Patents

Literature

341results about How to "Reduce production and use costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rhodococcus ruber strain and application thereof in treatment of wastewater containing organic pollutants

ActiveCN103627653AGood degradation effectReduce production and use costsBacteriaWater contaminantsEnvironmental chemistryEnvironmental geology

The invention discloses a Rhodococcus ruber strain and an application thereof in treatment of wastewater containing organic pollutants. The strain is named as Rhodococcus ruber ZHY1-6, the preservation number of the strain is CGMCC (China General Microbiological Culture Collection Center) No.8173. A microbial agent is prepared from the Rhodococcus ruber strain; the Rhodococcus ruber ZHY1-6 and the microbial agent are used in a treatment technology of treating wastewater containing organic pollutants, so as to degrade the organic pollutants in wastewater; when the strain and the microbial agent are used in treatment of high-salt phenol wastewater, hydrocarbon-containing wastewater and perfume wastewater, cost of wastewater treatment is reduced, and the strain and the microbial agent have important significance in protecting ecological environment and people health.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

Composite glaze, composite glaze slip and 4-8 degree soft-surface wear-resistant porcelain antique brick

The invention relates to a composite glaze, a composite glaze slip and a 4-8 degree soft-surface wear-resistant porcelain antique brick. The composite glaze slip comprises the following components inparts by mass: 51-55 parts of a high temperature matte transparent wear-resistant frit, 35-39 parts of matte transparent component glaze, and 7-11 parts of wear-resistant antiskid dry particles, and the sum of mass of the three components is 100 parts. After the composite glaze is sintered, a soft-surface wear-resistant glaze layer whose glossiness is 4-8 degrees is formed.

Owner:MONALISA GRP CO LTD

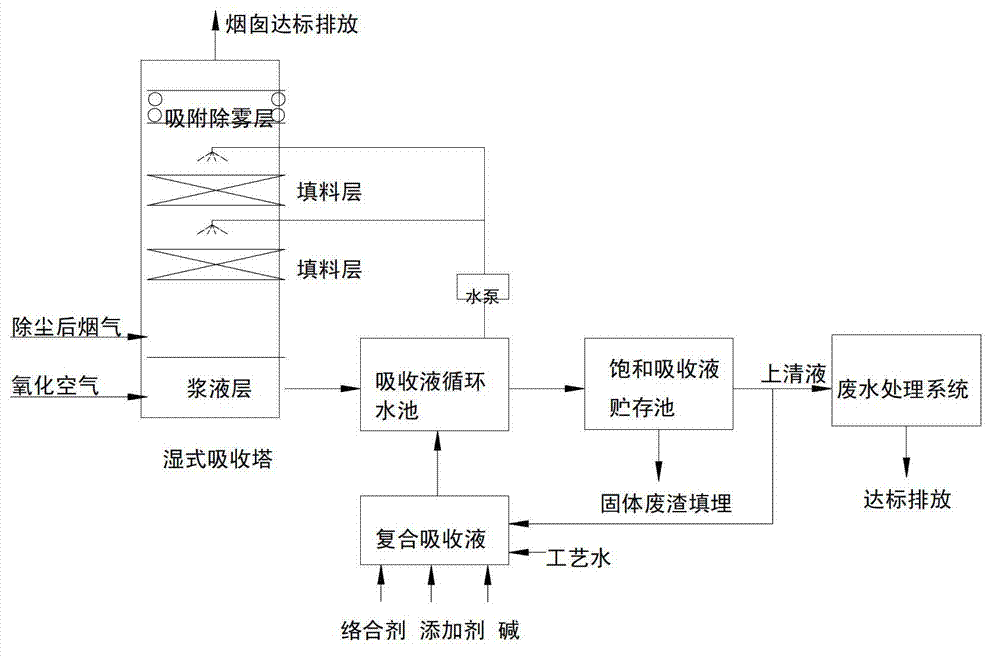

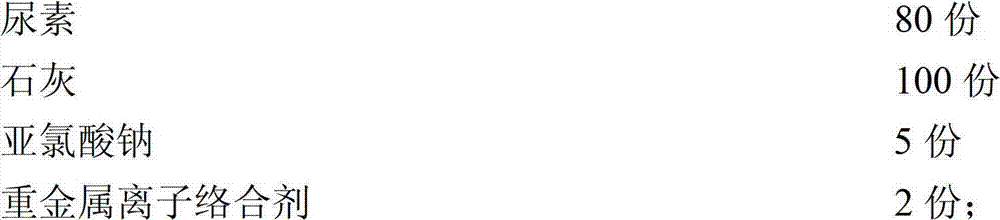

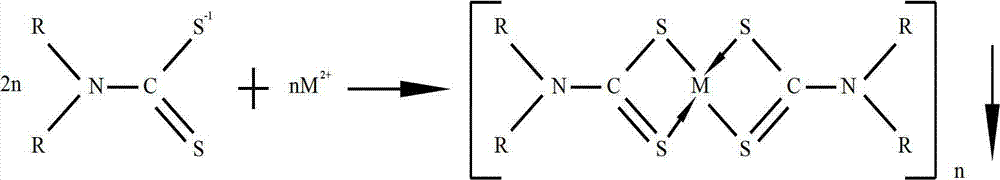

Method for collaboratively controlling multi-pollutants produced from waste incineration smokes

ActiveCN102921278AEfficient removalConvenient sourceDispersed particle separationAir quality improvementMulti pollutantLitter

The invention discloses a method for collaboratively controlling multi-pollutants produced from waste incineration smokes. By developing a novel compound absorption liquid and improving the structure of the conventional absorption tower, multiple pollutants in waste incineration smokes are simultaneously and efficiently removed in a same device with the adoption of a two-stage serial processing mode of oxidation absorption / complexation and adsorption. The method concretely comprises the following steps of: cleaning and removing SO2, HCl, HF, NOX, heavy metal and part of dioxin in waste incineration smokes by using a mixed absorption liquid of alkali, an oxide addition and a heavy metal ionic complex agent, and stabilizing the heavy metal so as to avoid secondary volatilization of the heavy metal; and further absorbing the dioxin and the heavy metal in the smokes via a demister which is made of an adsorption material and serially connected at the top of the absorption tower so that the discharge of the smokes is finally up to the standard. The invention has the advantages of simple method and device, easiness in operation, running and management, small occupied area, low overall operating cost, high pollutant removing efficiency and the like.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

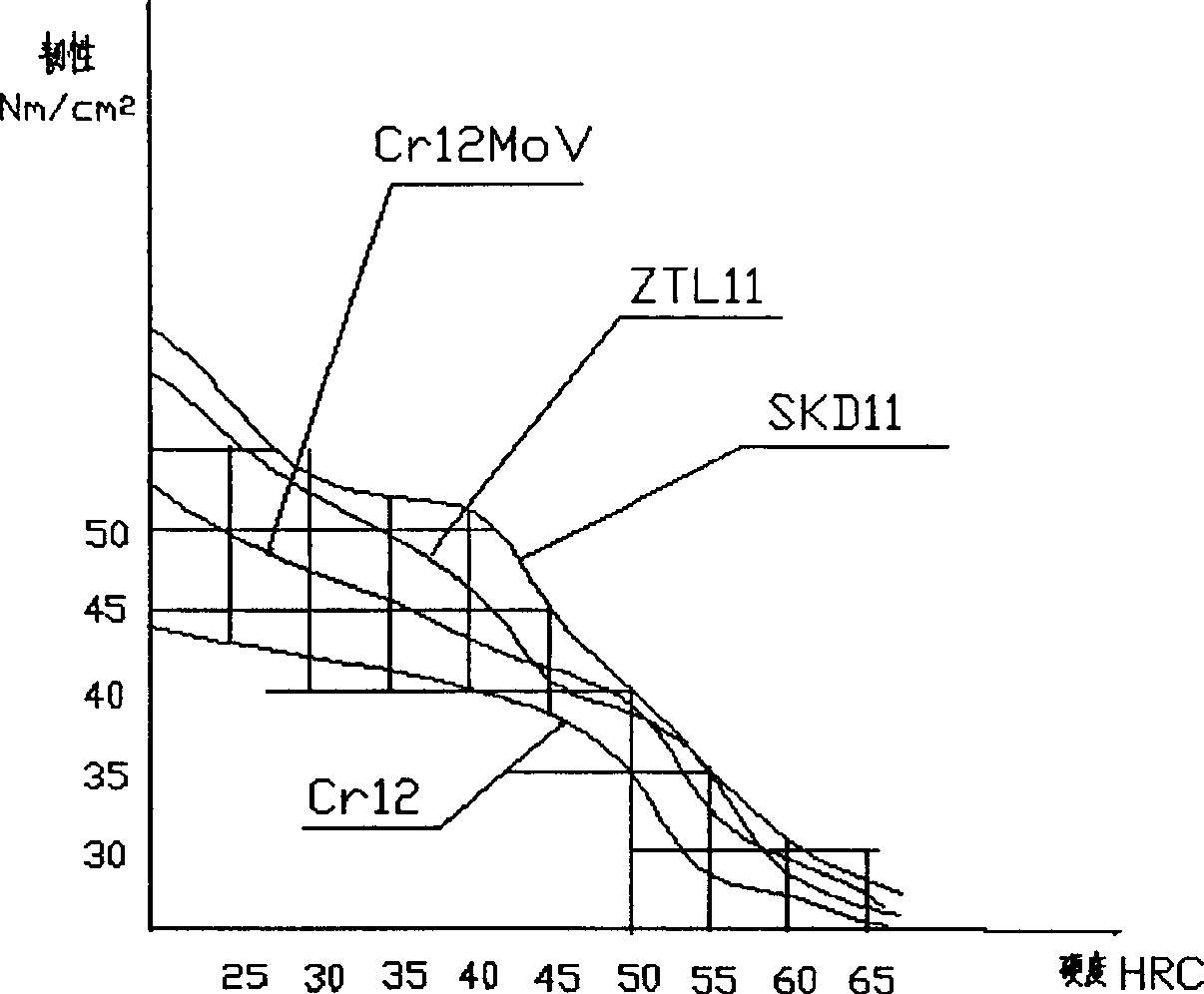

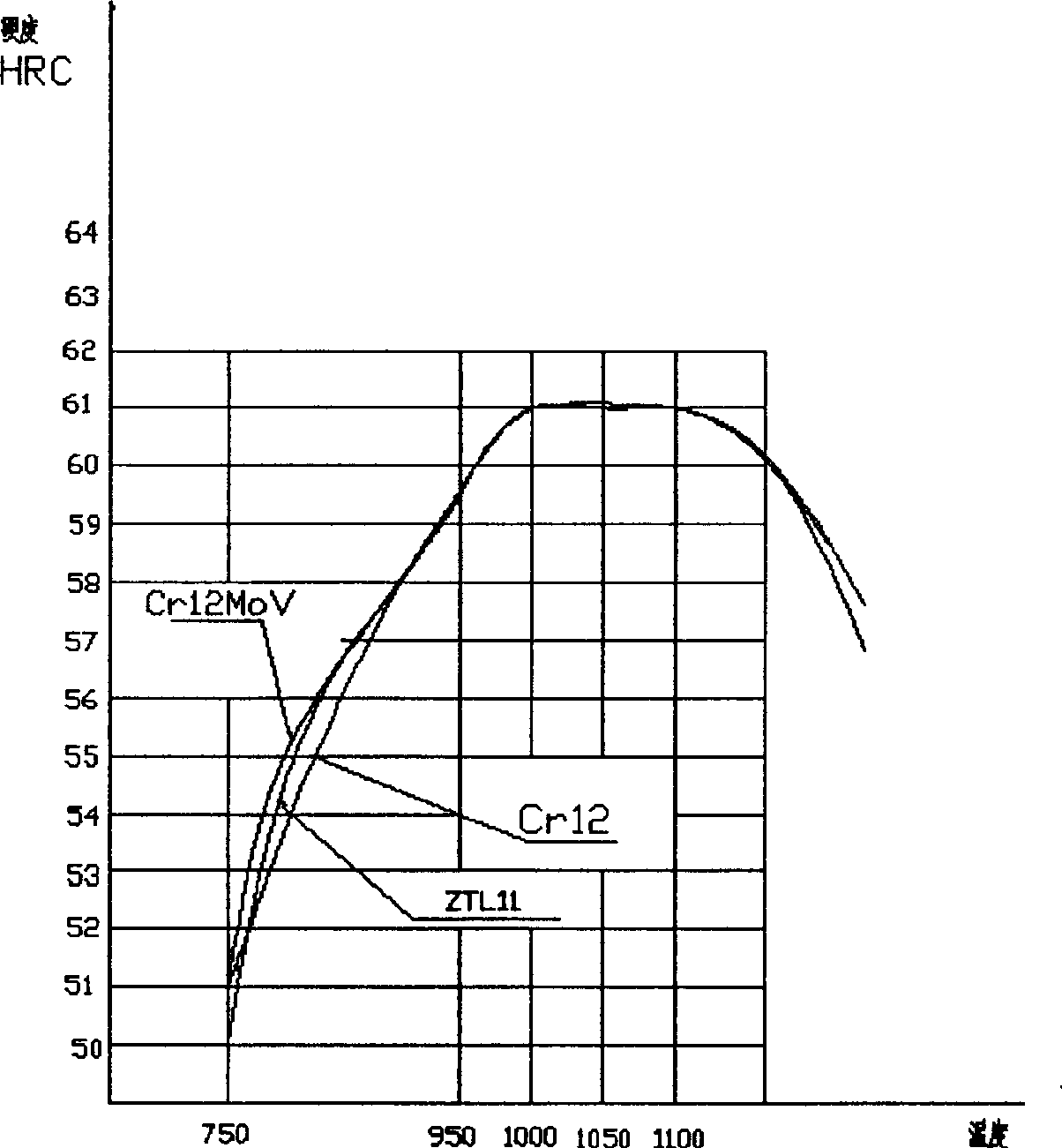

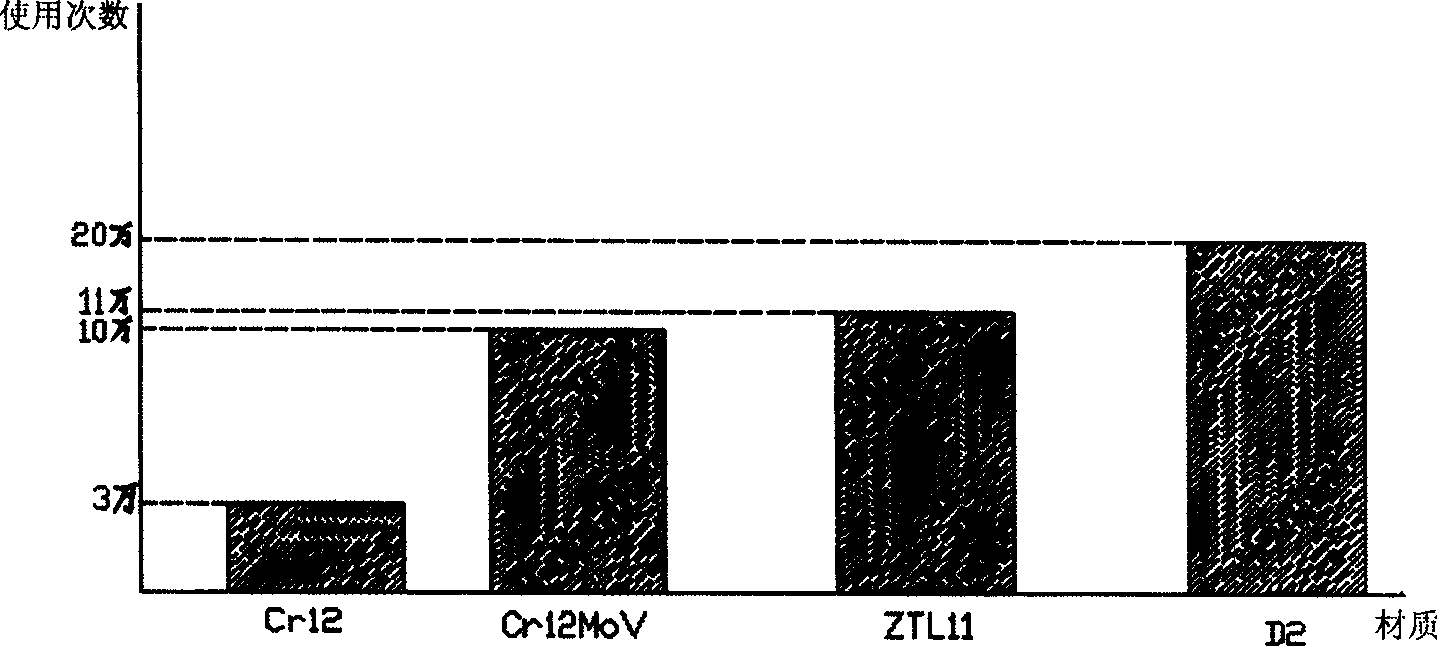

Cold working die steel material and production technology thereof

InactiveCN101381844AImprove wear resistanceEasy to processProcess efficiency improvementElectric furnaceTrace elementPrice ratio

The invention provides a cold-working die steel material, which comprises the following trace elements in percentage by weight: 0.95 to 1.05 percent of C, 0.35 to 0.45 percent of Mn, 0.55 to 0.65 percent of Si, 7.55 to 8.5 percent of Cr, 0.45 to 0.55 percent of Mo, 0.35 to 0.45 percent of V, less than or equal to 0.025 percent of S, and less than or equal to 0.025 percent of P. The cold-working die steel material has simple technical process and easily-controlled operation, adopts alloying and modification treatment, has good hardenability, stable temper resistance, higher wear resistance and good processability, can improve work efficiency, reduce production cost, reduce or avoid moulds from breaking and cracking, and has long service life, high performance-price ratio and wide application.

Owner:尚宗文

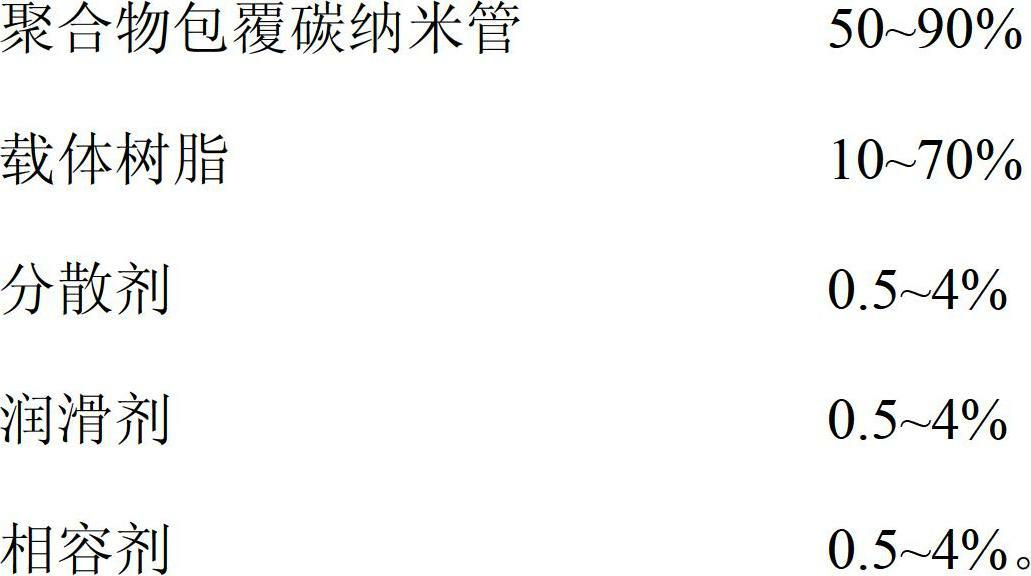

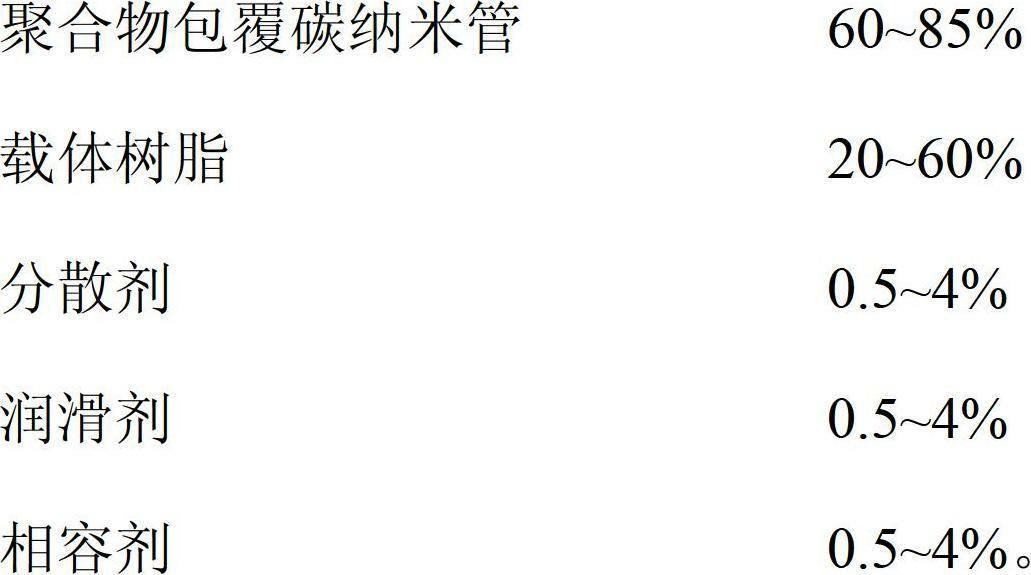

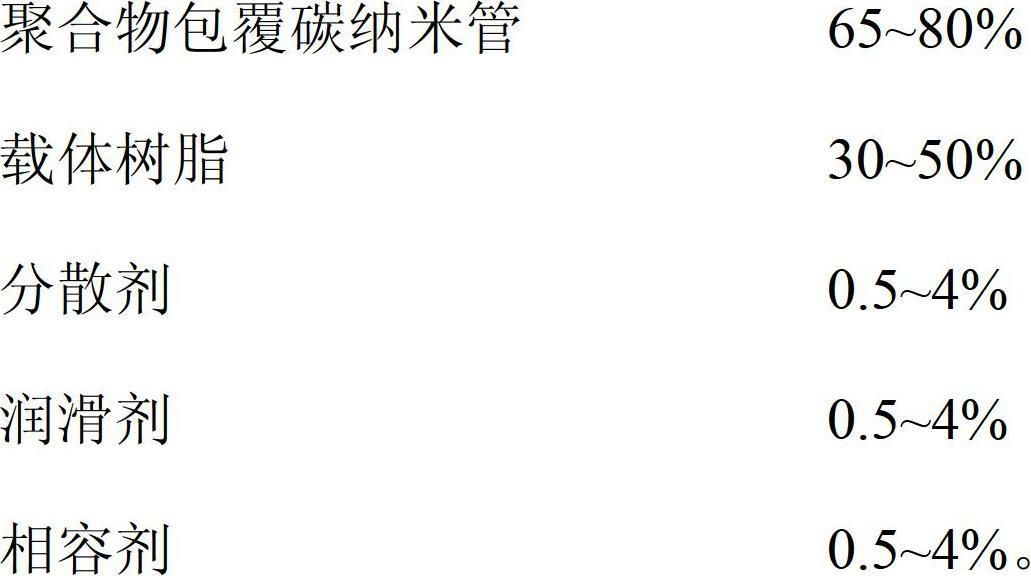

Macromolecule conductive master batches

The invention relates to macromolecule conductive master batches which comprise, by mass ratio, 50% to 90% of polymer coated carbon nanometer tubes and 10% to 70% of carrier resin. Plastic finished products obtained through the conductive master batches are low in production utilization cost, the pipe surface is smooth, dispersity is good, no air bubble is inside products, and the quality is stable; the conductivity property (surface and internal resistance) achieves 5000 omegas on the premise of not increasing the cost, so that products have excellent antistatic properties.

