Sweet sorghum stalk squeezing device

A sweet sorghum and stalk technology, applied in the field of sweet sorghum stalk pressing devices, can solve problems such as difficulty in obtaining sweet sorghum juice, continuous defects in sweet sorghum stalk pretreatment, and stable material guidance, and achieve improved pressing Quality and Continuity, Improving Pressing Efficiency, Effect of Improving Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

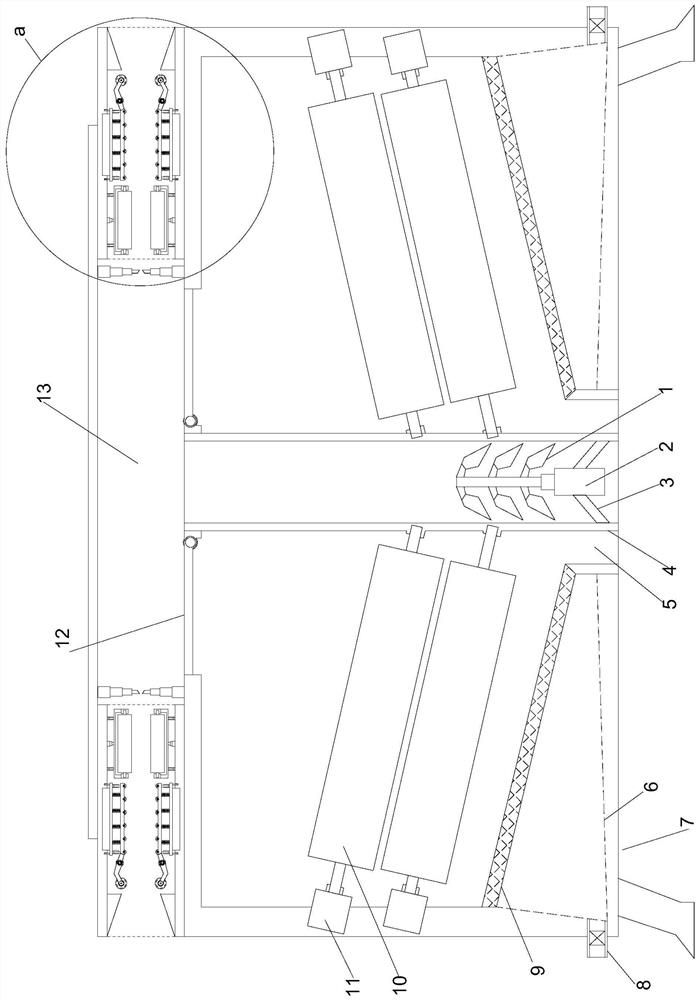

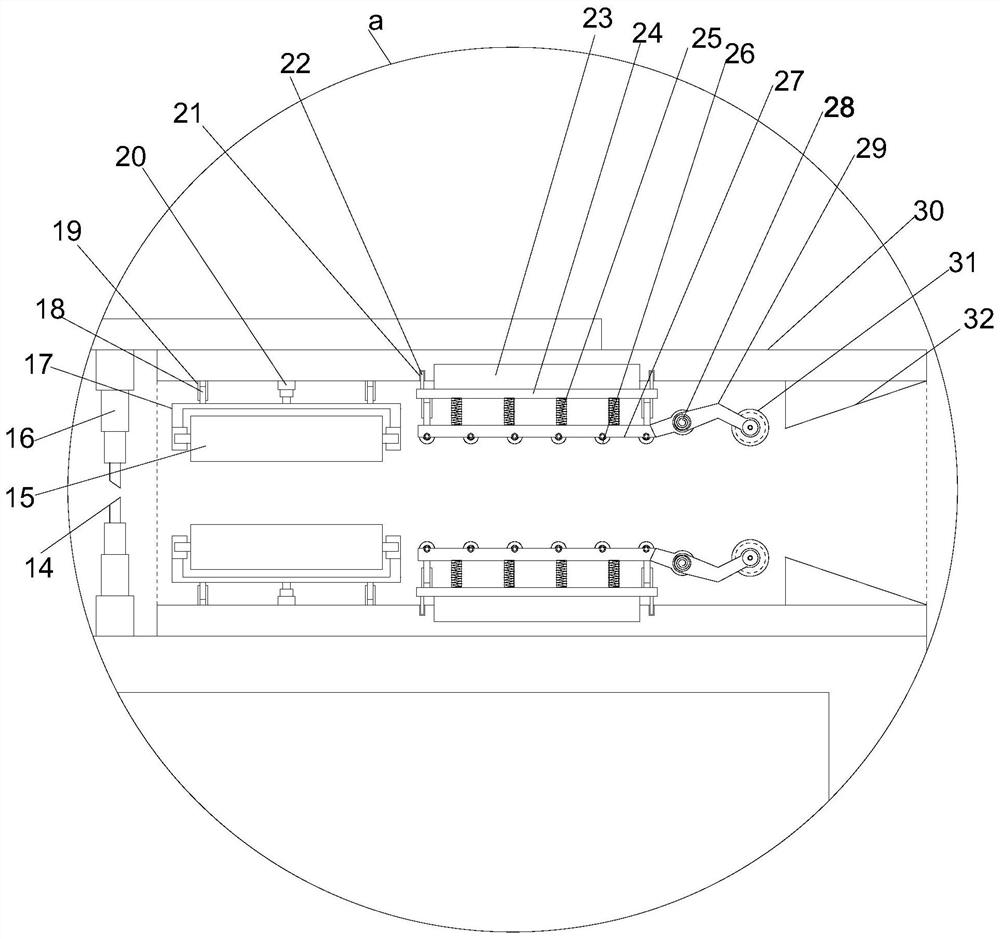

[0022] see Figure 1~3 , in an embodiment of the present invention, a sweet sorghum stalk pressing device includes a horizontally arranged support installation cylinder 7, the four corners of the lower end of the support installation cylinder 7 are all provided with support installation columns, and the middle position of the upper end of the support installation cylinder 7 is horizontally arranged. Material guide installation cylinder 13, the middle position of support installation cylinder 7 is vertically provided with