Preparation method of high-gel-strength, high-viscosity and high-acyl gellan gum

A high-viscosity, high-gel technology, applied in the field of microbial fermentation, can solve the problems of low gel strength, viscosity and gel strength cannot meet high performance at the same time, and achieves improved dissolution rate, good industrial adaptability and application prospects. , the effect of reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

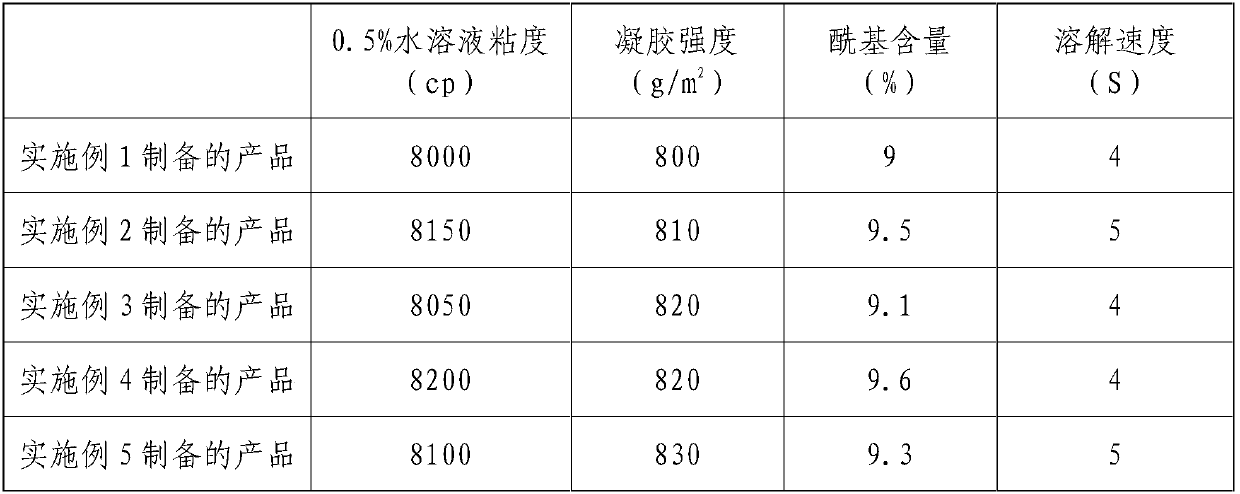

Examples

Embodiment 1

[0055] The preparation method of gellan gum with high gel strength, high viscosity and high acyl group comprises the following process steps:

[0056] A. Inoculate Sphingomonas sp. (Sphingomonas sp.) CGMCC No.14238 according to the inoculation amount of 10%-20% to a high carbon-nitrogen ratio after sterilization and containing carbon source, nitrogen source and necessary nutrients in the fermentation medium;

[0057] B. Adjust the pH of the fermentation medium to 7.0, and carry out aerated fermentation under the condition that the temperature is 35°C and the ventilation rate is 0.3vvm;

[0058] C, ferment for 20-30 hours and add sterile water and oxygen-carrying agent;

[0059] D. When the viscosity of the culture medium no longer increases or the fermentation period is less than or equal to 50 hours, the fermentation ends;

[0060] E. After the fermentation is finished, the fermentation broth is post-extracted to prepare gellan gum with high gel strength, high viscosity and...

Embodiment 2

[0069] The difference between this embodiment and embodiment 1 is:

[0070] B. Adjust the pH of the fermentation medium to 7.5, and carry out aerated fermentation under the condition that the temperature is 37°C and the ventilation rate is 0.8vvm;

[0071] Fermentation medium in steps A and B is made up of the following raw materials of mass percentage:

[0072] Glucose or maltose 4%; soybean protein isolate 0.3%; sodium nitrate 0.2%; calcium carbonate 0.15%; potassium dihydrogen phosphate 0.25%; silicone defoamer 0.15%; the balance is sterile water.

[0073] The process condition of adding sterile water and oxygen-carrying agent in the step C is:

[0074] After 20-30 hours of fermentation, sterilized water accounting for 5% of the volume of the fermentation broth and 0.6% of the oxygen-carrying agent for the volume of the fermentation broth were supplemented, and the oxygen-carrying agent was selected from Tween 20.

[0075] Adjust the pH of the fermented broth after fermen...

Embodiment 3

[0077] The difference between this embodiment and embodiment 1 is:

[0078] B. Adjust the pH of the fermentation medium to 7.2, and carry out aerated fermentation under the condition that the temperature is 36°C and the ventilation rate is 0.5vvm;

[0079] Fermentation medium in steps A and B is made up of the following raw materials of mass percentage:

[0080] Glucose or maltose 3.5%; soybean protein isolate 0.2%; sodium nitrate 0.15%; calcium carbonate 0.12%; potassium dihydrogen phosphate 0.2%; organic silicon defoamer 0.1%; the balance is sterile water.

[0081] The process condition of adding sterile water and oxygen-carrying agent in the step C is:

[0082] After 20-30 hours of fermentation, sterilized water accounting for 4% of the volume of the fermentation broth and 0.5% of the oxygen-carrying agent for the volume of the fermentation broth were supplemented, and the oxygen-carrying agent was selected from the combination of hydrogen peroxide and Tween 20.

[0083] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com