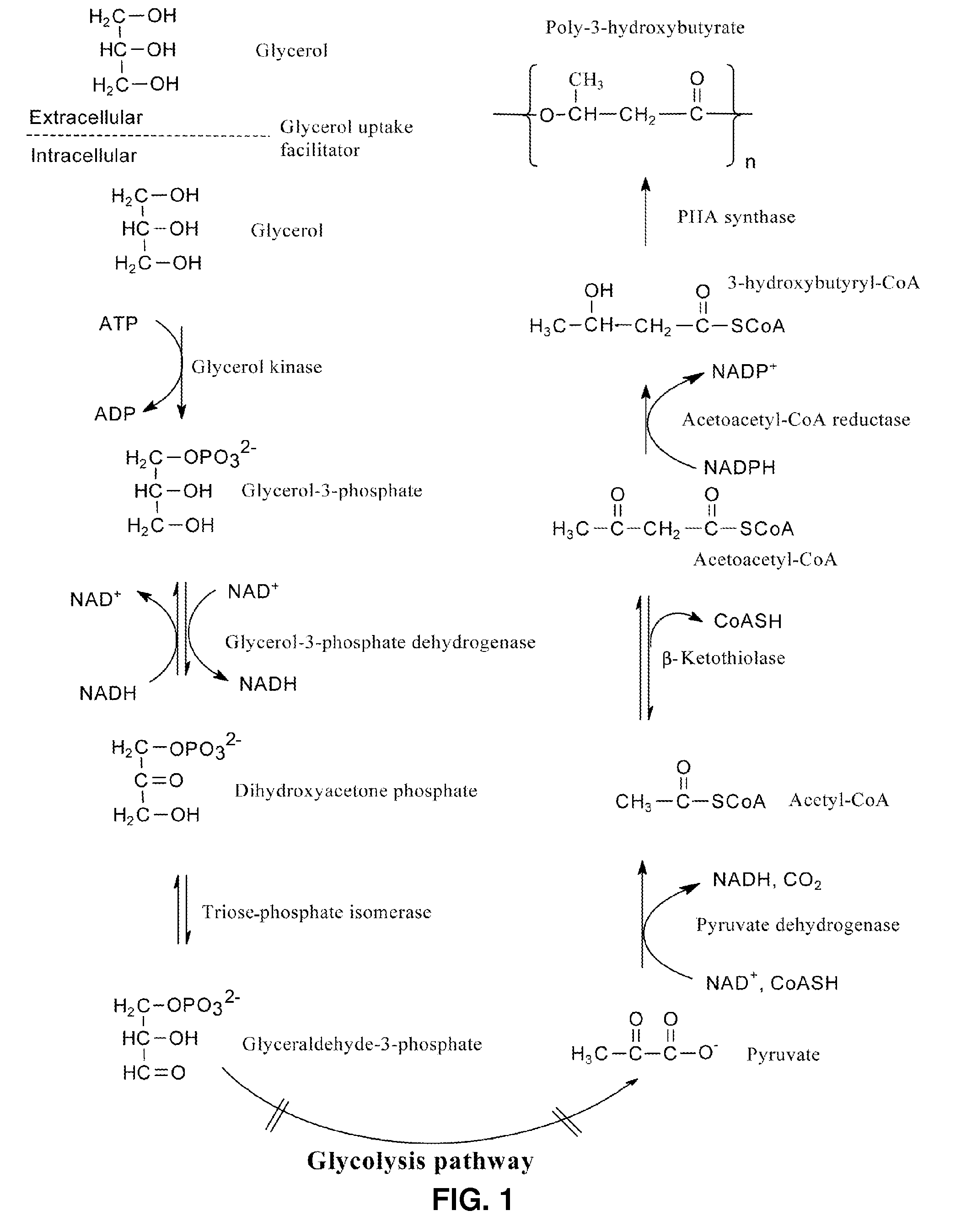

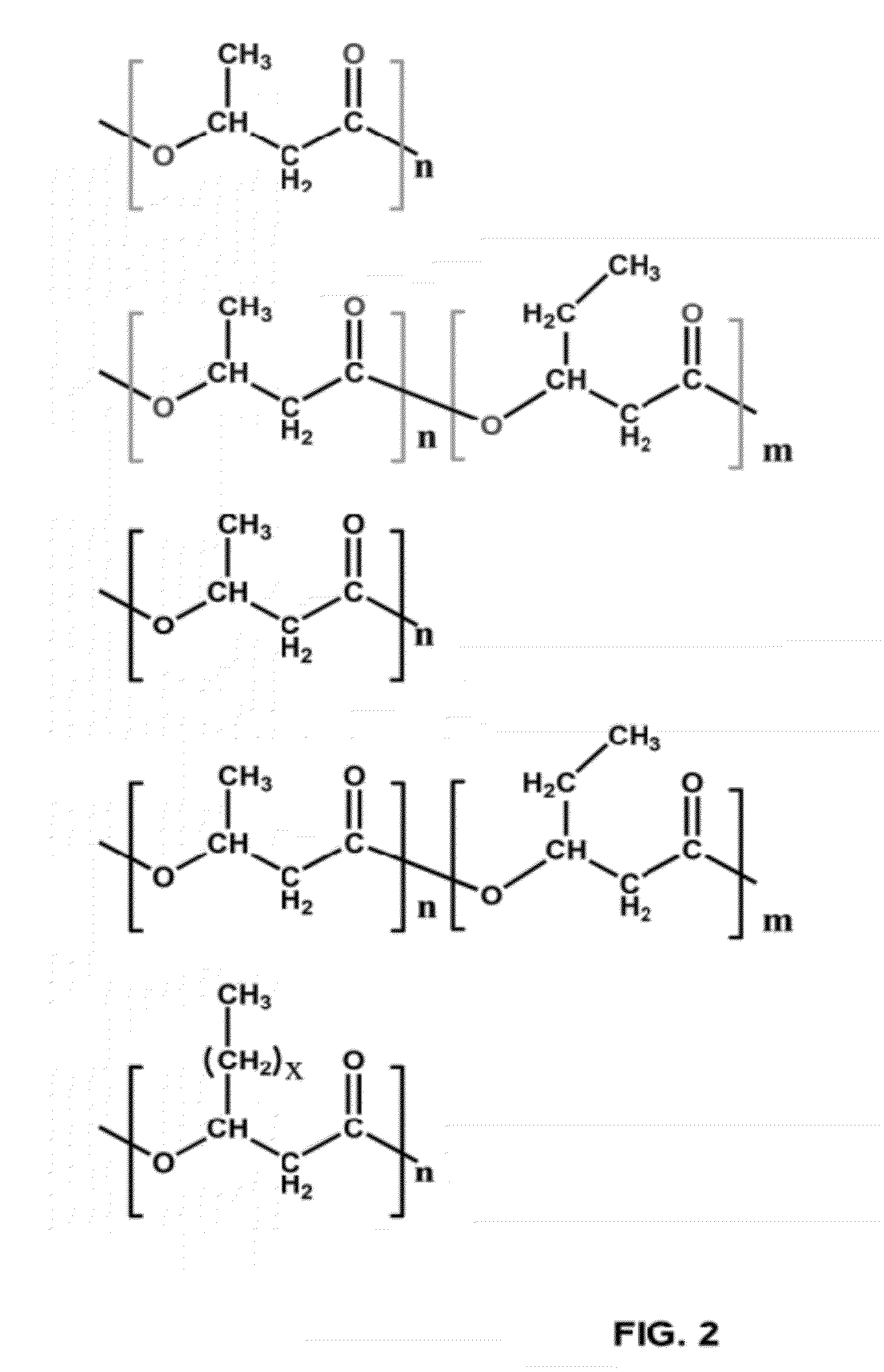

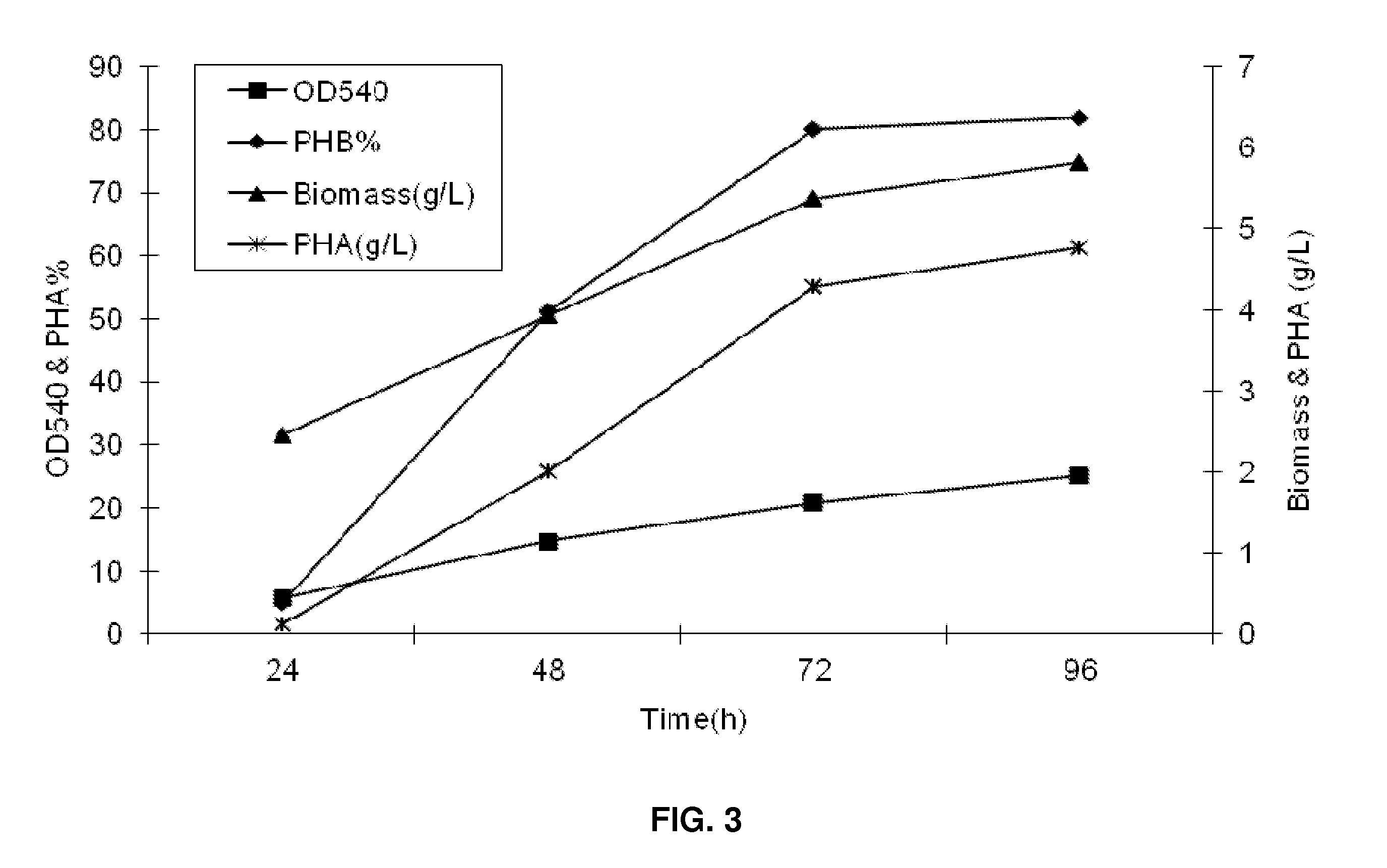

Methods for producing polyhydroxyalkanoates from biodiesel-glycerol

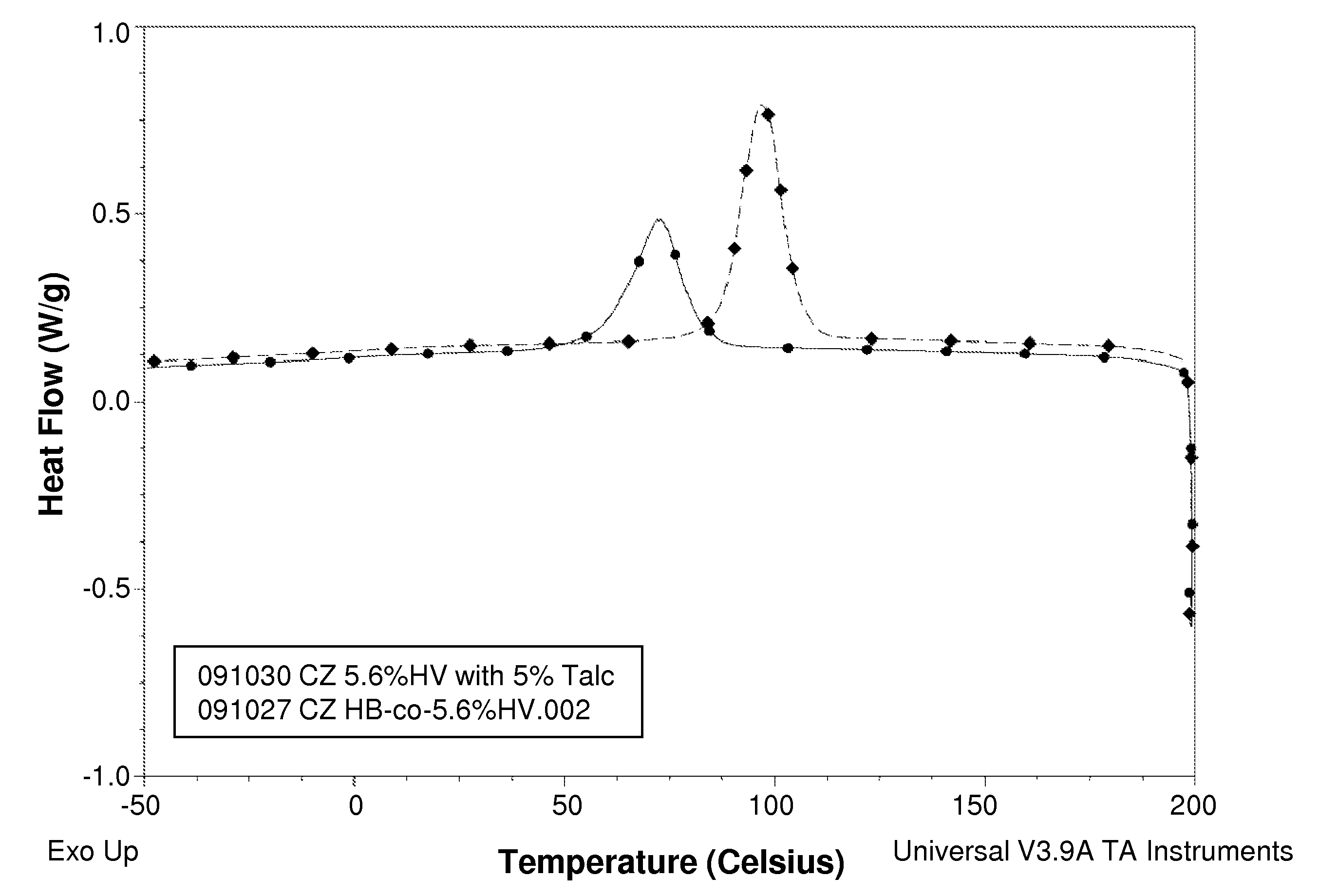

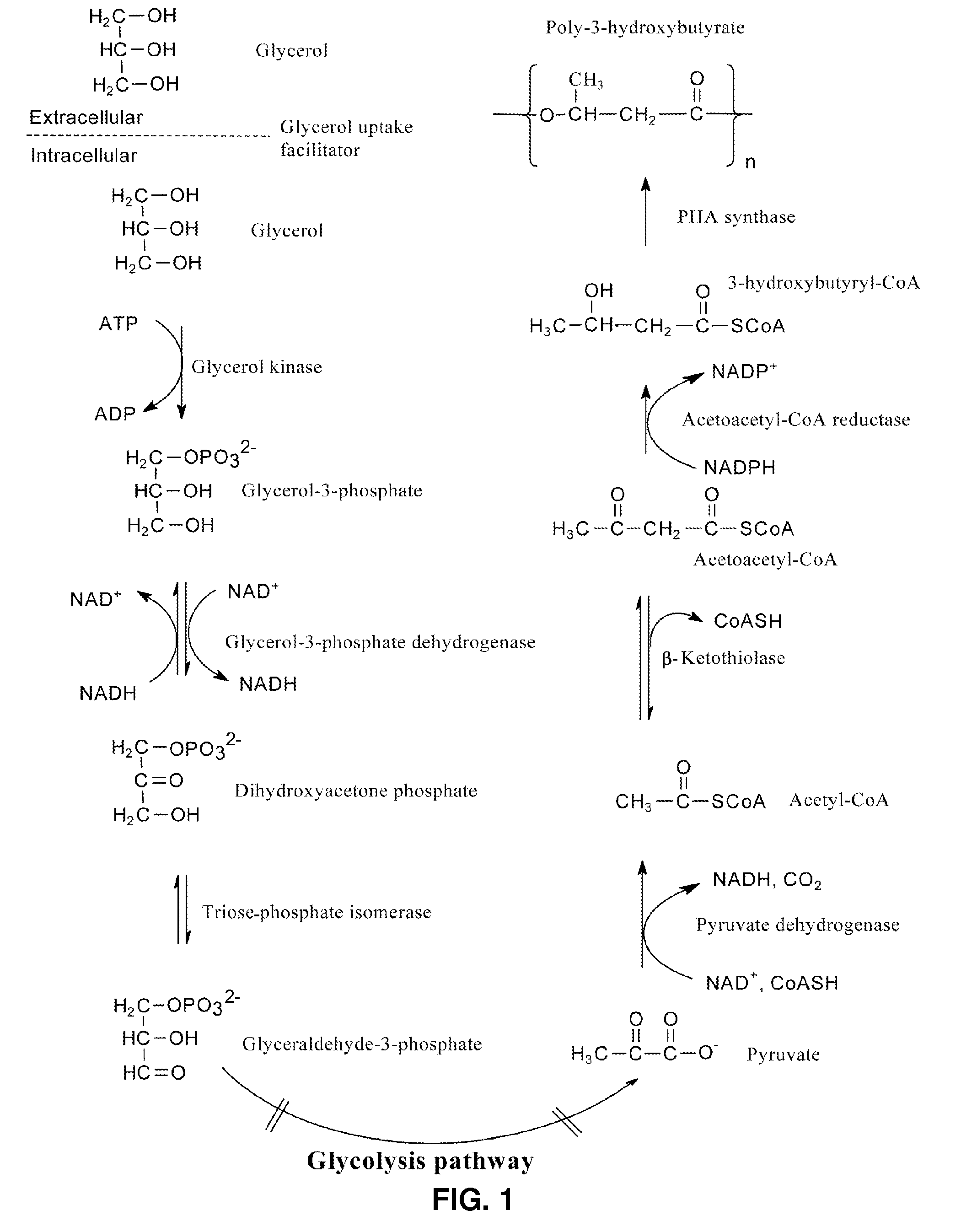

Methods are provided for producing biodegradable polyhydroxyalkanoates (PHAs) with desired geometry, molecular mass, mechanical and / or physical-chemical properties from glycerol, an inexpensive carbon source and byproduct of the biodiesel industry. Microorganisms capable of converting carbon to PHA can be used to convert biodiesel-glycerol to poly-3-hydroxybutyrate (PHB) or other monomer or copolymer PHAs via fermentation. The microorganisms are cultured in a medium comprising glycerol as a primary carbon source and one or more low molecular mass organic acids as a secondary carbon source. Biomass can be harvested from the culture medium and crude PHA extracted and purified, thereby recovering purified PHA with the desired property. After PHA isolation, a nucleating agent can be added to improve certain physical-chemical properties of the PHA, e.g., crystallization temperature, to enhance performance of the PHA during injection molding.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Resin composition, and method for producing the same

A resin composition having excellent impact resistance and heat resistance, comprising a poly-3-hydroxybutyrate, and a core-shell latex rubber comprising an acrylic rubber and / or silicone-acrylic rubber copolymer as a core component and polymethyl methacrylate as a shell component, or a specific thermoplastic polyurethane, is disclosed. The resin composition satisfies the following requirements (c) and (d): (c) a crystallization temperature when heated from room temperature to 180° C. at a temperature rising rate of 80° C. / min by a differential scanning calorimeter, maintained at 180° C. for 1 minute, and then cooled at a temperature lowering rate of 10° C. / min is 110-170° C.; and (d) a weight average molecular weight (Mw) in terms of polystyrene conversion when a chloroform soluble component is measured with a gel permeation chromatography is 100,000-3,000,000.

Owner:TOSOH CORP

Methods for producing polyhydroxyalkanoates from biodiesel-glycerol

ActiveUS20120135480A1Increased elongation-to-breakIncreased resistance to breakingBiofuelsFermentationBiodieselGlycerol

Methods are provided for producing biodegradable polyhydroxyalkanoates (PHAs) with desired geometry, molecular mass, mechanical and / or physical-chemical properties from glycerol, an inexpensive carbon source and byproduct of the biodiesel industry. Microorganisms capable of converting carbon to PHA can be used to convert biodiesel-glycerol to poly-3-hydroxybutyrate (PHB) or other monomer or copolymer PHAs via fermentation. The microorganisms are cultured in a medium comprising glycerol as a primary carbon source and one or more low molecular mass organic acids as a secondary carbon source. Biomass can be harvested from the culture medium and crude PHA extracted and purified, thereby recovering purified PHA with the desired property. After PHA isolation, a nucleating agent can be added to improve certain physical-chemical properties of the PHA; e.g., crystallization temperature, to enhance performance of the PHA during injection molding.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Resin composition, and method for producing the same

