Patents

Literature

43 results about "Sphingomonas sp." patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

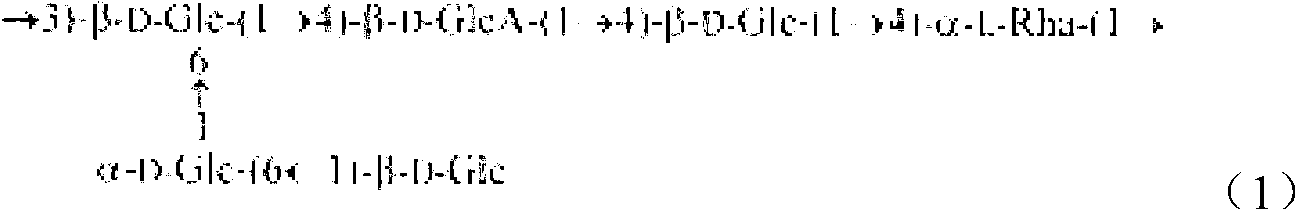

Sphingomonas sp. and application in preparation of rhamsan gum

ActiveCN103013863AEasy to operateExtensive culture conditionsBacteriaMicroorganism based processesInorganic saltsMicroorganism

The invention discloses sphingomonas sp. The sphingomonas sp. is named as sphingomonas sp. PG-8 and was collected in China General Microbiological Culture Collection Center (CGMCC), the registration number is CGMCC NO. 6833, and the collection data is November 15th, 2012. The invention also discloses application of the sphingomonas sp. in preparation of rhamsan gum. The strain is cultured in a culture medium containing carbon sources, nitrogen sources and inorganic salts, and 5 to 50g / L of rhamsan gum can be accumulated under optimized conditions. The strain can be cultured by using multiple carbon sources and nitrogen sources, the culture conditions are extensive, the operation is convenient and simple, the yield of the rhamsan gum is high, the production cost is low, and the rhamsan gum can be widely applied in the fields of food addition, petroleum drilling and the like.

Owner:NANJING UNIV OF TECH

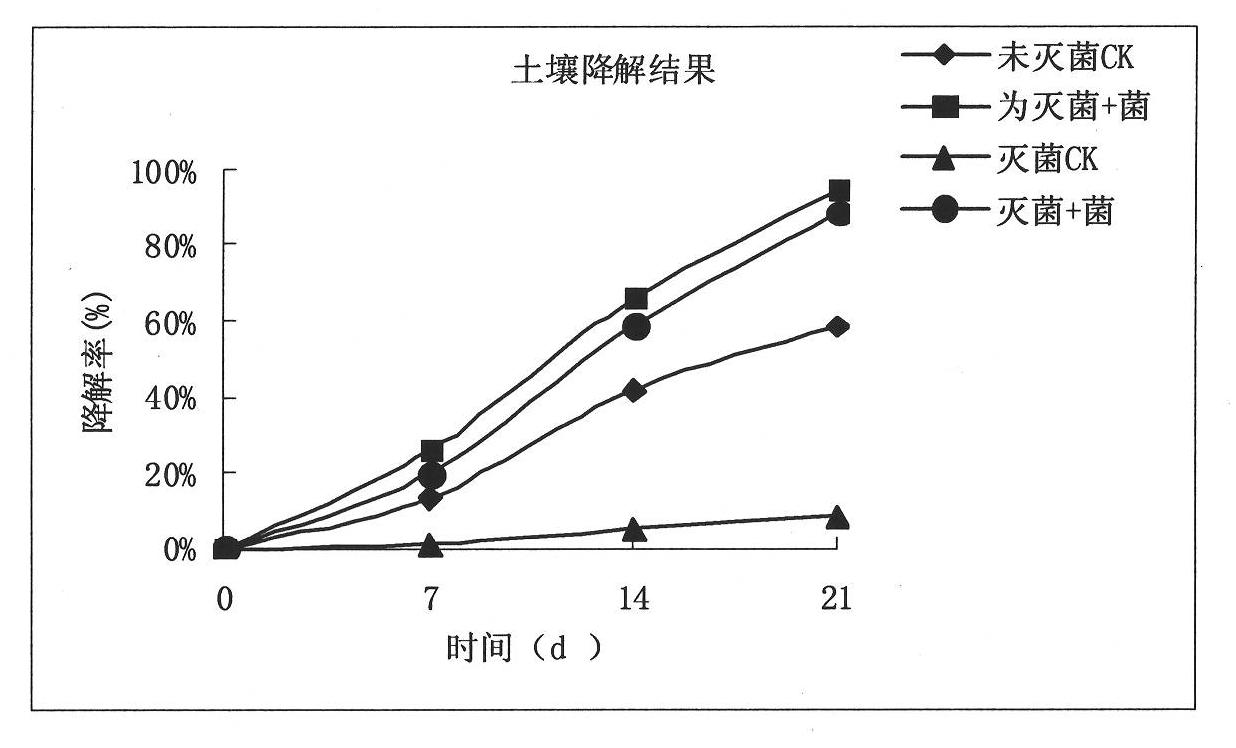

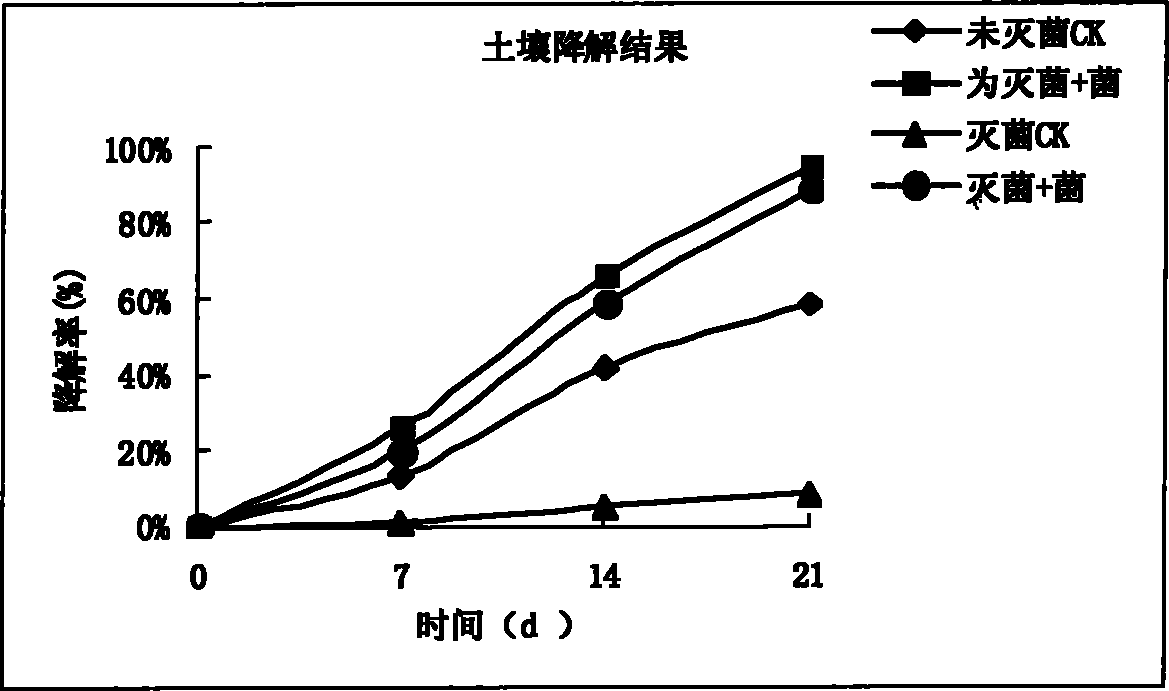

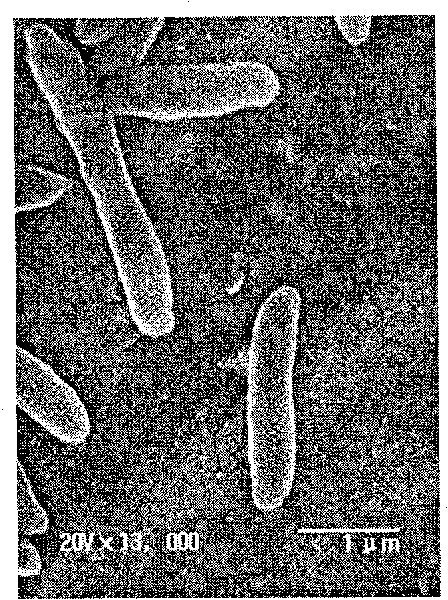

Bacterium for degrading chlorpyrifos pesticide residue and produced bacterium formulation

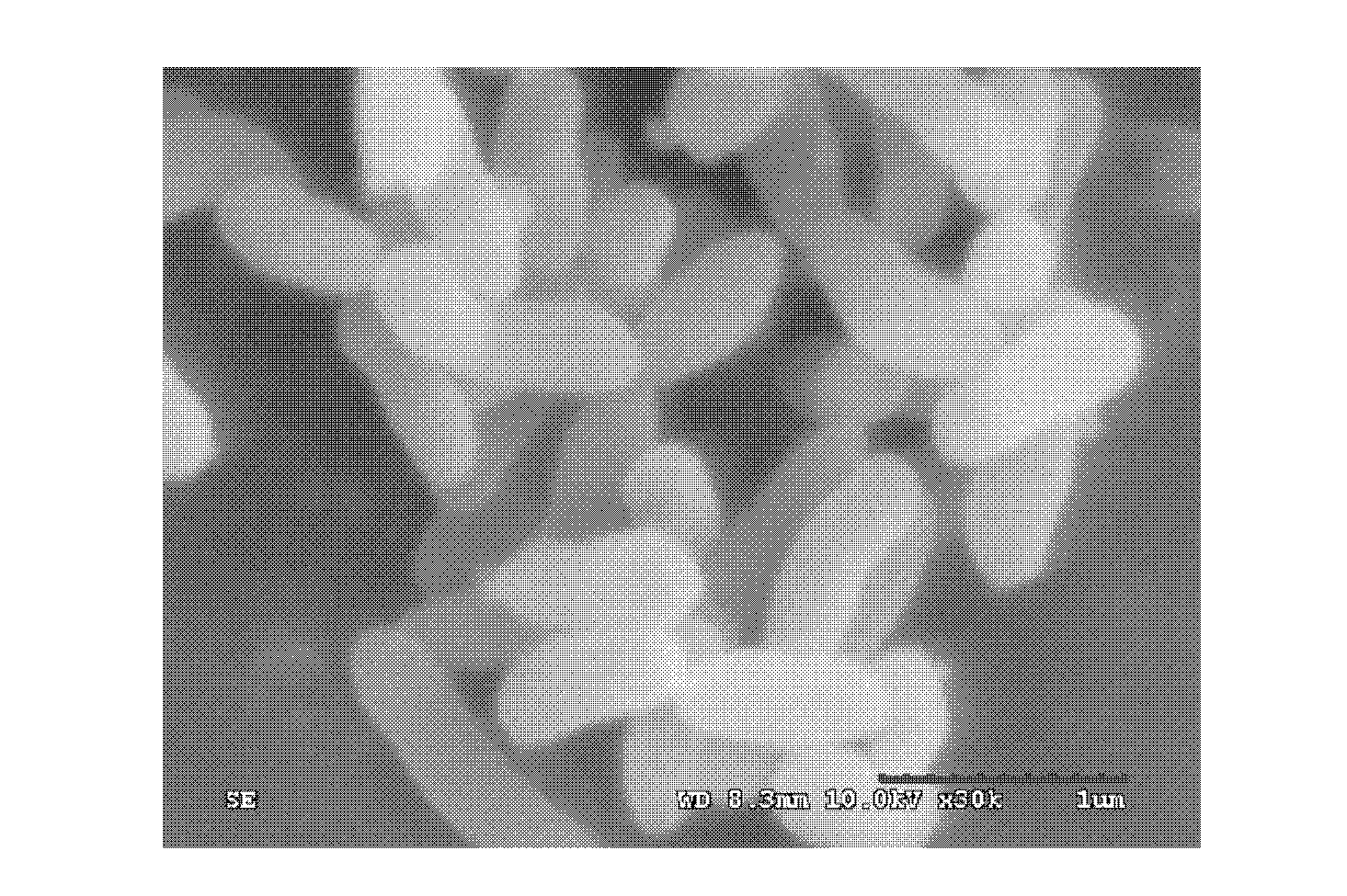

The invention provides a prodegradant which can dispel the organic phosphorus pesticide residue of chlorpyrifos. The used strain is Gram's stain reaction hysteroptosis Dsp-2 which is Sphingomonas sp. The main biology characteristic is G-; the thaliana is the rod type of asporous whose size is 1.0-1.5um; the scavenger enzyme is male and the oxidative enzyme is female which can not be hydrolysed starched and be gelatin liquidated; the methyl red reaction is female and not to produce the indole with the aquolysis temperature 80 deg. The Genbank landing number of the strain 16S rDNA is AY994060.

Owner:NANJING AGRICULTURAL UNIVERSITY

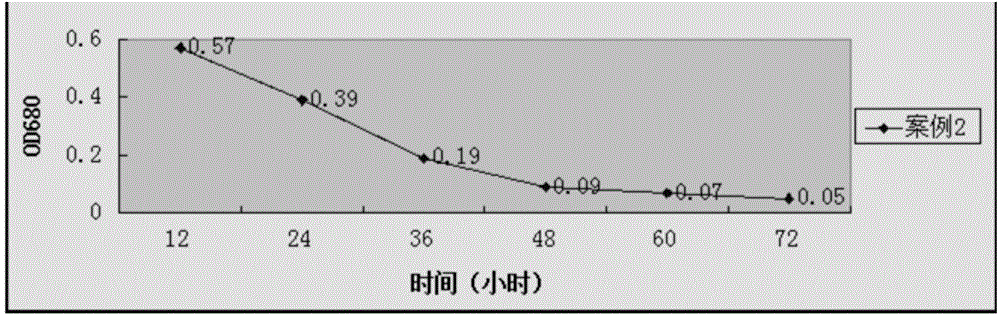

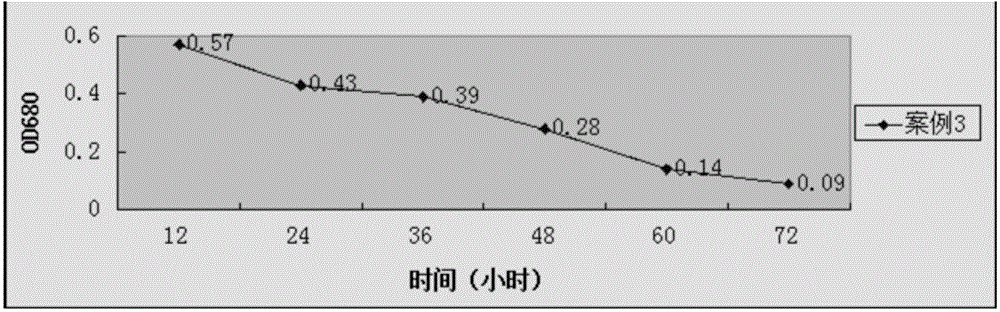

Alga lysing biological preparation and application thereof

ActiveCN105309479AAlgae-dissolving effect is goodEnhanced inhibitory effectBiocideDisinfectantsBacillus licheniformisVitamin C

The invention discloses an aga lysing biological preparation and an application thereof. The preparation is prepared through mixing Bacillus subtilis, Bacillus licheniformis, Bacillus laterosporus, Streptococcus faecalis, photosynthetic bacteria, Sphingomonas sp., vitamin C, vitamin E and lactose. The above product has good stability and high efficiency, and consumes an extremely low amount of oxygen and rapidly degrades microcystis and other pollutants in culture water in the application process in order to effectively improve the environment of the water. The preparation is nontoxic and harmless to environment, people and animals, has no residuals, can substantially improve and purify the environment and the culture body and effectively avoid bursting of cyanobacterial bloom, and also can improve the immunity of aquatic product animals and reduce the incidence of diseases to make the ecologic system of the whole culture water tend to balance and go well.

