Patents

Literature

217results about How to "Will not affect the use effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of embossing laminating release paper

ActiveCN101597874AWon't happenUnity of depthPaper coatingLaminationLow-density polyethylenePulp and paper industry

The invention discloses a production technology of embossing laminating release paper, the production technology is characterized by comprising the following steps: 1) preparing laminating paint, adding the high-density polyethylene and the low-density polyethylene into a stirring vessel to mix and stir for 5-10 minutes to mix evenly, the weight ratio of the high-density polyethylene and the low-density polyethylene is 1:1.5-2, and then heating, bridging, heating and melting, pressing and extruding the mixture. 2) preparing the embossing laminating release paper, laminating the extruded polyethylene mixture to the surface of the paper by a composite wheel, pressing and compositing the mixture by the composite wheel, and cooling the temperature at 30-40 DGE C after compositing, continually moving the paper after laminating driven by a roller and cooling the paper at the temperature of 12-20 DGE C, and side cutting, rolling, packaging for the paper, finally, coating silicon oil on the surface of the laminating paper to prepare the finished product of the embossing laminating release paper. The invention has convenient production technology; the embossing laminating release paper prepared by the production technology has the advantages of beautiful shape and good use effect, can be widely used in the technology of manufacturing the embossing laminating release paper.

Owner:FOSHAN NANHAI DISTRICT XINYONGTAI ADHESIVE PROD CO LTD

Water diamond lapping liquid and its preparation method and use

InactiveCN101186804AEnvironmentally friendlyAccelerated corrosionPolishing machinesOther chemical processesAlloySuspending Agents

The invention provides aqueous diamond polishing liquid, process for preparation and purpose. The main components are diadust, dispersion stabilizer, suspending agent, pH modifying agent, antiseptic agent, organic solvent and deionized water. The preparing technique of the invention is that organic solvent, diadust, prior prepared suspending agent, deionized water and dispersion stabilizer are mixed, then the mixture is stirred or supersonically dispersed uniformly, finally pH modifying agent and antiseptic agent are added, and the preparation is accomplished after shaking up. The lapping liquid can be widely used in grinding and polishing in various departments and areas of optical instruments, glasses, ceramics, rigid alloy, diamonds, artificial lens, optical fiber, LED display, integrated circuit, semiconductor, hard disk and the like. The lapping liquid can be kept in uniform and stable state, generates no precipitation, delamination or invalidation.

Owner:BEIJING GRISH HITECH

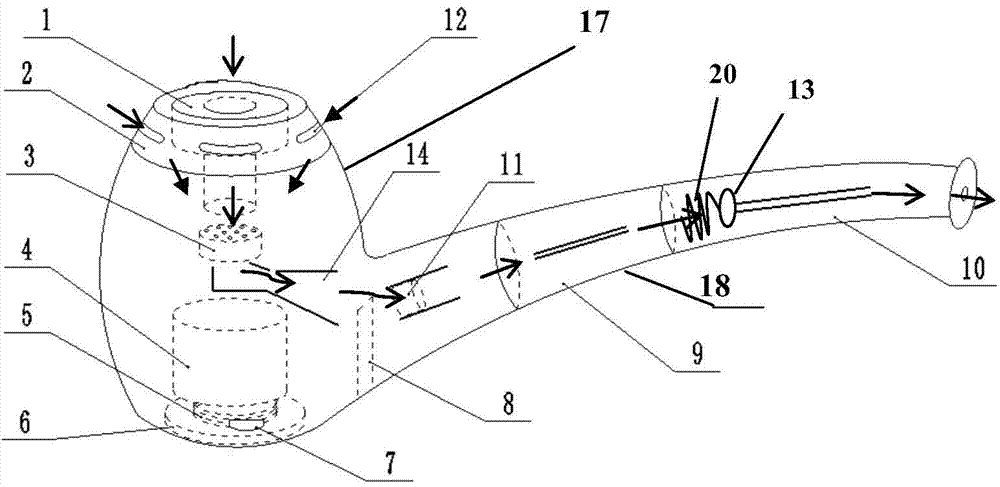

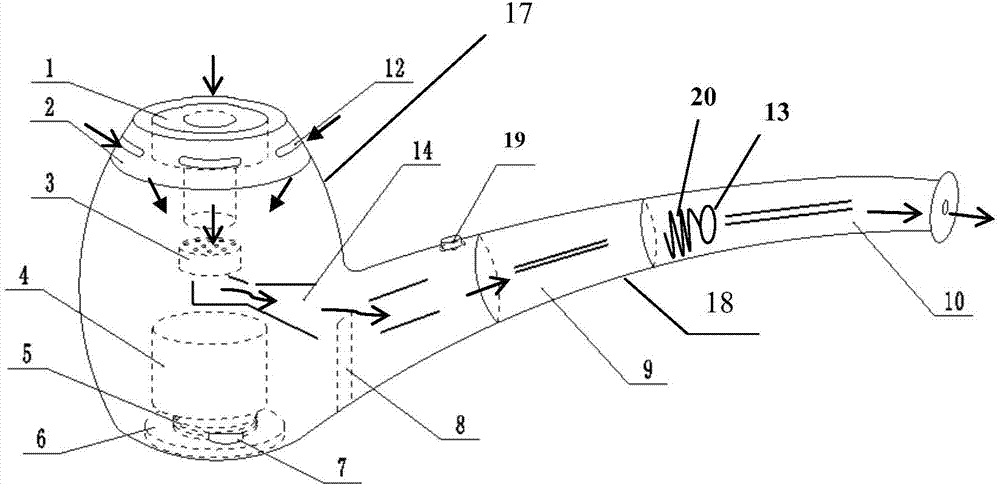

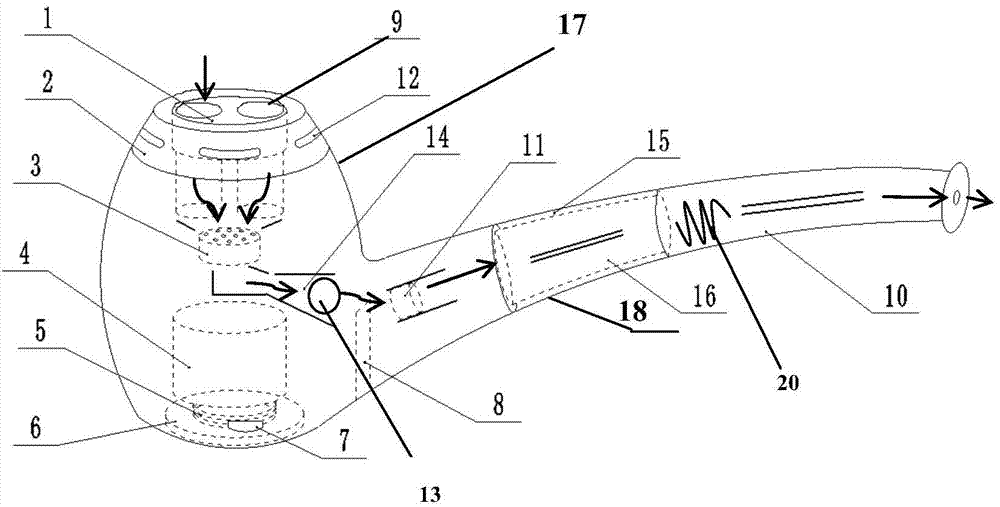

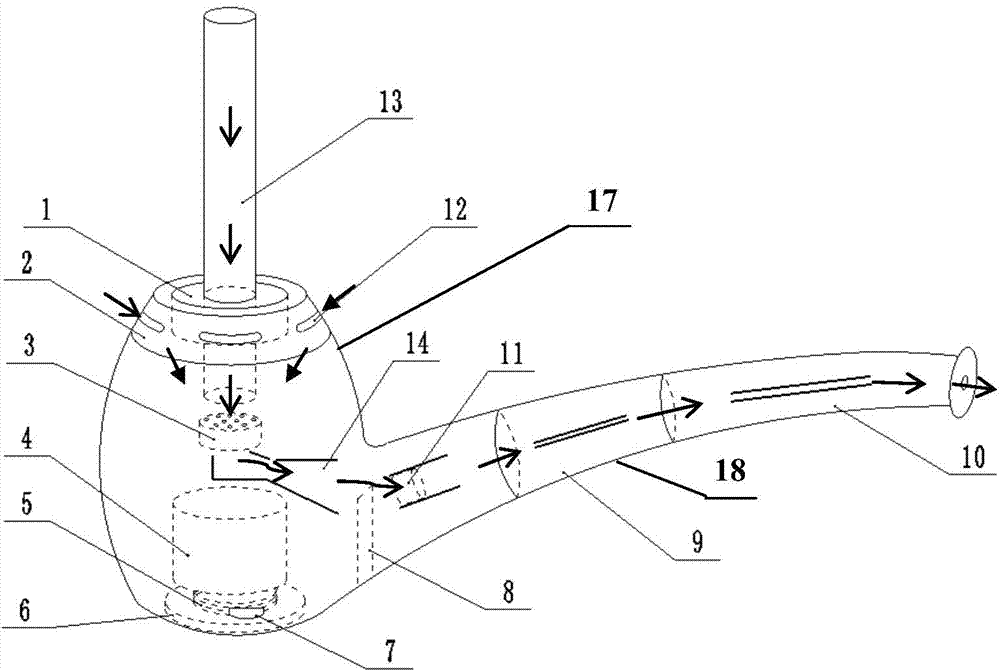

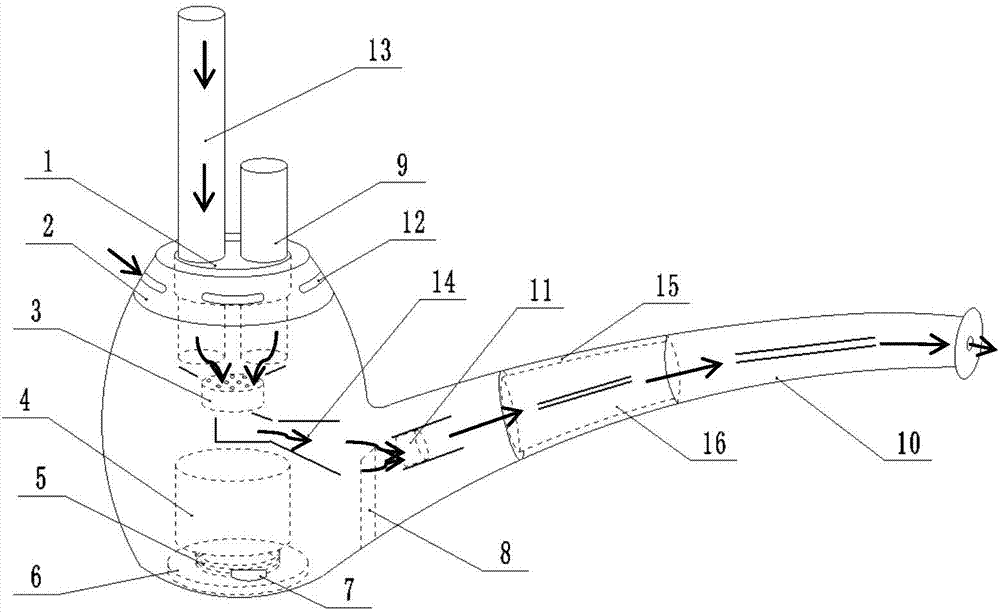

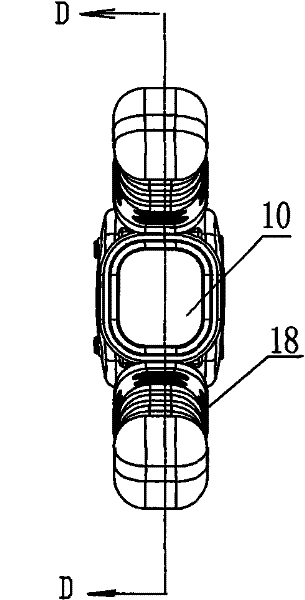

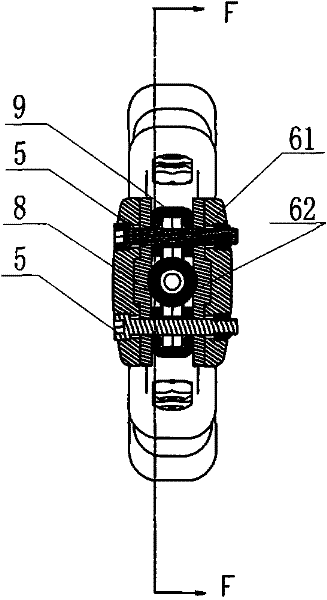

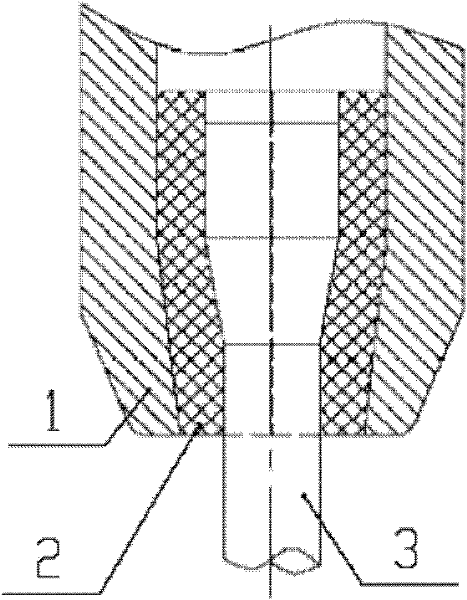

Electric heating type tobacco pipe with electronic cigarette suction function

The invention relates to an electric heating type tobacco pipe with an electronic cigarette suction function. The electric heating type tobacco pipe comprises a pipe bowl (17), a pipe handle (18), a suction mouth section (10), a switch and an electronic atomizer (9), wherein the pipe bowl (17), the pipe handle (18) and the suction mouth section (10) are connected in sequence, the pipe bowl (17) comprises a solid tobacco product containing cavity (1) which runs through the pipe bowl (17) or is positioned in the pipe bowl (17) and is provided with an electric heater, an auxiliary air inlet (12) which runs through the upper wall or the side wall of the pipe bowl (17) and a power supply (4) which is positioned in the pipe bowl (17), and the electronic atomizer (9) and the solid tobacco product containing cavity (1) are connected in series or in parallel. The electric heating type tobacco pipe with the electronic cigarette suction function has the effects of being capable of increasing the electric heating type cigarette suction sensory quality, reducing the harmfulness of smoking and increasing the smoke plumpness and / or reducing the stimulation of nicotine in smoke to throats or nasal cavities of smokers.