The present invention discloses a resin composition having excellent impact resistance and heat resistance, which comprises poly-3-hydroxybutyrate and core-shell latex rubber or specific thermoplastic polyurethane, the core-shell latex rubber Contains acrylic rubber and / or silicone-acrylic rubber copolymer as core component and polymethyl methacrylate as shell component. The resin composition meets the following requirements (c) and (d): (c) when heated from room temperature to 180° C. at a rate of 80° C. / min by a differential scanning calorimeter, kept at 180° C. for 1 minute, and then When cooled at a cooling rate of 10°C / min, the crystallization temperature is 110 to 170°C; and (d) when the chloroform-soluble content is measured by gel permeation chromatography, the weight average molecular weight (Mw) in terms of polystyrene is 100,000 -3,000,000.

Owner:TOSOH CORP

PLA (Poly Lactic Acid) and PHBV (Poly Hydroxyl Butyrate Valerate) blending modification polyester filament and preparation method thereof

InactiveCN102995160AFast degradationFeel goodFilament forming substance formingMelt spinning methodsPolyesterState of art

The invention discloses a functional PET technology, and particularly relates to a poly 3-hydroxybutyrate-3-hydroxyvalerate and poly lactic acid blending modification polyester filament and a preparation method thereof. The invention aims at overcoming the defects in the prior art and providing a PLA (Poly Lactic Acid) and PHBV (Poly Hydroxyl Butyrate Valerate) blending modification polyester filament which is quick in degradation velocity, high in softness, good in handfeel, and easy to color and a preparation method thereof. The polyester filament consists of 20-50wt% of PLA and the balance of PHBV, can satisfy the existing pursue of people, and has the characteristics that under the condition that the quality of cloth is met, abundant colors can be selected by people, so that the more choices are provided.

Owner:新凤鸣集团股份有限公司

High polymer-based cigarette filter material with excellent temperature control effect and preparation method thereof

ActiveCN109674087AHigh self-transition latent heatPromote degradationTobacco smoke filtersPolymer scienceCooling effect

The invention discloses a high polymer-based cigarette filter material with an excellent temperature control effect and a preparation method thereof. The high polymer-based cigarette filter material is obtained by using a high polymer material with excellent biodegradability as a base material and adding a microcapsule phase change material and nano particles with high heat conductivity coefficients, wherein the high polymer material is one or more of polycaprolactone, polyhydroxyalkanoate, poly 3-hydroxybutyrate, a polyglycolide polymer material; and the microcapsule phase change materials ismicroencapsulated polyethylene glycol, the polyethylene glycol is used as a core material, and polyacrylonitrile is used as a wall material. The preparation method can be used for preparing a multi-component high polymer-based composite material which is cheap, safe, harmless and suitable for cigarette filters, and has the relatively high latent heat of phase change and heat transfer capability.The high polymer-based cigarette filter material with the excellent temperature control effect can be used as a novel cigarette filter to effectively reduce the mainstream smoke of cigarettes, and hasthe characteristics of low addition amount, obvious cooling effect, and significant reduction of harmful substances in smoke.

Owner:UNIV OF SCI & TECH OF CHINA

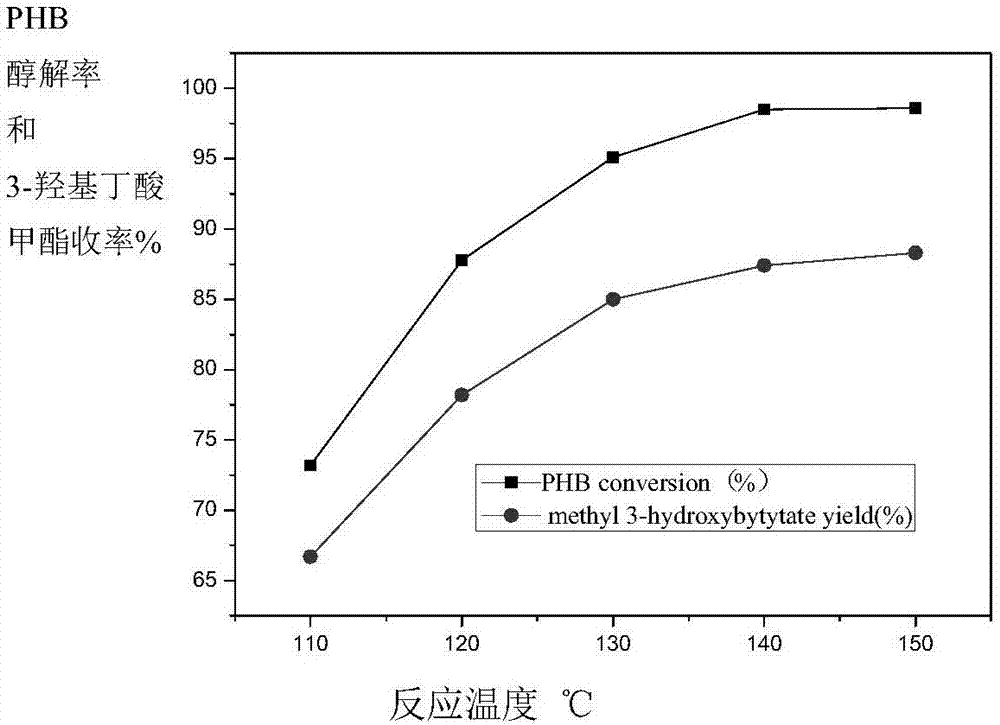

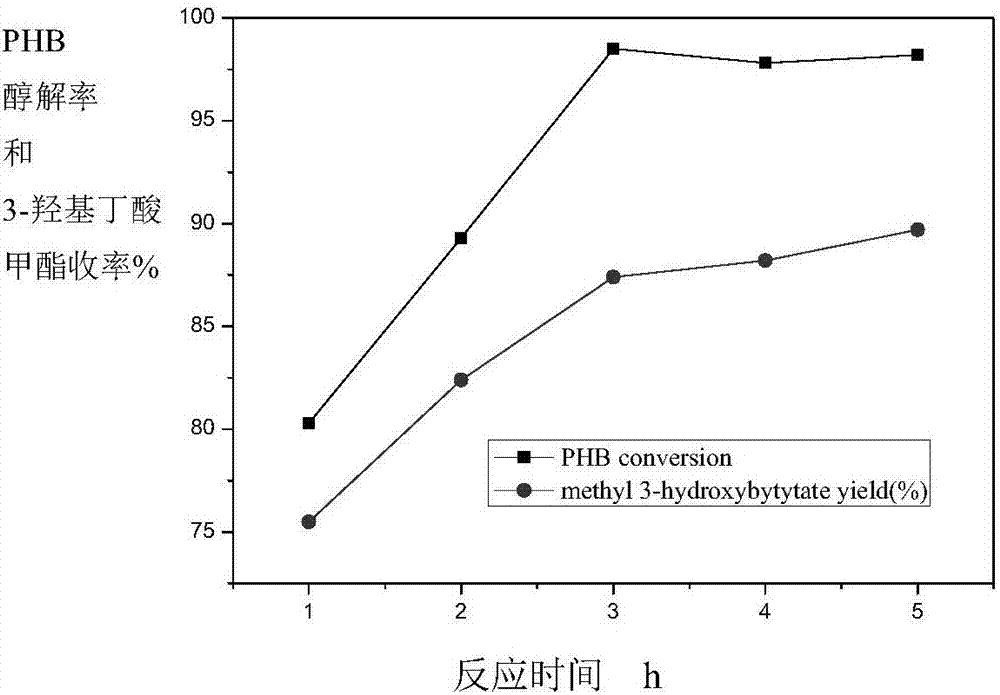

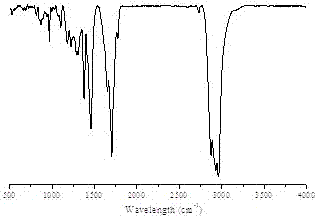

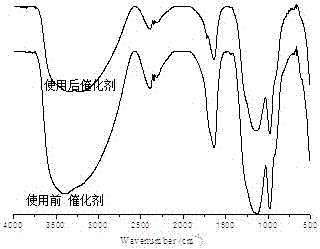

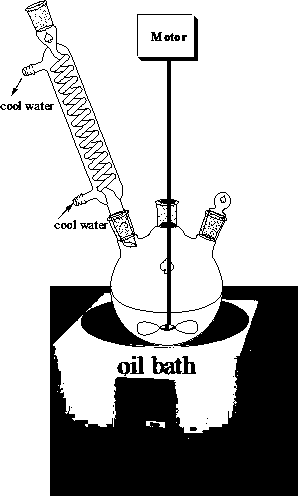

Method for catalytic alcoholysis of poly-3-hydroxybutyrate by means of double-acid ionic liquid