Owner:HUAZHONG AGRI UNIV

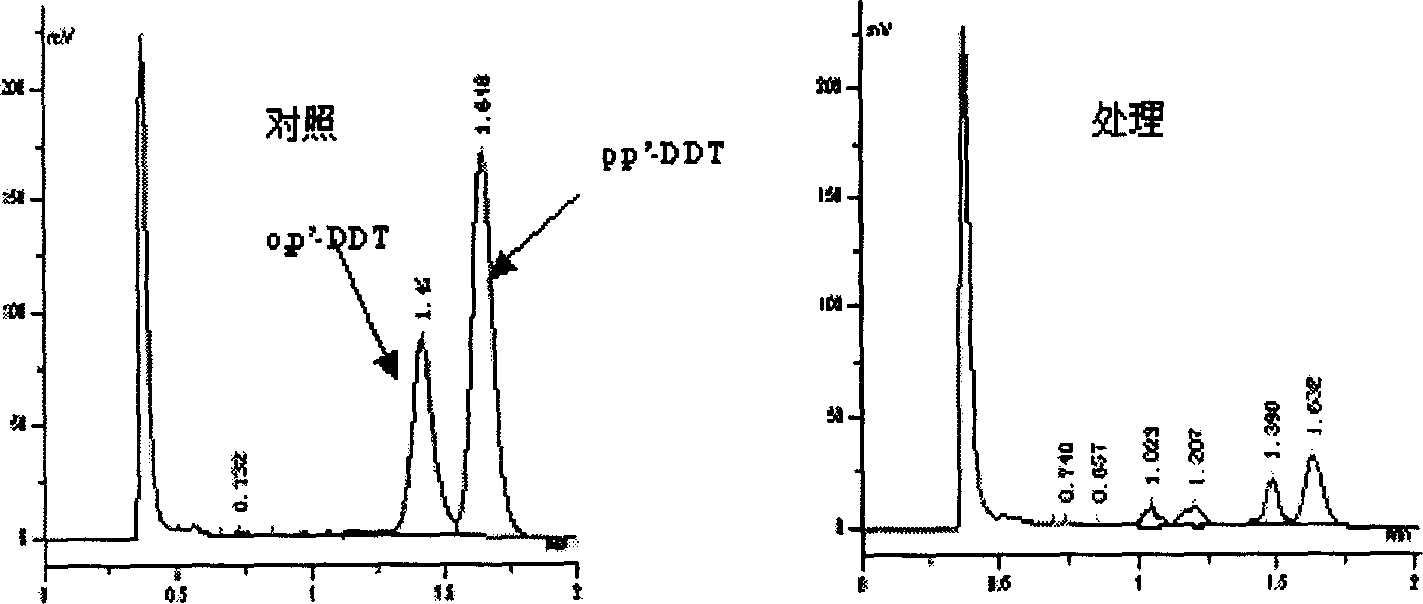

Degradating bacteria for hexachlorocyclohexane pesticide residue and its produced strain

InactiveCN1648238AEfficient degradationEfficient degradation efficiencyBacteriaMicroorganismSphingomonas sp.

The present invention provides a kind of bacteria preparation for efficiently degrading hexachlorocyclohexane (HCH) pesticide residue. The strain BHC-A is Sphingomonas sp., can growth with HCH as the unique carbon source and energy source, and degrade alpha-HCH, beta-HCH, gamma-HCH and delta-HCH in short time at high efficiency. The present invention solves the difficult problem of aerobically biodegrading beta-HCH, and can mineralize 5 mg / L beta-HCH completely within 12 hr. Applying the degrading bacteria product directly can lower the residual HCH amount in soil by over 95 % to lower the HCH residue in agricultural product.

Owner:NANJING AGRICULTURAL UNIVERSITY

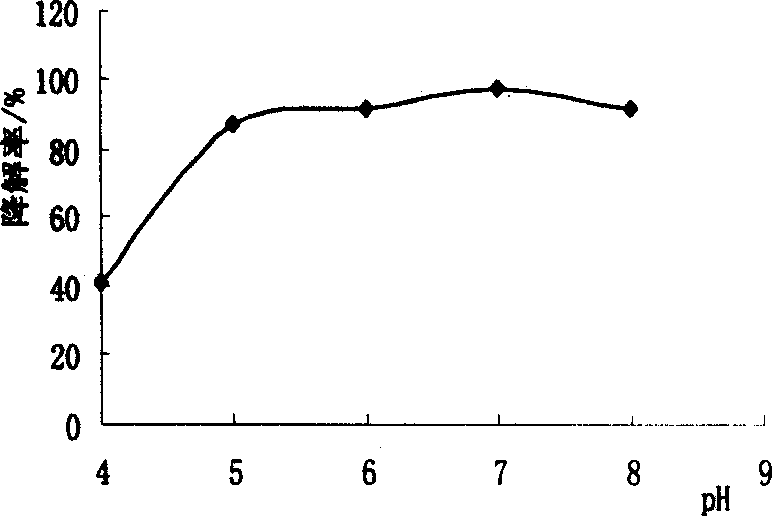

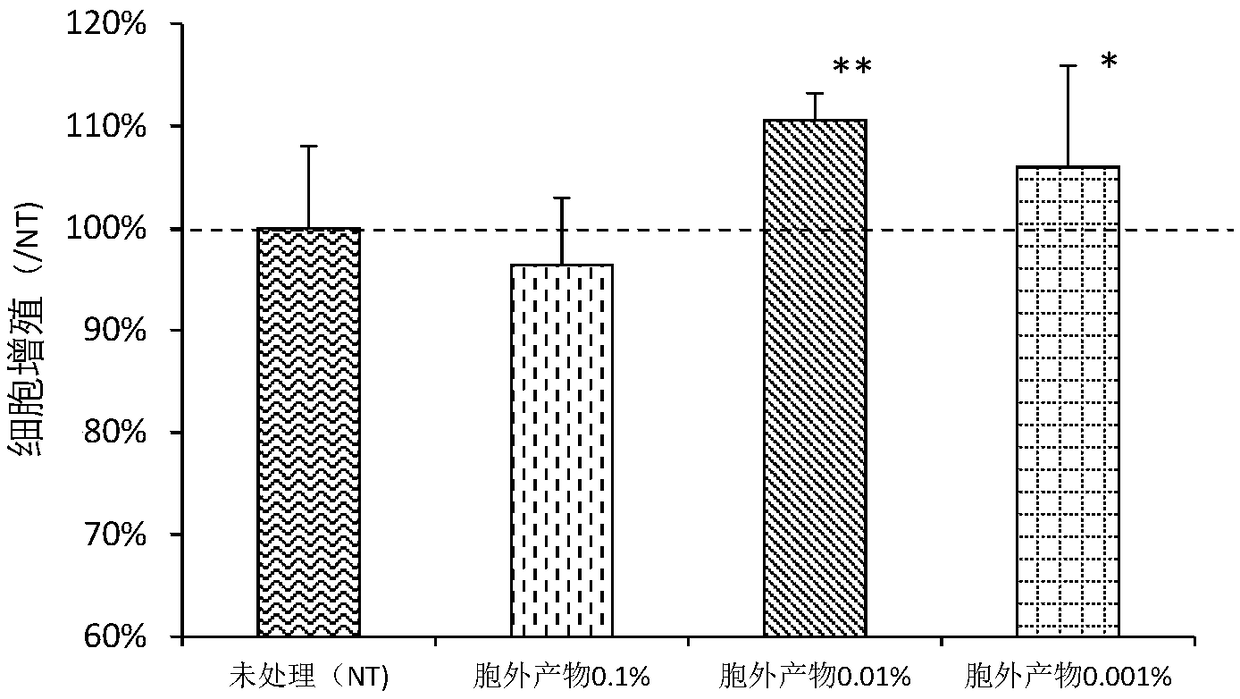

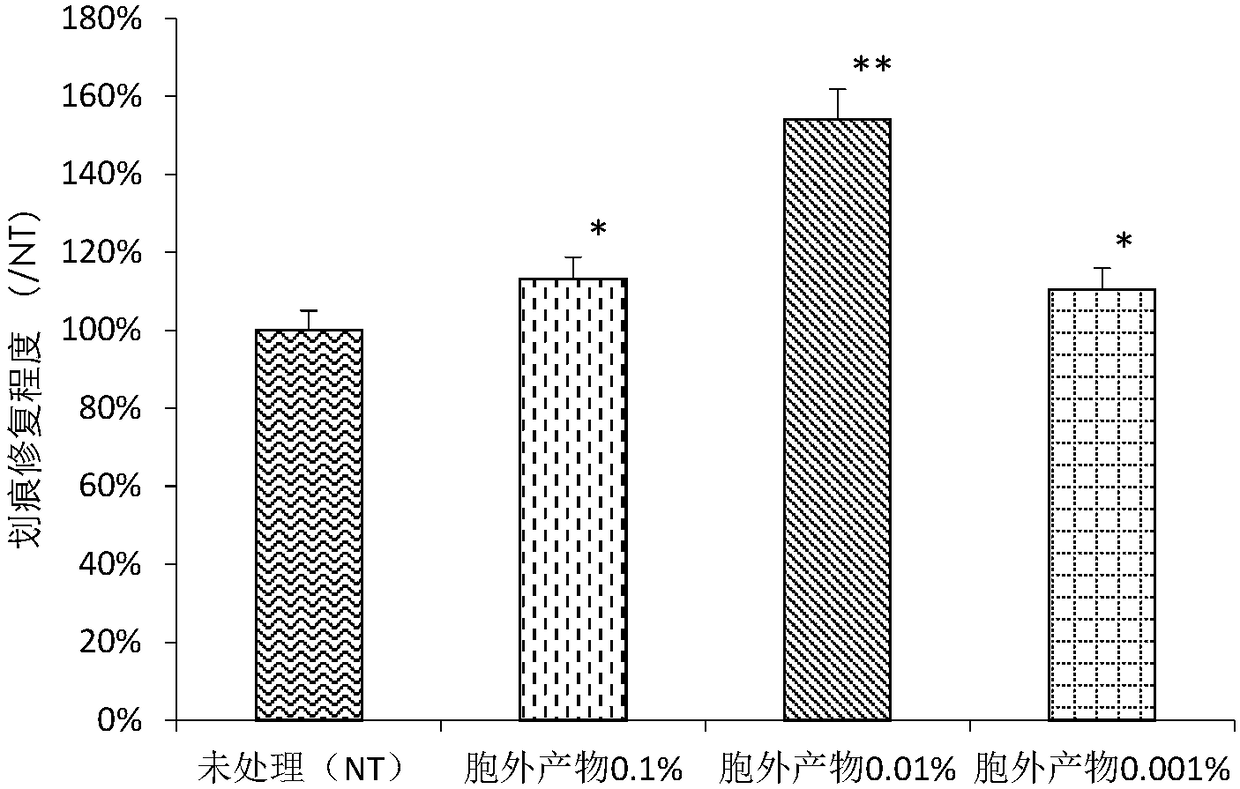

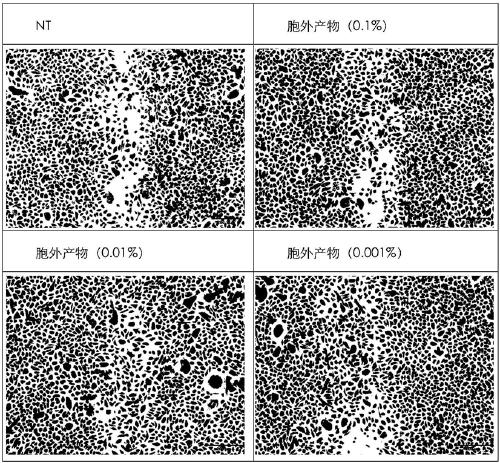

Sphingomonas sp., extracellular product thereof, preparation method and application thereof

ActiveCN109234180APromote proliferationPromote repairCosmetic preparationsBacteriaSphingomonas sp.Microbiology

The invention provides a Sphingomonas sp., an extracellular product thereof, and a preparation method. The sphingomonas sp. Is Sphingomonas sp. JA. Deposited as CCTCC NO: M 2017211. MS-001-A-04 strain. The invention also discloses the application of the extracellular product of Sphingomonas sp. In skin cell proliferation, repair and anti-aging, as well as an anti-aging preparation containing the extracellular product of Sphingomonas sp. For promoting cell proliferation and / or migration.

Owner:JALA GROUP CORPORATION

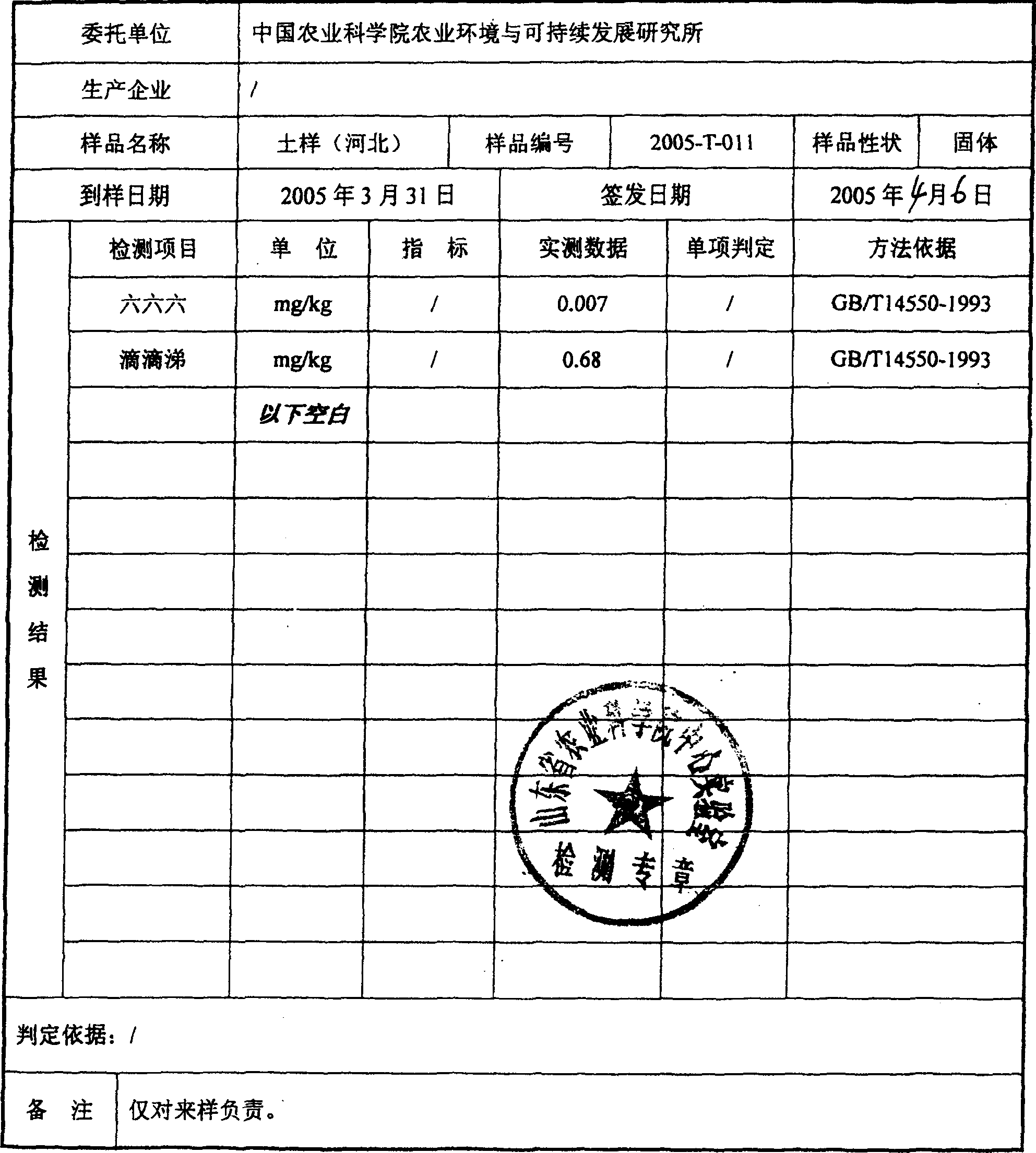

DDT pesticide residue degradation bacterium and produced bacterium agent

InactiveCN1793334AEasy to useReduce production and use costsBacteriaSphingomonas sp.Pesticide residue

The invention provides DDT pesticide residue degrading bacterial and its produced bacterial agent. The used strain is gram stain reaction positive bacterial strain DB-1. And it is sphingomonas sp by identifying. Its main bionomics is G-; thallus is short baculiform and its size is 0.28 um-0.54um*0.69um-0.85umum its end has flagellum; concurrently character like oxygen; catalase and oxidase are positive; V.P. and indole reactions are negative; it can not hydrolyze starch, oxidize glucose to produce acid, and make litmus milk acid solidify. The strain 16S rDNA Genbank debarkation number is AY947554. The degrading bacterial product can reduce pesticide residue by over 90%, and produce green farm products.

Owner:NANJING AGRICULTURAL UNIVERSITY

Sphingomonas sp. and method for preparing diutan gum fermentation liquid by using same

ActiveCN104293720AIncrease production capacityHigh yieldBacteriaMicroorganism based processesSphingomonas sp.Culture fluid

The invention belongs to the preparation of microbial polysaccharides, and in particular relates to sphingomonas sp. and a method for preparing a diutan gum fermentation liquid by using the same. The method comprises the following steps: inoculating sphingomonas sp. with the collection number of CGMCC No.9531 into a sterilized culture solution containing a carbon source, a nitrogen source and necessary nutrient substances; adjusting the pH value of the culture solution, and performing aeration stirring fermentation; and performing process steps such as fermentation ending when the viscosity of the culture solution does not increase any more or the fermentation cycle of the culture solution is less than or equal to 65 hours. Sphingomonas sp. and the method for preparing the diutan gum fermentation liquid by using sphingomonas sp. disclosed by the invention can be used for solving the technical problems of high production cost, low yield and the like caused by unreasonable process design in the prior art, and have the advantages of high yield, good temperature resistance of products, low fermentation cost and the like.