Owner:CHINA TOBACCO YUNNAN IND

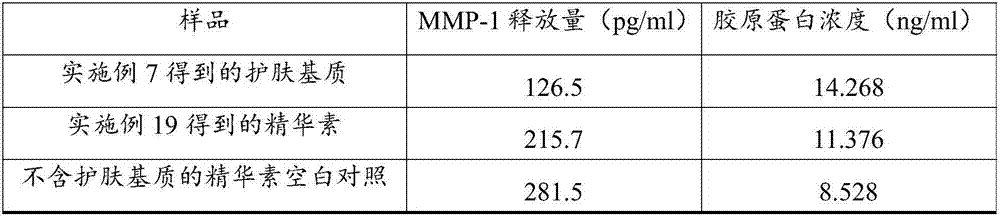

Skin-care substrate, preparation method and application thereof, and cosmetic and preparation method thereof

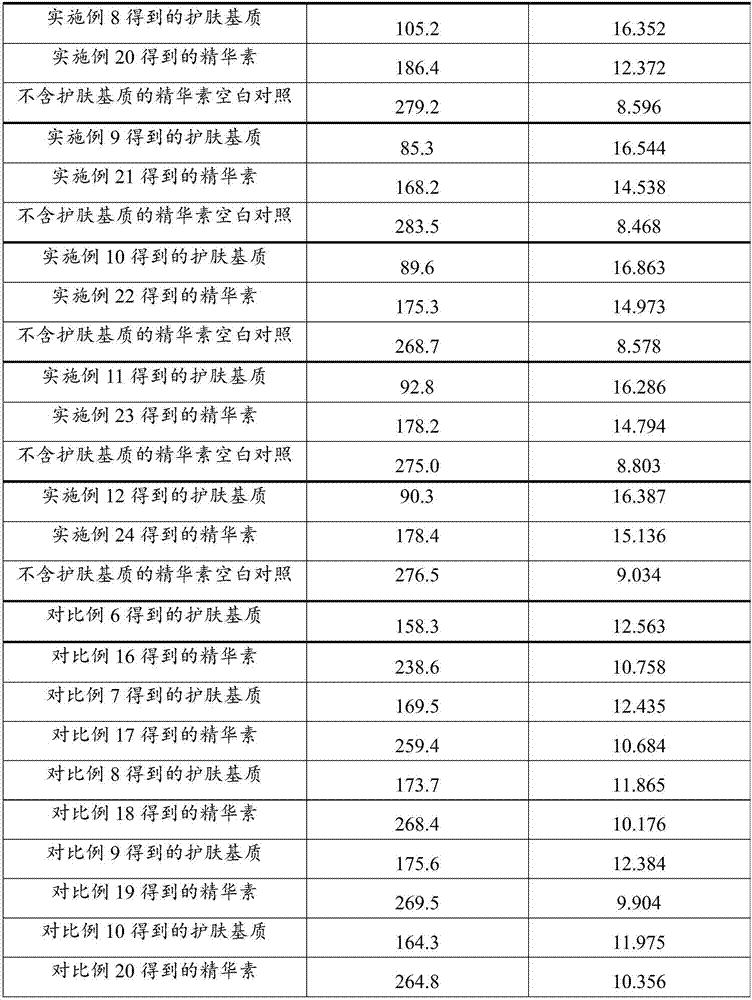

ActiveCN107362129AGood synergyMaximum protection against infrared raysCosmetic preparationsToilet preparationsAdditive ingredientCarboxylic acid

The invention discloses a skin-care substrate, a preparation method and the application thereof, a cosmetic and a preparation method thereof, and relates to the technical field of cosmetics. The skin-care substrate comprises the following components: tetrahydromethyl pyrimidinyl carboxylic acid, a thermus thermophilus fermentation product, a buddleja officinalis extract, recombinant human-sourced collagen and water, wherein the weight percents of the tetrahydromethyl pyrimidinyl carboxylic acid, the thermus thermophilus fermentation product, the buddleja officinalis extract and the recombinant human-sourced collagen in the skin-care substrate are not lower than 1%. The problems that most of the conventional anti-aging products are based single antioxidation or single collagen supplement or the like, are not significant in anti-aging effect, and do not have an infrared-resisting effect are solved. By taking the tetrahydromethyl pyrimidinyl carboxylic acid, the thermus thermophilus fermentation product and the buddleja officinalis extract as main functional components in the skin-care substrate, and through synergistic compounding of the recombinant human-sourced collagen, and through a synergistic effect of the components, the skin-care substrate has the infrared-resisting and anti-aging efficacies.

