Large-caliber reversing valve

A reversing valve, large-diameter technology, applied in valve details, multi-port valves, valve devices, etc., can solve problems such as inability to apply fluid media, and achieve good fluid control characteristics, large effective flow area, and small fluid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings; it should be noted that: this embodiment is descriptive, not restrictive, and cannot be used to limit the protection scope of the present invention.

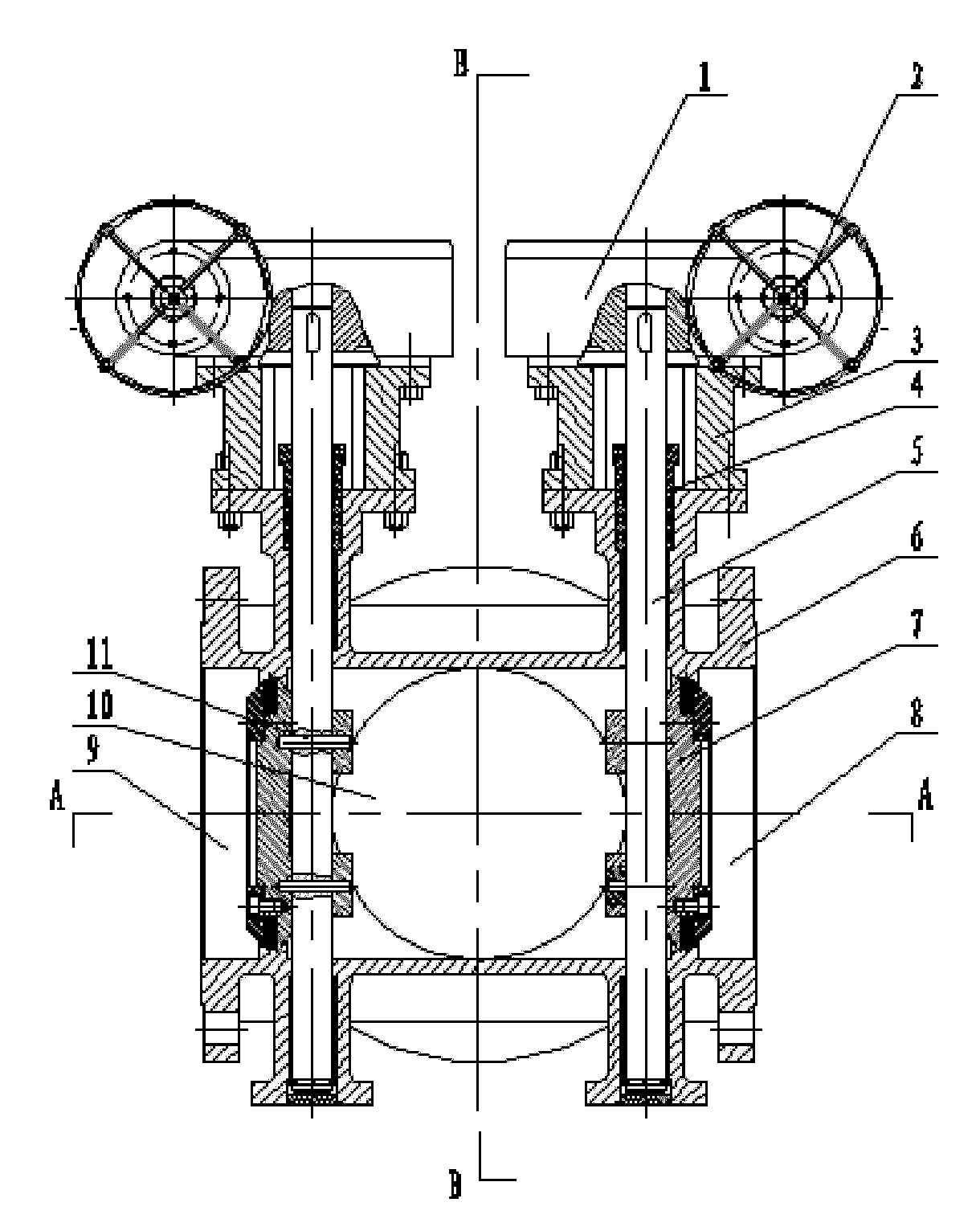

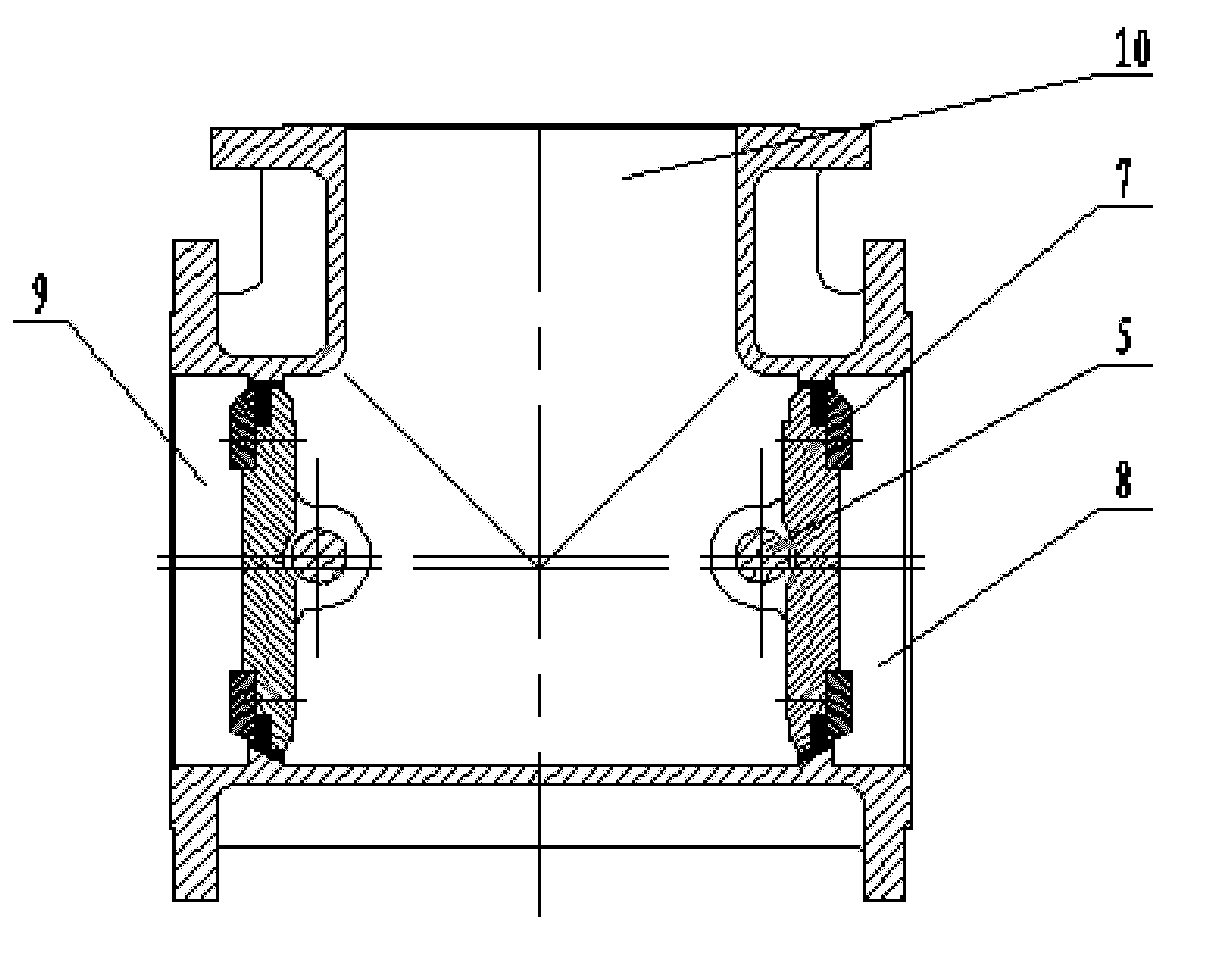

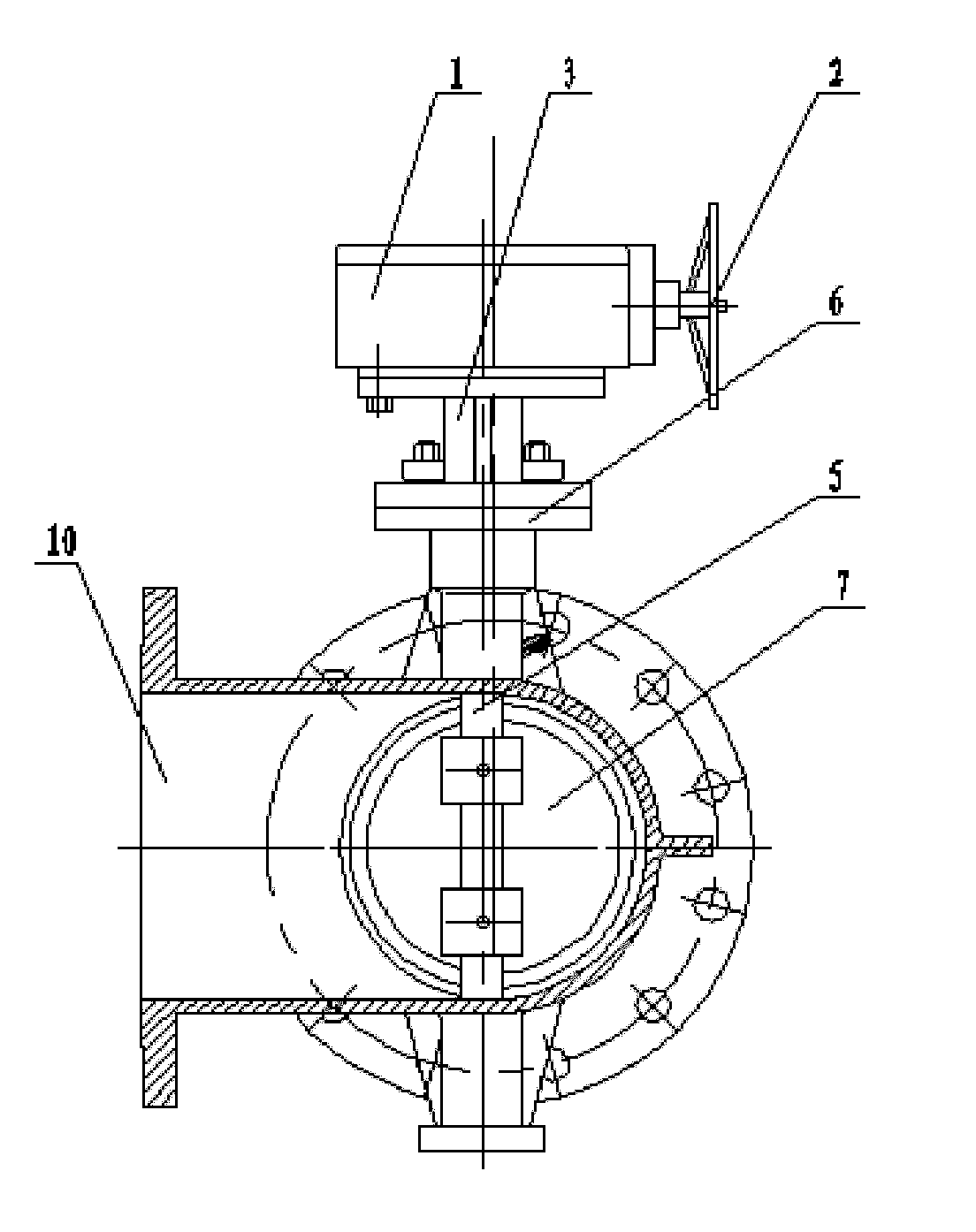

[0018] A large-diameter reversing valve is composed of a valve body 6, a butterfly plate 7, a valve stem 5, a driving device 1 and other components. The reversing valve belongs to a three-way valve, and a fluid medium inlet 10, Two mirror-symmetrical outlets 8 and 9 are mirror-symmetrically installed on the valve body of each outlet with a butterfly plate, valve body bracket 3, valve stem and driving device, wherein each valve stem is fixed on the valve body through a lock pin 11. A packing 4 is installed between the valve stem and the valve body on each butterfly plate; the driving device can be manually driven by a manual runner 2 as shown in this embodiment, or can be automatically driven by a motor or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com