Self-tightening type seed crystal chuck

A seed crystal chuck, self-tightening technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of inconvenient disassembly operation, complex chuck junction structure, serious production accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

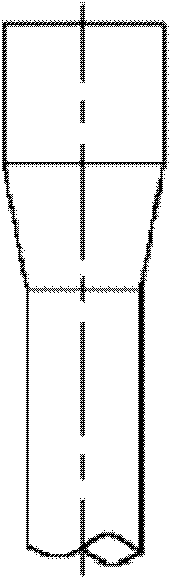

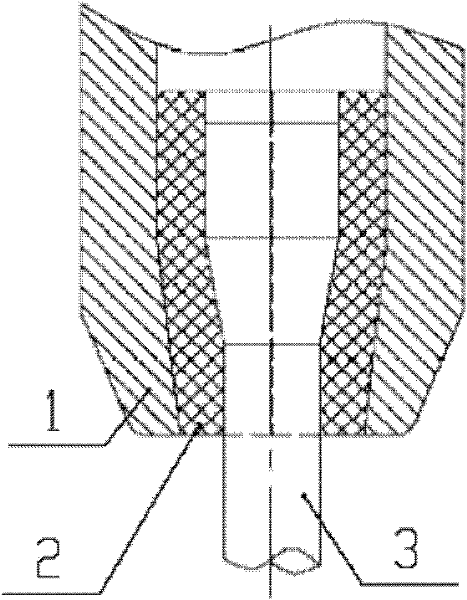

[0021] The self-tightening seed crystal chuck in the present invention comprises a sleeve 1 of molybdenum material and two semicircular clips 2 of high-strength graphite material ringed on the inner wall of the sleeve 1, and the inner wall of the sleeve 1 has a shaft facing downward. The taper of heart contraction, the taper can be set between 0.5 ° ~ 2 ° (preferably 1 °), the clip 2 has an external shape that matches the taper; the inner diameter of the upper opening of the clip 2 is larger than its The inner diameter of the opening at the lower end and the inner wall of the clip between the opening at the upper end and the opening at the lower end are transitioned by a tapered surface.

[0022] Before pulling the crystal in the single crystal furnace, two pieces of graphite clips 2 are installed in the sleeve 1, and the middle of the clips 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com