Owner:GUANGDONG MARUBI BIOLOGICAL TECH CO LTD

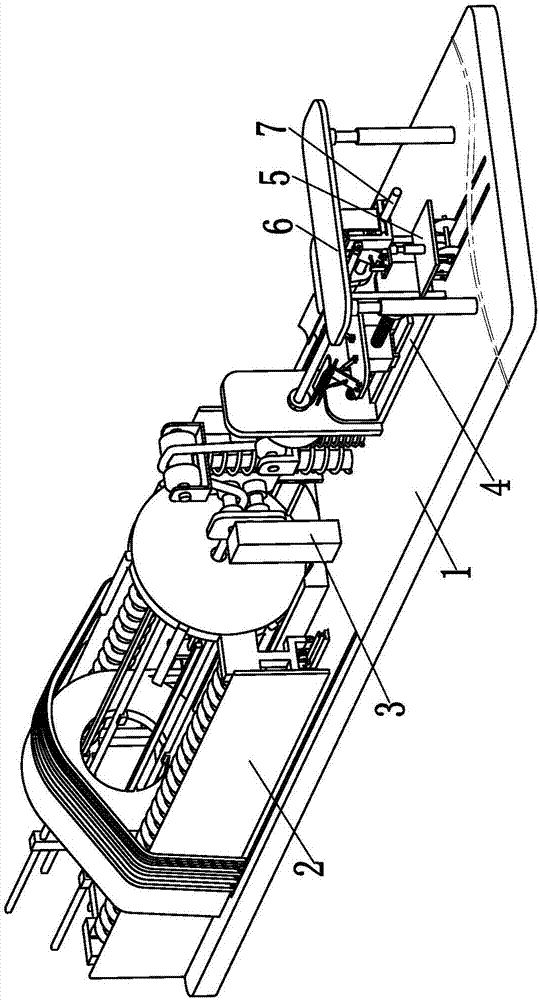

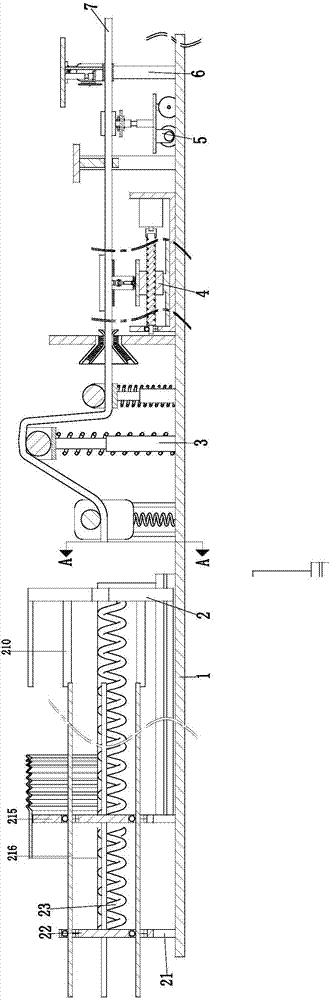

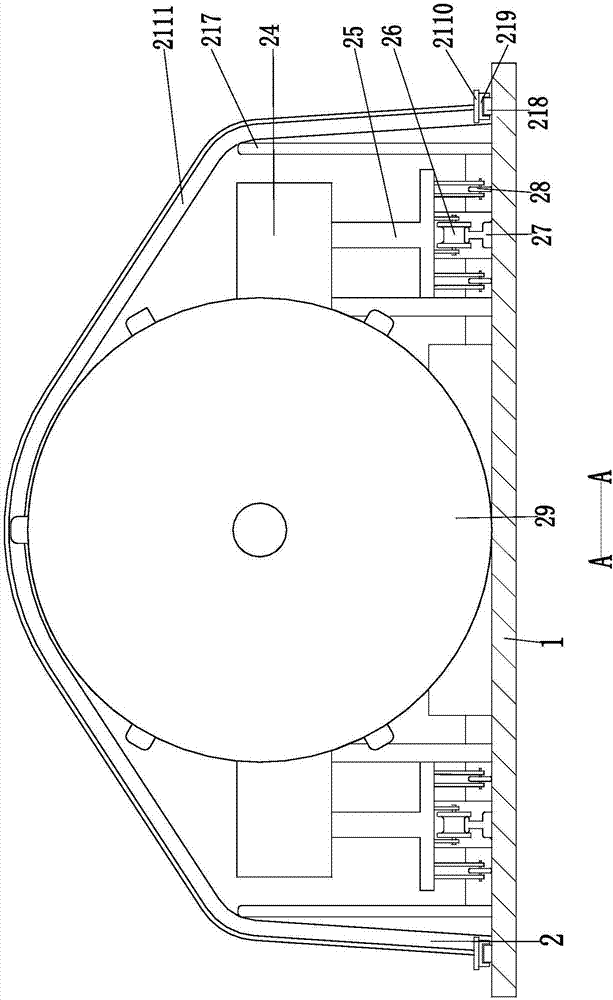

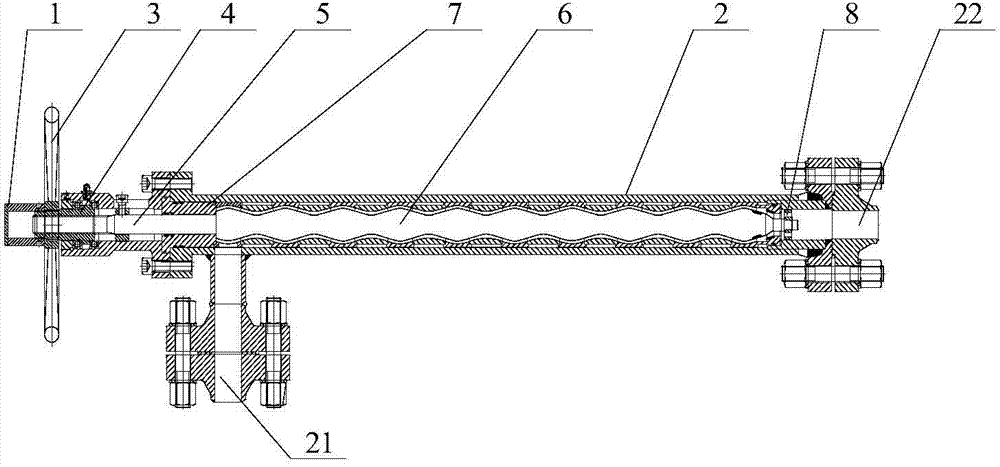

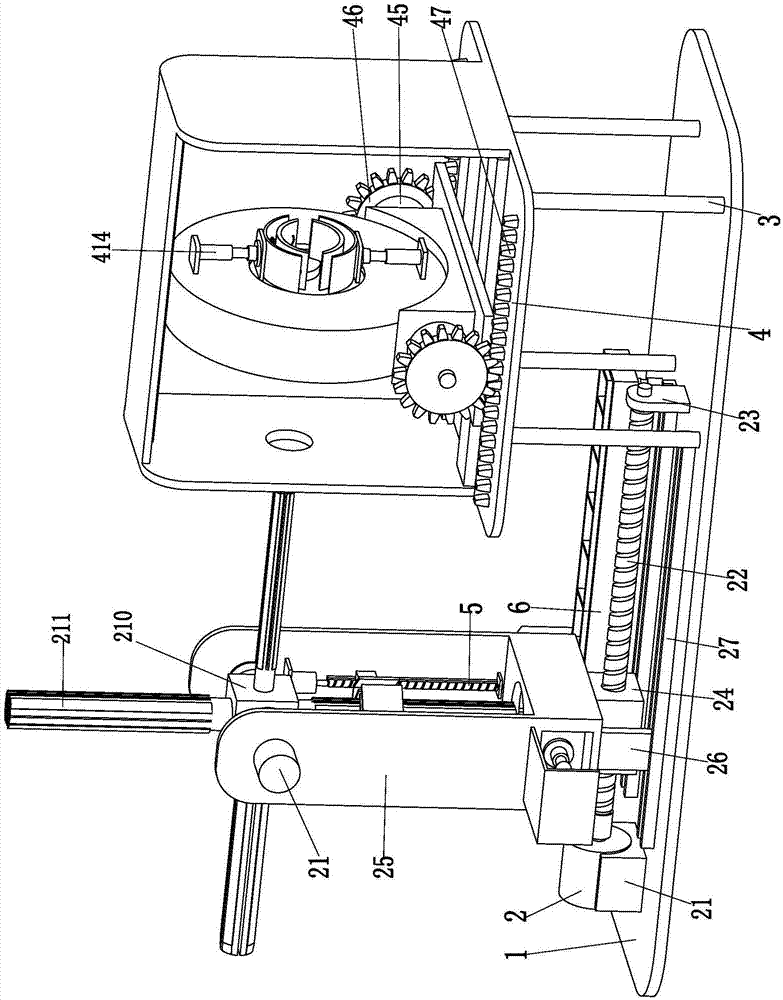

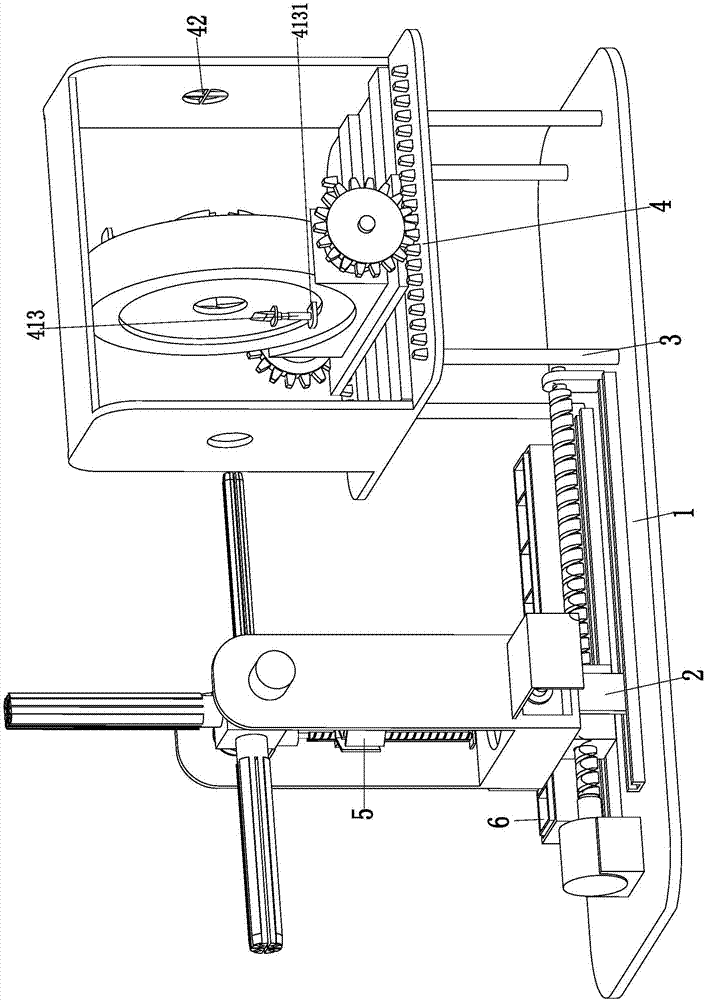

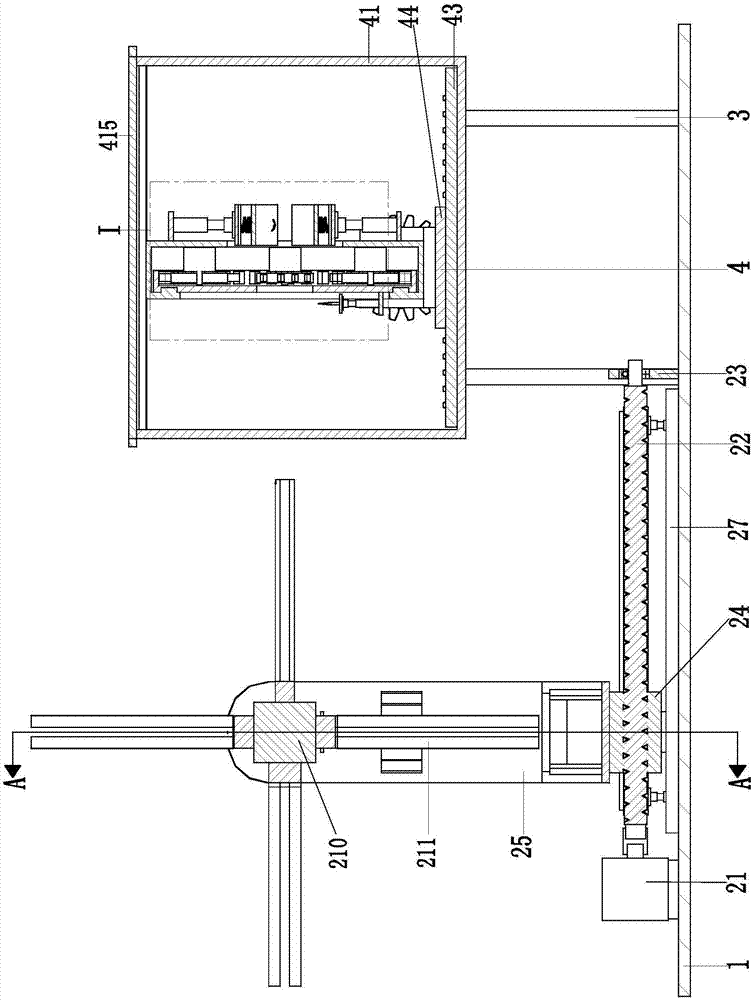

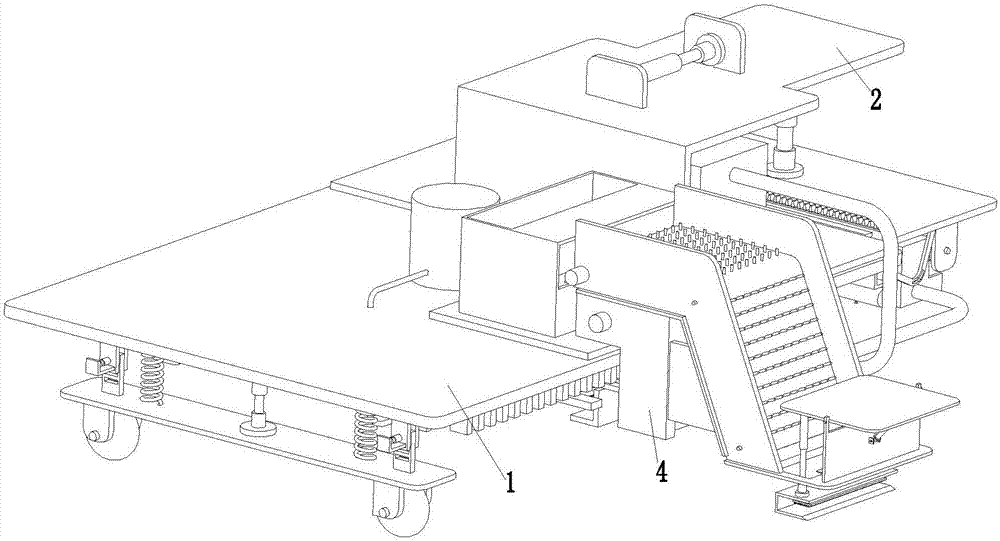

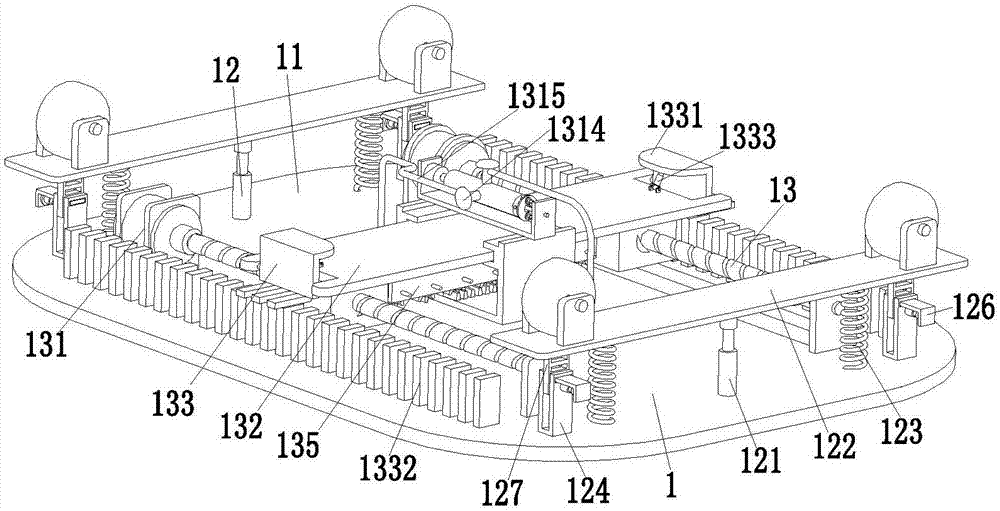

Automatic accurate cutting equipment of PVC (Poly Vinyl Chloride) wired hose

InactiveCN107053297ALabor intensiveReduce labor intensityMetal working apparatusBatch operationEngineering

The invention relates to automatic accurate cutting equipment of a PVC (Poly Vinyl Chloride) wired hose. The equipment comprises a baseplate, wherein a support device, a tension device, an auxiliary device, a driving device and a shearing device are sequentially arranged on the baseplate from back to front and are cooperated to complete the automatic accurate cutting of the PVC wired hose. By means of the equipment disclosed by the invention, the problems that in a conventional PVC wired hose shearing process, cuts are uneven during manual shearing process of the PVC wired hose, error exists during the manual measurement process of the PVC wired hose, the using effect of the PVC wired hose is influenced, the PVC wired hose is easily deformed during manual tensioning process, the manual shearing of the PVC wired hose is high in the labor intensity and low in the working efficiency and is not suitable for batch operation and the like can be solved; and the function of automatically and accurately cutting the PVC wired hose can be realized.

Owner:绍兴天波制伞有限公司

Bacterium of degrading residual of organophorus pespared agent of bacterium

InactiveCN1563356AWill not affect the use effectEasy to useBacteriaPesticide residuePseudomonas putida

A bacterial strain for eliminating organophosphorous residue is Granis staining reaction negative bacteria DLL-1 identified as pseudomonas putida. Its biological feature is G- with thallus being short bar shape, tail end being oval and single end being grown thickly with flagellum. The Genbank landing number of 16S rDNA for the bacterial strian is AF 447394.

Owner:NANJING AGRICULTURAL UNIVERSITY

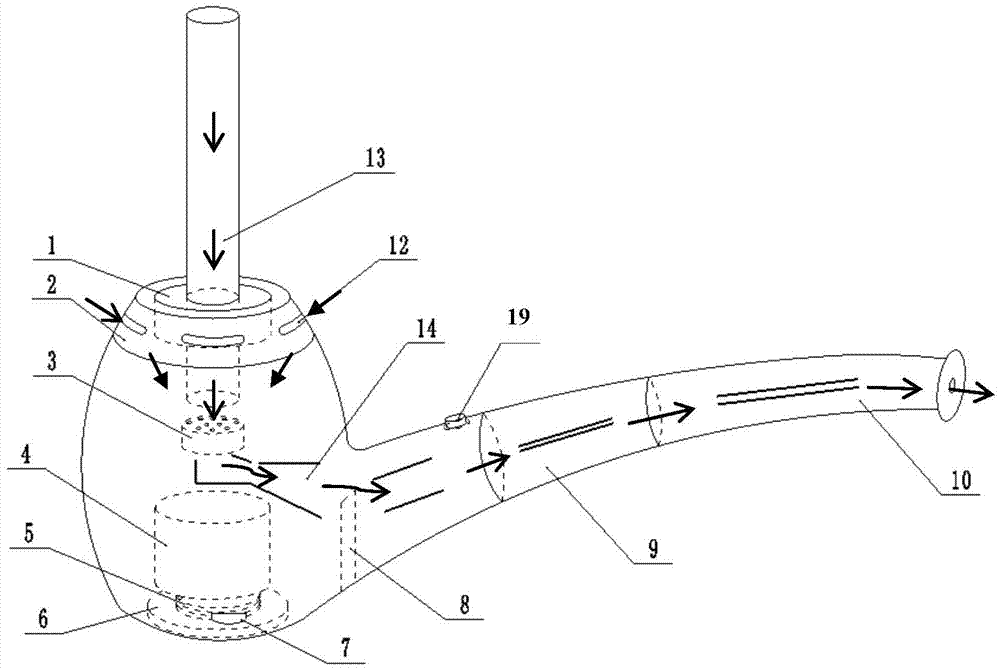

Tobacco pipe with electronic atomization function

The invention relates to a tobacco pipe with an electronic atomization function. The tobacco pipe comprises a pipe bowl (17), a pipe handle (18), a suction mouth section (10), a switch and an atomizer (9), wherein the pipe bowl (17), the pipe handle (18) and the suction mouth section (10) are connected in sequence, the pipe bowl (17) comprises a cigarette containing unit (1) which runs through the top of the pipe bowl (17), an auxiliary air inlet (12) which runs through the upper wall or the side wall of the pipe bowl (17) and a power supply (4) which is positioned in the pipe bowl (17), and the atomizer (9) and the cigarette containing unit (1) are connected in series or in parallel. The tobacco pipe with the electronic atomization function has the effects of being capable of increasing the cigarette suction sensory quality and reducing the harmfulness of smoking.

Owner:CHINA TOBACCO YUNNAN IND

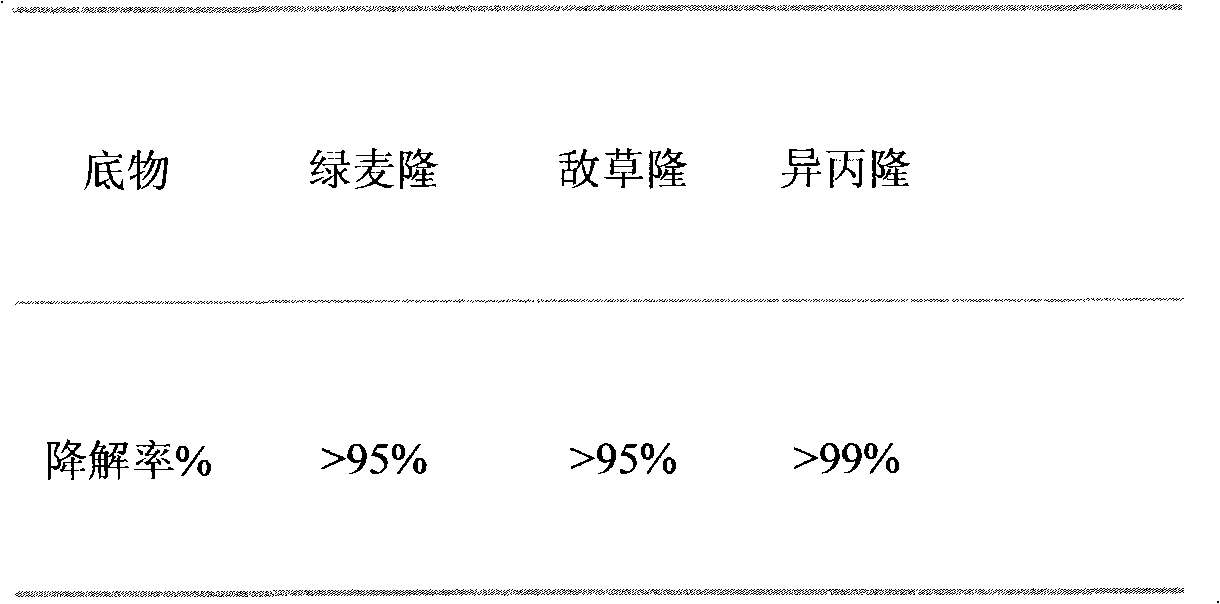

Chlorotoluron pesticide residue degradation strain agent prepared by the strain

InactiveCN101338286AWill not affect the use effectEasy to useBacteriaMicroorganism based processesStandard problemPesticide residue

The invention provides a pesticide-degrading bacterium for removing the residue of a herbicide of chlorotoluron; the bacterium that is used is gram staining reaction negative bacilli YBL3 which is identified to be Sphingobium sp. The bacterium is preserved in China Center for Type Culture Collection in May 23rd, 2008 and the preservation number of the bacterium is CCTCC M208076. The technique for producing the bacterium includes: slant seed-shake flask seed-seed pot-production pot-product (the packaging formulation is liquid bacterium or solid absorption bacterium). The product of the degrading bacterium can be directly applied to reduce the pesticide residue in the crops by more than 90 percent, thus solving the over standard problem of the pesticide residue in agricultural production and being capable of producing green agricultural products with no poison and social effects of pollution.

