Degradable material for oil and gas field operation and preparation method thereof

A technology for degradable materials and oil and gas fields, applied in the field of degradable materials and their preparation, which can solve the problems of inability to dissolve, high safety risk, slow dissolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

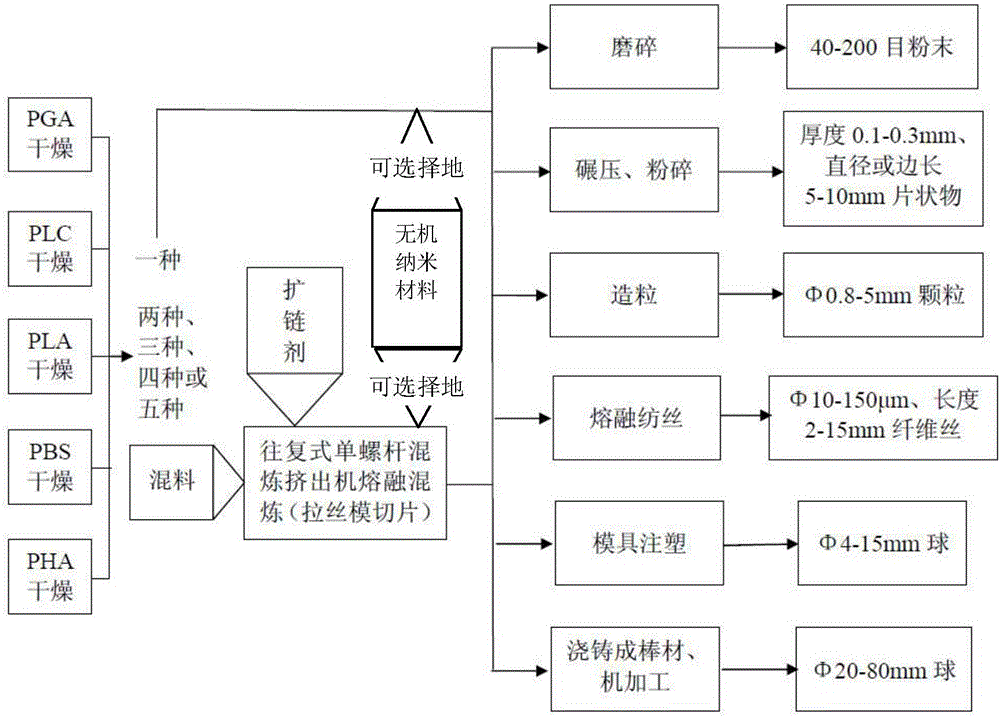

[0090] This embodiment provides a degradable material for oil and gas field operations, such as figure 1 As shown, it is prepared by the following steps:

[0091] (1) Stir and dry polycaprolactone chips with a weight average molecular weight (Mw) of 90,000 at 50-55°C and a vacuum of 90 kPa for 13 hours; Acetic acid slices were stirred and dried for 4 hours at 100-105 ° C and a vacuum of 90 kPa; polylactic acid slices with a weight average molecular weight (Mw) of 100,000 were stirred and dried at 90-95 ° C and a vacuum of 90 kPa for 6.0 hours; the weight average molecular weight (Mw) is 50,000 polybutylene butyrate at 70-75 ° C, vacuum 90 kPa, stirred and dried for 9.0 hours; the weight average molecular weight (Mw) is 60,000 polybutylene - 3-hydroxybutyrate was stirred and dried for 4.0 hours at 100-105°C and a vacuum of 90 kPa; the moisture content was lower than 0.1wt%, preferably lower than 0.01wt%;

[0092] (2) Get 150 kilograms of polycaprolactone slices, 300 kilograms...

Embodiment 2

[0098] This embodiment provides a degradable material for oil and gas field operations, such as figure 1 As shown, it is prepared by the following steps:

[0099] (1) Stir and dry polycaprolactone chips with a weight average molecular weight (Mw) of 30,000 at 50-55°C and a vacuum of 90 kPa for 11 hours; Acetic acid slices were stirred and dried for 4 hours at 100-105°C and a vacuum of 90 kPa; , stirred and dried for 9.0 hours; poly-3-hydroxybutyrate with a weight average molecular weight (Mw) of 40,000 was stirred and dried for 4.0 hours at 100-105°C and a vacuum of 90 kPa; the moisture content was lower than 0.1 wt%, preferably less than 0.01wt%;

[0100] (2) Get 280 kilograms of polycaprolactone slices, 320 kilograms of polyglycolic acid slices, 250 kilograms of polybutylene butyrate lactone slices and 150 kilograms of poly-3-hydroxybutyrate slices after the above-mentioned dehydration is added to In a stainless steel mixer with a stirring device, heat up to 50°C, and mix...

Embodiment 3

[0106] This embodiment provides a degradable material for oil and gas field operations, such as figure 1 As shown, it is prepared by the following steps:

[0107] (1) Stir and dry polyglycolic acid slices with a weight average molecular weight (Mw) of 60,000 at 90-100°C and a vacuum of 90 kPa for 4 hours; Butylene glycol ester slices were stirred and dried for 9 hours at 70-75°C and a vacuum of 90 kPa; poly-3-hydroxybutyrate slices with a weight average molecular weight (Mw) of 50,000 were placed at Under the vacuum degree of 90 kPa, stir and dry for 4 hours, so that the moisture content is lower than 0.1wt%, preferably lower than 0.01wt%;

[0108] (2) Take 100 kilograms of polyglycolic acid slices, 500 kilograms of polybutylene succinate slices and 400 kilograms of poly-3-hydroxybutyrate slices after dewatering and add them to a stainless steel mixer with stirring device , heat up to 50°C, and mix for 10 minutes at a vacuum of 90 kPa;

[0109] (3) Add the mixture of polygl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com