Gellan gum efficient production strain and its application

A technology for producing strains, gellan gum, applied in the direction of bacteria, microorganisms, microorganism-based methods, etc., can solve problems such as unreached, and achieve the effect of increasing sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

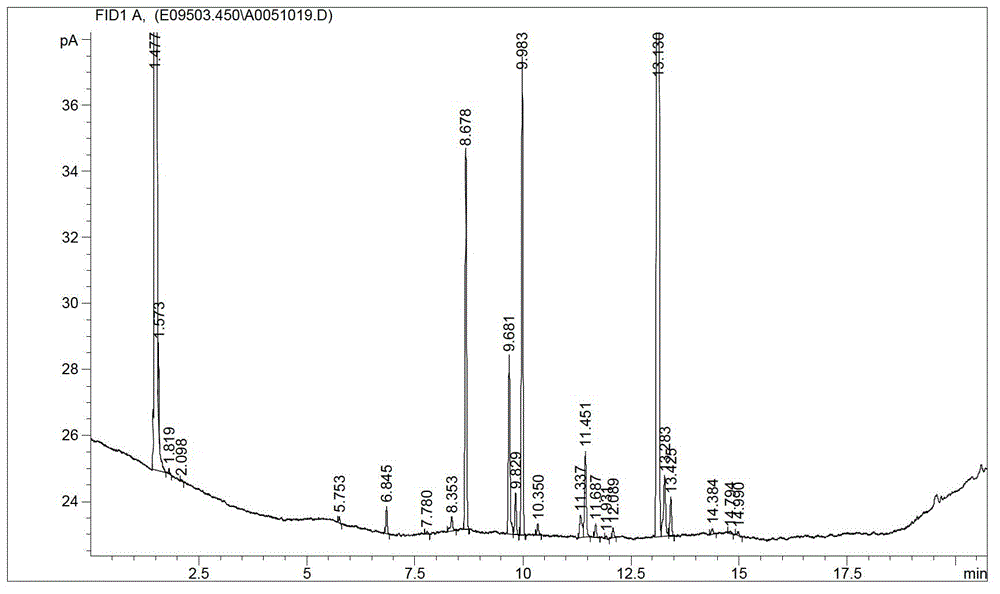

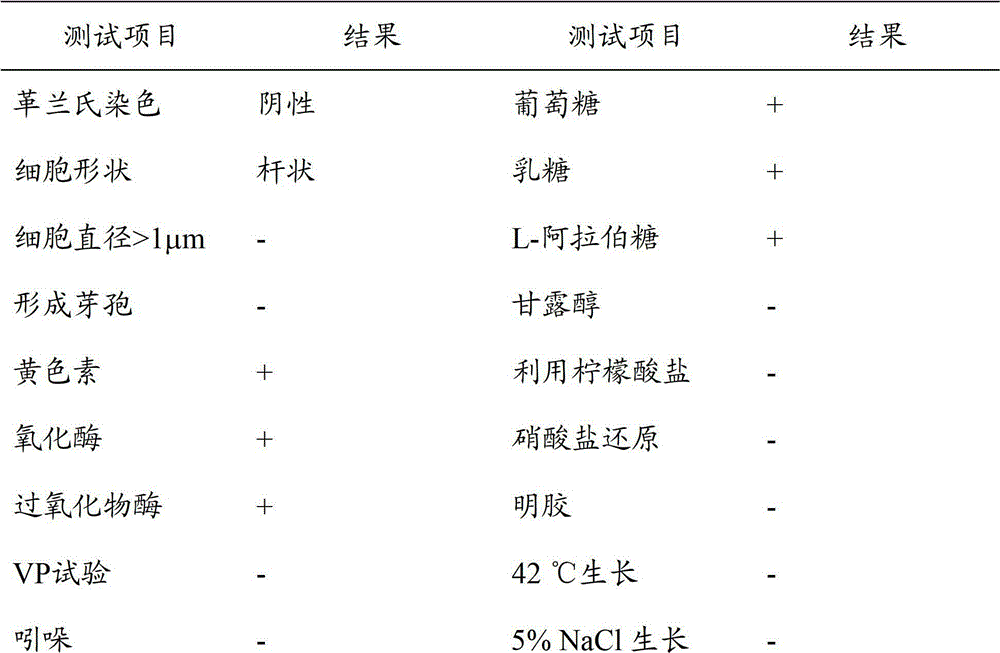

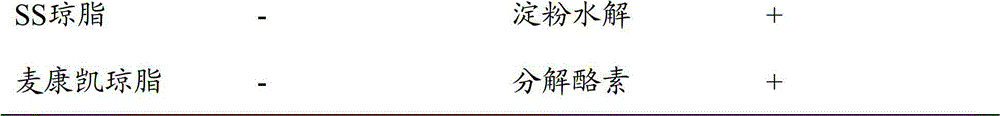

Image

Examples

Embodiment 1

[0056] (1) Activation of the Sphingomonas paucimobilis strain FJAT-5627: Streak inoculation of the Sphingomonas paucimobilis strain FJAT-5627 described in claim 1 on the strain culture base, and cultured in a constant temperature incubator for 48 hours, and the culture temperature was set at 30±1°C; among them, the components of the strain culture medium: beef extract 0.3%, peptone 0.5%, glucose 1.0%, yeast extract 0.1%, Agar powder 1.8%, prepared with distilled water, pH7.2;

[0057] (2) Preparation of seed liquid: Inoculate a single colony of Sphingomonas paucimobilis strain FJAT-5627 obtained in step (1) into 350ml of seed liquid medium, and place it in a constant temperature shaker Shaking culture for 18 hours, temperature 30±1°C, speed 180r / min; Among them, the components of the seed liquid medium: 1.0% sucrose, 1.0% soluble starch, 0.3% peptone, 0.1% yeast powder, prepared with distilled water, pH 7.2;

[0058] (3) Preparation of fermentation broth: Transfer the seed li...

Embodiment 2

[0061] (1) Activation of the Sphingomonas paucimobilis strain FJAT-5627: Streak inoculation of the Sphingomonas paucimobilis strain FJAT-5627 described in claim 1 on the strain culture base, and cultured in a constant temperature incubator for 48 hours, and the culture temperature was set at 30±1°C; among them, the components of the strain culture medium: beef extract 0.3%, peptone 0.5%, glucose 1.0%, yeast extract 0.1%, Agar powder 1.8%, prepared with distilled water, pH7.2;