Owner:DONGGUAN DECHENG PLASTIC TECH

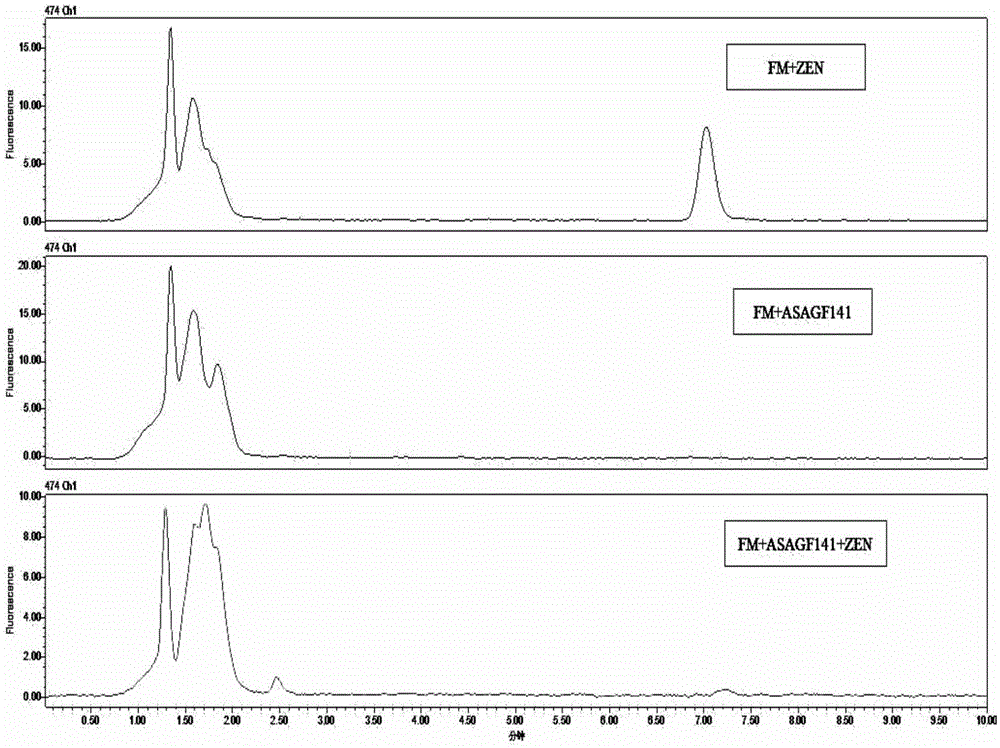

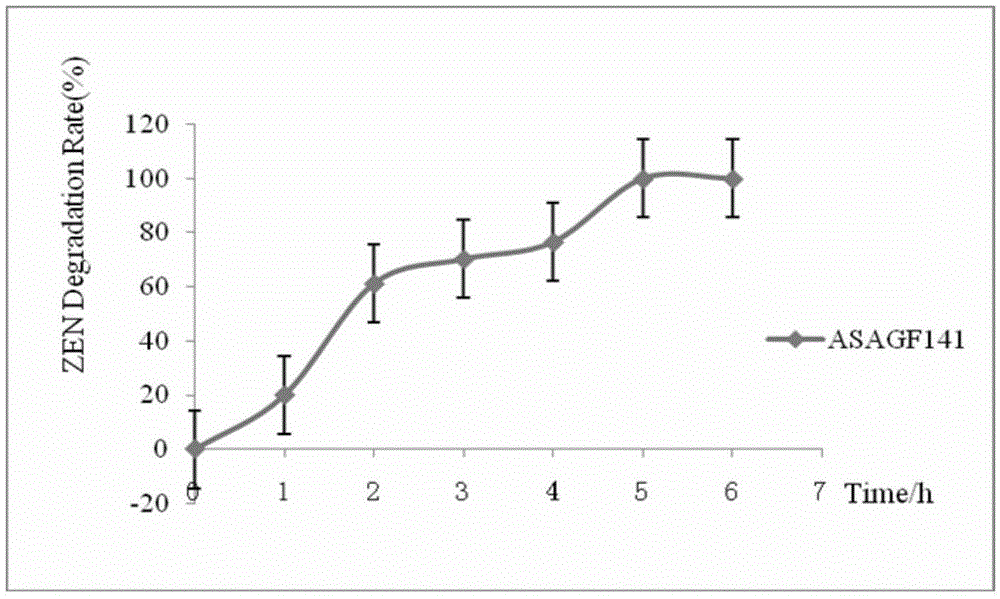

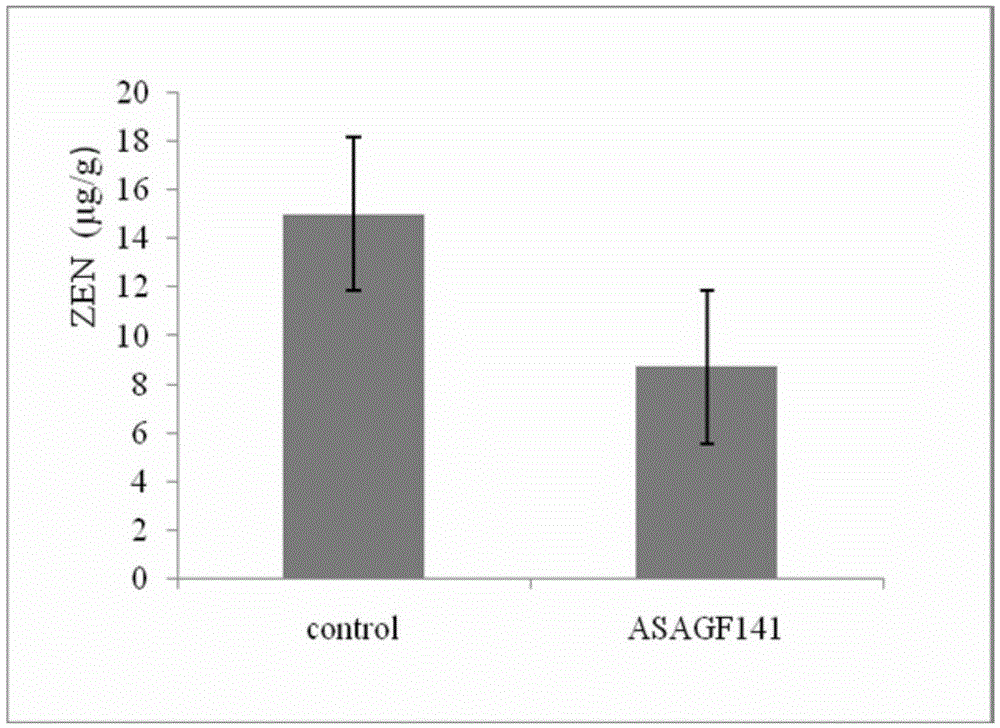

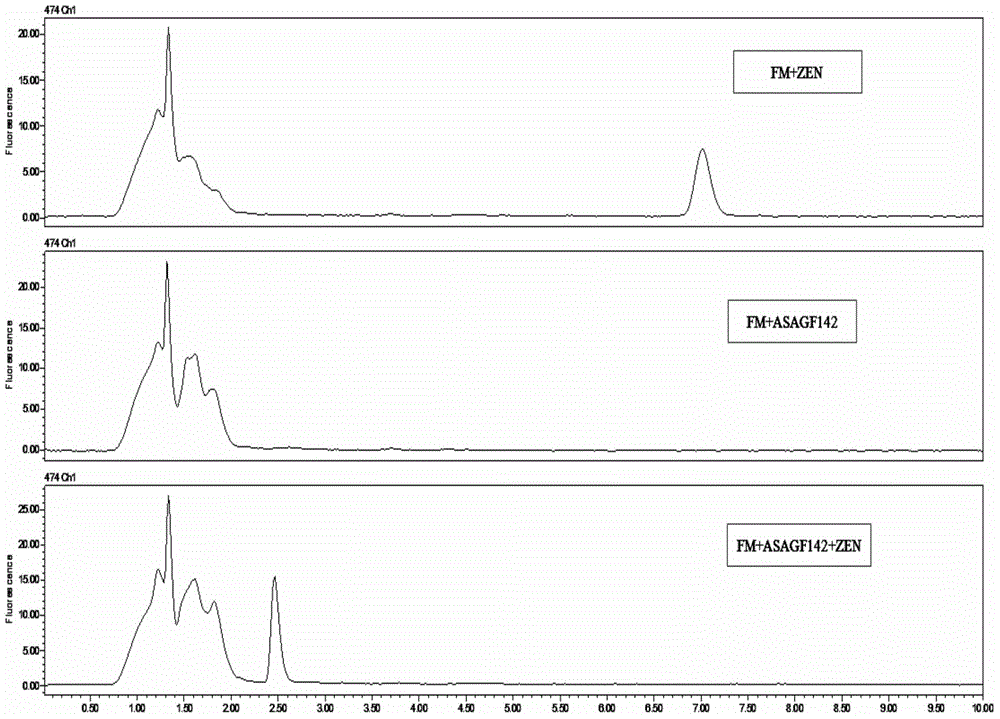

Bacillus subtilis for effectively degrading zearalenone and application thereof

ActiveCN105385616AEfficient degradationEfficient production and degradationBacteriaMicroorganism based processesMicrobiologyVirgibacillus species

The invention discloses Bacillus subtilis for effectively degrading zearalenone and application thereof. The preservation serial number of the Bacillus subtilis ASAGF141 is CGMCC No.9463. The invention further provides bactericide containing preserved strains and a preparation method of the bactericide; besides, the invention further provides application of the strains or the bactericide to degradation of the zearalenone. According to the Bacillus subtilis for effectively degrading zearalenone and application thereof, the trains can completely degrade the 20 microgram / ml zearalenone within a short time, and the degradation rate is 10%.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

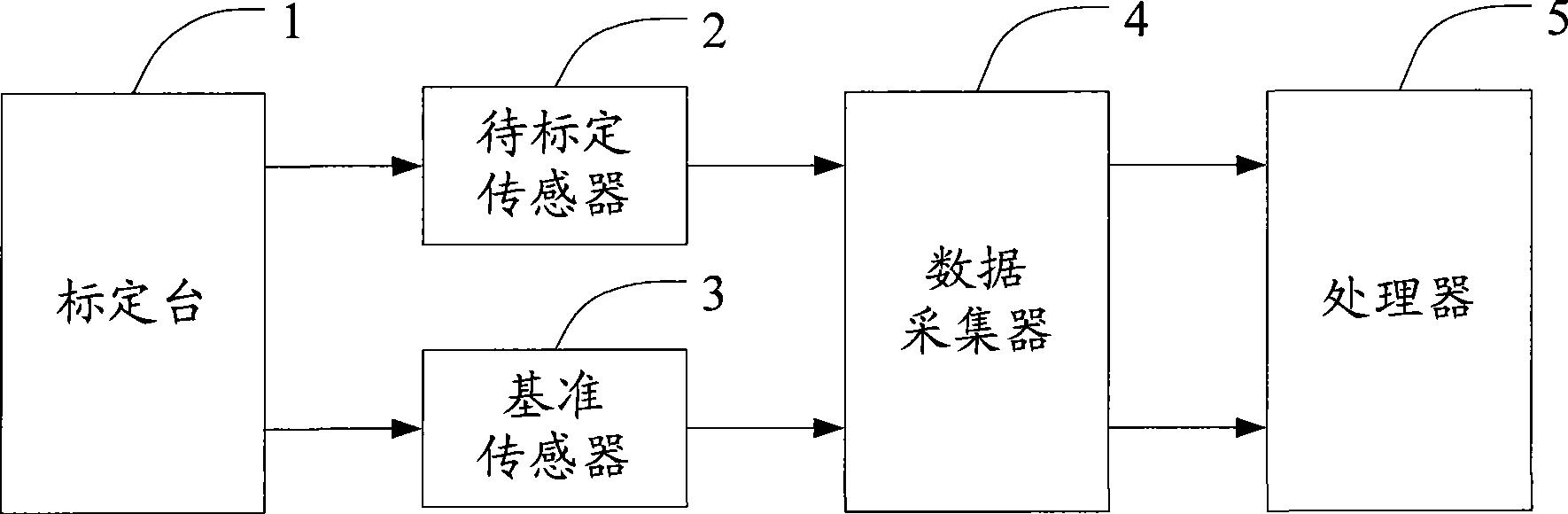

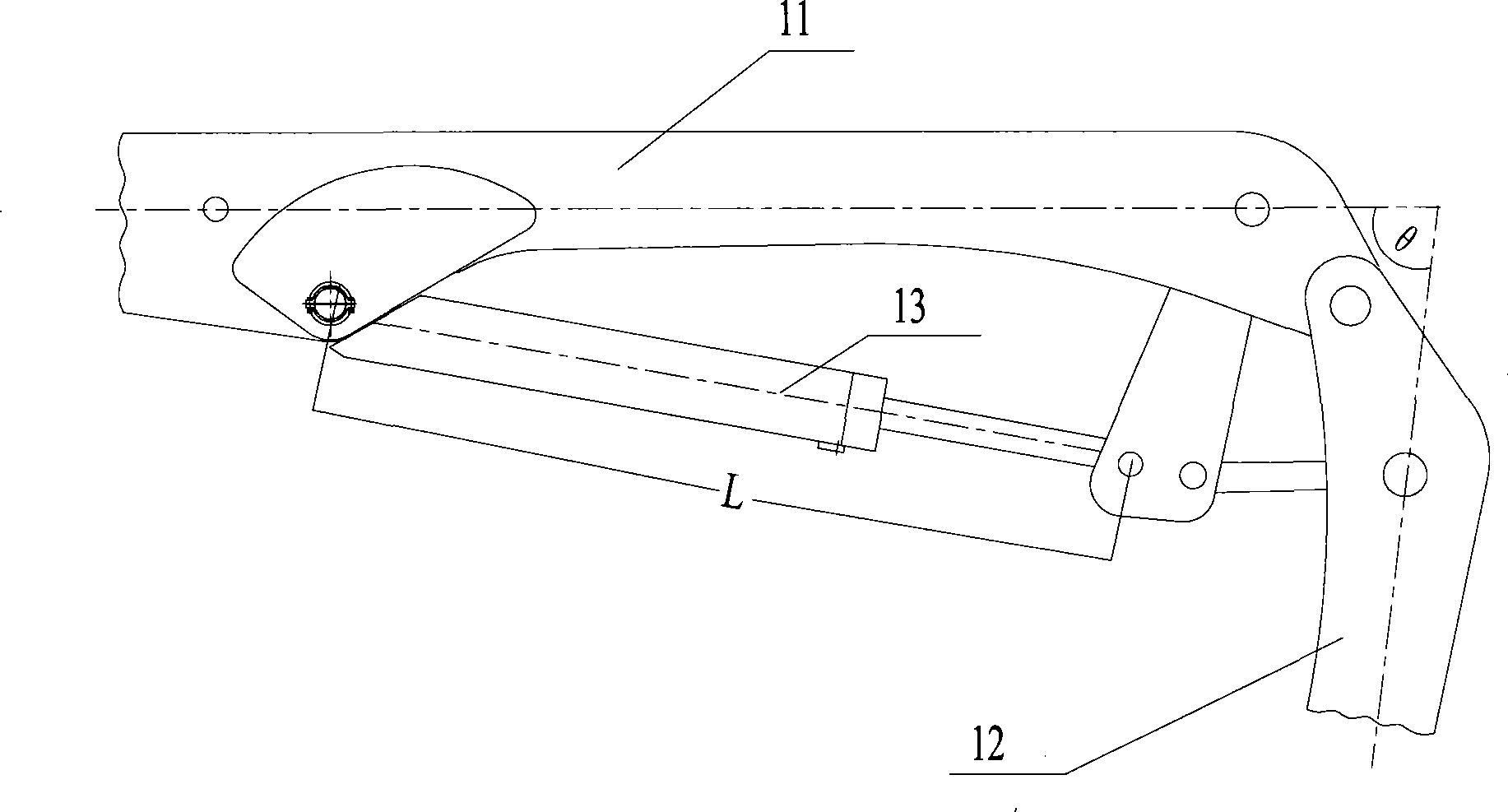

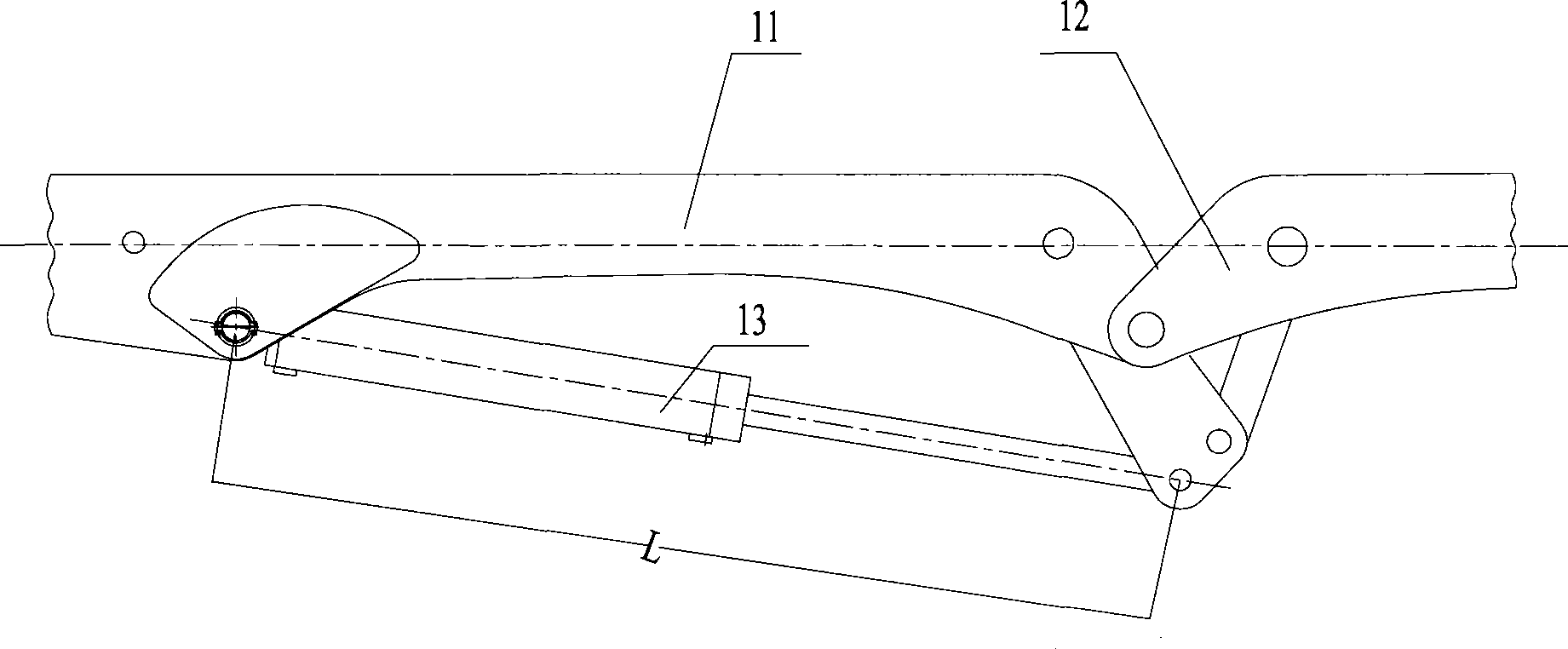

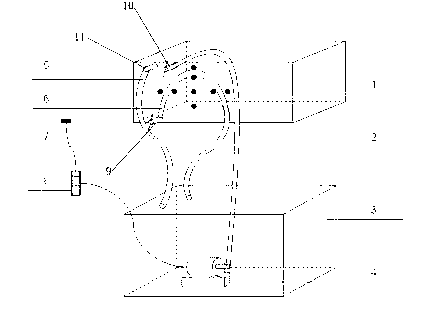

Method and device for calibrating sensor for measuring angle of mechanical arm or manipulator

InactiveCN101451832AEliminate errorsGuaranteed Calibration AccuracyMeasurement devicesEngineeringManipulator

The invention discloses a sensor scaling method for measuring angles of mechanical arm and mechanical hand, comprising the steps of: pre-storing data lists between the mechanical arm and mechanical hand driving mechanism length, between angle of the mechanical arm and angle of the mechanical hand; searching for the data lists by acquiring a measurement value of the sensor to be scaled on the mechanical arm and mechanical hand driving mechanism length, and acquiring theoretical values of the angles of mechanical arm and mechanical hand corresponding to the measurement value of the sensor to be scaled on the mechanical arm and mechanical hand driving mechanism length, as scaled reference values of the sensor to be scaled; comparing and analyzing the measurement value of the sensor to be scaled and the scaled reference values, and scaling the sensor to be scaled. The invention, with no limitation of own installation means of the sensor, can accurately scale when the mechanical arm or mechanical hand is in any status. On this basis, the invention also discloses a sensor scaling device for measuring angles of mechanical arm and mechanical hand.

