Patents

Literature

49 results about "Hand riveter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

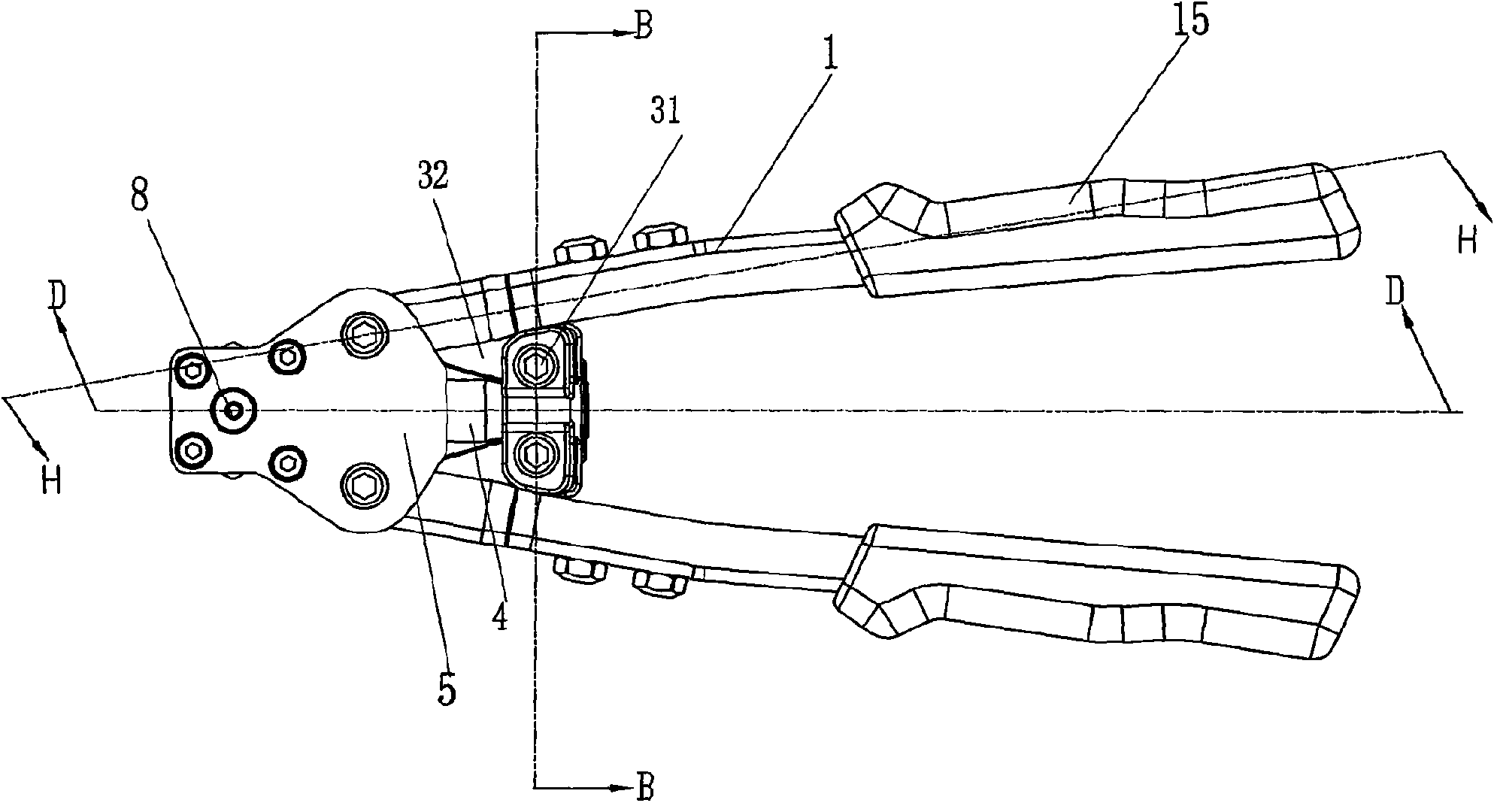

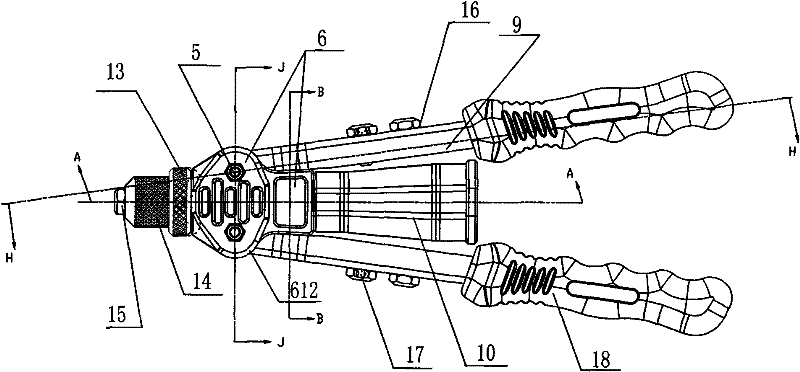

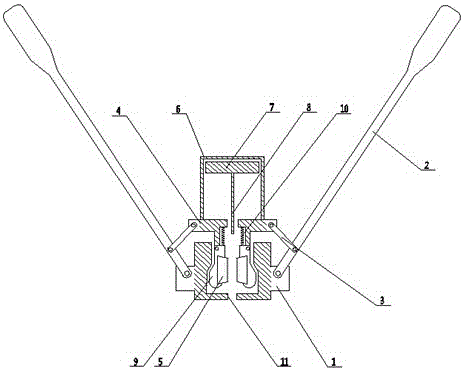

Double handle hand riveter

The invention discloses a double handle hand riveter comprising a riveter base, a regulating mechanism, a riveter holding mechanism, one end of which is hinged with two handles on both sides of the riveter base and a tie bar in a central hole of the riveter base, characterized in that rear end of the tie bar is provided with a fixed groove embedded with a fixed piece, both sides of which are respectively connected with the handles via a connecting rod; one end of the collecting rod is connected with the fixed piece via a second screw shaft and the other end is hinged with the handle. Handle matching grooves are arranged on both sides of the base. The handles are respectively hinged with the riveter base via a first screw shaft in the handle matching groove. The connecting rod is hinged with the handle via a pin rod. The hand riveter can be handle screw by replacing riveter holding mechanism with a screw holding mechanism. Manufacturing process of the fixed groove, the tie bar and the fixed piece on the tie bar is simple and reduces cost. Due to rational connection among the collecting rod, the handle and the riveter base, volume of the invention is reduced.