ActiveCN107188802AImprove performanceHigh purityPreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsPoly-3-hydroxybutyrateAlcohol

The invention provides a method for catalytic alcoholysis of poly-3-hydroxybutyrate by means of a Bronsted-Lewis double-acid ionic liquid. The method includes the steps that according to a molar ratio of nPHB to n catalysts as 1 to 0.01-0.1, poly-3-hydroxybutyrate and the catalyst Bronsted-Lewis double-acid ionic liquid are mixed, small molecular alcohol is added, and an alcoholysis reaction is conducted at 100-160 DEG C. According to the method for alcoholysis and recycling of poly-3-hydroxybutyrate with the Bronsted-Lewis double-acid ionic liquid as a catalyst to catalyze a waste material PHB, the product obtained with the method is high in purity, and the catalyst is stable in performance and can be repeatedly used. The conversion rate of the material PHB reaches 100%, the product yield reaches 92% or above, the recycled poly-3-hydroxybutyrate is an important chemical raw material, and excellent economic benefits and environmental benefits can be obtained by means of the method.

Owner:QINGDAO UNIV OF SCI & TECH

Degradable resin material for operation of oil and gas field and preparation method thereof

The invention provides a degradable resin material for operation of an oil and gas field and a preparation method thereof. The method comprises the step of performing a melt-mixing reaction on polymer of two or three of polyglycolic acid, butylene succinate and poly-3-hydroxybutyrate with a chain extender to prepare resin alloy, namely the degradable resin material for operation of the oil and gas field. The degradable resin material prepared by the method can be prepared into flakes, powder, particles, spheres and other shapes, or one of polyglycolic acid, butylene succinate and poly-3-hydroxybutyrate is prepared into flakes, powder, particles, spheres and other shapes. The degradable resin material can be used for temporarily plugging and reducing filtration to protect reservoirs, temporarily plugging blast-holes, constructed reservoirs and the like in various oil and gas field constructing operations, such as well drilling, completion and repairing and acid fracturing. The degradable resin material has the advantages of complete degradability and zero harm to stratum.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

High-strength and anti-impacting natural rubber cable sheathing material

ActiveCN106117644AHigh strengthGood compatibilityInsulated cablesInsulated conductorsLow-density polyethylenePolymer science

The invention discloses a high-strength and anti-impacting natural rubber cable sheathing material. The high-strength and anti-impacting natural rubber cable sheathing material is prepared from the following raw materials: natural rubber, polyvinyl chloride, low-density polyethylene, an ethylene-vinyl acetate copolymer, zinc oxide, stearic acid, sulfur, high-abrasion-resisting furnace black, carbon nanotubes, nano calcium carbonate, montmorillonoid, zirconium diboride, calcium sulfate whiskers, lignocellulose short fibers, cotton short fibers, an accelerant M, an accelerant BZ, a poly-3-hydroxybutyrate-4-hydroxybutyrate, epoxy soybean oil, an anti-aging agent RD, an anti-aging agent MB, p-aminodiphenyl amine, gamma-epoxypropoxy propyltrimethoxysilicane and vinyltriethoxysilane. The high-strength and anti-impacting natural rubber cable sheathing material disclosed by the invention is high in strength, good in anti-impacting performance, excellent in anti-aging performance and long in service life.