Owner:张星昊

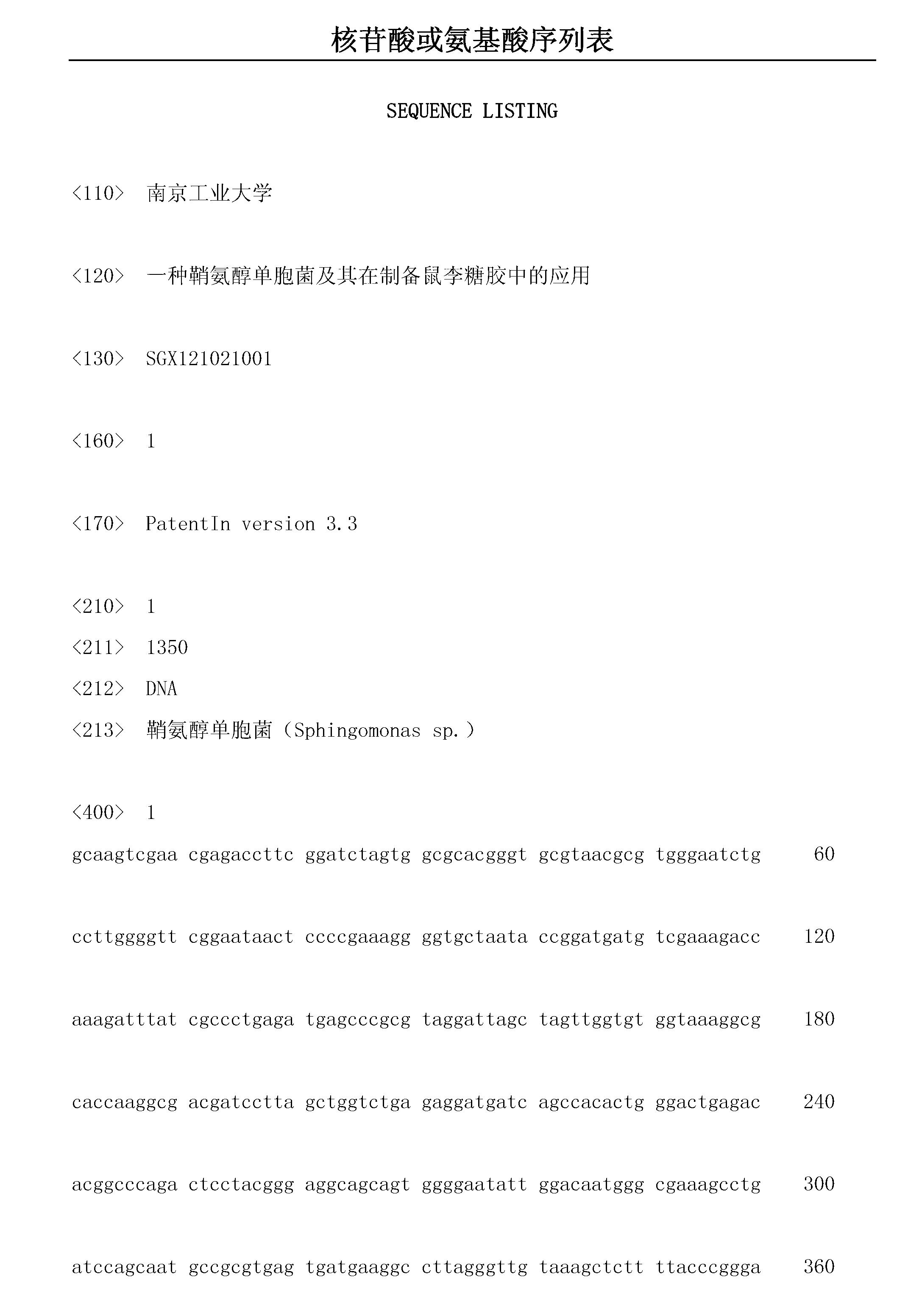

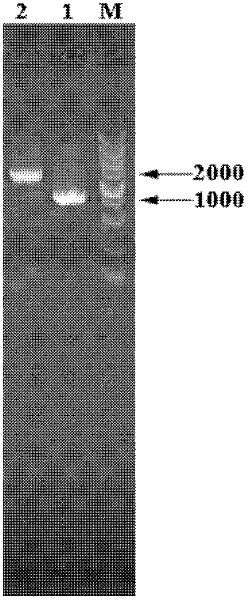

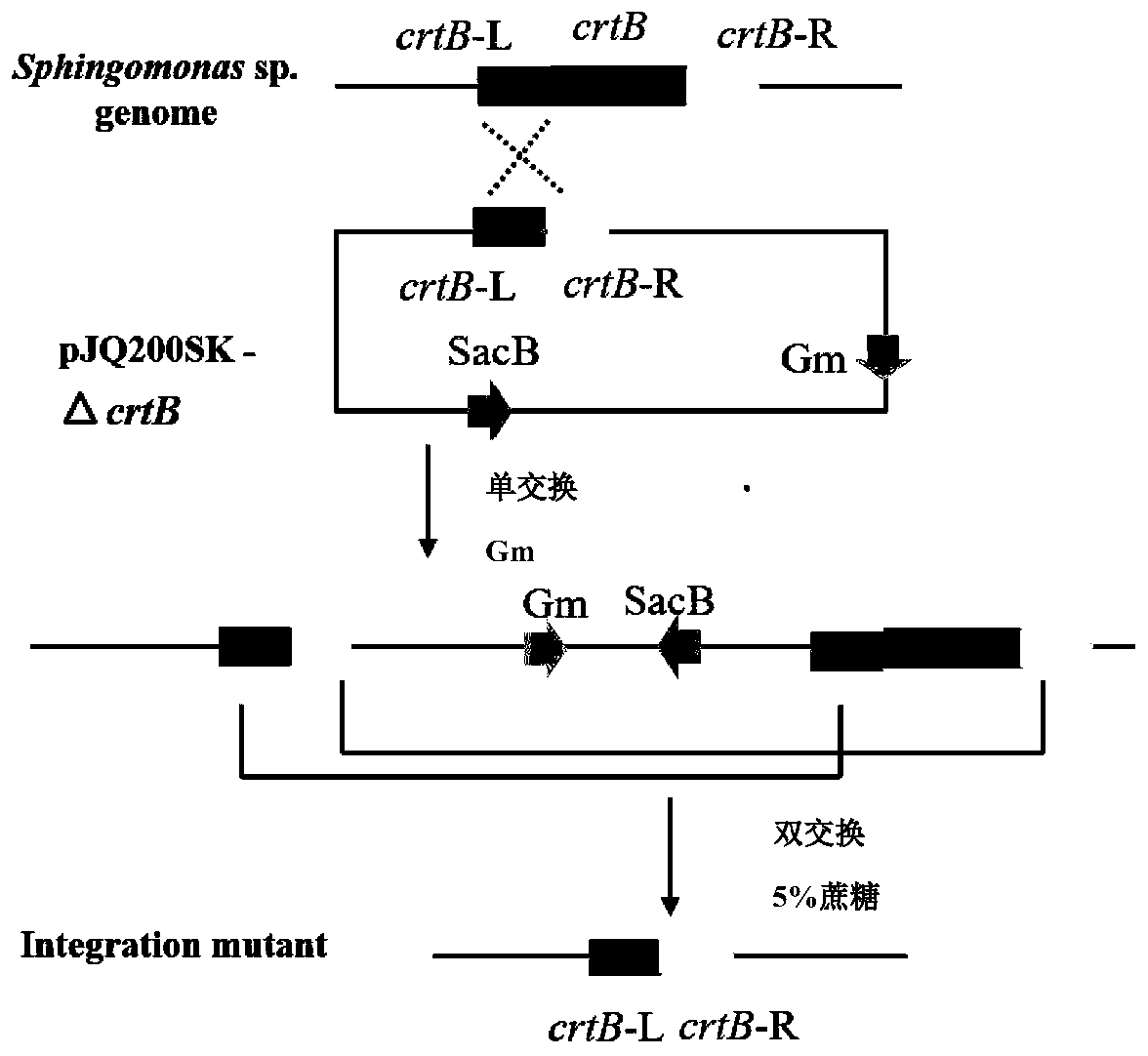

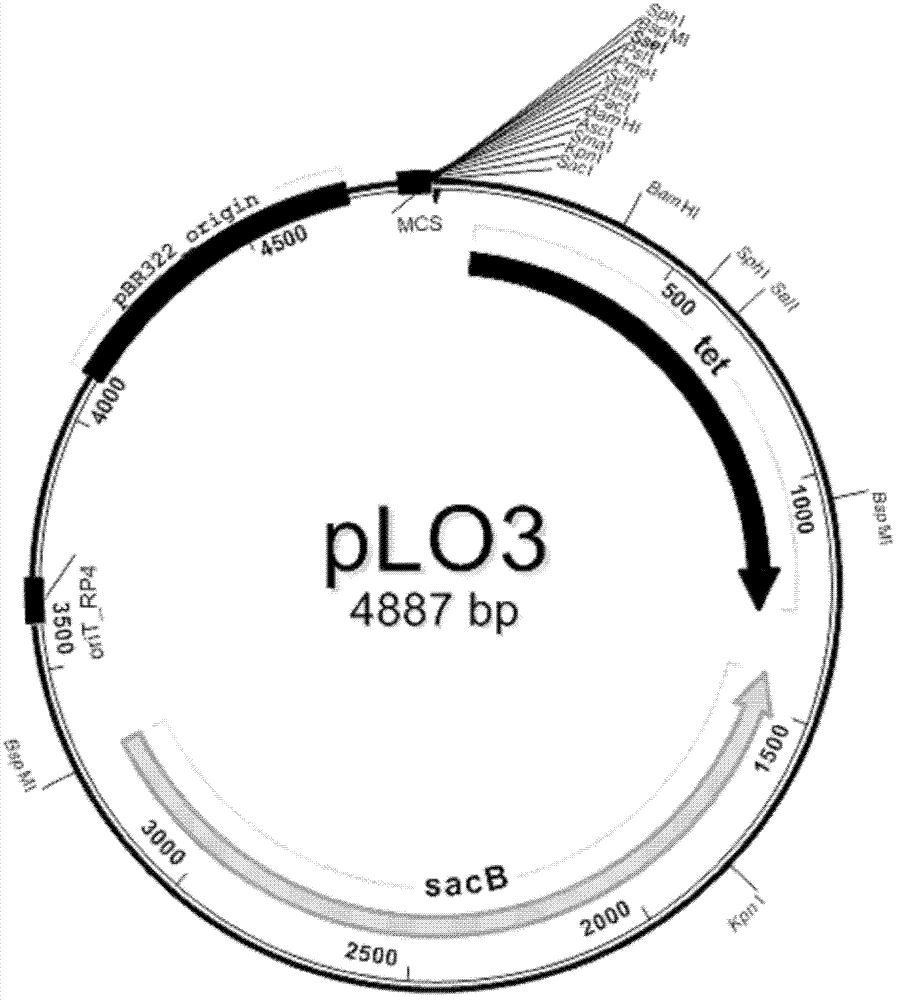

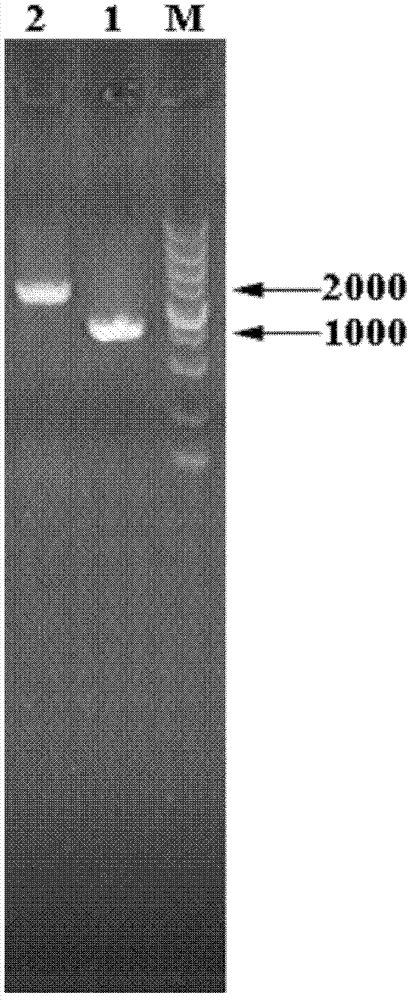

Lycopene Cyclase Gene of Sphingomonas paucimobilis and Its Application

The invention provides the DNA sequence of a lycopene cyclase gene (crtY) in sphingomonas sp., a recombinant strain lacking lycopene cyclase and use thereof. The nucleotide sequence of the crtY gene is represented by SEQ ID NO.1. The DNA sequence of the lycopene cyclase gene (crtY) in sphingomonas sp., which is provided by the invention, lays a foundation for the genetic modification of a sphingomonas sp. carotenoid biological synthesis means. In addition, compared with a wild strain, the sphingomonas sp. recombinant strain lacking the lycopene cyclase gene, which is constructed by a gene knockout method, has the advantages that: the gellengum yield is basically unchanged; and lycopene can be produced in the production of gellengum by fermentation. And the strain can be used for further gene knockout or metabolic engineering modification.

Owner:ZHEJIANG UNIV

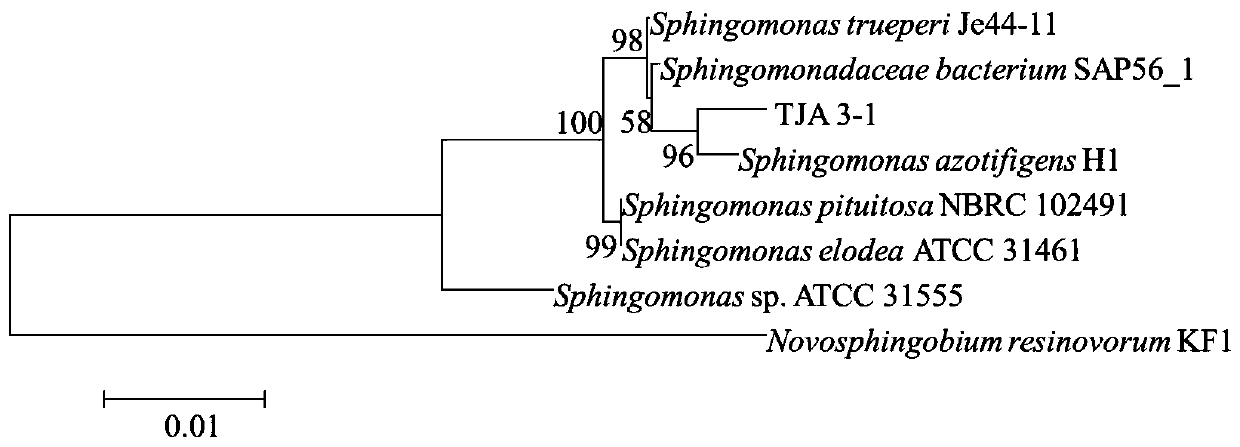

Welan gum high-producing strain sphingol monad TJA 3-1 and method and application thereof for producing welan gum

InactiveCN109988731AExpand sourceImprove temperature resistanceBacteriaMicroorganism based processesMicroorganismGellan gum

The invention relates to welan gum high-producing strain sphingol monad TJA 3-1. The name of the welan gum high-producing strain sphingol monad TJA 3-1 is TJA 3-1, the classification name is Sphingomonas sp., the preservation number is CGMCC No.15057, the preservation date is 13th December, 2017, 3 yard 1, Beichen West Road, Chaoyang District, Beijing, and the preservation institution is China General Microbiological Culture Collection Center. The strain can be fermented and produced with low-cost molasses as a raw material, the viscosity of fermentation liquor reaches 10500 mPa.s, the yield of the welan gum reaches 21 g / L, and still has good temperature resisting performance at the temperature of 160 DEG C, and a new path for producing the welan gum is provided.

Owner:TIANJIN AGRICULTURE COLLEGE

Fluoroglycofen degrading bacteria and bacterial agent prepared from same

ActiveCN101928687AEasy to useReduce production and use costsBacteriaMicroorganism based processesAmyrisSphingomonas sp.

The invention provides a degrading bacterial agent for removing fluoroglycofen residue, and belongs to the field of biological high technology. The strain is gram-negative bacteria MBLHY-1 which are found to be sphingomonas sp. through identification; and biologically, the strain is gram-negative, rodlike, sporeless and 0.8-1.3*0.5-0.6mu m long with polarflagella, is catalase-positive, oxidase-negative, voges-proskauer reaction-positive and methyl red reaction-negative, cannot hydrolyze starch or liquefy gelatin, does not generate indole, and can hydrolyze Tween-80. The pesticide residue in soil is reduced by over 90 percent and the problem that the pesticide residue exceeds the standard in agricultural production is solved by directly applying a degrading bacteria product; and nontoxic and pollution-free agricultural products can be produced.

