Low-speed stop valve group

A shut-off valve and valve cavity technology, applied in the direction of lift valve, balance valve, valve device, etc., can solve the problems of emulsion leakage in the liquid supply pipeline, affecting normal work, difficult to screw the shut-off valve, etc., to reduce the labor intensity of operation. , Improve safety and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

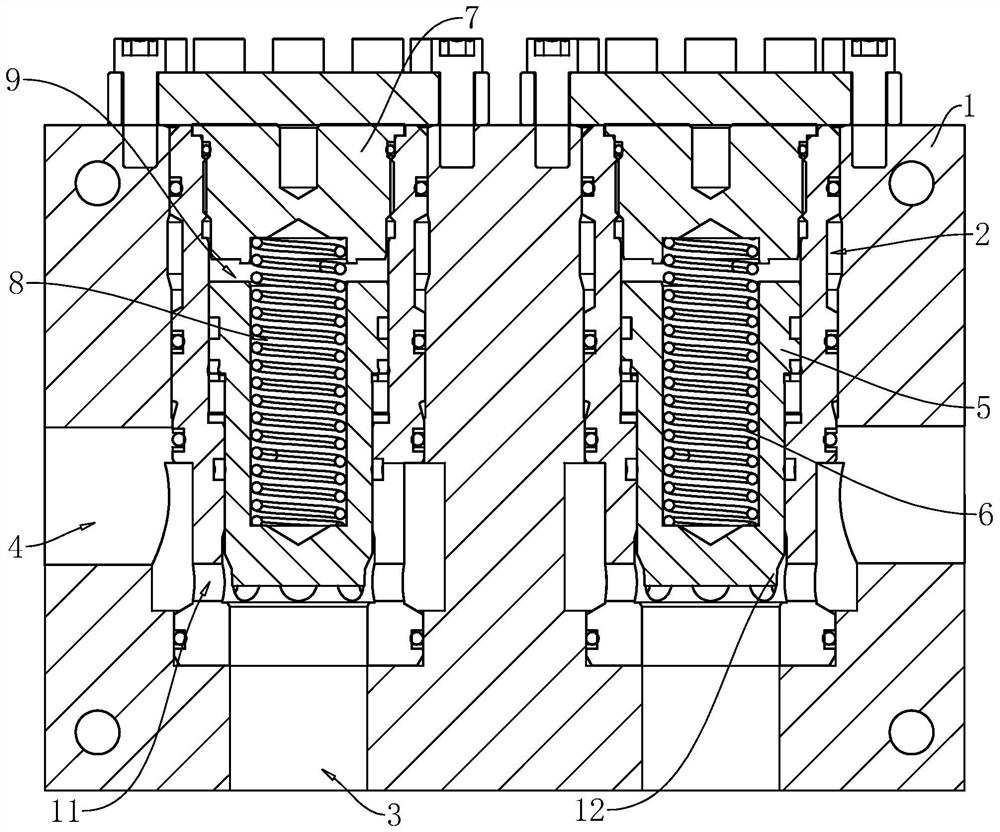

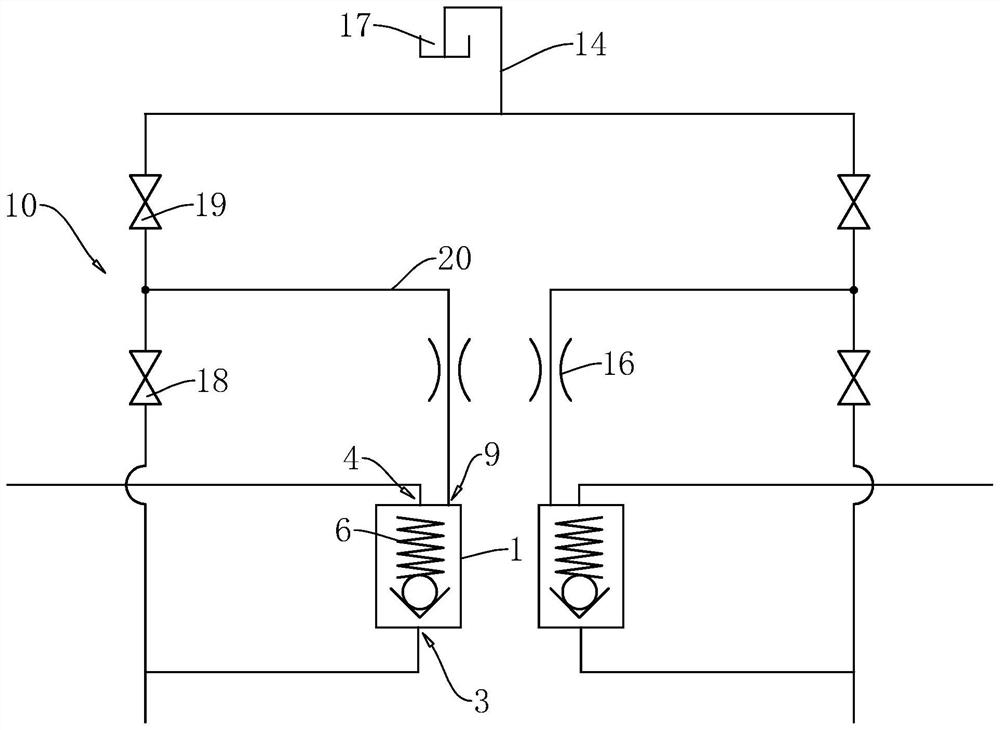

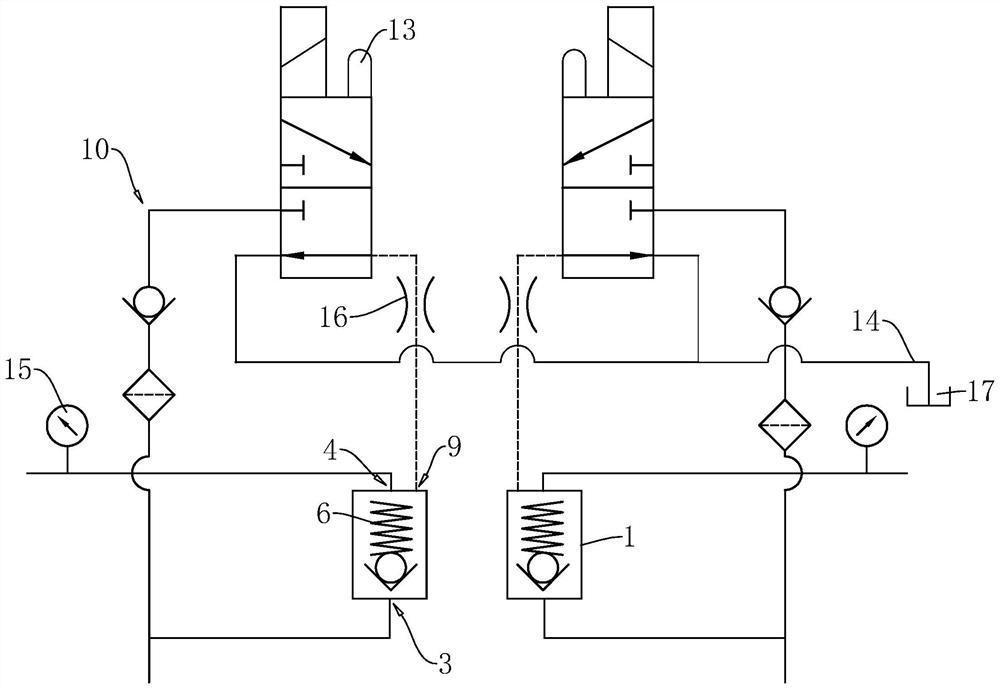

[0048] refer to figure 1 and image 3 , the difference between this embodiment and the first embodiment is that the control oil circuit 10 is different. Specifically, the control oil circuit 10 includes a two-position three-way solenoid valve 13 coupled with a central controller (not shown in the figure). One of the ports of the solenoid valve 13 is communicated with the liquid inlet 3, and the other port on the same side of the two-position three-way solenoid valve 13 is provided with a pressure relief port 14, and the pressure relief port 14 can lead to the emulsion tank 17. The interface on the opposite side of the three-way solenoid valve 13 is communicated with the control liquid port 9; the central controller is connected to the central console for man-machine interaction for communication. It is realized by the way of optical fiber ring network transmission communication.

[0049] In addition, three centralized control stations are provided in the central pumping stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com