Silicon wafer processing device

A processing device and silicon crystal technology, applied in the direction of fine working devices, stone processing equipment, working accessories, etc., can solve the problems of low equipment utilization, high production and use costs, single function, etc., to achieve high clamping efficiency and reduce Cost of production and use, simple effect of switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to describe in detail the technical content, structural features, achieved objectives and effects of the technical solution, the following detailed descriptions are given in conjunction with specific embodiments and accompanying drawings.

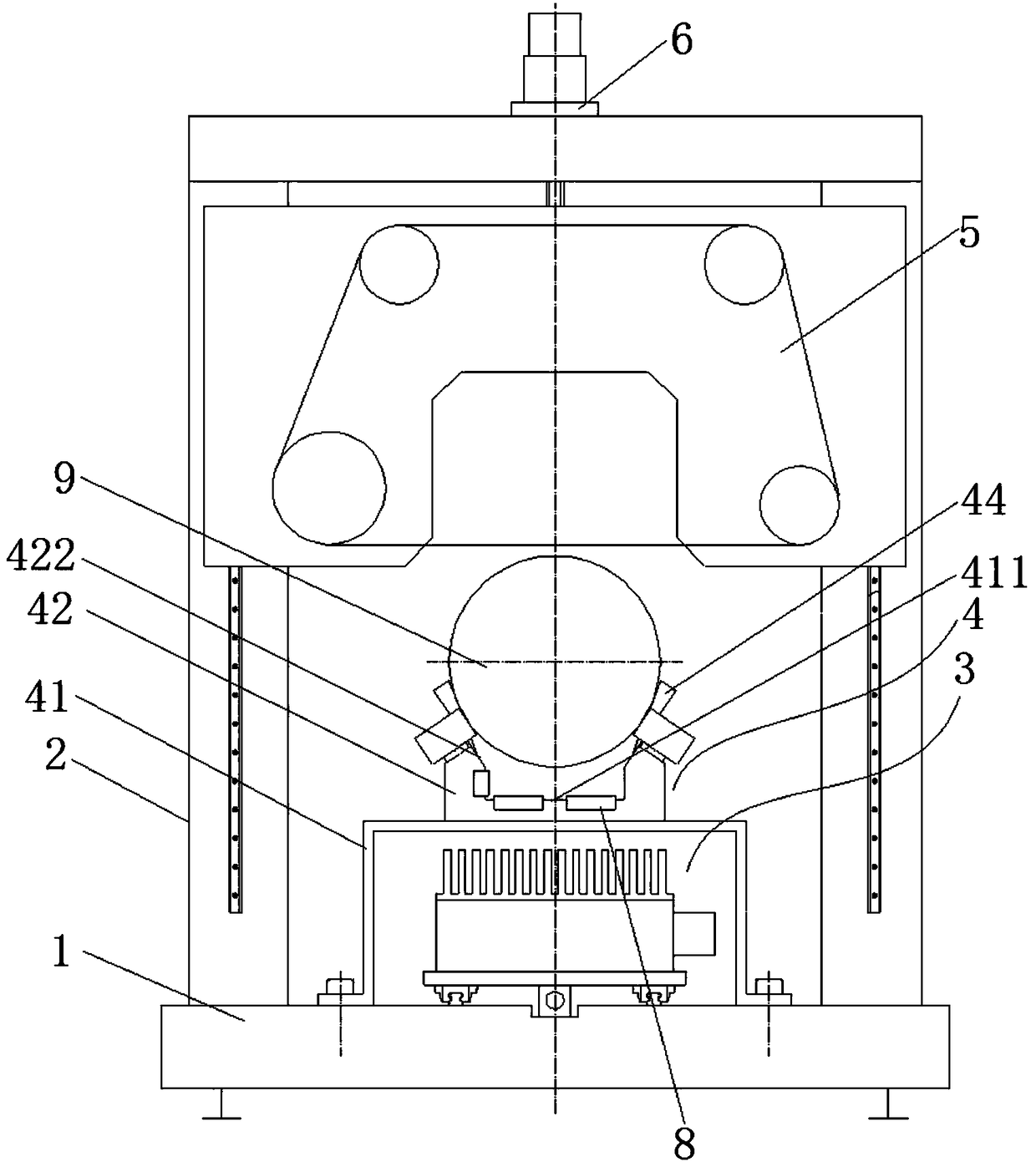

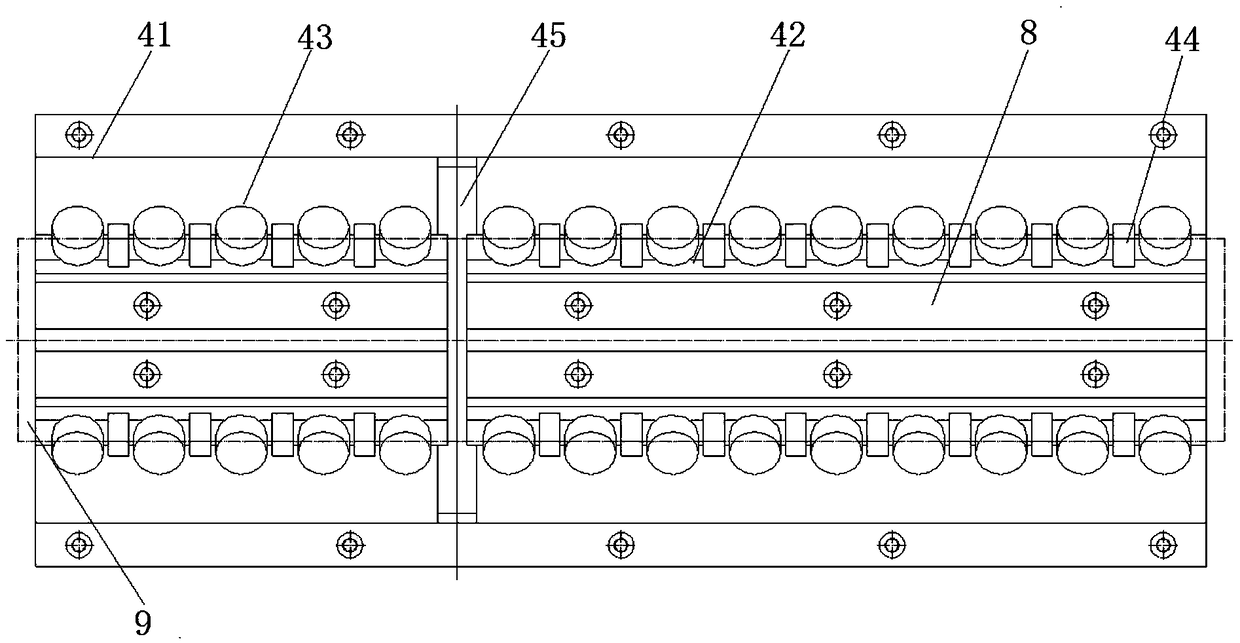

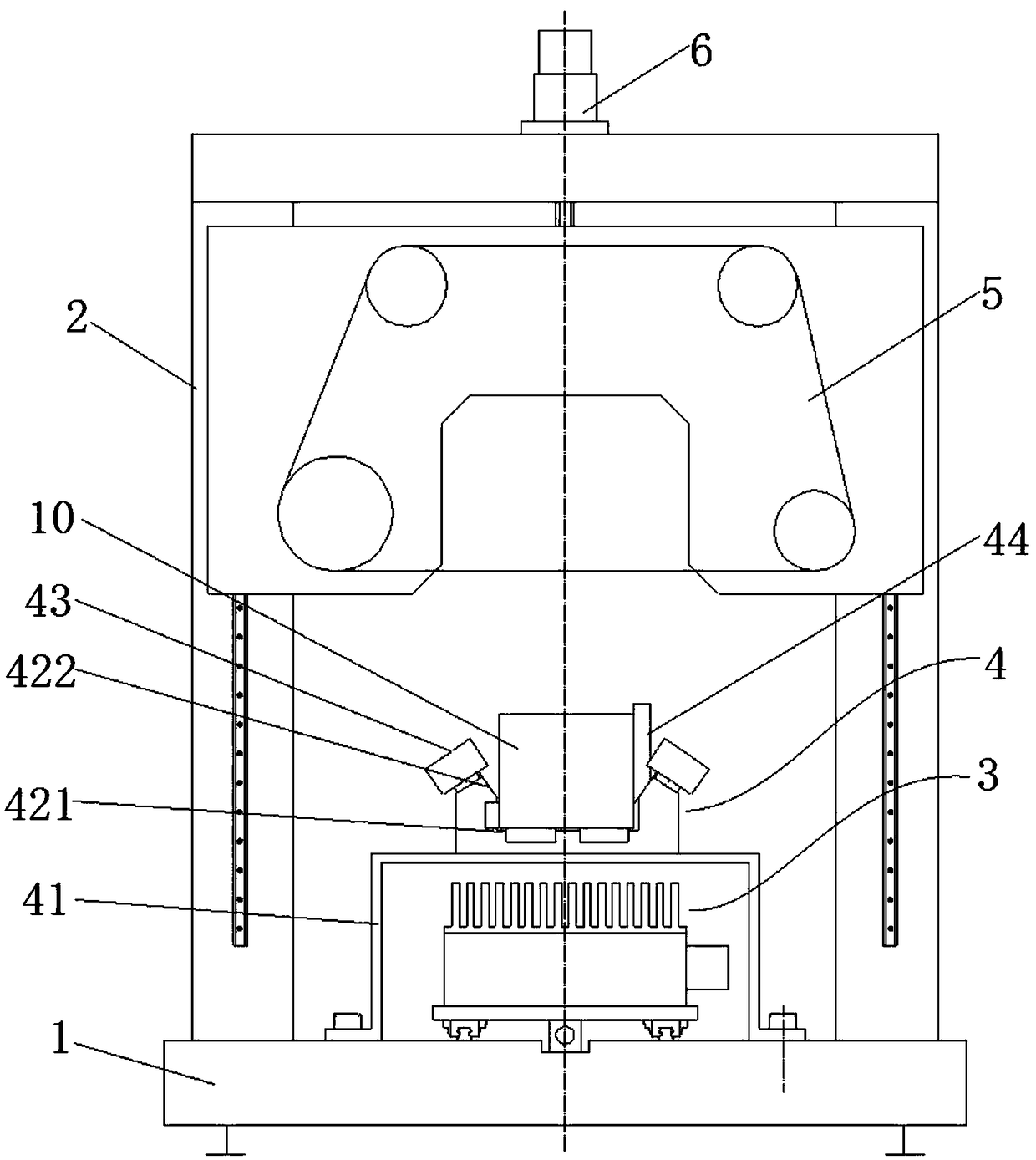

[0052] See Figure 1 to Figure 6 , The present invention provides a silicon crystal processing device, the processing device includes a base 1, a frame 2, a square opening and clamping mechanism 3, a silicon crystal cutting and clamping mechanism 4, and a wire saw cutting machine 5; the frame 2 Set on the base 1; the base 1 and the bracket fixed on the base 1 are used as the main structure of the silicon crystal processing device of the present invention to carry and fix other components, such as: square clamping mechanism 3, wire saw cutting machine 5 Wait.

[0053] The square rooting and clamping mechanism 3 is used to load and fix the seed crystal rods to be square rooted. The specific structure is as follows: the square ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com