Owner:NANJING AGRICULTURAL UNIVERSITY

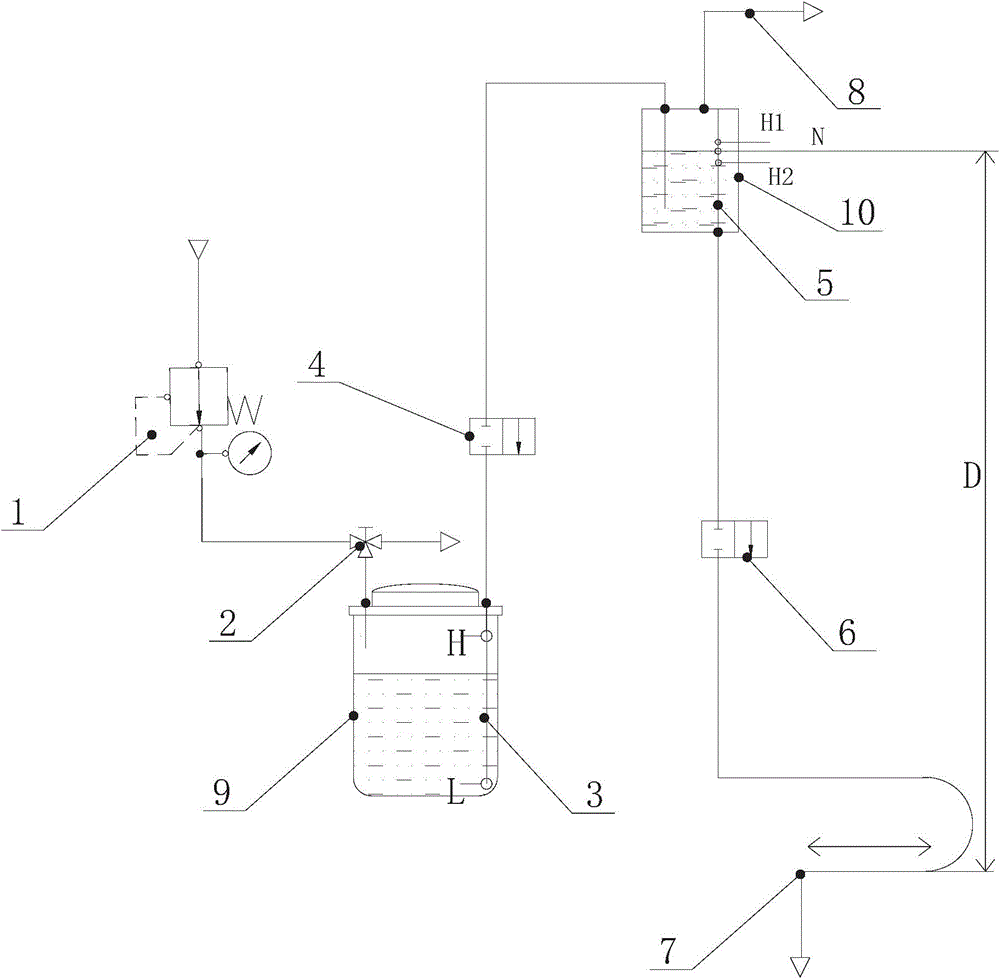

Liquid quantitative supply device

ActiveCN104555870ASimple structureReduce manufacturing costLiquid transferring devicesControl systemEngineering

The invention belongs to the technical field of wafer gluing-development crafts, particularly provides a liquid quantitative supply device. The liquid quantitative supply device comprises a liquid supplement bucket, a liquid supply tank, a nozzle connecting pipe, a gas source and a control system, wherein the liquid supplement bucket is connected with the gas source and the liquid supply tank through a gas pipeline and a liquid supplement pipeline respectively; a liquid supplement medical liquid valve is arranged on the liquid supplement pipeline; the nozzle connecting pipe is positioned below the liquid supply tank, and communicated with the liquid supply tank through a liquid supply pipeline; a liquid supply medical liquid valve is arranged on the liquid supply pipeline; both the liquid supplement medical liquid valve and the liquid supply medical liquid valve are connected with the control system; the control system enables the distance between the work position of the liquid level in the liquid supply tank and the nozzle connecting pipe to be constant through the liquid supplement medical liquid valve and the liquid supply medical liquid valve, so that a liquid can be quantitatively supplied under constant pressure. The liquid quantitative supply device has the advantages that pressure generated from the self weight of the liquid is used for the liquid supply; as both the liquid supplement medical liquid valve and the liquid supply medical liquid valve are connected with the control system, automatic liquid supplement and quantitative supply can be realized; bubbles can be removed from the liquid during the liquid supply process.

Owner:SHENYANG KINGSEMI CO LTD

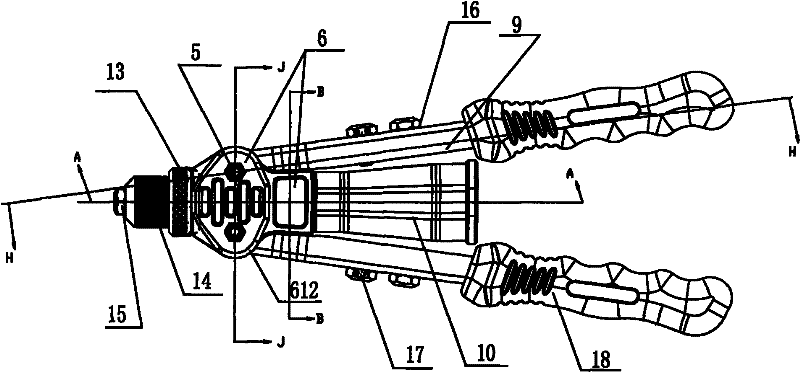

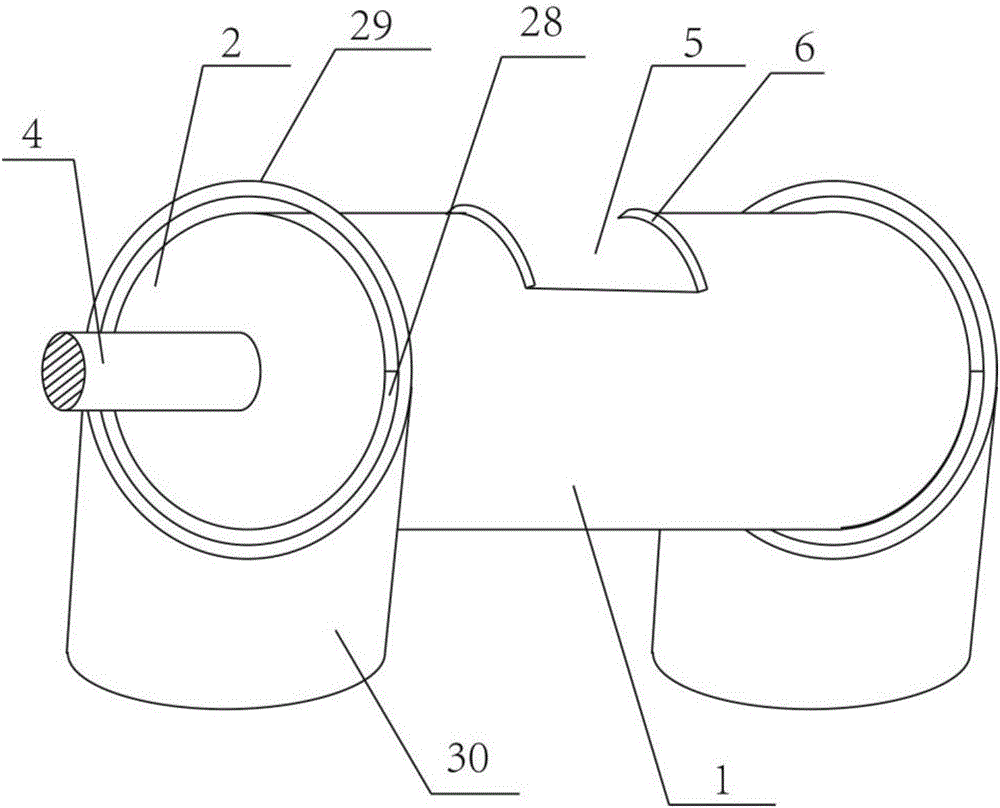

Small and skillful dual-handle hand riveter

The invention discloses to a small and skillful dual-handle hand riveter, which comprises a riveter seat, a rivet adjusting mechanism, a rivet gripping mechanism, two handles and a pull rod, wherein the rivet adjusting mechanism is arranged at the front end of the riveter seat, the rivet gripping mechanism is installed in the rivet adjusting mechanism, one end of one handle and one end of the other handle are respectively hinged with the two sides of the riveter seat, and the pull rod is movably inserted in the center hole of the riveter seat. The invention is characterized in that all or large part of the pull rod is provided with a rear part, and the pull rod, the fixing piece of a pull rod telescopic mechanism arranged at the end of the pull rod and connecting rods arranged on the two sides of the fixing piece and respectively hinged with the heads of the handles are arranged in the cavity of the riveter seat; and handle matching grooves are arranged on the two sides of the riveter seat. The invention has the advantages that since the length of the handles is shortened, all or large part of the pull rod is provided with the rear part, and the pull rod, the fixing piece of the pull rod telescopic mechanism arranged at the end of the pull rod and connecting rods arranged on the two sides of the fixing piece and respectively hinged with the heads of the handles are arranged in the cavity of the riveter seat, the gripping force and the stability of the hand riveter are greatly improved, the appearance is tidier and cleaner, the use is handy and ingenious, and the carrying, the packaging and the transportation are convenient.

Owner:余姚市嘉合工具厂 +1

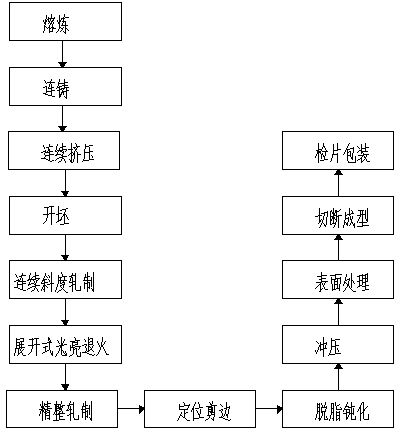

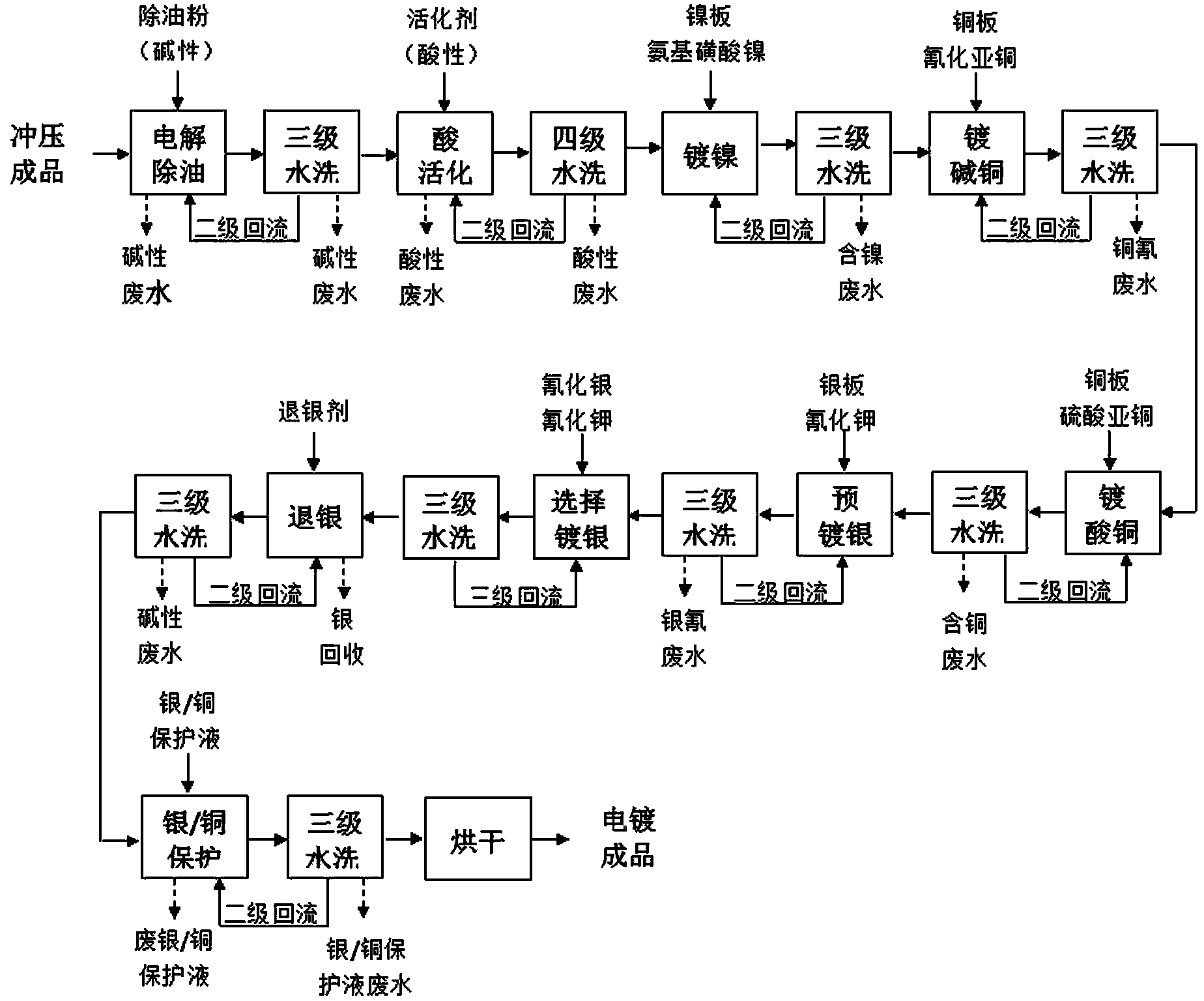

Semi-conductor lead framework production process

ActiveCN103928351AExact widthAdequate heat dissipationSemiconductor/solid-state device manufacturingMechanical engineeringSemiconductor

The invention relates to a semi-conductor lead framework production process which includes the steps of smelting, continuous casting, continuous extrusion, cogging, severe convection annealing, continuous inclination rolling, spreading-type bright annealing, finishing rolling, positioning-type edge shearing, degreasing passivation, stamping, surface processing, cutting forming and detection piece packaging. The production process is characterized in that the two work procedures of finishing rolling and positioning-type edge shearing are provided with continuous grooving procedures, when continuous grooving is carried out, precise grooving processing is carried out through a grooving machine, the rotation speed of the grooving machine is 1800-2000 r / min, the flow of cooling liquid is 45-50 L / min, and dovetail groove forming achieving through the process cannot cause strip width changes after forming, and the size of a formed semi-conductor lead framework is accurate.

Owner:SICHUAN JINGJIAN ELECTRONICS MATERIAL

Bacterium for degrading chlorpyrifos pesticide residue and produced bacterium formulation

The invention provides a prodegradant which can dispel the organic phosphorus pesticide residue of chlorpyrifos. The used strain is Gram's stain reaction hysteroptosis Dsp-2 which is Sphingomonas sp. The main biology characteristic is G-; the thaliana is the rod type of asporous whose size is 1.0-1.5um; the scavenger enzyme is male and the oxidative enzyme is female which can not be hydrolysed starched and be gelatin liquidated; the methyl red reaction is female and not to produce the indole with the aquolysis temperature 80 deg. The Genbank landing number of the strain 16S rDNA is AY994060.

Owner:NANJING AGRICULTURAL UNIVERSITY

Bacterium for degrading phoxim pesticide residue and produced bacterium formulation

The invention provides a degradation bacillus which can dispel the phoxime pesticide residue and its prodegradant. The used strain is Gram's staining reaction hysteroptosis X-12 which is Ochrobactrum.sp. The main biology characteristic is G-; the thaliana is the rod type whose size is (1.58-2.61)mu m*(0.79-1.23)mu m; it has flagellation around it and facultative anaerobes; the hydrogen peroxidase, oxidative enzyme, oxidation of ethanol and V.P. reaction is positive; the ketole reaction is negative; it can not be hydrolysed starched and oxide glucose to generate the acid so that the coagulate dydimic acid cow's milk; the Genbank landing number of the strain 16S rDNA is DQ093374.

