Polyhydroxyalkanoates-hydroxyl alkoxyl alkyl acid ester and biosynthesis production method thereof

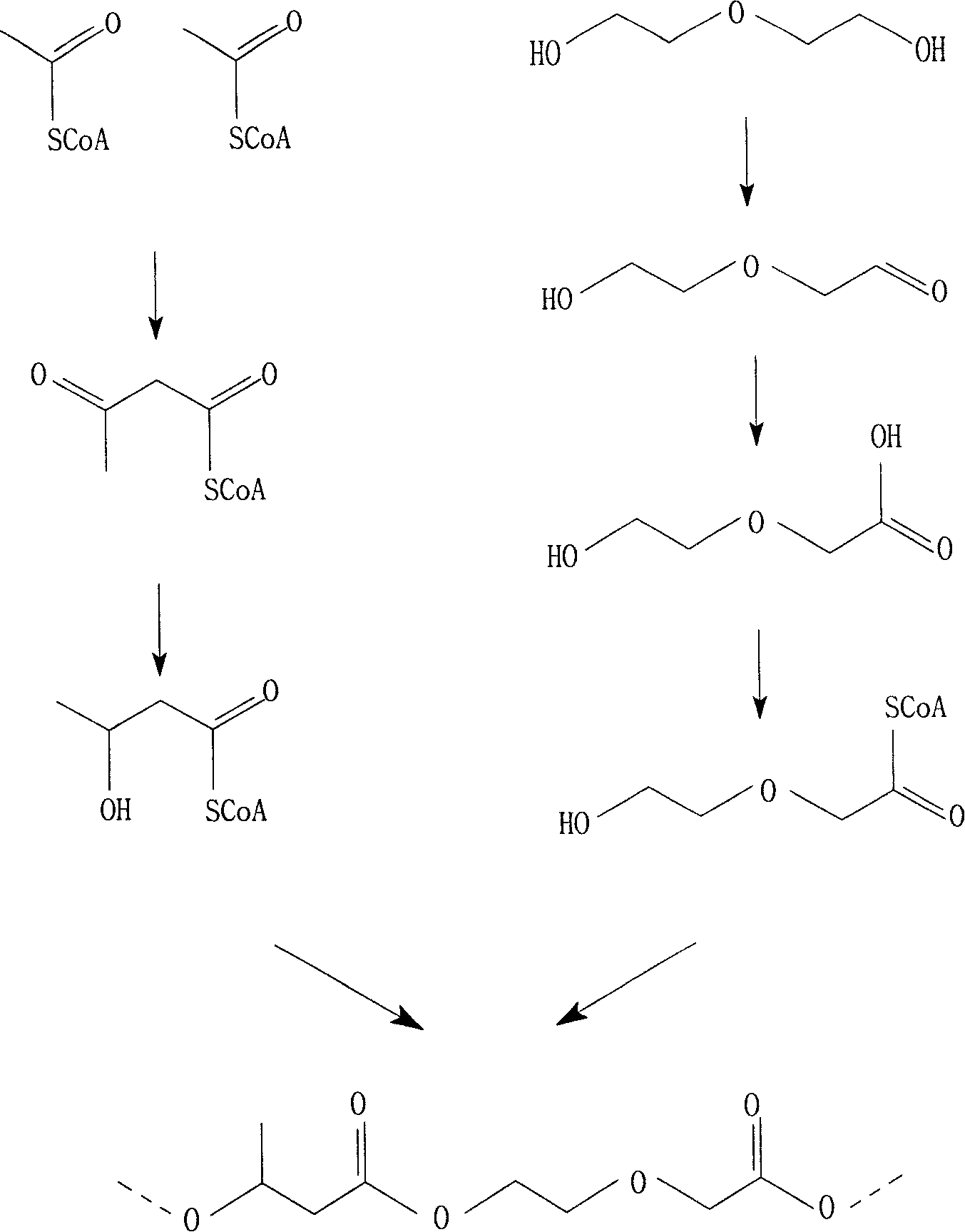

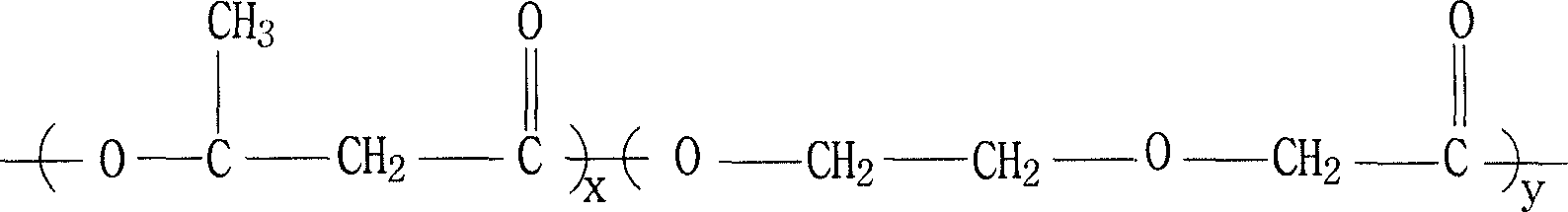

A hydroxyethoxy acetate, biosynthesis technology, applied in the field of polyhydroxyester, can solve the problems of affecting the degradation rate, strong