Bookblock online inversion detection method and device

A detection device and book block technology, applied in the direction of book binding, transportation and packaging, and the compound continuous process of book processing, can solve the problems of low production efficiency, affecting the yield of finished products, and can not eliminate the problem of cost failure, so as to improve Production efficiency, the effect of eliminating defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

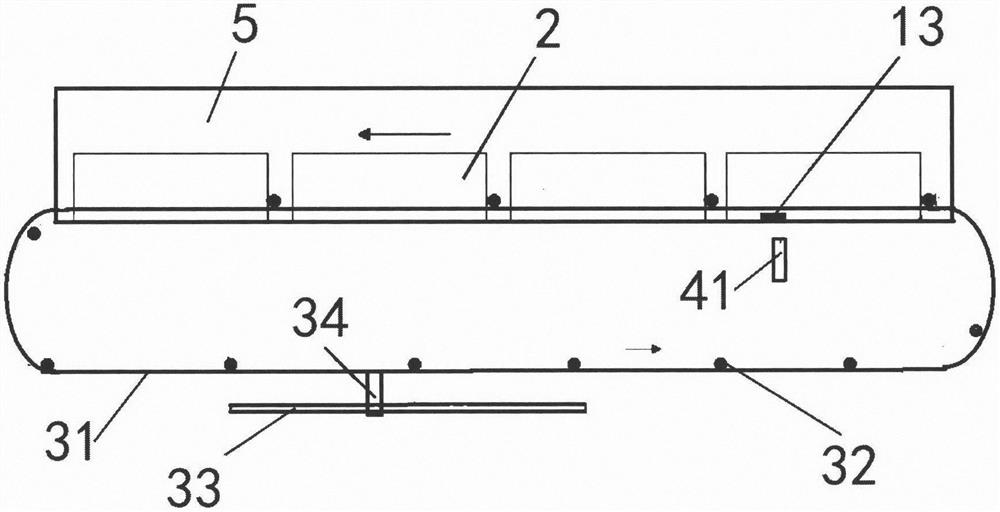

[0035] Such as image 3 As shown, the present embodiment is a device for detecting book blocks online, including: a conveyor belt 5, which can be a part of the hardcover linkage production line, or can be set independently, and its function is to bind the finished book blocks 1 Transmitting to the next process, it also includes an endless belt 31, a scanner 41, a proximity switch 34, a mounting rod 33 and a control device. A part of the endless belt 31 is arranged above the conveyor belt 5 and moves forward synchronously with the conveyor belt 5. The remaining part is outside the conveyor belt 5. On the endless belt 31, there are evenly distributed some push sticks 32. The distance between the two push sticks should be greater than the length of the book block 1. The scanner 41 is arranged on the upper side of the conveyor belt 5 to detect the passing The folding block 13 of the book block 1 above the conveyor belt 5, the proximity switch 34 is fixed on the installation rod 33...

Embodiment 2

[0039] On the basis of Embodiment 1, a selector switch is also provided, and the selector switch is used to set the conveying direction of the book block. The direction of the book block transmission is correct. If the forward foot is selected, if the scanner does not detect a folded block, it will be judged that the book block is in the correct direction. Otherwise, it will be judged that the book block is reversed.

Embodiment 3

[0041] This embodiment provides a method for detecting book blocks online, including the following steps:

[0042] A. Prepare the book block online reversing detection device described in the foregoing embodiment 1;

[0043] B. Adjust the position of the proximity switch 34 according to the distance between the folding block 13 and the front end of the book block 1 in the conveying direction;

[0044] C. Start the book block online reversing detection device. After the control device receives the signal of the proximity switch, it controls the scanner to detect and judge whether the folded block is detected;

[0045] D. If the folded block is detected, it is judged that the direction of the book block transmission is correct;

[0046]E. If the folding block is not detected, it is judged that the direction of the book block transmission is wrong and correct, the control device sends out a warning message, and drives the actuator to push the book block 1 out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com