Owner:NANJING AGRICULTURAL UNIVERSITY

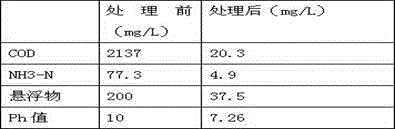

Environmental protection process for processing coal chemical industrial wastewater

ActiveCN104496114APromote degradationImprove biological treatment efficiencyFood processingAnimal feeding stuffBacillus licheniformisSphingomonas sp.

The invention belongs to the field of environmental protection of wastewater treatment, and discloses an environmental protection process for processing coal chemical industrial wastewater. According to the process, a microbial preparation is utilized, and comprises enterococcus faecalis, bacillus licheniformis, baumanii, rhodococcus, sphingomonas sp and pseudomonas fluorescens. According to the process disclosed by the invention, various pollutants in the coal chemical industrial wastewater can be effectively removed; and the environmental protection process accords with the emission standard.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

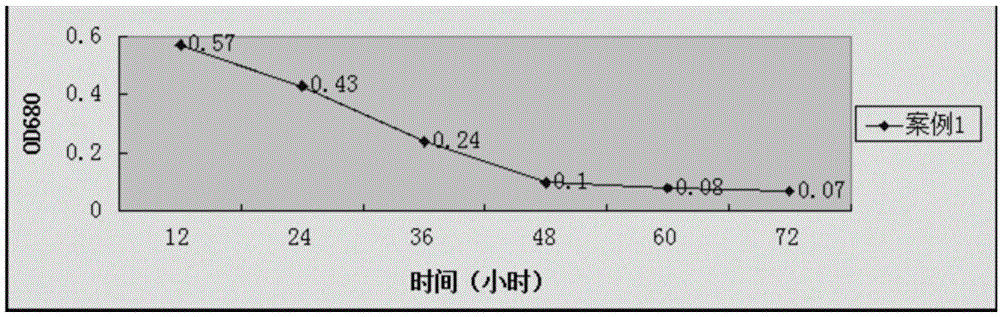

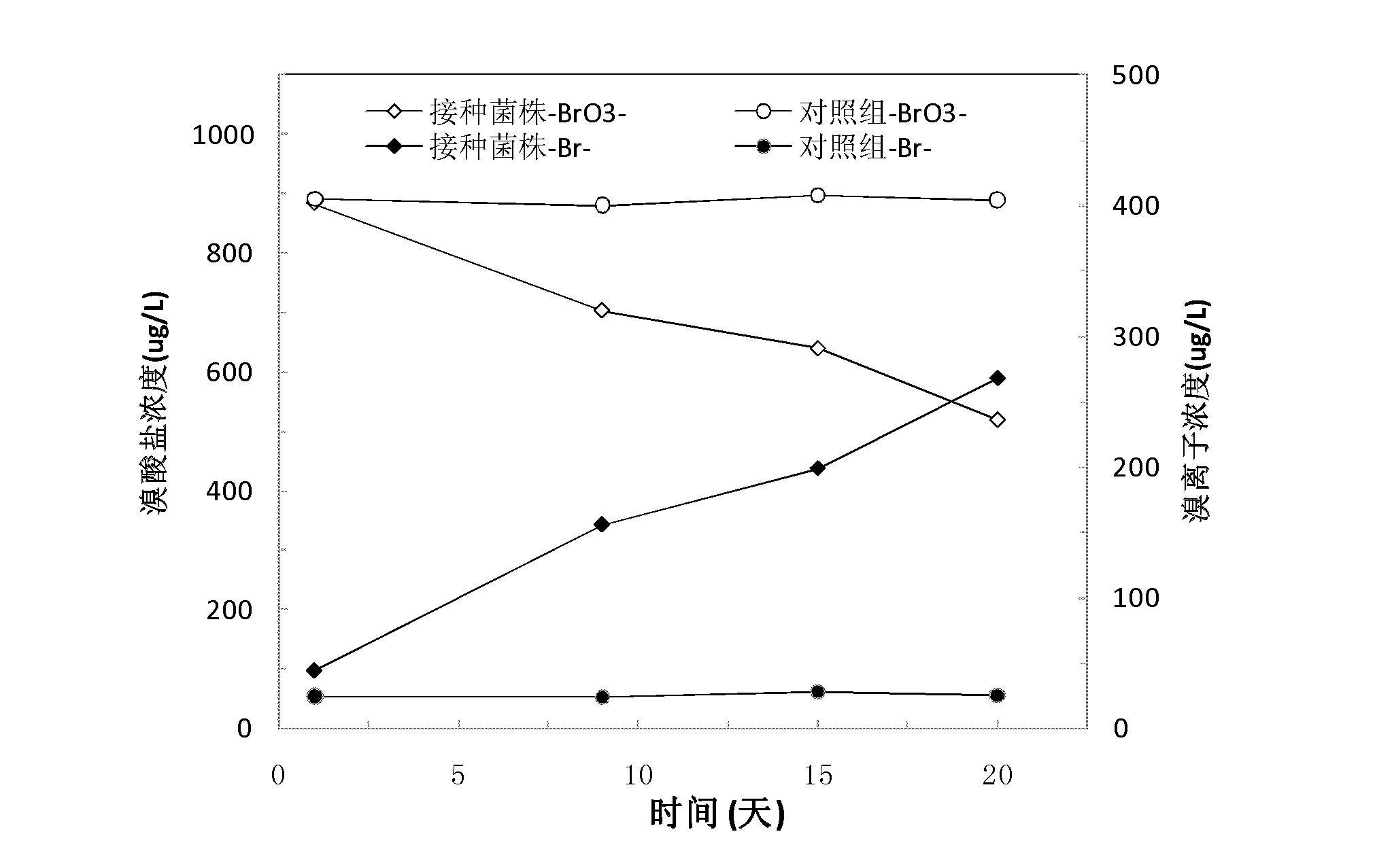

Sphingomonas sp.815Y strain for degrading bromate and application of Sphingomonas sp.815Y strain

ActiveCN103103146APromote degradationFast degradationBacteriaMicroorganism based processesMicroorganismSphingomonas sp.

The invention discloses a Sphingomonas sp.815Y strain for degrading bromate and application of the Sphingomonas sp.815Y strain, wherein the microbial preservation number of the Sphingomonas sp.815Y strain is CGMCC (China General Microbiological Culture Collection Center) No.4721. The Sphingomonas sp.815Y strain is obtained by screening from the natural world, can be used for effectively degrading the bromate, is high in degrading efficiency, can be inoculated and applied to a biological activated carbon process, has the capabilities of effectively removing the bromate produced in an ozonization process of drinking water and the bromate in polluted drinking water and improving the safety of the drinking water and has a favorable application prospect in terms of drinking water treatment.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

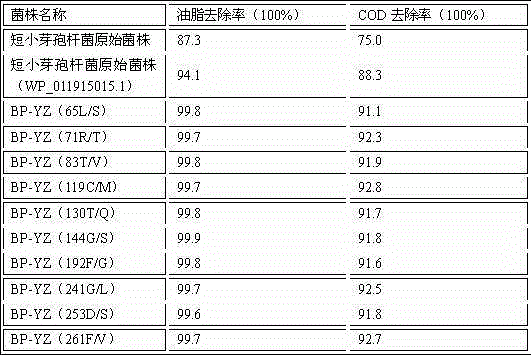

Microbial preparation for treating high-grease restaurant wastewater and application of microbial preparation

InactiveCN105219687AEfficient purificationRemove high oil pollutionBacteriaHydrolasesSphingomonas sp.Thiobacillus

The invention relates to a microbial preparation for treating high-grease restaurant wastewater and application of the microbial preparation, discloses a method for removing pollutants from urban restaurant wastewater and belongs to the field of wastewater treatment. According to the method, a complex microbial inoculant is used and comprises 15 parts of rhodococcus, 10 parts of thiobacillus denitrificans, 6 parts of sphingomonas sp. and 30 parts of bacillus pumilus. The method has the advantages that microorganisms are mainly used for treating the pollutants, the grease pollutants in the restaurant wastewater can be removed effectively, input cost is low, and accordingly, the method is promising in application prospect.

Owner:NINGBO BLUE ENVIRONMENT SCI & TECH CO LTD

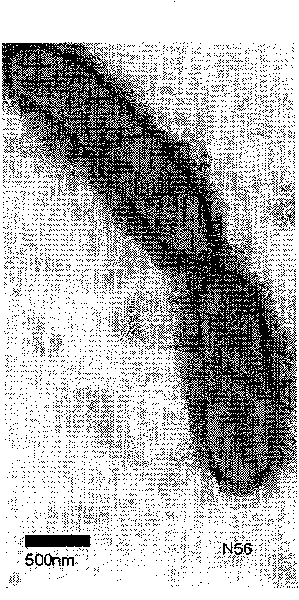

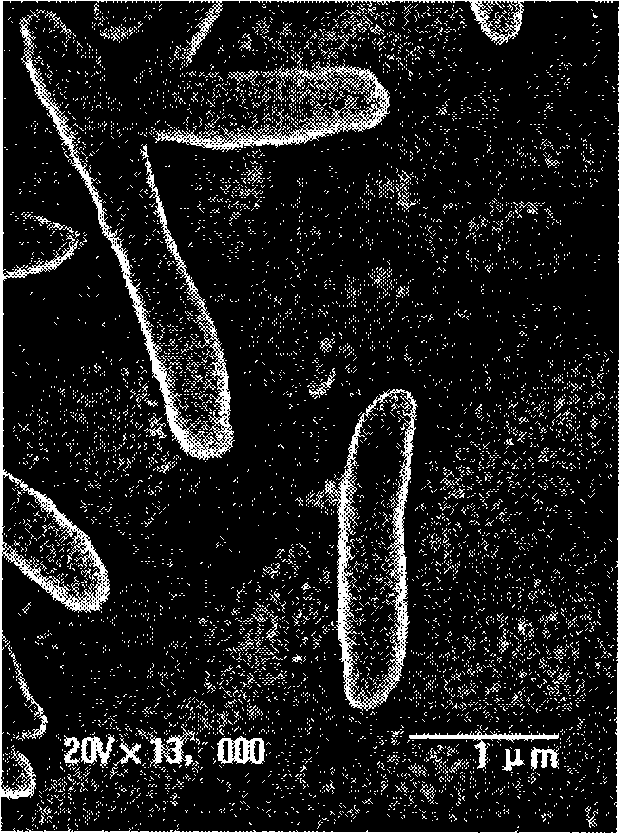

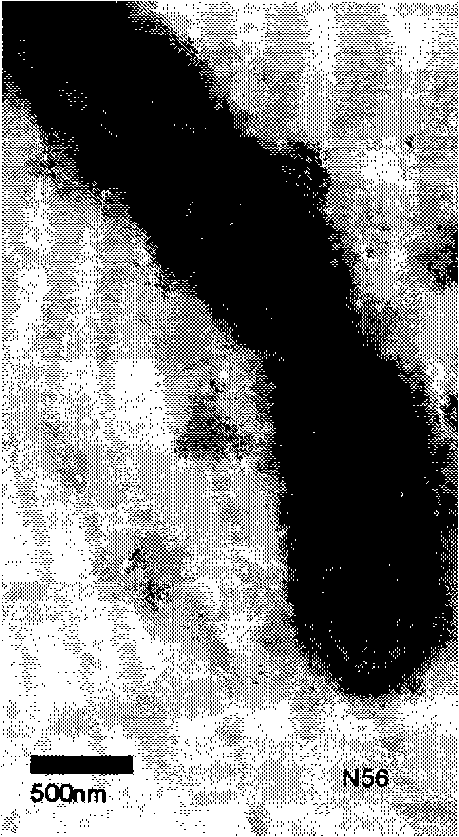

Mangrove plant rhizosphere growth promoting azotobacter (DZY-N56) and uses thereof

InactiveCN101319198BGood growth promoting effectIncrease production capacityBacteriaMicroorganism based processesSphingomonas sp.Rhizophora stylosa

The invention provides redwood plant rhizosphere promoting azotobacteria (DZY-N56) and an application thereof. The bacteria is Sphingomonas sp. DZY-N56, is sieved and separated from a redwood plant rhizosphere sediment sample in a tropical mangrove zone, contains a nif gene nifH and 16S rDNA as shown by SEQ1, and is preserved in China Center for Type Culture Collection with a preservation No. of CCTCC NO: M207120. The strain has high biological nitrogen fixation activity, and can obviously promote plant growth by using microbial inoculum which contains the bacteria for inoculation of redwood plants such as mangrove, Rhizophora stylosa, bruguiera gymnorrhiza and so on, thereby the strain can be applied to prepare biological azotobacterin for promoting the growth of the mangrove plants.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Mangrove plant rhizosphere growth promoting azotobacter (DZY-N56) and uses thereof

InactiveCN101319198AGood growth promoting effectIncrease production capacityBacteriaMicroorganism based processesSphingomonas sp.Nif gene

The invention provides redwood plant rhizosphere promoting azotobacteria (DZY-N56) and an application thereof. The bacteria is Sphingomonas sp. DZY-N56, is sieved and separated from a redwood plant rhizosphere sediment sample in a tropical mangrove zone, contains a nif gene nifH and 16S rDNA as shown by SEQ1, and is preserved in China Center for Type Culture Collection with a preservation No. of CCTCC NO: M207120. The strain has high biological nitrogen fixation activity, and can obviously promote plant growth by using microbial inoculum which contains the bacteria for inoculation of redwood plants such as mangrove, Rhizophora stylosa, bruguiera gymnorrhiza and so on, thereby the strain can be applied to prepare biological azotobacterin for promoting the growth of the mangrove plants.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

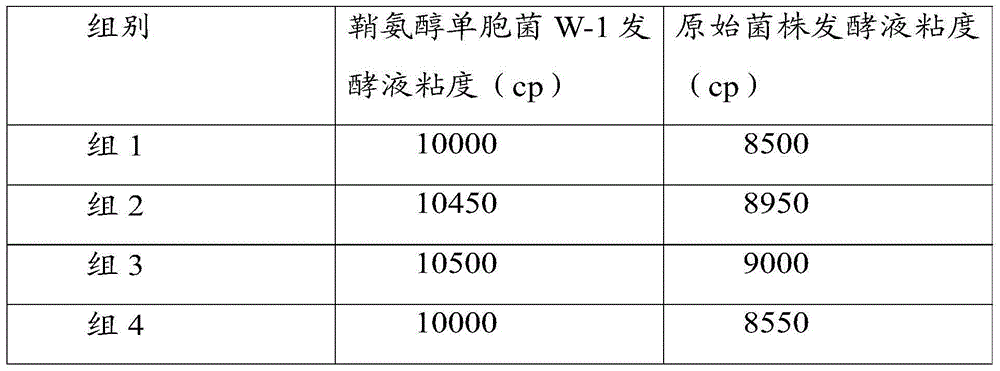

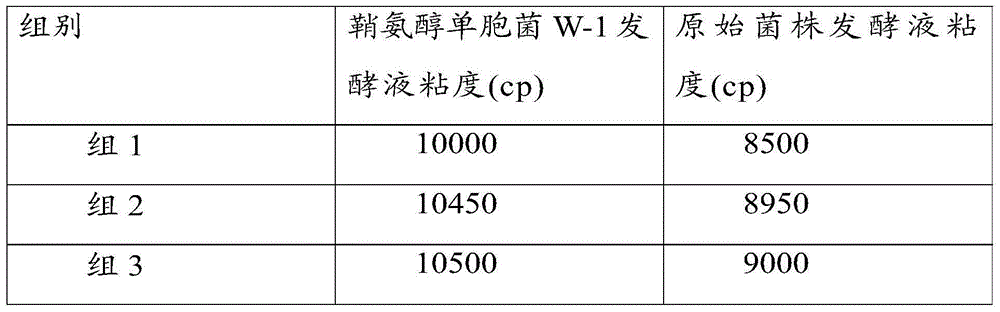

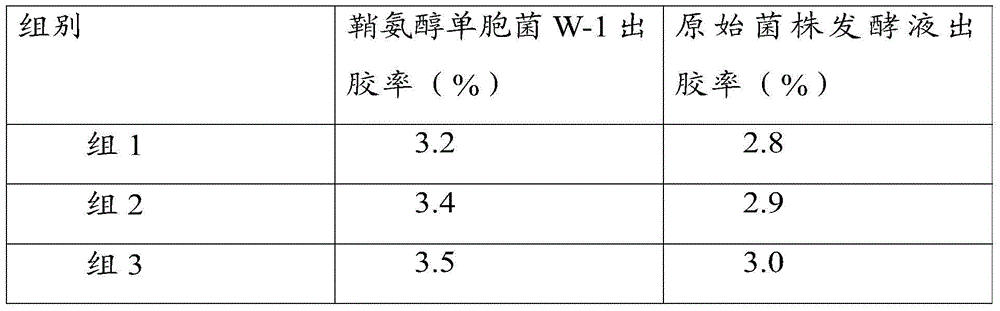

High-performance welan gum strain and application thereof

ActiveCN104531580AHigh glue rateHigh viscosityBacteriaMicroorganism based processesMicroorganismSalt resistance

The invention belongs to the field of production of welan gum and particularly relates to a high-performance welan gum strain and application thereof. The high-performance welan gum strain is collected in the China General Microbiological Culture Collection Center (CGMCC) on November 3, 2014 as the name of (Sphingomonas sp.) W-1 with the collection number of CGMCC No.9919. The high-performance welan gum strain provided by the invention is prepared by carrying out ultraviolet mutagenesis screening on an original strain. Compared with the original strain, the high-performance welan gum strain has short growth cycle. The welan gum obtained by fermenting by using the welan gum strain has high yield, high viscosity, good salt resistance and good high-temperature resistance. The invention further provides application of the high-performance welan gum strain to fermentation of welan gum.