Owner:SANY HEAVY IND CO LTD (CN)

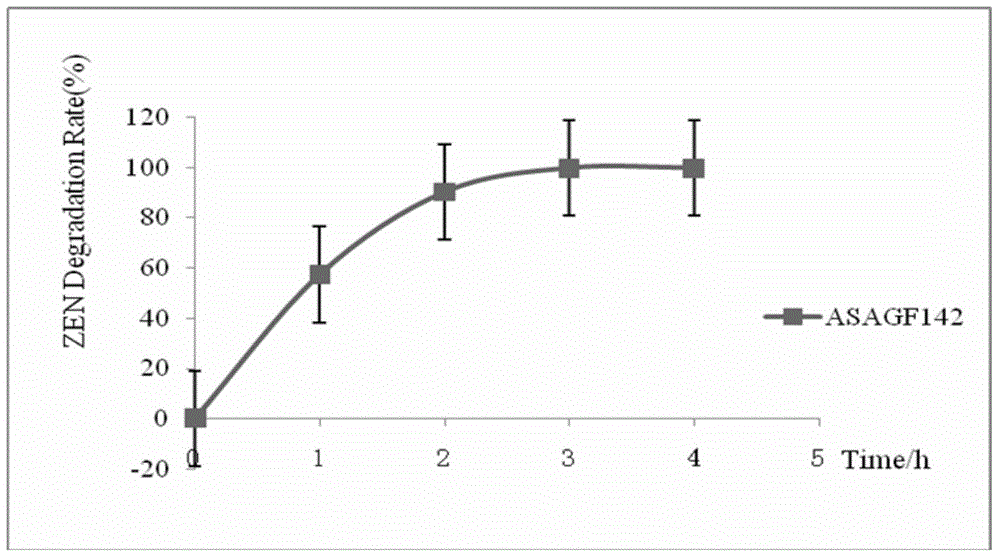

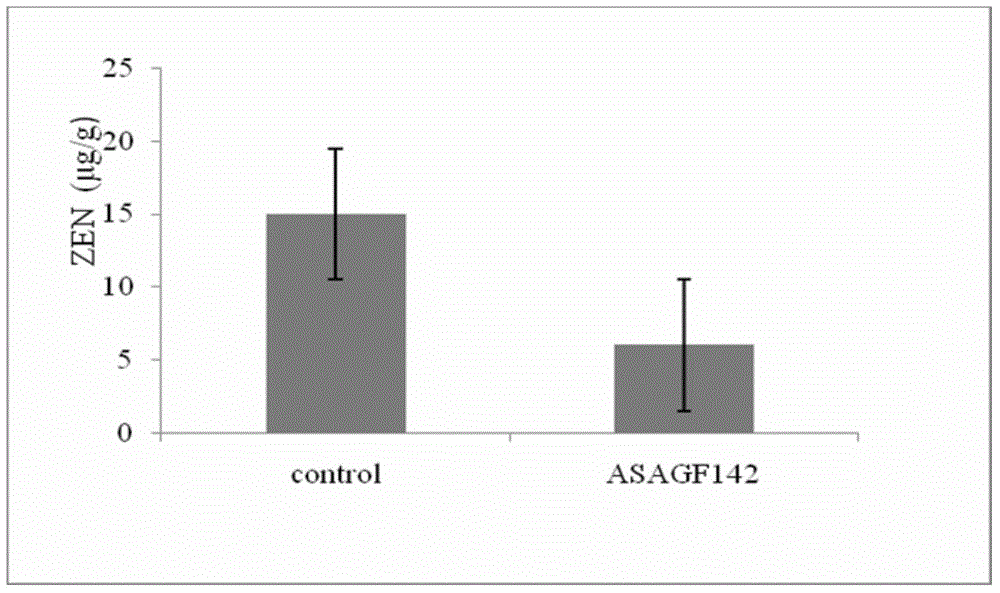

Bacillus amyloliquefaciens capable of degrading ZEN (zearalenone) efficiently and application of bacillus amyloliquefaciens

ActiveCN105087444AEfficient degradationEfficient degradation abilityBacteriaMicroorganism based processesBacillus amyloliquefaciensMicrobiology

The invention discloses bacillus amyloliquefaciens capable of degrading ZEN (zearalenone) efficiently and an application of the bacillus amyloliquefaciens. The collecting number of the bacillus amyloliquefaciens ASAGF142 is CGMCC (China General Microbiological Culture Collection Center) No. 9464. The invention further provides an inoculant comprising the collected strain and a preparation method of the inoculant. Besides, the invention provides the application of the strain or the inoculant in degradation of ZEN. The strain can degrade 20 mu g / ml of ZEN completely in short time, and the degradation rate is 100%.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

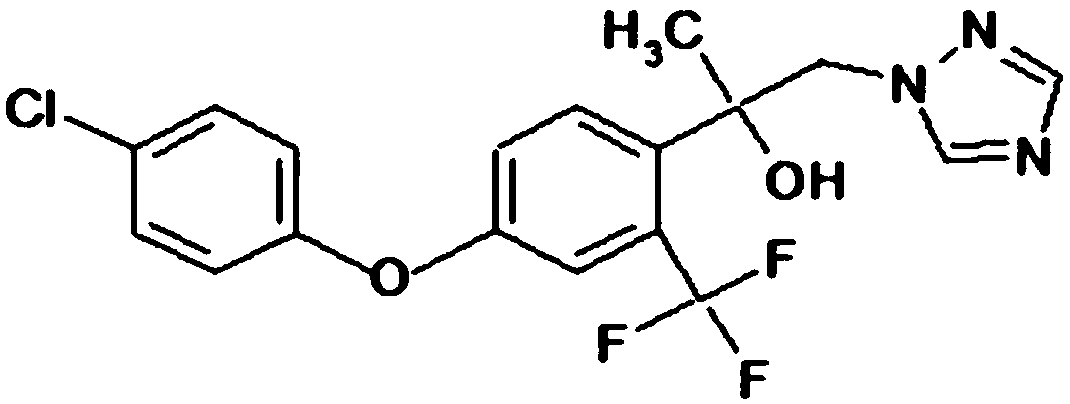

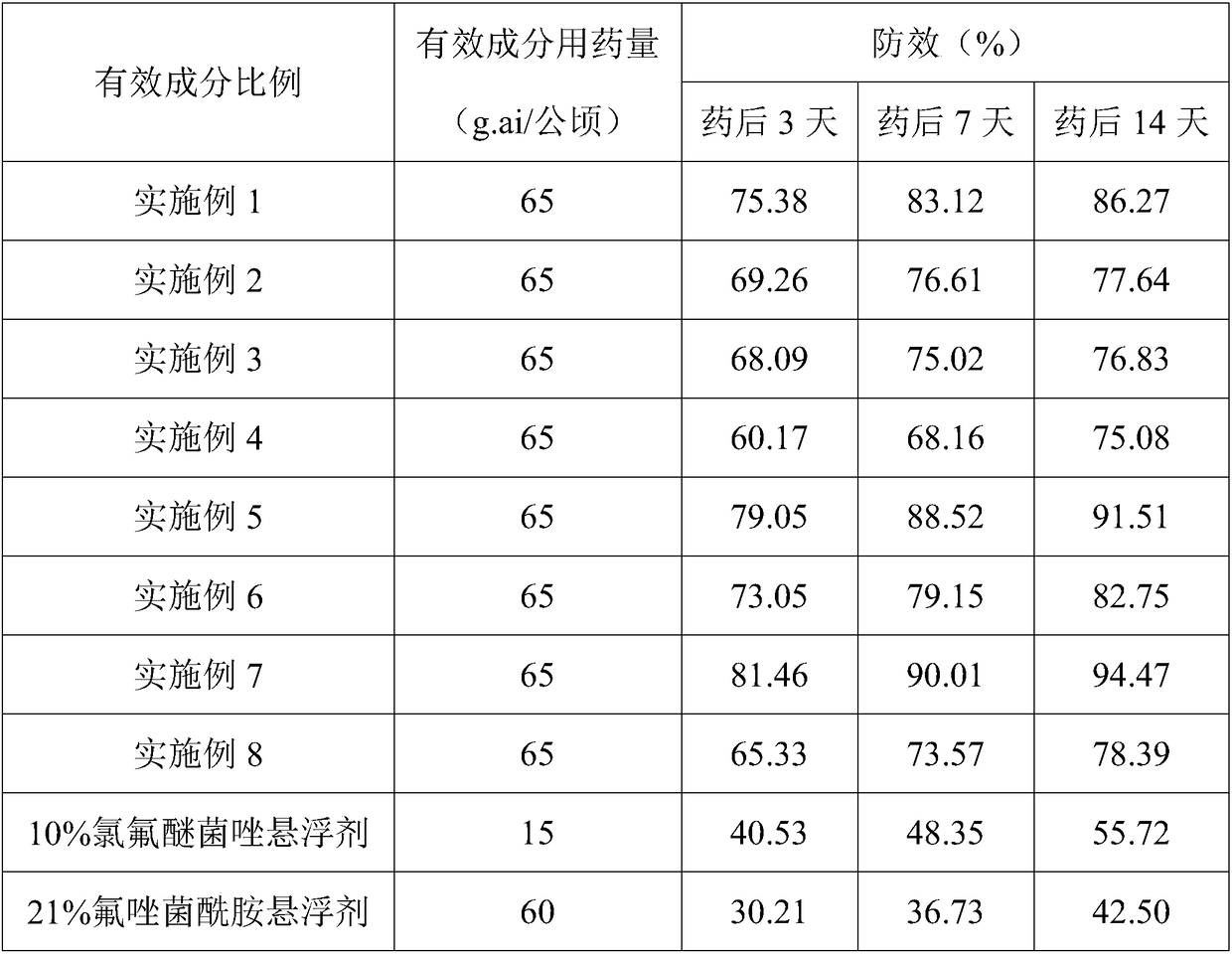

Bactericidal composition containing mefentrifluconazole and fluxapyroxad

InactiveCN108541711AReduce production and use costsReduce the workload of prevention and treatment and the cost of medicationBiocideFungicidesControl effectBotrytis cinerea

The invention discloses a bactericidal composition containing mefentrifluconazole and fluxapyroxad. The bactericidal composition is characterized by containing active ingredients of mefentrifluconazole and fluxapyroxad, the mass ratio of mefentrifluconazole to fluxapyroxad is 1:50 to 50:1, preferably, 1:30 to 30:1, more preferably, 1:20 to 20:1, further more preferably, 1:10 to 10:1, and the mostpreferably, 1:1, 1:2, 1:3, 1:5, 2:3, 5:7, 2:1 and 3:8, and the active ingredients of mefentrifluconazole and fluxapyroxad account for 1%-80% of the mass of the composition. Mefentrifluconazole and fluxapyroxad are compounded in a certain proportion, so that the bactericidal composition has a higher control effect on botrytis cinerea and rice sheath blight.

Owner:FOSHAN RUISHENGTONG TECH CO LTD

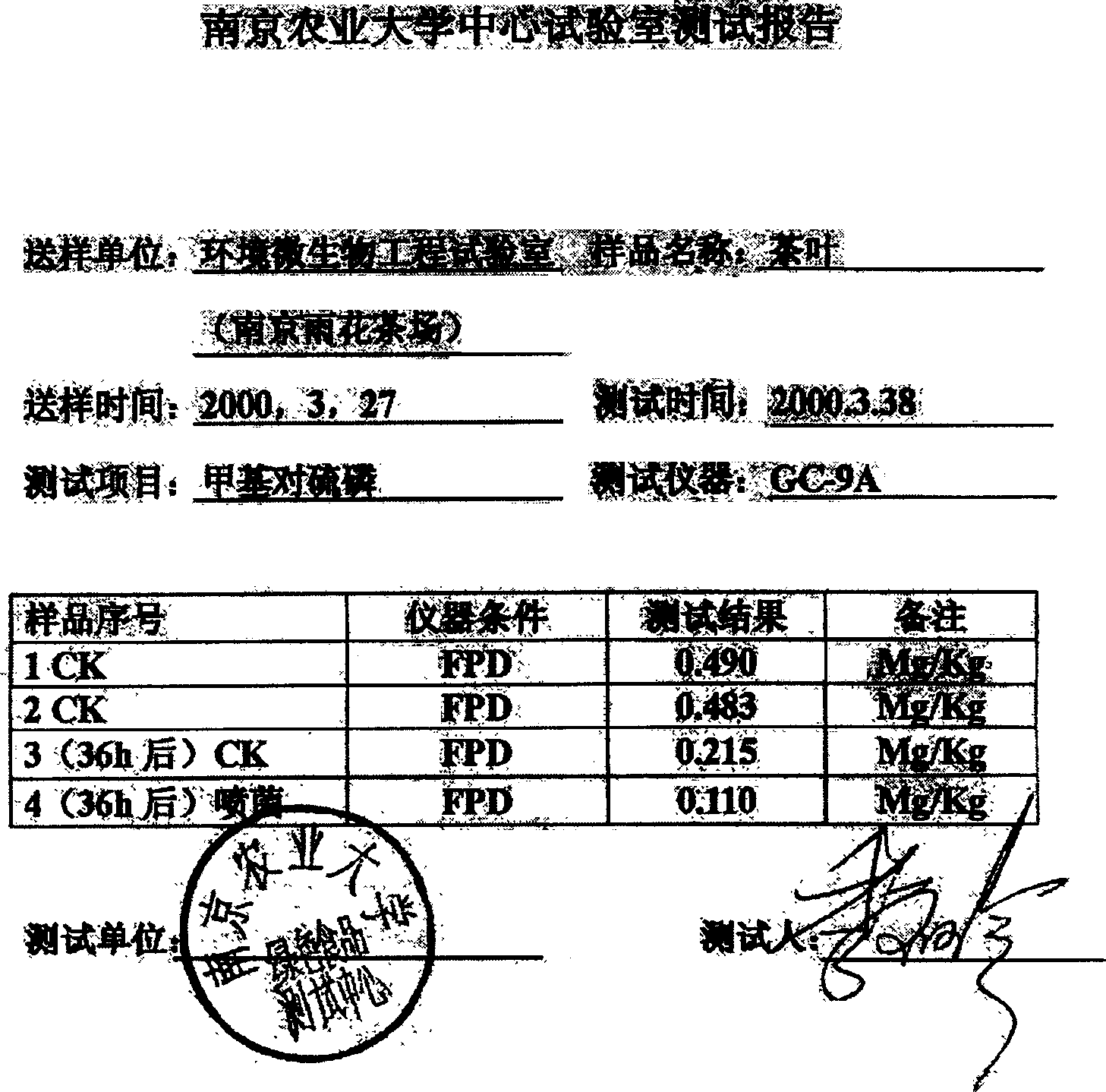

Bacterium of degrading residual of organophorus pespared agent of bacterium

InactiveCN1563356AWill not affect the use effectEasy to useBacteriaPesticide residuePseudomonas putida

A bacterial strain for eliminating organophosphorous residue is Granis staining reaction negative bacteria DLL-1 identified as pseudomonas putida. Its biological feature is G- with thallus being short bar shape, tail end being oval and single end being grown thickly with flagellum. The Genbank landing number of 16S rDNA for the bacterial strian is AF 447394.