Owner:袁建明

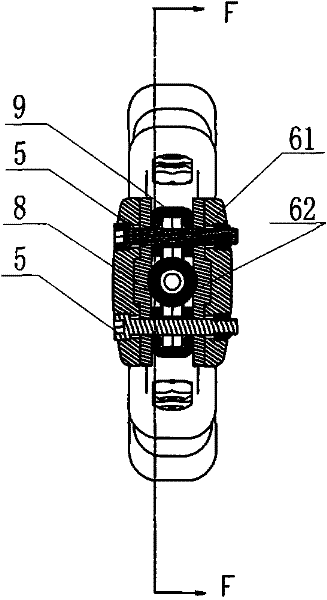

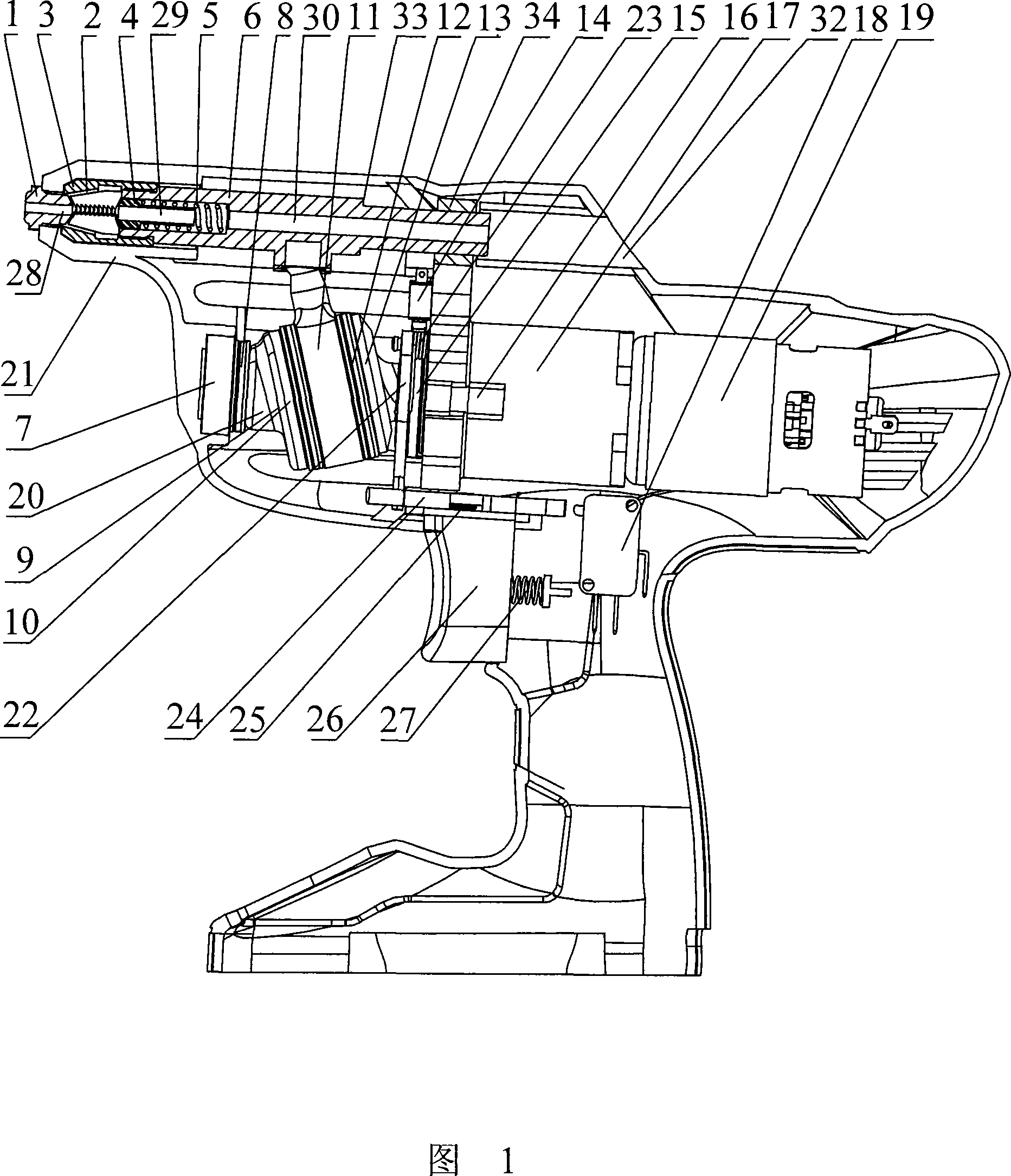

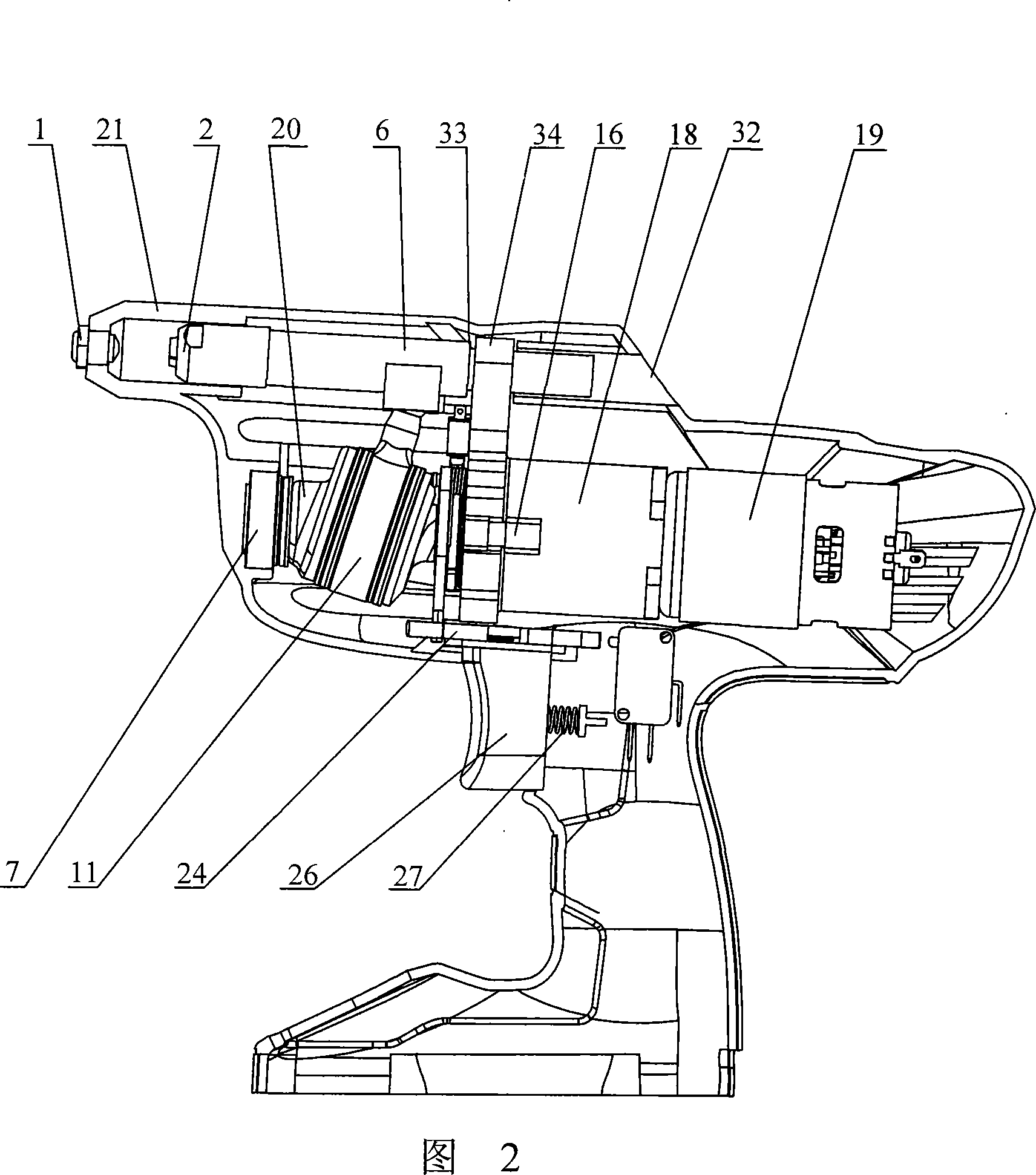