[0062] (2) Preparation of seed liquid: Inoculate a single colony of Sphingomonas paucimobilis strain FJAT-5627 obtained in step (1) into 350ml of seed liquid medium, and place it in a constant temperature shaker Shaking culture for 18 hours, temperature 30±1°C, speed 180r / min; Among them, the components of the seed liquid medium: 1.0% sucrose, 1.0% soluble starch, 0.3% peptone, 0.1% yeast powder, prepared with distilled water, pH 7.2;

[0063] (3) Preparation of fermentation broth: Transfer the seed li...

Embodiment 3

[0066] (1) Activation of the Sphingomonas paucimobilis strain FJAT-5627: Streak inoculation of the Sphingomonas paucimobilis strain FJAT-5627 described in claim 1 on the strain culture base, and cultured in a constant temperature incubator for 48 hours, and the culture temperature was set at 30±1°C; among them, the components of the strain culture medium: beef extract 0.3%, peptone 0.5%, glucose 1.0%, yeast extract 0.1%, Agar powder 1.8%, prepared with distilled water, pH7.2;

[0067] (2) Preparation of seed liquid: Inoculate a single colony of Sphingomonas paucimobilis strain FJAT-5627 obtained in step (1) into 350ml of seed liquid medium, and place it in a constant temperature shaker Shaking culture for 18 hours, temperature 30±1°C, speed 180r / min; Among them, the components of the seed liquid medium: 1.0% sucrose, 1.0% soluble starch, 0.3% peptone, 0.1% yeast powder, prepared with distilled water, pH 7.2;

[0068] (3) Preparation of fermentation broth: transfer the seed li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com