hydrophobicity, etc., and achieve the effects of wide application, good processing performance, and excellent biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

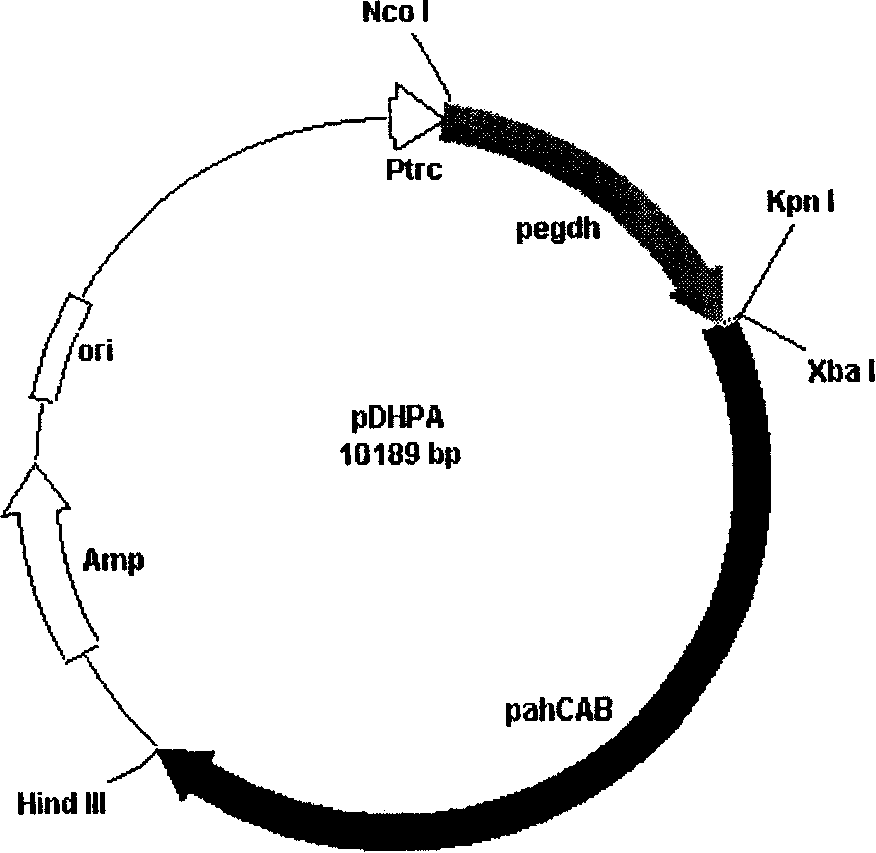

[0033] Example 1 Construction of an engineering strain for the production of poly-3-hydroxybutyrate-β-hydroxyethoxyacetate