Owner:NANJING AGRICULTURAL UNIVERSITY

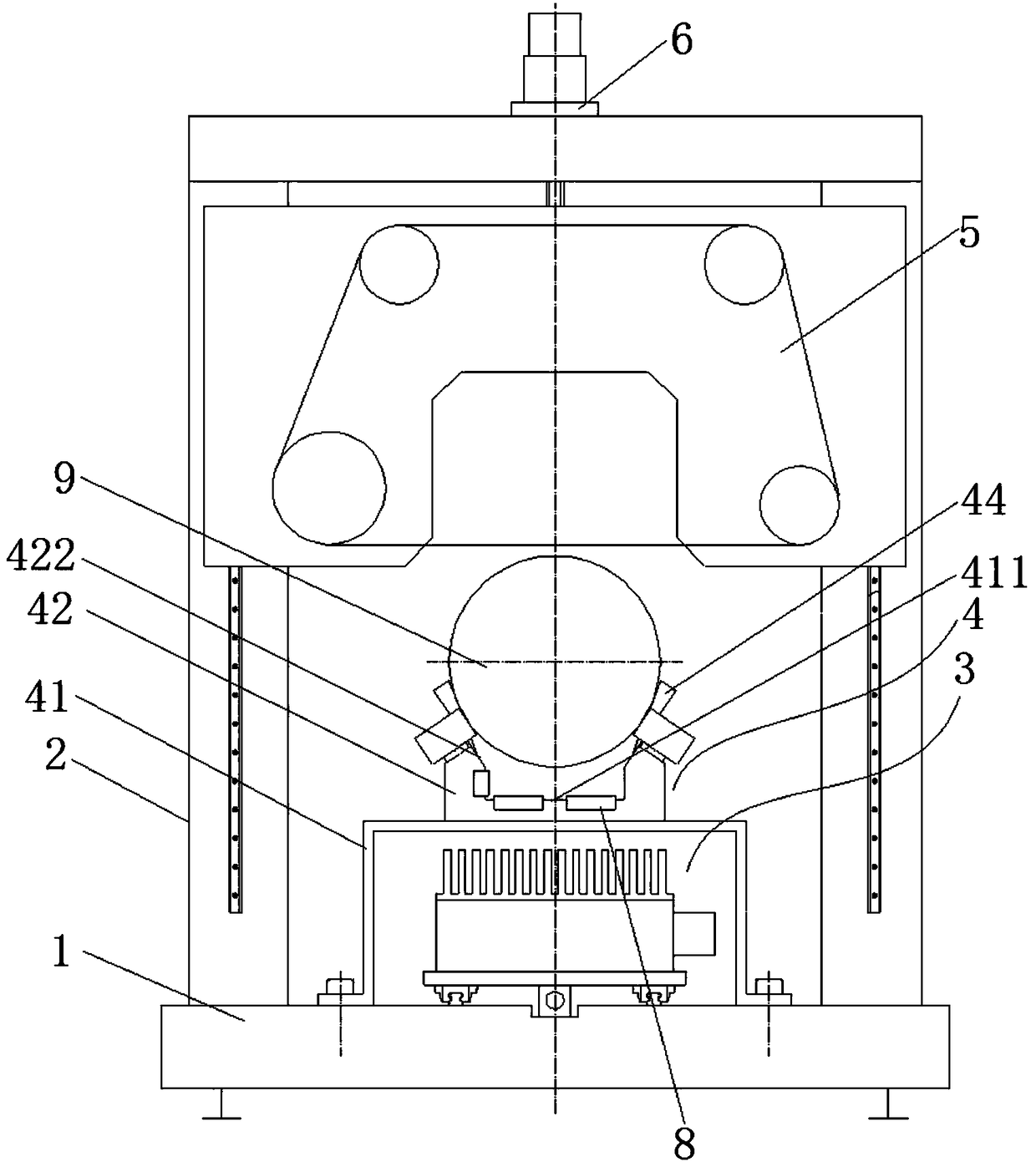

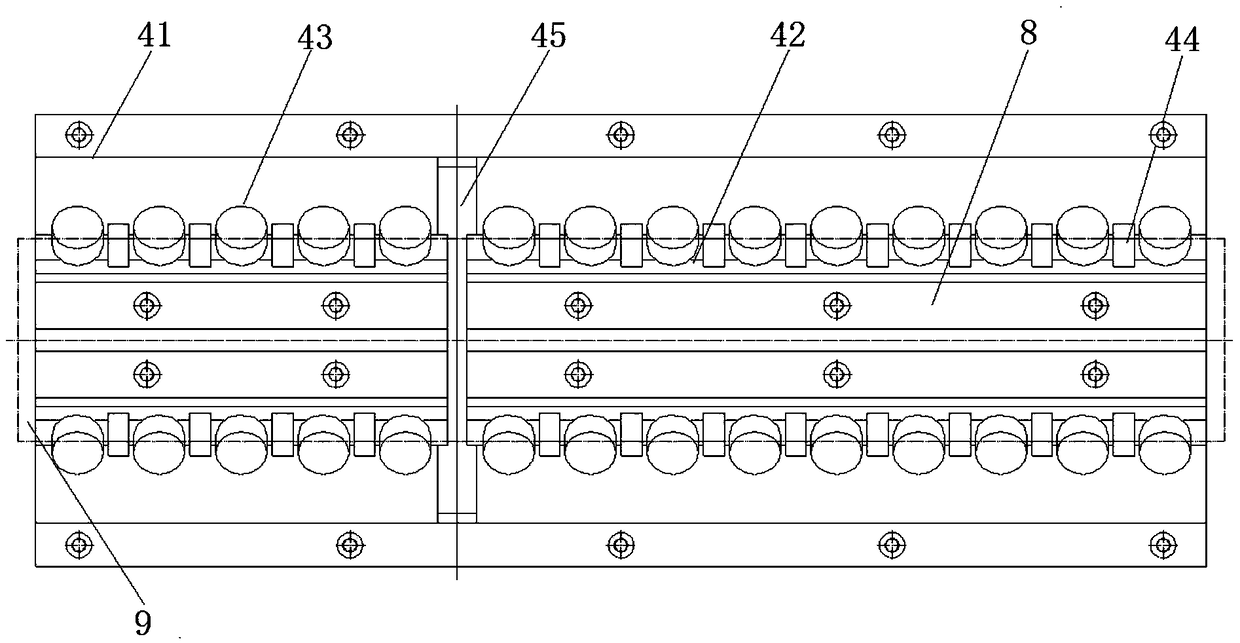

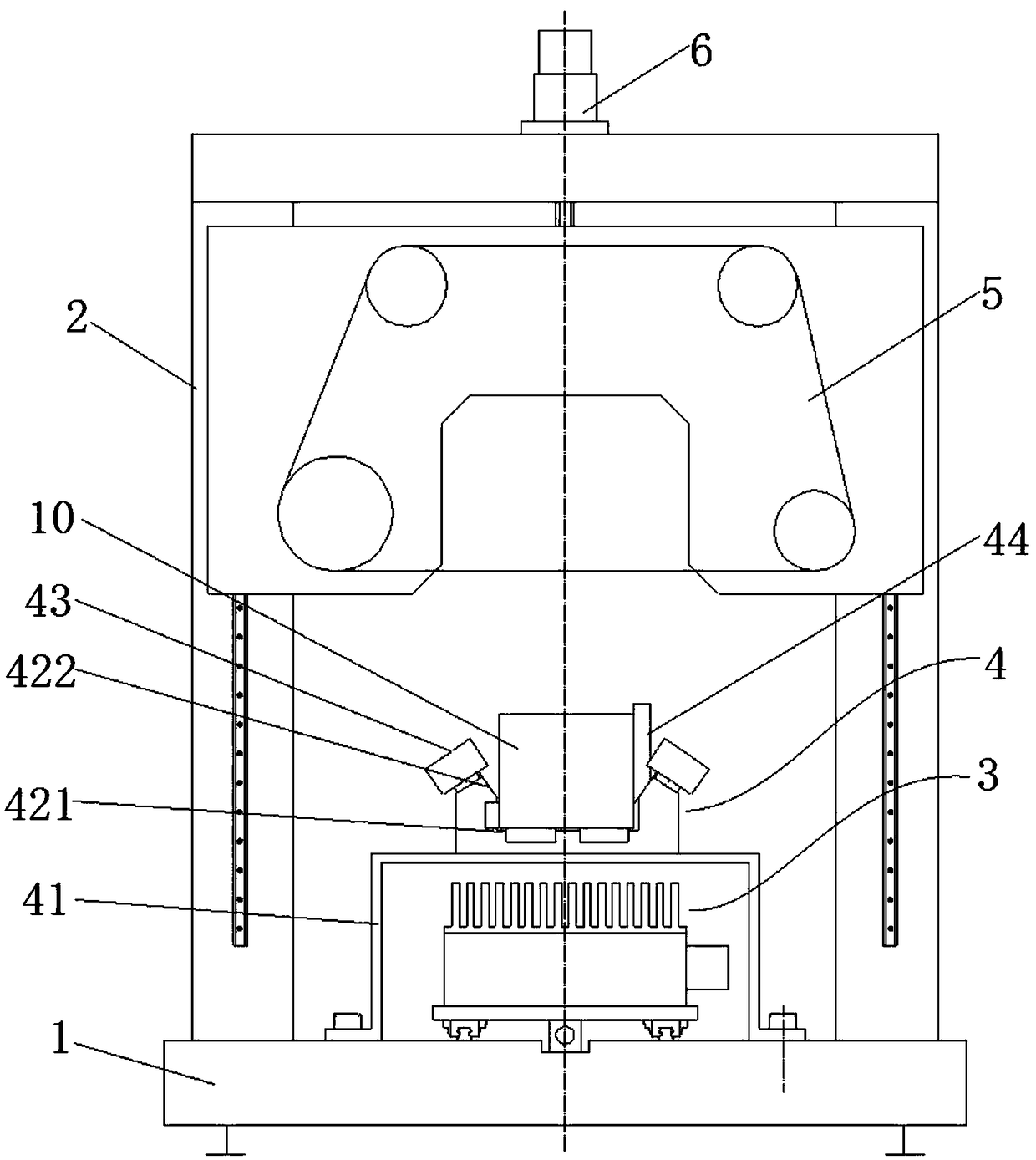

Silicon wafer processing device

ActiveCN108262869AAchieve truncationImplementor sliceWorking accessoriesFine working devicesEngineeringWire saw

The invention relates to a silicon wafer processing device. The silicon wafer processing device comprises a base, a rack, a squaring clamping mechanism, a silicon wafer cut-off clamping mechanism anda wire saw cutting machine, wherein the squaring clamping mechanism is used for clamping to-be-squared seed crystal rods, the silicon wafer cut-off clamping mechanism is used for clamping single-crystal silicon rods or polycrystalline silicon blocks to be cut-off, and the wire saw cutting machine is used for squaring the seed crystal rods and cutting off the single-crystal silicon rods or the polycrystalline silicon blocks. The silicon wafer processing device integrates the silicon wafer squaring and cut-off functions, not only can achieve squaring of the seed crystal rods, but also can achieve cutting off or slicing of the single-crystal silicon rods or the polycrystalline silicon blocks, the structure is simple and compact, the production cost and using cost of manufacturers are reduced,and the equipment utilization rate is increased.

Owner:福州天瑞线锯科技有限公司

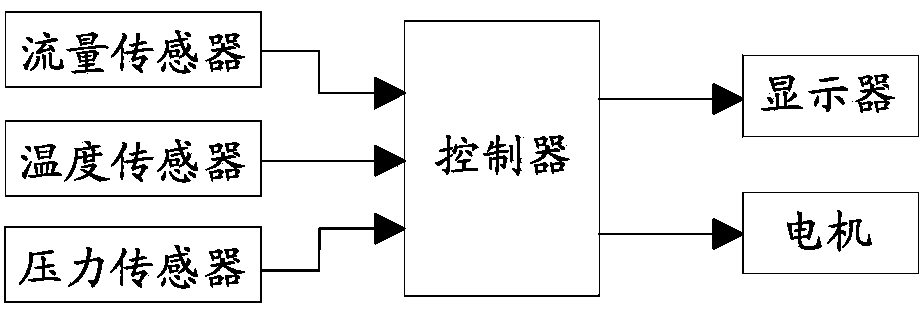

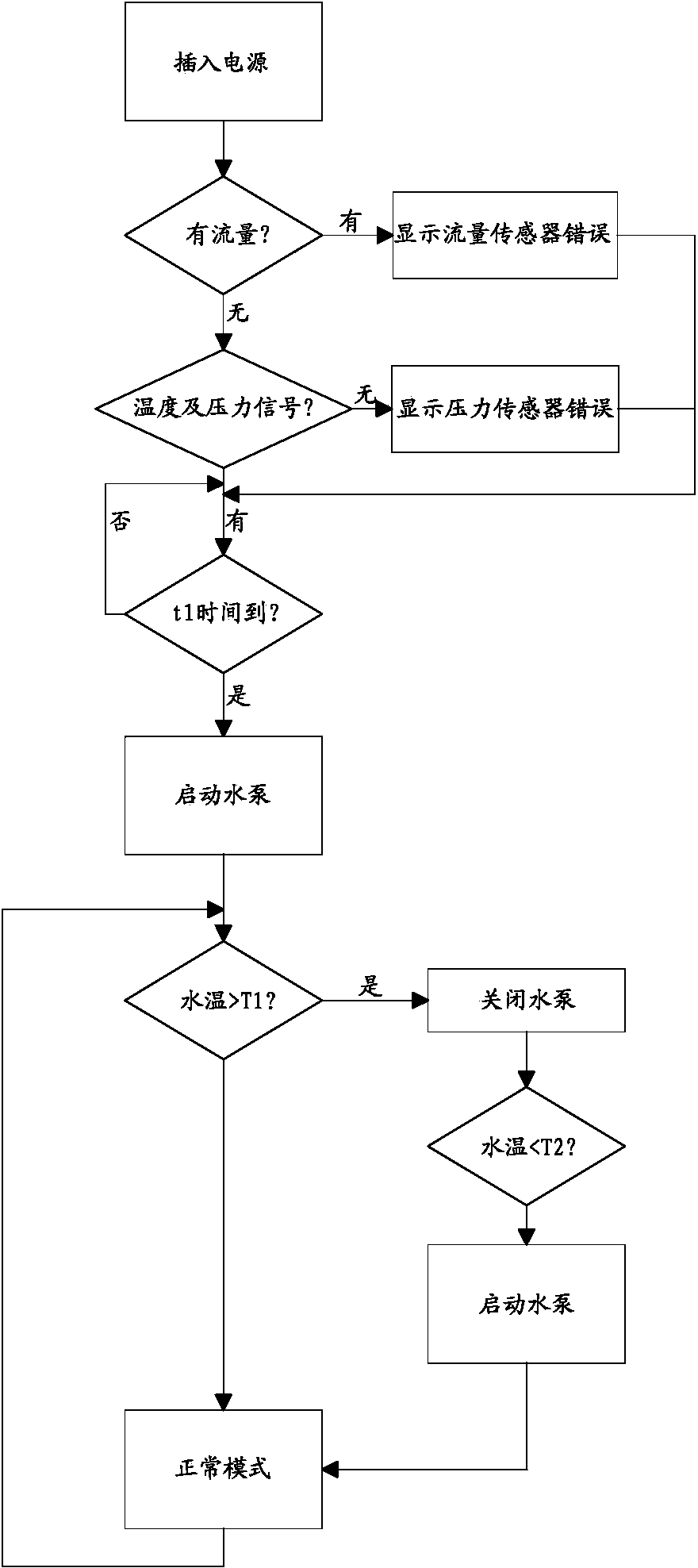

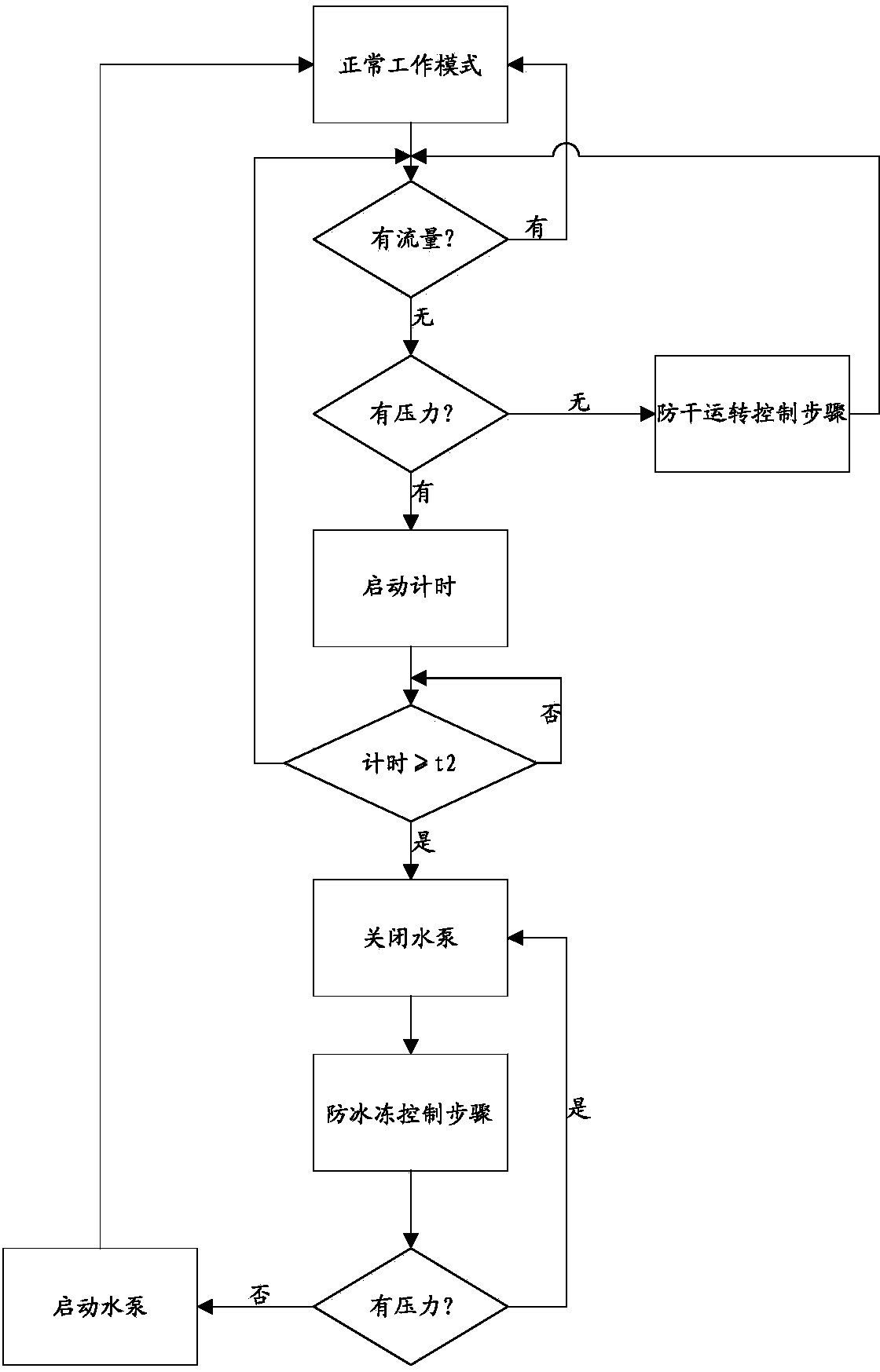

Water pump anti-freezing control system and control method thereof

ActiveCN104005944AReduce production and use costsReduce misrunsPositive displacement pump componentsPump controlMotor shaftImpeller

The invention provides a water pump anti-freezing control system and control method thereof, and belongs to the technical field of water pumps. The control system and method solve the problems that the anti-freezing technology of an existing water pump is complex and limitation is high. The water pump anti-freezing control system comprises a flow sensor, a temperature sensor, a pressure sensor, a displayer and a controller, wherein the flow sensor is arranged on a water pump water inlet, the temperature sensor and the pressure sensor are arranged at the bottom of a water cavity of a water pump, a motor shaft of a motor is connected with an impeller of the water pump, the flow sensor, the temperature sensor and the pressure sensor are respectively connected with the signal input end of the controller, and the displayer and the motor are respectively connected with the signal output end of the controller. The water pump anti-freezing control method includes the steps of (1) sensor detection, (2) water temperature detection, (3) dry running detection and (4) freezing detection. The water pump anti-freezing control system and the control method thereof can achieve a water pump anti-freezing function, the structure is simple, practicality is good, and production and use cost is low.

Owner:TAIZHOU HAPPY WATER PUMP

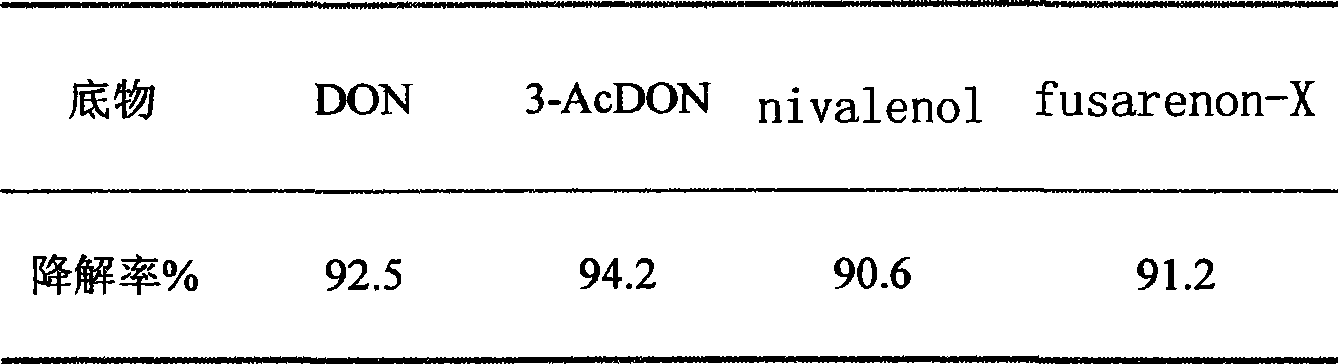

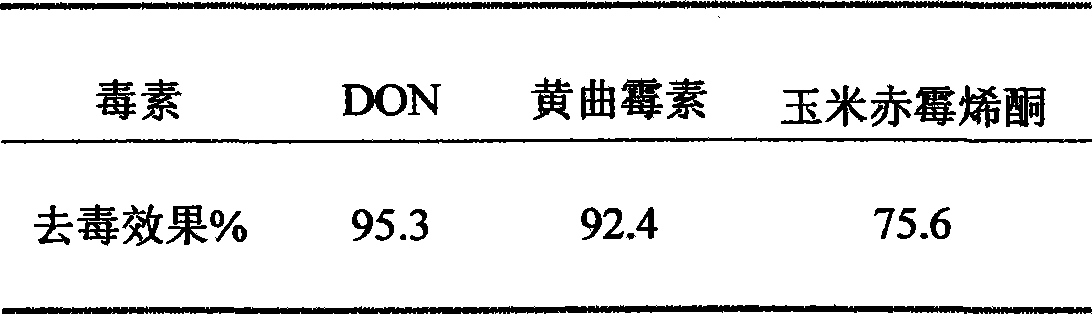

Bacterial strain capable of degrading mold toxin and formulation preparation method thereof

The invention relates to a mycotoxin degrading bacterial strain and a method for preparing the preparation of the same, and is characterized in that the accession number of the bacterial strain is CCTCC M 208087; the bacterium is short-rod shaped, non spore forming, gram-negative, ivory when cultured in colony in a TSA culture medium and aerobic; catalase-positive, oxidase-negative,urease-positive and indophenol reaction negative, capable of hydrolysising esculin, incapable of dual hydrolysising Arginine, casein and starch, incapable of decomposing tyrosine and liquefying glutin, capable of using glucose, incapable of using L-arabinose, D-mannose and maltose; the accession number of the strain 16S rDNA in Genbank is EU794908. The invention also provides the method for preparing liquid microbial inoculums, solid microbial inoculums and mycotoxin absorbents with the strain.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

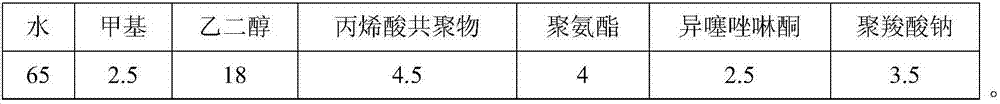

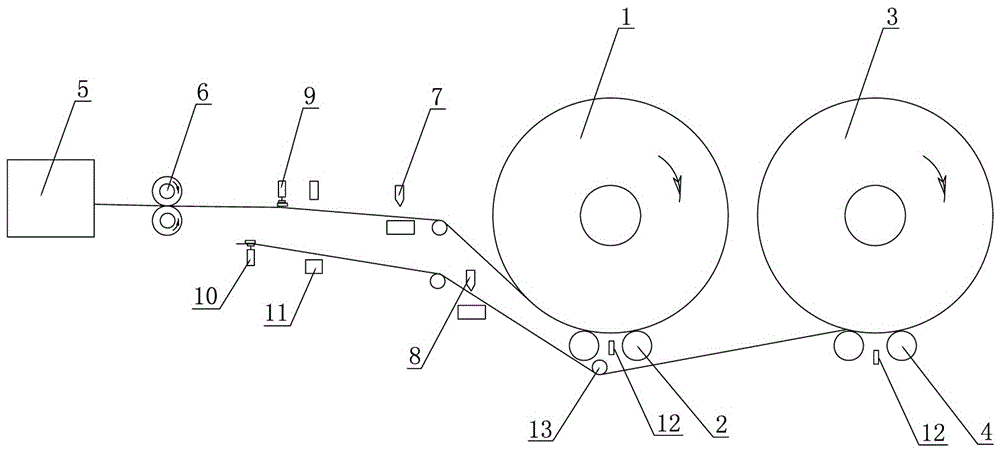

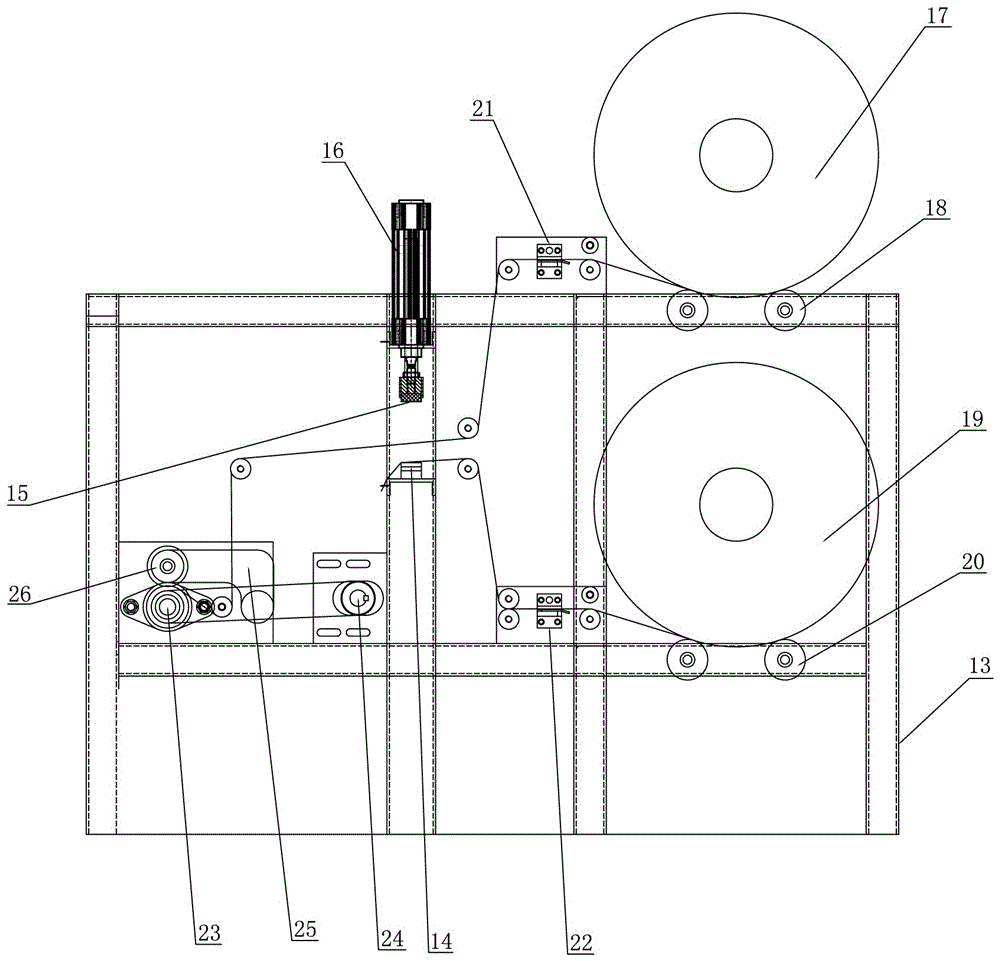

Automatic film changing device of film wrapping machine

InactiveCN106043810AIncrease profitReduce production and use costsWrapping material feeding apparatusWebs handlingEngineeringElectrical and Electronics engineering