Owner:ANHUI ELECTRIC GRP SHARES

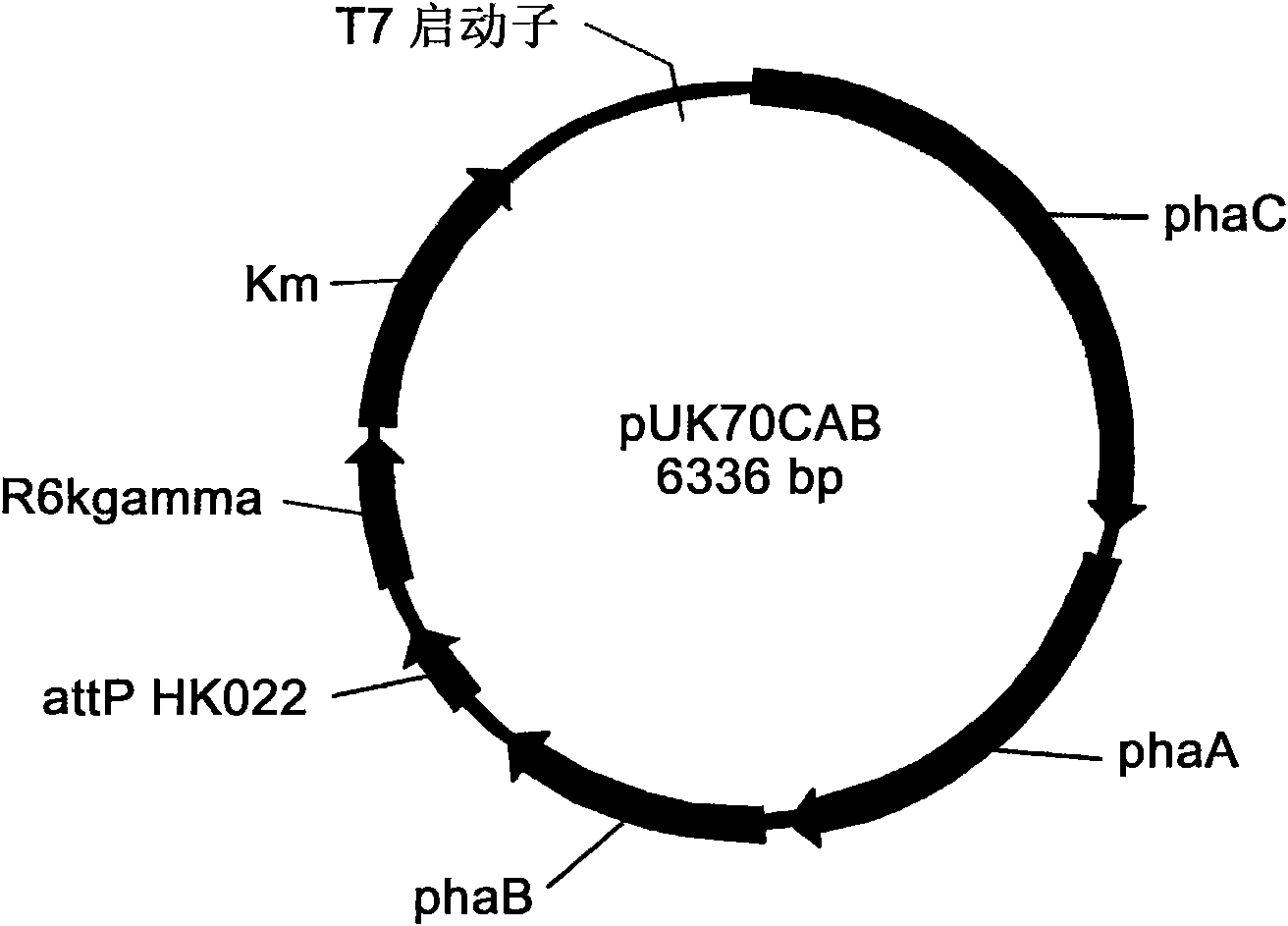

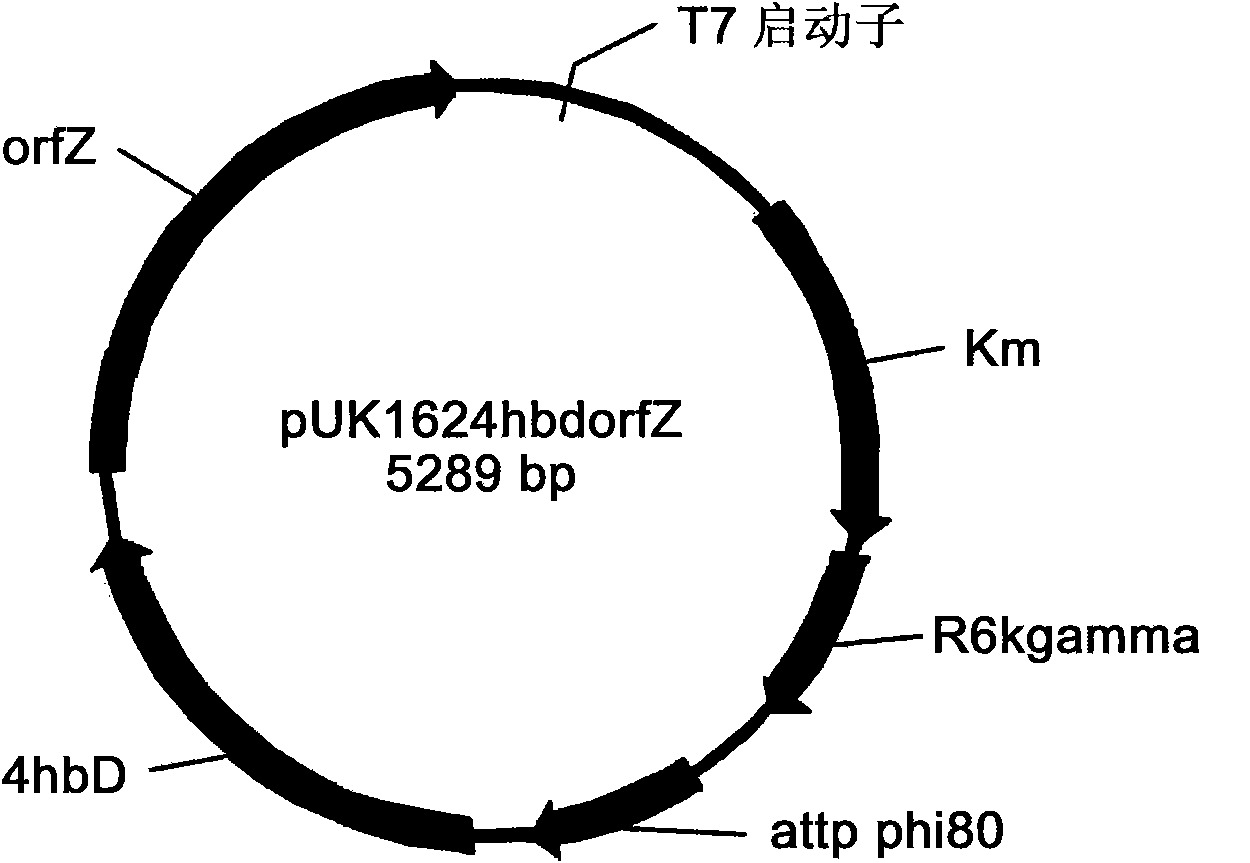

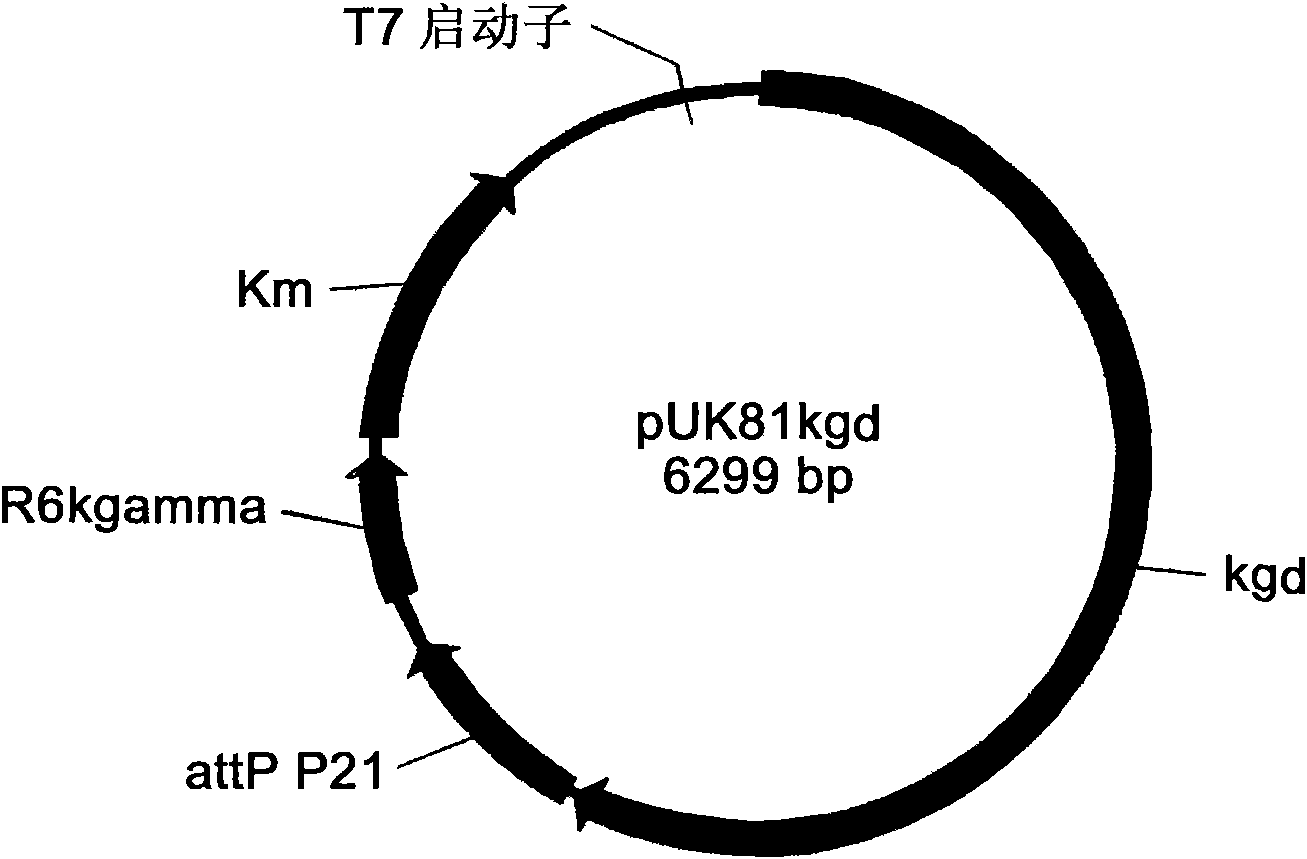

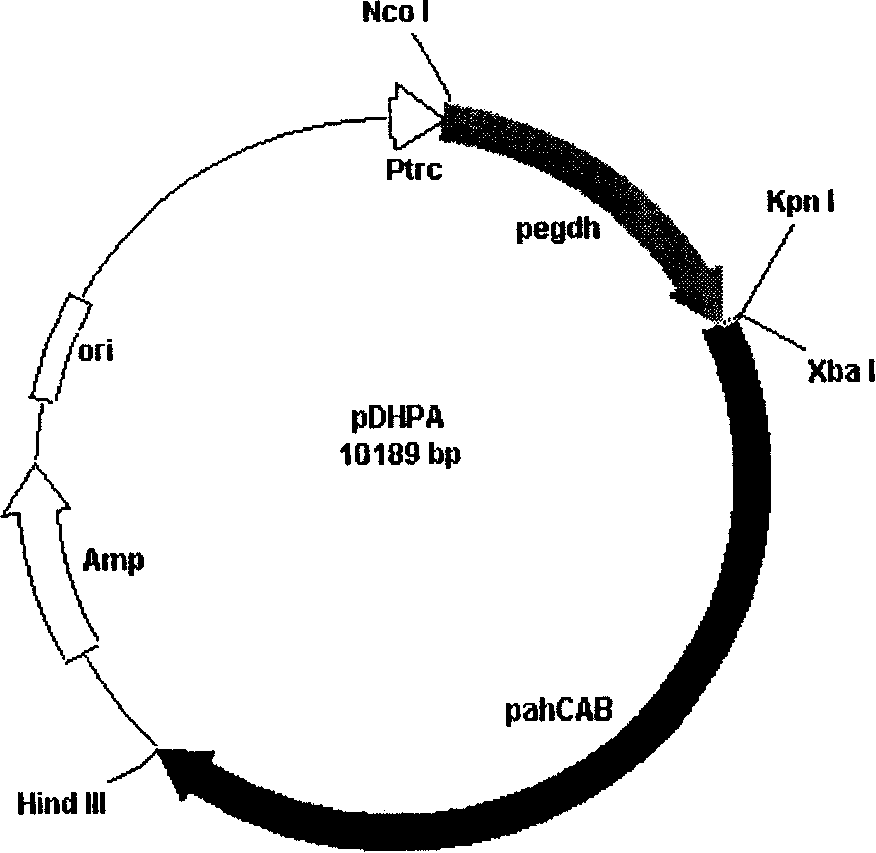

Engineering bacterium containing 2-oxoglutarate decarboxylase gene kgd and applications thereof

InactiveCN102382789AReduce manufacturing costBacteriaMicroorganism based processesCoenzyme A biosynthesis2-Oxoglutarate Dehydrogenase

The invention belongs to the technical field of genetic engineering and fermentation, and particularly discloses an engineering bacterium for producing 3-hydroxybutyric acid and 4-hydroxybutyric acid copolyester (P3HB4HB) by utilizing a sugar carbon source. Exogenous genes needed for combining the P2HB4HB are recombined and integrated on the genome of the engineering bacterium and comprise poly-3-hydroxybutyrate synthetic gene phaCAB and 4-hydroxybutyryl coenzyme A which is transferase gene orfZ, 4-hydroxybutyric acid dehydrogenase gene 4hbD and 2-oxoglutarate dehydrogenase gene kgd. By utilization of the engineering bacterium, the P3HB4HB can be produced by using the sugar carbon source with relatively cheap price, the production cost is effectively reduced, and the large-scale industrial production and the commercial application and development are pushed.

Owner:TIANJIN GREENBIO MATERIAL CO LTD

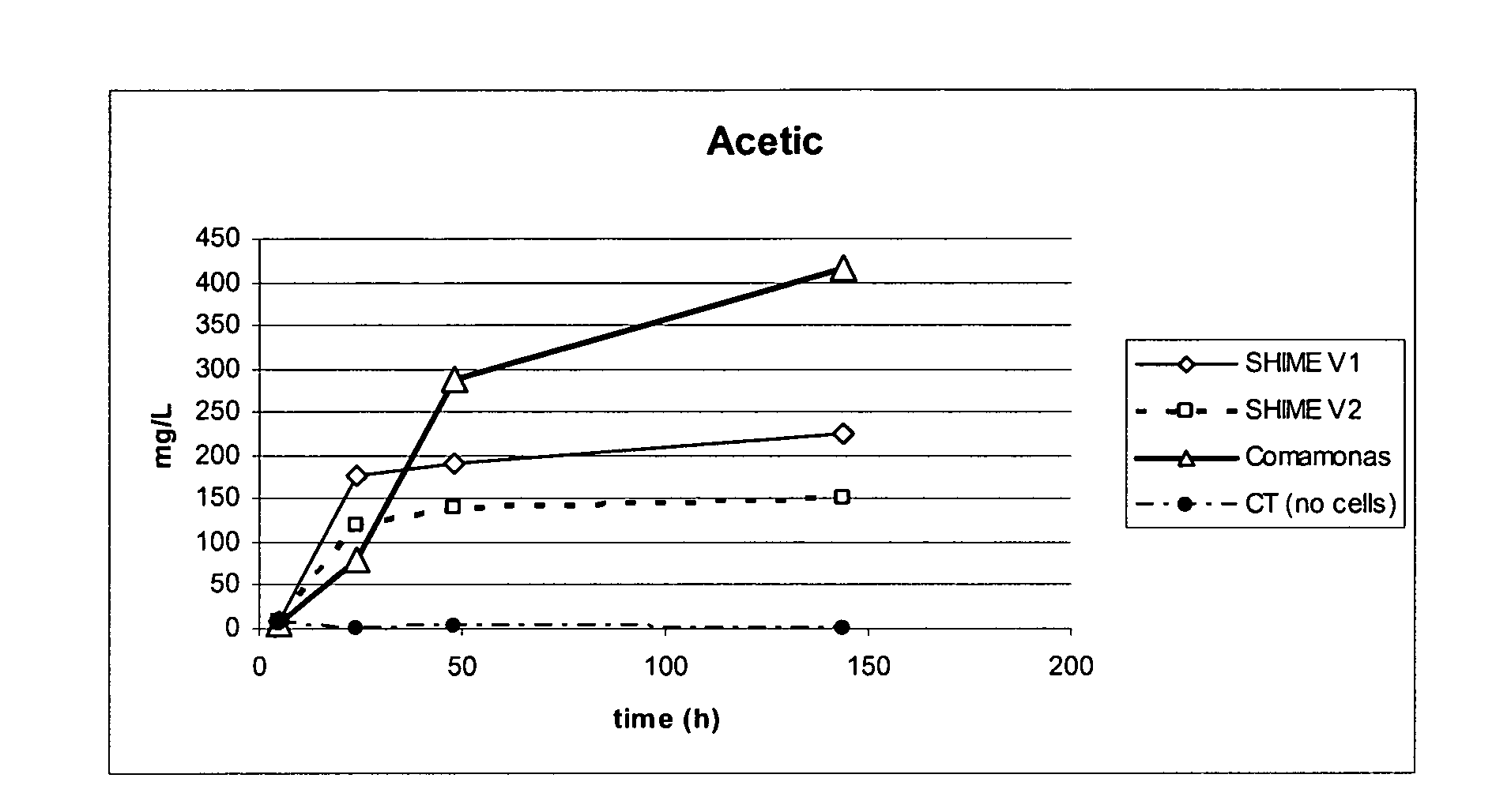

Hydroxybutyrate and poly-hydroxybutyrate as components of animal feed or feed additives

ActiveUS8603518B2Optimized formulaSmall particlesAntibacterial agentsBiocideEscherichia coliIntestinal microorganisms

This invention relates to the use of hydroxybutyrate and poly hydroxybutyrate as components of animal feed or feed additives, as well as to compositions, feed additives and feed containing them. The inventors surprisingly found that hydroxybutyrate and poly-hydroxybutyrate, preferably 3-hydroxybutyrate and poly-3-hydroxybutyrate, have a great potential for use in animal feed for modulation of the gut flora. More precisely, it has been found that poly-3-hydroxybutyrate or a microbial strain capable for producing poly-3-hydroxybutyrate can be used as a potential growth promoter or gut flora modulator by releasing SCFA, preferably 3-hydroxy butyric acid, in the gut micro flora. Further, the inventors found that 3-hydroxybutyrate and poly-3-hydroxybutyrate have a great potential for suppressing or inhibiting pathogenic bacteria in the gastro intestinal tract, e.g. have a antimicrobial activity against strains of Vibrio, E. coli and Salmonella.

Owner:UNIV GENT

Anti-bacterial and acid-alkali-resistant medical material and preparation method thereof

InactiveCN106479097AImprove antibacterial propertiesGood acid and alkali resistancePolyethylene glycolSulfanilamide

The invention discloses an anti-bacterial and acid-alkali-resistant medical material and a preparation method thereof. The medical material is prepared from main ingredients including pharmaceutical grade polyvinyl alcohol, polypropylene resin, poly-3-hydroxybutyrate and polyethylene glycol fatty acid ester mixed with pentaerythritol oleate, octenyl succinic acid modified starch, citrate, N-butylcyanoacrylate, sulfanilamide, sodium citrate, polyactic acid fibers, aluminium silicate ceramic fibers, magnesium carbonate, gaseous-phase white carbon black, malic acid, a dispersing agent and a stabilizer by mixing, stirring, high-temperature sintering, grinding, high-pressure calcination, acid leaching, ultrasonic dispersion, screw extrusion, injection molding treatment and the like. The anti-bacterial and acid-alkali-resistant medical material has an excellent anti-bacterial property and acid and alkali resistance, can meet requirements of the industry and has better application prospect.

Owner:金福兴

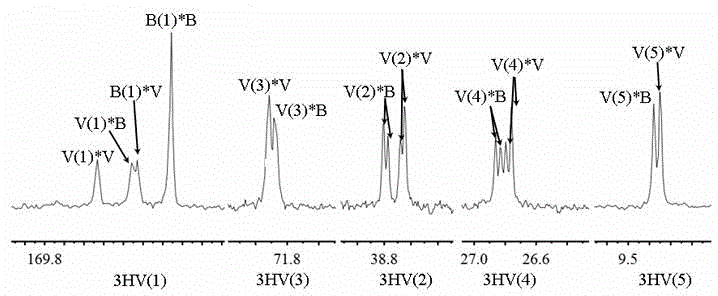

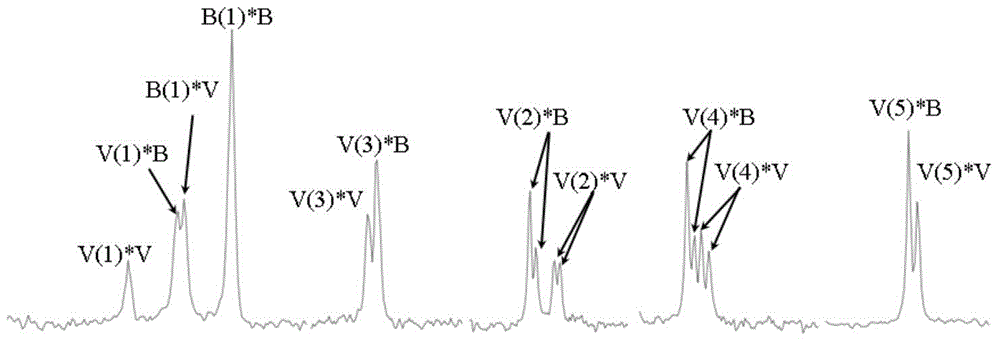

PHBV (polyhydroxylbutyrate valerate) polymer, preparation method and hemostatic material manufactured by using PHBV polymer

ActiveCN104448258AImprove adsorption capacityGood coagulationMicroorganism based processesAbsorbent pads3-Hydroxypentanoic acidInternal pressure

The invention discloses a PHBV (polyhydroxylbutyrate valerate) polymer, a preparation method and a hemostatic material manufactured by using the PHBV polymer. The PHBV polymer is a copolymer of 3-hydroxybutyrate (3HB) and 3-hydroxyvalerate (3HV), and the main chain of the polymer includes at least 50 blocks of poly 3-hydroxybutyrate and at least 50 blocks of poly 3-hydroxyvalerate. The preparation method comprises: inoculating Haloferax mediterranei ES1 strains to a fermentation medium, and automatically feeding 2M hydrochloric acid solution or 2M sodium hydroxide solution under the condition that the fermentation temperature is 37 DEG C, the stirring revolution speed is 300-500r / min and the ventilatory capacity is 1.25: 1vvm to stabilize the pH value at 6.9-7.1; fermenting for 36-48h under the condition that the ventilatory capacity is 1.25: 1vvm and the inner pressure of a tank body is 1 atmosphere; and extracting the PHBV polymer from the fermentation solution.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

Method of using poly-3-hydroxybutyrate to prepare liquid fuel

ActiveCN107057746ASolve the problem of severe inactivation during repeated useAvoid harsh conditionsLiquid hydrocarbon mixture productionBio-feedstockPoly-3-hydroxybutyrateHydrogen

The invention provides a method of using poly-3-hydroxybutyrate to prepare a liquid fuel; method comprises: adding the catalyst aluminum dihydrogen phosphate and poly-3-hydroxybutyrate into a high-temperature high-pressure reactor, reacting at 210-270 DEG C for 3-12 hours to obtain the liquid fuel. Aluminum dihydrogen phosphate is used as a catalyst herein, poly-3-hydroxybutyrate may be further catalytically converted at the mild temperature (210-270 DEG C) to prepare an oil product; the technical process of the method is simple and convenient to perform, and the method has industrial application prospect; the yield of oil the product is up to 36.9% by weight, the contents of carbon and hydrogen in the oil product are up to 84.5% by weight and 11.5% by weight respectively, and caloric value is up to 42 MJ / kg, which is equal to that of conventional commercial oxygen-bearing gasoline; under catalysis of the aluminum dihydrogen phosphate, the poly-3-hydroxybutyrate is converted into hydrocarbons mainly in decarboxylation form, and the decarboxylation rate is up to 73%.