Owner:NANJING AGRICULTURAL UNIVERSITY

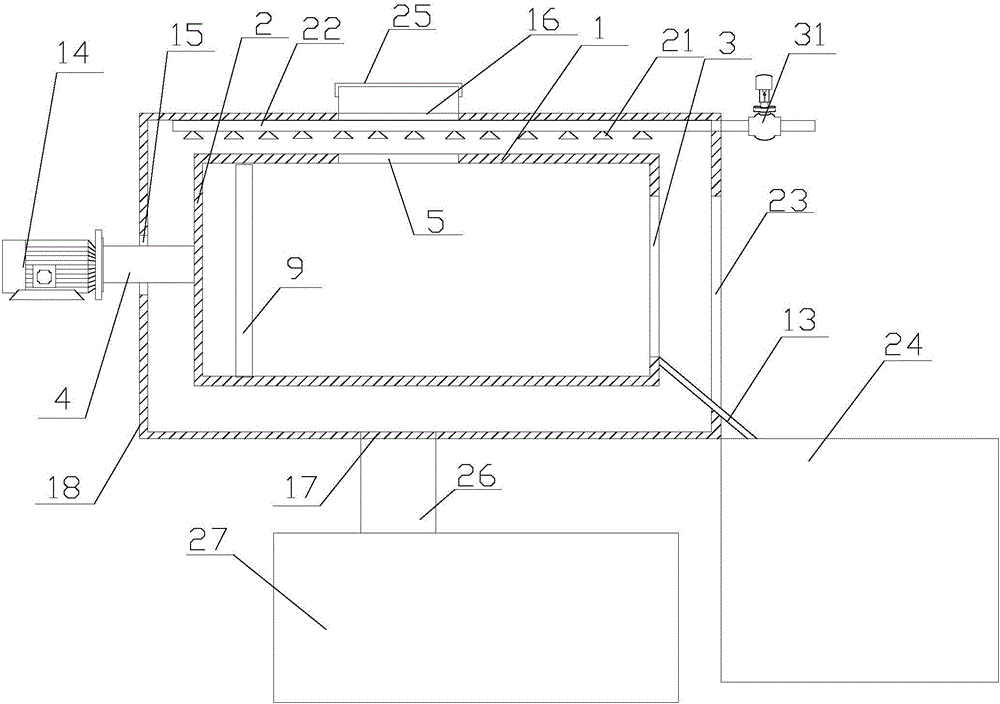

Solid kitchen waste treatment device

ActiveCN106140794AWon't happenWill not affect the use effectSolid waste disposalTransportation and packagingPulp and paper industryWaste treatment

The invention discloses a solid kitchen waste treatment device. The treatment device is a pulping barrel; the pulping barrel includes an outer sleeve and a turnover cylinder; the outer sleeve and the turnover cylinder are both horizontal cylinders; the cylinders are cavity structures; the turnover cylinder is positioned in the outer sleeve, and includes a shell, a left baffle plate, a right door and a rotating shaft; the shell is manufactured by a screen; the outer sleeve includes a cylinder body, a feed port and a liquid outlet; and the cylinder body includes a left side plate, a surrounding plate and a right side plate. After simple solid-liquid separation treatment of kitchen wastes, obtained solid mixtures can be deeply treated by the device, so that plastic bags, plastic bottles and food residues are separated more thoroughly, and a lot of plastic chips cannot be generated.

Owner:深圳市绿境生物质能源科技有限公司

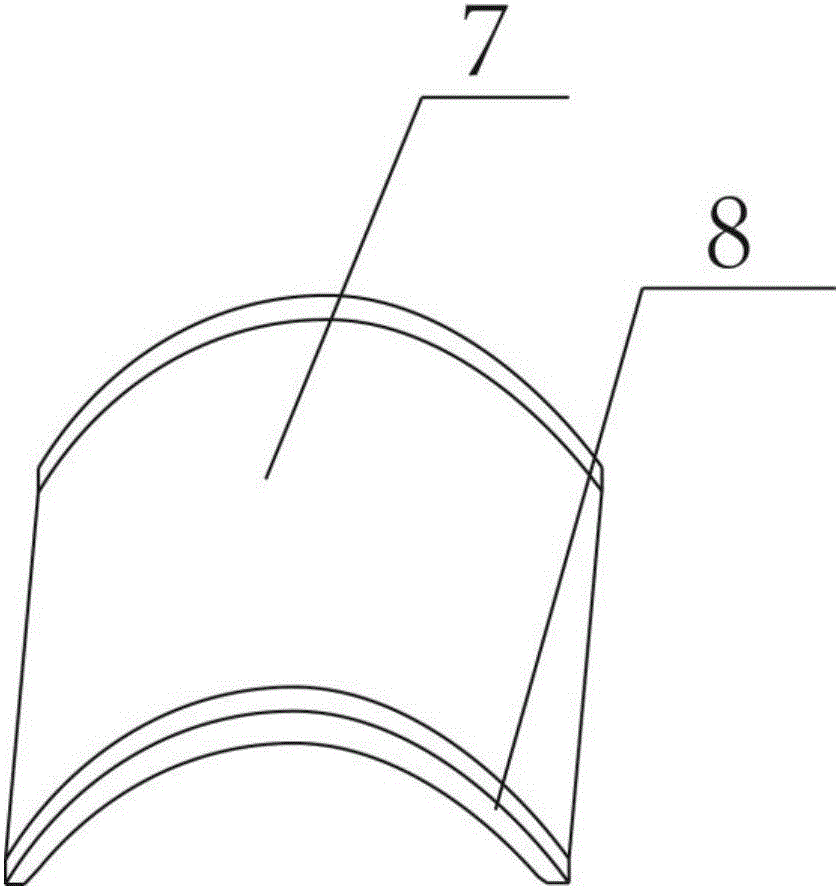

Self-tightening type seed crystal chuck

InactiveCN102312288ASimple structureEasy to operatePolycrystalline material growthBy pulling from meltEngineeringSingle crystal growth

The invention relates to auxiliary equipment of Czochralski silicon single crystal growth equipment and aims at providing a self-tightening type seed crystal chuck. The self-tightening type seed crystal chuck comprises a sleeve and clamping pieces annularly arranged in the inner wall of the sleeve; the inner wall of the sleeve has a conicity contracted downwards towards an axle center, and the clamping pieces have an external shape cooperating with the conicity; the internal diameter of an opening at the upper end in the clamping pieces is greater than the internal diameter of an opening at the lower end in the clamping pieces, and the inner walls of the clamping pieces located between the upper opening and the lower opening transit in a conical face form. When the chuck provided in the invention is used, all the parts of the chuck are automatically strained by the gravity of seed crystals, and the weight of the seed crystals continuously increases in the process of crystal pulling, which enables a frictional force to increase continuously, thereby increasingly lowering down the possibility of skidding. Since the seed crystal chuck comprises a few parts and the construction of the chuck is utmostly simplified, the chuck is very convenient to operate during utilization.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

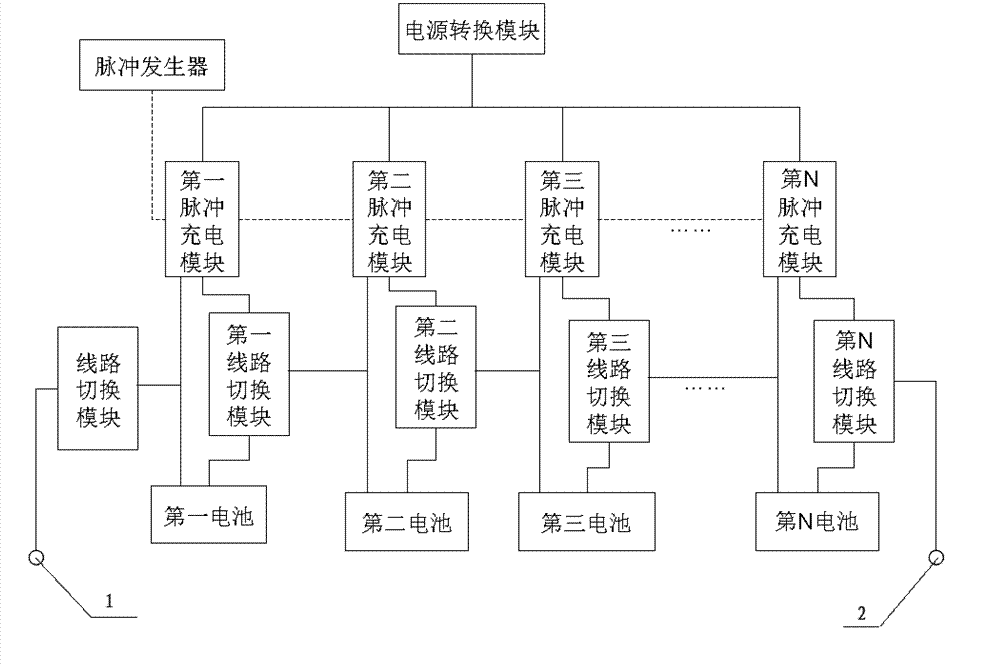

Battery pack charging method and its realizing apparatus

ActiveCN102769153AExtended service lifeWill not affect the use effectBatteries circuit arrangementsSecondary cells charging/dischargingElectrical batteryEngineering

A battery pack charging method and its realizing apparatus belongs to the technical field of charging. Charging of batteries in series makes the batteries easily damaged. The invention is characterized in that individual batteries in parallel are separately charged and a circuit is switched after charging through a circuit switching module such that the batteries form a battery pack. A charging device comprises a pulse generator and at least two charging circuits which are arranged fore and aft. Each charging circuit comprises a pulse current charge module and a circuit switching module. The pulse current charge module is respectively connected with a power supply switching module and the circuit switching module through connecting lines. The pulse current charge module is provided with a directly connected connecting line which is connected with battery electrodes. The circuit switching module is provided with two switch connecting lines, which are respectively used to connect with the battery electrodes and the directly connected connecting line of the pulse current charge module of the rear charging circuit. The pulse generator is connected with the pulse current charge module of each circuit through the connecting line. Therefore, charging when battery capacity is saturated and the phenomenon that the battery capacity can not be charged to a saturated state are avoided, thus protecting the batteries.

Owner:陈钢

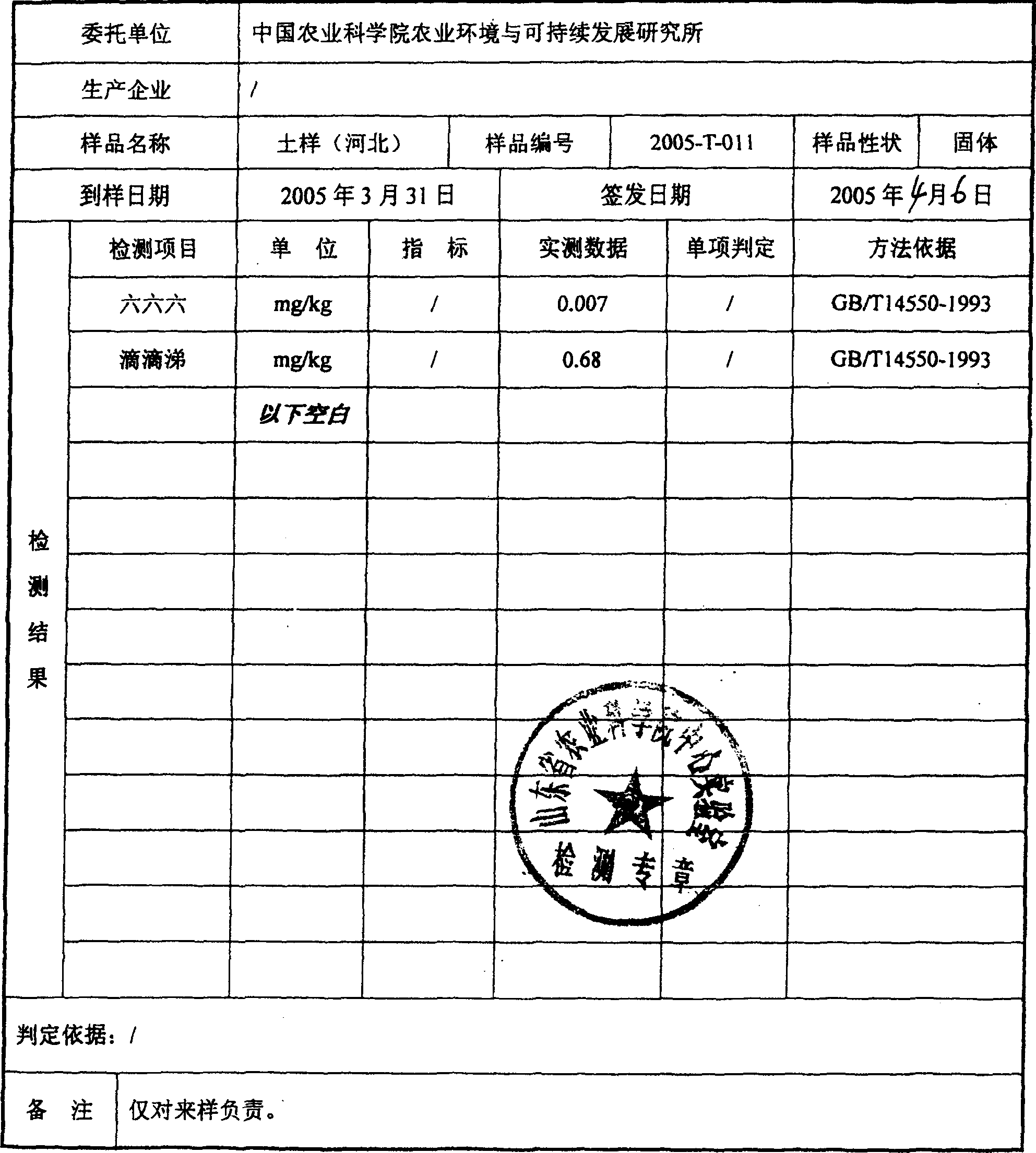

Degradating bacteria for hexachlorocyclohexane pesticide residue and its produced strain

InactiveCN1648238AEfficient degradationEfficient degradation efficiencyBacteriaMicroorganismSphingomonas sp.

The present invention provides a kind of bacteria preparation for efficiently degrading hexachlorocyclohexane (HCH) pesticide residue. The strain BHC-A is Sphingomonas sp., can growth with HCH as the unique carbon source and energy source, and degrade alpha-HCH, beta-HCH, gamma-HCH and delta-HCH in short time at high efficiency. The present invention solves the difficult problem of aerobically biodegrading beta-HCH, and can mineralize 5 mg / L beta-HCH completely within 12 hr. Applying the degrading bacteria product directly can lower the residual HCH amount in soil by over 95 % to lower the HCH residue in agricultural product.

