Method for preparing 3-aminobutyric acid by using poly-3-hydroxybutyrate

A technology of hydroxybutyrate and aminobutyric acid, which is applied in chemical instruments and methods, preparation of cyanide reaction, preparation of organic compounds, etc., can solve the problem of high cost, limitation of industrial production and application of 3-aminobutyric acid, and production scale Small problems, to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

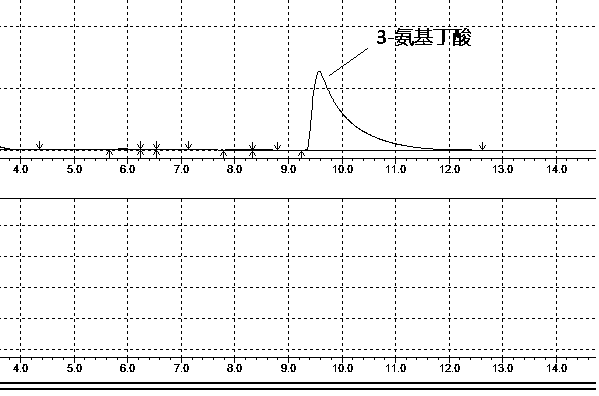

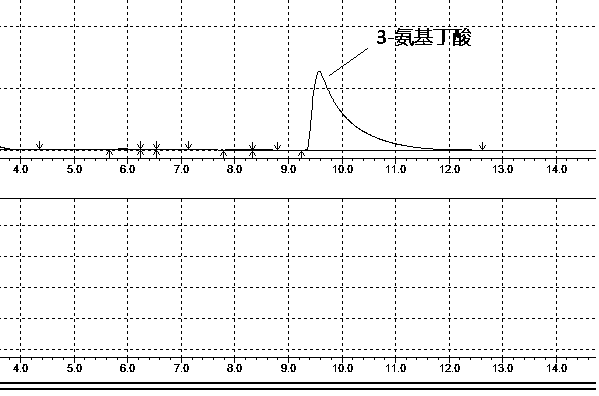

Image

Examples

Embodiment 1

[0017] A method for preparing 3-aminobutyric acid with poly 3-hydroxybutyrate, the method is as follows:

[0018] (1) Put 1 g of poly-3-hydroxybutyrate and 30 ml of ammonia water (28% concentration) into the reactor, and seal the reactor;

[0019] (2) Turn on the stirrer to make it rotate at 500 rpm, and raise the temperature to 160° C. at a rate of 6 degrees per minute, and keep it at 160° C. for 12 hours. After the reaction was complete, it was cooled to room temperature, and 1.2 g of 3-aminobutyric acid was obtained through quantitative analysis by high performance liquid chromatography. Based on the initial mass of poly-3-hydroxybutyrate, the yield of 3-aminobutyric acid obtained was 120%, and the selectivity of 3-aminobutyric acid was 100%.

Embodiment 2

[0021] A method for preparing 3-aminobutyric acid with poly 3-hydroxybutyrate, the method is as follows:

[0022] (1) Put 1 g of poly-3-hydroxybutyrate and 30 ml of ammonia water (28% concentration) into the reactor, and seal the reactor;

[0023] (2) Turn on the stirrer to make it rotate at 500 rpm, and raise the temperature to 180° C. at a rate of 6 degrees per minute, and keep it at 180° C. for 16 hours. After the reaction was complete, it was cooled to room temperature, and 1.18 g of 3-aminobutyric acid was obtained through quantitative analysis by high performance liquid chromatography. Based on the initial mass of poly-3-hydroxybutyrate, the yield of 3-aminobutyric acid obtained was 118%.

Embodiment 3

[0025] A method for preparing 3-aminobutyric acid with poly 3-hydroxybutyrate, the method is as follows:

[0026] (1) Put 1 g of poly-3-hydroxybutyrate and 30 ml of ammonia water (28% concentration) into the reactor, and seal the reactor;

[0027] (2) Turn on the stirrer to make it rotate at 500 rpm, and raise the temperature to 120° C. at a rate of 6 degrees per minute, and keep it at 120° C. for 24 hours. After the reaction was complete, it was cooled to room temperature, and 0.91 g of 3-aminobutyric acid was obtained through quantitative analysis by high performance liquid chromatography. Based on the initial mass of poly-3-hydroxybutyrate, the yield of 3-aminobutyric acid obtained was 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com