Patents

Literature

158 results about "Sphingomonas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

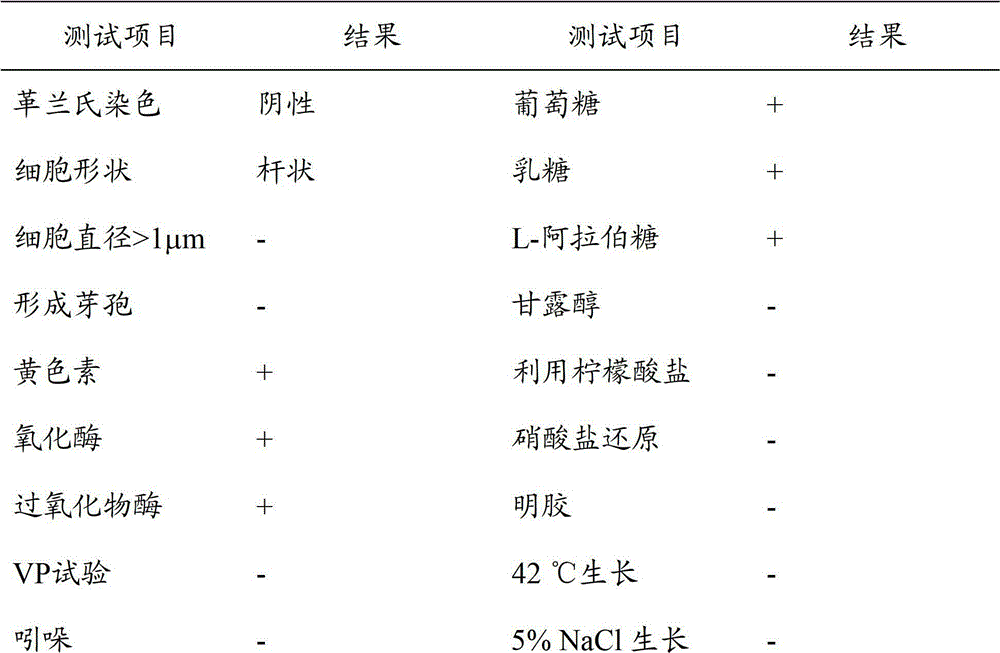

Sphingomonas was defined in 1990 as a group of Gram-negative, rod-shaped, chemoheterotrophic, strictly aerobic bacteria. They possess ubiquinone 10 as their major respiratory quinone, contain glycosphingolipids (GSLs), specifically ceramide, instead of lipopolysaccharide (LPS) in their cell envelopes, and typically produce yellow-pigmented colonies.

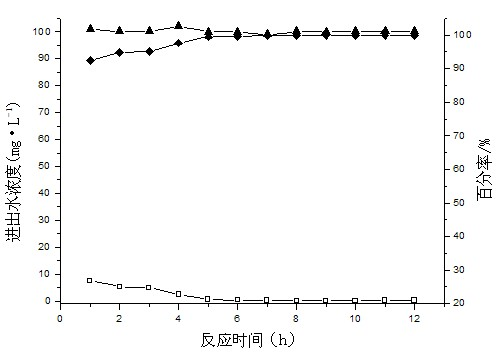

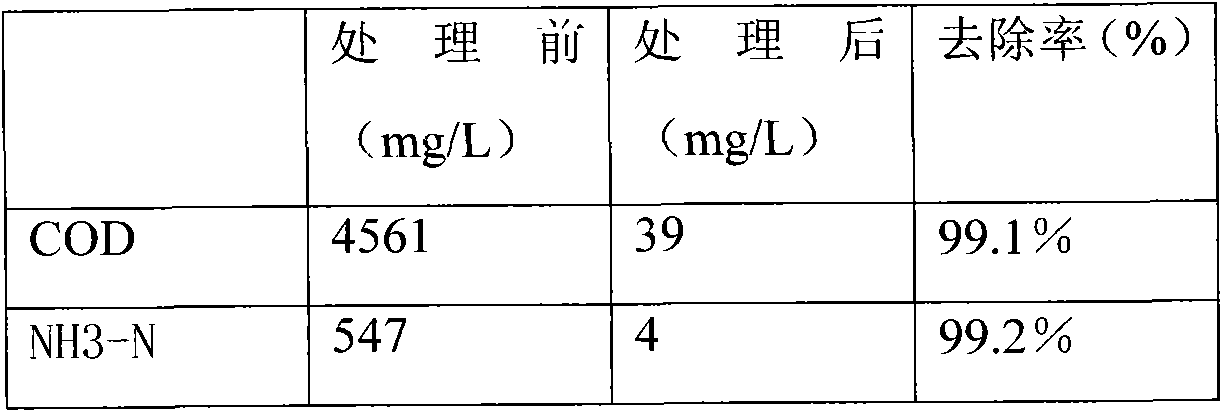

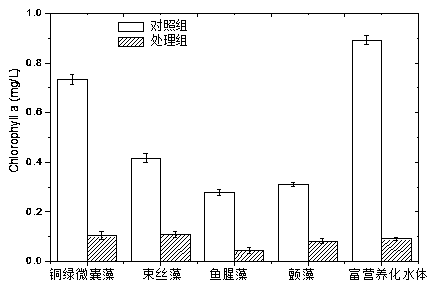

Sphingomonas strain and application thereof in water treatment

InactiveCN102168054APromote degradationReduce concentrationBacteriaMicroorganism based processesIndustrial waste waterWater source

The invention belongs to the technical fields of environmental engineering and bioengineering and particularly relates to a sphingomonas strain and applications thereof in the aspects of shortcut nitrification-denitrification of nitrogen-containing industrial waste water and domestic sewage and treatment of a polluted water source. The sphingomonas strain is separated from a Taihu water in China,is a local strain and has high safety; and the strain can be grown in a basic medium, wherein in the basic medium, CO2 is used as a carbon source and energy or CO2 and an organism are used as a mixedcarbon source and energy, and ammonia nitrogen or nitrate nitrogen is used as a nitrogen source. The bacterium liquid, the dormancy cell and the immobilized strain of the sphingomonas can decompose ammonia nitrogen into nitrite nitrogen and simultaneously can decompose the ammonia nitrogen into nitrogen, can be used as denitrification microorganism for converting the ammonia nitrogen into the nitrite nitrogen and the nitrogen, thereby achieving the shortcut nitrification-denitrification. The strain can rapidly decompose the ammonia nitrogen and is suitable for treating the nitrogen-containingindustrial waste water and domestic sewage as well as polluted water source.

Owner:NANJING UNIV

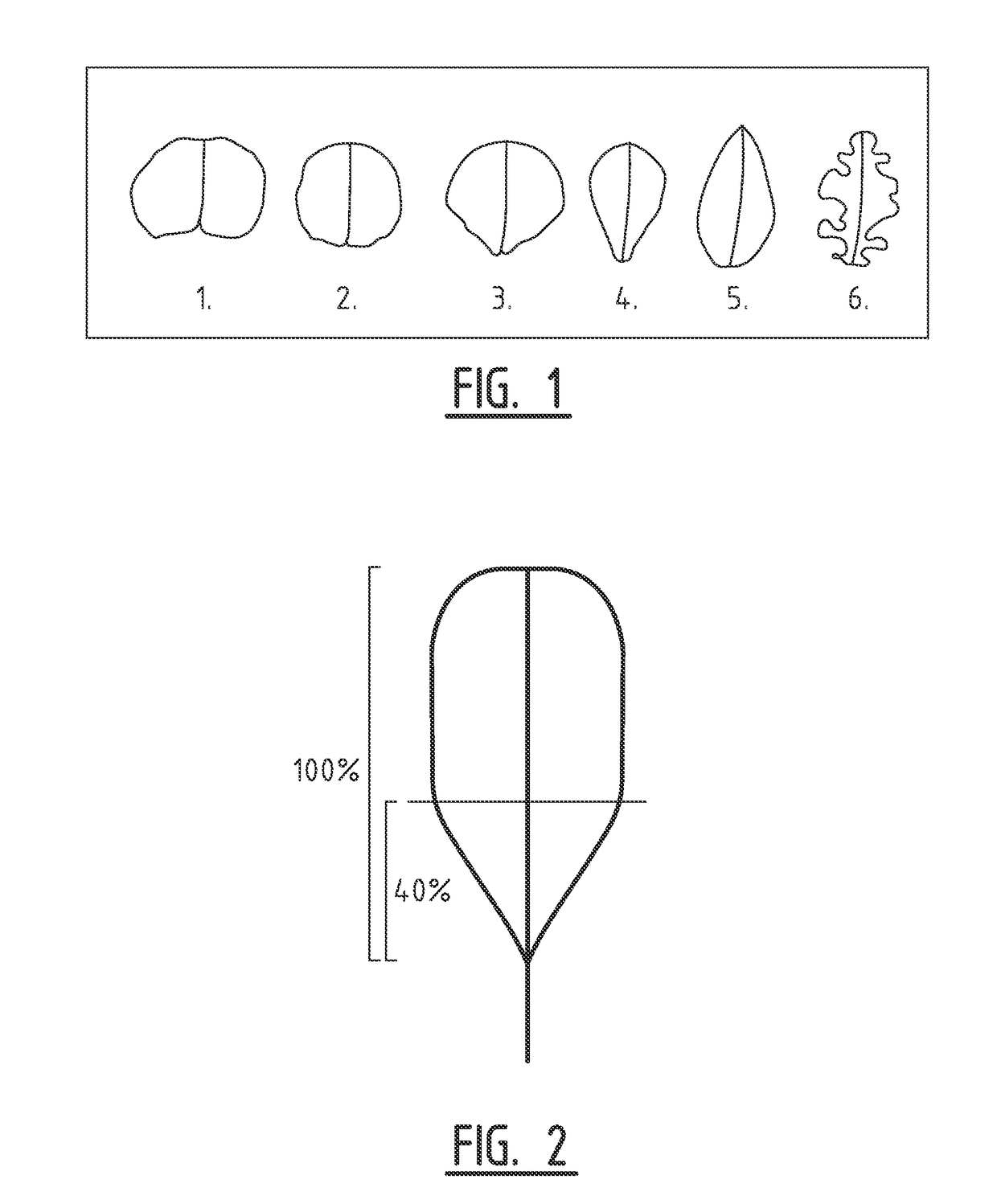

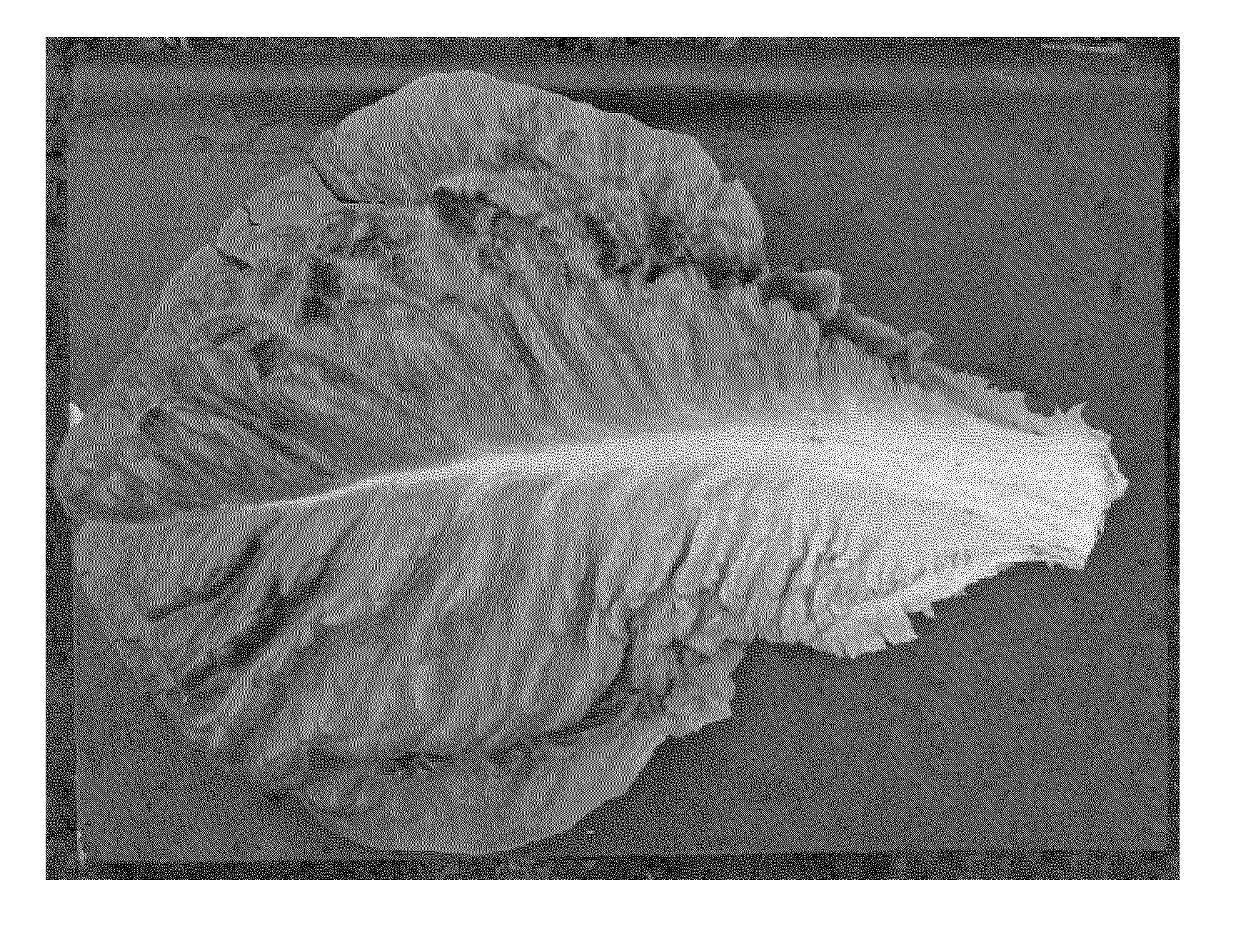

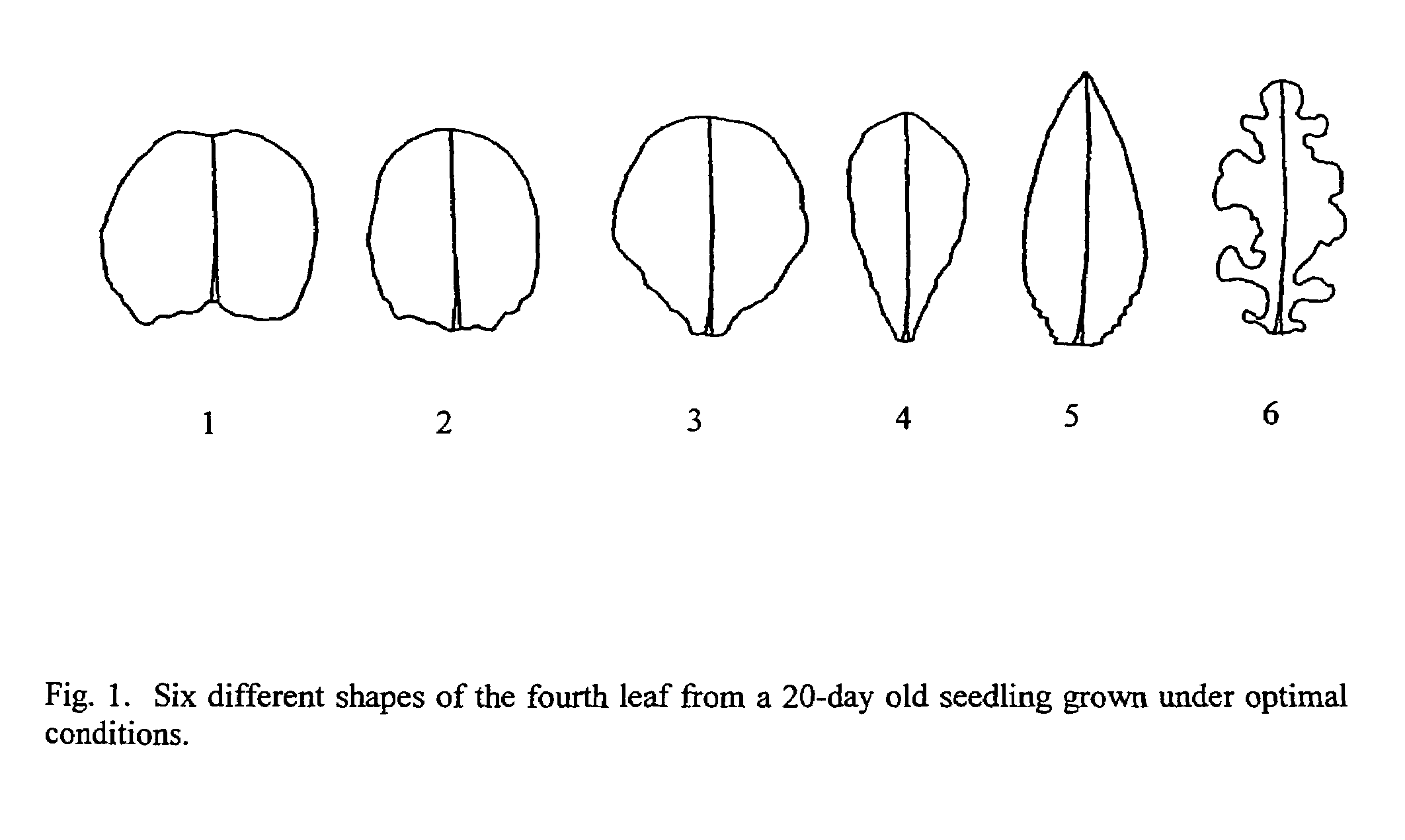

Lettuce variety 41-187 RZ

InactiveUS9814210B2Microbiological testing/measurementAngiosperms/flowering plantsBremia lactucaeRoot rot