Owner:NANJING AGRICULTURAL UNIVERSITY

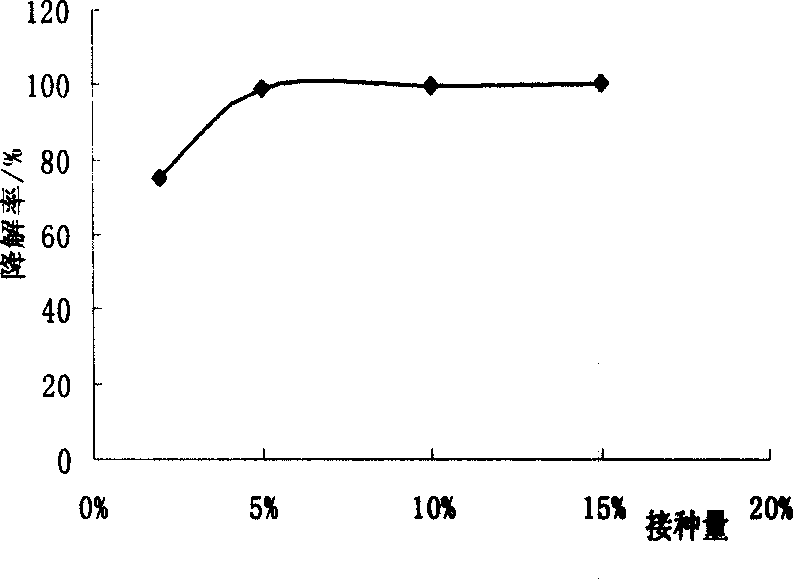

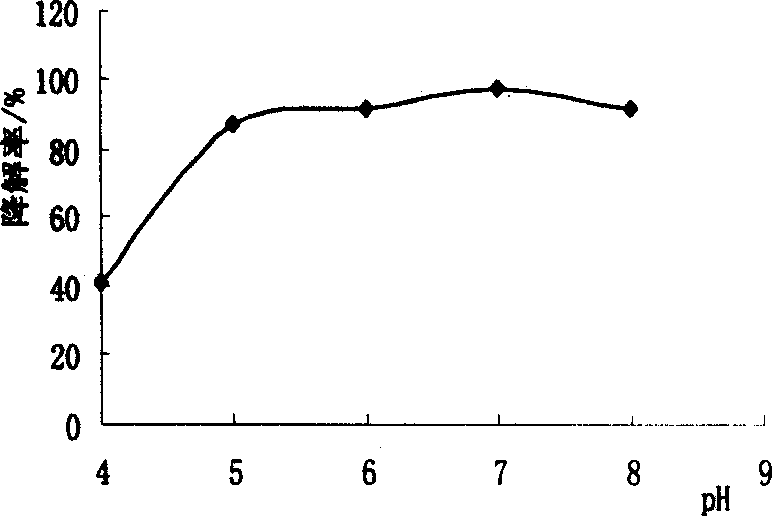

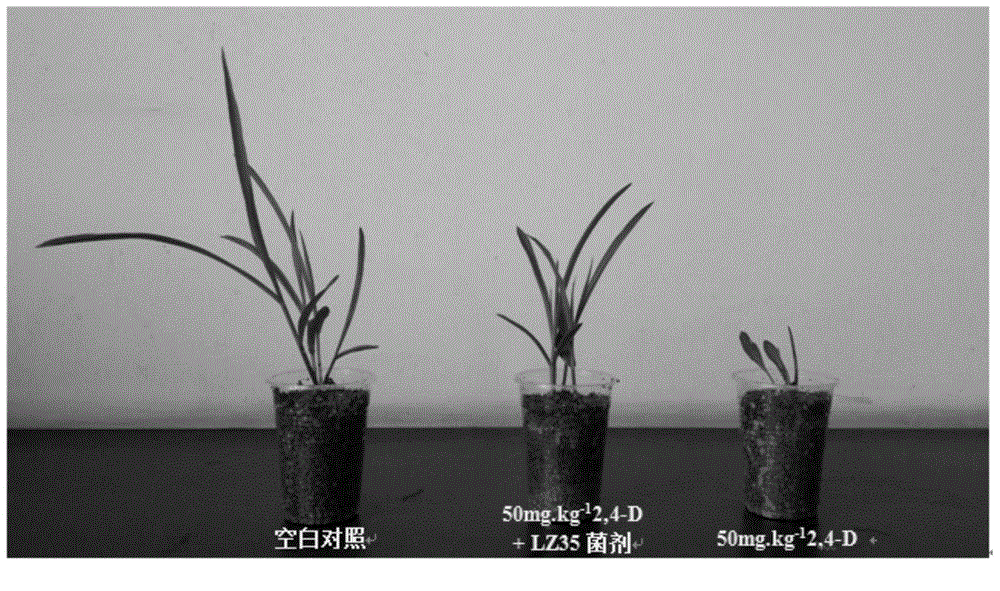

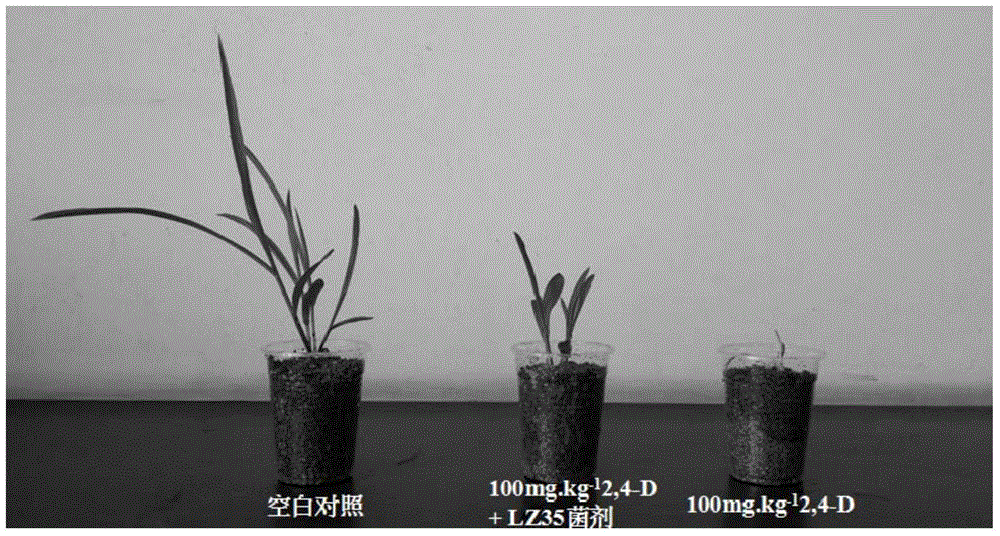

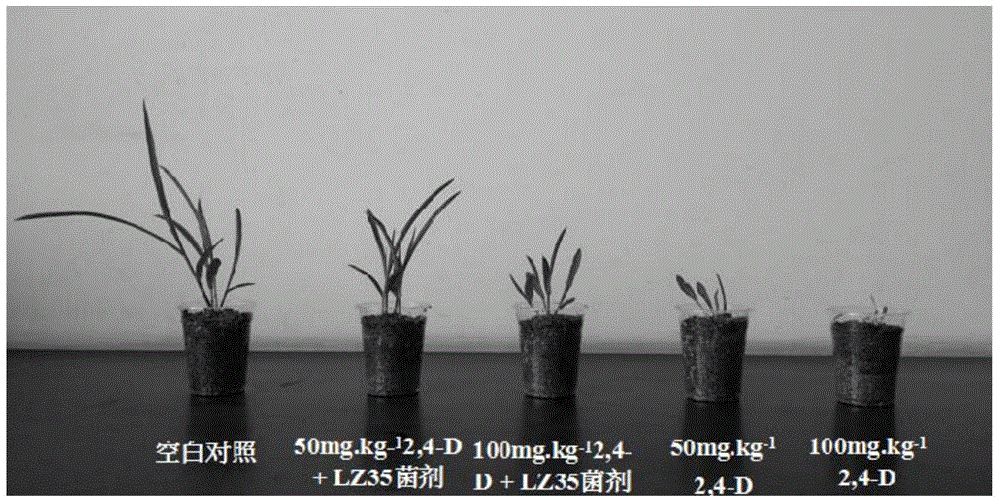

Degradation strain of herbicide 2, 4-D, produced inoculum and application thereof

ActiveCN104962491AReduce production and use costsEasy to useBacteriaContaminated soil reclamationGramCrop

The invention discloses a degradation strain of herbicide 2, 4-D (2, 4-dichlorophenoxy acetic acid), a produced inoculum and application thereof. The strain is preserved in China Center For Type Culture Collection on April 15, 2015, and the strain preservation number is CCTCC NO:M2015235. The strain is gram staining reaction negative strain LZ35, which is identified as Achromobacter sp. The 2, 4-D degradation strain LZ35 can be applied to degradation of the herbicide 2, 4-D. A degradation inoculum produced from the 2, 4-D degradation strain LZ35 can degrade 99% of 100mg / L 2, 4-D in a liquid culture medium within 2 days, and direct application of the inoculum can significantly reduce crop phytotoxicity, solve the exceeding herbicide residue problem in agricultural production and produce non-toxic and nuisanceless green agricultural products.

Owner:NANJING AGRICULTURAL UNIVERSITY

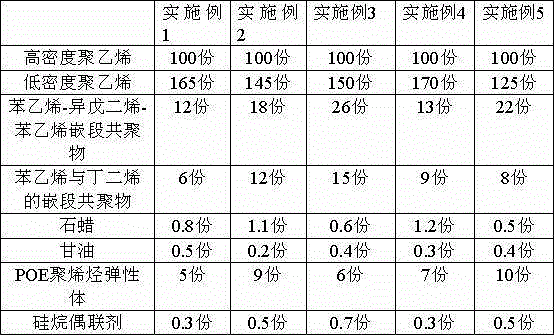

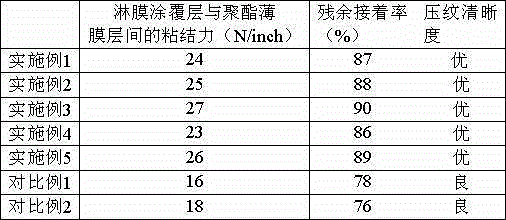

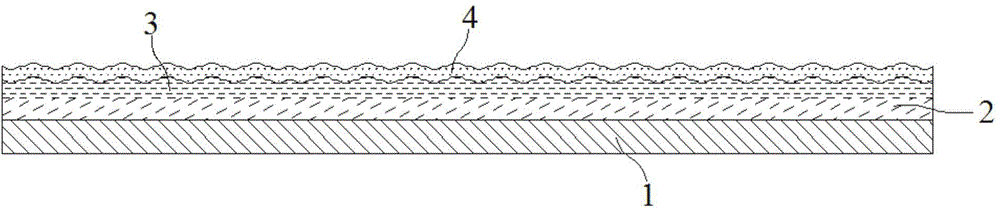

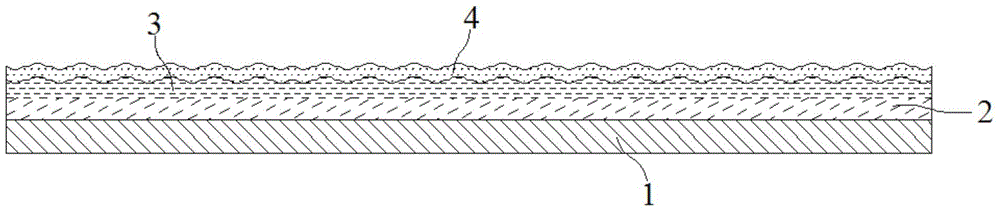

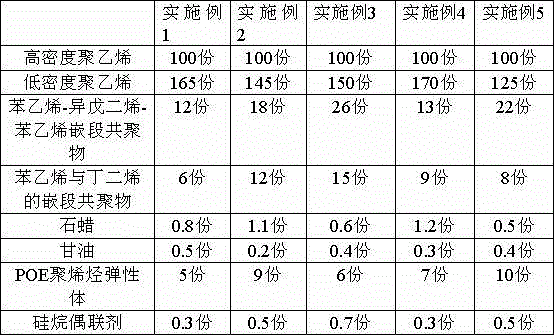

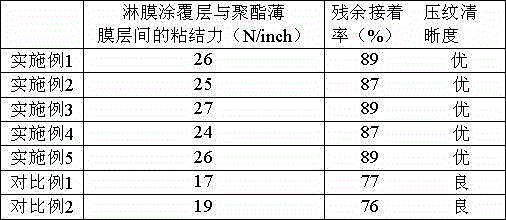

Embossing release film

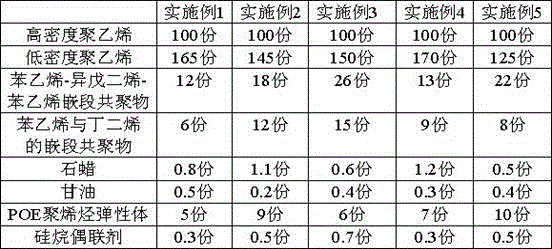

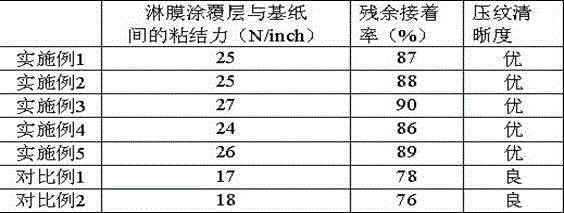

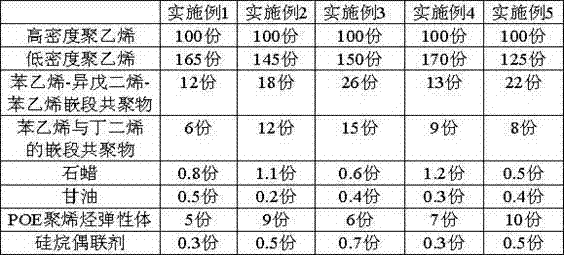

ActiveCN104999751ANot easy to fall offImprove anti-static effectNon-fibrous pulp additionSynthetic resin layered productsLow-density polyethyleneElastomer

The invention discloses an embossing release film. The embossing release film comprises a polyester film layer and a spraying film coating layer with which the surface of the polyester film layer is coated. The surface, back on to the polyester film layer, of the spraying film coating layer is provided with an embossing pattern area, and the surface of the embossing pattern area is coated with an organosilicone release agent layer. The spraying film coating layer comprises, by weight, 100 parts of high-density polyethylene, 120-180 parts of low-density polyethylene, 10-30 parts of styrene-isoprene-styrene triblock copolymers, 5-15 parts of segmented copolymers of styrene and butadiene, 0.5-0.15 part of paraffin, 0.1-0.5 part of glycerinum, 5-10 parts of POE and 0.3-0.8 part of coupling agent, wherein the POE is a high polymer of ethylene and butane or a high polymer of ethylene and octylene. Netted grain formed through the embossing release film is clear and uniform in depth, and distribution lines are uniform. When formed embossing spraying film release paper is pasted on a pressure-sensitive adhesive, no bubble will be generated between the embossing spraying film release paper and the pressure-sensitive adhesive, and therefore the use effect will not be affected.

Owner:太仓斯迪克新材料科技有限公司

Bacterium for degrading monocron pesticide residue and produced bacterium formulation

The invention provides a degradation bacillus which can dispel the long-lasting phosphorus pesticide residue and its producing bacillus. The strain is Gram's stain reaction hysteroptosis m-1 in the field of Paracoccus.sp.; the main biology characteristic is G-; the thaliana is the short rod type which likes oxygen and dislikes sport; the scavenger enzyme and the oxidative enzyme is positive; it can not use citrate and nitrate to reduction the positive; the denitrifying reaction generates the gas.