The invention discloses an automatic film changing device for a film wrapping machine, which comprises: a film heat-sealing knife is arranged in a frame, a film pressure seat is arranged above the film heat-sealing knife, and the film pressure seat is driven close to the film-bonding cylinder Or away from the film heat-sealing knife, two film roll racks with film rolls are arranged on the frame on the side of the film heat-sealing knife, and a detection alarm is set between each film roll rack and the film heat-sealing knife Mechanism, when the film of the film roll on the film roll placement rack passes between the film heat sealing knife and the film press seat and enters the film wrapping machine, the film head of the film roll on the other film roll placement rack is also at the film heat Between the sealing knife and the film pressure seat; when the detection and alarm mechanism corresponding to the film roll being used by traction detects that the film roll is completely used up, the film connecting cylinder will cooperate with the film heat-sealing knife to place it between the film heat-sealing knife and the The two films between the film press seats are bonded together by heat and pressure. The invention has the advantages of simple structure and high film utilization rate.

Owner:ZHANGJIAGANG DESHUN MACHINERY

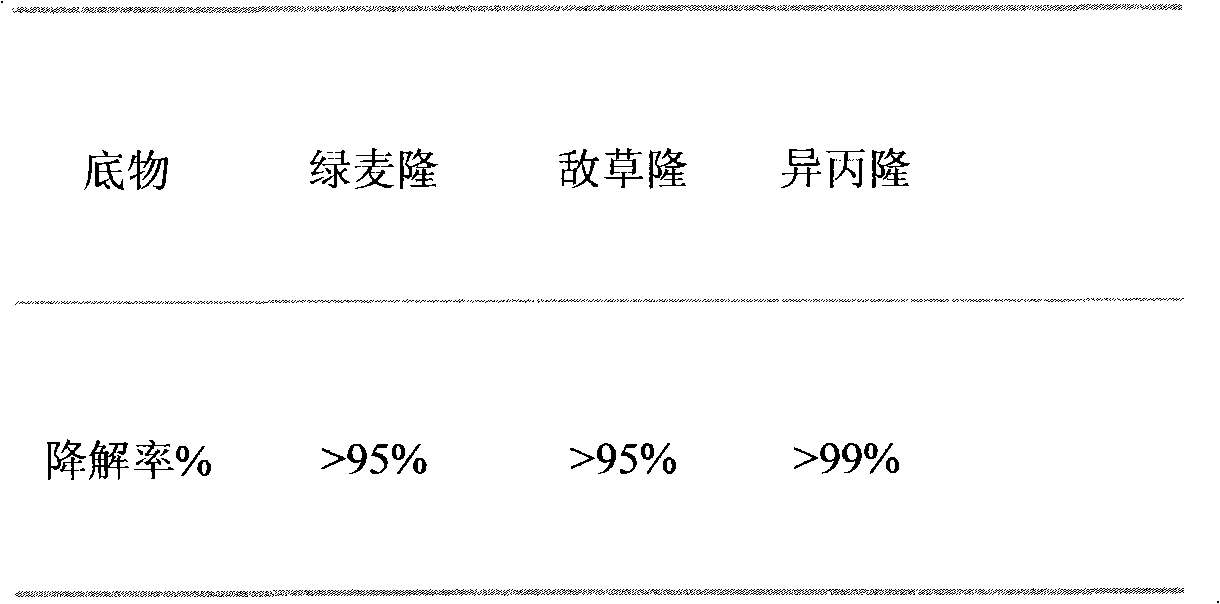

Chlorotoluron pesticide residue degradation strain agent prepared by the strain

InactiveCN101338286AWill not affect the use effectEasy to useBacteriaMicroorganism based processesStandard problemPesticide residue

The invention provides a pesticide-degrading bacterium for removing the residue of a herbicide of chlorotoluron; the bacterium that is used is gram staining reaction negative bacilli YBL3 which is identified to be Sphingobium sp. The bacterium is preserved in China Center for Type Culture Collection in May 23rd, 2008 and the preservation number of the bacterium is CCTCC M208076. The technique for producing the bacterium includes: slant seed-shake flask seed-seed pot-production pot-product (the packaging formulation is liquid bacterium or solid absorption bacterium). The product of the degrading bacterium can be directly applied to reduce the pesticide residue in the crops by more than 90 percent, thus solving the over standard problem of the pesticide residue in agricultural production and being capable of producing green agricultural products with no poison and social effects of pollution.

Owner:NANJING AGRICULTURAL UNIVERSITY

Automatic irrigation device

InactiveCN103053389ASimple structureReasonable designSelf-acting watering devicesWater storageSiphon

The invention relates to an automatic irrigation device and belongs to the technical field of irrigation devices. The automatic irrigation device comprises a cultivation box and a water storage box. The cultivation box is located above the water storage box. An inlet pipe, an overflow pipe and a siphon are disposed between the cultivation box and the water storage box. One end of the inlet pipe is connected with an inlet valve fixed on the cultivation box, close to the top edge. The other end of the inlet pipe is connected with a water pump fixed in the water storage box. One end of the overflow pipe is connected with an overflow valve fixed on the cultivation box, close to the top edge. The other end of the overflow pipe extends into the water storage box. One end of the siphon is connected with a drain valve fixed at the bottom of the cultivation box. The other end of the siphon extends into the water storage box. A body of the siphon is fixed on the wall of the cultivation box and is bent up along the wall of the cultivation box. The action of the inlet pipe, the water pump, a timer and the siphon allows for automatic irrigation between the cultivation box and the water storage box. The automatic irrigation device is applicable to the fields of facility agriculture, scientific research and household gardening, is widely applicable and is simple, reliable and low in production and application costs.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

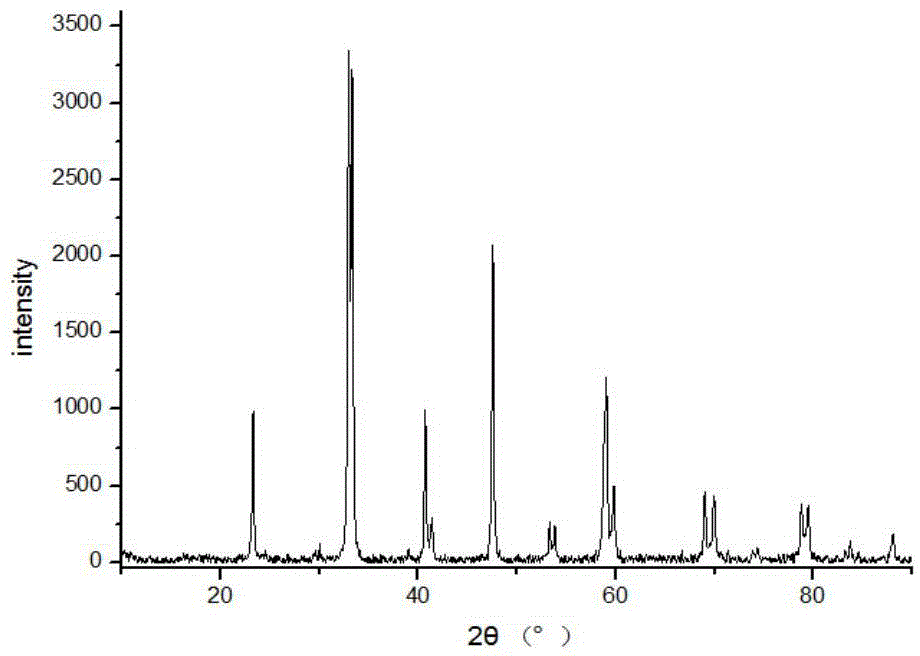

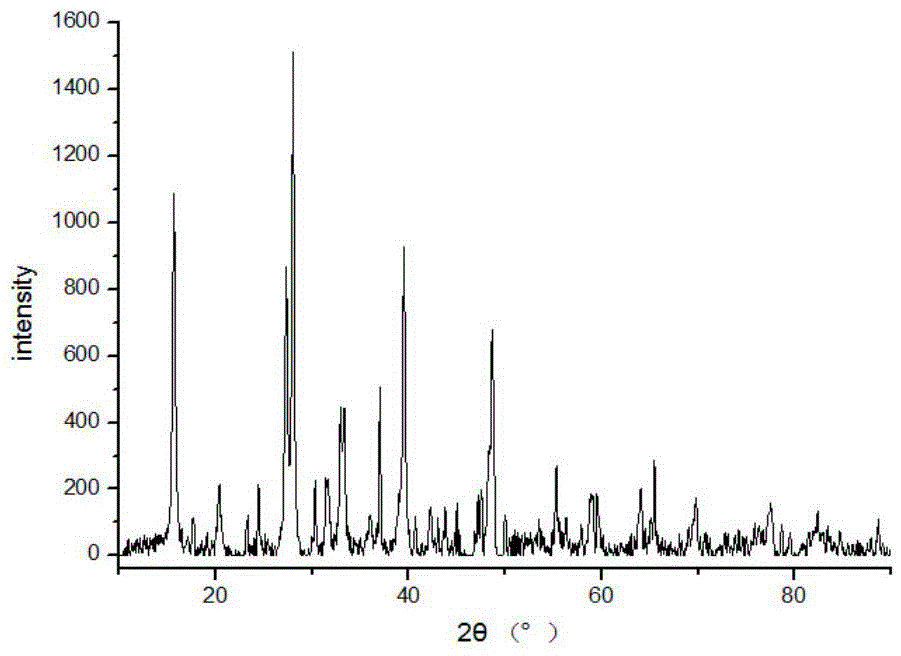

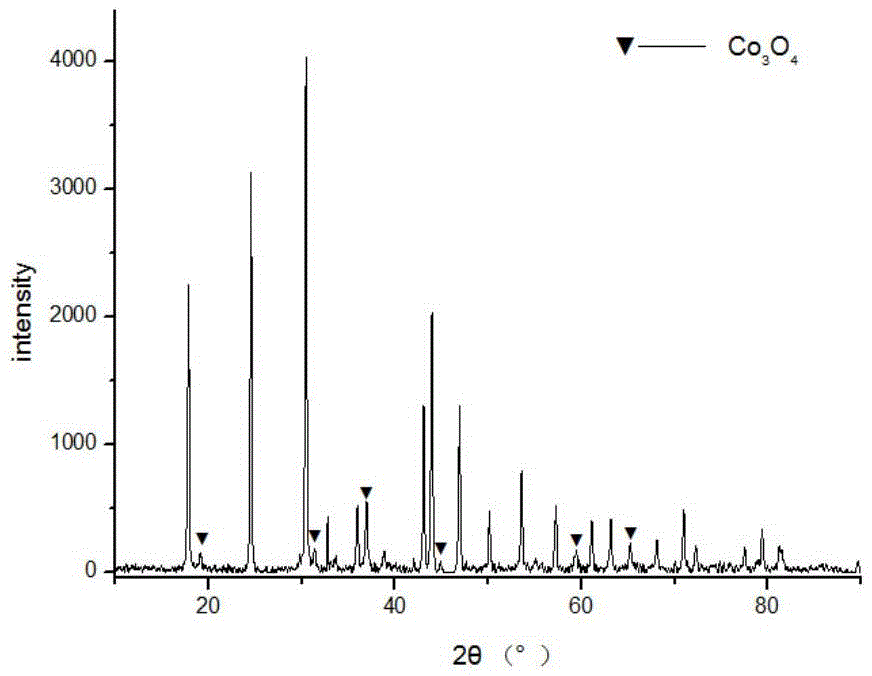

Graphene oxide rare earth compound catalytic material and preparation method thereof

ActiveCN104307530AUnique Surface Interface StructureHigh catalytic activityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCombustionHydrazine compound

The invention discloses a graphene oxide rare earth compound catalytic material and a preparation method thereof. The catalytic material comprises the following raw materials in percentage by mass: 0.47-1.48% of graphene oxide, 11.71-28.25% of perovskite type rare earth oxide and 70.62-87.82% of an additive. The catalytic material is prepared from graphene oxide, perovskite type rare earth oxide and the additive by using a hydrothermal method; the perovskite type rare earth oxide is ABO3 oxide; the additives are ethanediamine, hydrazine hydrate or urea. The catalyst disclosed by the invention is excellent in methane combustion catalytic activity, the initial combustion temperature is 300 DEG C, complete conversion can be achieved at 405 DEG C, the activity effect is relatively good, the initial combustion temperature is identical, and the complete conversion temperature is reduced by 85 DEG C.

Owner:HEBEI UNIV OF TECH

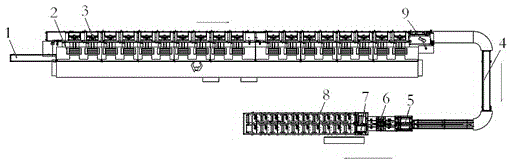

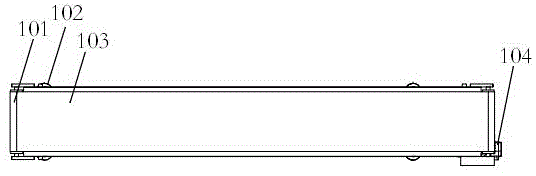

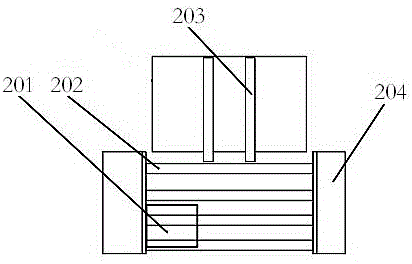

Automatic card book text production line and automatic card book text production process

The invention discloses an automatic card book text production line and an automatic card book text production process. The production line comprises a fold rear conveyor belt, a paper delivery machine, an anilox gluing machine, a connection conveyor belt, a turning-round machine, a piling machine, a distribution machine and a flat pressing machine, and further comprises a control cabinet for carrying out power distribution on the production line. The production process comprises the following steps: delivering paper, gathering, gluing, mounting, conveying, turning round, piling, distributing and flatly pressing. Relatively thick paper sheets can be produced, the use amount of glue is reduced and the production efficiency and the production quality are improved.

Owner:佛山市金页盈信智能机械有限公司

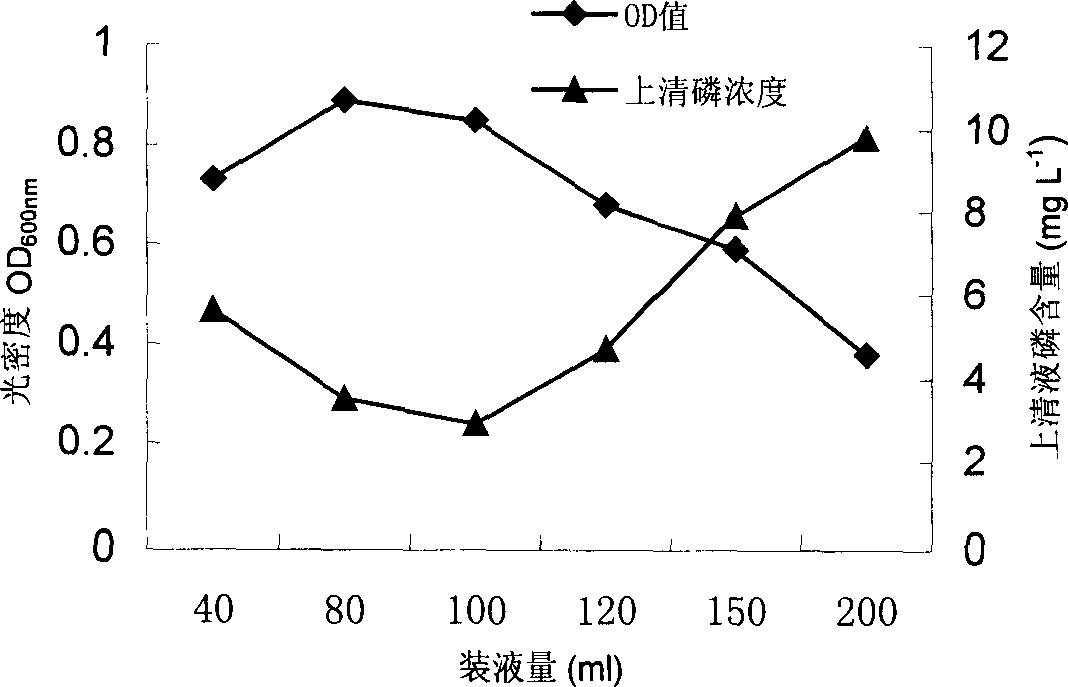

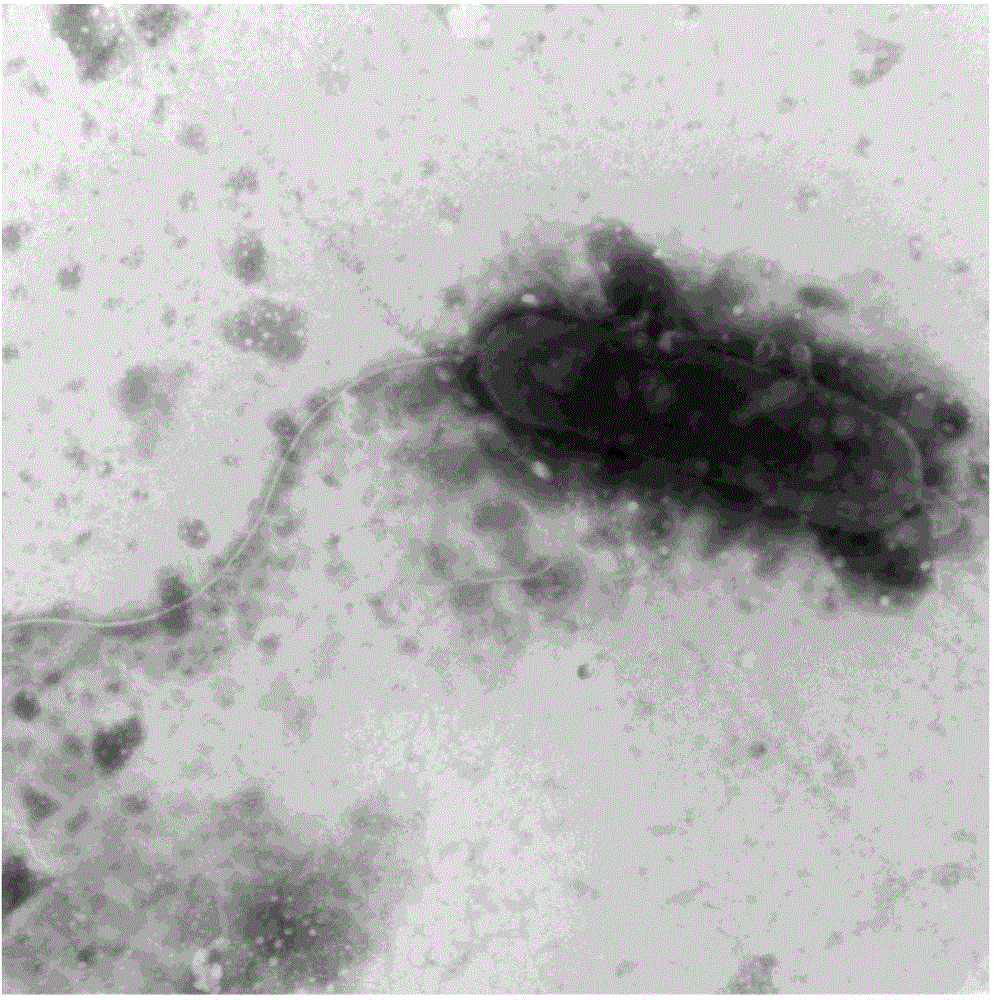

Highly effective phosphorus removal bacteria and its produced bacteria formulation

InactiveCN1807585AEasy to useReduce production and use costsBacteriaMicroorganism based processesBiological propertyPseudomonas putida

The bacterium agent in this invention is used to biologically strenghen dephosphor- ization process in urban sewage treatment plant. It has mainly two uses: quickly start the biodephosphorization ability of new sewage treatment plant; resume the strong biodephosphorization ability of exasperate dephosphorization system. It is made from high efficient ployphospher bacterial strain GM6, and it is odor Pseudomonas putida from appraising result. Its main biocharacteristic is G-. Its thalli is rhabditiform with the size of 0. 7í‡2. 5ª–m, and it is facultative anaero-bic; it is positive in indole reaction, oxidase and sulfate reduction reaction; while negative in methyl red test, V-P reaction, citrate test and hydrogen sulfide reaction; the number of the strain 16S rDNA is DQ133506. The strain can be used to sewage dephosphorization.