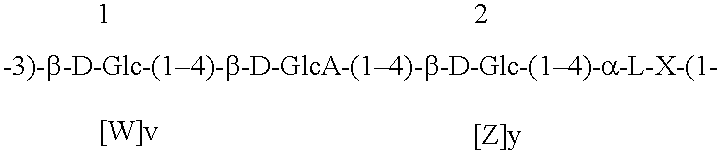

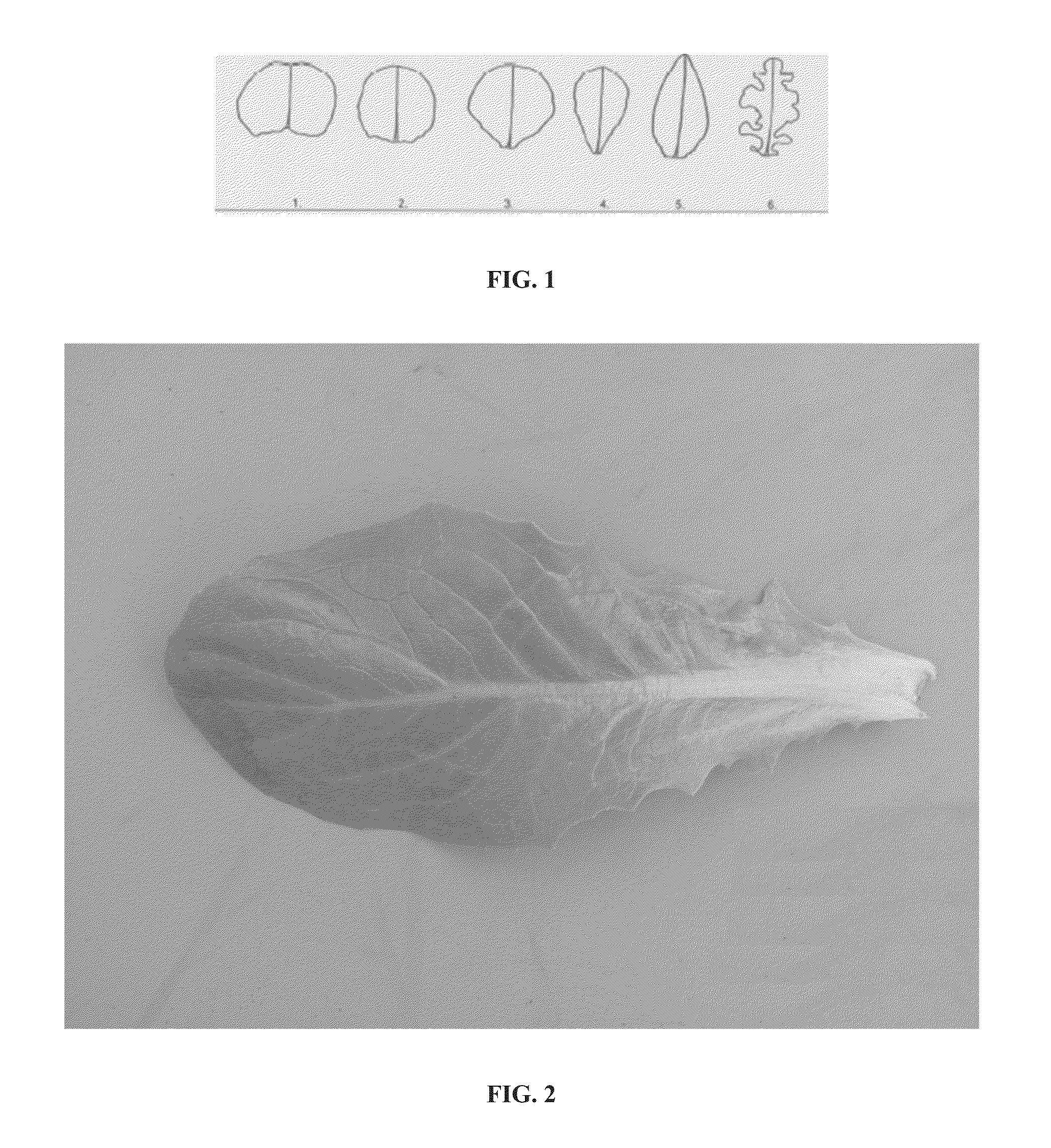

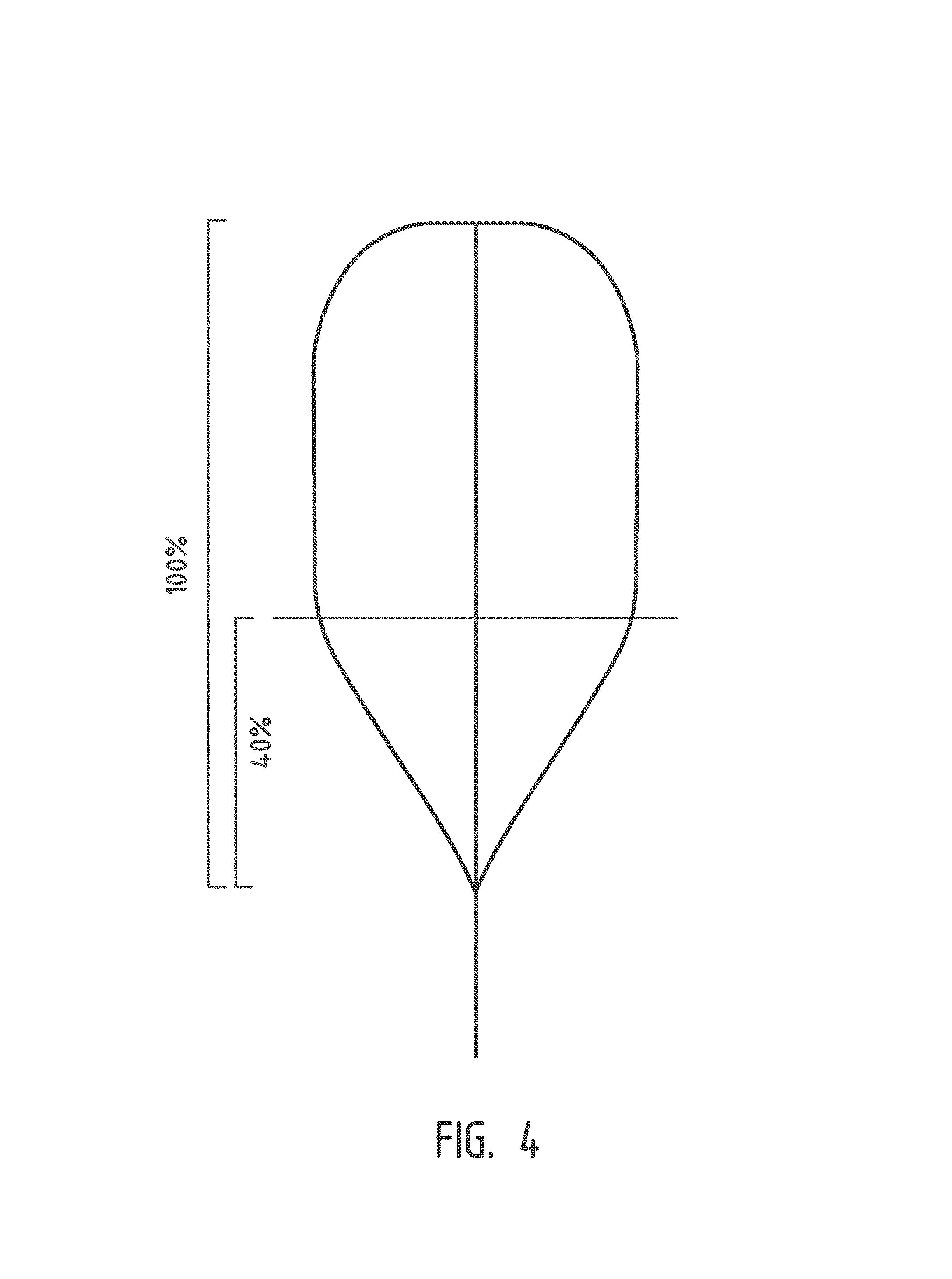

The present invention relates to a Lactuca sativa seed designated 41-187 RZ, which exhibits a combination of traits including resistance against downy mildew (Bremia lactucae) races Bl:1 to Bl:17, Bl:21, Bl:23 and Ca-I to Ca-VI, currant-lettuce aphid (Nasonovia ribisnigri) biotype Nr:0, lettuce mosaic virus (LMV), and corky root rot (Sphingomonas suberifaciens), as well as having a reduced wound-induced surface discoloration. The present invention also relates to a Lactuca sativa plant produced by growing the 41-187 RZ seed. The invention further relates to methods for producing the lettuce cultivar, represented by lettuce variety 41-187 RZ.

