Upper plate of waterproof plug mold for automobile wire harness and plug connector

A technology for automotive wiring harnesses and connectors, which is applied in the production of dust-proof, splash-proof, waterproof or fireproof parts and drip-proof fields of automotive wiring harnesses and connectors, and can solve the problems affecting the quality of waterproof plug products, poor positioning effect, and poor operation. The problem of high cost is to eliminate the occurrence of defective products, facilitate mold positioning, and reduce the burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

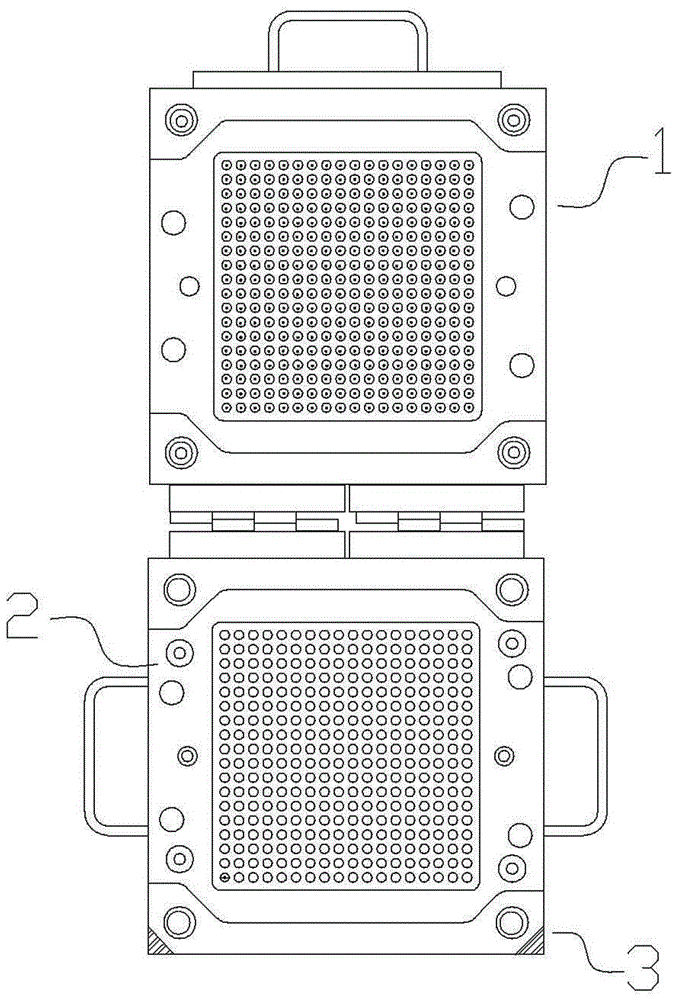

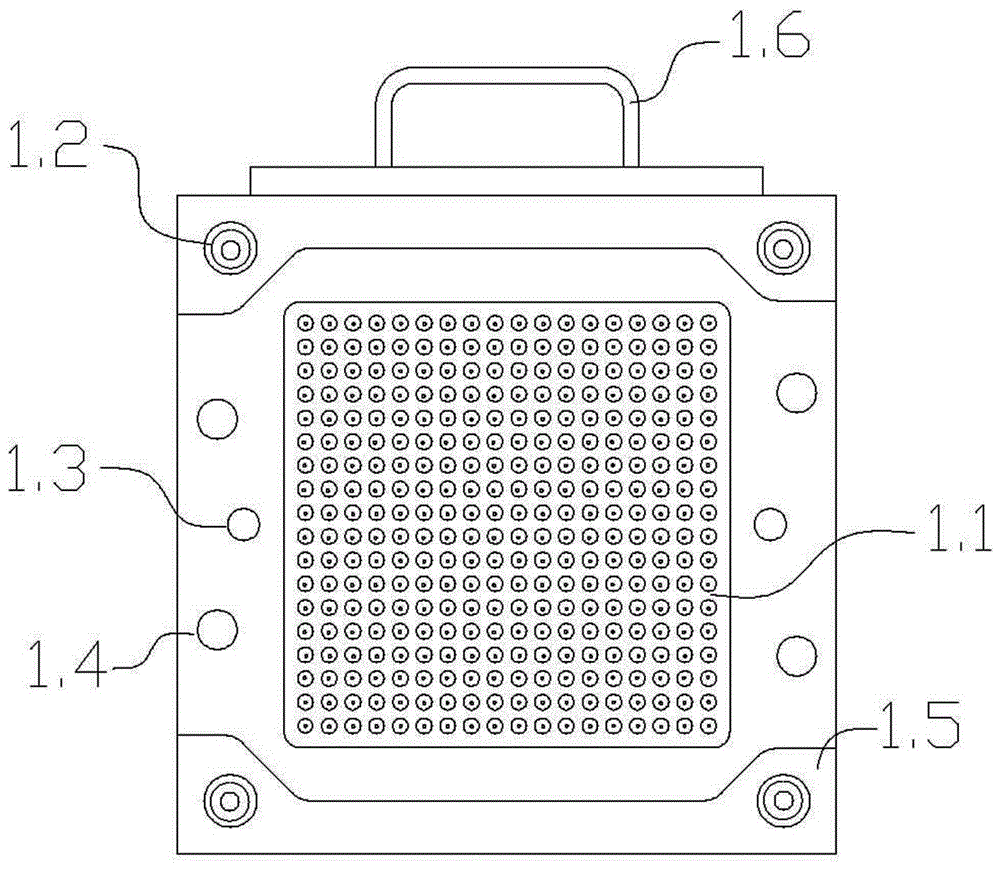

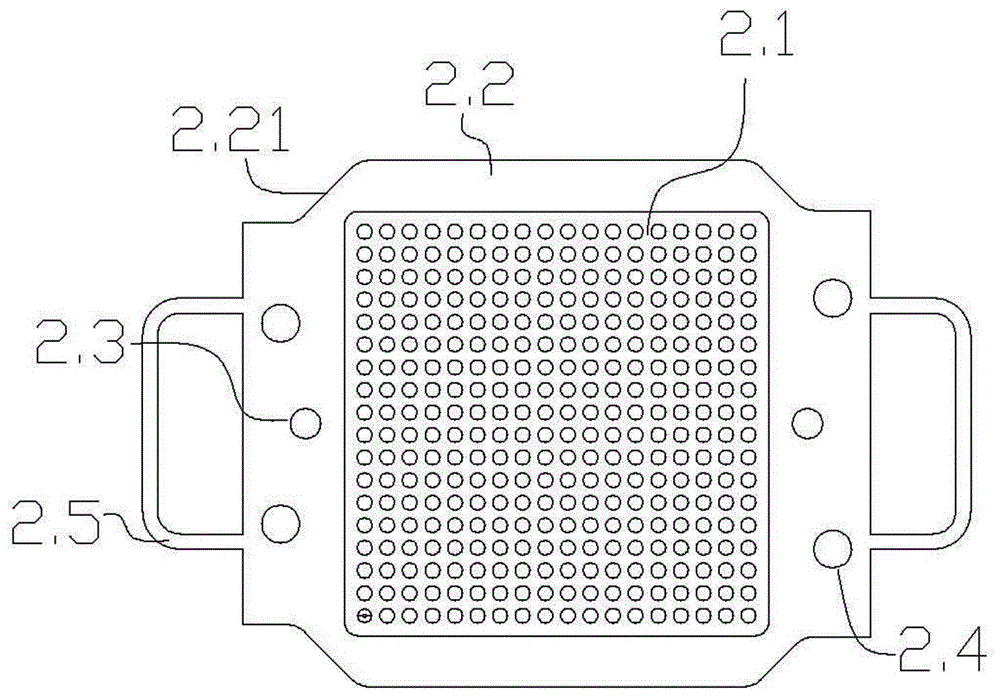

[0036] Example 1: Reference Figure 1~Figure 4 , an automobile wiring harness and connector waterproof plug mold, including an upper plate 1 and a lower plate 2 hinged to each other, and a detachable middle plate arranged between the upper plate 1 and the lower plate 2;

[0037] The middle part of the upper plate 1 is provided with a terminal mold hole group 1.1, and the middle part of the middle plate 2 and the middle part of the lower plate 3 are respectively provided with a plug body mold hole group 2.1 and a sealing part mold that are intended to be adapted. Hole group 3.1 is used to mold various parts of the automobile wiring harness and connector waterproof plug;

