Small and skillful dual-handle hand riveter

A riveting gun and handle-type technology, which is applied in the field of compact double-handled riveting guns, can solve problems such as easy deviation and skew, uneven gripping force, and influence of gripping force, so as to avoid shifting and Distortion, clean appearance and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

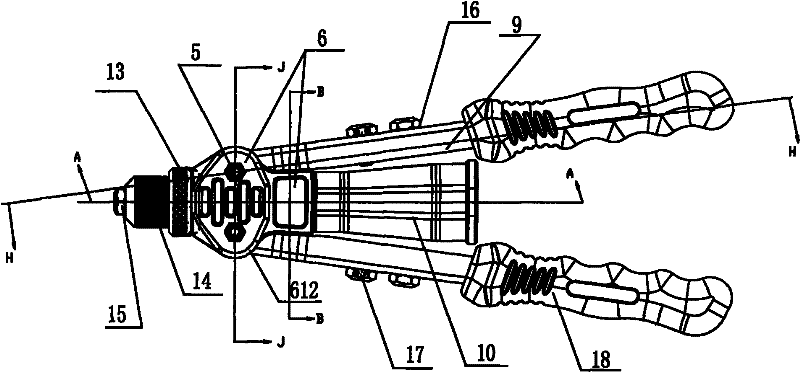

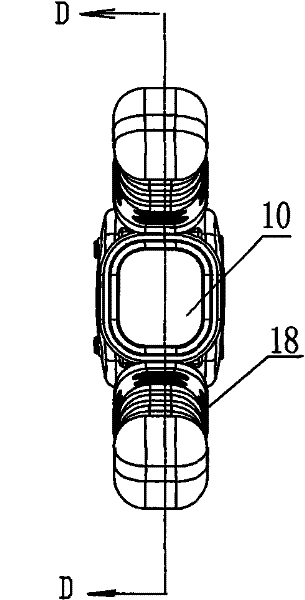

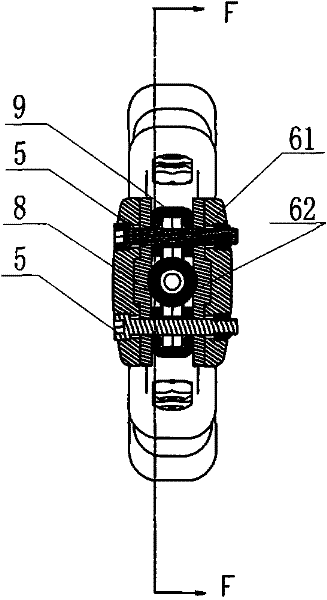

[0038] Such as Figure 1 to Figure 8 Shown: a kind of small and exquisite type double handle riveting gun, including riveting gun seat 6 ( figure 1 , 5), the rivet adjustment mechanism arranged at the front end of the rivet holder 6, the rivet gripping mechanism installed in the rivet adjustment mechanism, one end of which is respectively connected to the two sides of the rivet holder 6 through the screw shaft 5 The two hinged handles 9 of the rivet holder are movably inserted into the pull rod 8 in the central hole 12 of the rivet holder 6 . The whole of the pull rod 8 and the fixed piece 7 and one end of the pull rod telescopic mechanism on the end of the pull rod are respectively hinged to both sides of the fixed piece 7, and the other end is respectively close to the screw shaft 5 and hinged to the connecting rod 20 of the head of the handle 9. All are arranged in the cavity of described riveting gun seat 6, and the length of described pull rod 8 is shortened; Both sides...

Embodiment 2

[0051] Another situation is: sometimes when a product with a longer adjustment seat of the rivet adjustment mechanism at the front of the riveting gun is required, the pull rod needs to be extended to the rivet during operation. At this time, most of the pull rod 8 and its rear part, The fixed piece 7 and one end of the pull rod telescopic mechanism at the end of the pull rod are respectively hinged on both sides of the fixed piece 7, and the other end is respectively close to the screw shaft 5 and the connecting rod 20 at the head of the handle 9 is hinged. Inside the rivet gun seat 6 cavities. The pull rod still needs to keep the original length, and the front part of the pull rod still exposes the rivet gun seat, and other structures are the same as in embodiment 1.

[0052] But because the outer layer of the part of the front part of the tie rod exposed to the rivet gun seat is covered by the catch seat and the adjustment seat, the front part of the tie rod cannot be direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com