Owner:DONGGUAN UNIV OF TECH

Polymeric membrane material for packaging and preparation method thereof

The invention belongs to the field of packaging materials, and relates to a polymeric membrane material for packaging and a preparation method thereof. The polymeric membrane material is prepared from the following constituents: 35-60 parts of polypropylene, 4-10 parts of polycaprolactone, 5-16 parts of polytrimethylene terephthalate, 3-9 parts of poly(butylene succinate), 2-5 parts of dioctyl terephthalate, 0.5-1.5 parts of tributyl phosphate, 4-8 parts of polyethylene glycol acrylate, 2-6 parts of poly-3-hydroxybutyrate, and 0.5-1.2 parts of diethyl phthalate. The preparation method comprises the following steps: (1) starting a high-speed mixer, and sequentially feeding the raw materials into a high-speed mixer to be mixed; (2) using a twin-screw extruder to squeeze the mixed membrane materials at high temperature; (3) using a high-temperature casting machine to cast the mixed materials squeezed by the twin-screw extruder to form a membrane; (4) cooling the packaging membrane material cast by the casting machine, so as to obtain the polymeric membrane material for packaging.

Owner:SUZHOU DINGLI PACKAGING

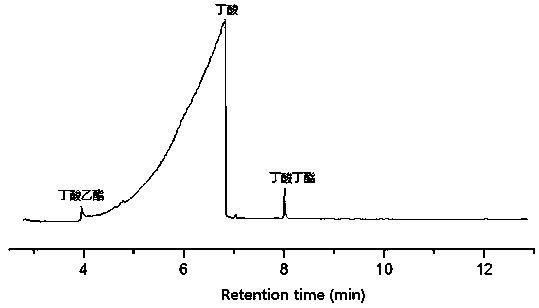

Method for preparing n-butyric acid from poly 3-hydroxybutyrate

InactiveCN109265335AHigh purityOrganic compound preparationPreparation from carboxylic acid esters/lactonesPoly-3-hydroxybutyrateLiquid product

The invention relates to a method for preparing n-butyric acid from poly 3-hydroxybutyrate. The method comprises the following steps that poly 3-hydroxybutyrate is put into a sealed device; hydrogen gas is introduced for eliminating air; after the pressure of initial hydrogen gas is 2 to 6 MPa, stirring reaction is performed for 6 to 36h at 190 to 240 DEG C; the n-butyric acid is obtained. The preparation method provided by the invention has the advantages that catalysts and reaction catalysts are not needed; under the hydrogen gas atmosphere condition, the poly 3-hydroxybutyrate is convertedinto the n-butyric acid through one-step reaction; the conversion rate of the 3-hydroxybutyrate is 100 percent; the yield of the n-butyric acid reaches up to 97 percent; the purity of the n-butyric acid in the obtained liquid product reaches up to 98 percent; the additional continuous separation process of the obtained n-butyric acid product is not needed.

Owner:DONGGUAN UNIV OF TECH

PE (Poly Ethylene) heat shrink film and preparation method thereof

InactiveCN106009185AHigh transparencyHigh surface glossFlat articlesLinear low-density polyethyleneFire retardant

The invention discloses a PE (Poly Ethylene) heat shrink film and a preparation method thereof, and relates to the field of packing materials. The PE heat shrink film is prepared from the following raw materials in parts by weight: 40-60 parts of ethylene-ethylene vinyl acetate copolymer, 50-60 parts of poly-3-hydroxybutyrate, 60-70 parts of high density polyethylene, 40-50 parts of linear low density polyethylene, 1-2 parts of antioxygen, 1-3 parts of heat stabilizer, 1-5 parts of fire retardant, 1-3 parts of lubricating agent, 1-3 parts of antiblocking agent and 2-4 parts of plasticizer. Since the raw materials mutually cooperate and act, the prepared PE heat shrink film has various excellent properties, high impact resistance and tear resistance and good transparency and surface glossiness, is easy to degrade and does not pollute environment. The preparation method is simple and easy in operation, and can realize large-scale production.

Owner:桐城市华猫软膜有限公司

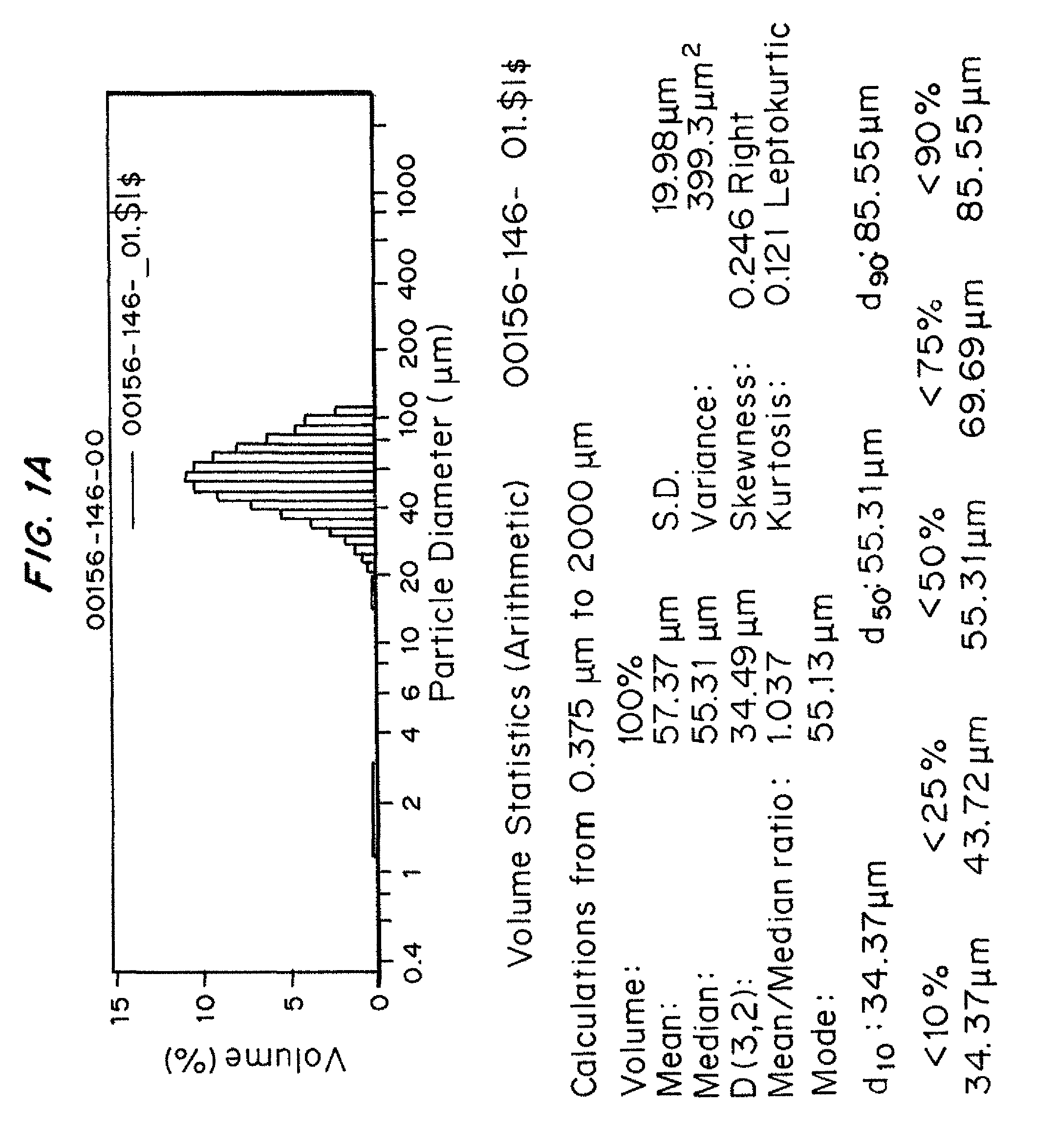

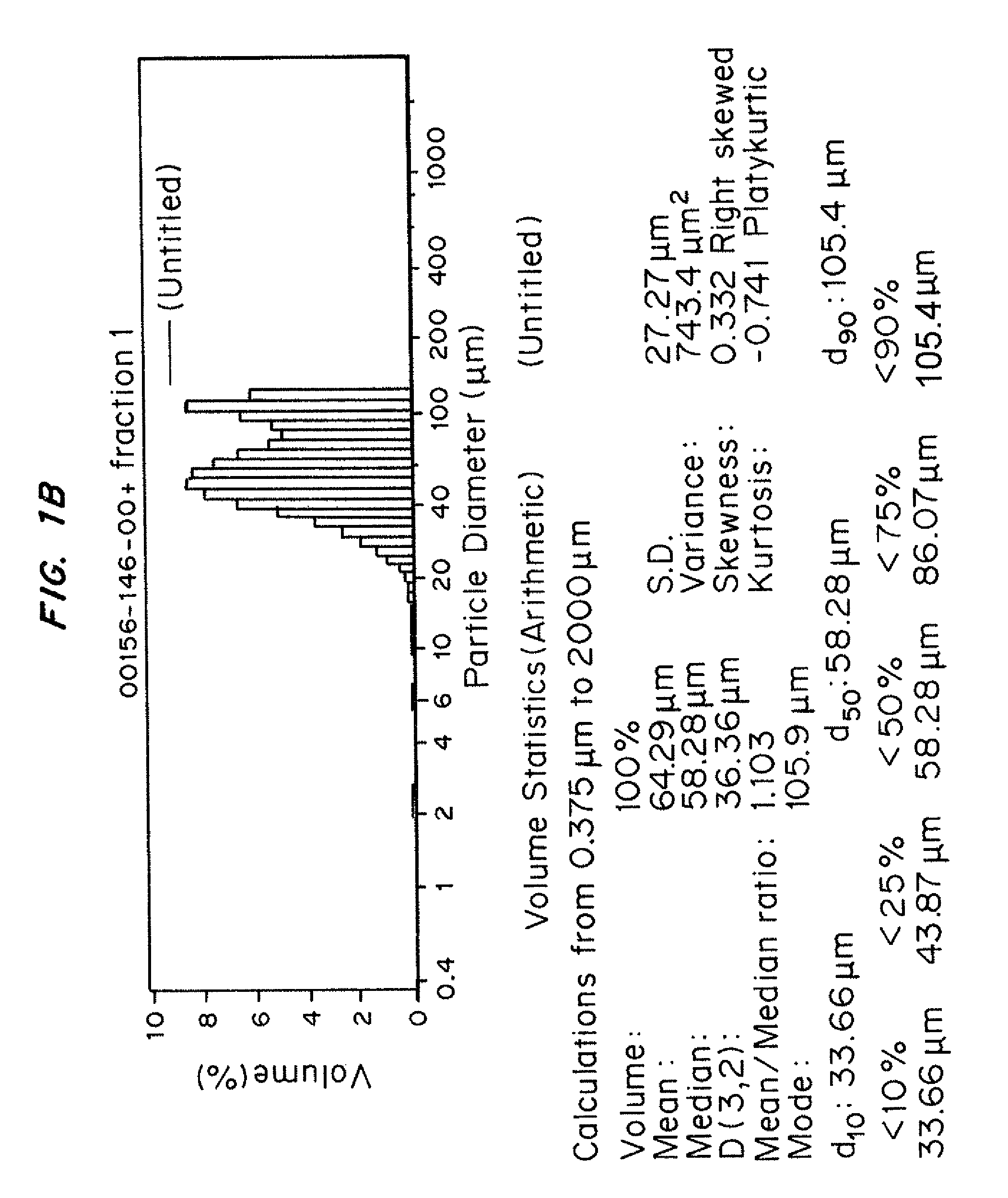

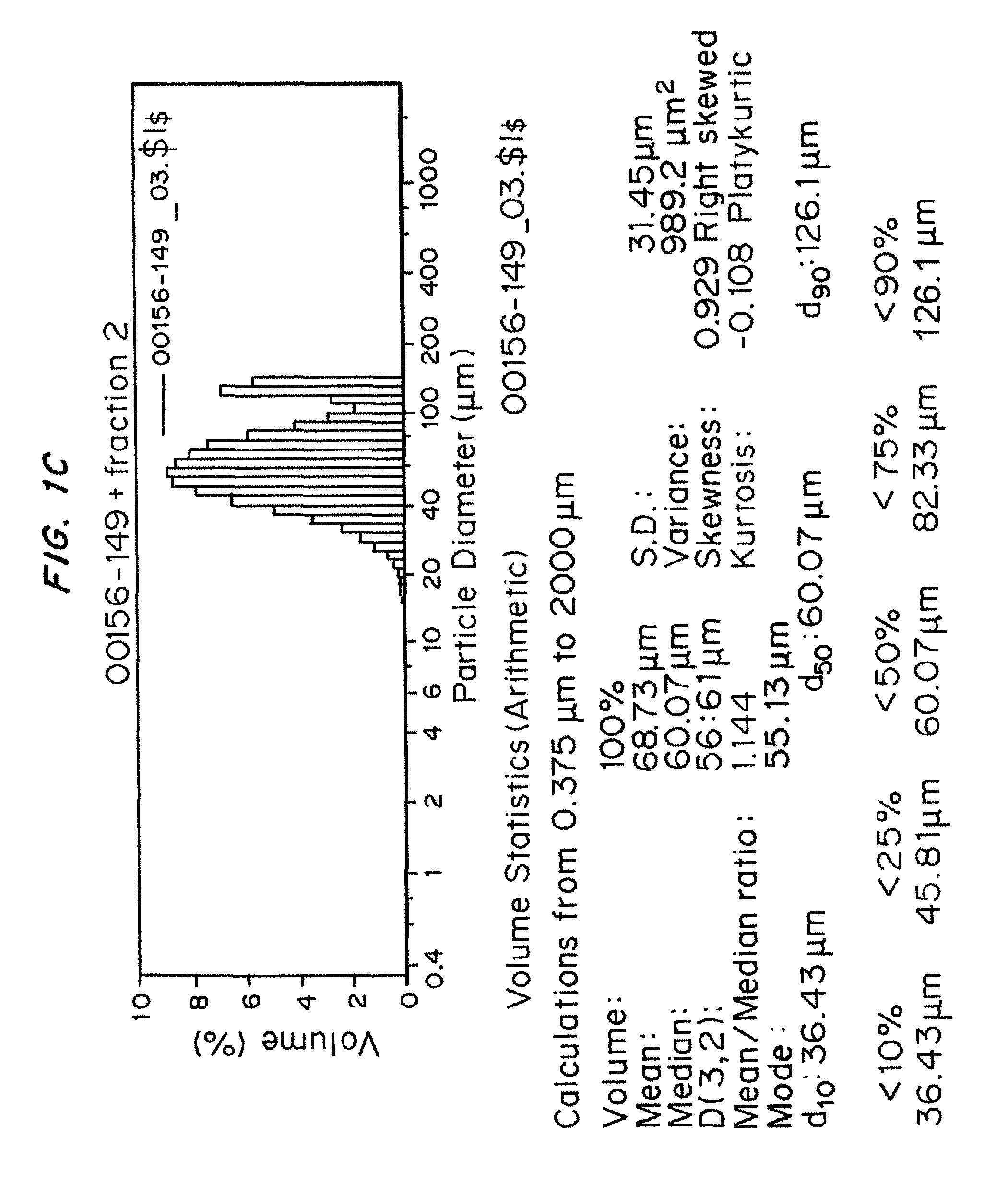

Injectable delivery of microparticles and compositions therefore

ActiveUS9216152B2Flow fastHigh solid contentOrganic active ingredientsPowder deliveryPoly-3-hydroxybutyrateNeedle size