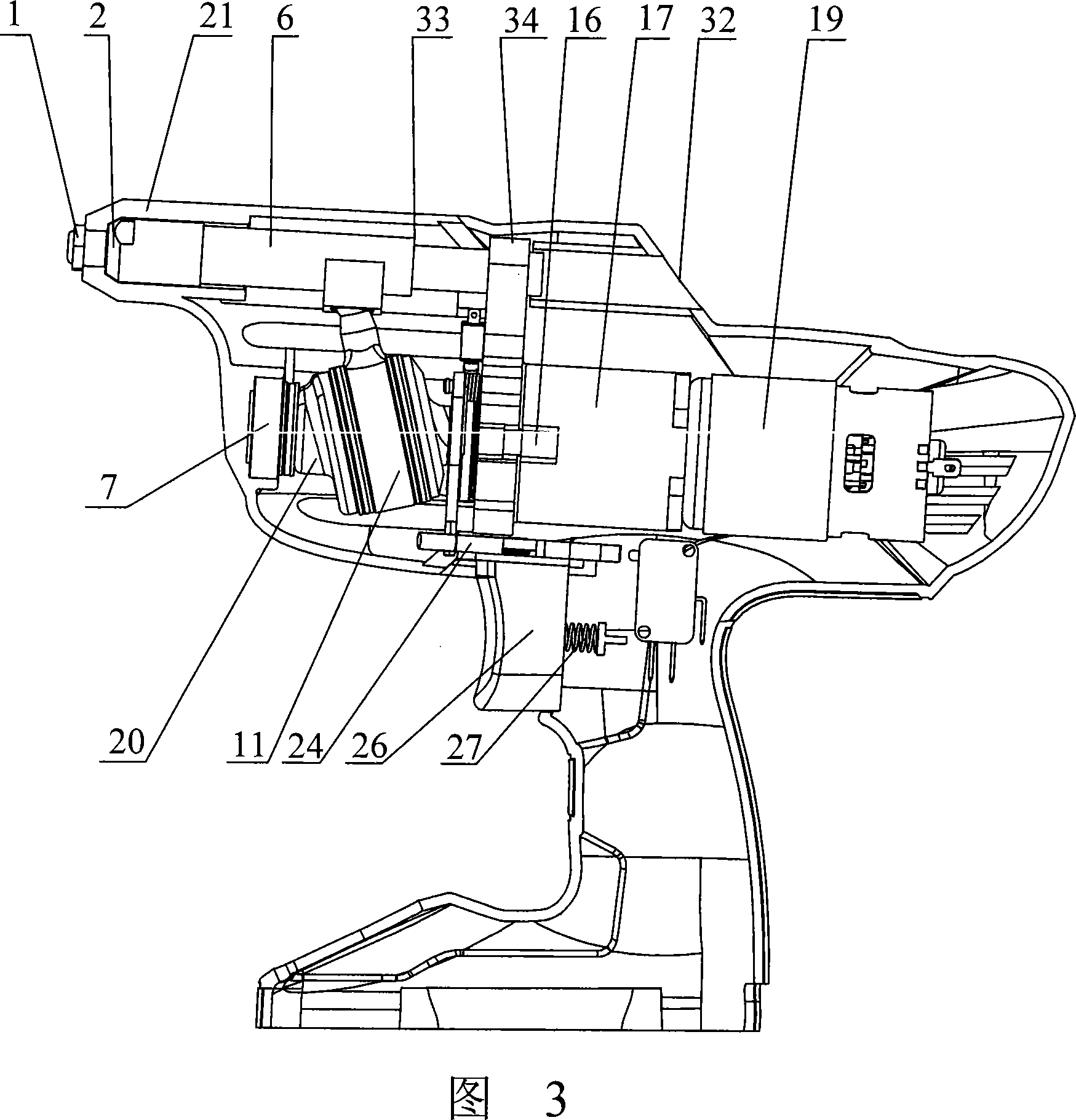

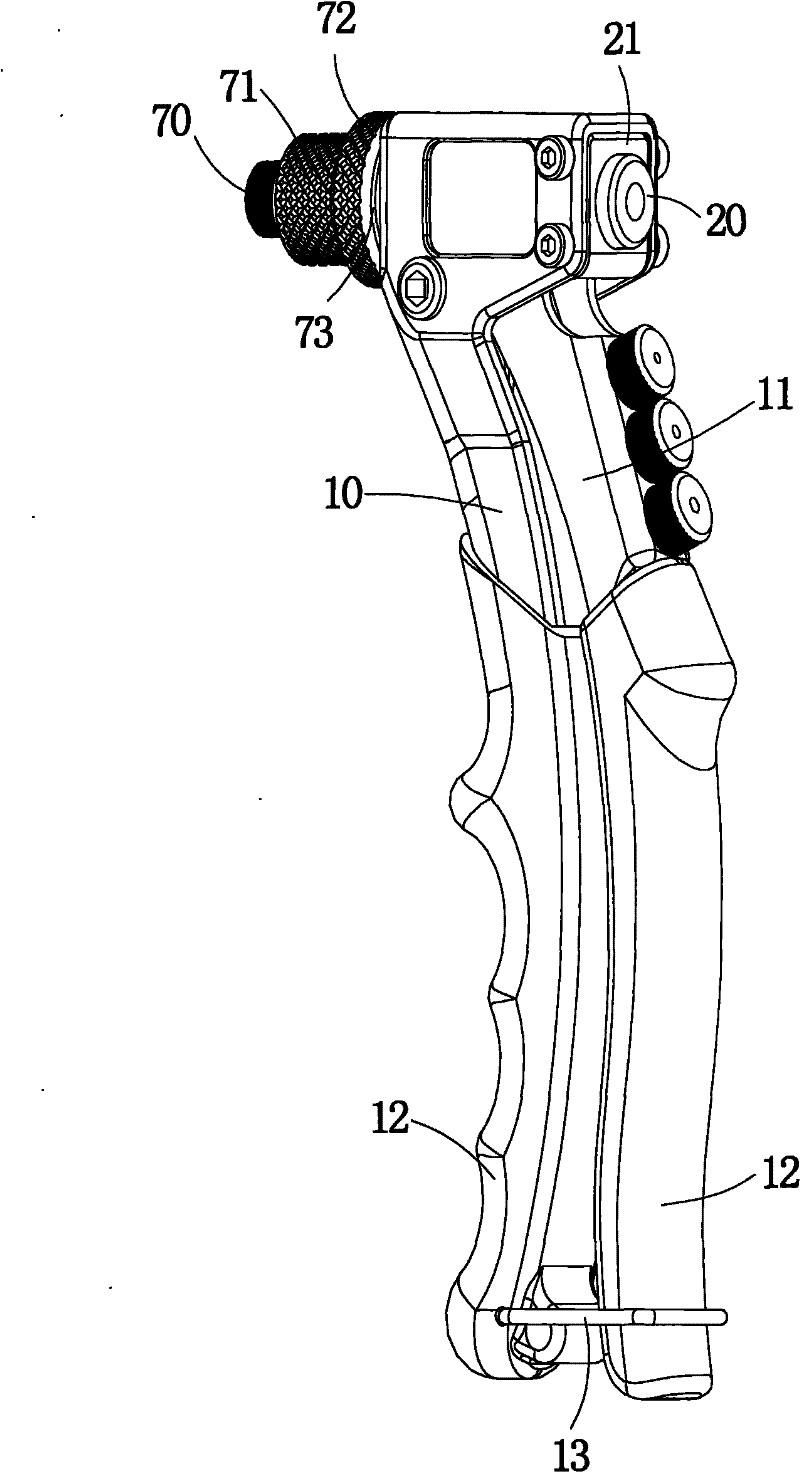