Owner:NANJING AGRICULTURAL UNIVERSITY

Foaming microporous glass pumice for chemical clarification and water quality filtration and preparation method thereof

InactiveCN103319094AEvenly distributedImprove the adsorption and filtration effectGlass shaping apparatusFiltrationWater quality

The invention relates to foaming microporous glass pumice for chemical clarification and water quality filtration. The pumice is characterized by comprising foaming micropores, wherein the aperture of the foaming micropores is 0.5-3mm, the water absorption is 15-30%, the strength is 3-8MPa and the density is 0.3-0.4g / cm<3>. The pumice is prepared by sintering a foaming mixture which comprises the following components in percentage by weight: 90-95% of glass powder, 2-5% of marble powder, 1-3% of aluminum oxide powder and 1-3% of calcite powder, wherein the fineness of glass powder is 40-100 mu m, the fineness of marble powder is 20-40 mu m, the fineness of aluminum oxide powder is 20-40 mu m and the fineness of calcite powder is 20-40 mu m. The invention further relates to a preparation method of the foaming microporous glass pumice for chemical clarification and water quality filtration. The pumice provided by the invention has the advantages of low using cost and long using period.

Owner:江苏晶瑞特环保新材料有限公司

Sphingosine monoucleosis for degrading cypermethrin and application thereof

ActiveCN104531589AReduce production and use costsEasy to useBacteriaMicroorganism based processesCypermethrinCarbofuran

The invention provides sphingosine monoucleosis WHSC-8T having the efficient degrading effect on cypermethrin pesticide residues and an application of the sphingosine monoucleosis. A bacterial strain is preserved in the typical culture collection center of China on November 18, 2014, and the collection serial number is CCTCC NO: M2014575. The sphingosine monoucleosis has the remarkable degrading effect on the pesticide residues of cypermethrin, phoxim, chlorpyrifos, isoprocarb, carbofuran and the like, and the rate of degrading the cypermethrin is more than 91.3%. The pesticide residue degrading bactericide has the advantages of being low in production and use cost, convenient to use, good in removing effect and suitable for being used and popularized in grain, oil and vegetable production export bases across the country or areas with pollution-free food brand marks in a large-area mode.

Owner:HENGSHUI UNIVERSITY

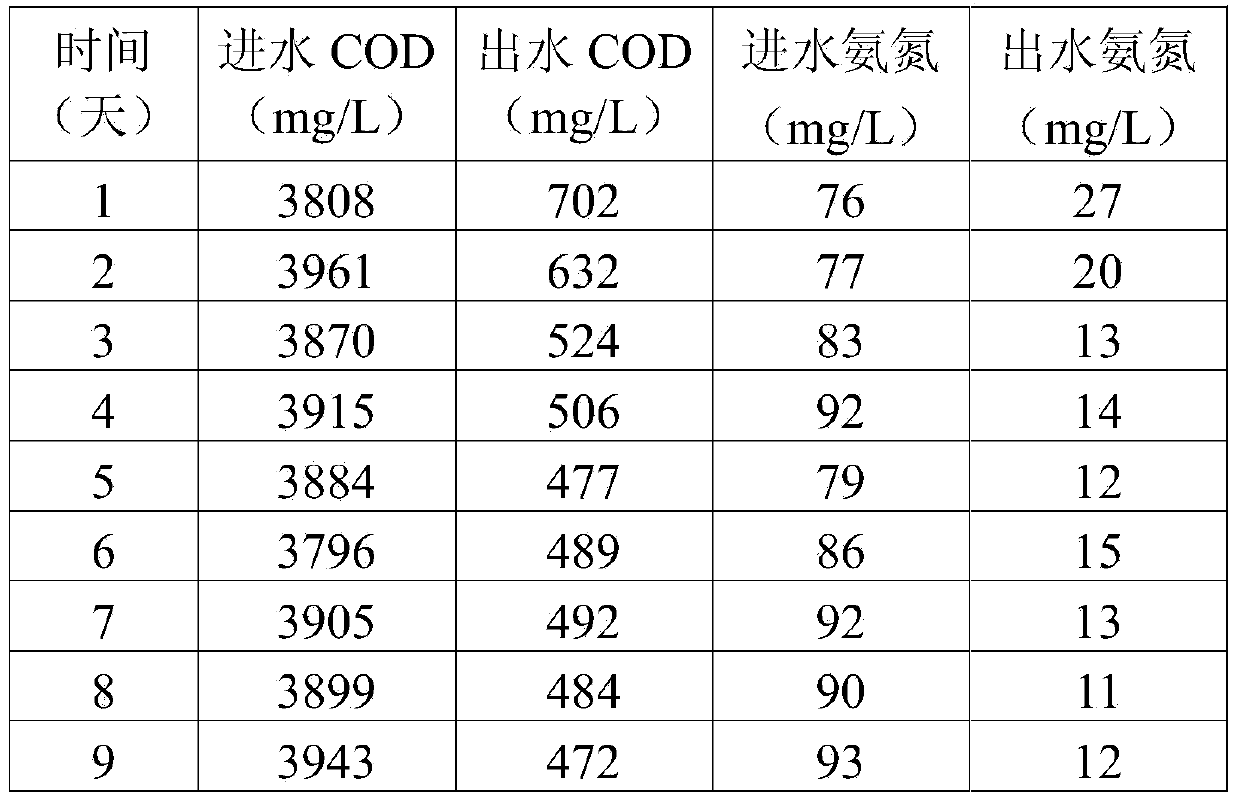

Diaphorobacter strain and application thereof

InactiveCN101892174AStrong resistanceAdaptableBacteriaWater contaminantsEcological environmentPhysical well being

The invention discloses a Diaphorobacter strain and application thereof. The strain is Diaphorobacter sp. SG-51 CGMCC No.3511. A bacterial agent provided by the invention has the active ingredient of the strain Diaphorobacter sp. SG-51 CGMCC No.3511. The strain has wide degradation spectrum and has the degradation rate for various toxic compounds of over 90 percent. The bacterial agent is a novel aromatic organic pollutant degradation bacterial agent, and has the advantages of low production and use cost, convenient use, wide degradation spectrum and good removing effect. The strain and the bacterial agent are suitable for treating wastewater generated in the modern coking and vaporization processes, and organic wastewater containing phenol, methylphenol, parachlorophenol and pyridine generated in other production processes of the petrochemical industry, and can ensure that corresponding organic matter residue meets the wastewater emission standard. The invention successfully solves the problem of low removing effect on phenol and derivatives thereof, and benzene or other heterocyclic compounds from the wastewater treatment, reduces workload in the production process and using process, reduces production and use cost, and has significance for protecting ecological environment and protecting human health.

Owner:PEKING UNIV

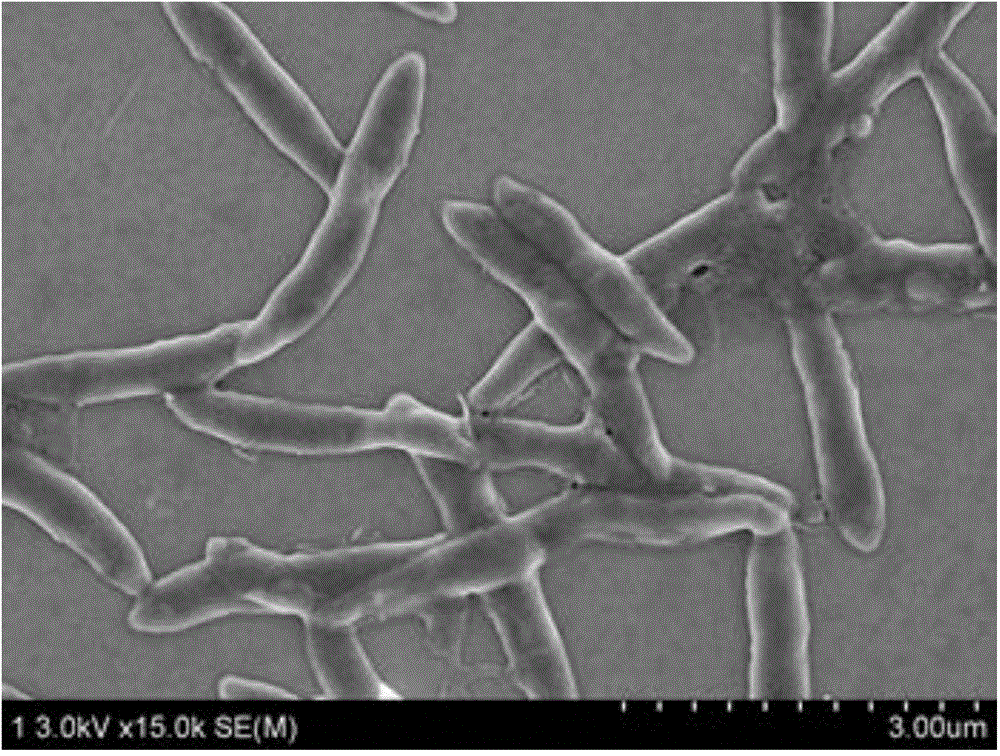

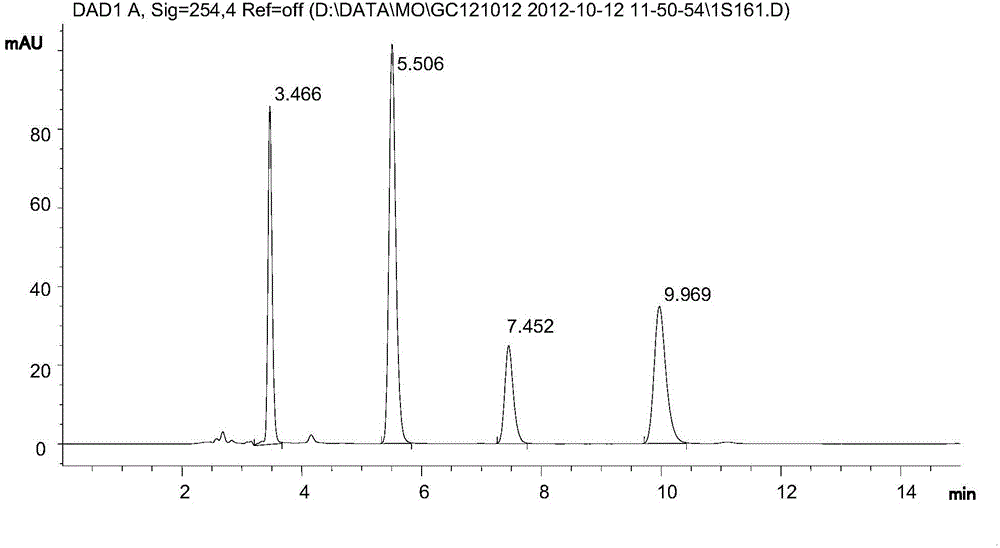

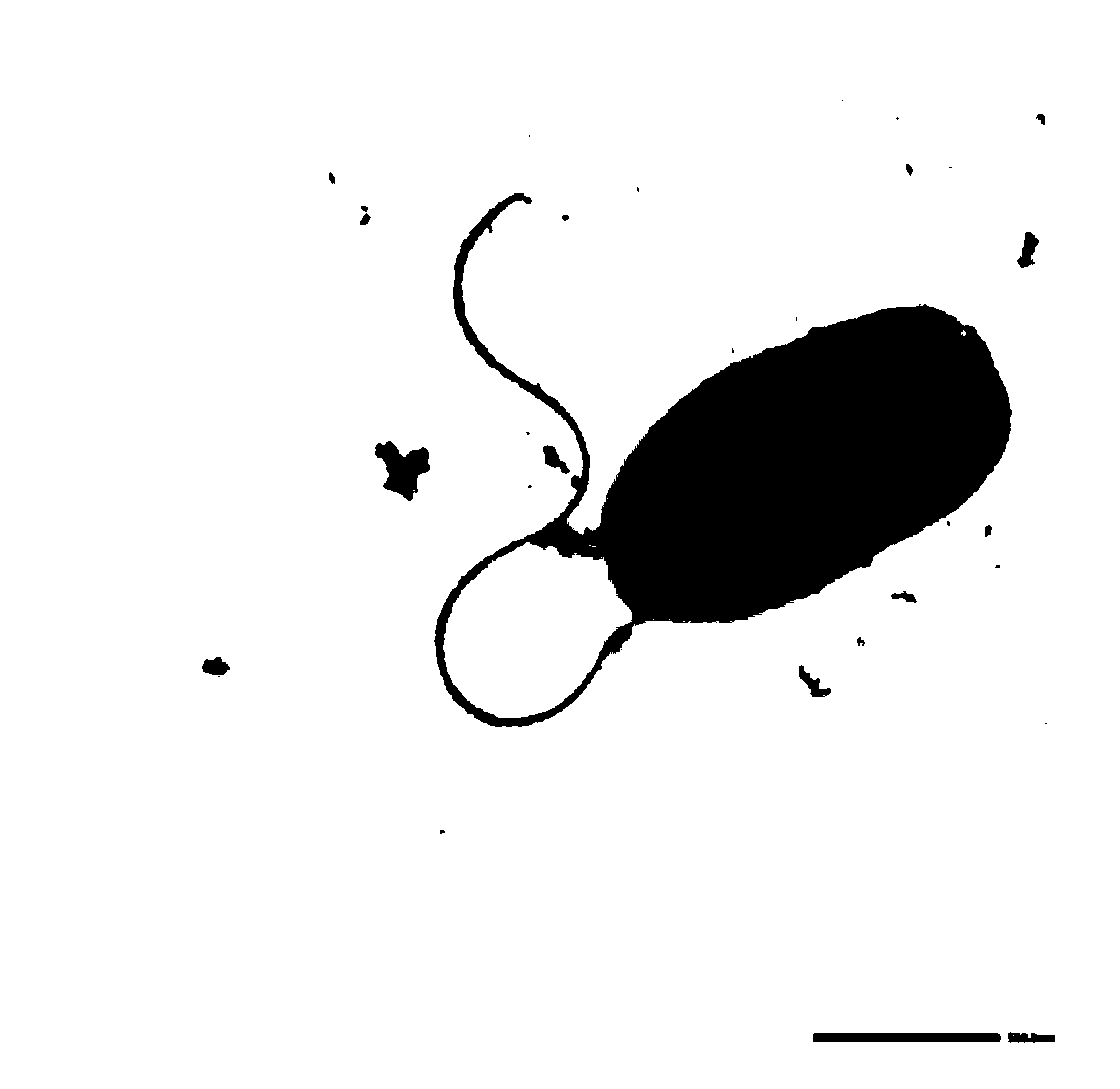

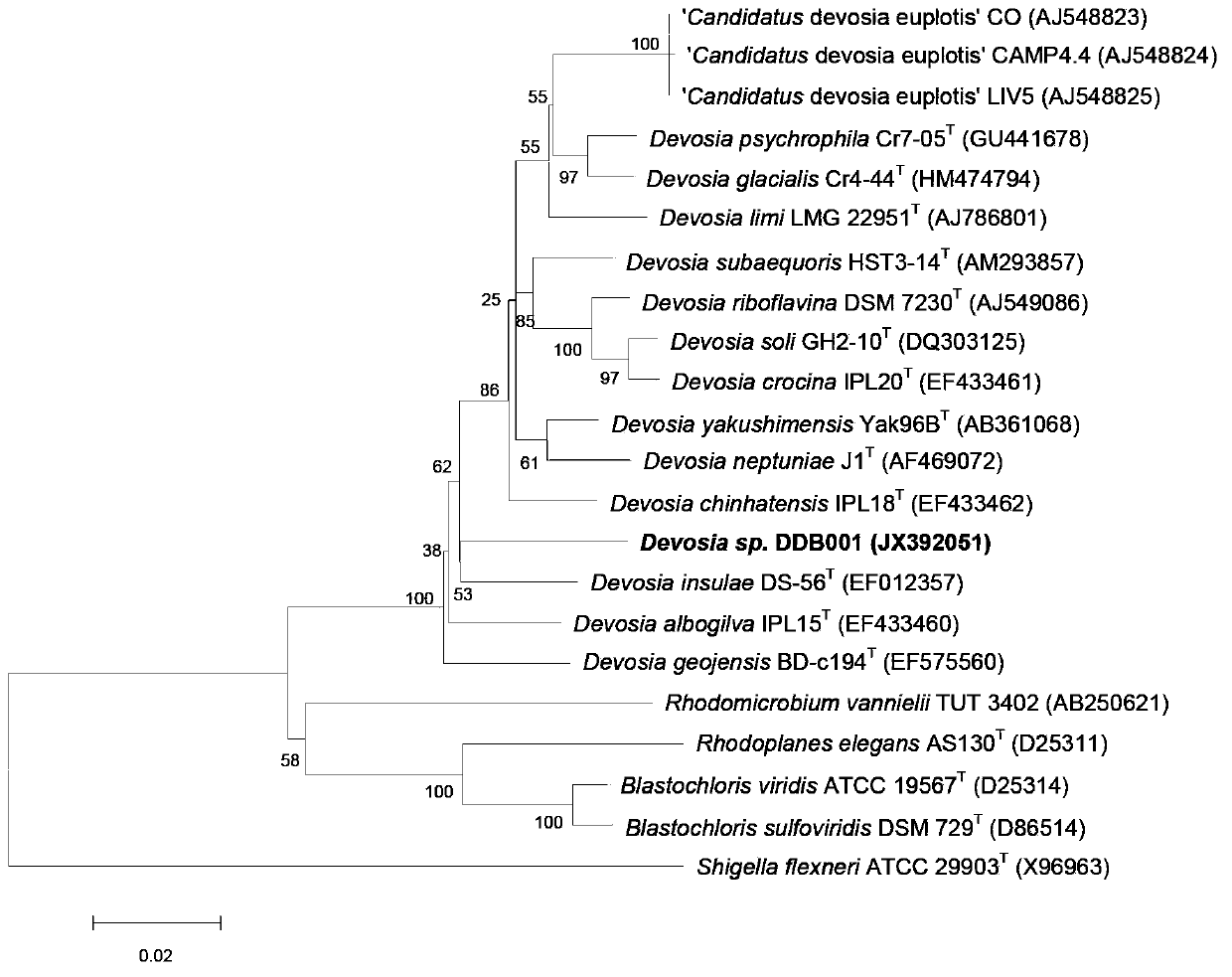

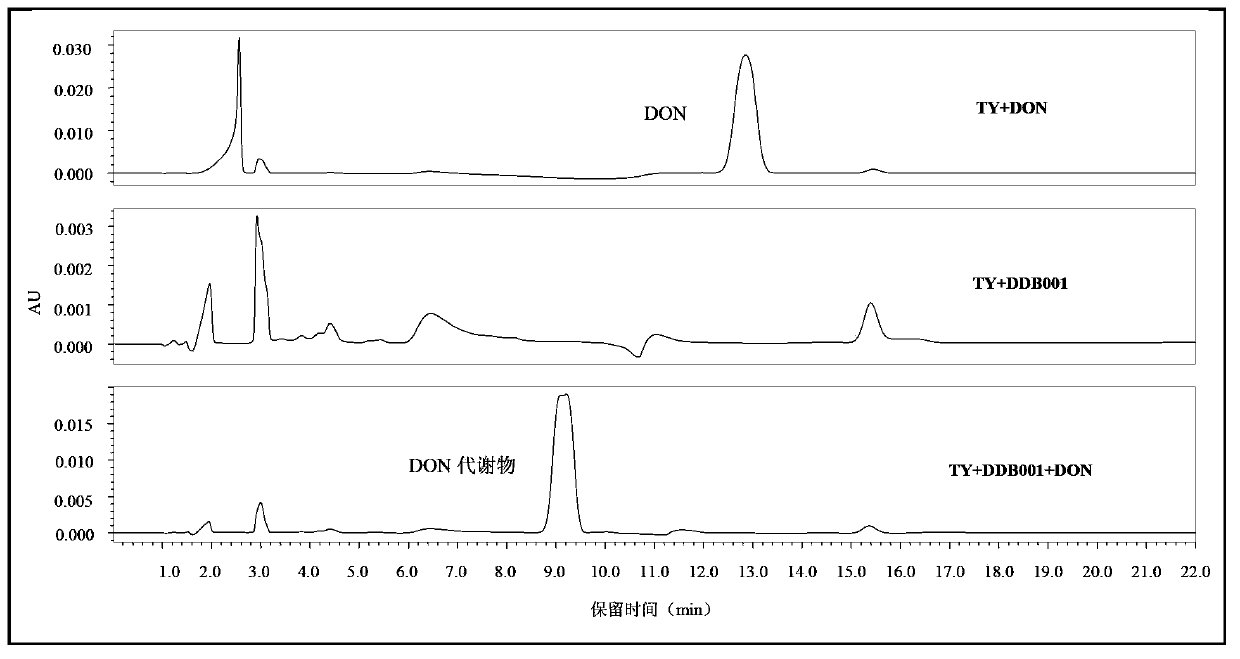

Devosia sp and application thereof in degrading vomitoxin

ActiveCN103387950APromote degradationDegradation safetyBacteriaMicroorganism based processesFungicideDevosia sp.