Compositions and methods of making and using of microparticle compositions that provide faster flow or improved injectability through smaller or small-diameter needles have been developed. Notably, the microparticle compositions can be successfully delivered or administered through smaller-diameter needles than other microparticle compositions prepared from biocompatible or biodegradable polymers including, for example, poly(lactide), poly(lactide-co-glycolide), polycaprolactone, or poly-3-hydroxybutyrate. The microparticle compositions can exhibit a higher solids loading for a given needle size and / or faster flow through needles than other microparticle compositions. Further, blending or mixing the polymer of the microparticle composition with other polymer formulations can enhance the injectability of the resulting formulation.

Owner:EVONIK CORP +1

Resin composition containing poly-3-hydroxybutyrate polymer, and method for producing the same

A resin composition having excellent impact resistance and heat resistance, comprising a poly-3-hydroxybutyrate, and a core-shell latex rubber comprising an acrylic rubber and / or silicone-acrylic rubber copolymer as a core component and polymethyl methacrylate as a shell component, or a specific thermoplastic polyurethane, is disclosed. The resin composition satisfies the following requirements (c) and (d):(c) a crystallization temperature when heated from room temperature to 180° C. at a temperature rising rate of 80° C. / min by a differential scanning calorimeter, maintained at 180° C. for 1 minute, and then cooled at a temperature lowering rate of 10° C. / min is 110-170° C.; and(d) a weight average molecular weight (Mw) in terms of polystyrene conversion when a chloroform soluble component is measured with a gel permeation chromatography is 100,000-3,000,000.

Owner:TOSOH CORP

PE heat shrinkable film and preparation method thereof

InactiveCN110194860AEvenly dispersedImprove impact resistanceLinear low-density polyethylenePolymer science

The invention relates to the field of packaging materials, particularly to a PE heat shrinkable film and a preparation method thereof, wherein the PE heat shrinkable film is prepared from the following raw materials by weight: 40-60 parts of an ethylene-vinyl acetate copolymer, 50-60 parts of poly-3 hydroxybutyrate, 60-70 parts of high-density polyethylene, 40-50 parts of linear low-density polyethylene, 1-2 parts of an antioxidant, 1-3 parts of a heat stabilizer, 1-5 parts of a flame retardant, 1-3 parts of a lubricant, 1-3 parts of an opening agent, 2-4 parts of a plasticizer, and 5-10 partsof modified kaolin powder. According to the present invention, the tensile strength of the PE heat shrinkable film prepared based on the technical scheme is improved to a certain extent; and by modifying the kaolin with cetyltrimethoxysilane, the modified kaolin can be uniformly dispersed into the polyethylene matrix so as to increase the impact resistance and the toughness of the PE heat shrinkable film and improve the processing rheology of the PE heat shrinkable film.

Owner:桐城市华猫软膜有限公司

Poly-3-hydroxybutyrate composite material and preparation method thereof

InactiveCN108219407AImprove mechanical propertiesImproved rheological behaviorPoly-3-hydroxybutyrateTwo step

Owner:HUBEI GUANGHE BIO TECH

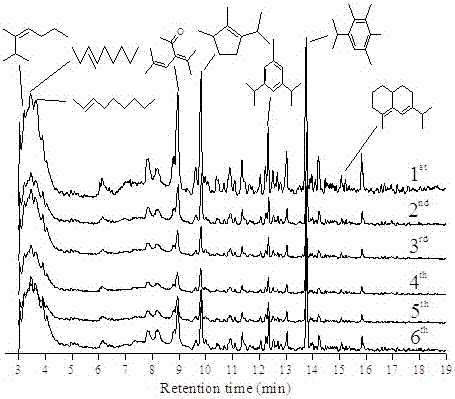

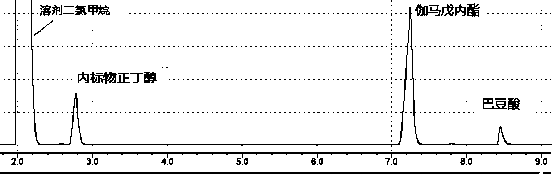

Method for preparing crotonic acid through catalytic conversion of poly-3-hydroxybutyrate by using solid catalyst

ActiveCN109704953AHigh yieldEasy to operatePreparation from carboxylic acid esters/lactonesPoly-3-hydroxybutyrateBoiling point

The invention relates to a method for preparing crotonic acid through catalytic conversion of poly-3-hydroxybutyrate by using a solid catalyst. The method comprises the following steps: poly-3-hydroxybutyrate, the solid catalyst and a gamma valerolactone solvent are mixed, and stirred and react for 1 to 24 hours at 120 to 180 DEG C to obtain crotonic acid; wherein the solid catalyst is one or moreof a solid acid catalyst or a solid base catalyst. The invention takes stable and high boiling point gamma valerolactone as solvent, solid acids and solid bases which are easy to separate and recoverand reusable are used as catalysts, so as to convert environmentally friendly and renewable poly-3-hydroxybutyrate into crotonic acid, and that yield of crotonic acid is as high as 85%, which has theprospect of industrialization. In addition, gamma valerolactone is used as the reaction solvent and has high stability and negligible loss in the preparation of crotonic acid. The separation and recovery process of solid catalyst after reaction is simple and has good reusability.