flow guide installation cylinder 4, and flow guide installation cylinder 4 vertically runs through support installation cylinder 7, and the middle position of the lower half section of described flow guide installation cylinder 4 is vertically arranged. Directly provided with diversion motor 2, the outer side of diversion motor 2 is equiangularly provided with several diversion installation columns 3, and diversion installation column 3 is all fixed on the inne...

Embodiment 2

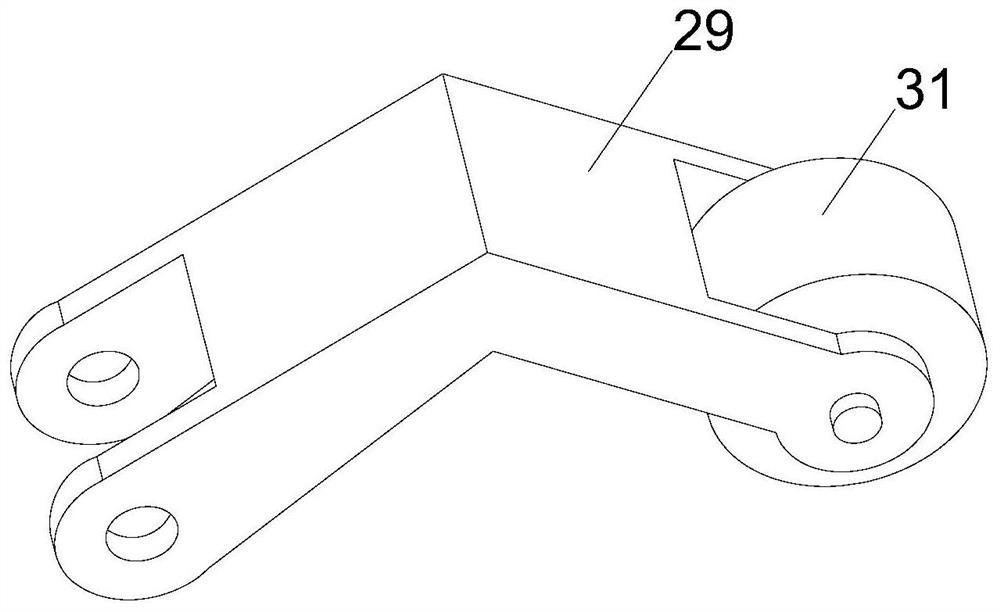

[0025] On the basis of Embodiment 1, the telescopic displacement of the telescopic mounting plate 24 is realized through the control of the telescopic airbag 23 and the cooperation of the positioning mounting column 21 and the positioning mounting hole 22, and then under the action of the return spring 25, it adapts to different The diameter of the sweet sorghum stalk guide ensures the smooth and stable guide of the material, and also ensures the subsequent cleaning and cutting operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com