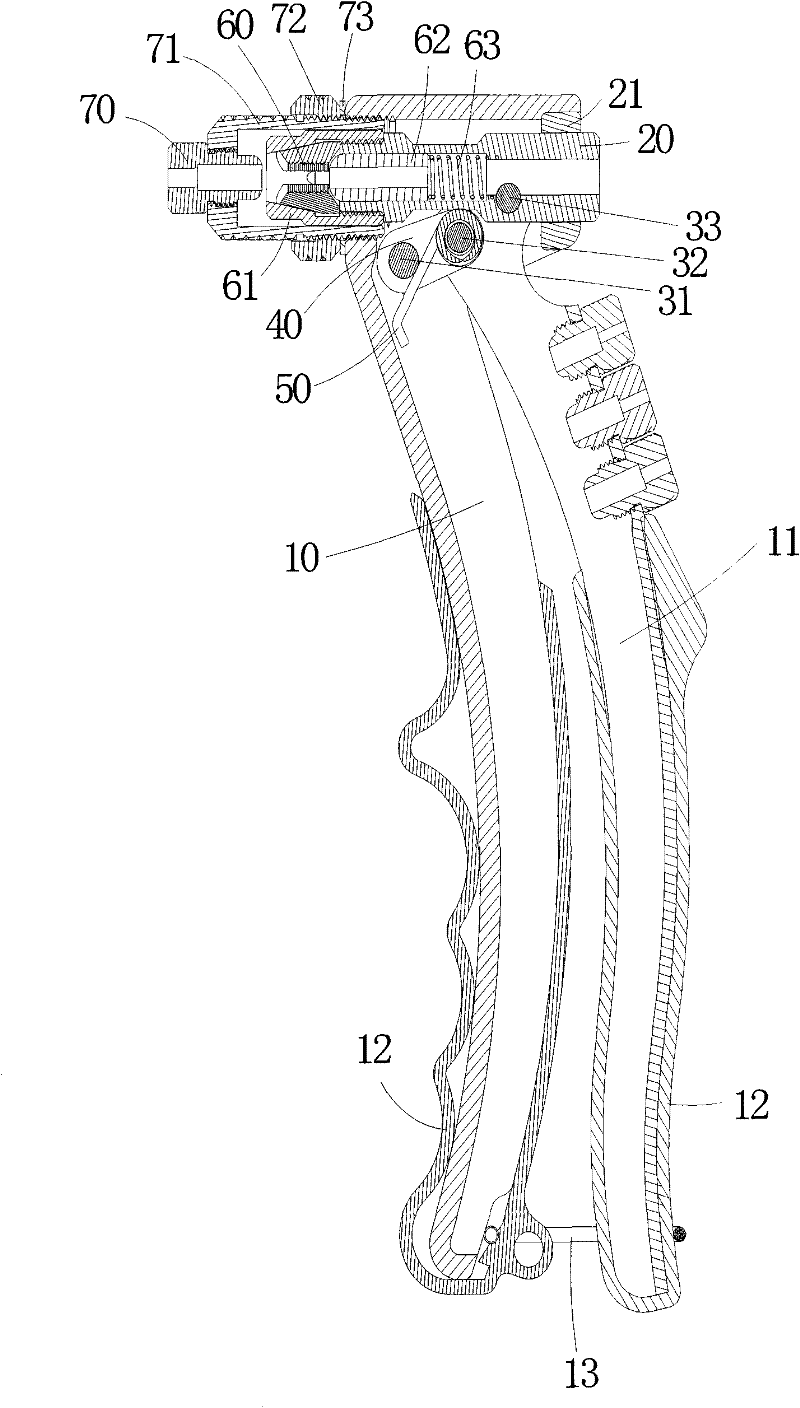

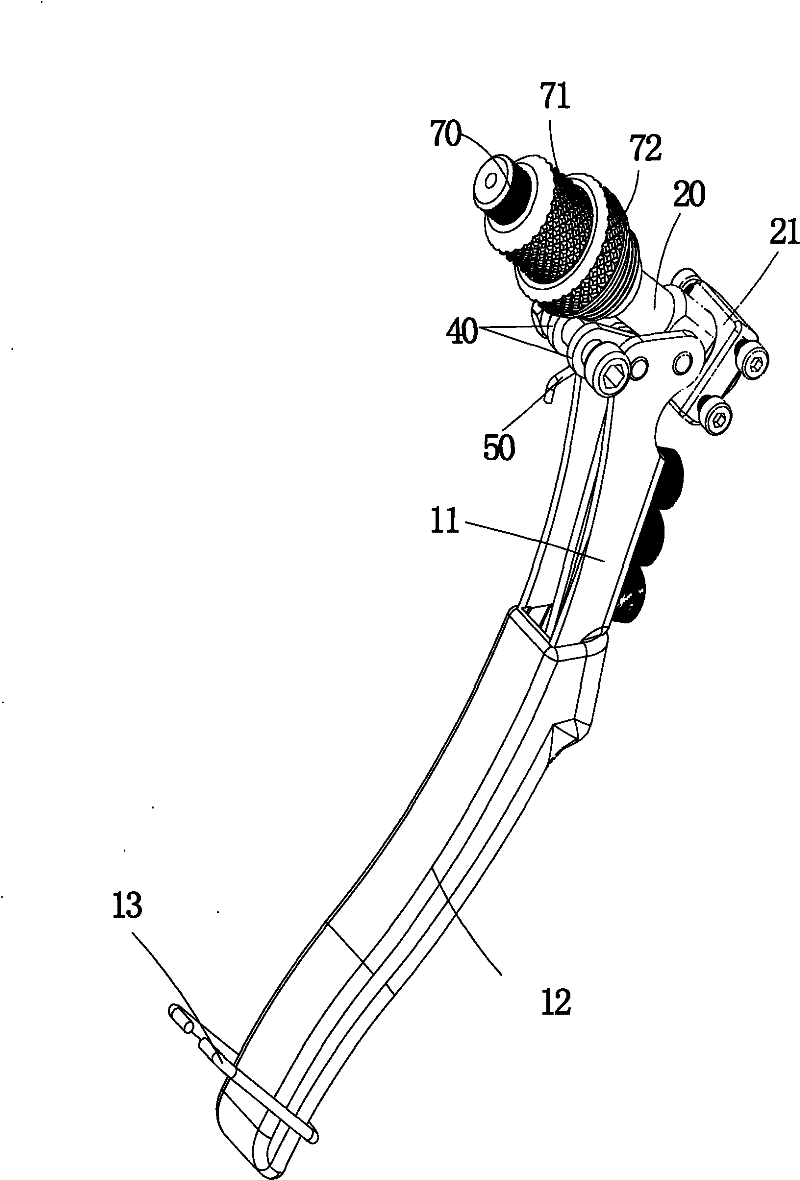

