Partition plate for plate mold and automatic partition plate adjusting device

An automatic adjustment and partition technology, applied in the direction of mold fixtures, mold auxiliary parts, manufacturing tools, etc., can solve the problems of raw material waste, large impact force of the partition, and high equipment input cost, so as to avoid low production efficiency and increase Installation stability, the effect of increasing the weighing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

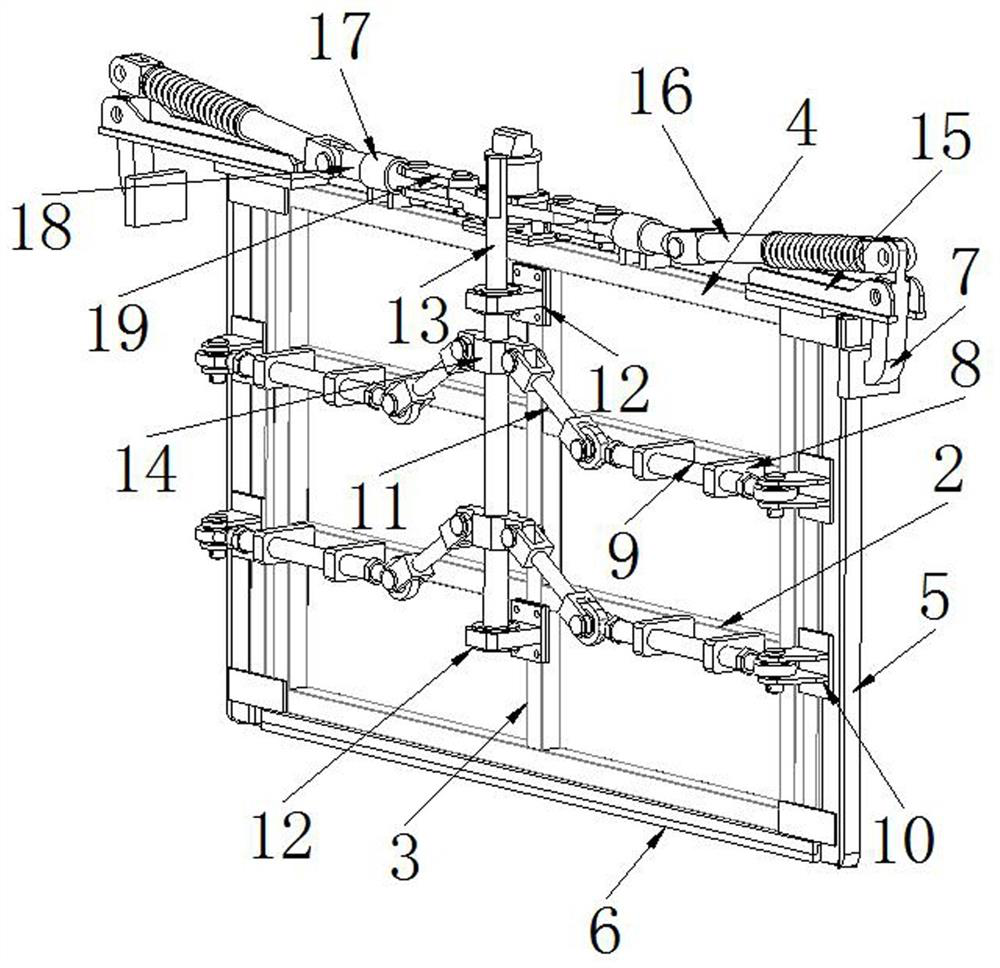

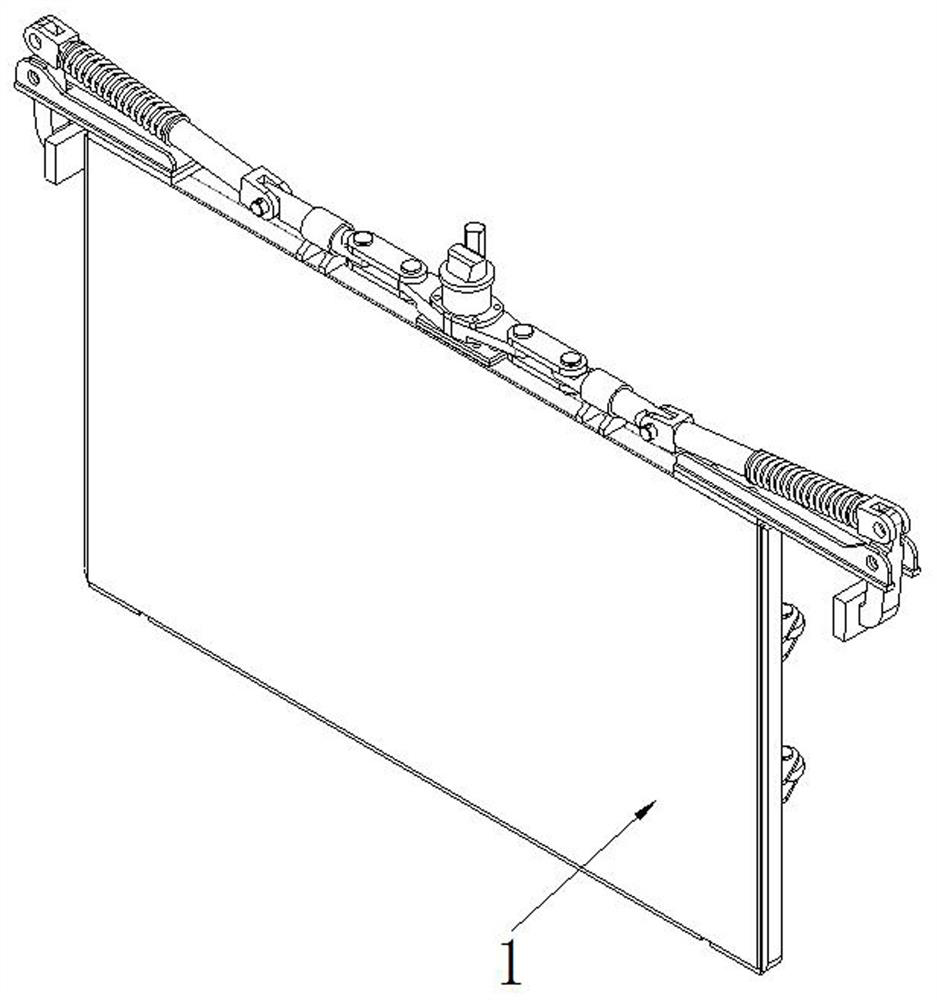

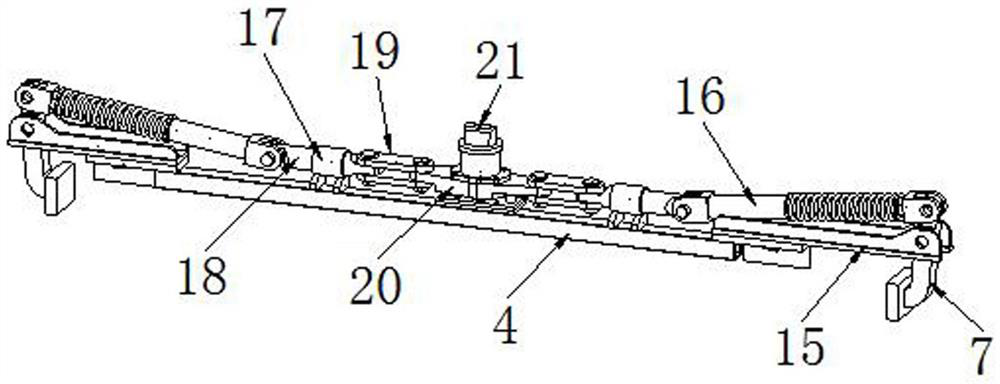

[0074] see figure 1 and figure 2 , one side of the baffle 1 is flat, such as figure 2 As shown, turn the plane side toward the side that needs to be filled with materials, and press the partition plate into the mold 32. At this time, a downward pressure is continuously provided on the upper part of the partition plate to ensure that the bottom plate 6 and the mold 32 are in contact with each other. The bottom is in direct and close contact, and then the side plate 5 is pushed outward by the side plate ejection mechanism, so that the surface of the side plate 5 is in contact with the inner wall of the mold 32. In the preliminary installation of the partition plate, the locking claw 7 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com