Owner:INNER MONGOLIA RAINBOW BIOTECH CO LTD

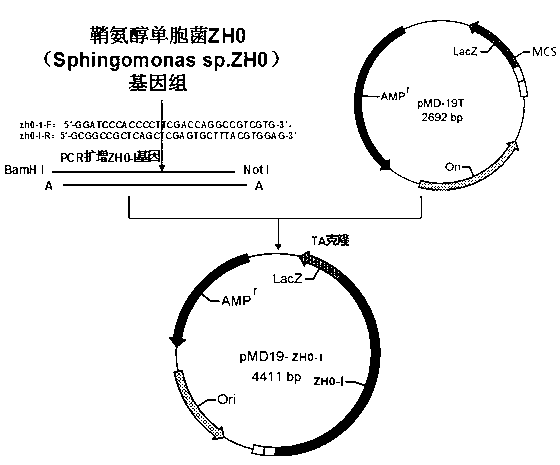

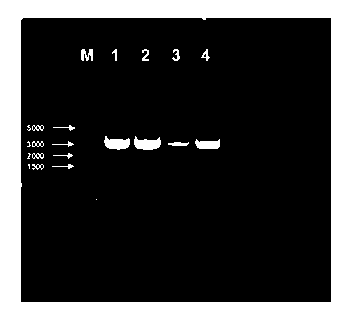

Prokaryotic expression vector of sphingomonassp.ZHO alginate lyase ZHO-I and application thereof

InactiveCN103215297ASolve the problem of low enzyme productionBroad substrate specificityFermentationVector-based foreign material introductionSphingomonas sp.Prokaryotic expression

The invention discloses a prokaryotic expression vector pGEX-4T-1-ZHO-I for efficiently expressing sphingomonassp.ZHO alginate lyase ZHO-I. The vector is a prokaryotic expression vector containing sphingomonassp.ZHO alginate lyase gene ZHO-I. The prokaryotic expression vector disclosed by the invention can obtain an expression product alginate lyase ZHO-I in a short time, and the obtained recombinant alginate lyase ZHO-I has wide substrate specificity; both PloyG and PloyM can be used as a substrate, and the enzyme activity can reach 53.2U / mg; the prokaryotic expression vector is a difunctional enzyme with broad application prospect; and the prokaryotic expression vector and the whole expression system disclosed by the invention are easy to operate and is favorable for the industrial production.

Owner:KUNMING UNIV OF SCI & TECH

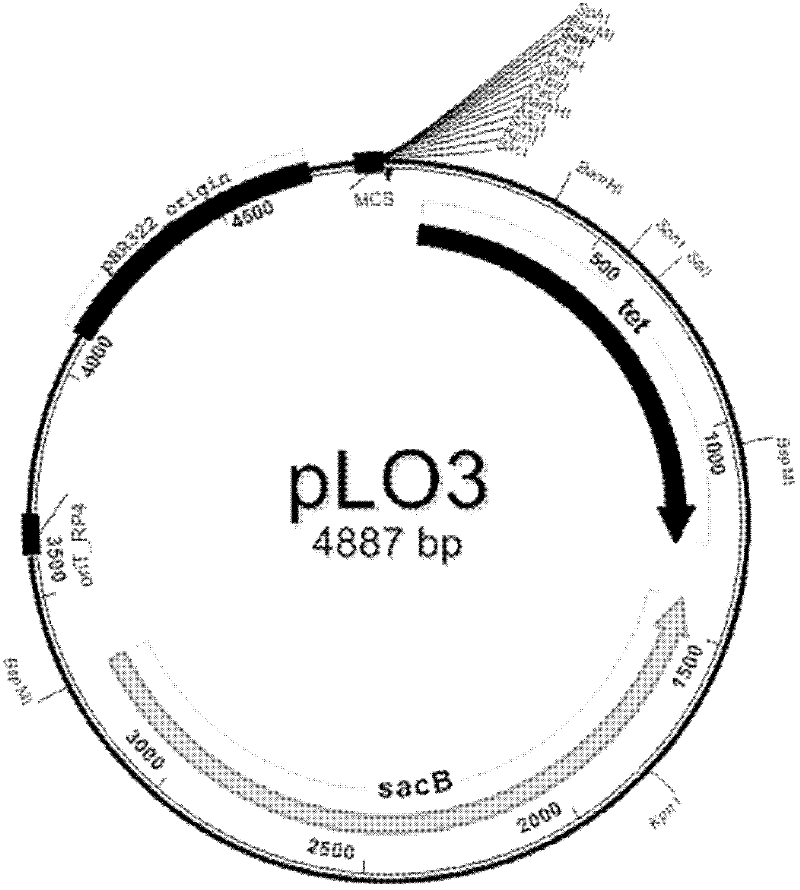

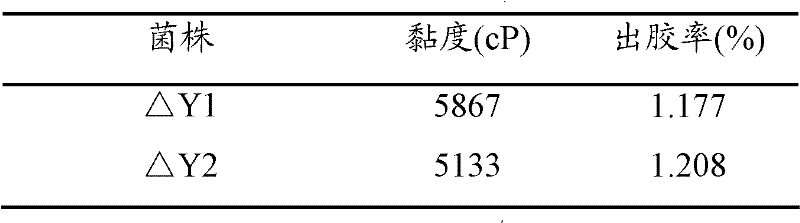

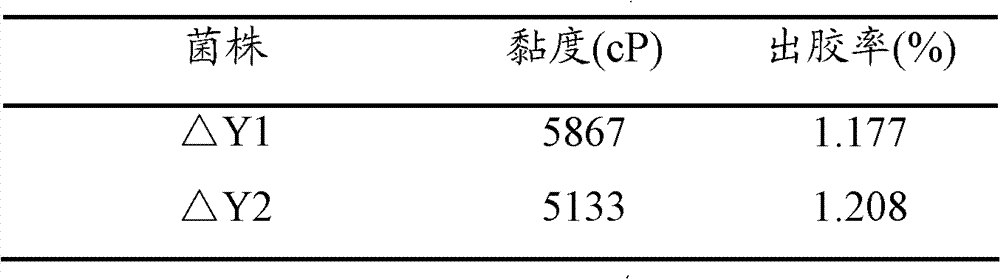

Pigment-free low-molecular weight Welan gum production strain and construction method and application thereof

ActiveCN110144318AHigh polysaccharide yieldRaise the level of fermentationBacteriaTransferasesSphingomonas sp.Enzyme Gene

The invention discloses a pigment-free low-molecular weight Welan gum production strain. Sphingomonas sp. HT-1 (CCTCC NO: M2012062) is taken as an original strain to respectively construct a pigment-deficient and decapsulated-structure sphingomonas genetically engineered strain WG-1, a pigment and degrading enzyme gene-deficient sphingomonas engineered strain WG-2, and a pigment and degrading enzyme gene-deficient and decapsulated-structure sphingomonas genetically engineered strain WG-3. The yield of the Welan gum produced by the sphingomonas strain WG-2 in the invention is increased by 10% to 30% compared with the original strain, reaching 35 to 45g / L, and the molecular weight is not significantly changed (Mn: 10000 to 20000kDa). The sphingomonas strain WG-1 and the sphingomonas strain WG-3 in the invention are fermented to produce low-molecular weight Welan gum (Mn: 500 to 1000kDa), and the yield of the Welan gum produced by the decapsulated-structure strain WG-3 is increased by 20%to 30% compared with the strain WG-1, reaching 20 to 25g / L. The strain constructed by the invention can obtain Welan gum products of different molecular weight ranges, and significantly improves thefermentation level of Welan gum.

