Composite glaze, composite glaze slip and 4-8 degree soft-surface wear-resistant porcelain antique brick

A technology of antique bricks and glazes, which is applied in the field of ceramic building materials, can solve the problems of non-existence, poor anti-slip force, weak gloss effect, etc., and achieve the effect of increasing anti-slip force, reducing glaze defects, and smooth and delicate touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

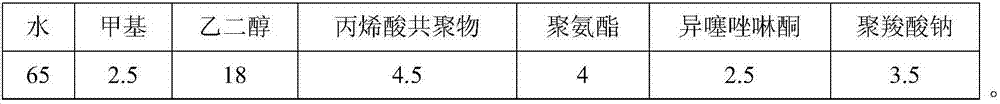

Examples

Embodiment 1

[0056] Embodiment 1 (taking 600*600mm product production as example)

[0057] 1. Prepare brick surface effect requirements according to the 4-8 degree soft surface wear-resistant brick, low light and micro melting high white bottom glaze formula composition: IL: 8.32%; SiO 2 : 46.45%; Al 2 o 3 : 24.96%; CaO: 7.49%; MgO: 3.67%; K 2 O: 2.59%; Na 2 O: 0.29%; ZnO: 0.89%; ZrO 2 : 4.56%.

[0058] The 4-8 degree soft surface wear-resistant composite glaze is composed of high-temperature matt transparent wear-resistant frit A (abbreviated as frit A), sub-surface transparent component glaze B, and wear-resistant anti-skid dry grain C. Three materials are mixed in proportion. High-temperature matt transparent wear-resistant frit A formula ingredients are: IL: 0.02%; SiO 2 : 47.12%; Al 2 o 3 : 19.7%; CaO: 6.5%; MgO: 1.97%; K 2 O: 5.87%; Na 2 O: 3.15%; ZnO: 5.21%; SrO: 3.77%;

[0059] Sub-surface transparent component glaze B formula components are: IL: 12.05%; SiO 2 : 46.7%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com