Owner:DONGGUAN UNIV OF TECH

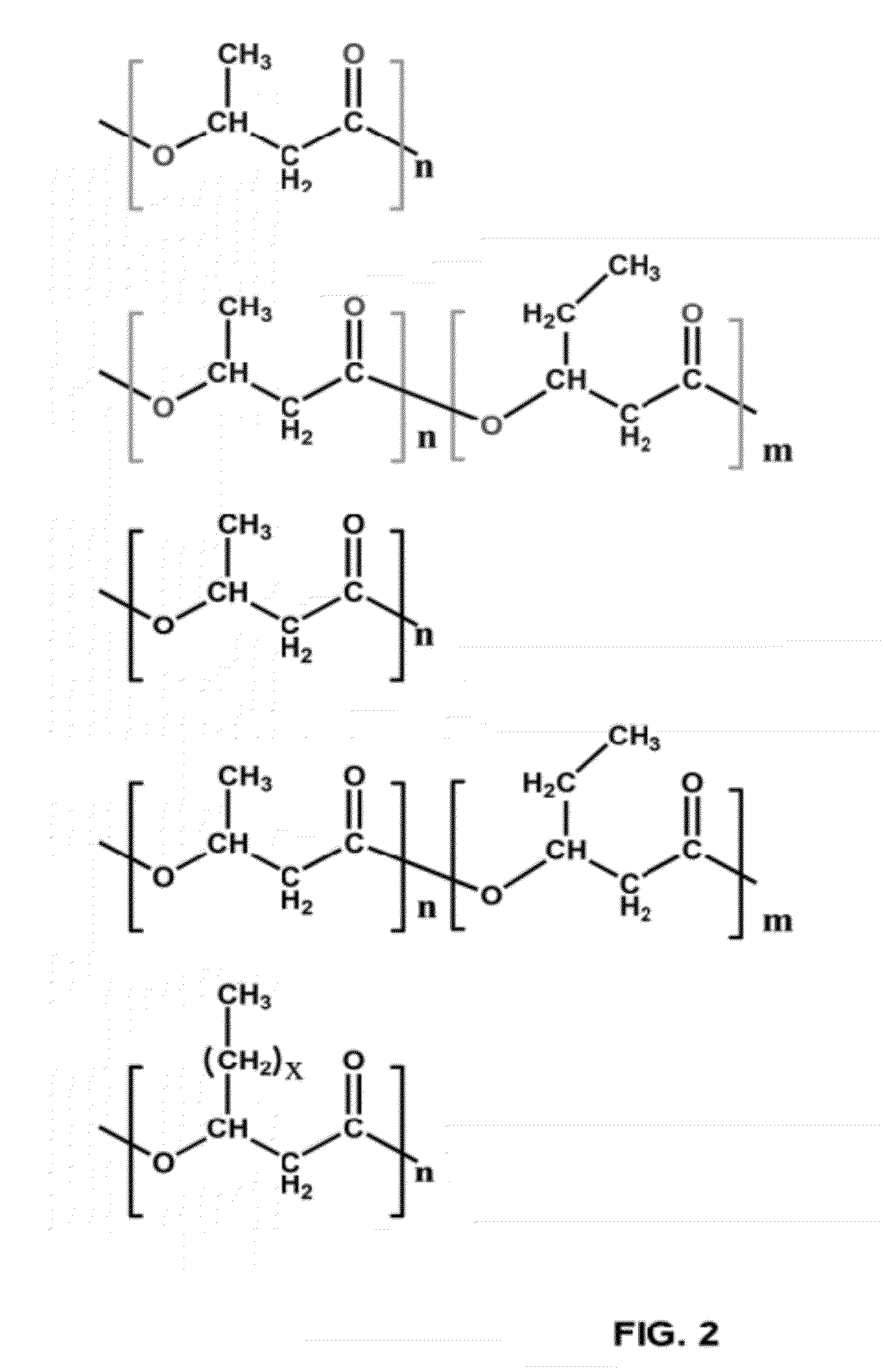

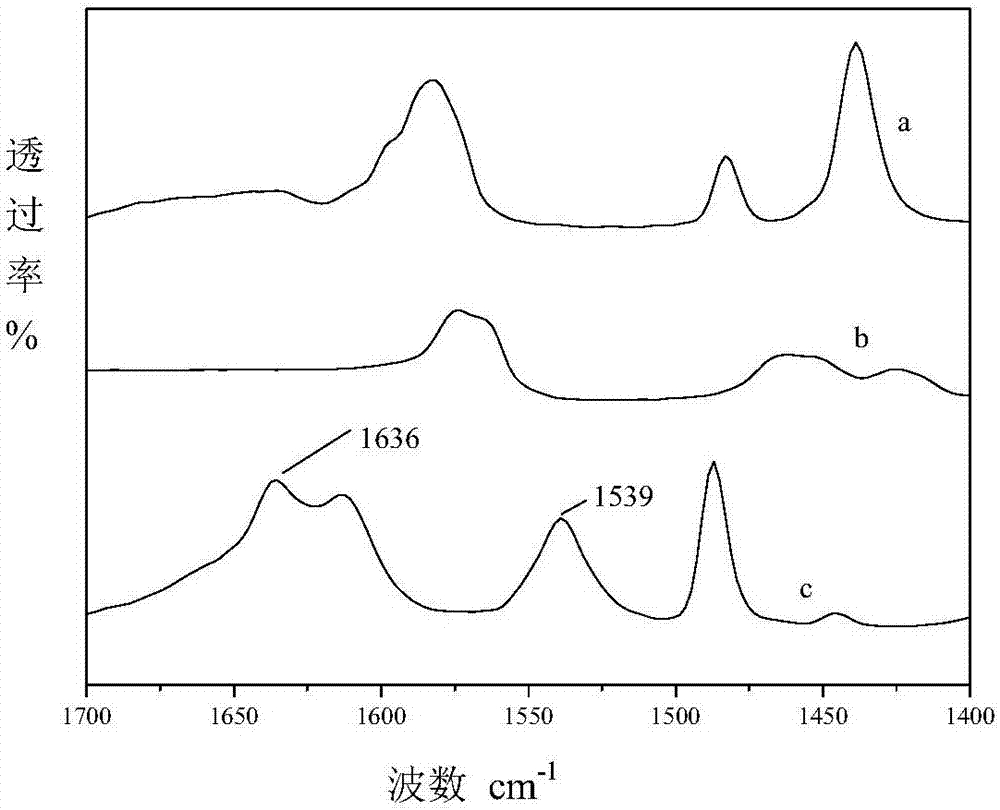

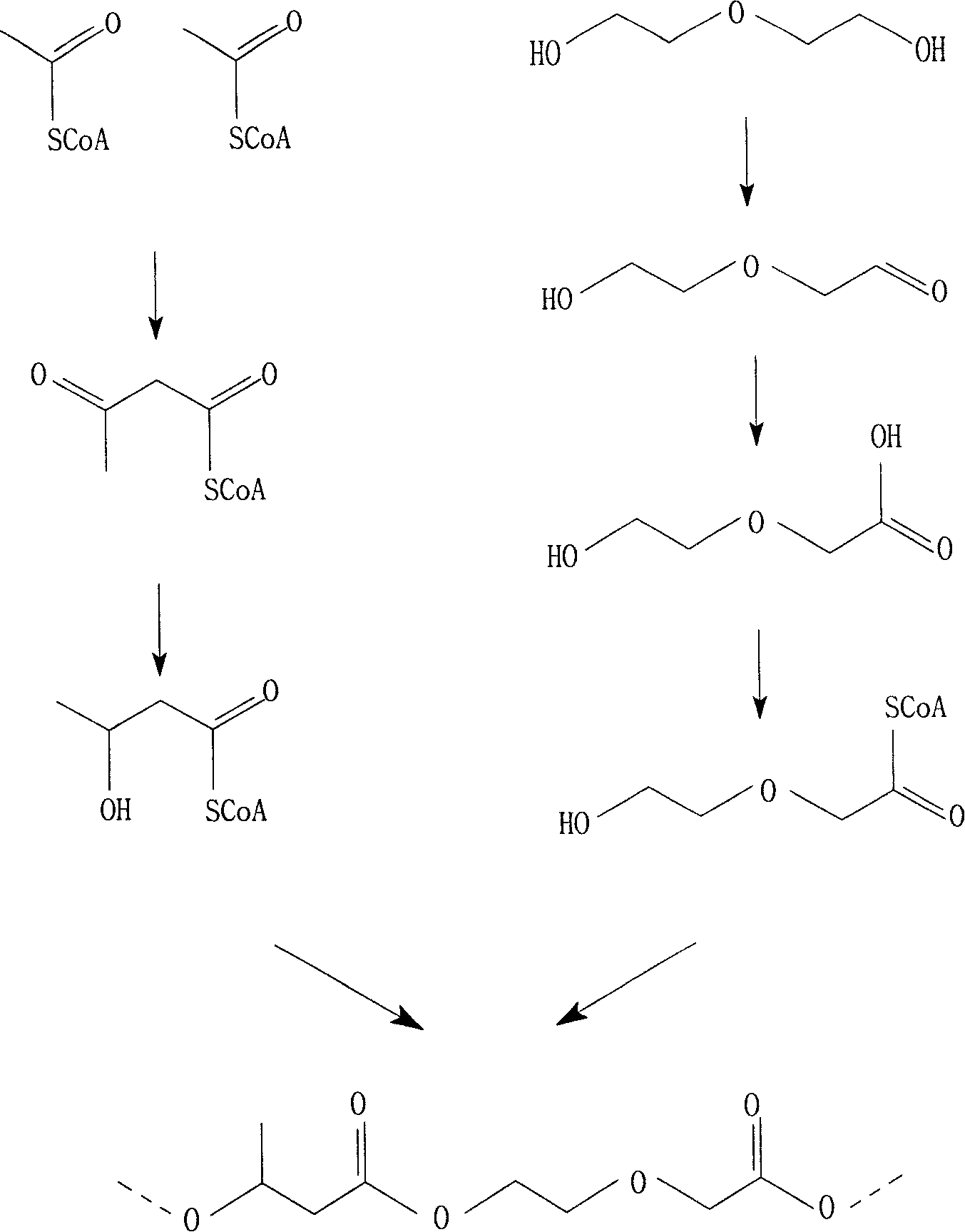

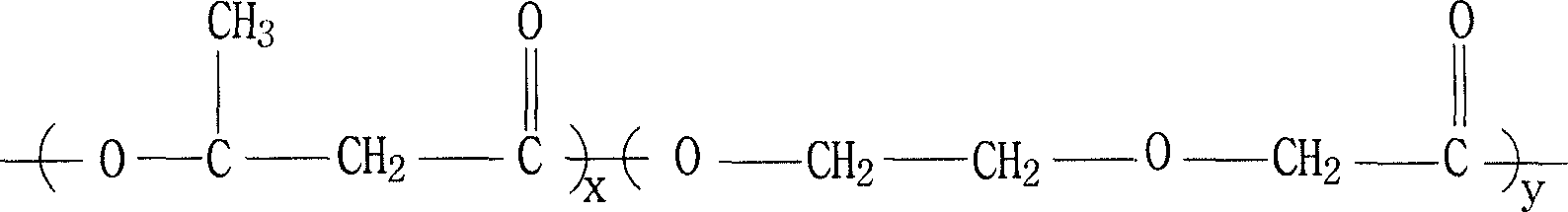

Polyhydroxyalkanoates-hydroxyl alkoxyl alkyl acid ester and biosynthesis production method thereof

InactiveCN101195677AImprove thermal stabilityAdjustable hardnessBacteriaRecombinant DNA-technologyHydroxybutyric acidMicroorganism

The invention relates to a poly-3-hydroxybutyrate-beta-hyoroxyetohxy acetate copolymer, which formula is represented as pattern, wherein x, y are positive integers. The invention further provides a biological synthesis preparation method of the copolymer, which uses gene recombination microbiological fermentation to produce poly-3-hydroxybutyrate-beta-hyoroxyetohxy acetate copolymer. When PHB and HEA are conjugated into copolymer, tissue engineering eliminates body repellent action, with good thermal stability, which content can be adjusted according to demand to adjust rigidity and flexibility. The good biological degradation, biological compatibility and processability of the product expand application in tissue engineering and medicine fields.

Owner:深圳市奥贝尔科技有限公司

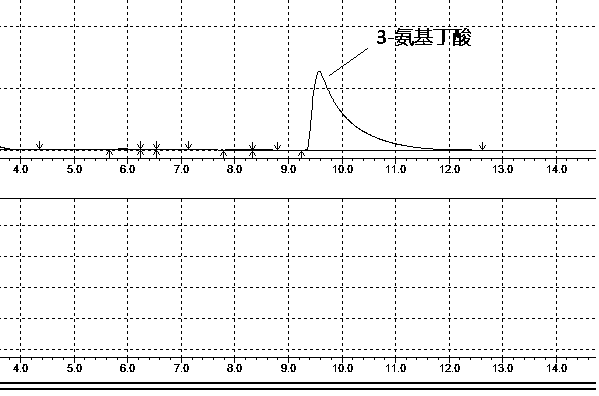

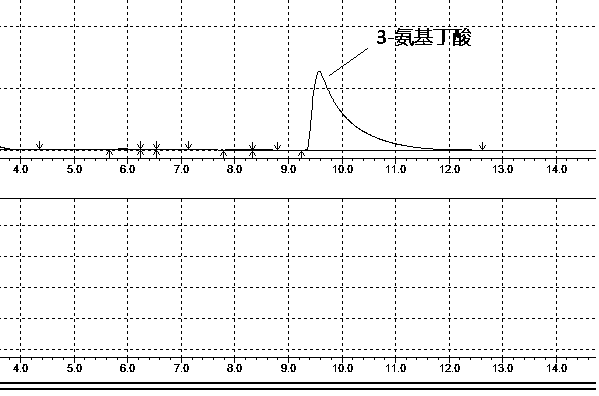

Method for preparing 3-aminobutyric acid by using poly-3-hydroxybutyrate

ActiveCN109836345ASimple processOrganic compound preparationAmino-carboxyl compound preparationPoly-3-hydroxybutyrateRoom temperature

The invention provides a method for preparing 3-aminobutyric acid by using poly-3-hydroxybutyrate, and the method comprises the following steps: (1) adding the poly-3-hydroxybutyrate and ammonia waterinto a reaction container, and sealing the reaction container; and (2) opening a stirrer, heating the reaction container, and after the reaction is finished, cooling to room temperature to obtain the3-aminobutyric acid. The method disclosed by the invention is used for preparing the 3-aminobutyric acid by using the poly-3-hydroxybutyrate, the mass yield of the obtained 3-aminobutyric acid is 120% based on the content of the poly-3-hydroxybutyrate, namely, the yield reaches 100% of the theoretical yield. The adopted process is very simple, the reaction raw materials are the poly-3-hydroxybutyrate and the ammonia water, no catalyst or other additives are needed, the selectivity of the 3-aminobutyric acid can reach 100%, and the method has an industrial prospect.

Owner:DONGGUAN UNIV OF TECH

Method for synthesizing poly-3-hydroxybutyrate/3-polyhydroxybutyrate from wooden carbon source domesticated sewage mixed with bacteria

InactiveCN109097429ALow costIncrease productionMicroorganism based processesFermentationActivated sludgePretreatment method

The invention relates to a method for synthesizing poly-3-hydroxybutyrate / 3-polyhydroxybutyrate (PHBV) from wooden carbon source domesticated sewage mixed with bacteria. The method comprises the following steps: (1) carrying out hydrolysis and enzymolysis on a wooden biological resource by using a hydrothermal pretreatment method; (2) by taking the hydrolysis and enzymolysis product as a carbon source, domesticating sewage with activated sludge by using an aerobiotic dynamic material supply method, and enriching bacteria capable of synthesizing polyhydroxyalkanoate (PHA); (3) accumulating PHAby controlling an unbalanced nutrition environment, and increasing the yield of PHA, thereby finally confirming that the accumulated PHA is PHBV. With the comparison between dry cell weights of different experiment groups and data of PHBV yields, optimal culture conditions can be acquired. After 9 accumulation cycles of the domesticated activated sludge, 303.7-1084.4 mg / of PHBV can be produced, PHB accounts for 40.45-69.14%, and PHV accounts for 30.86-59.55%; finally, at a pH value of 7 and a total sugar concentration of 1700 mg / , the yield of the PHBV meets the maximum value under a condition of sufficient inorganic salt components and oxygen.

Owner:TIANJIN UNIV OF SCI & TECH

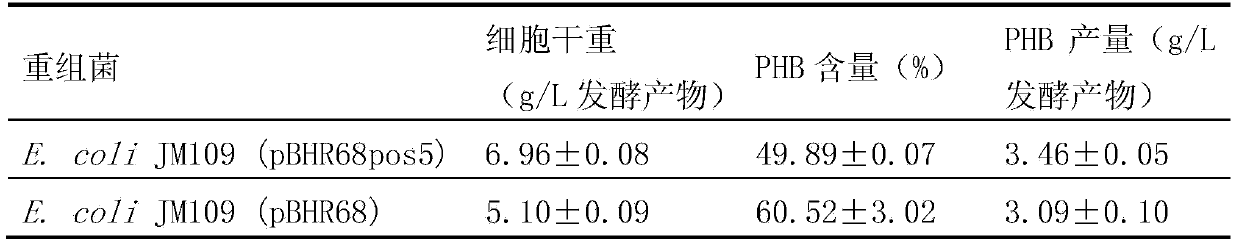

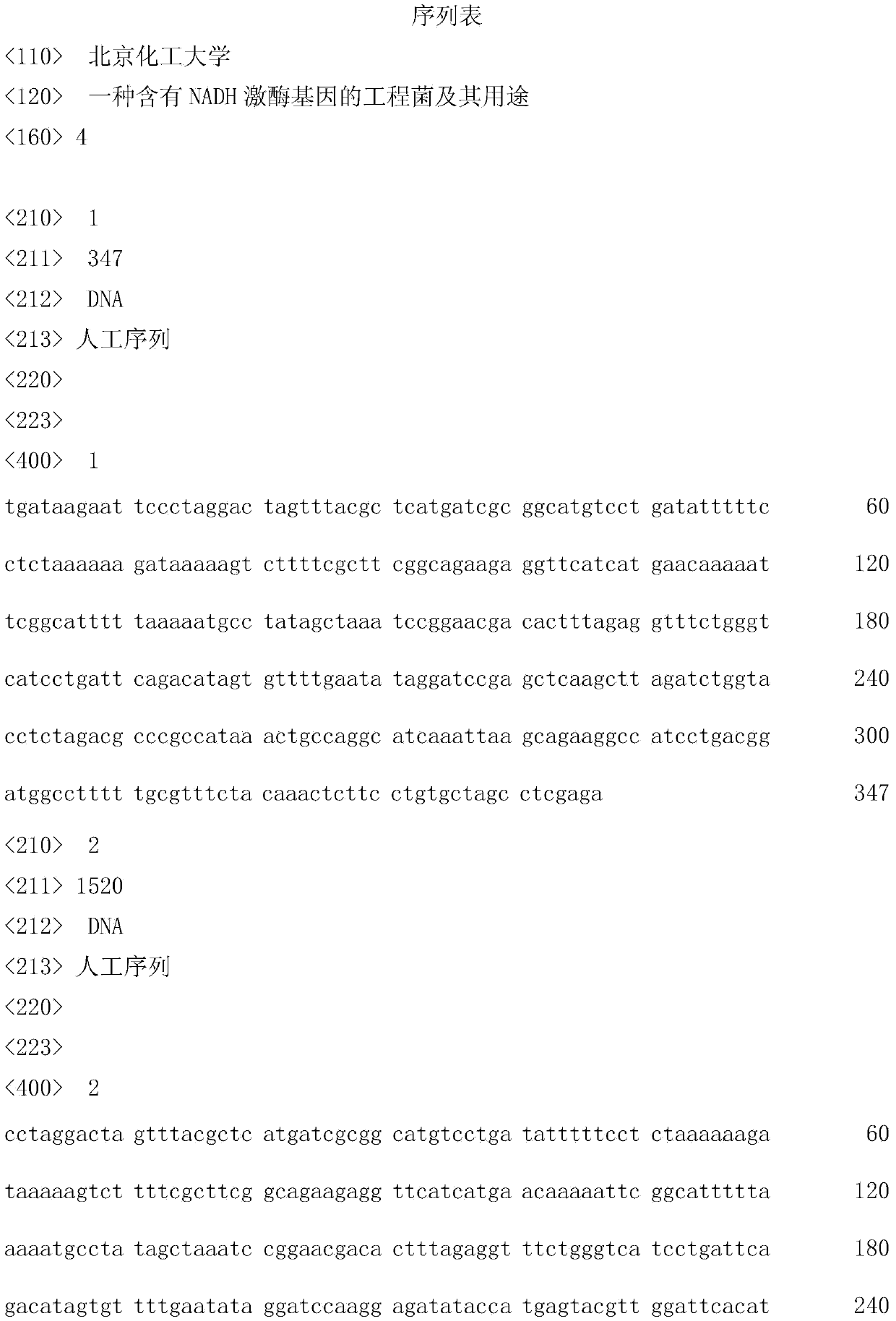

Engineering bacterium containing NADH (nicotinamide adenine dinucleotide) kinase gene and application thereof

ActiveCN103740630AEasy to synthesizePromote conversionBacteriaMicroorganism based processesPoly-3-hydroxybutyrateNADH kinase

The invention discloses an engineering bacterium containing an NADH (nicotinamide adenine dinucleotide) kinase gene and an application thereof. The invention provides a method for constructing a recombinant bacterium. The method is characterized by guiding an NADH kinase coding gene pos5 and a PHB (poly-beta-hydroxybutyrate) synthetic gene phbCAB into a target bacterium to obtain the recombinant bacterium. Experiments prove that the NADH kinase gene in the recombinant bacterium can promote transformation of NADH in cells to NADPH (nicotinamide adenine dinucleotide phosphate), thus improving synthesis of NADPH-dependent poly-3-hydroxybutyrate. Compared with former strains, the engineering bacterium has higher PHB production efficiency.