Owner:NANJING UNIV OF TECH

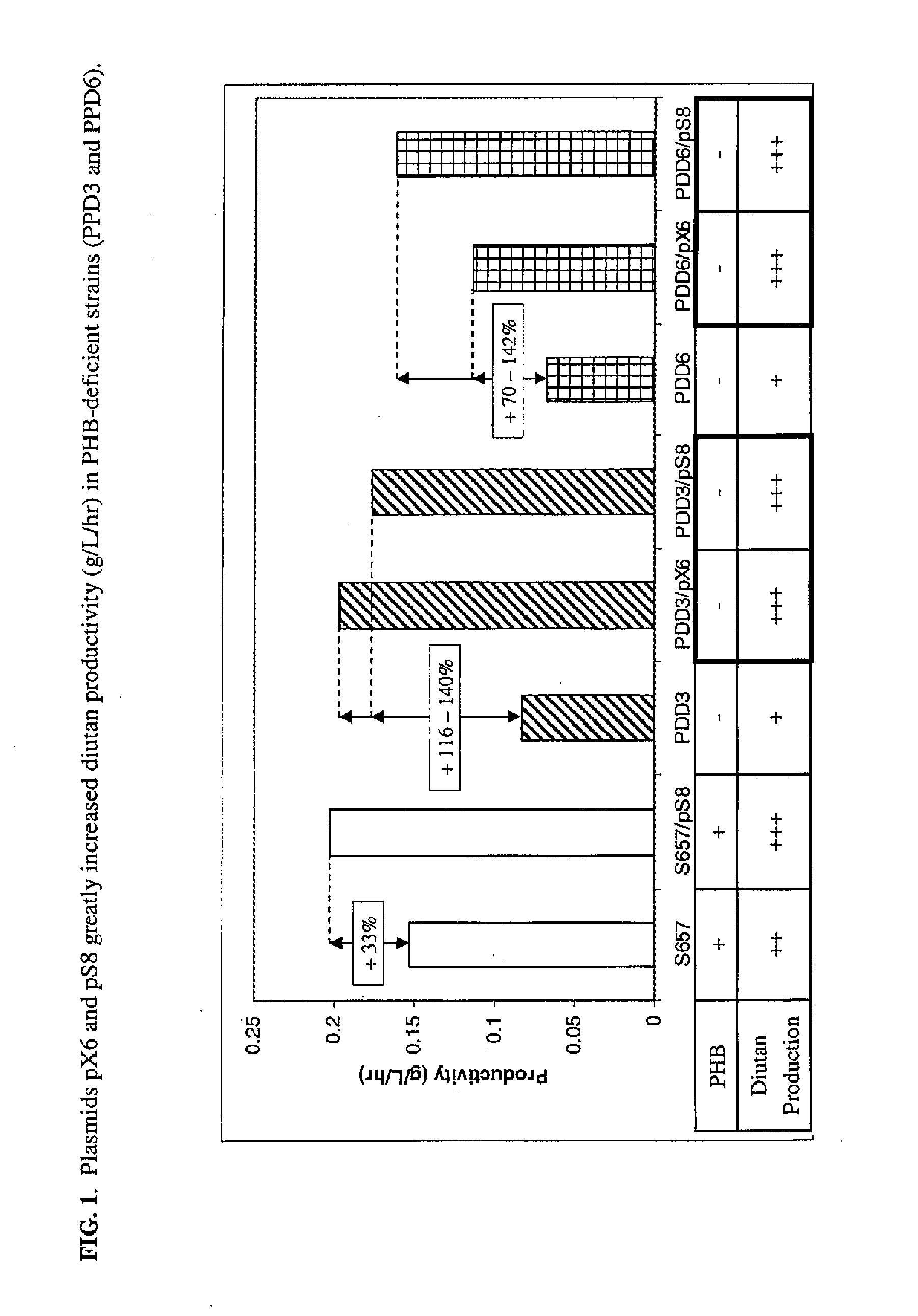

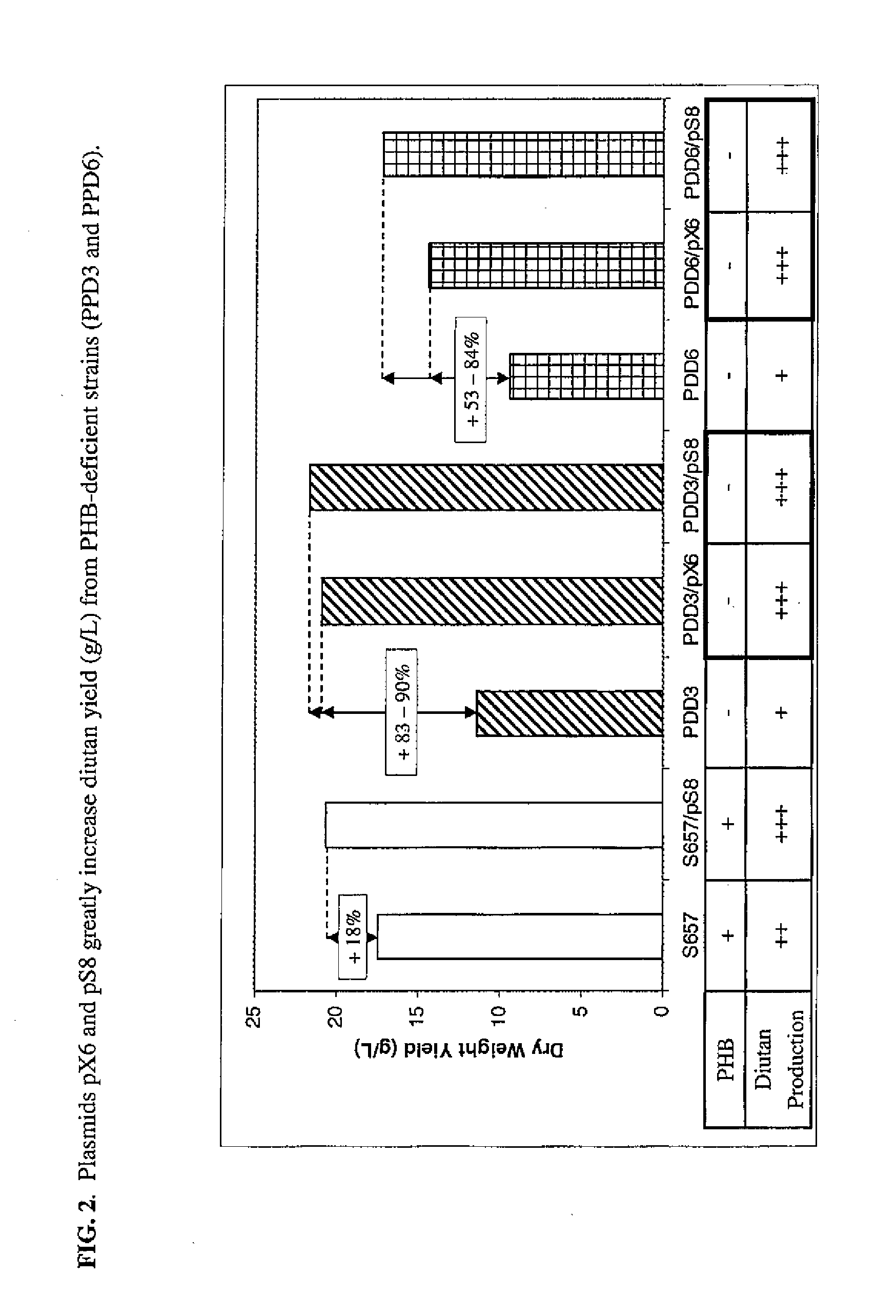

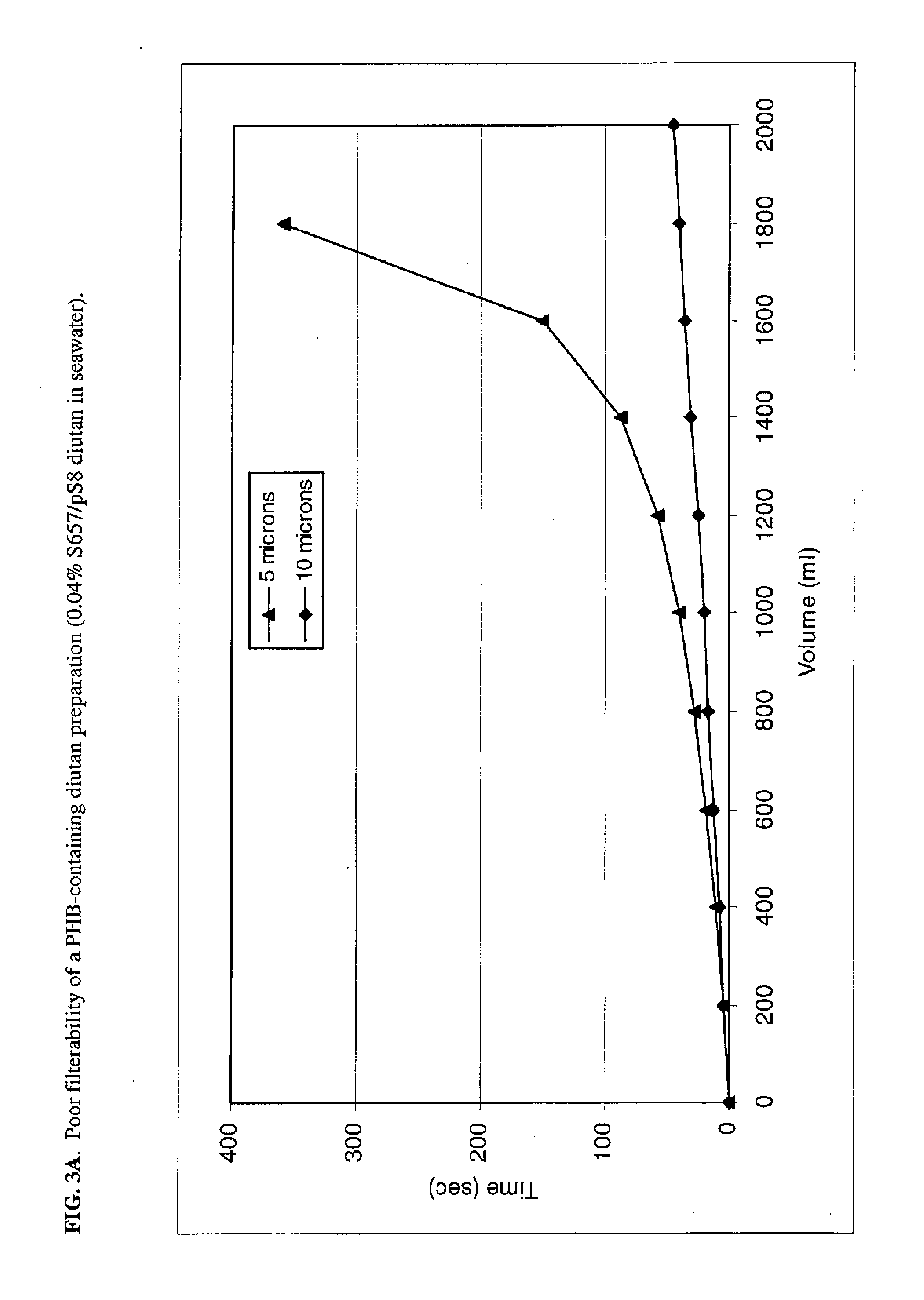

Sphingomonas Strains Producing Greatly Increased Yield of PHB-Deficient Sphingan (Diutan)

ActiveUS20130189748A1Low sphingan productivityImprove productivityBacteriaFermentationBiotechnologyPersonal care

Owner:CP KELCO U S INC

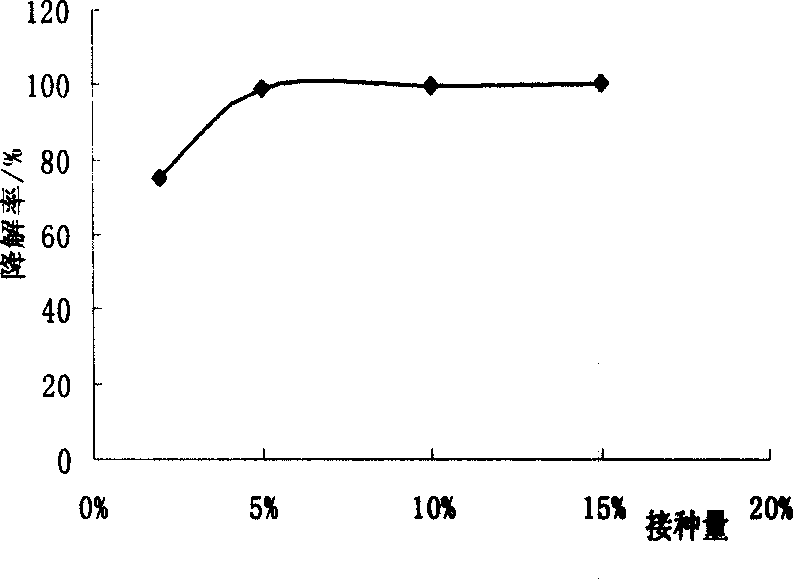

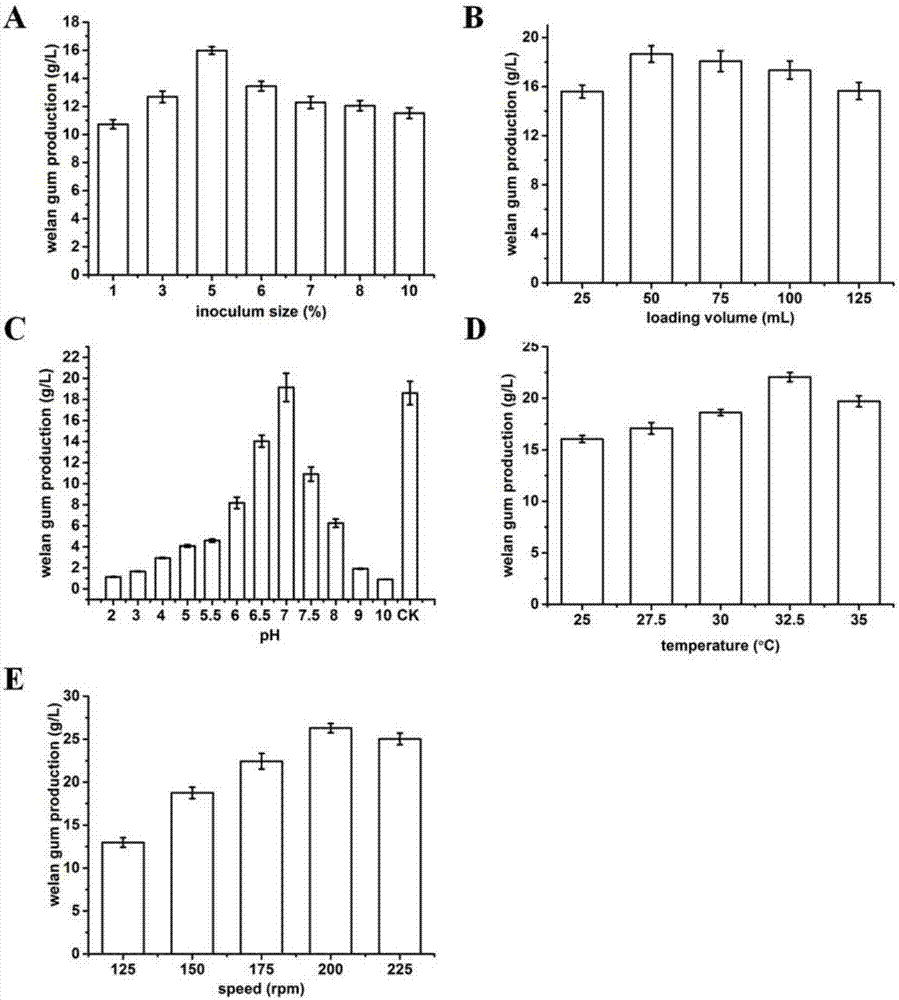

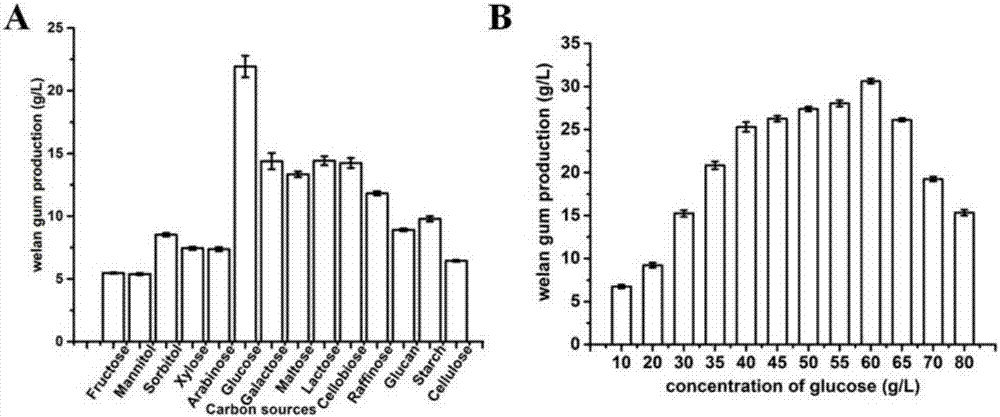

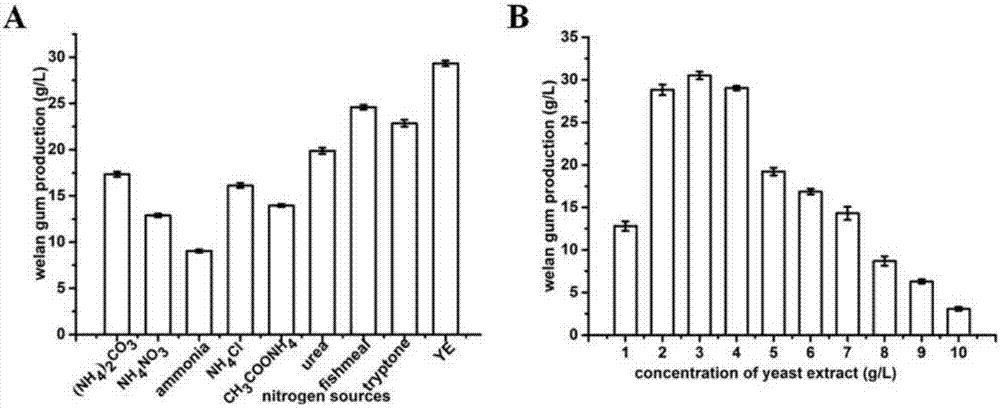

Fermentation process for production of welan gum via Sphingomonas sp.WG

InactiveCN106906163ASimple production processIncrease productionBacteriaMicroorganism based processesGellan gumYeast

The invention relates to a fermentation process for production of welan gum via Sphingomonas sp.WG, specifically to a high-yield fermentation production process for welan gum, belonging to the technical field of fermentation engineering. The fermentation process for production of welan gum via Sphingomonas sp.WG is characterized in that a fermentation medium is composed of (g / L) 72.4 of glucose, 3.58 of yeast powder, 3 of K<2>HPO<4>, 0.1 of MgSO<4> and 0.1 of ZnSO<4> and has a pH value of 7.0; and fermentation conditions comprise a culture volume of 50 mL (in a 250-mL Erlenmeyer flask), an inoculation amount of 2.5 ml (5%, v / v), an initial pH value of the medium of 7, a culture temperature of 32.5 DEG C, a shaking-table rotating speed of 200 rpm and fermentation time of 72 h, and fermentation is accomplished under the fermentation conditions. Under the above-mentioned fermentation conditions, the output of welan gum reaches 40.47 g / L, being 2.53 times of the output before optimization (15.98 g / L), and the output reaches a leading level in the world. The fermentation production process for the welan gum is low in cost, simple to operate, high in efficiency, easy to promote and beneficial for realizing large-scale industrial production of the welan gum, and has high economic benefits and good application prospects.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

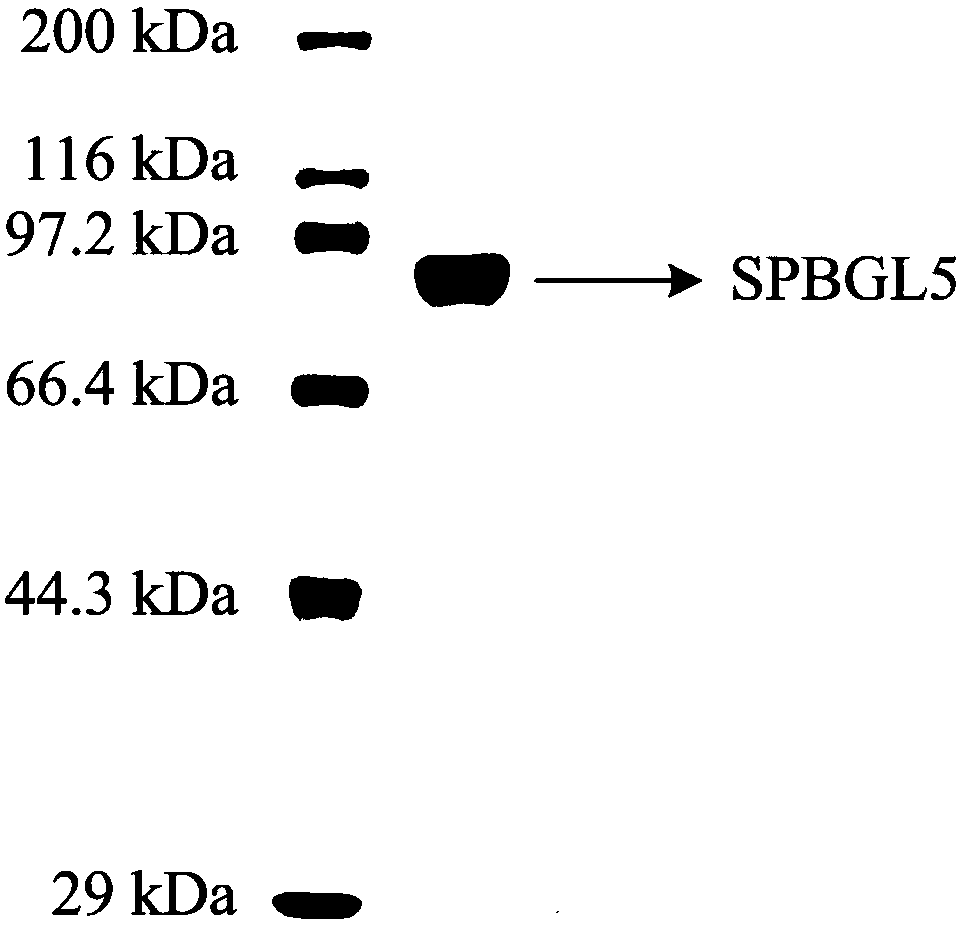

Applications of beta-glucosidase SPBGL5 in hydrolysis of xylan polysaccharide substances

ActiveCN107699551AGreat application potentialFermentationGlycosylasesEscherichia coliSphingomonas sp.

The invention belongs to the technical field of enzymology engineering, and particularly relates to applications of beta-glucosidase SPBGL5 in hydrolysis of xylan polysaccharide substances. Accordingto the present invention, a recombinant Escherichia coli strain containing a beta-glucosidase gene spbgl5 from Sphingomonas sp. ATCC 31461 is constructed, wherein the gene is subjected to induced expression and nickel affinity chromatography purification in Escherichia coli to obtain an expression product beta-glucosidase SPBGL5; and the obtained beta-glucosidase SPBGL5 has the activities of beta-glucosidase, further has the activities of beta-xylosidase and beta-arabinosidase, can separately hydrolyze beech xylan, birch xylan, oat xylan, corncob xylan, wheat araboxylan and lichenin, and has great application potential in degradation of various xylan polysaccharide substances.

Owner:GUANGXI ACAD OF SCI

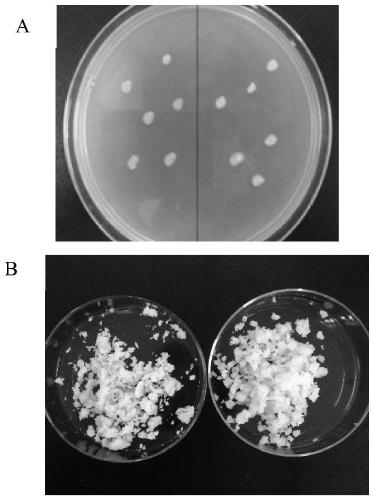

Yellow pigments generation deficient Sphingomonas strain and application thereof in gellan gum production

ActiveUS8685698B2Reduce the amount requiredAvoid prolonged useBacteriaUnicellular algaeGellan gumMicroorganism

A yellow pigments generation deficient Sphingomonas strain (Sphingomonas sp. ZD001) and application thereof in preparing gellan gum by microbial fermentation are provided. The strain is preserved in China Center for Type Culture Collection (CCTCC) with the address of Wuhan University, Wuhan, 430072, China, the preservation date of the strain is 10 Sep. 2009, and the preservation serial number is CCTCC No: M 209298. The main beneficial effect of the present invention is that the fermented liquor contains no yellow pigments but is milky white, colorless superior gellan gum can be obtained by only depositing polysaccharide with a small quantity of ethanol or isopropanol, so that the post purification and de-coloration techniques of gellan gum production can be simplified, the yield can be enhanced, and the production cost can be reduced.