Owner:RIJK ZWAAN ZAADTEELT & ZAADHANDEL BV

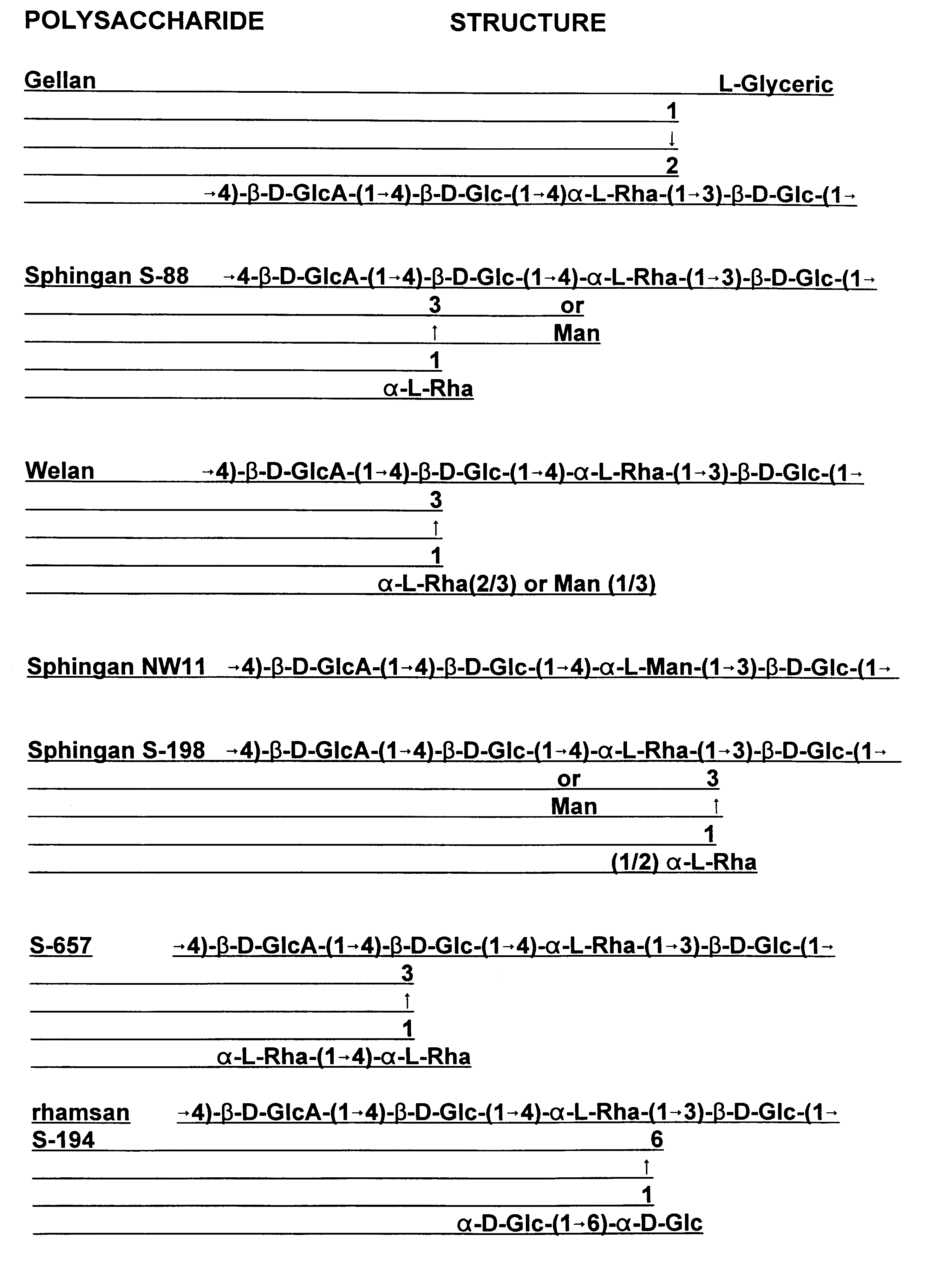

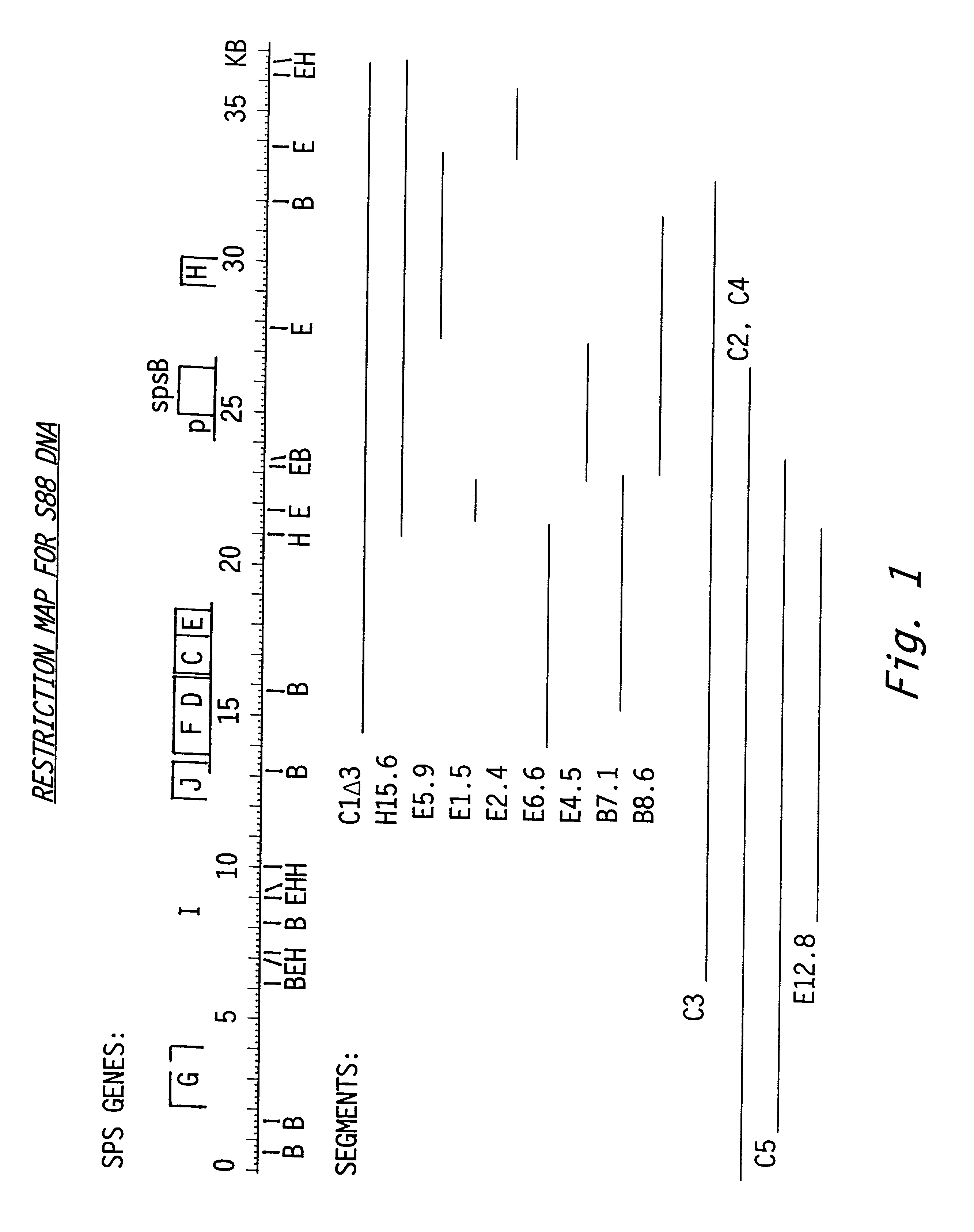

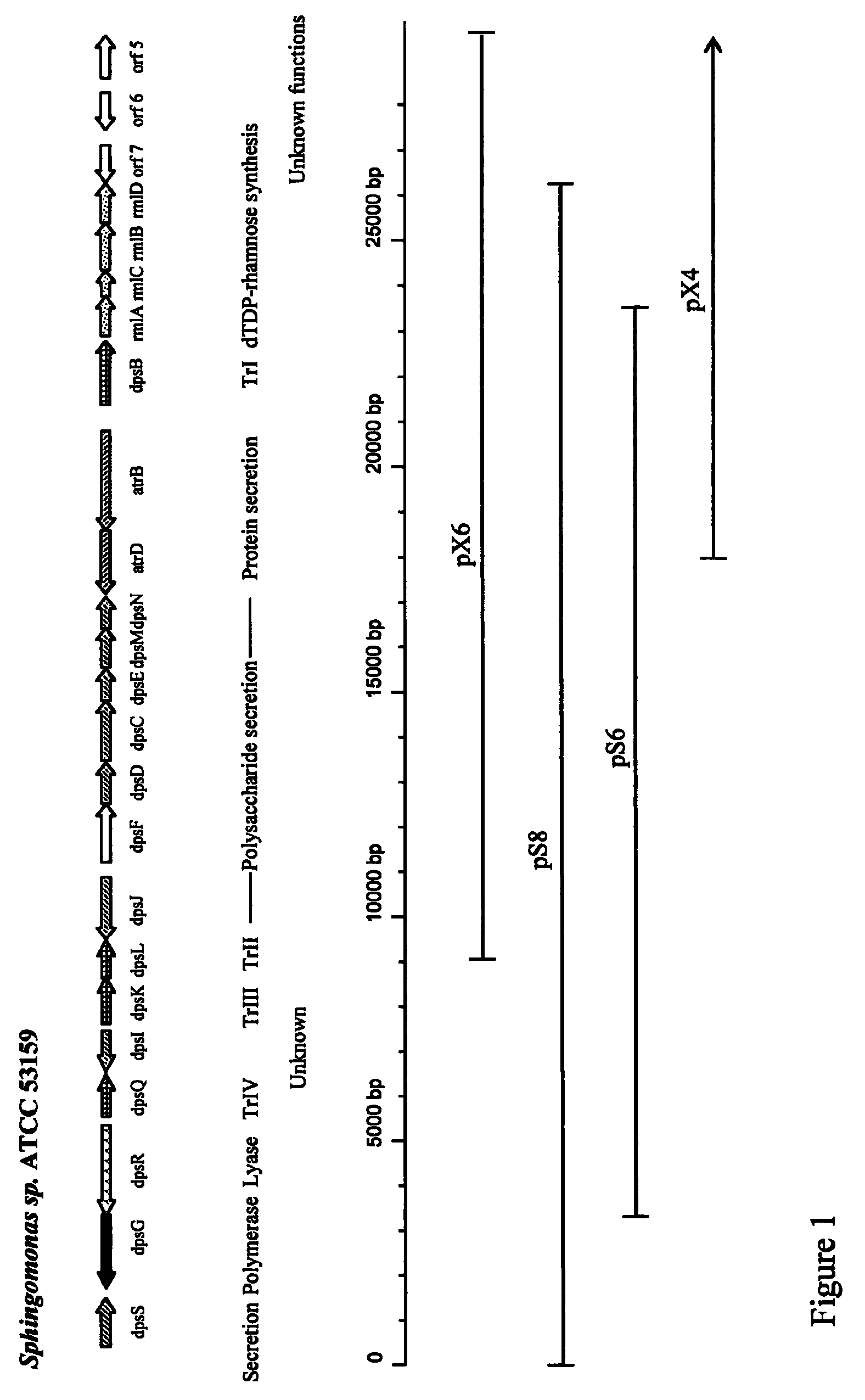

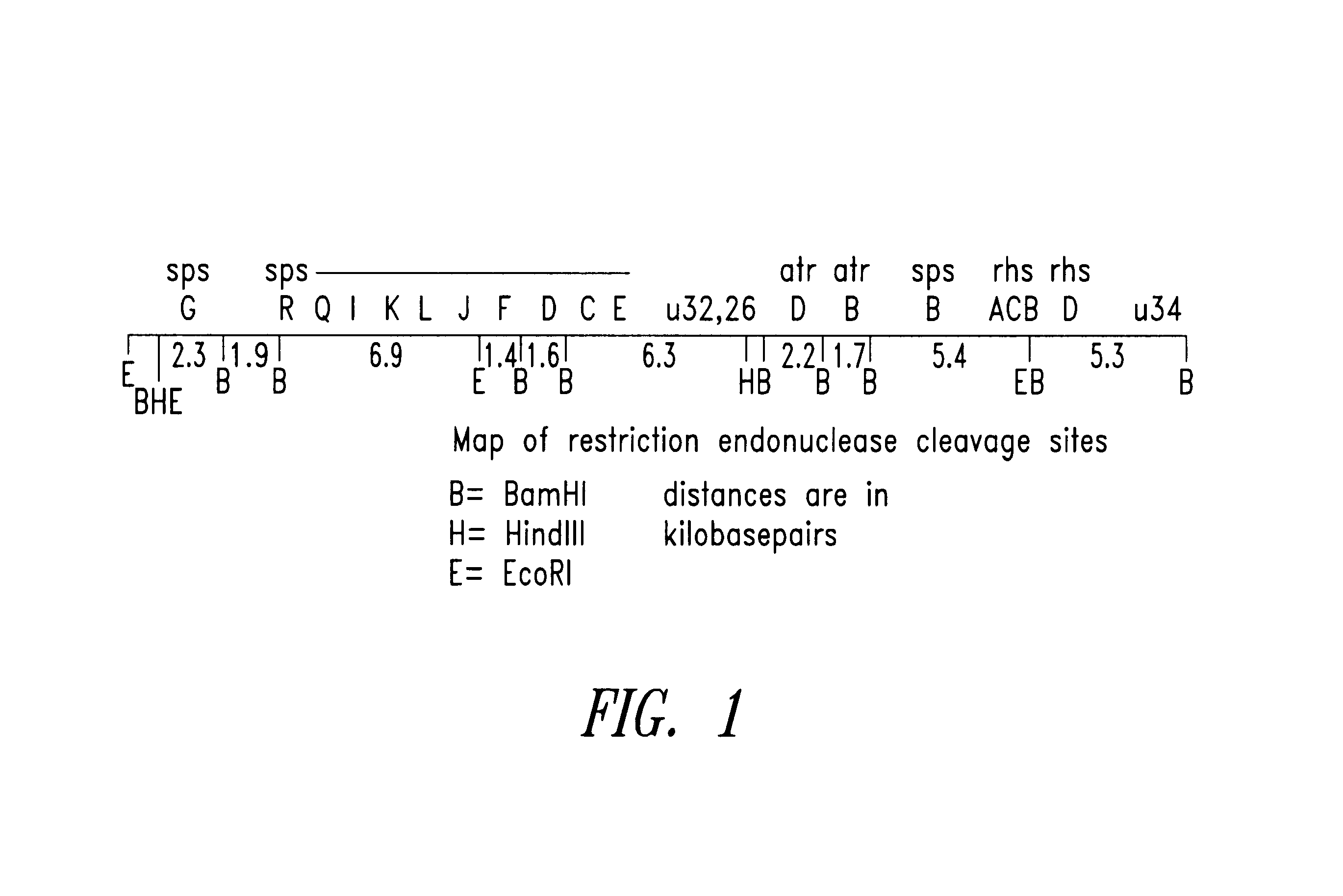

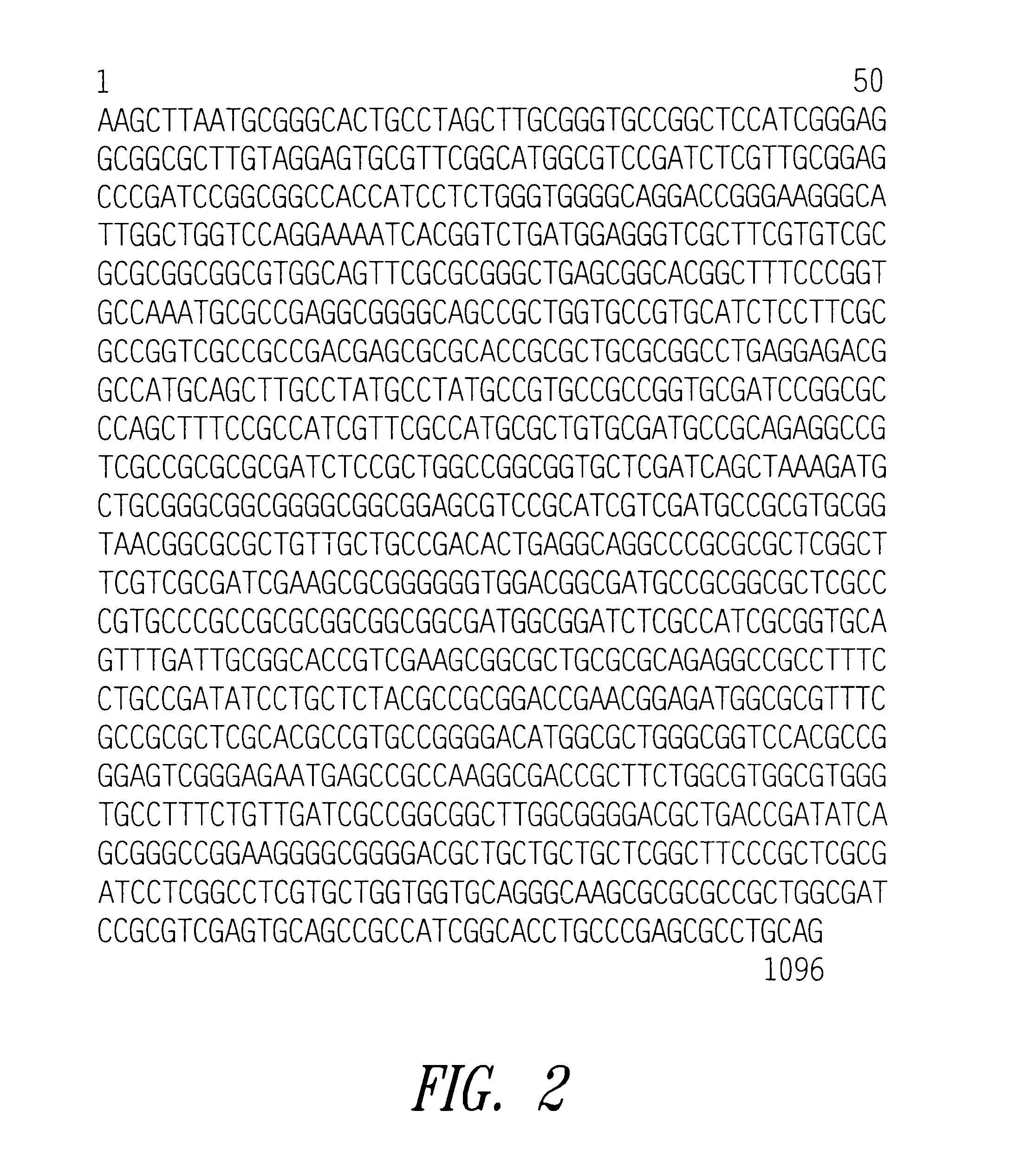

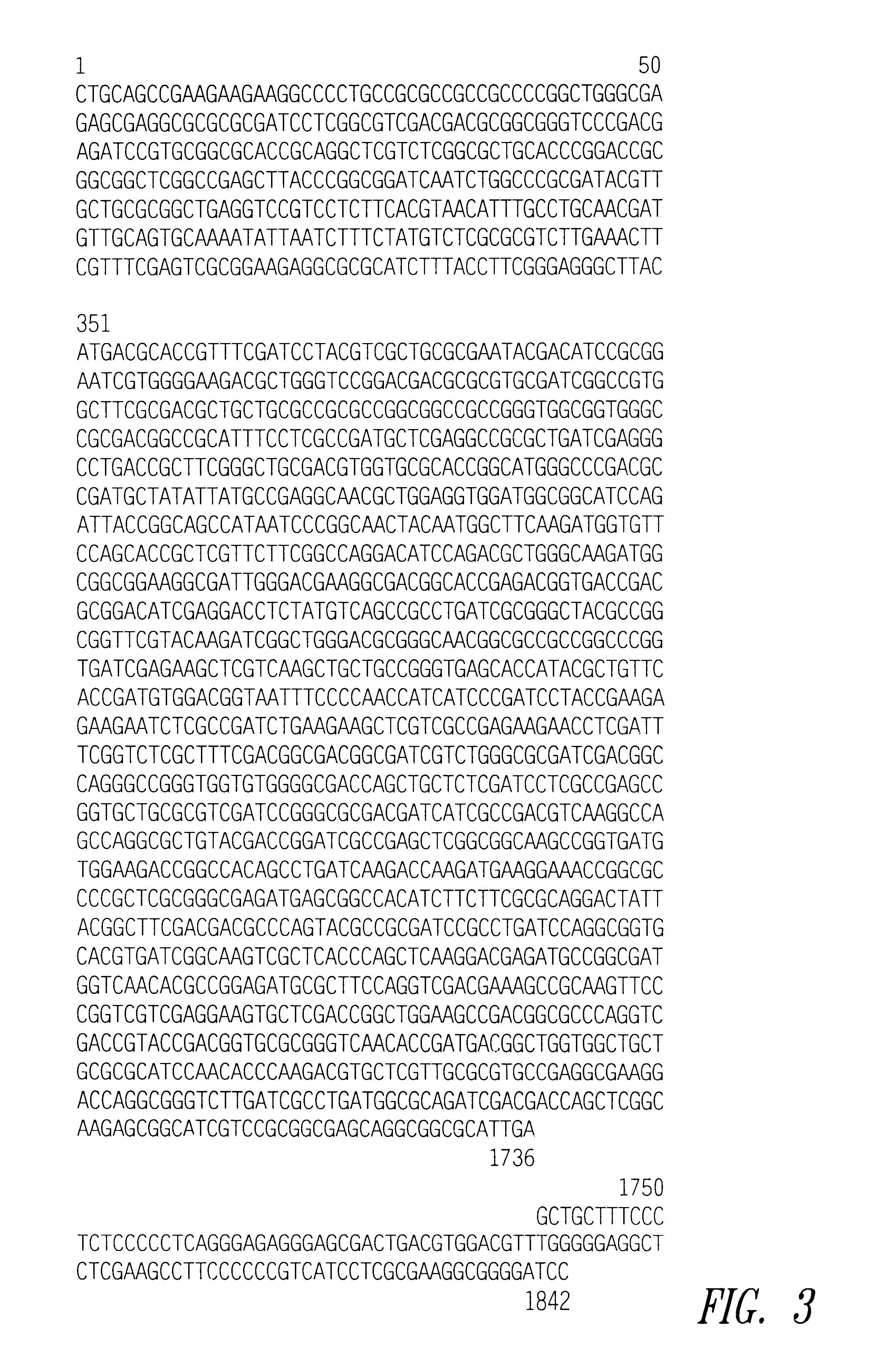

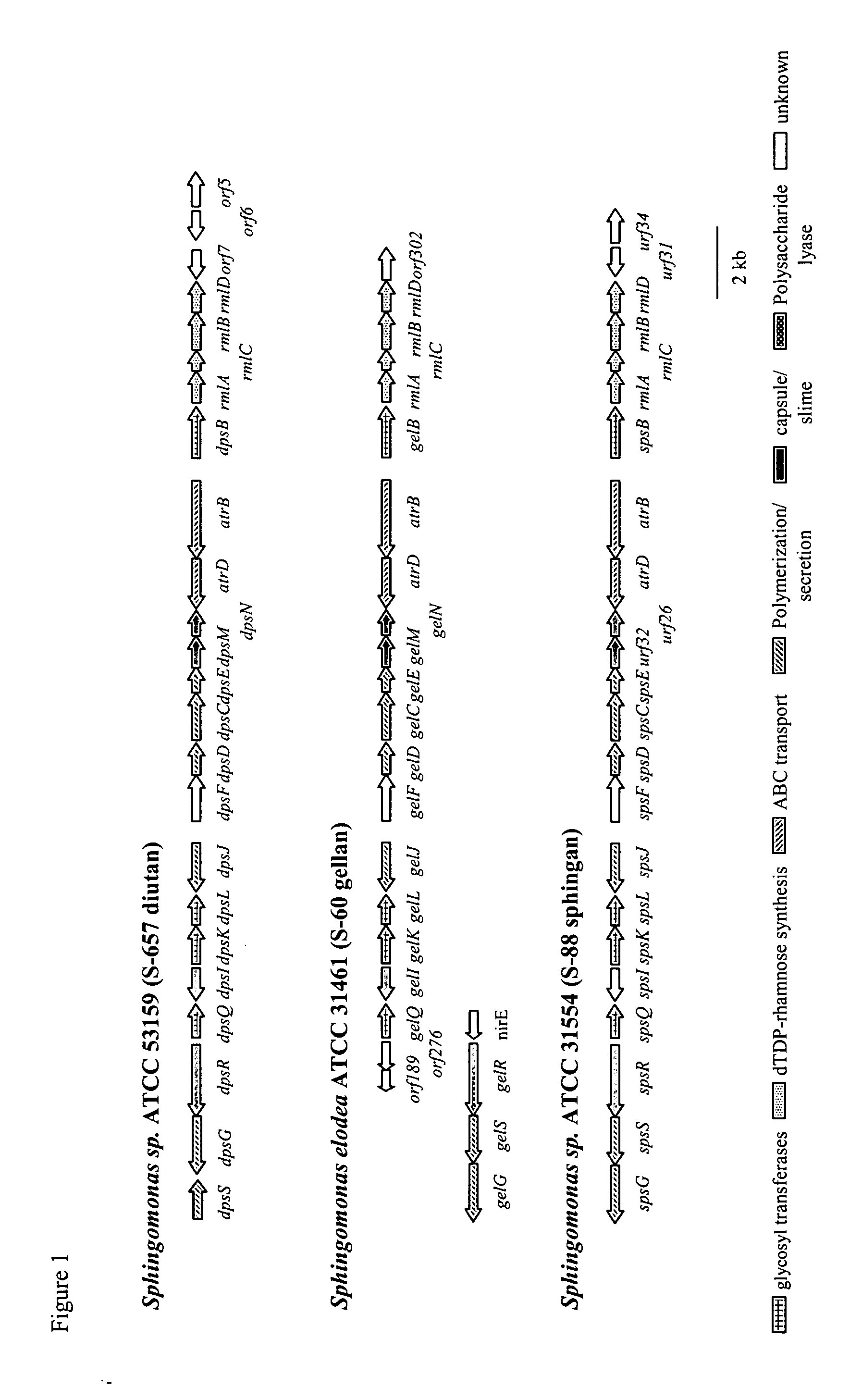

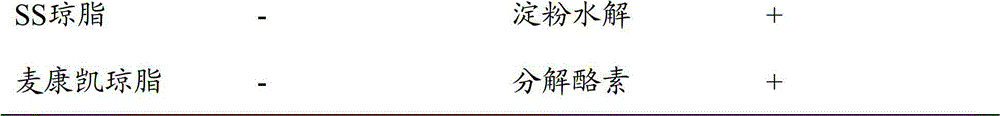

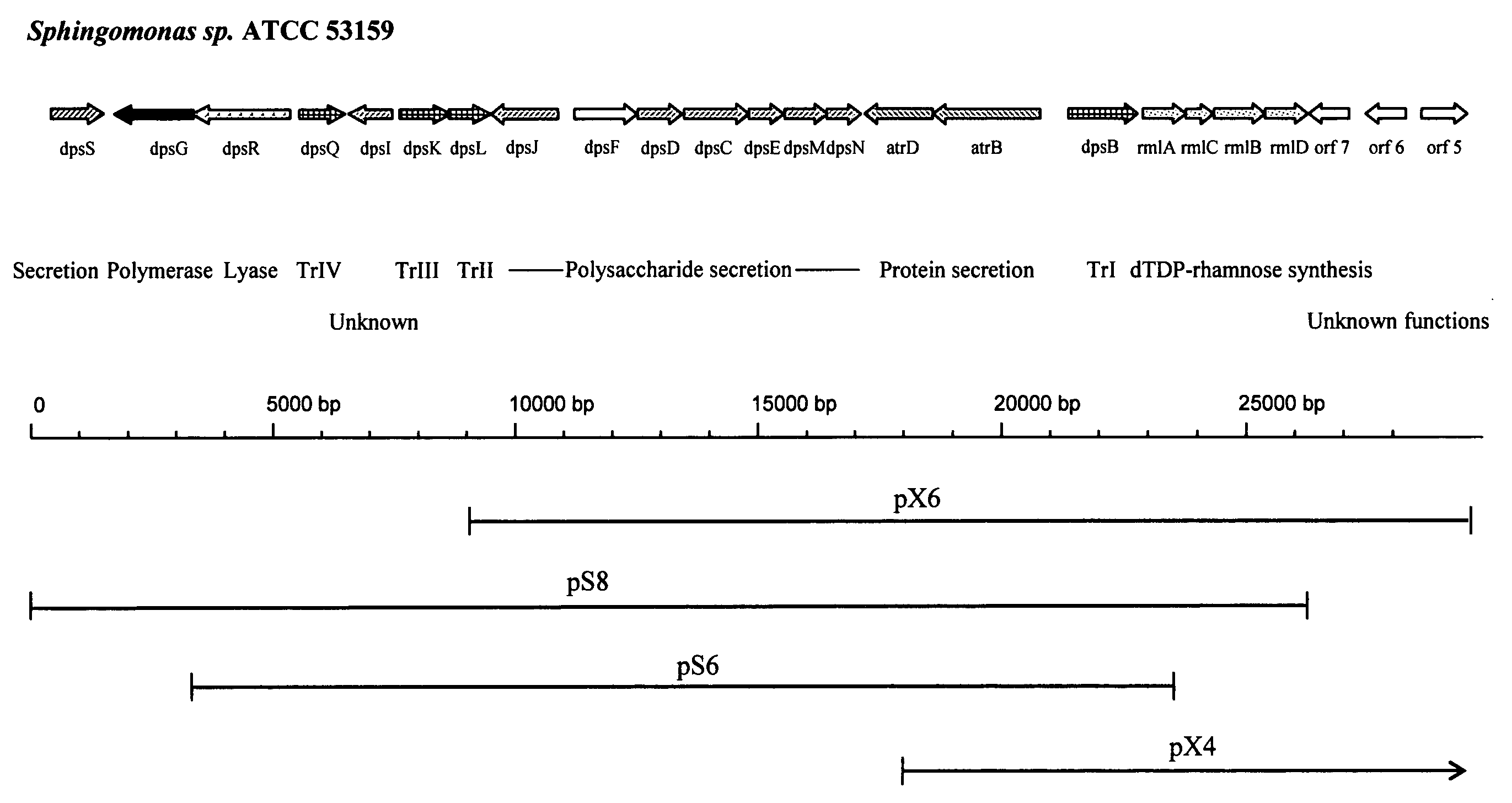

DNA segments and methods for increasing polysaccharide production

InactiveUS6284516B1Increase productionEnhance sphingan productionSugar derivativesBacteriaBiotechnologyBacteroides

The present invention relates to DNA segments isolated from Sphingomonas sp. and involved in the biosynthetic production of sphingan polysaccharides to increase the production of the polysaccharide in engineered microorganisms. The present invention also relates to methods of engineering strains of Sphingomonas to produce bacteria which are hyperproducers of sphingan, methods of identifying and utilizing DNA fragments useful to enhance production of sphingan in bacteria and the hyperproducer bacteria.