Owner:BEIJING UNIV OF CHEM TECH

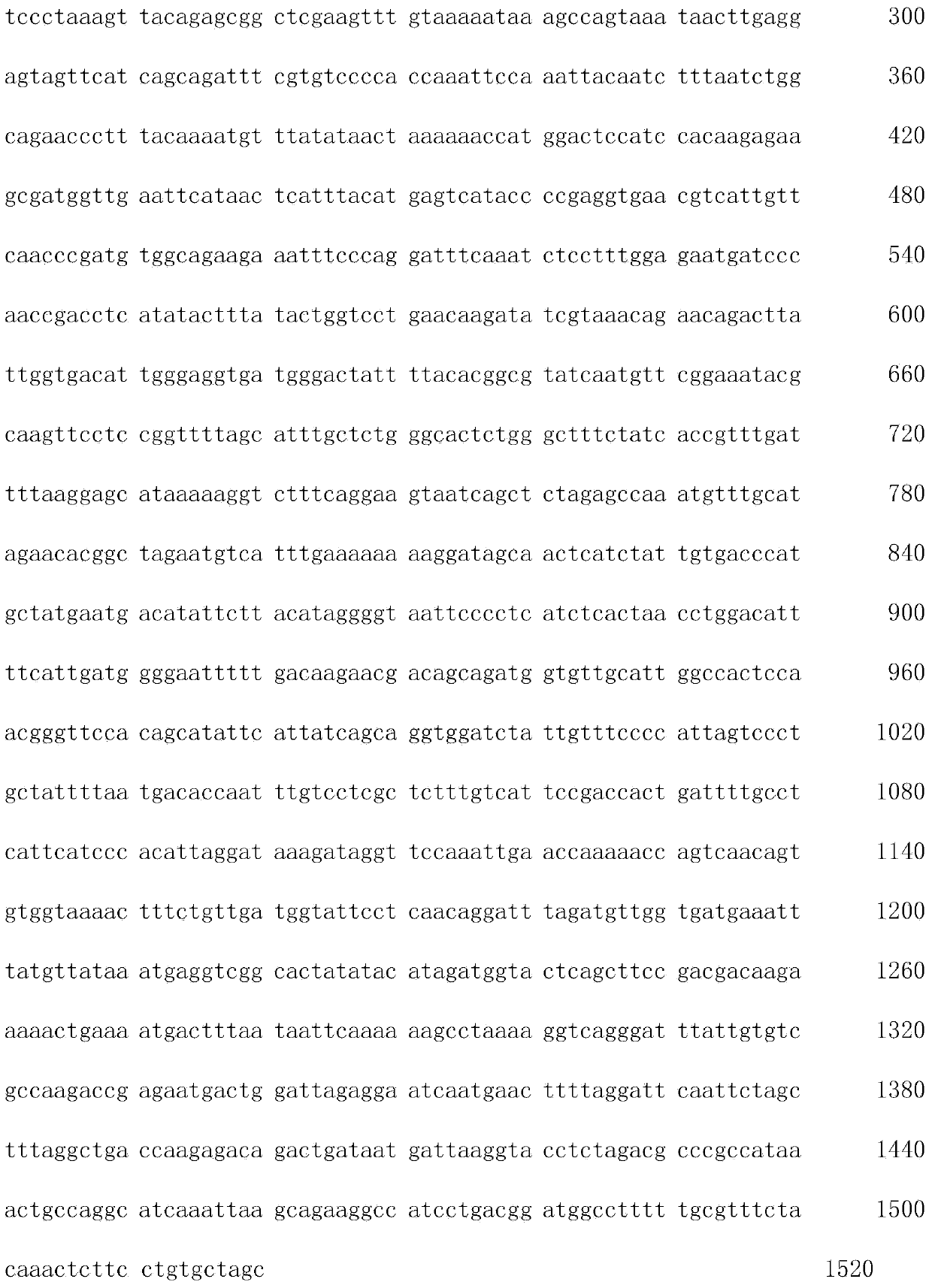

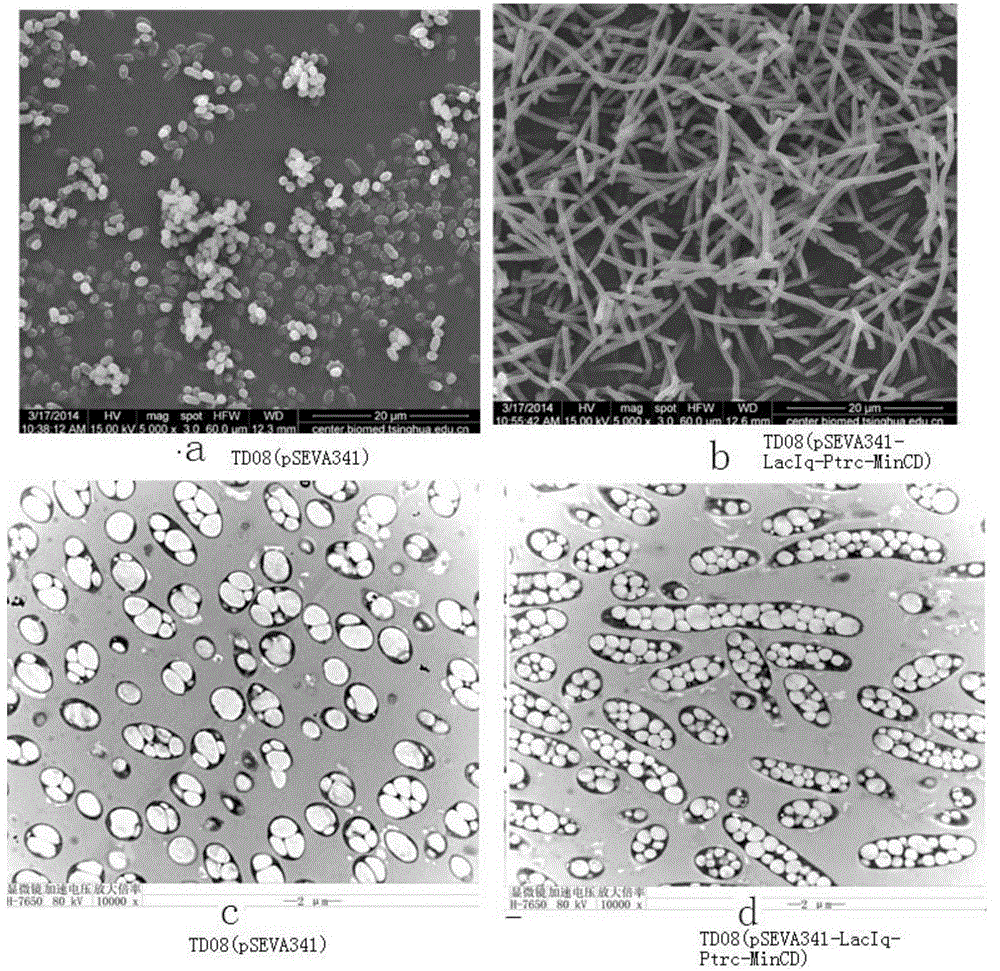

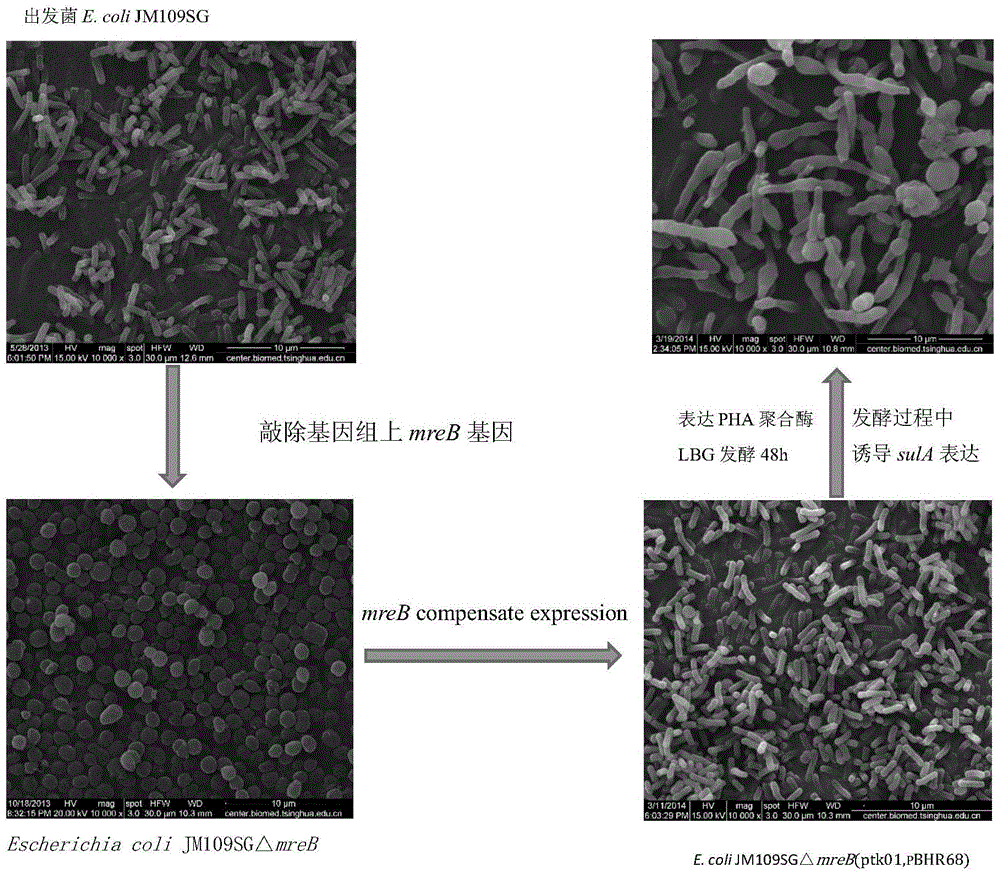

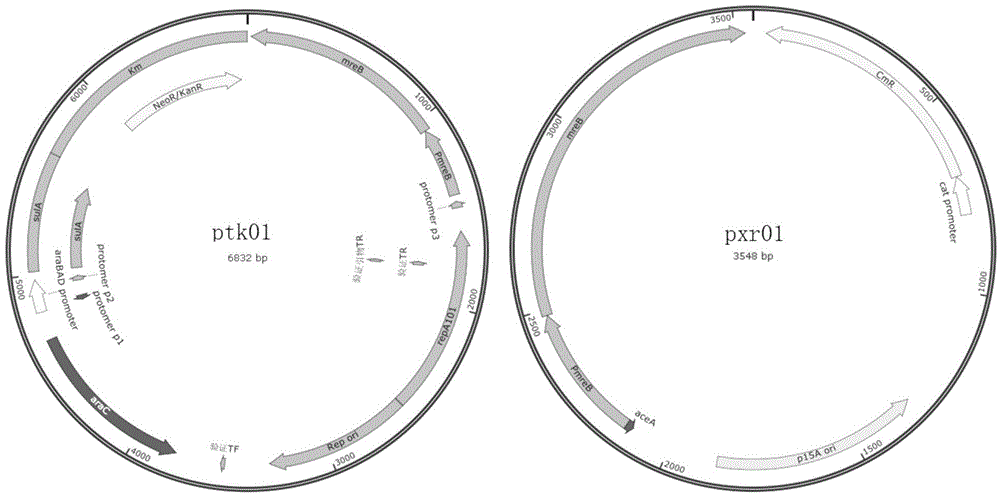

Method for increasing microbe intracellular inclusion accumulation amount by increasing bacteria volume

ActiveCN105331568AIncrease productionSimple production processBacteriaMicroorganism based processesPoly-3-hydroxybutyrateMicroorganism

The invention discloses a method for increasing microbe intracellular inclusion accumulation amount by increasing bacteria volume. The method can increase the accumulation amount of a microbe intracellular inclusion, which is characterized in that microbe volume is increased by reforming the gene which can influence the microbe volume, and the accumulation amount of the microbe intracellular inclusion can be increased. The experiment proves that the method can construct engineering bacteria for increasing the bacteria volume, so that output of poly(3-hydroxybutyrate)(PHB), protein, polyphosphoric acid and carboxysome can be increased, and the some engineering bacteria poly(3-hydroxybutyrate)(PHB) can reach as high as 80% of dry cell weight which is increased by 30%. According to the invention, production process is simple, cost is low, and application prospect is wide.

Owner:TSINGHUA UNIV

Biodegradable wire used for fused deposition molding and preparation method thereof

ActiveCN107141737APromote degradationImprove solubilityAdditive manufacturing apparatusMonocomponent polyesters artificial filamentPolymer scienceAntioxidant

The invention discloses a biodegradable wire used for fused deposition molding and a preparation method thereof. The wire is prepared from 100 parts of poly 3-hydroxybutyrate-co-3-methyl-3-hydroxyvalerate copolymer (the number average molecular weight is 5-150 thousand), 10-25 parts of plasticizer, 10-15 parts of chaotropic agent, 0.1-1 part of antioxidant, 0.1-8 parts of filler and auxiliaries, wherein the molar ratio of a 3-methyl-3-hydroxyvalerate chain segment in a copolymer is 20-35%, the plasticizer refers to one or a mixture of triethyl citrate, acetyl tributyl citrate, pentaerythritol and bisphenol A, and the chaotropic agent refers to one or a mixture of polyvinyl alcohol and polyethylene glycol. After the chaotropic agent and the plasticizer are added, the biodegradable wire can be removed completely in a very short period of time, the chaotropic agent a has certain plasticization effect on the biodegradable wire, and through the synergistic effect of the plasticizer and the chaotropic agent, the processability and mechanical properties of the biodegradable wire can be further improved.

Owner:HENAN INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com