Owner:NANJING AGRICULTURAL UNIVERSITY

Low shearing adjusting valve

ActiveCN103498645AWill not affect the use effectReduce shear forceWell/borehole valve arrangementsSealing/packingBack cuttingHead to head

The invention discloses a low shearing adjusting valve which comprises a valve body and an adjusting device. The valve body comprises an adjusting part and a valve cylinder which are arranged front and back in sequence. A lead screw nut is arranged in the adjusting part. The lead screw nut is clamped in a clamping groove in the inner wall of the adjusting part, and the lead screw nut is matched with the clamping groove. The lead screw nut can rotate around the center axis of the lead screw nut in the clamping groove. The adjusting device comprises an adjusting handle and an adjusting rod. The adjusting handle and the lead screw nut are fixed. The adjusting rod comprises a mounting part and a rod body which are arranged front and back in sequence. The mounting part and the lead screw nut are mounted in a threaded mode. The rod body is arranged in the valve cylinder and comprises a plurality of back-cutting cones which are connected front and back in sequence in a head-to-head-tail-to-tail mode. According to the low shearing adjusting valve, the adjusting handle and the adjusting rod are arranged, the adjusting rod can be driven to move front and back by rotating the adjusting handle lead screw nut, and accordingly the function that flow is adjusted by changing the cross section area of a flow channel is achieved, the area of the flow channel is changed gradually during an adjusting process, generated shearing force is small, and the using effect of solution injection cannot be affected.

Owner:ZHEJIANG JINLONG AUTOMATIC CONTROL EQUIP

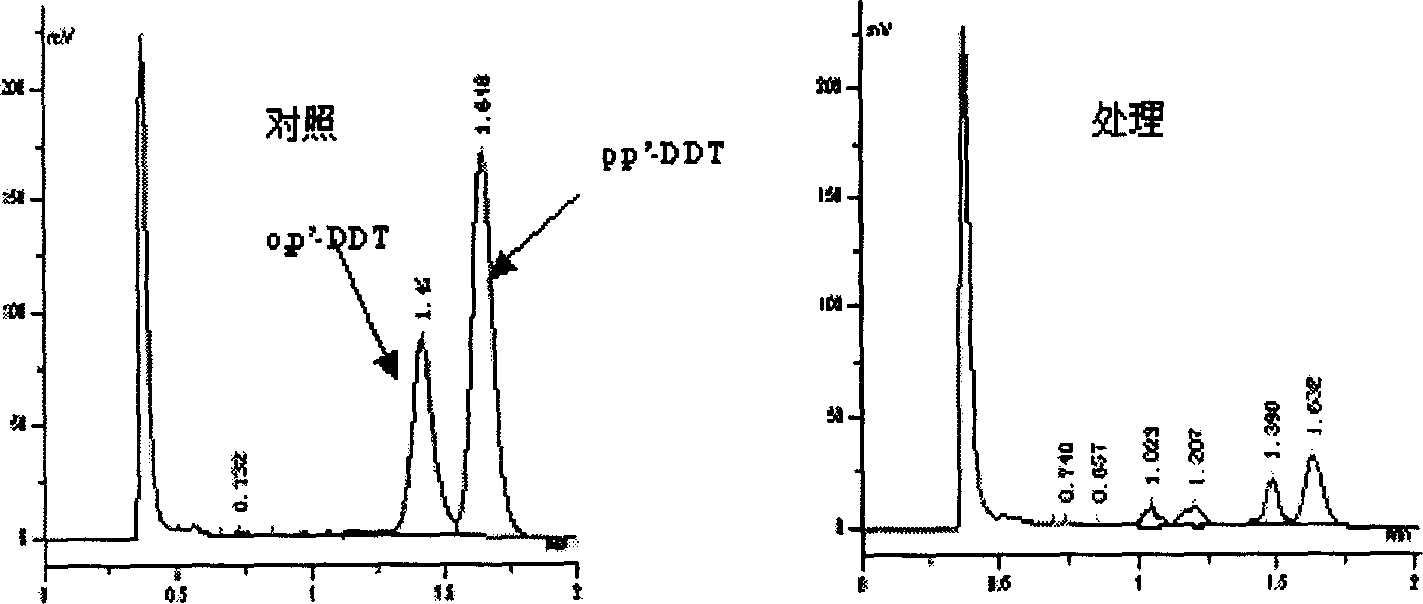

DDT pesticide residue degradation bacterium and produced bacterium agent

InactiveCN1793334AEasy to useReduce production and use costsBacteriaSphingomonas sp.Pesticide residue

The invention provides DDT pesticide residue degrading bacterial and its produced bacterial agent. The used strain is gram stain reaction positive bacterial strain DB-1. And it is sphingomonas sp by identifying. Its main bionomics is G-; thallus is short baculiform and its size is 0.28 um-0.54um*0.69um-0.85umum its end has flagellum; concurrently character like oxygen; catalase and oxidase are positive; V.P. and indole reactions are negative; it can not hydrolyze starch, oxidize glucose to produce acid, and make litmus milk acid solidify. The strain 16S rDNA Genbank debarkation number is AY947554. The degrading bacterial product can reduce pesticide residue by over 90%, and produce green farm products.

Owner:NANJING AGRICULTURAL UNIVERSITY

Automatic processing equipment for tubular polyethylene plastic films

InactiveCN107160469ASimple incisionSmooth cutMetal working apparatusAutomatic test equipmentEngineering

The invention relates to automatic processing equipment for tubular polyethylene plastic films. The automatic processing equipment for the tubular polyethylene plastic films comprises a bottom plate. A conversion support device is installed on the bottom plate and provided with clamping devices. A collecting device is arranged on the bottom plate. Supporting columns are installed at the front end of the bottom plate. A cutting device is installed at the upper ends of the supporting columns. The conversion support device, the clamping devices, the cutting device and the collecting device are used in cooperation to complete an automatic processing process of polyethylene film rolls. By means of the automatic processing equipment, the problems that existing tubular polyethylene films are prone to deformation in the cutting process as being wound around paper shells, the paper shells around which the polyethylene films are wound differ in internal diameter, the cutting precision of the tubular polyethylene films is poor, incisions are uneven, the processed tubular polyethylene films need to be conveyed and stacked manually, the labor intensity is high, operation is complex and the working efficiency is low can be solved, and the function of automatic processing of the tubular polyethylene plastic films can be achieved.

Owner:佛山市晟美包装制品有限公司

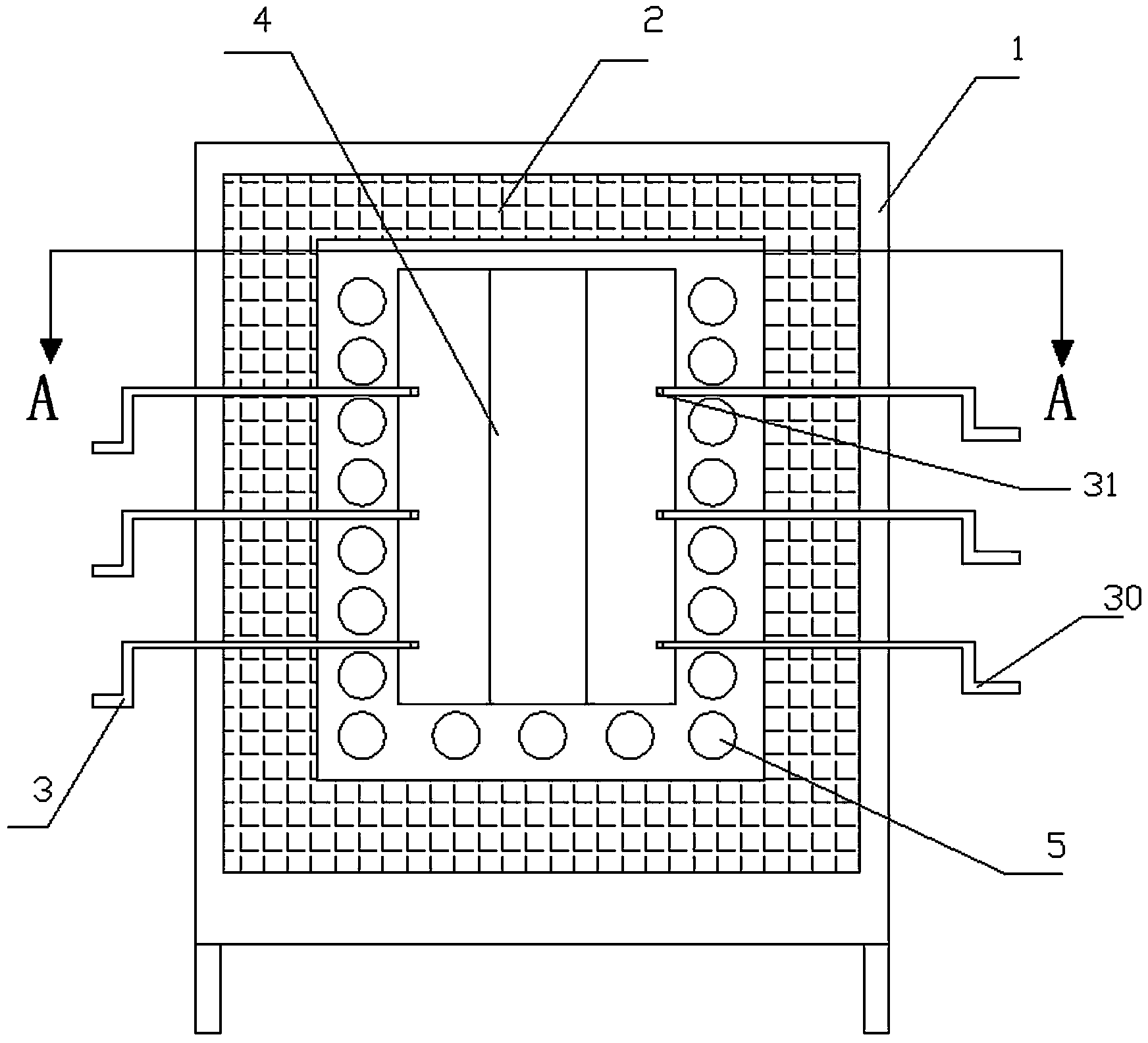

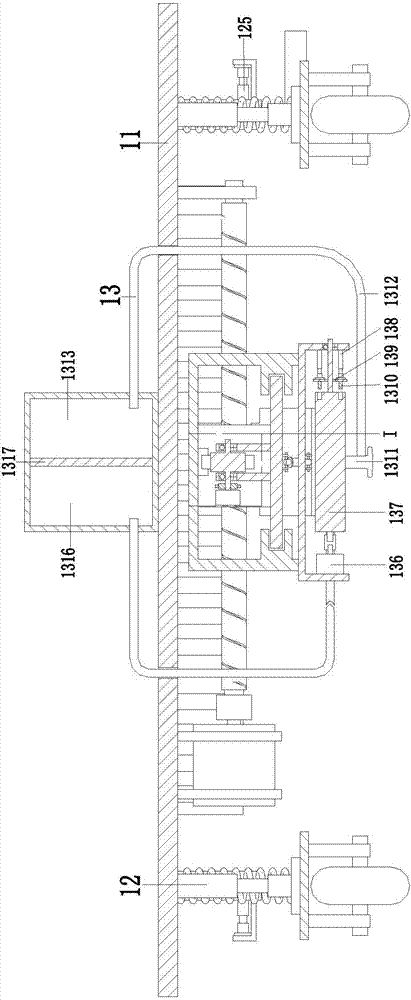

Gypsum concrete dusting pavement intelligent restoring construction integrated machine

InactiveCN108004901AWill not affect the use effectReduce contact areaRoad cleaningRoads maintainencePhysical healthArchitectural engineering

The invention relates to a gypsum concrete dusting pavement intelligent restoring construction integrated machine. The gypsum concrete dusting pavement intelligent restoring construction integrated machine comprises a moving device; a cleaning device is mounted at the front end of the moving device; a spreading and rolling device is mounted at the right end of the moving device; the moving devicecomprises a mobile bottom plate; two moving auxiliary mechanisms are mounted at the lower end of the mobile bottom plate; the two moving auxiliary mechanisms are symmetrically positioned on the frontand rear sides of the mobile bottom plate; and a scribing mechanism is mounted at the lower end of the mobile bottom plate. According to the gypsum concrete dusting pavement intelligent restoring construction integrated machine, problems that man power is needed to move the machine on the pavement by means of the existing moving equipment, the dusting concrete pavement needs to be manually cleanedand wetted, the dust is more by manually cleaning the dusting concrete pavement, the environment is polluted, the physical health is affected and protective cloth needs to be manually laid during repairing the concrete pavement can be solved; and a function of intelligent and mechanical restoring construction of the concrete dusting pavement can be realized.