Owner:CP KELCO U S INC

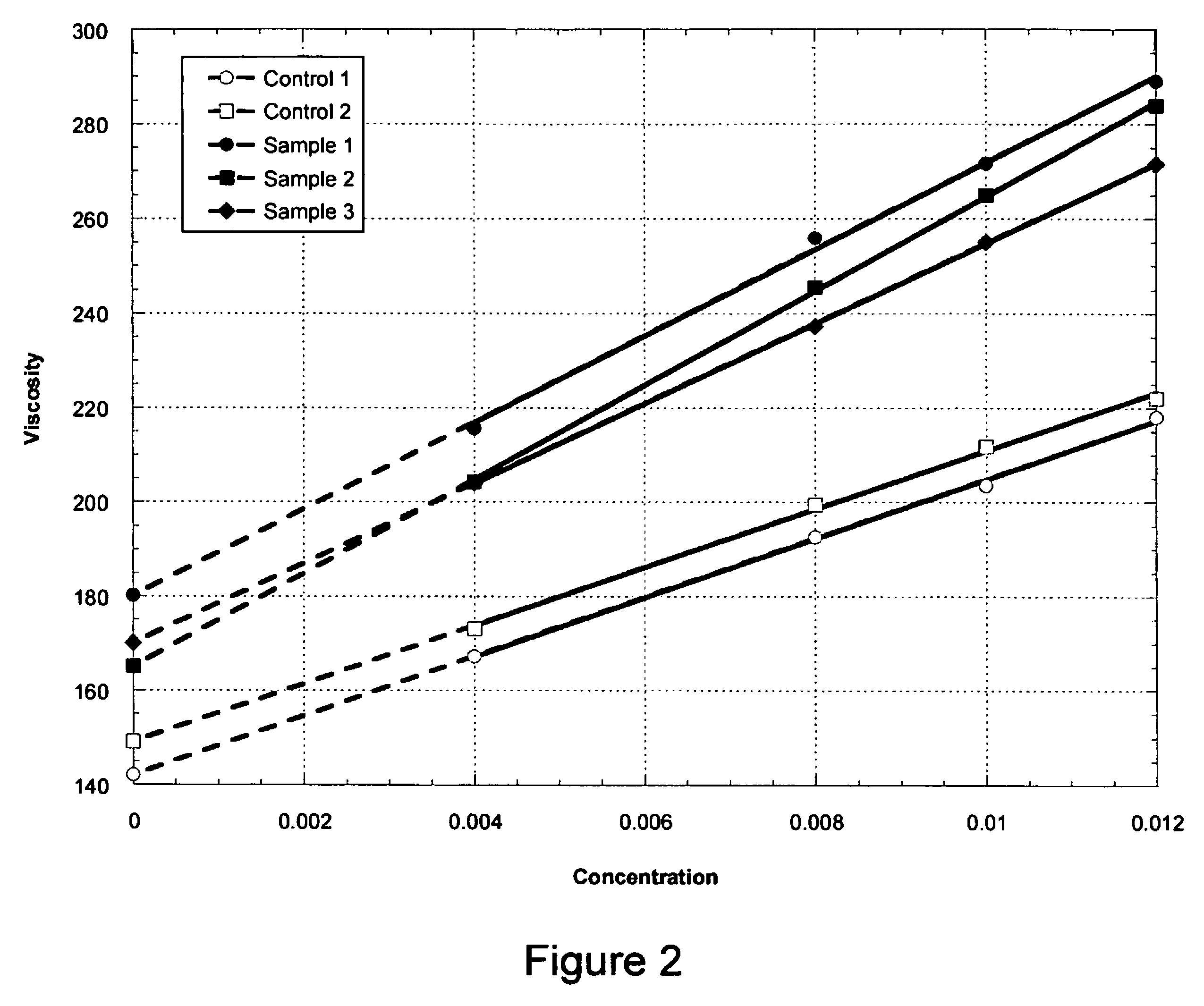

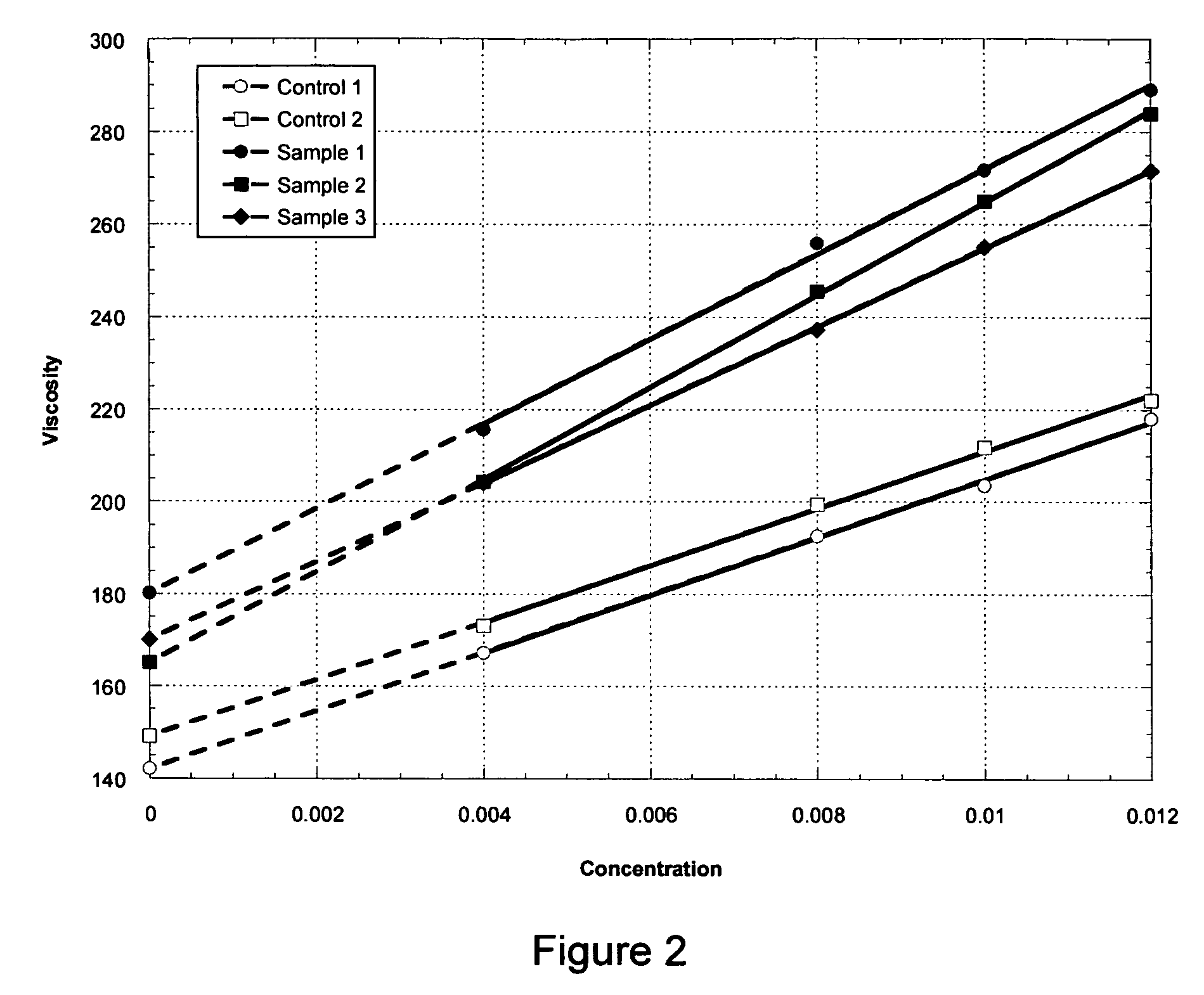

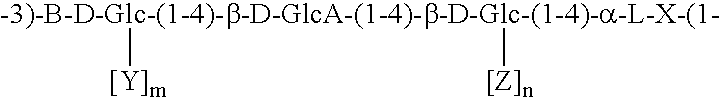

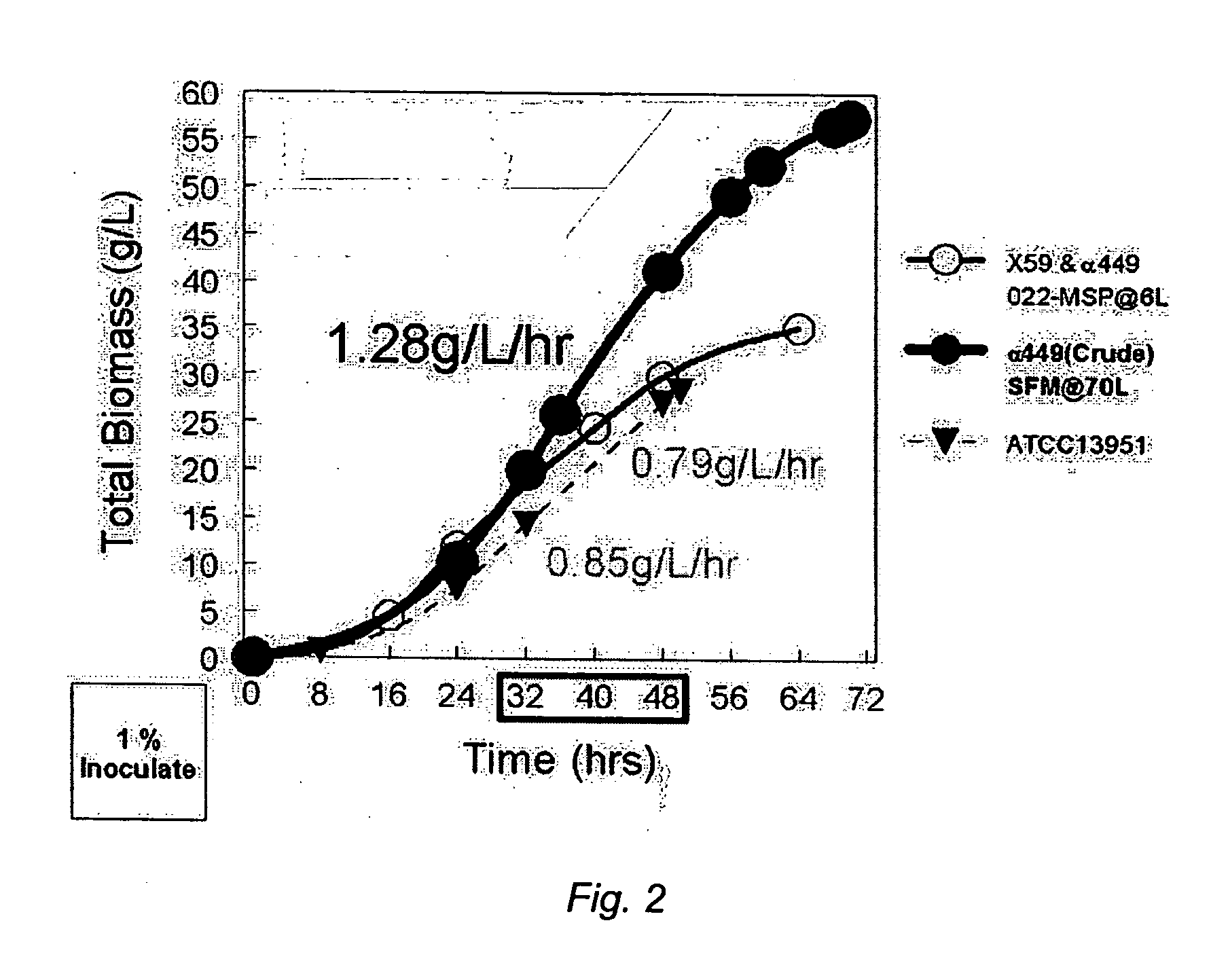

High viscosity diutan gums

ActiveUS7868167B2Increase productionImproved viscosity propertiesBiocideBacteriaBiotechnologyPhysical property

The production of a diutan polysaccharide exhibiting increased viscosity properties as compared with previously produced polysaccharide of the same type of repeating units. Such an improved diutan polysaccharide is produced through the generation of a derivative of Sphingomonas sp. ATCC 53159 that harbors a multicopy broad-host-range plasmid into which genes for biosynthesis of diutan polysaccharide have been cloned. The plasmid provides the capability within the host Sphingomonas strain to produce multiple copies of genes for such polysaccharide synthesis. In such a manner, a method of not just increased production of the target diutan polysaccharide, but also production of a diutan polysaccharide of improved physical properties (of the aforementioned higher viscosity) thereof is provided. Such a diutan polysaccharide has proven particularly useful as a possible viscosifier in oilfield applications and within cement materials. The inventive methods of production of such an improved diutan polysaccharide, as well as the novel cloned genes required to produce the improved diutan within such a method, are also encompassed within this invention. Additionally, the novel engineered Sphingomonas strain including the needed DNA sequence is encompassed within this invention.

Owner:CP KELCO U S INC

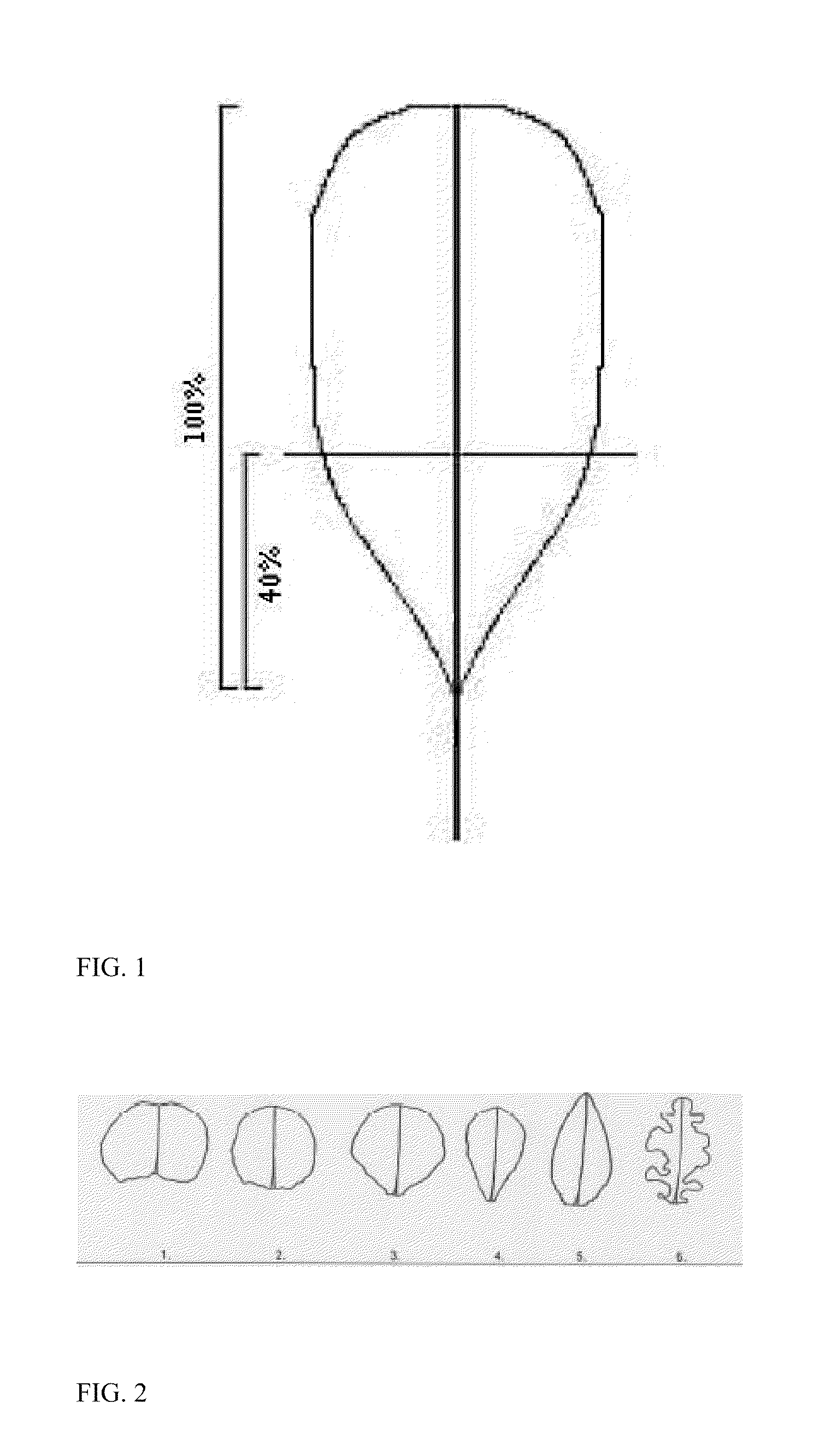

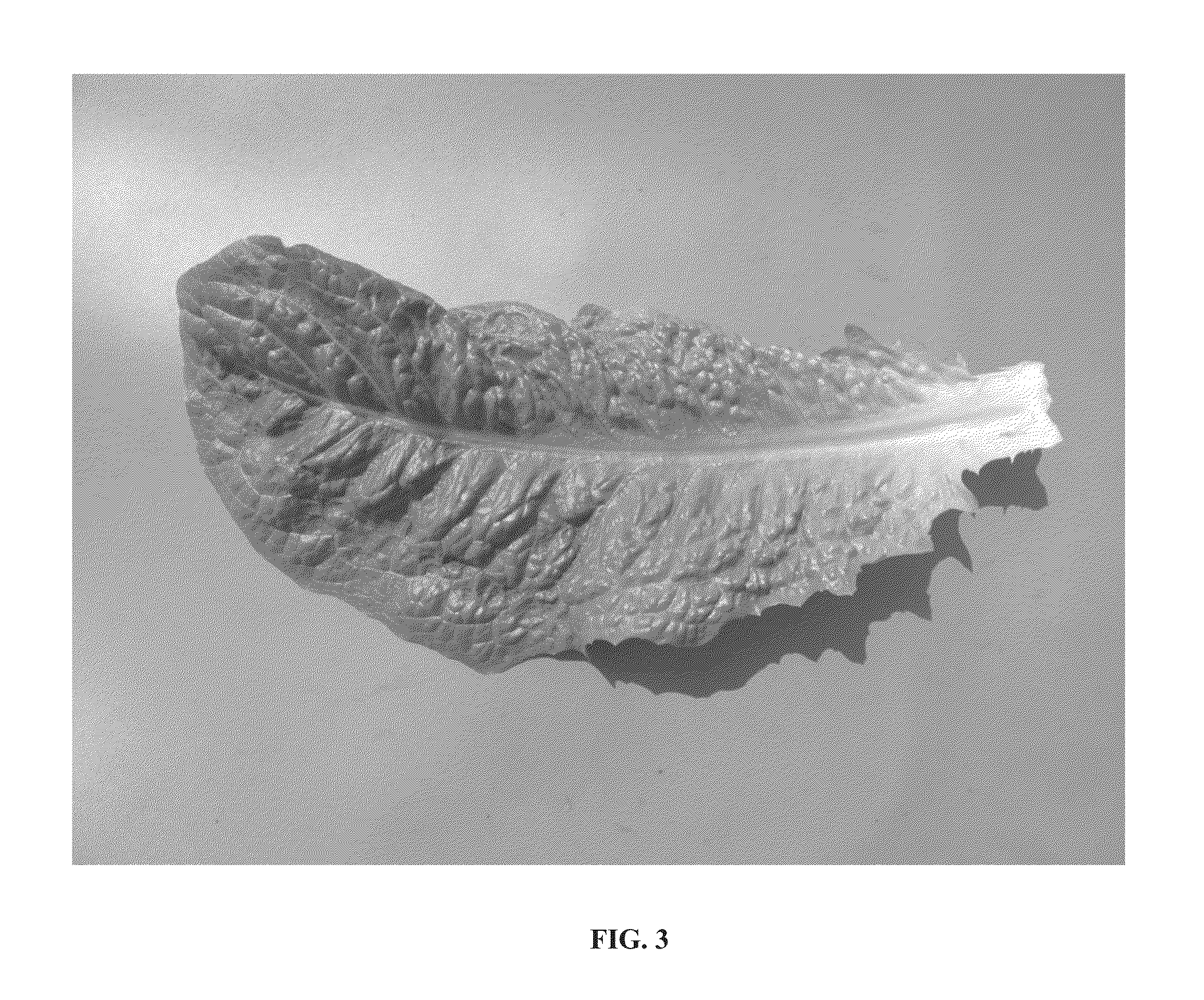

Lettuce variety 41-49 rz

ActiveUS20110191890A1Microbiological testing/measurementPlant genotype modificationBremia lactucaeSphingomonas

The present invention relates to a Lactuca sativa L. var. longifolia Lam seed designated as 41-49 RZ, which has leaves with a hollow main vein, broad base leaves, and exhibits resistance against downy mildew (Bremia lactucae Regel), currant-lettuce aphid (Nasonovia ribisnigri), corky root (Sphingomonas suberifaciens) and lettuce mosaic virus (LMV). The present invention also relates to a Lactuca sativa L. var. longifolia Lam plant produced by growing the “41-49 RZ” seed. The invention further relates to methods for producing the lettuce cultivar, represented by lettuce variety 41-49 RZ.

Owner:RIJK ZWAAN ZAADTEELT & ZAADHANDEL BV

Production of modified polysaccharide S-7

A modified S7 polysaccharide is disclosed. The polysaccharide contains 20% less glucose that S7. An S7c6 gene cluster is disclosed. A mutated Sphingomonas is also disclosed.

Owner:SHIN ETSU BIO INC +1

Lettuce variety

The present invention relates to a Lactuca sativa L. var. longifolia Lam seed designated as 41-52 RZ, referred to as Nirvanus, which exhibits resistance against downy mildew (Bremia lactucae Regel), currant-lettuce aphid (Nasonovia ribis-nigri), corky root (Sphingomonas suberifaciens) and lettuce mosaic virus (LMV), the representative seed having been deposited with the National Collections of Industrial, Marine and Food Bacteria (NCIMB) in Bucksburn, Aberdeen AB21 9YA, Scotland, UK and assigned NCIMB Acession No. 41326. The present invention also relates to a Lactuca sativa L. var. longifolia Lam plant produced by growing the 41-52 RZ (Nirvanus) seed. The invention further relates to methods for producing the lettuce cultivar, represented by lettuce variety 41-52 RZ.

Owner:RIJK ZWAAN ZAADTEELT & ZAADHANDEL BV

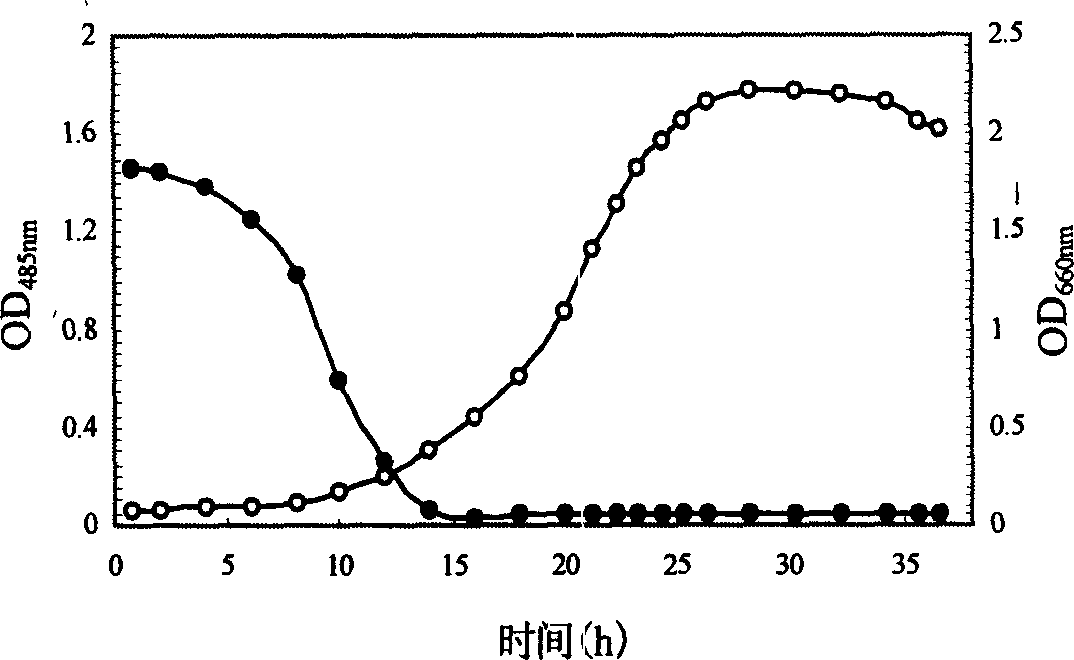

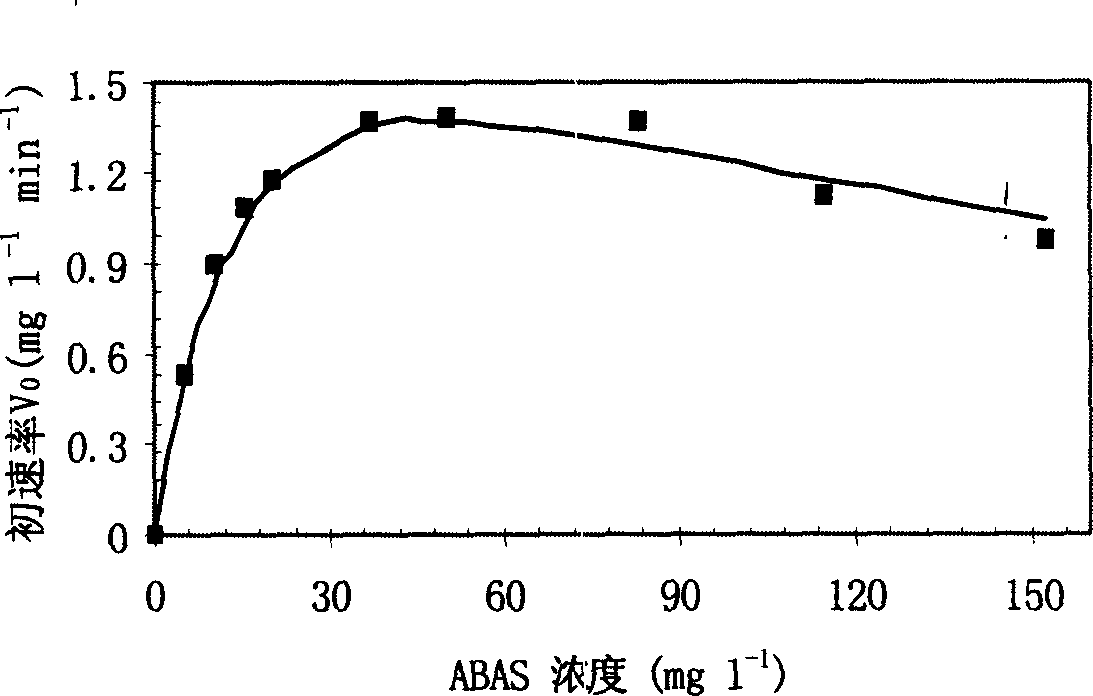

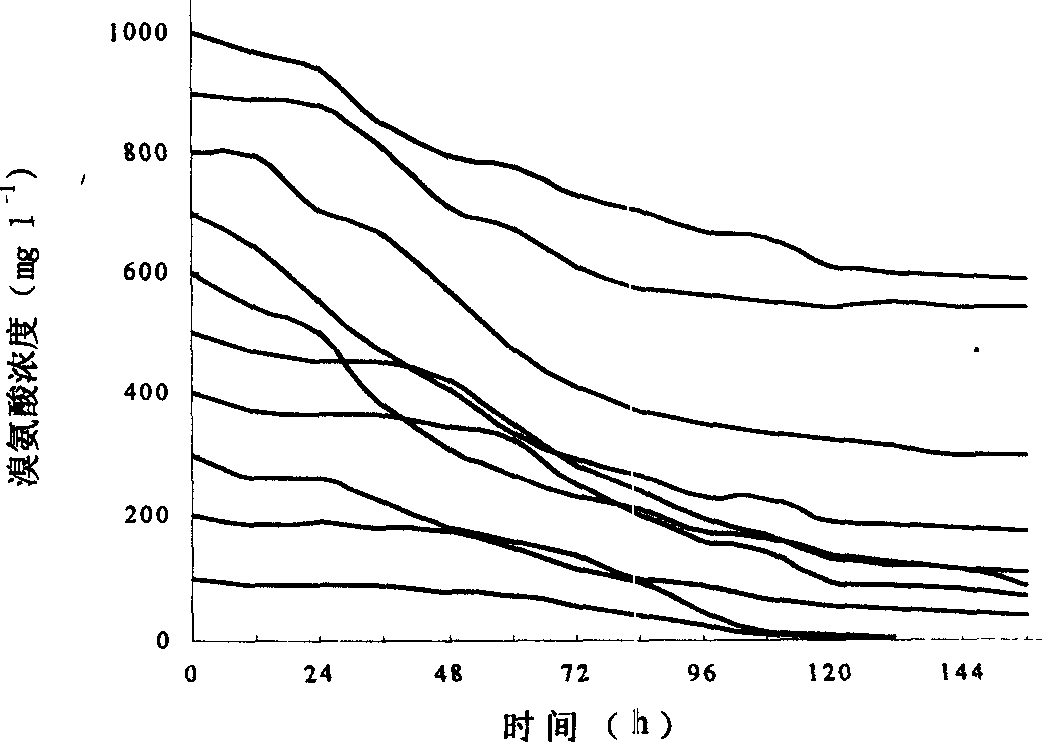

Sphingol monospore bacterial strain and its application in anthraquinone dye waste water decolour

InactiveCN1618953AStrong decolorization abilityFast degradationBacteriaWater/sewage treatmentSludgeBio engineering

A sphingomonas xenophaga QYY (CGMCC No.1172) is disclosed, which features that the bromamino acid as the intermediate of anthraquinone dye is the unique carbon and nitrogen sources for its growth, so its cells can destroy the anthraquinone rings. As a result, it has strong decolor capacity and can be used to decolor the sewage of anthraquinone dye.