[0038] Wherein, the upper plate 1 is also provided with a first lower plate positioning member 1.2, which cooperates with the upper plate positioning member 3.2 on the lower plate 3, and the first lower plate positioning member 1.2 and the upper plate positioning Part 3.2 forms the function of mutual limitati...

Embodiment 2

[0044] Example 2: Reference Figure 5 , the difference from Example 1 is that: the end die hole group 1.1, the plug body die hole group 2.1 and the sealing part die hole group 3.1 are divided into two sections; the middle plate located on the lower plate 3 The positioning piece 3.3 is not arranged symmetrically with the central axis of the lower plate 3, which facilitates the positioning of the middle plate and prevents reverse installation. At the same time, the position of the middle plate positioning piece adapter hole 1.3 on the upper plate 1 is relatively The position of the middle plate positioning member 3.3 is adjusted accordingly.

Embodiment 3

[0045] Example 3: Reference Figure 6 , the difference from Example 1 is that: the die hole group 1.1 of the end, the die hole group 2.1 of the plug body and the mold hole group 3.1 of the sealing part are divided into three sections; the upper plate 1 is not provided with a first The middle plate limiter 1.5 is provided with an upper plate exhaust channel 1.7 communicating with it around the end die hole group 1.1 of the upper plate 1, and the lower plate is provided with a position that is in line with the upper plate exhaust channel 1.7 Corresponding lower panel exhaust channel 1.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com