Owner:倪敏芳

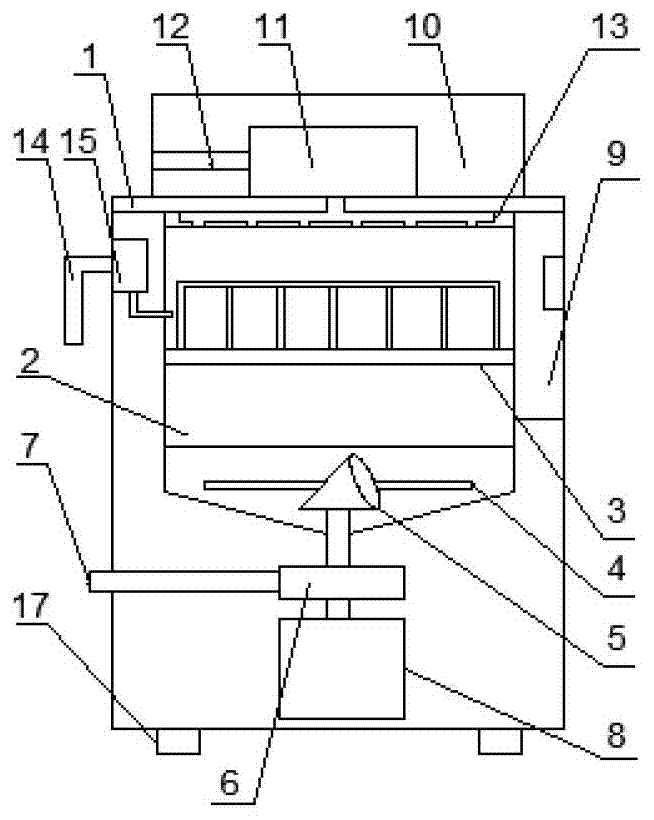

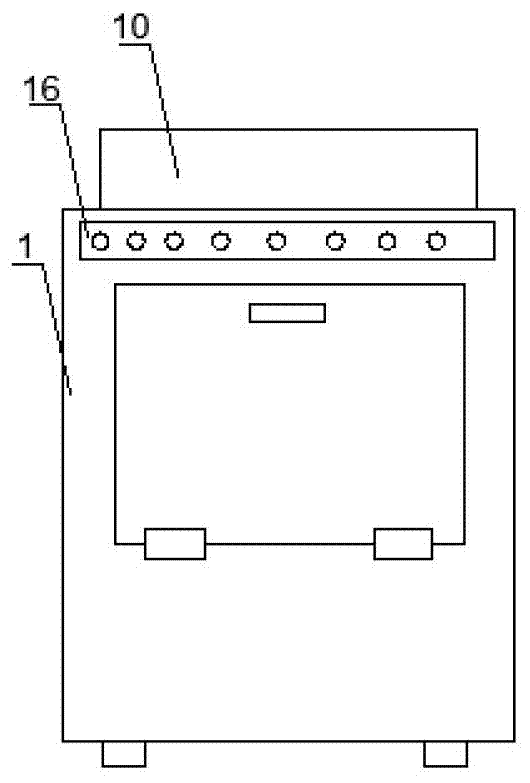

Novel dishwasher

PendingCN107374539ASolve the problem that it cannot be driedWill not affect the use effectTableware washing/rinsing machine detailsElectric machineryEngineering

The invention discloses a novel dishwasher. The dishwasher comprises an outer shell, an inner barrel is arranged in the outer shell, a tableware rack is arranged in the middle of the inner barrel, and an impeller is arranged at one end of the inner barrel; heaters are arranged at both ends of the impeller, and the impeller is electrically connected with a motor through a transmission shaft in the middle; a draining pump is arranged at the bottom end of the inner barrel, and a draining pipeline is arranged at one end of the draining pump; a protecting cover is arranged on the surface of the top end of the outer shell, an air heater is arranged in the protecting cover, an air inlet is formed in one end of the air heater, an air outlet is formed in the bottom end of the air heater, and the air outlet runs through the outer shell and reaches the top end of the interior of the inner barrel. According to the novel dishwasher, a blow-drying mechanism is arranged on the surface of the top end of the outer shell, and tableware in the inner barrel can be blow-dried after cleaned, so that the use effect of the tableware is not affected when a worker takes it out, the tableware can be put into use once the tableware is taken out, and the problem that by means of an existing dishwasher, the tableware can only be cleaned but cannot be dried is solved.

Owner:浙江默客机电有限公司

Exhaust type embossed substrate applied to release paper

InactiveCN106142808AImprove anti-static effectNot easy to fall offLamination ancillary operationsLaminationLow-density polyethyleneElastomer

The invention discloses a manufacturing method of embossed release paper. The manufacturing method of the embossed release paper comprises the following steps: adding 100 parts of high-density polyethylene, 120-180 parts of low-density polyethylene, 10-30 parts of styrene-isoprene-styrene block copolymers, 5-15 parts of styrene-butadiene block copolymers, 0.5-1.5 parts of paraffin, 0.1-0.5 part of glycerinum, 5-10 parts of POE polyolefin elastomers and 0.3-0.8 part of coupling agents into a stirrer for stirring; heating and bridging the mixture via two screws at a feeding opening of a laminating machine to obtain the molten mixture; further heating the molten mixture to 220-250 DEG C again at a feeding screw to obtain a fluid mixture; heating the fluid mixture to 260-280 DEG C again at a screw outlet, changing the fluid mixture into a cloth-shaped mixture, and extruding the cloth-shaped mixture. The embossed release paper manufactured by the method is clear in embossed mesh lines, uniform in depth and uniform in distribution lines; no bubbles are generated between the formed embossed lamination release paper and a pressure-sensitive adhesive when the embossed polyethylene-coated release paper is fit with the pressure-sensitive adhesive.

Owner:斯迪克新型材料(江苏)有限公司

Embossed release paper

InactiveCN104846691ANot easy to fall offImprove anti-static effectPaper coatingCoatingsLow-density polyethyleneElastomer

The invention discloses an embossed release paper. The embossed release paper comprises base paper and a film-coated layer coating the surface of the base paper. The surface, opposite to the base paper, of the film-coated layer has an embossing pattern zone, and the surface of the embossing pattern zone is coated by an organosilicon release agent layer. The film-coated layer comprises the following components by weight: 100 parts of high-density polyethylene, 120 to 180 parts of low-density polyethylene, 10 to 30 parts of styrene-isoprene-styrene block copolymer, 5 to 15 parts of styrene-butadiene block copolymer, 0.5 to 1.5 parts of paraffin, 0.1 to 0.5 part of glycerol, 5 to 10 parts of POE polyolefin elastomer and 0.3 to 0.8 part of a coupling agent, wherein the POE polyolefin elastomer is polymer of ethylene and butylene or polymer of ethylene and octylene. A reticular pattern formed in the invention has clear and equally-deep amboss and uniform distribution lines; and no bubble occurs between the formed embossed film-coated release paper and a pressure-sensitive adhesive during bonding of the embossed film-coated release paper with the pressure-sensitive adhesive, so usage effect is not affected.

Owner:斯迪克新型材料(江苏)有限公司

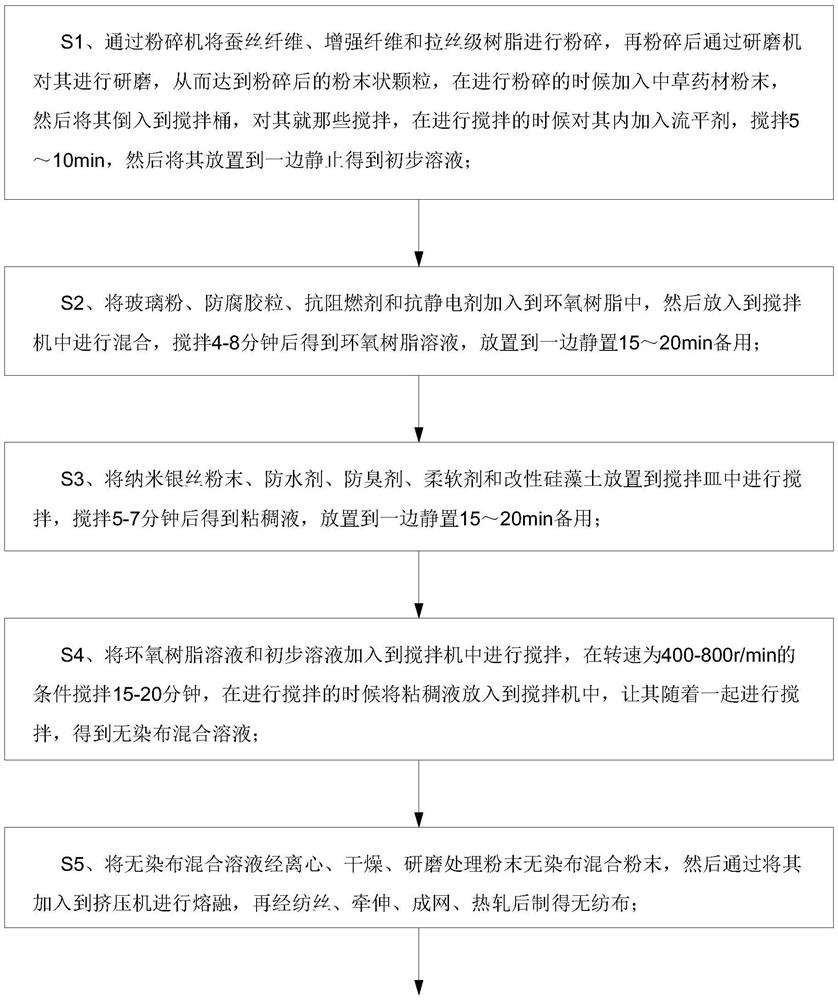

Antibacterial composite non-woven fabric and preparation method thereof

InactiveCN112411012AGood stretch resistanceAvoid damageElectroconductive/antistatic filament manufactureFlame-proof filament manufactureAnti bacterialChinese herbs

The invention discloses an antibacterial composite non-woven fabric and a preparation method thereof. The antibacterial composite non-woven fabric comprises the following raw material in parts by weight: 50-200 parts of silk fibers. Through cooperation of wire drawing level resin, glass powder and a plasticizer, the tensile effect is better during use, so that the stability during use is ensured,and the damage caused by excessive stress is avoided; through arrangement of nano silver wire powder and Chinese herbal medicine powder, the antibacterial ability of the material can be effectively improved during use, so that the normal use of the material cannot be influenced by bacteria breeding during use; and through cooperation of the plasticizer and a leveling agent, the effect of the material formed in a drying and film-forming process during use is better, and the surface is flatter and smoother.

Owner:江门市多美无纺布有限公司

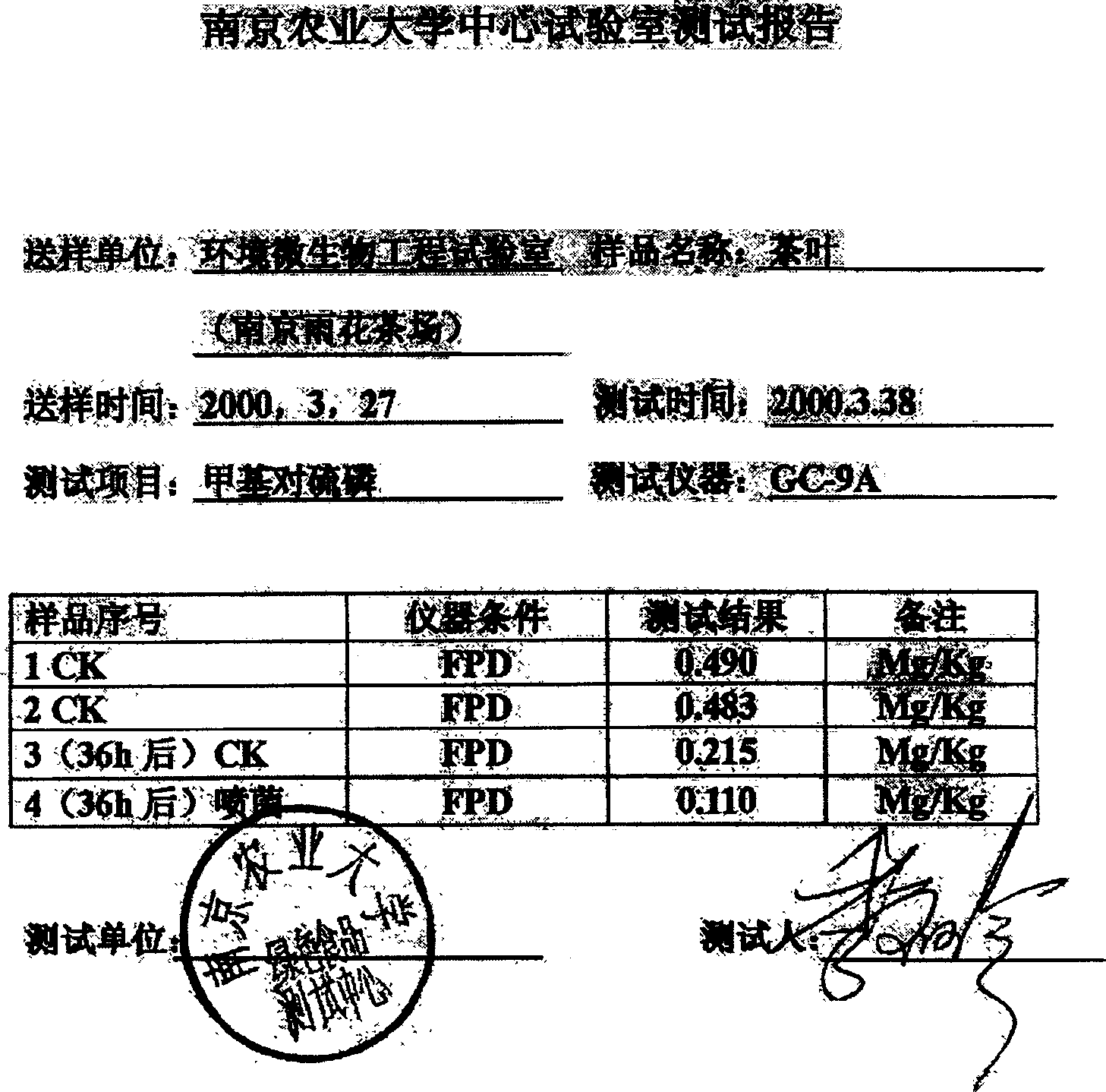

Method for preparing methyl parathion degradation bacterium and enzyme preparation thereof

InactiveCN101168731AWill not affect the use effectEasy to useBacteriaPesticide residueMethyl parathion

The invention relates to methyl parathion degradation fungus and the preparing method of the enzyme preparation thereof, and belongs to the biological high technical field. The methyl parathion degradation fungus strain is plesiomus shigelloides, and the production process of liquid enzyme preparation adopts the steps of slant culture, seed liquid shaking, seed fermenter, fermenter, bacterial collection, mechanical cell crushing, clear liquid collection, (NH4)2SO4 fractional precipitation, HEPES buffer solution suspension, dialysis, and crude enzymes production. Enzyme dry powder preparation which is easy to be stored or transported can also be further refined, and processing steps added on the basis of the crude enzymes production are as follows: DEAE-Sephadex-A50 anion column chromatography, CM Sepharose Fast Flow cation column chromatography, dialysis, cryodesiccation and enzyme dry powder production. The direct application of the liquid crude enzymes preparation can ensure the organic phosphorus pesticide residue quantity in agricultural crops to be reduced by more than 90 percent, and the residual on the surface of garden spgarden stuff washed to be reduced by about 98 percent; after the enzyme dry powder preparation is diluted according to a specific proportion, the pesticide residue quantity can be reduced by more than 95 percent. The enzyme preparation product resolves the problem that the pesticide residue is over-standard in the agricultural production.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Production method of embossing laminating release film

InactiveCN104859270ANot easy to fall offImprove anti-static effectLamination ancillary operationsLaminationLow-density polyethyleneElastomer

The invention discloses a production method of an embossing laminating release film. The production method comprises the following steps of placing 100 parts of high density polyethylene, 120 to 180 parts of low density polyethylene, 10 to 30 parts of styrene-isoprene-styrene segmented copolymer, 5 to 15 parts of styrene and butadiene segmented copolymer, 0.5 to 1.5 parts of paraffin, 0.1 to 0.5 part of glycerin, 5 to 10 parts of POE (Polyolefin Elastomer) and 0.3 to 0.8 part of coupling agent into a stirrer to be stirred; performing heating bridging on the mixture through double screws of a laminating machine feeding inlet to obtain a molten mixture; further heating the molten mixture to 220 to 250 DEG C at the position of the feeding screws so as to obtain a fluid mixture and pressurizing the fluid mixture to 5 to 15 Mpa; heating the fluid mixture to 260 to 280 DEG C at the position of a screw outlet to form the fabric shape to be squeezed out. According to the embossing laminating release film, mesh patterns are clear in embossing and unified in depth, distribution lines are uniform, bubbles are not produced between formed embossing laminating release paper and a pressure sensitive adhesive during attachment, and accordingly the use effect is not affected.

Owner:斯迪克新型材料(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com