Owner:DALIAN UNIV OF TECH

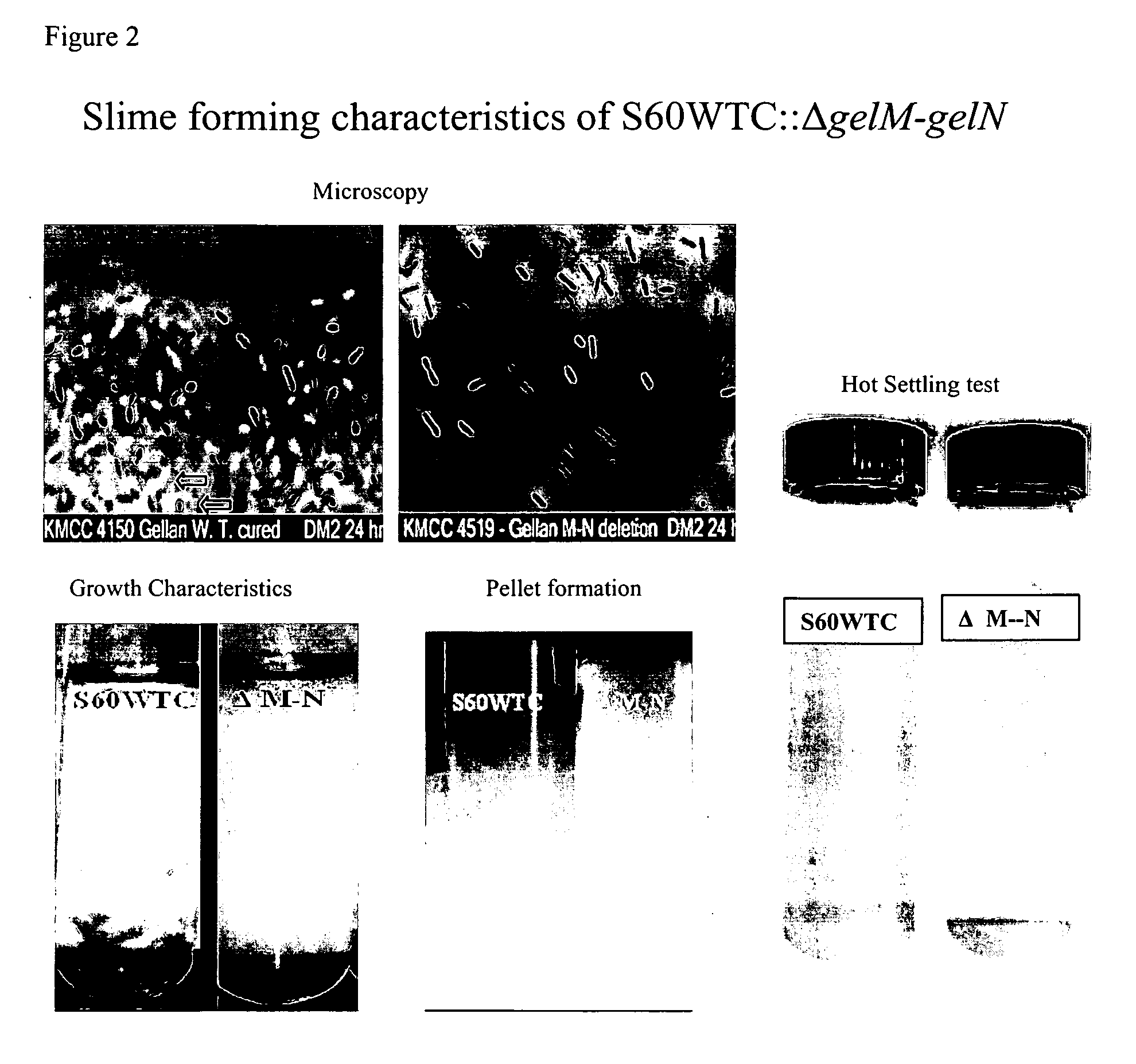

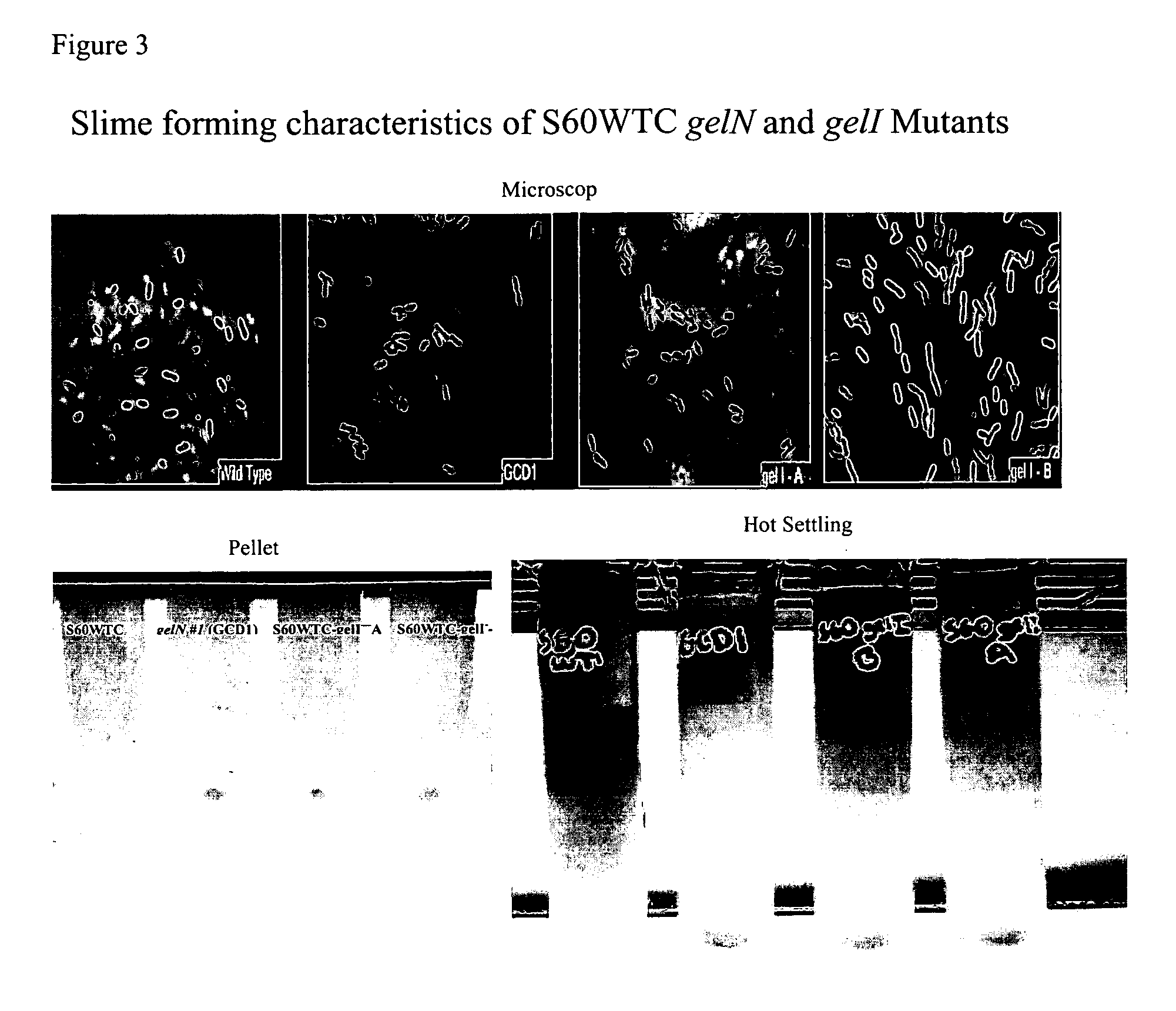

Targeted gene deletions for polysaccharide slime formers

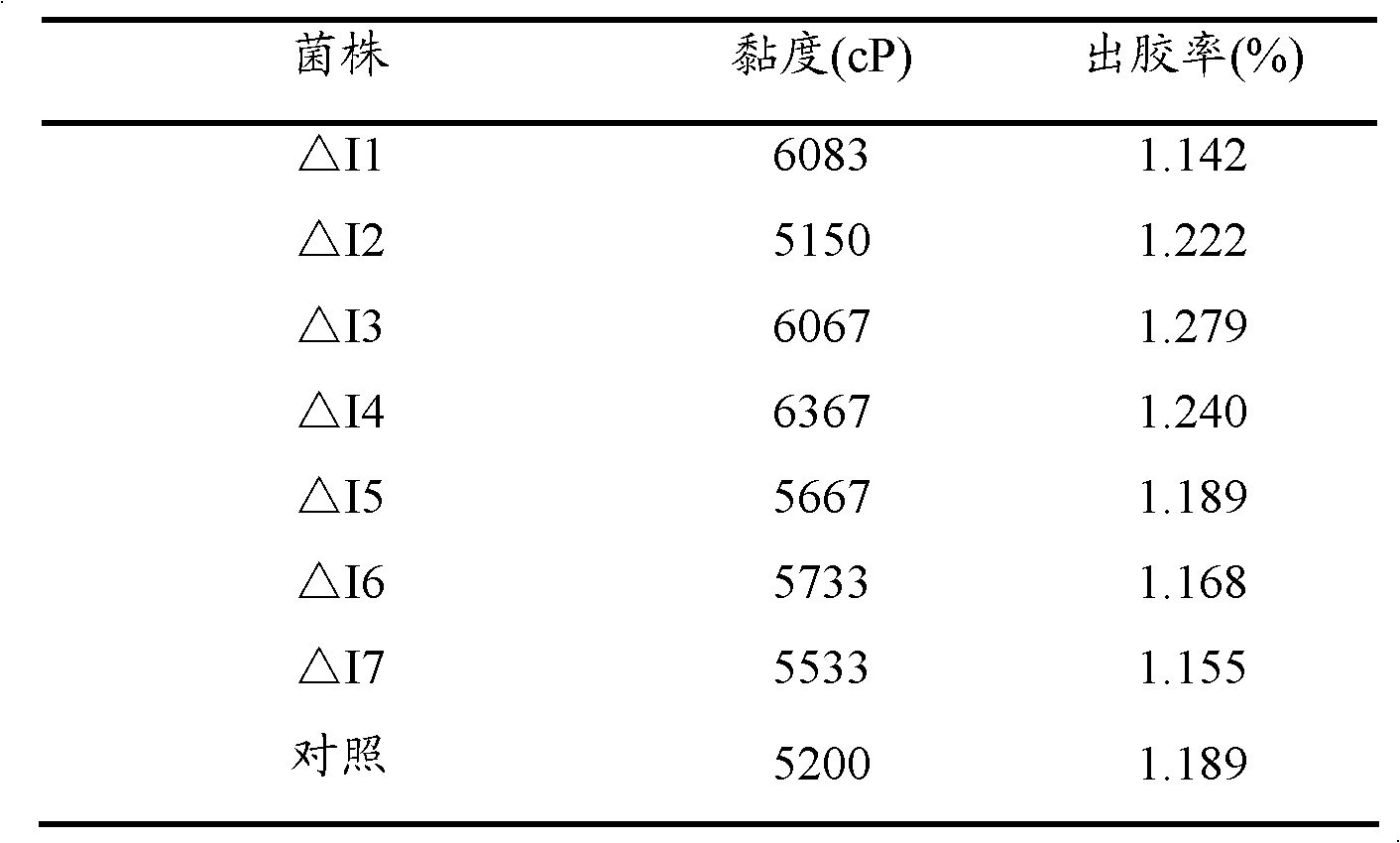

Sphingomonas strains have extracellular polysaccharide (e.g., gellan, diutan) that is firmly attached to the cell surface. This attachment may limit polysaccharide production by impairing uptake of nutrients into the cell or due to limited sites for polysaccharide biosynthesis on the cell surface. Two genes for polysaccharide biosynthesis, designated gelM and gelN in gellan-producing strains and dpsM and dpsN in diutan-producing strains, have been inactivated by deletion mutations and shown to produce polysaccharide that is not firmly attached to the cell surface, i.e., slime form. Another gene for polysaccharide biosynthesis, designated gelI in gellan producing strains, was inactivated by insertion mutation and also shown to produce the slime phenotype. The homologous gene dpsi in the diutan producing strain should also be involved in the attachment of the polysaccharide to the cell surface. The slime characteristic was demonstrated by the ability of the cells to be centrifuged and the lack of cell clumping as seen under the microscope or in diluted suspensions. The diutan slime mutants had somewhat increased productivity and the recovered diutan product had significantly improved rheology. Gellan slime mutants had lower broth viscosity which facilitates mixing during fermentation; however, the recovered gellan product had lower gel strength than the gellan produced from a capsular strain. A deletion in a gene gelR, which encodes a protein with homology to surface proteins and outer membrane proteins and weak homology to proteins with polysaccharide degradation activity, was shown to restore higher gel strength to the slime form of gellan, and to produce gellan of higher gel strength than that of the capsular gellan producing strains.

Owner:CP KELCO U S INC

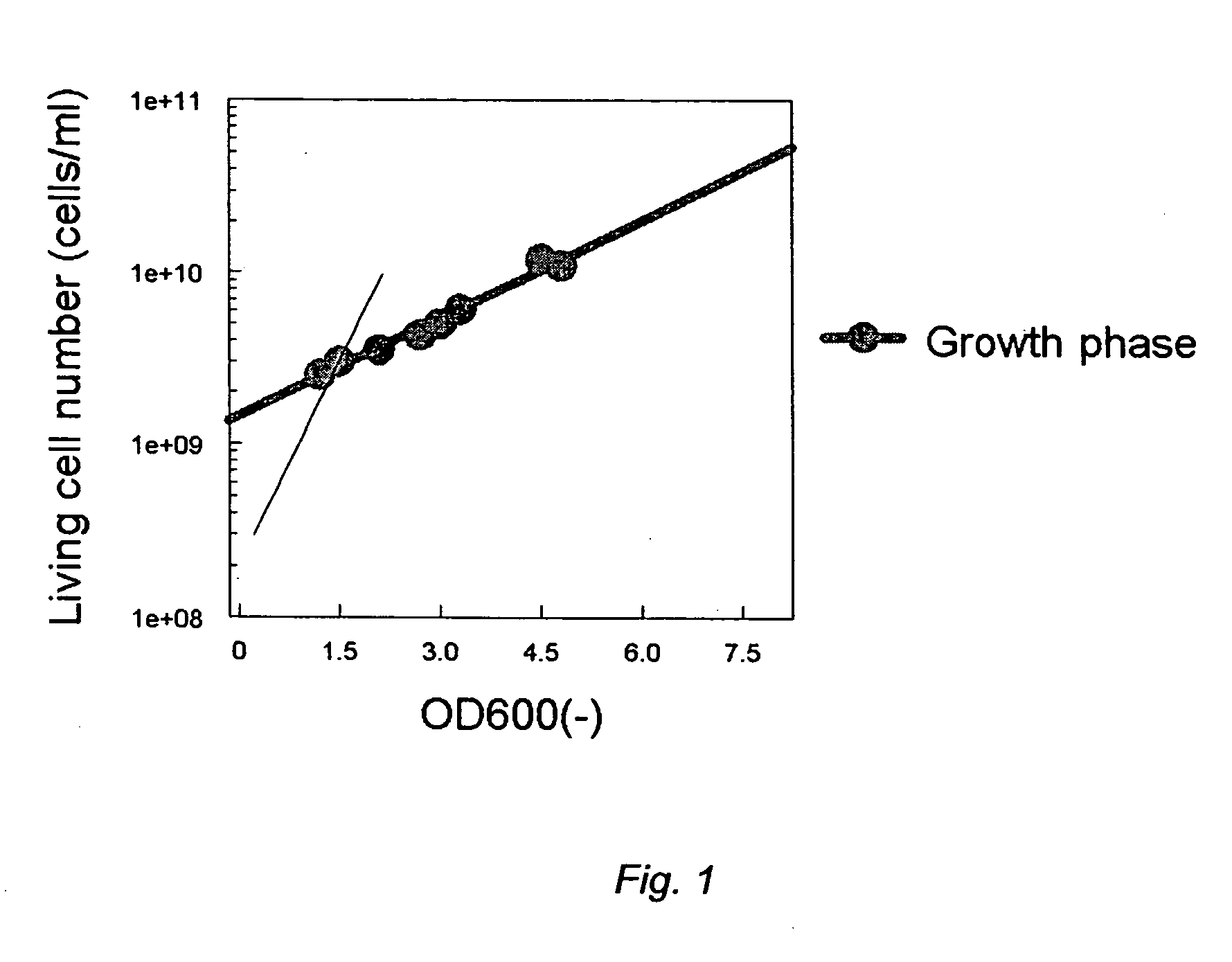

Gellan gum efficient production strain and its application

InactiveCN102747016AExpand sourceMeet the needs of industrial productionBacteriaMicroorganism based processesGellan gumSphingomonas paucimobilis

In the invention, a strain for efficient production of gellan gum is obtained by separation and screening of paddy root soil from Sha County, Sanming, Fujian province. The strain is Sphingomonas paucimobilis strain FJAT-5627. The invention also reveals a method for preparing gellan gum from the Sphingomonas paucimobilis strain FJAT-5627. The invention has the advantages that: a new Sphingomonas paucimobilis strain FJAT-5627 is provided and utilized to prepare gellan gum, and the prepared gellan gum has a yield meeting the industrialized production requirement, thereby increasing the sources of gellan gum production strains in line with the industrialized production requirements.

Owner:福建省农业科学院农业生物资源研究所

High viscosity diutan gums

ActiveUS20080319186A1Increased biosynthetic productionHigh viscosity propertySugar derivativesBacteriaBiotechnologyPhysical property

The production of a diutan polysaccharide exhibiting increased viscosity properties as compared with previously produced polysaccharide of the same type of repeating units. Such an improved diutan polysaccharide is produced through the generation of a derivative of Sphingomonas sp. ATCC 53159 that harbors a multicopy broad-host-range plasmid into which genes for biosynthesis of diutan polysaccharide have been cloned. The plasmid provides the capability within the host Sphingomonas strain to produce multiple copies of genes for such polysaccharide synthesis. In such a manner, a method of not just increased production of the target diutan polysaccharide, but also production of a diutan polysaccharide of improved physical properties (of the aforementioned higher viscosity) thereof is provided. Such a diutan polysaccharide has proven particularly useful as a possible viscosifier in oilfield applications and within cement materials. The inventive methods of production of such an improved diutan polysaccharide, as well as the novel cloned genes required to produce the improved diutan within such a method, are also encompassed within this invention. Additionally, the novel engineered Sphingomonas strain including the needed DNA sequence is encompassed within this invention.

