Package bag vacuum pumping ironing sealing device

A technology of vacuuming and packaging bags, applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems that packaging bags cannot be vacuumed and sealed immediately, defective products, and reduced production efficiency, etc. Eliminate secondary pollution or other problems, eliminate packaging defective products, and reduce the effect of intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

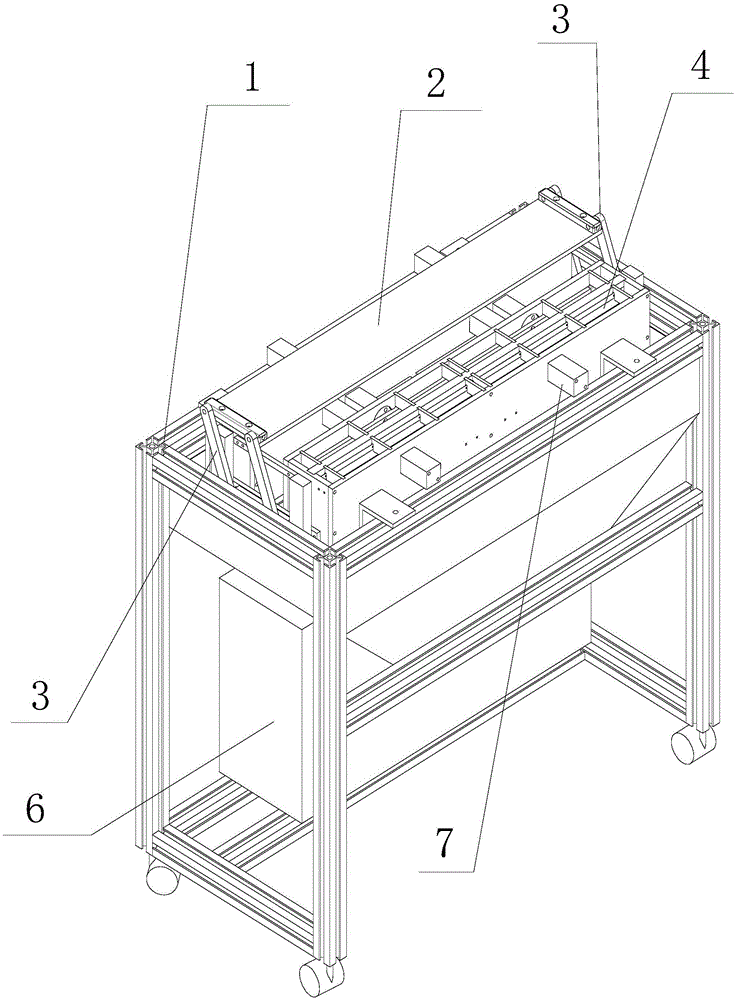

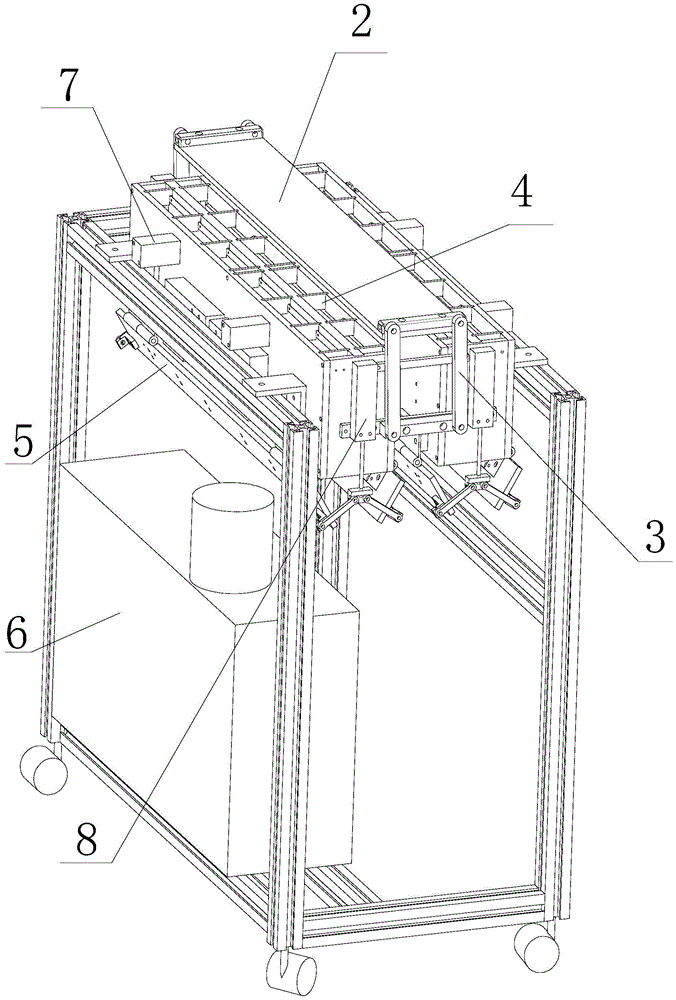

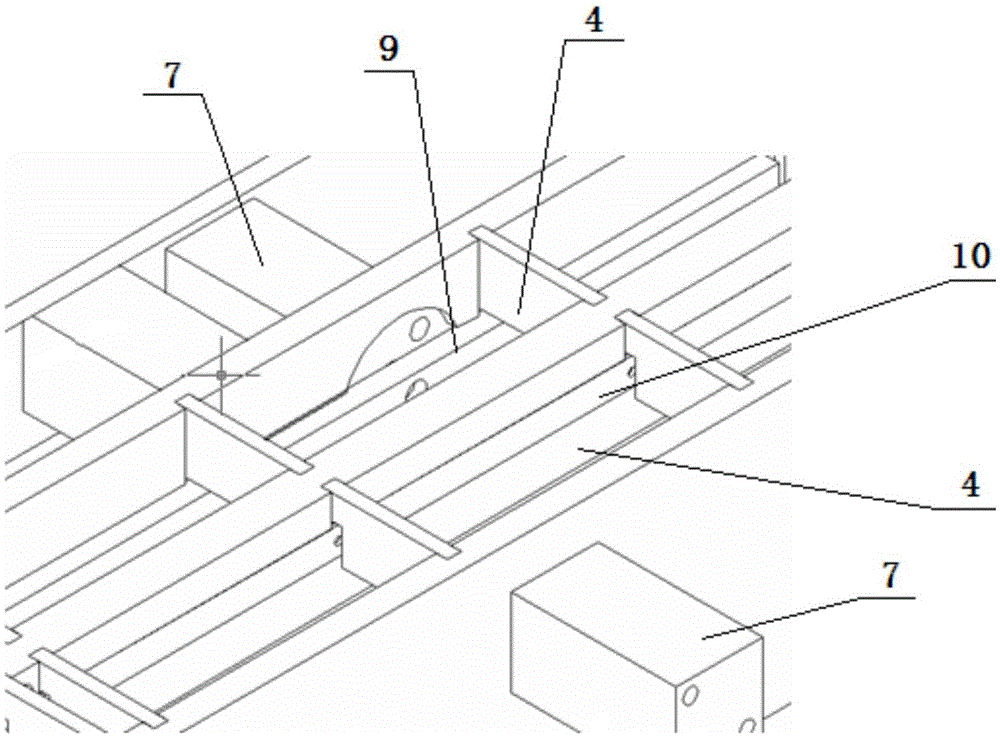

[0018] Referring to the accompanying drawings, reflecting a specific preferred structure of the present invention, the packaging bag vacuum sealing device includes a frame 1 and a control mechanism (not shown in the figure), and the top of the frame 1 is provided with twenty-four The vertical lattice body 4 installed side by side, the twenty-four lattice bodies 4 are divided into two groups of A and B and installed on the top of the frame 1, and the lattice bodies 4 of each group are divided into two parallel rows, and the two rows of lattice bodies 4 are back to back device, wherein the side of the device ironing bar 10 is located in the central position. On the frame 1, a movable upper sealing door 2 is installed through a four-coupling mechanism 3, and the size of the upper sealing door 2 is enough to cover the upper end faces of the inner cavities of twelve lattice bodies 4 of Group A or Group B. Correspondingly, the closed position of the upper airtight door 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com