The invention discloses devosia sp. and application thereof in degrading vomitoxin. The strain provided by the invention belongs to a new strain in the Devosia Nakagawa et al, and the preservation number of Devosia sp. DDB001 is CGMCC (China General Microbiological Culture Collection Center) No.7185. The invention also provides a fungicide containing the preserved strain and a preparation method thereof. Furthermore, the invention also provides an application of the strain or fungicide in degrading vomitoxin.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

Special adhesive resin for wire-frame-reinforced polyethylene tube and production method thereof

ActiveCN102161730APut an end toHigh tensile strengthPipe connection arrangementsGraft polymer adhesivesPolymer scienceCross linker

The invention relates to a special adhesive resin for a wire-frame-reinforced polyethylene tube and a production method thereof. The special adhesive resin for a wire-frame-reinforced polyethylene tube is mainly used for bonding the outer layer, wire and inner layer of a wire-mesh-frame-reinforced polyethylene tube. The special adhesive resin for a wire-frame-reinforced polyethylene tube is prepared from the following raw materials in percentage by weight: 30-90% of HDPE (high-density polyethylene), 8-40% of LLDPE (linear low-density polyethylene), 0.1-10% of maleic anhydride, 0.01-1% of peroxide crosslinking agent and 0.01-1% of acetone. The production method comprises the following steps: carrying out pre-reaction on the maleic anhydride, peroxide and acetone, mixing with the HDPE and LLDPE, and carrying out thermal granulation. By using the product provided by the invention, the peel strength among the outer layer, wire and inner layer of the wire-mesh-frame-reinforced polyethylene tube is up to more than 500N / 25mm.

Owner:SHANDONG DONGHONG PIPE IND

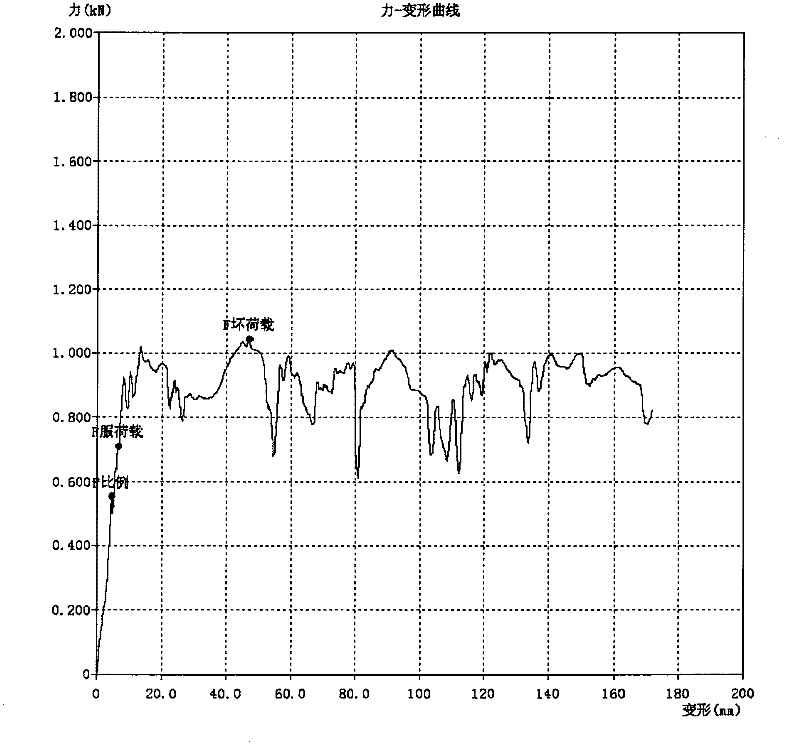

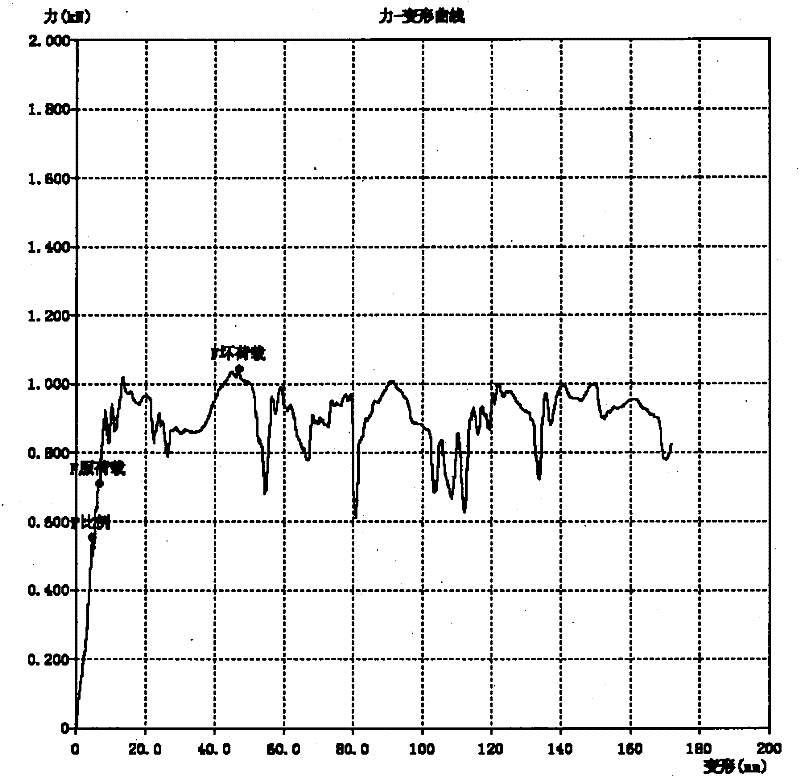

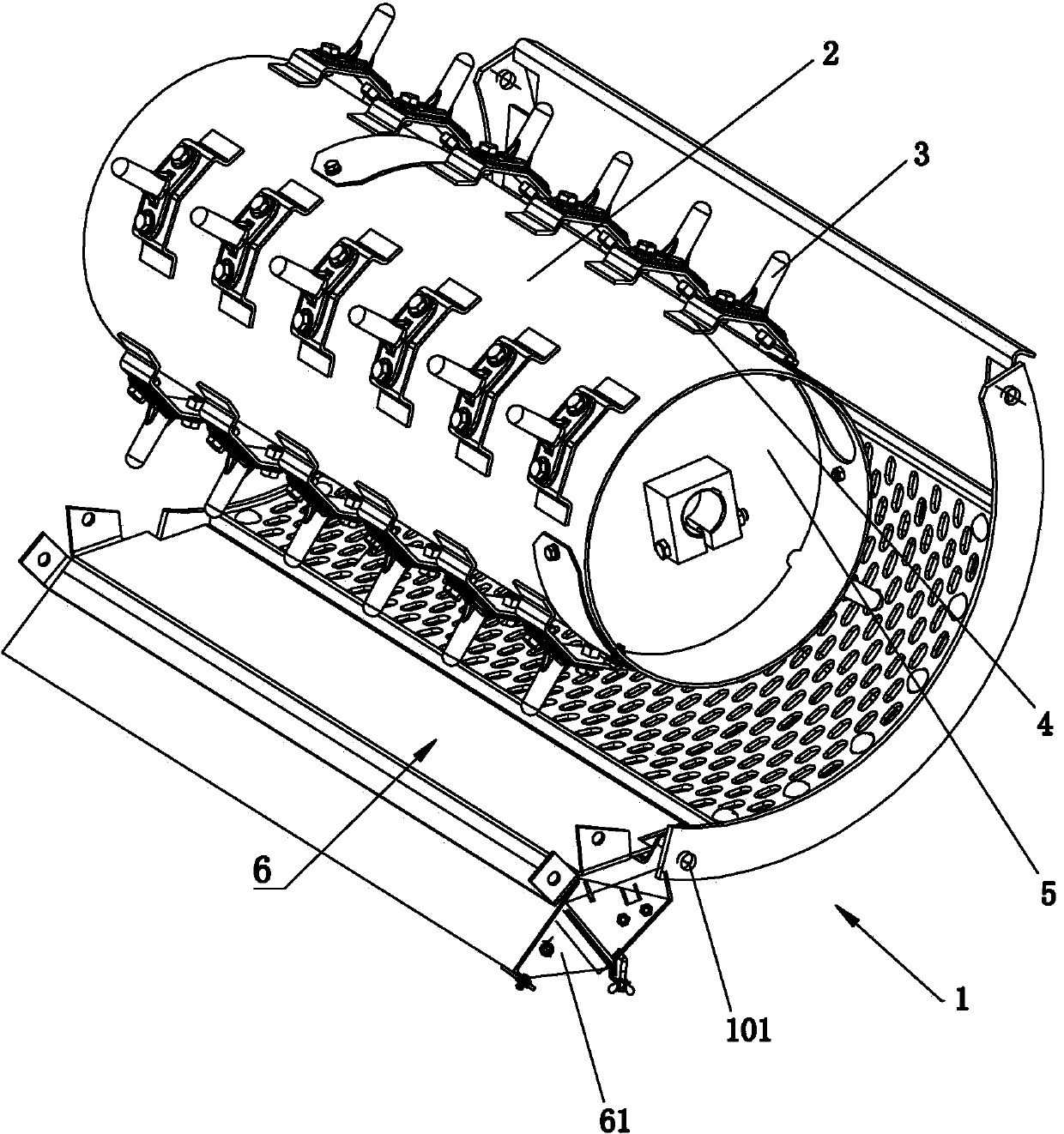

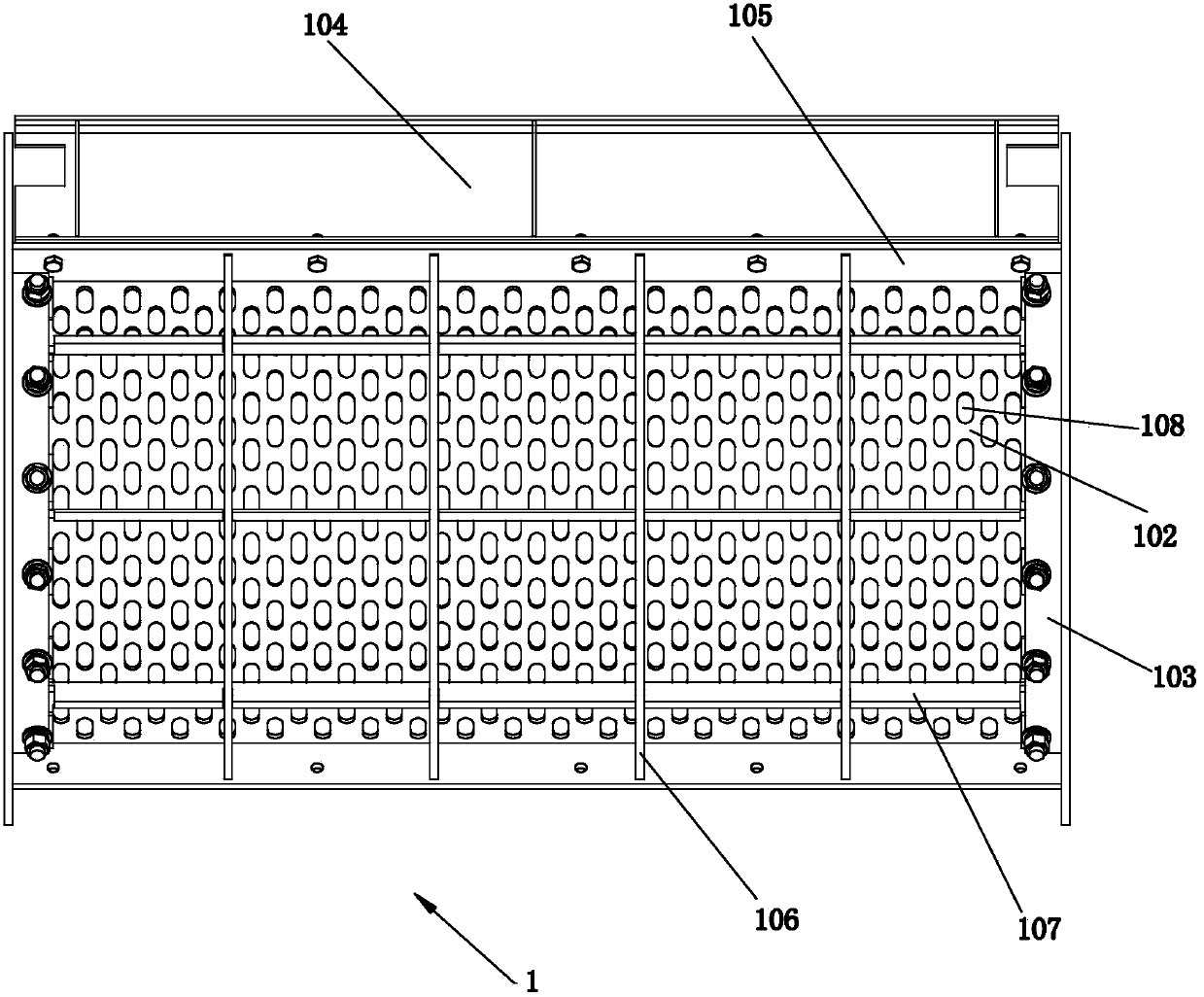

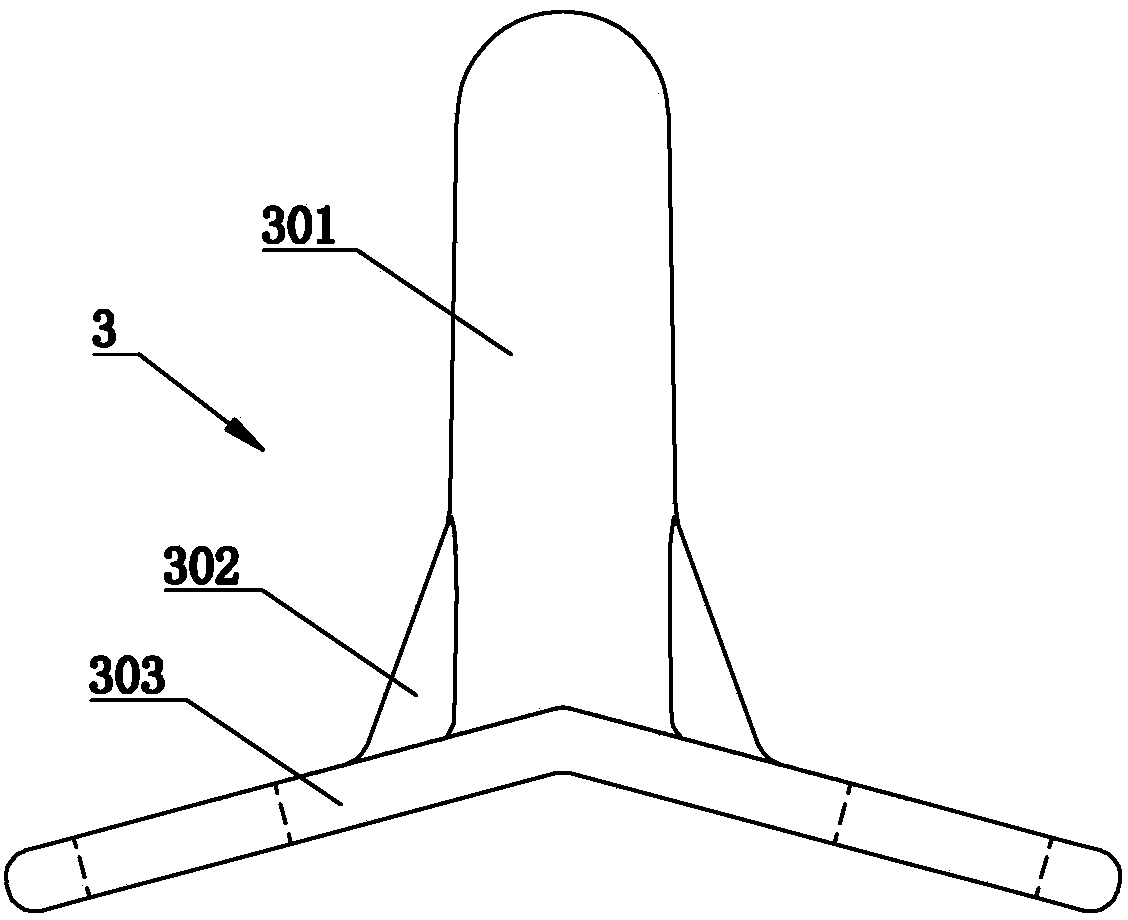

Corn grain threshing and separating device and combine harvester with separating device

The invention discloses a corn grain threshing and separating device and a combine harvester with the separating device. The corn grain threshing and separating device comprises a threshing roller which is provided with threshing teeth with ball-headed top ends, wherein a threshing concave plate is arranged below the threshing roller and is arranged on a mounting rack, and multiple columns of staggered elliptical holes are formed in the threshing concave plate; a stone collecting tank is arranged at one side, close to a corncob source, of the mounting rack, and a stone collecting tank cover plate is arranged above the stone collecting tank. Through the threshing teeth, grains are prevented from being crushed, and the threshing effect is enhanced; the threshing teeth are matched with the threshing concave plate, so that under the condition of guaranteeing low grain crushing rate, high threshing performance, screening performance and passing characteristic, the working strength, reliability and stability are improved through the mounting rack, and mounting and repair / maintenance are facilitated; the stone collecting tank is closed by the stone collecting tank cover plate, so that corncobs are prevented from falling into the stone collecting tank; meanwhile, through replacing a threshing and separating attachment, on the basis of realizing rice / wheat harvesting, the effect of harvesting corn crops is realized, and the use ratio of the harvester is increased.