Owner:CP KELCO U S INC

Lettuce variety 41-177 RZ

ActiveUS9161510B2Microbiological testing/measurementAngiosperms/flowering plantsBremia lactucaeRoot rot

Owner:RIJK ZWAAN ZAADTEELT & ZAADHANDEL BV

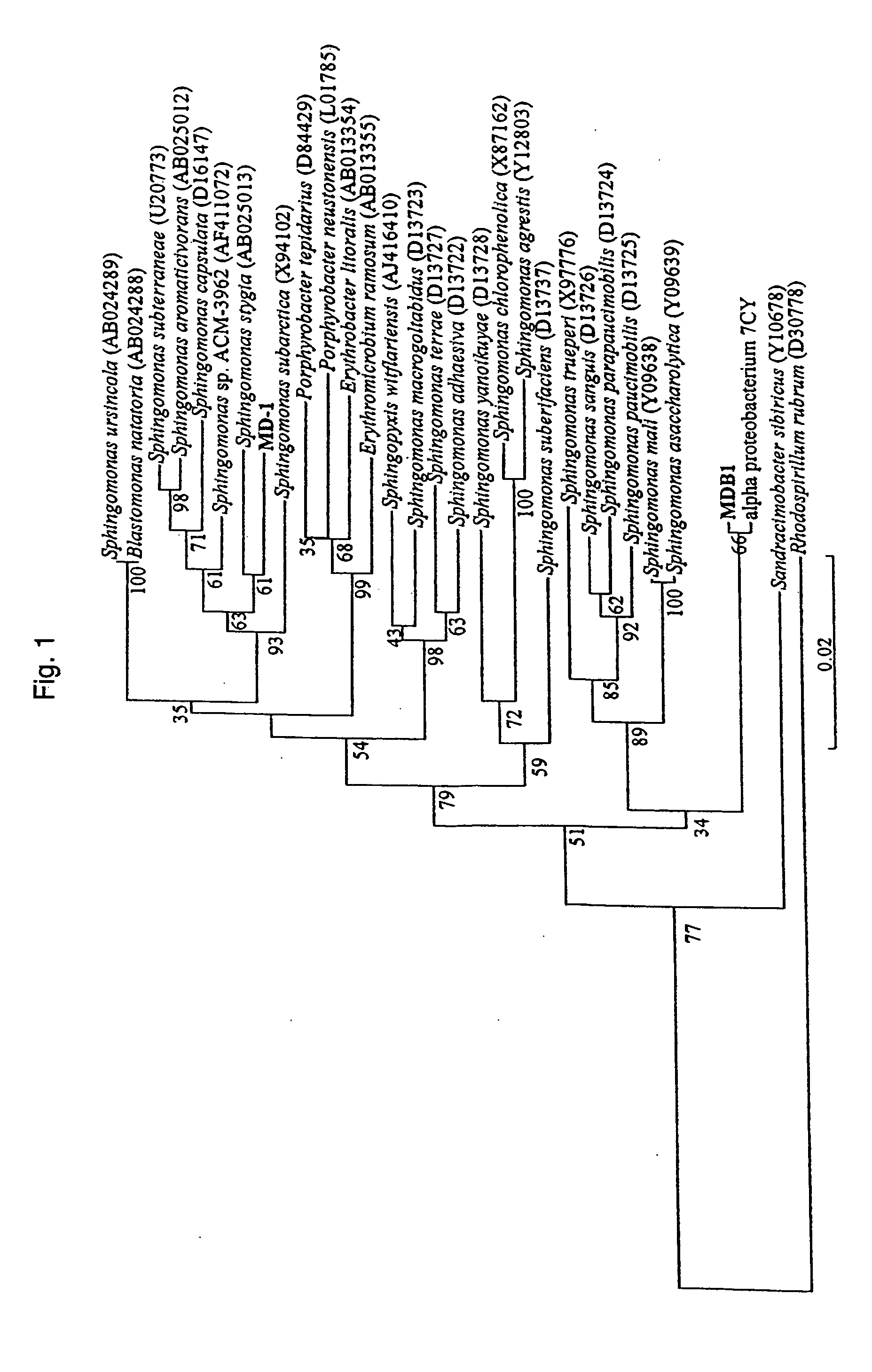

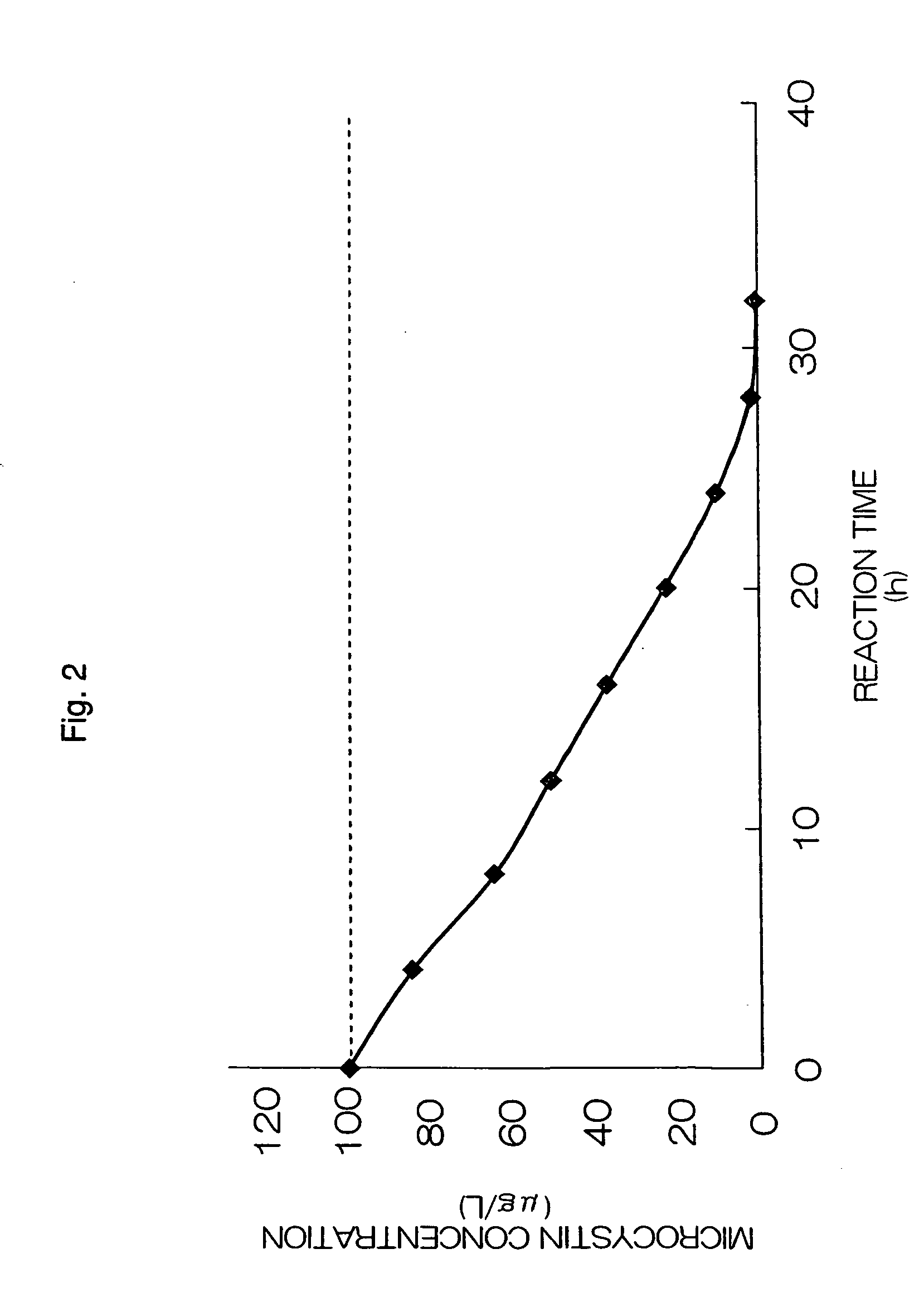

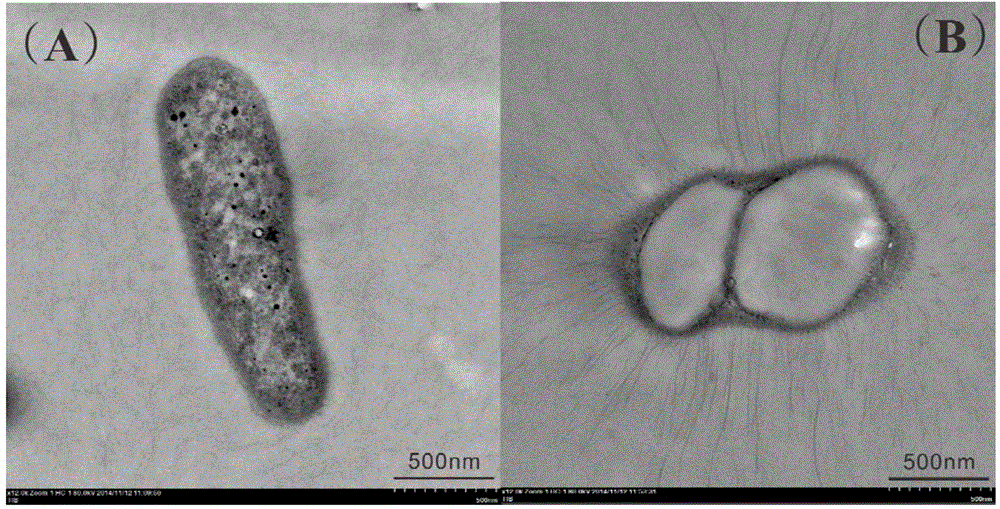

Method and equipment for treating microcystin-containing water

InactiveUS20060096915A1Easy to degradeEasily detoxificationSolid waste disposalWater contaminantsMicrocystinMicrocystis

The method for treating microcystin-containing water which detoxifies microcystin in the microcystin-containing water, the method comprises the step of: bringing the microcystin-containing water into contact with a Sphingomonas bacterium to degrade biologically the microcystin in the microcystin-containing water, wherein: the Sphingomonas bacterium is a strain FERM P-19480 which is deposited as strain MDB1 with International Patent Organism Depositary, National Institute of Advanced Industrial Science and Technology.

Owner:HITACHI LTD

Dendrobium candidum endophyte with growth promotion function and use thereof

InactiveCN101921718AAverage root length increaseShorten production timePlant growth regulatorsBiocideGrowth promotionMicrobiology

The invention discloses a sphingomonas sp. strain with preservation name of Sphingomonas (SH1), preserved in China Centre for Type Culture Collection (CCTCC) in Wuhan University, China, wherein the preservation date thereof is February 4, 2010 with preservation number thereof being CCTCC No: M 2010041. The invention also discloses a use of the sphingomonas sp. strain applied to promoting growth of dendrobium candidum, comprising the following specific uses: inoculating raw fermenting liquid or fermented liquid of the sphingomonas sp. strain CCTCC No: M 2010041 into a root of a dendrobium candidum seedling so as to promote the growth of the dendrobium candidum seedling.

Owner:ZHEJIANG SCI-TECH UNIV

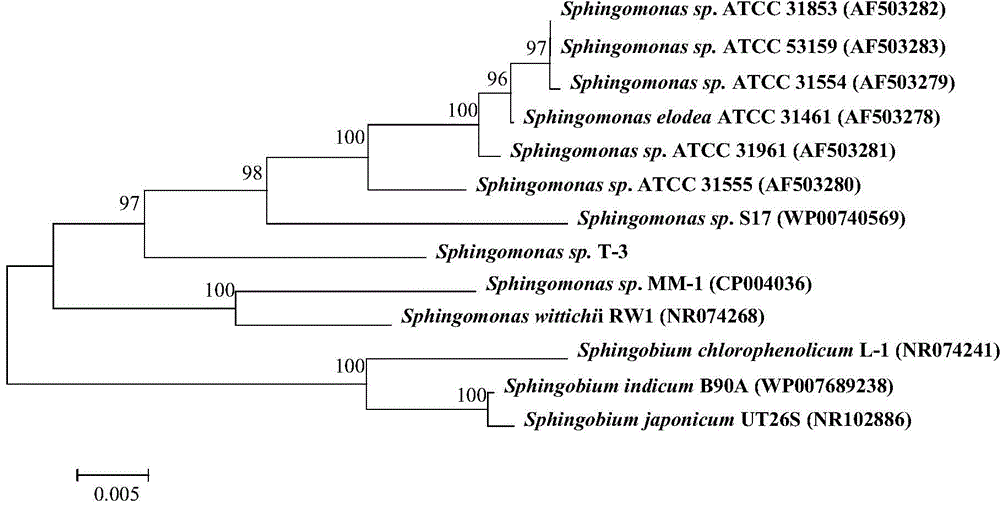

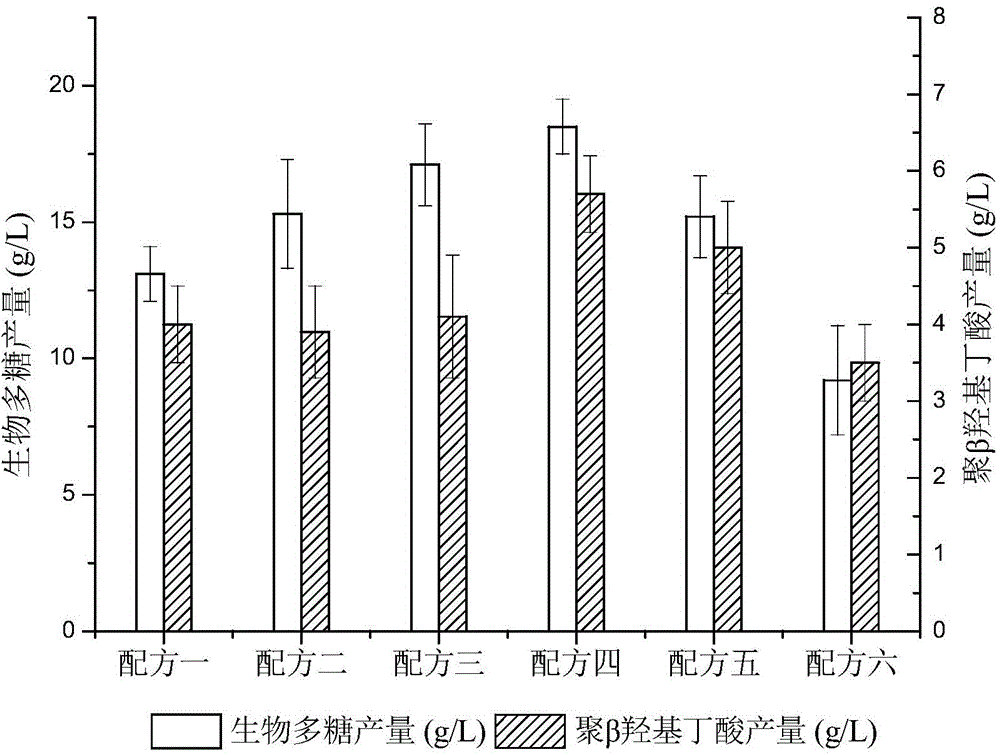

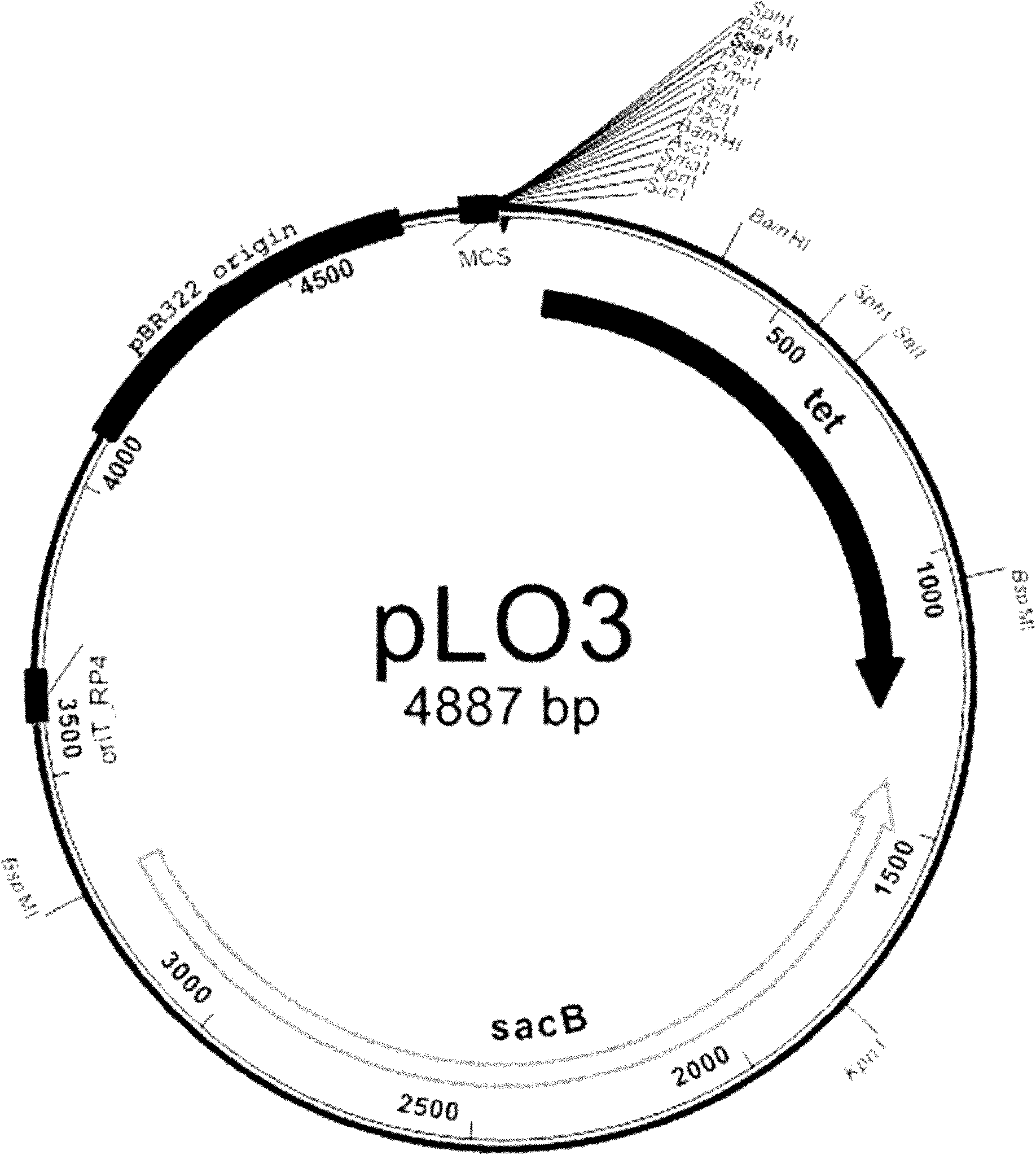

Sphingomonas sp. T-3 and method for producing biological polysaccharide and poly-beta-hydroxy-butanoic acid by co-fermentation

ActiveCN104651284AGood thickening effectGood shear thinning propertiesBacteriaMicroorganism based processesBiotechnologyFermentation

The invention relates to a Sphingomonas sp. T-3 and a method for producing biological polysaccharide and poly-beta-hydroxy-butanoic acid by co-fermentation. The collection number of the Sphingomonas sp. strain T-3 is CGMCC No.10150. The method comprises the following steps: carrying out activating culture on the strain T-3, inoculating into a seed culture medium, inoculating a seed solution into the fermentation culture medium, and culturing; and after the fermentation finishes, diluting with distilled water, heating, carrying out membrane separation to obtain a supernate and a thallus precipitate; regulating the pH value of the supernate to 3.0 or so with hydrochloric acid, regulating the pH value of the obtained precipitate to neutrality with NaOH, and drying to obtain the biological polysaccharide; and drying the thallus precipitate, extracting with chloroform, and drying the supernate to obtain the poly-beta-hydroxy-butanoic acid. In the strain T-3 fermentation process, abundant poly-beta-hydroxy-butanoic acid is accumulated in the cells, and abundant biological polysaccharide is secreted into the culture medium; and the two obtained products can be widely used in the fields of industry, food, medical treatment and the like.