Owner:ZHEJIANG UNIV +1

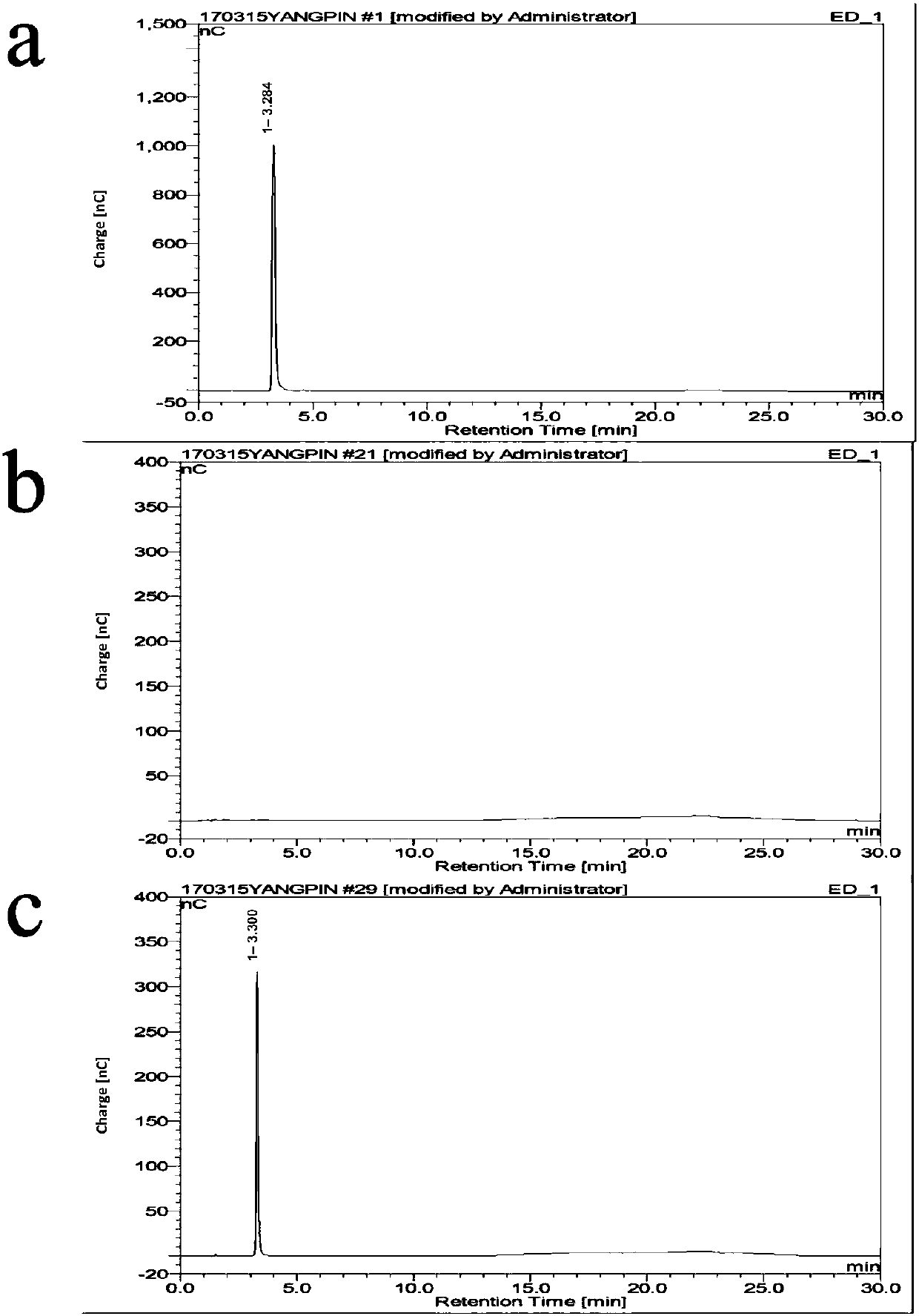

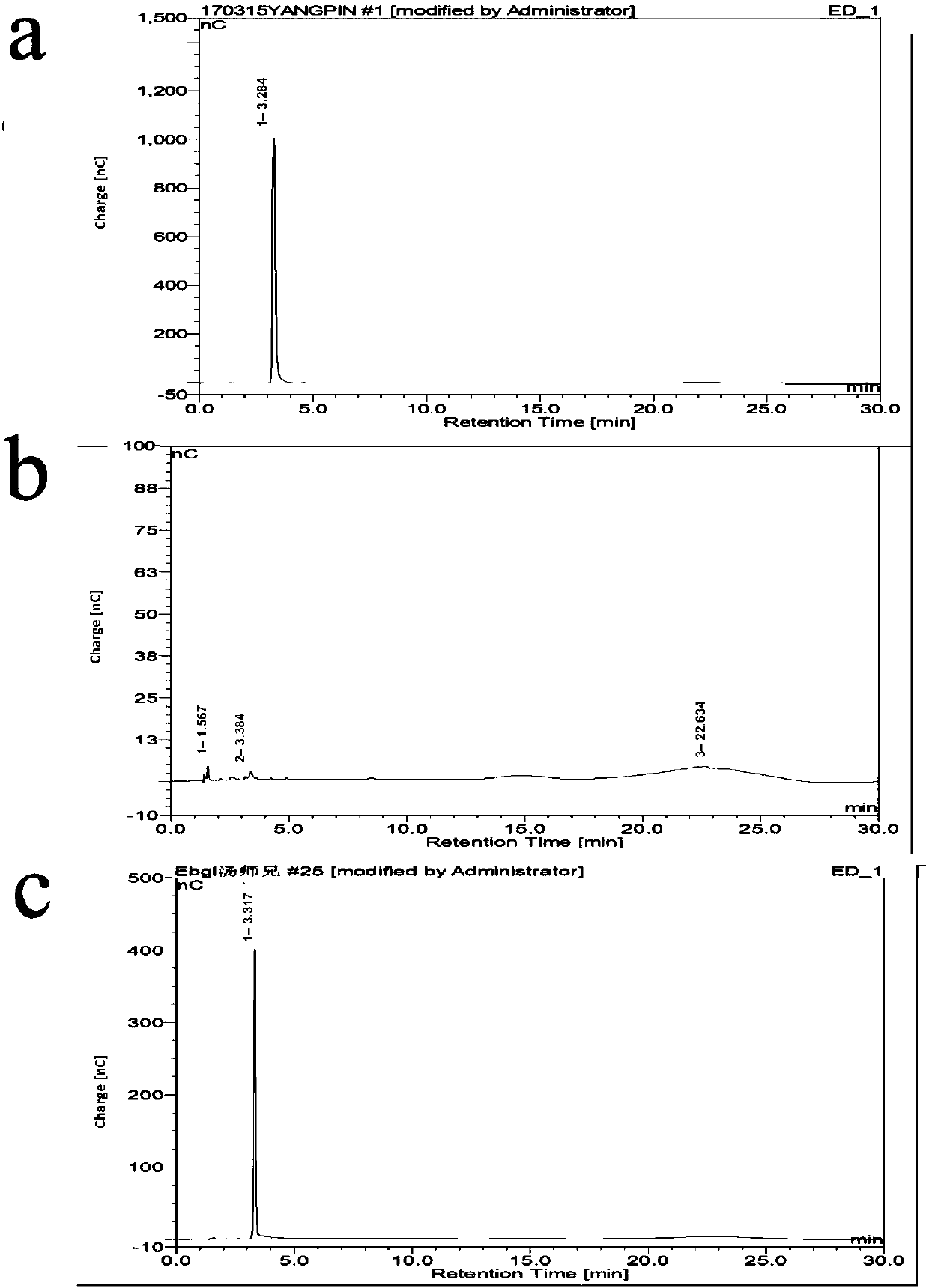

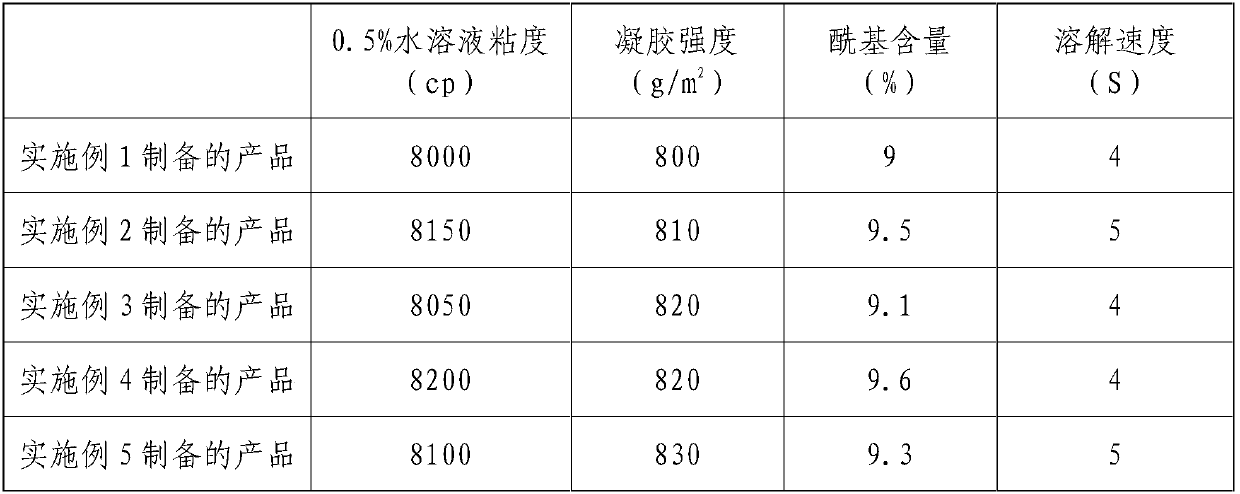

Preparation method of high-gel-strength, high-viscosity and high-acyl gellan gum

ActiveCN109251950AHigh purityHigh yieldMicroorganism based processesFermentationSphingomonas sp.High carbon

The invention belongs to microbial fermentation, and particularly relates to a preparation method of high-gel-strength, high-viscosity and high-acyl gellan gum. The preparation method comprises the process steps: sphingomonas sp. is inoculated to a fermentation medium with the high carbon-nitrogen ratio, wherein the fermentation medium is sterilized and contains a carbon source, a nitrogen sourceand necessary nutrient substances; the pH of the fermentation medium is adjusted for high-temperature aerated fermentation, fermentation is carried out for 20-30 hours, and sterile water and an oxygencarrying agent are supplemented; when the viscosity of a culture solution is not improved any longer or the fermentation period is less than or equal to 50 hours, fermentation is completed; and afterfermentation is completed, a fermentation solution is post-extracted, and the high-gel-strength, high-viscosity and high-acyl gellan gum is prepared. The technical problems that in the prior art, gellan gum has the low 0.5% aqueous solution viscosity, the low gel strength, the low acyl content and the like are solved, and the advantages that the prepared gellan gum product has the high acyl content, high dissolving speed, the high 0.5% aqueous solution viscosity, the high gel strength and the like are achieved.

Owner:HEBEI XINHE BIOCHEM

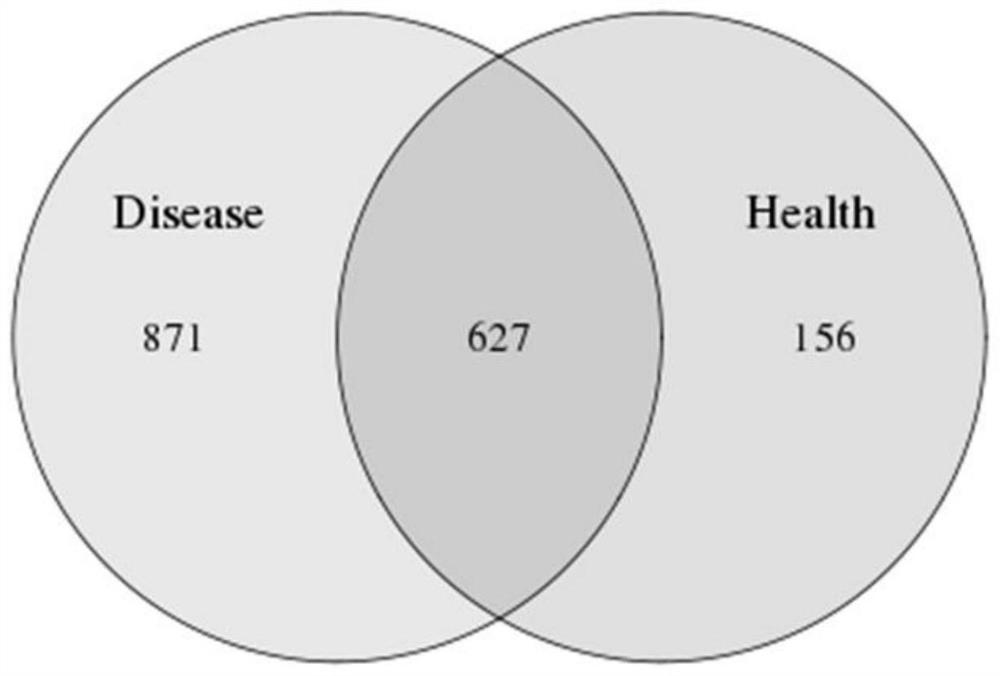

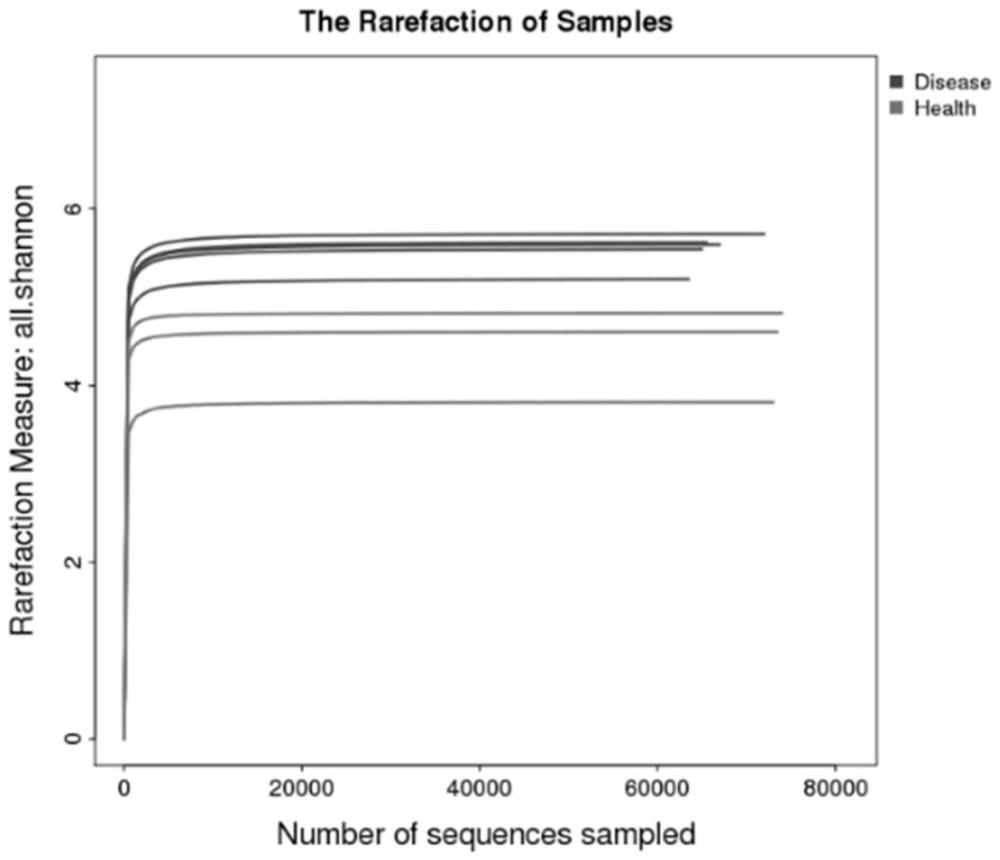

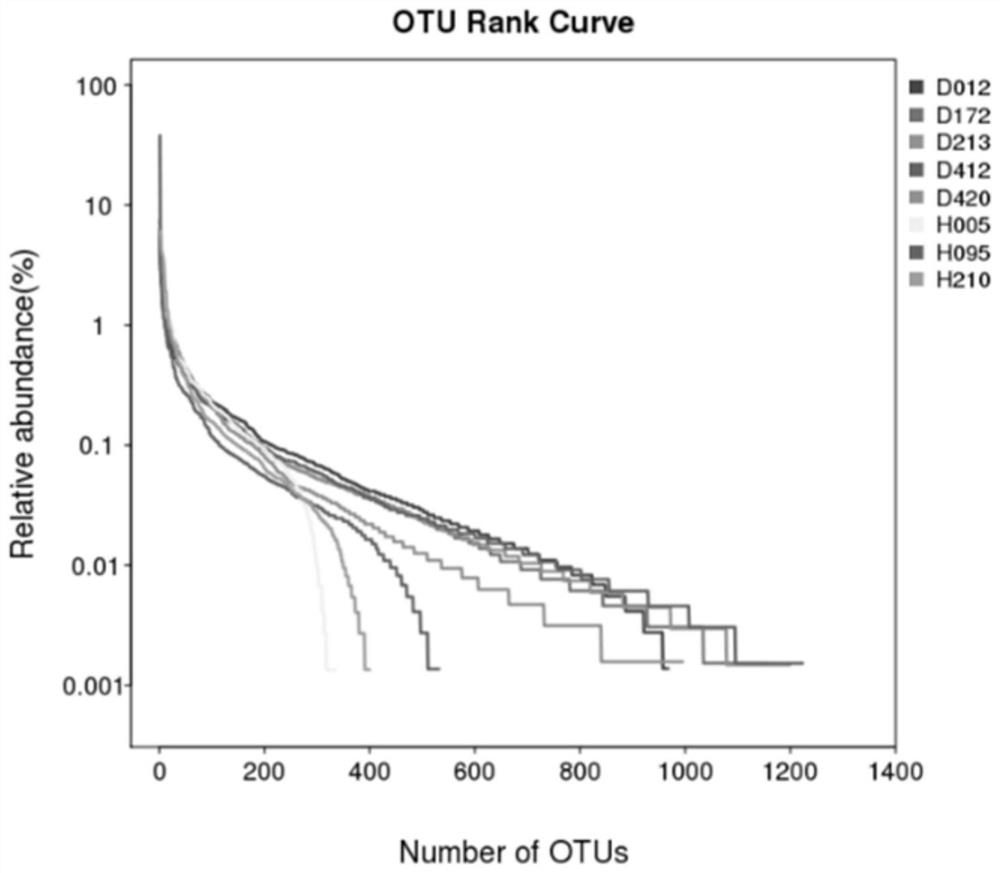

Microbial marker for bovine endometritis and application thereof

InactiveCN112080561AIncrease abundanceReduce abundanceMicrobiological testing/measurementMicroorganism based processesBiotechnologySpirochaetae

