Special adhesive resin for wire-frame-reinforced polyethylene tube and production method thereof

A technology of polyethylene pipe and steel wire skeleton, which is applied in the direction of pipeline connection arrangement, grafted polymer adhesive, pipe/pipe joint/pipe fitting, etc. It can solve the problems of easy air bubbles, difficult use, and low peel strength, etc. Achieve the effects of increasing adhesion, reducing production and use costs, and improving ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

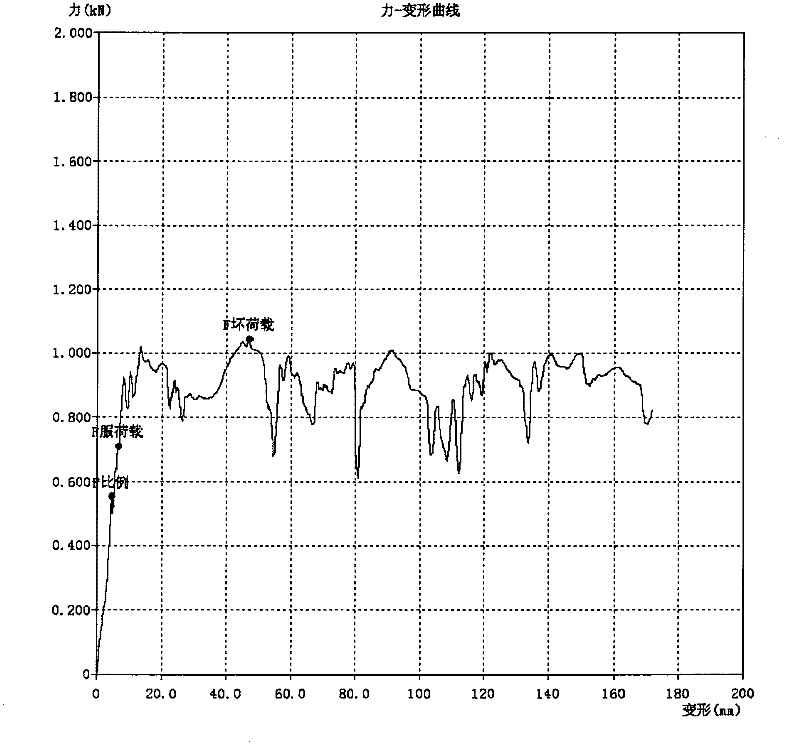

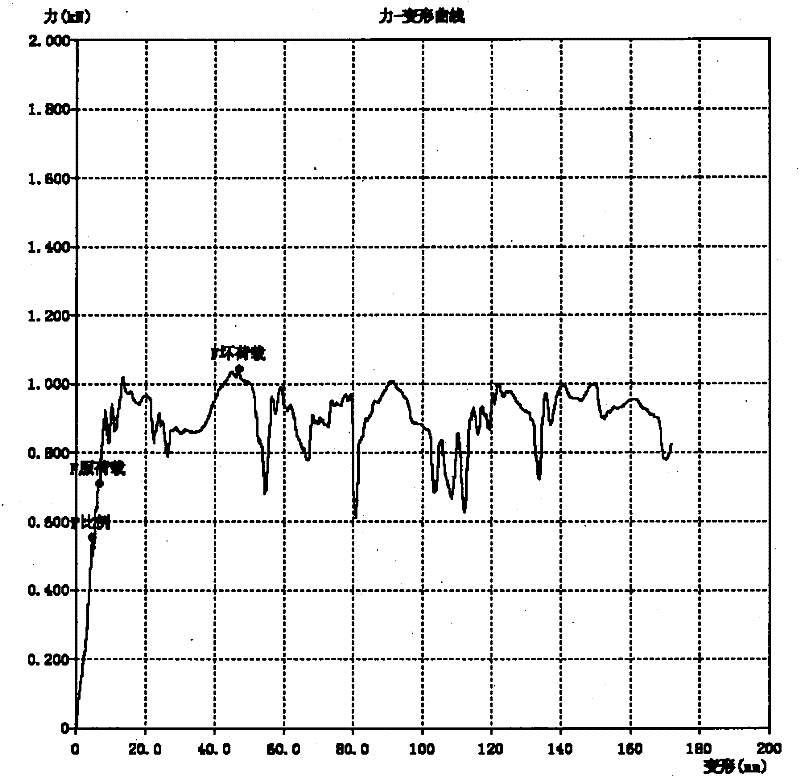

Image

Examples

Embodiment

[0017] Embodiment:: a special adhesive resin for steel wire skeleton reinforced polyethylene pipes, raw material composition weight ratio: HDPE70%, LLDPE20%, maleic anhydride 2%, dicumyl peroxide crosslinking agent 0.1%, acetone 0.1%.

[0018] Its production process includes the following steps:

[0019] First mix maleic anhydride and peroxide evenly;

[0020] Add acetone, then stir evenly to form a small material, and store it at room temperature at a temperature of 10°C-50°C for more than 10 hours. This process can make maleic anhydride, peroxide and acetone pre-react;

[0021] Add HDPE and LLDPE together with the above small ingredients into the mixer and stir for 1.5-10 minutes;

[0022] The above-mentioned mixture is sent to a twin-screw machine for grafting reaction and granulation, the melt temperature is controlled at 200°C-240°C, and the residence time of the material in the barrel is 30-240 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com