Owner:NANKAI UNIV

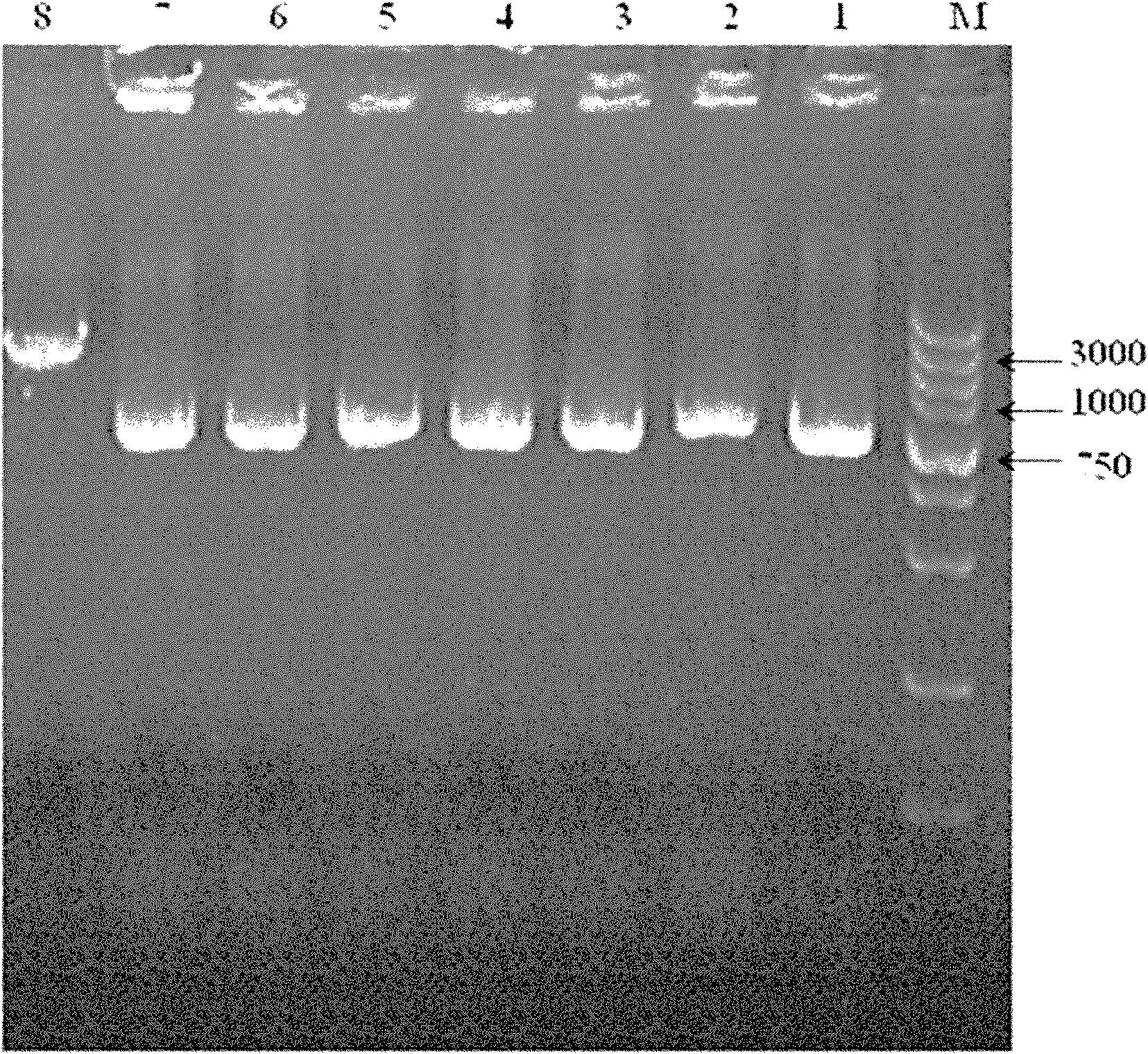

Phytoene desaturase gene of sphingomonas sp. and application thereof

InactiveCN101979587AReduce manufacturing costReduce dosageBacteriaMicroorganism based processesNucleotideA-DNA

The invention provides a DNA sequence of a phytoene desaturase gene of sphingomonas sp., a recombinant strain with phytoene desaturase lost and application thereof. The phytoene desaturase gene (crtI) of the sphingomonas sp. has a nucleotide sequence shown by SEQ ID No.1. The DNA sequence of the phytoene desaturase gene (crtI) of the sphingomonas sp. provided by the invention lays a foundation for the genetic transformation of a biological synthesis manner of sphingomonas sp. carotene. Moreover, compared with the wild strains, the sphingomonas sp. recombinant strain with the phytoene desaturase lost, which is constructed by a gene knockout method, has gellan glue yield unchanged, generates no uranidin, reduces the amount of ethanol or isopropanol which is used during gellan glue extraction and therefore reduces the production cost of the gellan glue; meanwhile, the strain can also be applied to the further gene knockout or metabolic engineering transformation.

Owner:ZHEJIANG UNIV

Special-purpose fruit tree biological organic fertilizer and preparation method thereof

InactiveCN103232303AImprove ventilationImprove physical and chemical propertiesFertilizer mixturesNutritionNutrient

The invention relates to a special-purpose fruit tree biological organic fertilizer and a preparation method thereof. The special-purpose fruit tree biological organic fertilizer is characterized by using 50%-65% (in percentage by weight) of fermented and cured organic matter as the material, wherein the organic matter is mixed with 10%-20% of powdered carbon, 5%-20% of shell powder, 1%-5% of seaweed meal, 1%-5% of chitin and 0.1%-0.2% of ocean brevibacillus laterosporus, bacillus subtilis and sphingomonas mixture powder (the weight ratio of the three bacteria being 1:1:1, and the number of effective microorganisms in each kilogram of the materials is 1012 or more). The special-purpose fruit tree biological organic fertilizer disclosed by the invention can be used for continuously supplying nutrients required by growth and development of the plant at each stage from the aspects including water retention, nutrition slow release and the like, can be used for improving the soil physical and chemical properties and promoting formation of soil aggregates. Most of materials used by the special-purpose fruit tree biological organic fertilizer are aquaculture by-products, so that the waste is changed into valuable, the environment-friendly effect is obvious and perpetual harms are not caused to the soil.

Owner:韩明三 +1

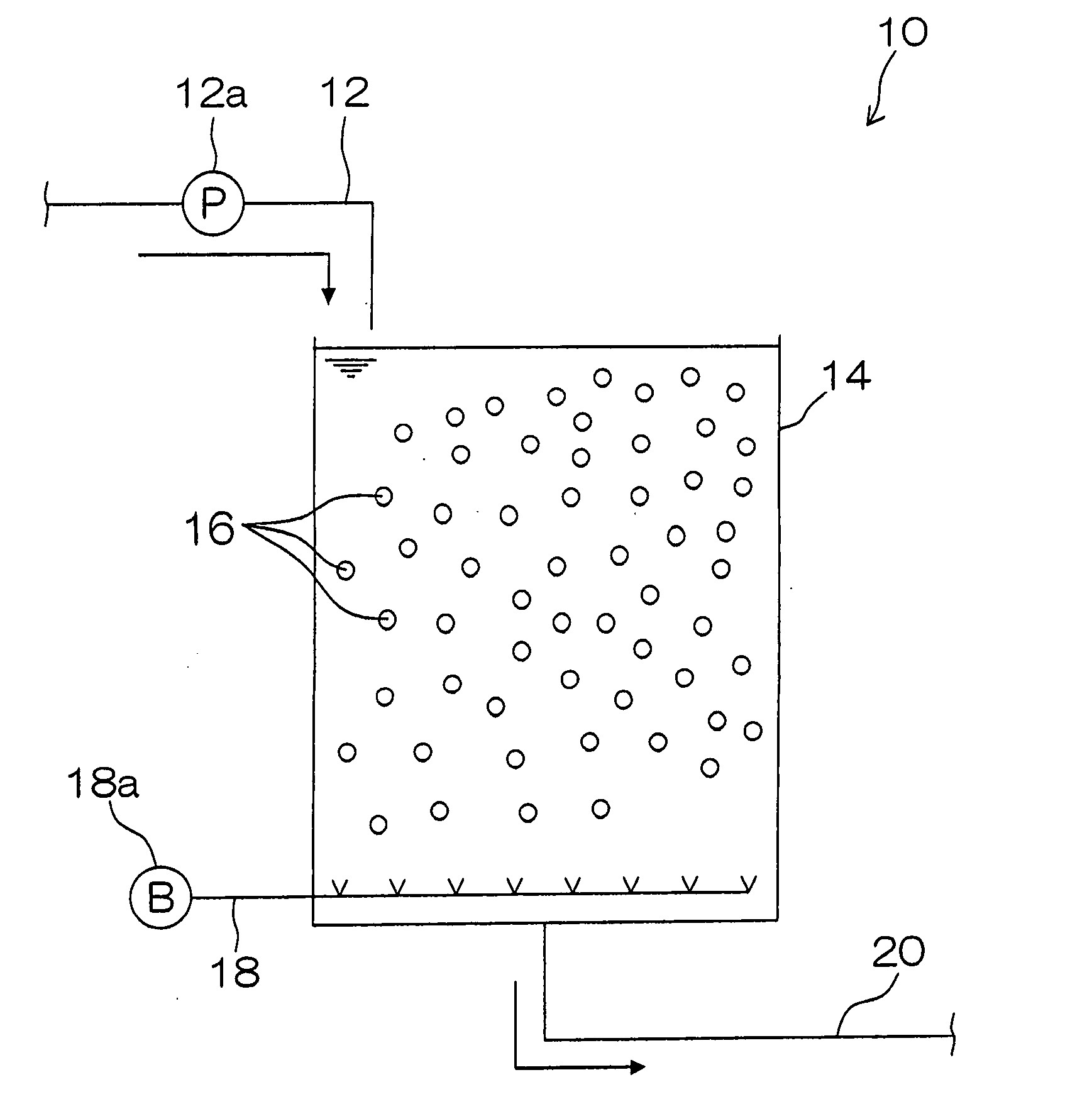

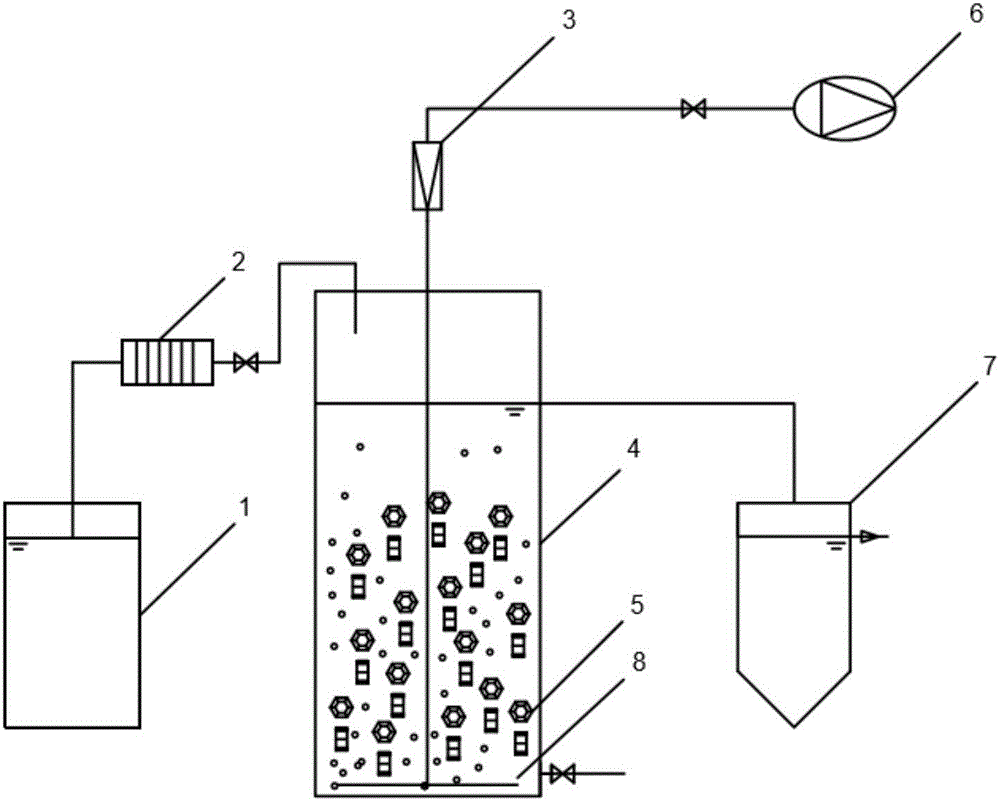

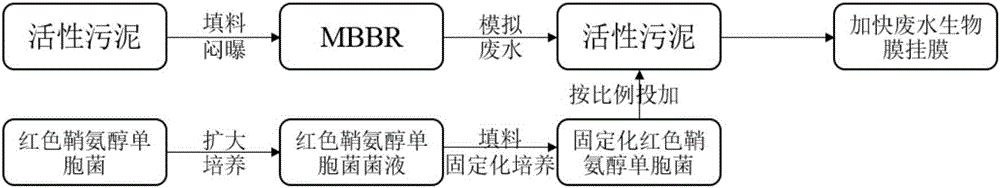

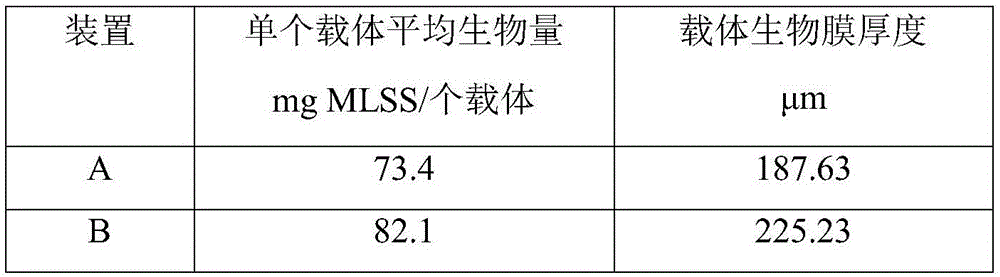

Device and method for rapid film culturing of wastewater biofilms

ActiveCN106430560AHang film fastEasy to operateSustainable biological treatmentBiological water/sewage treatmentAeration rateBiological membrane

The invention discloses a device and method for rapid film culturing of wastewater biofilms, and belongs to the technical field of wastewater treatment. For the problems of long film culturing time, weak firmness and easy falling of the wastewater biofilms in the prior art, the invention provides the device and method for the rapid film culturing of the wastewater biofilms. The device for the rapid film culturing of the wastewater biofilms comprises an MBBR, a water inlet tank is connected at the front end of the MBBR through a dosing pump, a sedimentation tank is connected at the rear end of the MBBR, an air pump supplies air for the MBBR through a pipeline, and an aerator is arranged at the bottom of the MBBR. The method for the rapid film culturing of the wastewater biofilms comprises the following steps: (1) preparing a filler with immobilized red sphingomonas; (2) carrying out aeration treatment; (3) adding the filler in the MBBR which is aerated, and adding a certain amount of the filler to an original reactor; (4) maintaining the aeration rate and a corresponding pH value until the required biofilms are obtained. By adopting the device and method for the rapid film culturing of the wastewater biofilms, the effects of the rapid film culturing speed, firm biofilms and low falling possibility can be realized.

Owner:NANJING UNIV

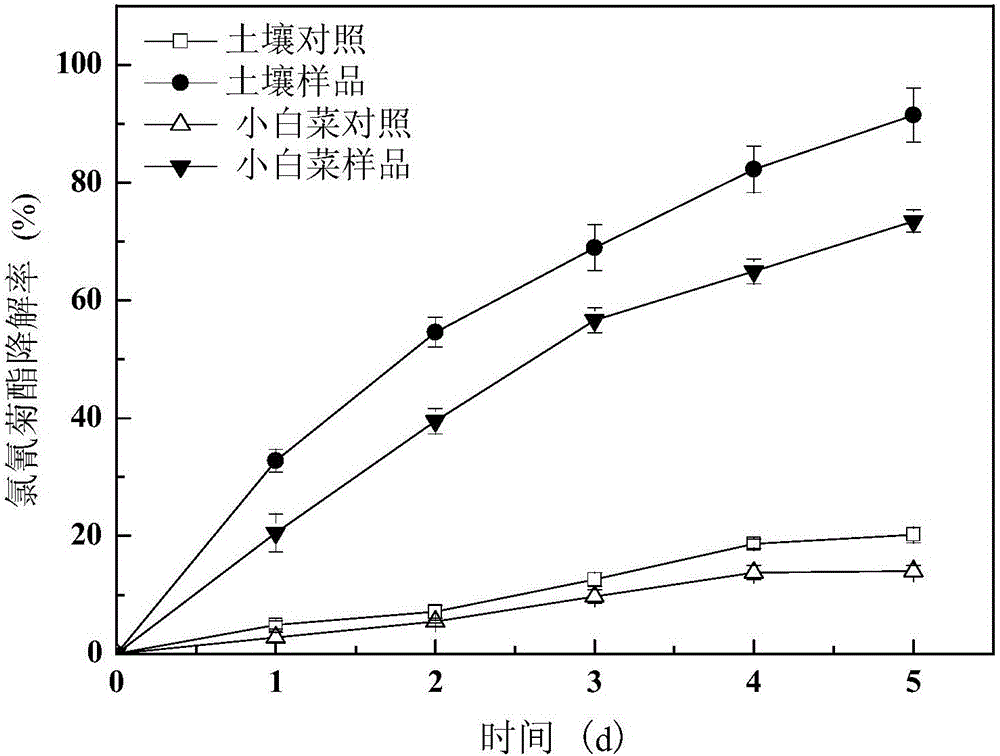

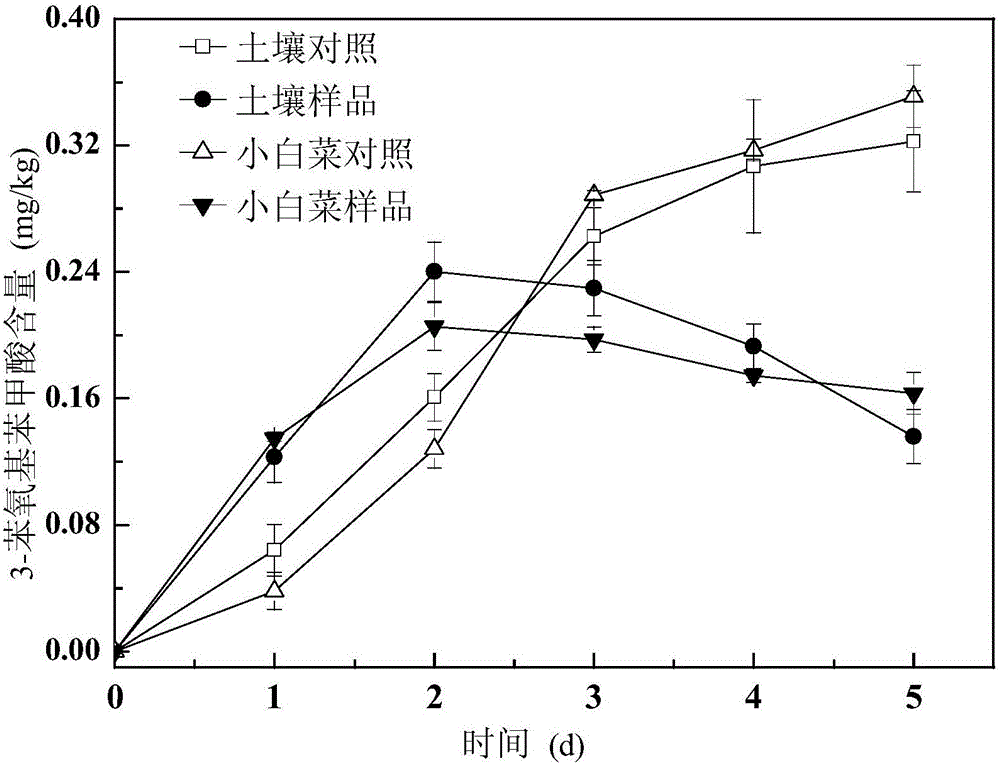

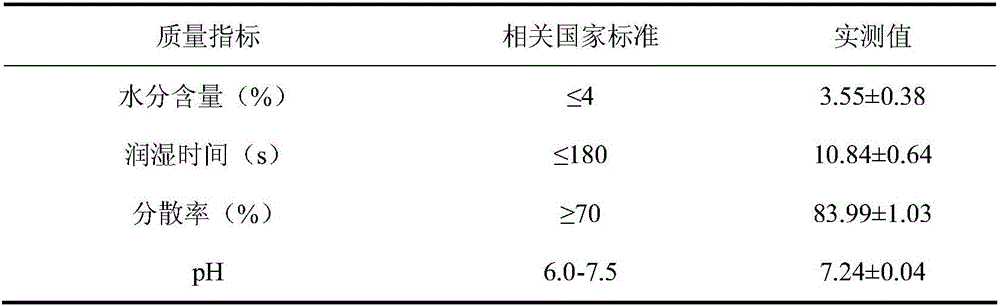

Wettability fungus powder capable of effectively degrading cypermethrin and 3-phenoxy benzoic acid and preparation method

ActiveCN105903148AResidual amount of 3-phenoxybenzoic acid decreasedGood dispersionContaminated soil reclamationBenzoic acidBiotechnology

The invention discloses wettability fungus powder capable of effectively degrading cypermethrin and 3-phenoxy benzoic acid and a preparation method. The wettability fungus powder comprises the raw materials of composite fungus liquid, diatomaceous earth, sodium lignin sulfonate, tween 80, skim milk powder and trehalose; and the composite fungus liquid consists of bacillus licheniformis B-1 fungus liquid and sphingomonas SC-1 fungus liquid. The method comprises the following steps: (1) the diatomaceous earth is added in the composite fungus liquid to obtain a carrier-fungus liquid mixture; the tween 80, the sodium lignin sulfonate, the skim milk powder and the trehalose are added in sterile water having the same volume with the composite fungus liquid to obtain auxiliary solution; and the auxiliary solution and the carrier-fungus liquid mixture are uniformly mixed to obtain fungicide mixed liquid; and (2) the fungicide mixed liquid obtained in the step (1) is dried by the following process parameters in sequence: a temperature from -46 to -48 DEG C is kept by 1.0-3.0 h; a temperature from -36 to -40 DEG C is kept by 1.0-3.0 h; a temperature from -26 to -30 DEG C is kept by 1.0-3.0 h; a temperature from -15 to -20 DEG C is kept by 1.0-3.0 h; a temperature from 0 to 4 DEG C is kept by 10-14 h; a temperature from 8 to 12 DEG C is kept by 1.0-3.0 h; a temperature from 30 to 40 DEG C is kept by 2.0-6.0 h; a temperature from 15 to 25 DEG C is kept by 20-24 h; and the wettability fungus powder is obtained.

