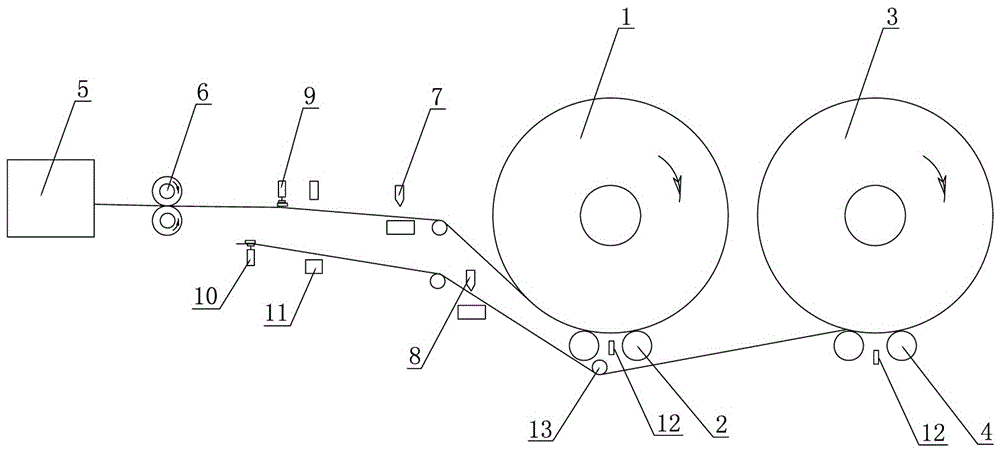

Automatic film changing device of film wrapping machine

A technology of automatic film changing and film wrapping machine, applied in the field of beverage packaging, can solve the problems of increasing production and use costs of enterprises, low film utilization rate, complicated operation, etc., to reduce production and use costs, improve film utilization rate, and simple and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

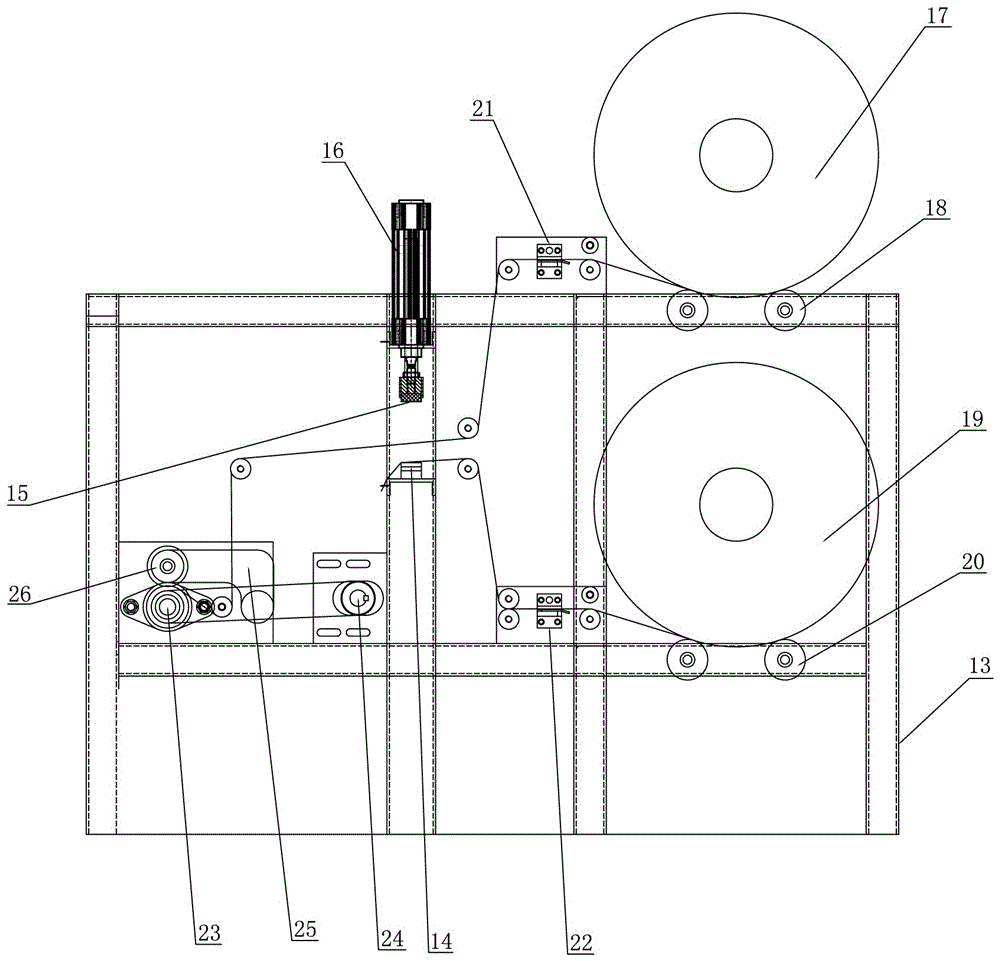

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] Such as figure 2As shown, the automatic film changing device of a film wrapping machine includes: a frame 13, a film heat-sealing knife 14 is arranged in the frame 13, a film pressure seat 15 is arranged above the film heat-sealing knife 14, and the film The press seat 15 is driven by the film-connecting cylinder 16 installed vertically on the frame 13 to approach or leave the film heat-sealing knife 14 downwards. The film head fixing part of the fixed film roll film head is provided with two film roll placement racks with film rolls placed on the frame 13 of the film inlet side of the film heat sealing knife 14, that is: for placing the first film roll 17 The first film roll placement rack 18 of the first film roll placement rack 18 and the second film roll placement rack 20 for placing the second film roll 19 are provided between eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com