[0034] According to literature reports (Sugimoto et al.2001 J.Bacteriol 183, 6694-6698), a pair of primers Pegdh1: 5'- CC ATG G AC AAA TTC GAC TTT GTC GTG-3' and Pegdh2:5'- GG TAC C TA GGT GTA AGA TTC GGC TTC ATC-3', introduced Nco I and Kpn I restriction sites at the 5' and 3' ends respectively, and amplified a 1.6kb polyethylene glycol desegregation site from Sphingomonas terrae genomic DNA by PCR. Hydrogenase gene coding sequence, PCR conditions: 94°C for 5 minutes, 94°C for 1 minute, 60°C for 1 minute, 72°C for 2 minutes, 35 cycles; 72°C for 7 minutes; store at 4°C. The PCR product was treated with T 4DNA ligase (Promega) was ligated with pGEM-T vector (Promega) at 16° C. for 12 hours to obtain plasmid pGEM-T / pegdh. Sequencing results showed that the cloned product was basically consistent with that reported in the literature, except that the s...

Embodiment 2

[0039] Example 2 Recombinant bacteria producing P3HBHEA

[0040] Bacterial growth medium (LB): yeast powder 5g / L, peptone 10g / L, NaCl 10g / L, pH7.2.

[0041] Fermentation medium: 4.5g / L KH 2 PO 3 , 3.6g / L (NH 4 ) 2 SO 4 , 1.23g / L MgSO 4 , 2.04g / LNH 4 Cl, 1g / L citric acid, 100mg / L ampicillin and 1ml / L trace elements ((g) in 1mol / L HCl: 0.05FeSO 4 ·7H 2 O, 0.011ZnSO 4 ·7H 2 O, 0.0025MnSO 2 4H 2 O, 0.005CuSO 4 ·5H 2 O, 0.05CoCl 2 ·6H 2 O, 0.1CrCl 3 ·6H 2 O, 0.01CaCl 2 ), pH6.92. Glucose 40g / L, diethylene glycol 1% (V / V).

[0042] The recombinant Escherichia coli containing the pDEPH plasmid obtained in Example 1 was inserted into a test tube containing 5 ml of LB culture solution with an inoculation volume of 100 μl, and cultured at 37° C. and 250 rpm for 5 hours. The bacteria cultured in the test tube were respectively inserted into 500ml Erlenmeyer flasks containing 125ml of fermentation medium, and cultured at 30°C and 250rpm for 40h. The cells were coll...

Embodiment 3

[0050] Example 3 Production of P3HBHEA copolymer

[0051] Get the recombinant escherichia coli containing the pDEPH plasmid obtained in Example 1, insert in the 3L fermenter with the inoculum size of 100ml, fermentation substrate: 4.72g / L KH 2 PO 3 , 4.62g / L (NH 4 ) 2 SO 4 , 1.23g / LMgSO 4 , 2.04g / L (NH 4 ) 2 HPO 4 , 1g / L citric acid, 100mg / L ampicillin and 1ml / L trace elements (in 1mol / L HCl (g): 0.05FeSO 4 ·7H 2 O, 0.011ZnSO 4 ·7H 2 O, 0.0025MnSO 2 4H 2 O, 0.005CuSO 4 ·5H 2 O, 0.0005 (NH 4 ) 6 Mo 7 o 24 4H 2 O, 0.0001Na 2 B 4 o 7 , 0.01CaCl 2 ), pH6.92.

[0052] Two-step fed-batch fermentation is adopted: the first step is the seed growth stage, cultured at 37°C for 8 hours; the second step is the polymer synthesis stage, cultured at 30°C for 32 hours, at this time, the fed-batch method is used to supplement glucose And diethylene glycol, add glucose 600g altogether, diethylene glycol 20g.

[0053] At the end of the fermentation, the bacteria were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com