Owner:黑龙江棒星食品科技股份有限公司

Preparation and method for restoring ammonia nitrogen-containing industrial sewage

ActiveCN103305443AEasy to prepareSimple and fast operationFungiBacteriaBacillus licheniformisArthrobacter globiformis

The invention discloses a preparation for restoring ammonia nitrogen-containing industrial sewage. The preparation is prepared from the following components: 100 parts of thiobacillus denitrificans, 80 parts of bacillus licheniformis, 60 parts of sphingomonas, 50 parts of phanerochaete chrysosporium, 40 parts of arthrobacter globiformis, 30 parts of alcaligenes faecalis, 10 parts of pseudomonas aeruginosa and 10 parts of bacillus cereus. The invention also discloses a preparation method of the preparation. The preparation disclosed by the invention is suitable for the treatment of high-ammonia nitrogen industrial sewage, is energy-saving and environment-friendly, and has better application prospects.

Owner:山东天智信息科技有限公司

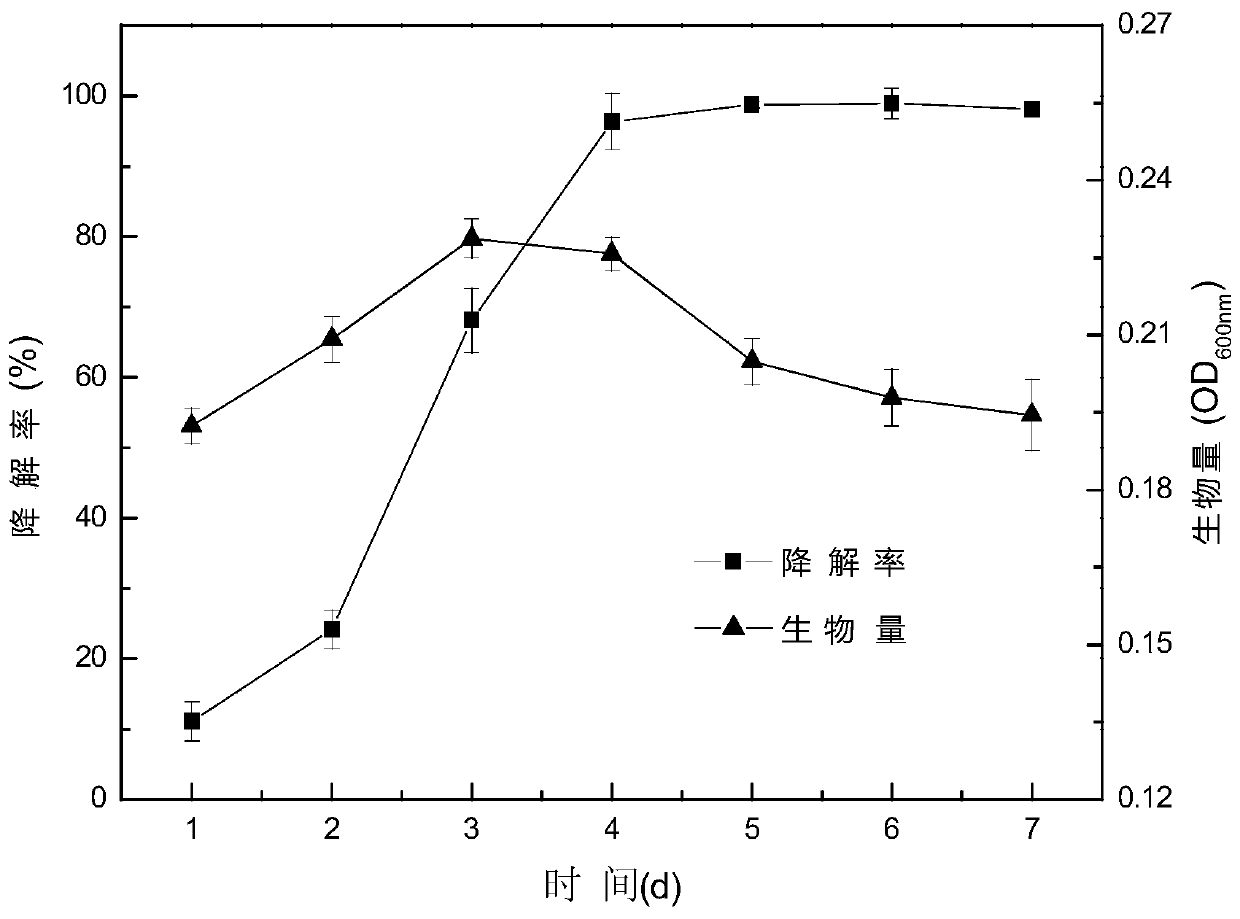

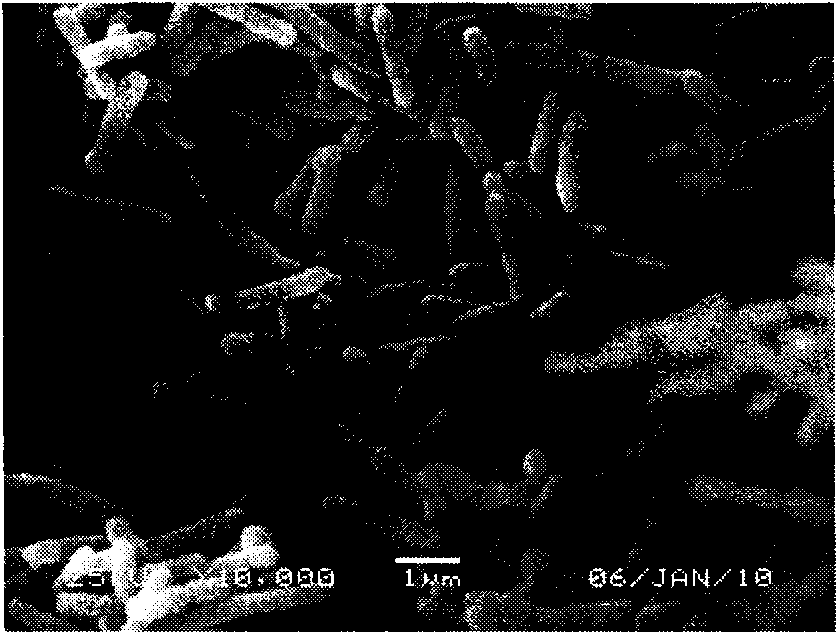

Sphingomonas capable of degrading triphenyl phosphate and domestication method and application thereof

The invention discloses a sphingomonas capable of degrading triphenyl phosphate and a domestication method and an application thereof. The Sphingomonas is preserved in the Guangdong Provincial Collection of Microorganisms and Cultures on April 19, 2019, and a preservation number is GDMCC No: 60633. The domestication method of the strain comprises the following steps: using a gradient concentration method to perform domestication of the triphenyl phosphate degrading bacteria, and separating and purifying the material to obtain the Sphingomonas sp. GY-1. The strain has the good degradation effect on triphenyl phosphate, and the use of the bacteria to treat polluted water bodies is low in cost. The Sphingomonas sp.GY-1provided by the present invention has the degradation rate on triphenyl phosphate to 98.77% after 5d, and the practical application value is high, which can provide a reference for solving the pollution control problem of an organic phosphorus flame retardant in water.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing a welan gum

ActiveCN1844155AImprove temperature resistanceViscosity does not decayFermentationGellan gumMicroorganism

This invention belonging to fermentation microbiology and extraction is a preparation method of mild-wheel gel. We use Sphingomonas sp CGMCC1561 as engineering strain, ferment under the conditions of 25-36deg C and PH 6.2-6.7, and extract mild-wheel gel from fermentation product. This invention overcomes many difficulities in previous methods, such as low adhesiveness (lower than 100cp), PH condition change in fermentation, high cost on medium, low durability of highly-densed calcium ion and so on.

Owner:HEBEI HENBO BIO TECH

High-efficiency strain for degrading polycyclic aromatic hydrocarbon and construction method and application thereof

ActiveCN101948772ALow costSimple and fast operationBacteriaHybrid cell preparationMicroorganismPolycyclic aromatic hydrocarbon

The invention discloses a high-efficiency strain for degrading polycyclic aromatic hydrocarbon and a construction method and application thereof. Microbial parents provided by the invention are two gram negative bacteria, namely GY2B (sphingomonas) and GP3A (Pesudomonas); protoplasts of the two strains are fused; and genetic engineering special bacteria are constructed by recombining genes of the parents in the same cell. The high-efficiency strain combines the advantages of high degradability and high adaptability of two parent strains and is favorable for processing the polycyclic aromatic hydrocarbon PAHs.

Owner:广州市佳境水处理技术工程有限公司

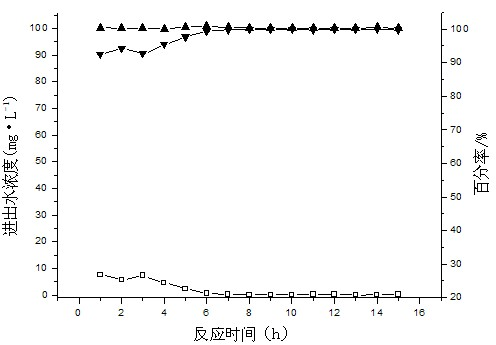

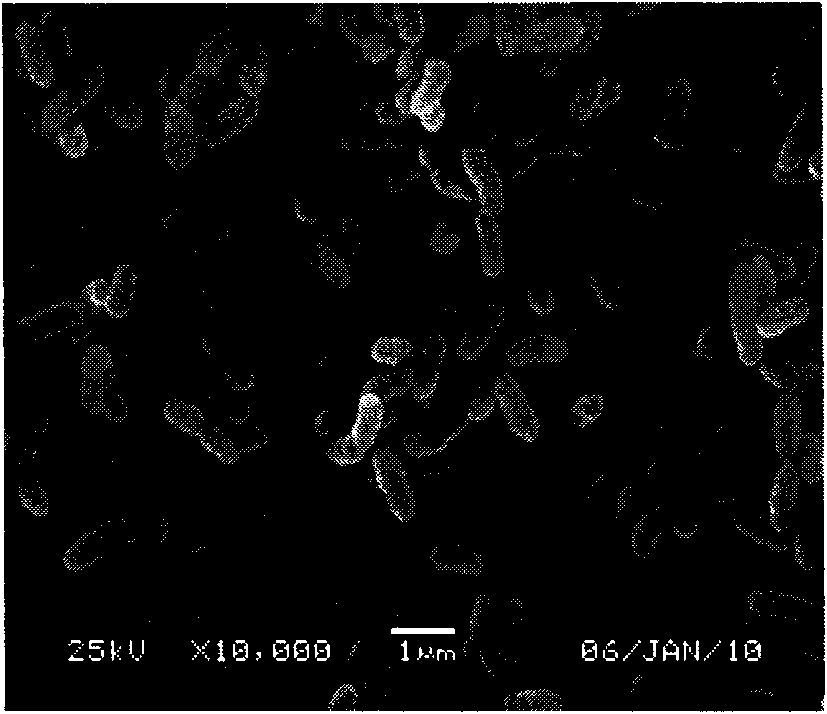

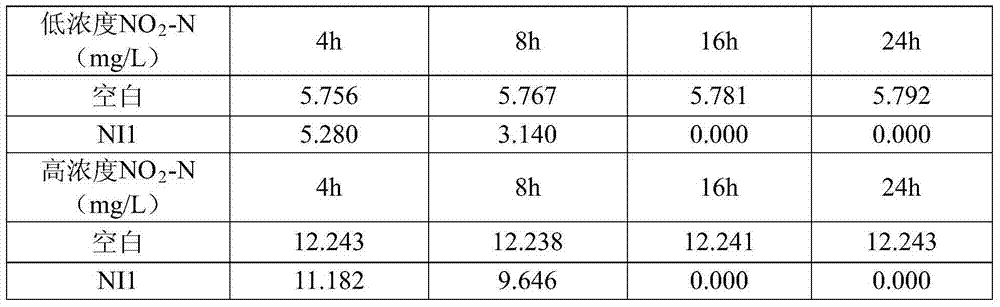

Sphingomonas paucimobilis

ActiveCN103484412AReduce nitrate nitrogenPromote degradationBacteriaMicroorganism based processesMicroorganismSphingomonas paucimobilis

The invention relates to the technical field of microorganism application, and particularly provides a sphingomonas paucimobilis strain. The sphingomonas paucimobilis strain is preserved in China center for type culture collection (CCTCC) in Wuhan University, Wuhan, China on September 29, 2013 with the preservation number of CCTCC NO: M2013456. The sphingomonas paucimobilis NI1 strain has an aerobic denitrification capacity, has simple nutritional requirements, can remarkably reduce nitrate nitrogen and nitrite nitrogen in a water body, can also effectively lower the content of ammonia nitrogen in domestic sewage, can be developed into an aquatic product microecological preparation, and has wide application prospect.

Owner:QINGDAO VLAND BIOTECH GRP

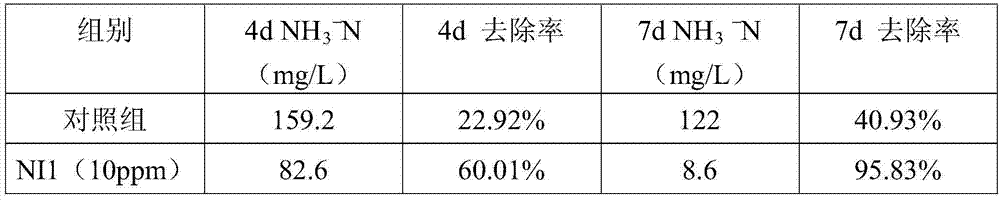

Mutant carotenoid ketolases

InactiveUS20070238149A1Improve conversion abilityHigh synthetic activityFungiBacteriaHeterologousAstaxanthin

CrtW carotenoid ketolases are provided that are useful for the production of astaxanthin and other cyclic ketocarotenoids. The mutant ketolase genes of the present invention encode polypeptides characterized by an improvement in astaxanthin synthesis activity when converting cyclic hydroxylated carotenoid intermediates into astaxanthin. Expression of the mutant carotenoid ketolases in heterologous hosts enabled increased production of astaxanthin relative to the Sphingomonas melonis DC18 CrtW.

Owner:EI DU PONT DE NEMOURS & CO

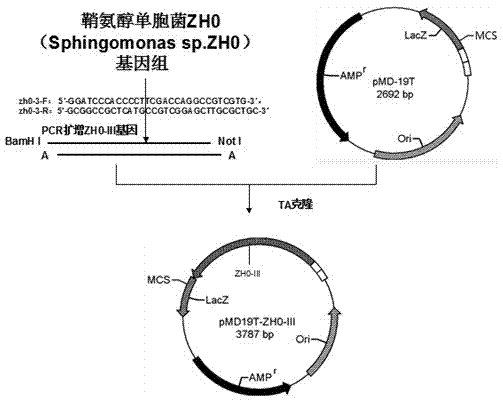

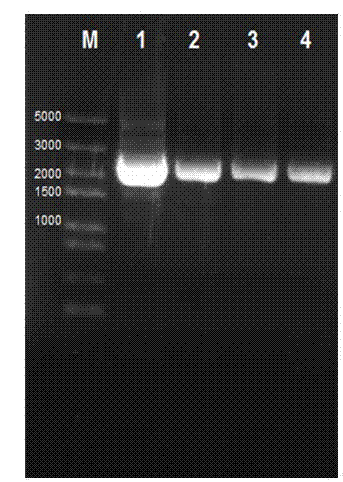

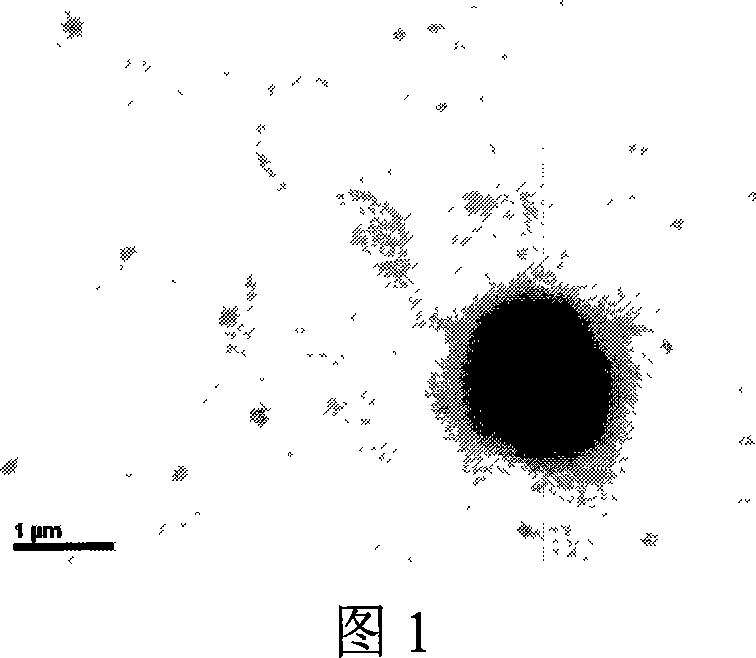

Sphingomonas alginate lyase gene ZH0-III as well as prokaryotic expression vector and application thereof

InactiveCN103173475ASolve the problem of low enzyme productionBroad substrate specificityMicroorganism based processesFermentationEscherichia coliProkaryotic expression

The invention discloses a sphingomonas alginate lyase gene ZH0-III and an efficient prokaryotic expression vector pGEX-4T-1-ZH0-II thereof. A Ptac promoter is utilized to control the expression of the prokaryotic expression vector pGEX-4T-1-ZH0-II in colon bacillus. The expression of the alginate lyase gene is performed by the colon bacillus expression vector, so that the alginate lyase ZH0-III as an express product can be obtained in a short time. The obtained recombinant alginate lyase gene ZH0-III is wide in substrate specificity, wherein the PloyG or the PloyM can be served as a substrate; and the enzyme activity can reach 63.8U / mg. The prokaryotic expression vector and the overall expression system are easy to operate, and are convenient for industrialized production.

Owner:KUNMING UNIV OF SCI & TECH

Novel strain sphingosine gingivalis ZUTE03 for producing coenzyme Q10 and uses thereof

InactiveCN101177670AHigh recovery rateReduce consumptionBacteriaFermentationSaponificationCo enzyme q10

The invention provides a new strain Sphingomonas sp.ZUTE03 that can produce coenzyme Q10 and is preserved in China Center for Type Culture Collection (CCTCC) on June 18, 2007, and the preservation number is CCTCC No. M207084. When the leavening of the invention is used for preparing the coenzyme Q10, a new technology of synchronization saponification extraction is adopted, which can save manpower, reagent and time with convenience and can improve the efficiency of the extraction technique for the coenzyme Q10 under the condition of nearly no damage of products.

Owner:ZHEJIANG UNIV OF TECH

Immobilized algae-lysing microorganism as well as preparation method and application thereof

InactiveCN108103051ALarge specific surface areaImprove adsorption capacityMicroorganism based processesOn/in organic carrierPseudomonasBioremediation

The invention provides an immobilized algae-lysing microorganism as well as a preparation method and an application thereof. The immobilized algae-lysing microorganism is prepared from raw materials in percentage by mass as follows: 40%-60% of algae-lysing microorganisms, 30%-50% of a carrier and 10%-20% of an immobilization material, wherein the algae-lysing microorganisms are one or more of bacillus, streptomyces, pseudomonas, sphingomonas, mycobacterium and shewanella with algae-lysing activity and are liquid, powdery or granular substances, with the viable count not lower than 1.0*10<10> cfu / g. The immobilized algae-lysing microorganism has a large specific surface area, good adsorption performance, high algae-lysing efficiency and environment adaptability, no secondary risk and the like, particularly has remarkable algae-lysing effects on microcystis, anabaena, aphanizomenon and other typical harmful algae and has better application prospects in the field of bioremediation of eutrophic water.

Owner:无锡市拜沃特环保科技有限公司 +1

Compositions and methods of using a regulator of biopolymer production

InactiveUS20060019354A1Suppressing exopolysaccharide productionSugar derivativesBacteriaBiotechnologyBiopolymer

The present invention provides nucleic acid sequences and variants thereof capable of modulating exopolysaccharide production in Sphingomonas, and provides methods of using such nucleic acid sequences to generate bacteria that hyper-produce exopolysaccharide in slime form.

Owner:SHIN ETSU CHEM IND CO LTD

The co-culture method of sphingomonas sp. bacterial strain and aspergillus sp. fungus strain, new Anti-cancer and antibiotic glionitrins derived from this co-culture method, and pharmaceutical composition containing glionitrins or pharmaceutically acceptable salt thereof as an active ingredient

The present invention relates to a co-culture method of Sphingomonas sp. bacterial strain and Aspergillus sp. fungus strain, in which the novel Sphingomonas sp. bacterial strain KMK-001 is cultured in a liquid medium and the novel Aspergillus sp. strain KMC-901 separately cultured in another liquid medium is added to the above culture solution, a novel glionitrin biosynthesized therefrom and a pharmaceutical composition comprising the said glionitrin or its pharmaceutically acceptable salt as an active ingredient. The glionitrin herein has strong cytotoxic effect on cancer cells and has antibiotic effect on 10 pathogenic bacteria including the novel Sphingomonas sp. bacterial strain KMK-001, so that it can be effectively applied in antibiotics or anti-cancer agents.

Owner:KOREA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com