Owner:LOVOL HEAVY IND

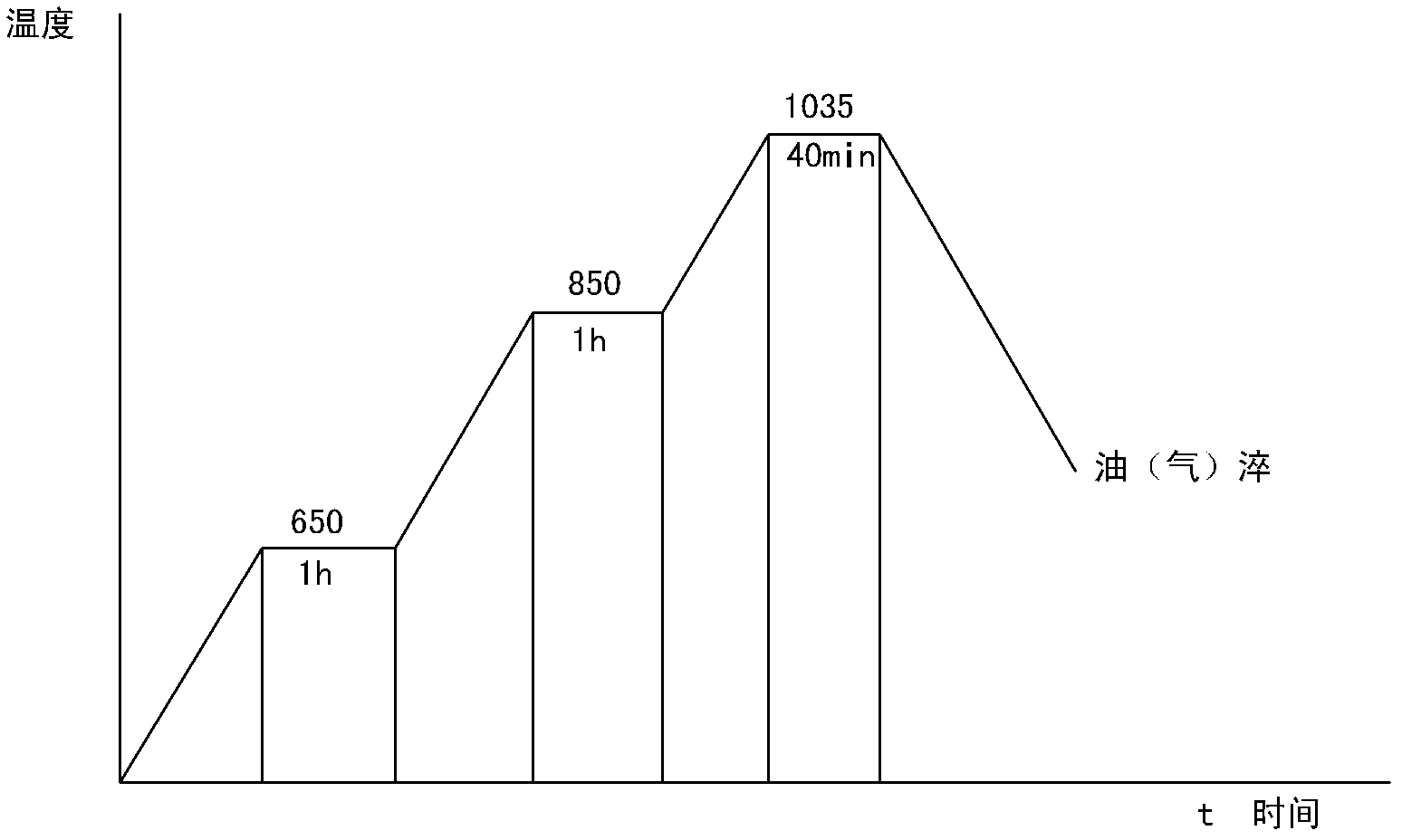

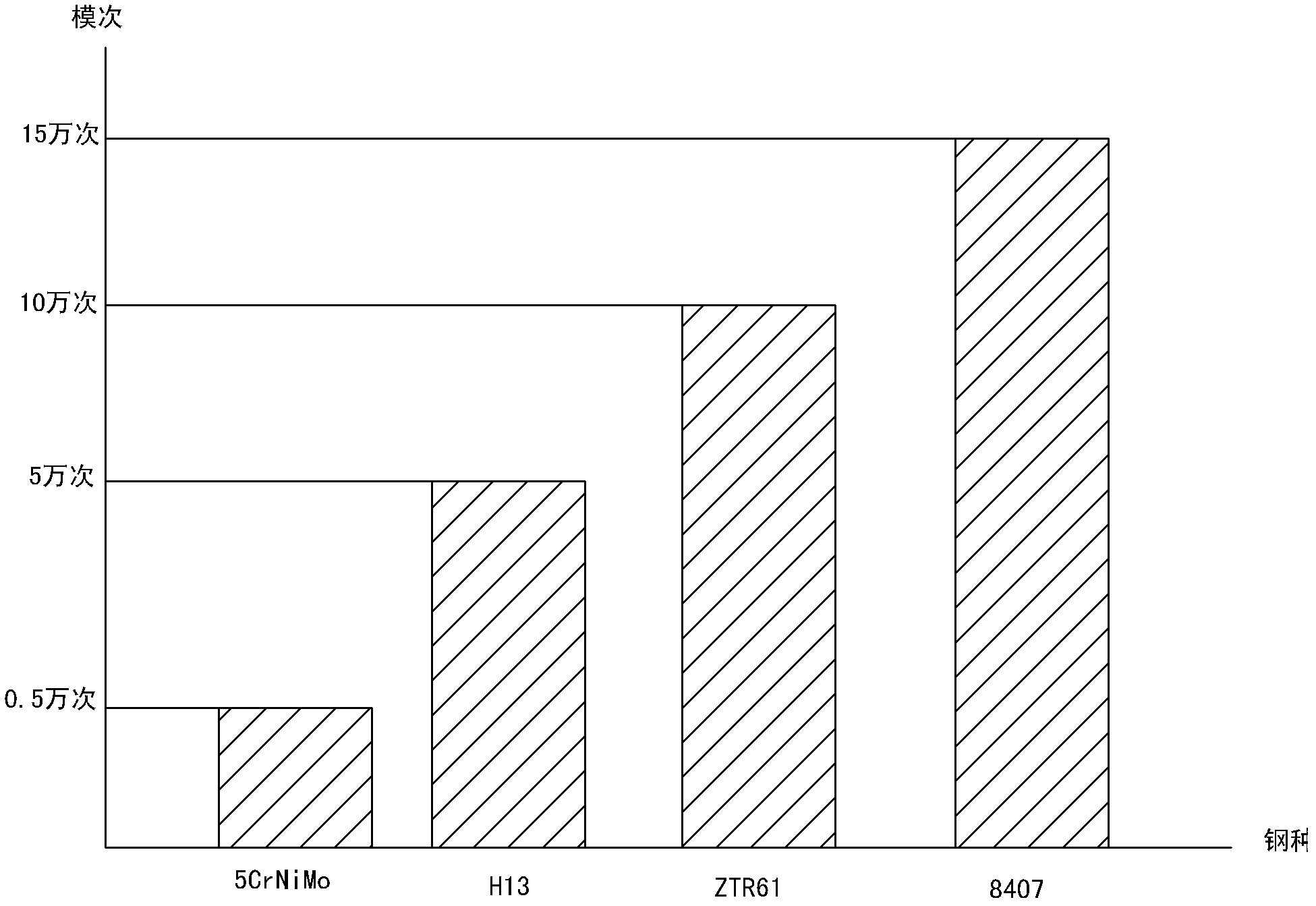

Steel material of hot-working die and its production process

The invention belongs to the metal material and processing technical field, which relates to a steel material of hot-working die and its production process. According to the invention, the steel material of hot-working die comprises the element components by weight percentages: 0.38 to 0.42 of C, 0.35 to 0.45 of Mn, 0.55 to 0.65 of Si, 5.0 to 5.5 of Cr, 0.2 to 0.25 of Mo, 1.0 to 1.5 of V, less than or equal to 0.025 of S, less than or equal to 0.025 of P and the balance of Fe. According to the invention, the production process comprises the following steps: a step of smelting technology, a step of casting molten steel to form steel ingot, a step of forging or rolling into sectional material and a step of spheroidizing sectional material and annealing process, so that the technical process is simple and the operation is easy to control. The invention has a good and scientific element ratio, alloying and modification processing are employed, the invention has the advantages of good heat stability, high heat resistant fatigue performance, wear resistance, good hardenability and less deformation, a vacuum heat treatment and a surface strengthening processing are added for improving the work efficiency, reducing production cost, reducing or avoiding dies from breaking and cracking, thereby the hot-working die has long service life, high performance-price ratio and wide application.

Owner:尚宗文

Foamed micropore glass pumice for soil improvement and preparation method thereof

The invention relates to foamed micropore glass pumice for soil improvement. The foamed micropore glass pumice is characterized by containing foamed micropores, wherein the pore sizes of the foamed micropores are 2-3 mm, the water absorption of the foamed micropores is 30-50%, the strength of the foamed micropores is 2-4 MPa, and the density of the foamed micropores is 0.2-0.3 g / cm<3>; and the foamed micropore glass pumice is prepared through sintering a foamed mixture which comprises the following ingredients in percentage by weight: 85-90% of glass powder, 3-8% of marble powder, 2-5% of silica powder and 2-5% of gypsum powder, wherein the fineness of the glass powder is 40-100 microns, the fineness of the marble powder is 20-40 microns, the fineness of the silica powder is 20-40 microns, and the fineness of the gypsum powder is 20-40 microns. The invention further relates a preparation method of the foamed micropore glass pumice for soil improvement. The foamed micropore glass pumice has the advantages that the hardening of soil can be improved, the water permeability and air permeability of the soil can be improved, and the breeding of pests and diseases can be reduced.

Owner:江苏晶瑞特环保新材料有限公司

Foamed micropore glass pumice for roof garden cultivation and preparation method thereof

The invention relates to a foamed micropore glass pumice for roof garden cultivation, which is characterized by containing foamed micropores, wherein the pore size of the foamed micropores is 0.2-5mm, the water absorptivity is 40-60%, the strength is 1-2.5 MPa, and the density is 0.15-0.25 g / cm<3>. The foamed micropore glass pumice is prepared by sintering a foamed mixture. The foamed mixture comprises the following components in percentage by weight: 80-90% of glass powder, 5-10% of marble powder, 1-5% of quicklime and 3-5% of quartz sand powder. The fineness of the glass powder is 40-100 mu m, the fineness of the marble powder is 20-40 mu m, the fineness of the quicklime is 20-40 mu m, and the fineness of the quartz sand powder is 20-40 mu m. The invention also relates to a preparation method of the foamed micropore glass pumice for roof garden cultivation. The invention has the advantages of light weight and air permeability, and can prevent diseases and worms from generation.

Owner:江苏晶瑞特环保新材料有限公司

Pseudomonas strain and application thereof

InactiveCN101935622AStrong resistanceAdaptableBacteriaWater contaminantsEcological environmentPhysical well being

The invention discloses a pseudomonas strain and application thereof. The strain provided by the invention is pseudomonas sp. SG-1 CGMCC No.3556. The microbial inoculum provided by the invention contains the active ingredient of pseudomonas sp. SG-1 CGMCC No.3556. The strain provided by the invention has a wider degradation spectrum and reaches the degradation rates to various toxic compounds over 75 percent. The microbial inoculum of the invention has the advantages of low production use cost, convenient use, wider degradation spectrum and good removal effect. The strain and the microbial inoculum provided by the invention are suitable for the biological treatment of Cr-contained wastewater generated in a tanning and dyeing process and wastewater generated in other petrochemical processes and can ensure that the toxic substance and Cr (VI) contents in the wastewater accord with the wastewater emission standard. The invention successfully solves the problem of poor toxic substance removal effect in a Cr-contained organic wastewater treatment process, reduces the workload in the production and use processes, decreases the production and use costs and has important meanings to protect the ecological environment and keep the body health of people.

Owner:PEKING UNIV

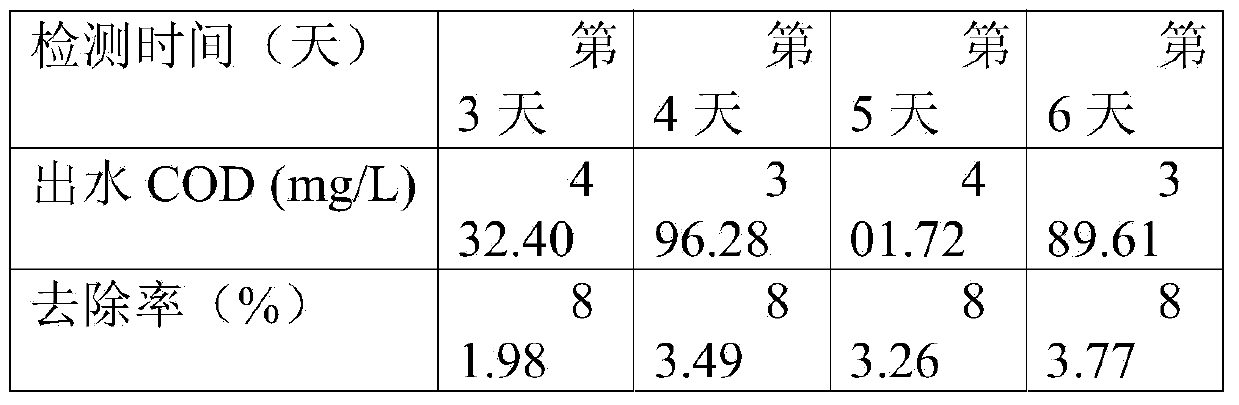

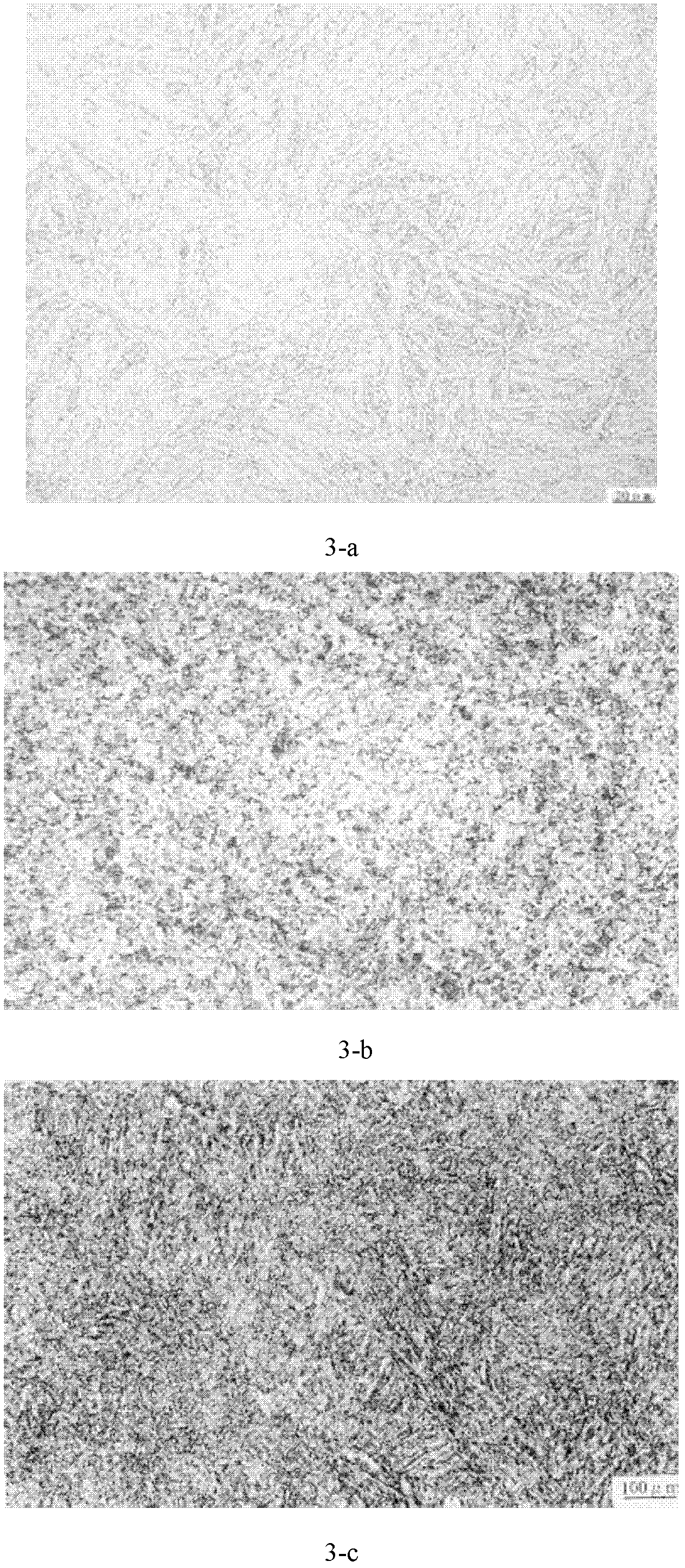

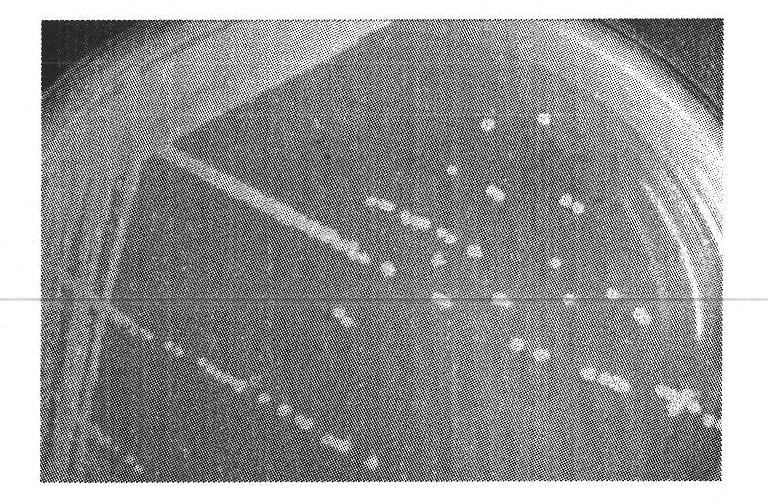

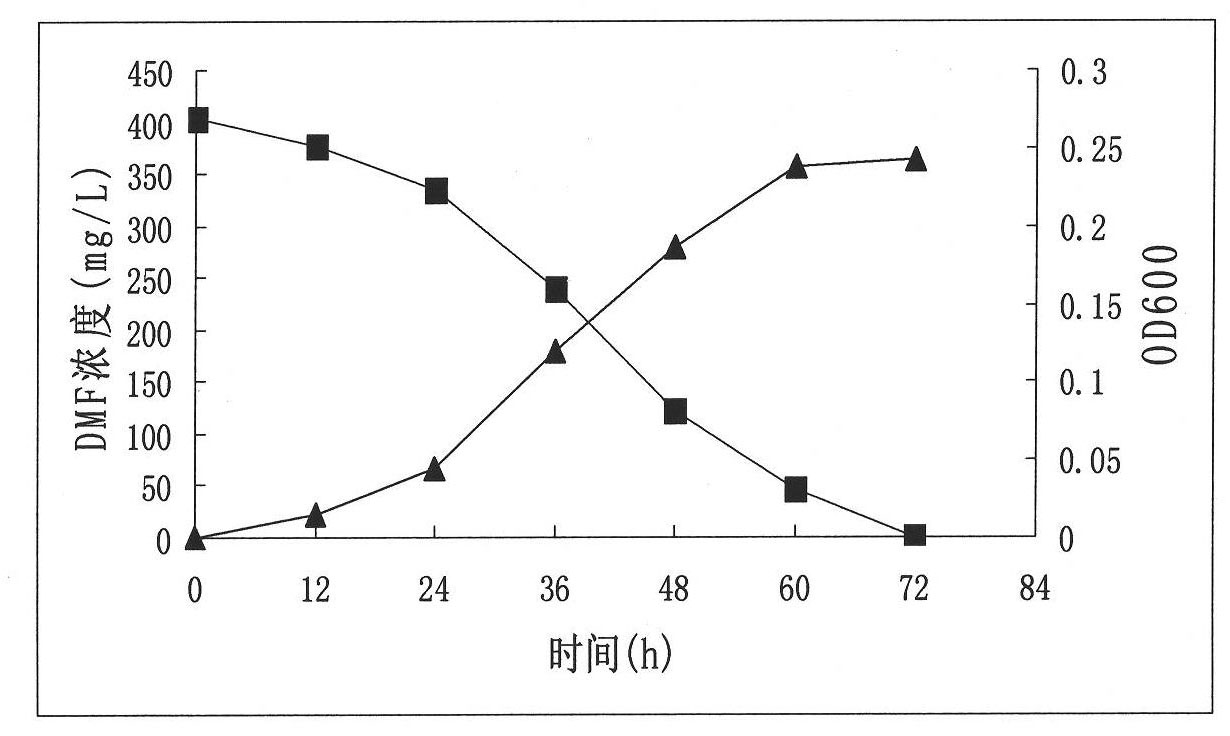

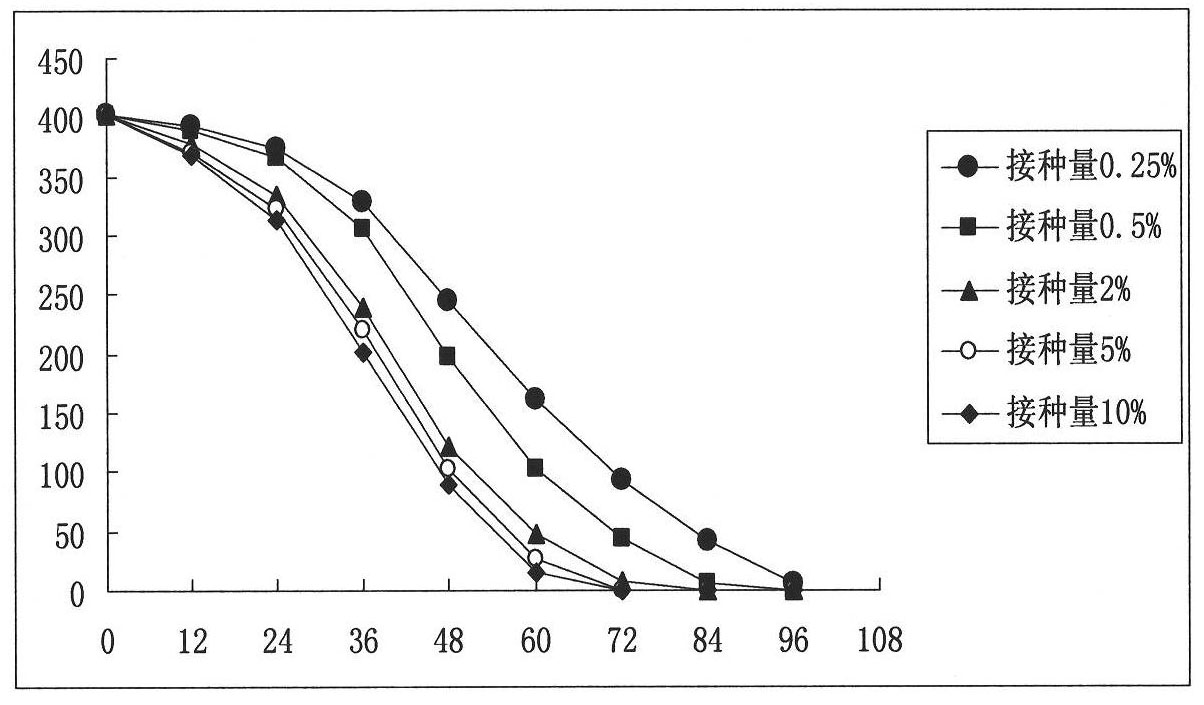

Dimethylformamide degrading bacteria and bacterial agent produced from same

ActiveCN101935626AEasy to useReduce production and use costsBacteriaWater contaminantsChemical oxygen demandBiology

The invention provides dimethylformamide (DMF) degrading bacteria and a bacterial agent produced from the same, which belong to the field of biological high technology. The strain is a Gram staining reaction negative bacteria strain DMF3 and is identified as pseudomonasplecoglossicida. The strain has the main biological characteristic of G<->, an irregular rod-shaped strain body, the size of about 0.5-1.0*1.5-5.0 mu m and no stipe or mycoclena, does not produce spore, is aerobic, undergoes strict respiratory metabolism and can grow by taking DMF as a unique carbon source and nitrogen source so as to be completely mineralized for releasing ammonia nitrogen. The strain can reduce the residual quantity of the DMF with certain concentration in waste water by over 95 percent at the temperature of 30 DEG C under the pH value of 7.0 within 3 days, so that the problem of difficult treatment of the DMF in chemical production waste water is solved, the chemical oxygen demand (COD) of the DMF waste water reaches the standard and the waste water can be discharged.

Owner:NANJING AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com