The invention discloses a microbial marker for bovine endometritis. The microbial marker comprises the following microorganisms with remarkably increased abundance: Bacteriodetes, Elusimicrobia, Verrucomicrobia, Spirochaetae and Lentisphaerae. The microbial marker also comprises the following microorganisms with remarkably increased abundance: Akkermansia, biogas bacillus, CF231 and Oscillosporia.The microbial marker also comprises the following microorganisms with remarkably decreased abundance: Ureaplasma urealyticum, Butyrivibrio, Doria, Sphingomonas sp, Rothia and Streptococcus. The invention discloses an application of the microbial marker for bovine endometritis in preparation of a tool for early screening or prediction of bovine endometritis. The applicant performs 16S rRNA gene sequencing on microbial DNA of a uterine mucus sample, compares structural differences of uterine florae between healthy and sick dairy cows, and finds differences in microbial community composition ofthe uterine florae between the healthy and sick dairy cows. The result provides a theoretical basis for better prevention and treatment of clinical endometritis.

Owner:ANHUI AGRICULTURAL UNIVERSITY

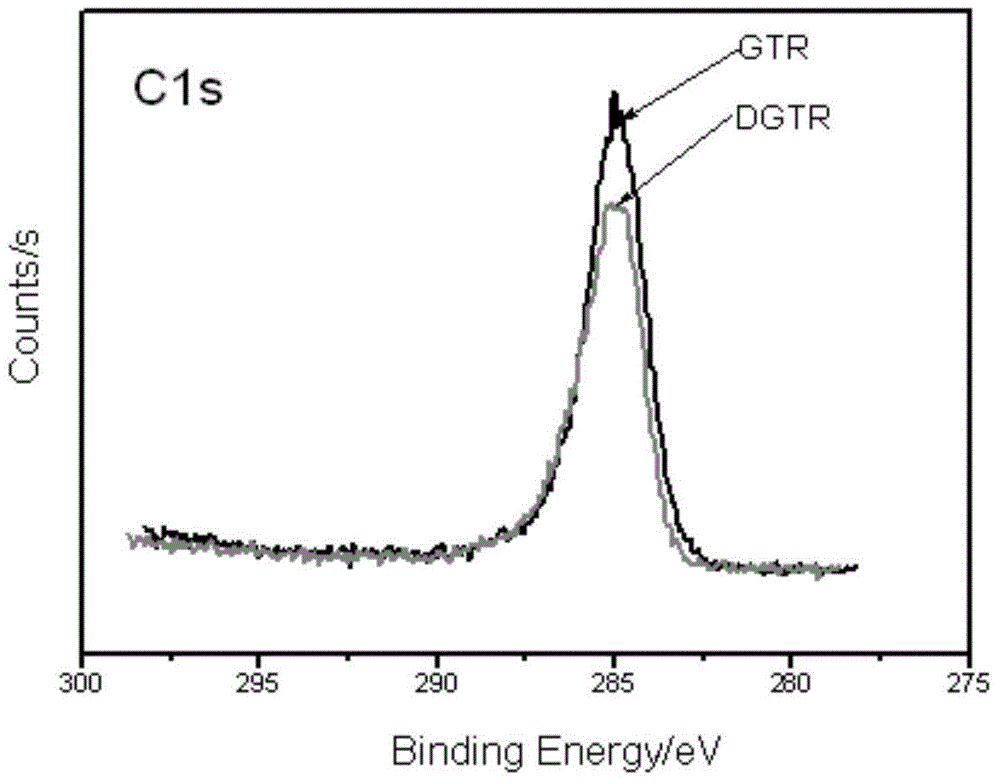

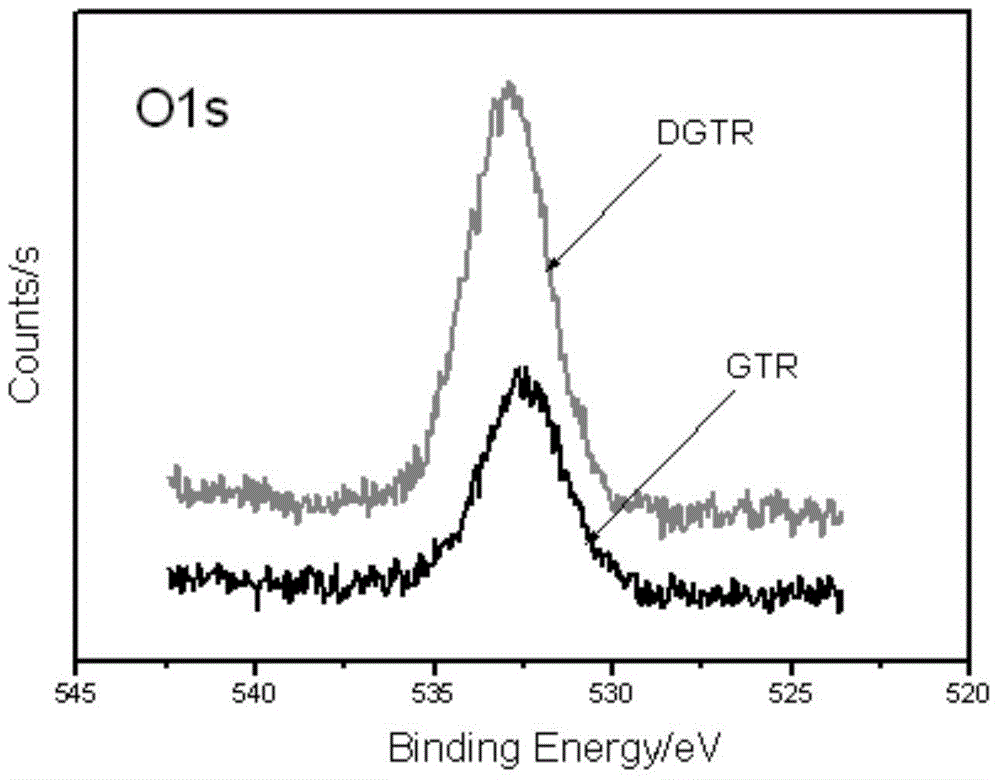

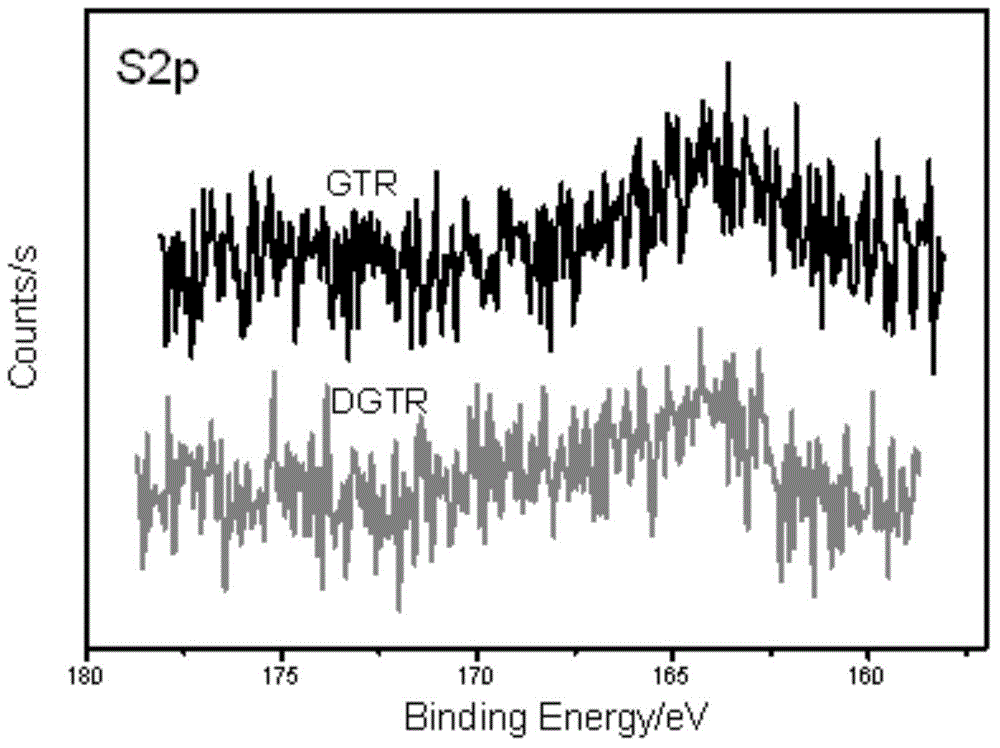

Method for desulfurization regeneration of waste rubber by mixing two types of microorganism bacteria

ActiveCN104962601AGood desulfurization effectSimple processMicroorganism based processesFermentationSphingomonas sp.Waste rubber

The invention provides a method for desulfurization regeneration of waste rubber by mixing two types of microorganism bacteria and relates to a desulfurization regeneration technology of the waste rubber. According to the method, an enzyme generated in the mixed growth process of sphingomonas sp. and gordonia sp. is used for performing desulfurization regeneration on the waste rubber. An early study shows that the sphingomonas sp. or the gordonia sp. has a good desulfurization effect on waste tread rubber, styrene-butadiene rubber and natural rubber, and in order to study mixed bacterial desulfurization, the system provided by the invention adjusts a culture medium for symbiosis of the two bacteria, and the two bacteria are mixed together to perform desulfurization regeneration on the waste rubber. A study finds that during co-culture desulfurization, the biomass of the mixture of the two types of bacteria is higher than that of a single strain, which shows that the two bacteria have a synergistic effect. According to the method provided by the invention, the inoculation means of the two types of bacteria and the influence of process conditions for growth and metabolism of the two types of bacterial on the desulfurization of the waste rubber are studied, so that a best process for co-culture desulfurization is determined. Compared with undesulfured waste rubber, the desulfurized rubber is increased in selling value, lowered in surface sulfur element content, and increased in oxygen content. Therefore, the mixing of the two types of the microorganism bacteria has a relatively obvious desulfurization effect on the rubber surface.

Owner:BEIJING UNIV OF CHEM TECH

An environmentally friendly process for treating coal chemical wastewater

ActiveCN104496114BPromote degradationImprove biological treatment efficiencyFood processingAnimal feeding stuffSphingomonas sp.Emission standard

The invention belongs to the field of environmental protection of wastewater treatment, and discloses an environmental protection process for processing coal chemical industrial wastewater. According to the process, a microbial preparation is utilized, and comprises enterococcus faecalis, bacillus licheniformis, baumanii, rhodococcus, sphingomonas sp and pseudomonas fluorescens. According to the process disclosed by the invention, various pollutants in the coal chemical industrial wastewater can be effectively removed; and the environmental protection process accords with the emission standard.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

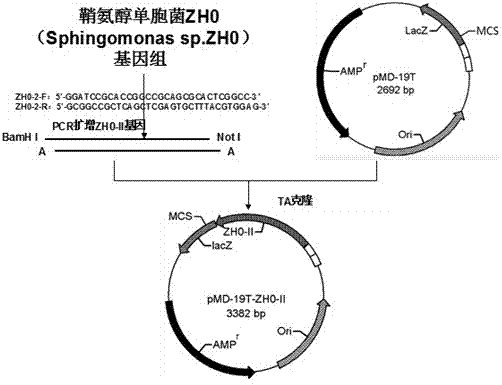

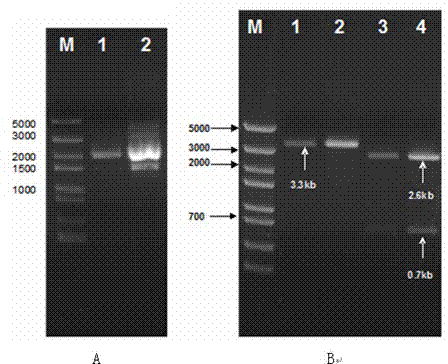

Sphingomonas alginate lyase gene ZH0-II as well as prokaryotic expression vector and application thereof

InactiveCN103173476ASolve the problem of low outputBroad substrate specificityMicroorganism based processesFermentationSphingomonas sp.Bacillus coli

The invention discloses a sphingomonas alginate lyase gene ZH0-II and an efficient prokaryotic expression vector pGEX-4T-1-ZH0-II thereof. A Ptac promoter is utilized to control the expression of the prokaryotic expression vector pGEX-4T-1-ZH0-II in colon bacillus. The expression of the alginate lyase gene is performed by the colon bacillus expression vector, so that the alginate lyase ZH0-II as an express product can be obtained in a short time. The obtained recombinant alginate lyase gene ZH0-III is wide in substrate specificity, wherein the PloyG or the PloyM can be served as a substrate; and the enzyme activity can reach 61.7U / mg. The prokaryotic expression vector and the overall expression system are easy to operate, and are convenient for industrialized production.

Owner:KUNMING UNIV OF SCI & TECH

Cable pit ash sluicing water treatment method

InactiveCN105330026ALarge biomassHigh tensile strengthBiological water/sewage treatmentThiobacillus ferrooxidansSphingomonas sp.

The invention belongs to the technical field of biological environmental protection, and discloses a cable pit ash sluicing water treatment method. The method adopts a specific biological preparation to treat ash sluicing water, and the biological preparation is prepared through culturing Thiobacillus ferrooxidans, Thiobacillus thiooxidans, Pseudomonas aeruginosa, Sphingomonas sp. and Scenedesmus obliquus, and mixing with a specific carrier. The biological preparation prepared in the invention can effectively treat ash sluicing water wastewater.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

Lycopene cyclase gene in sphingomonas sp. and use thereof

The invention provides the DNA sequence of a lycopene cyclase gene (crtY) in sphingomonas sp., a recombinant strain lacking lycopene cyclase and use thereof. The nucleotide sequence of the crtY gene is represented by SEQ ID NO.1. The DNA sequence of the lycopene cyclase gene (crtY) in sphingomonas sp., which is provided by the invention, lays a foundation for the genetic modification of a sphingomonas sp. carotenoid biological synthesis means. In addition, compared with a wild strain, the sphingomonas sp. recombinant strain lacking the lycopene cyclase gene, which is constructed by a gene knockout method, has the advantages that: the gellengum yield is basically unchanged; and lycopene can be produced in the production of gellengum by fermentation. And the strain can be used for further gene knockout or metabolic engineering modification.

Owner:ZHEJIANG UNIV

Method for synthesizing Welan gum with specific viscosity

InactiveCN106544377AHigh viscosityAchieve productionMicroorganism based processesFermentationGellan gumSucrose

The invention discloses a method for synthesizing Welan gum with specific viscosity and belongs to the field of biochemical engineering. The Welan gum is synthesized by sphingomonas sp. fermentation. The production of the Welan gum with the viscosity scope being 1.5-3.8 Pas is implemented by controlling the condition that a fermentation medium is composed of 40 g / L of sucrose, 0-4 g / L of beef extract, 0-4 g / L of sodium nitrate, 0.6 g / L of KH2PO4 and 0.2 g / L of MgSO4.7H2O at the pH value of 7.0. The method for synthesizing the Welan gum with the specific viscosity is simple and practicable.

Owner:JIANGNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com