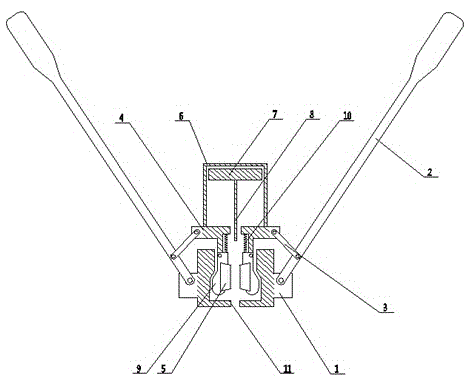

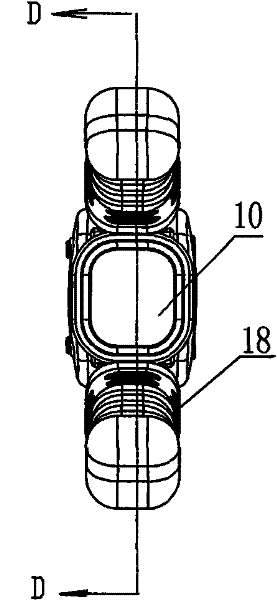

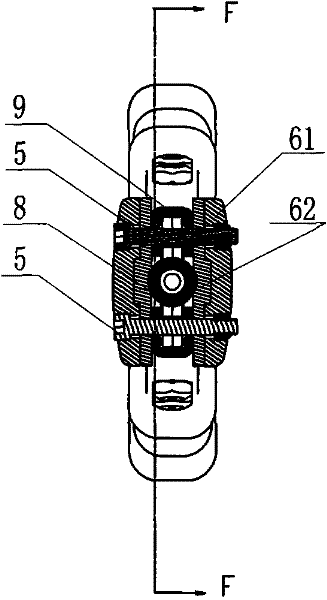

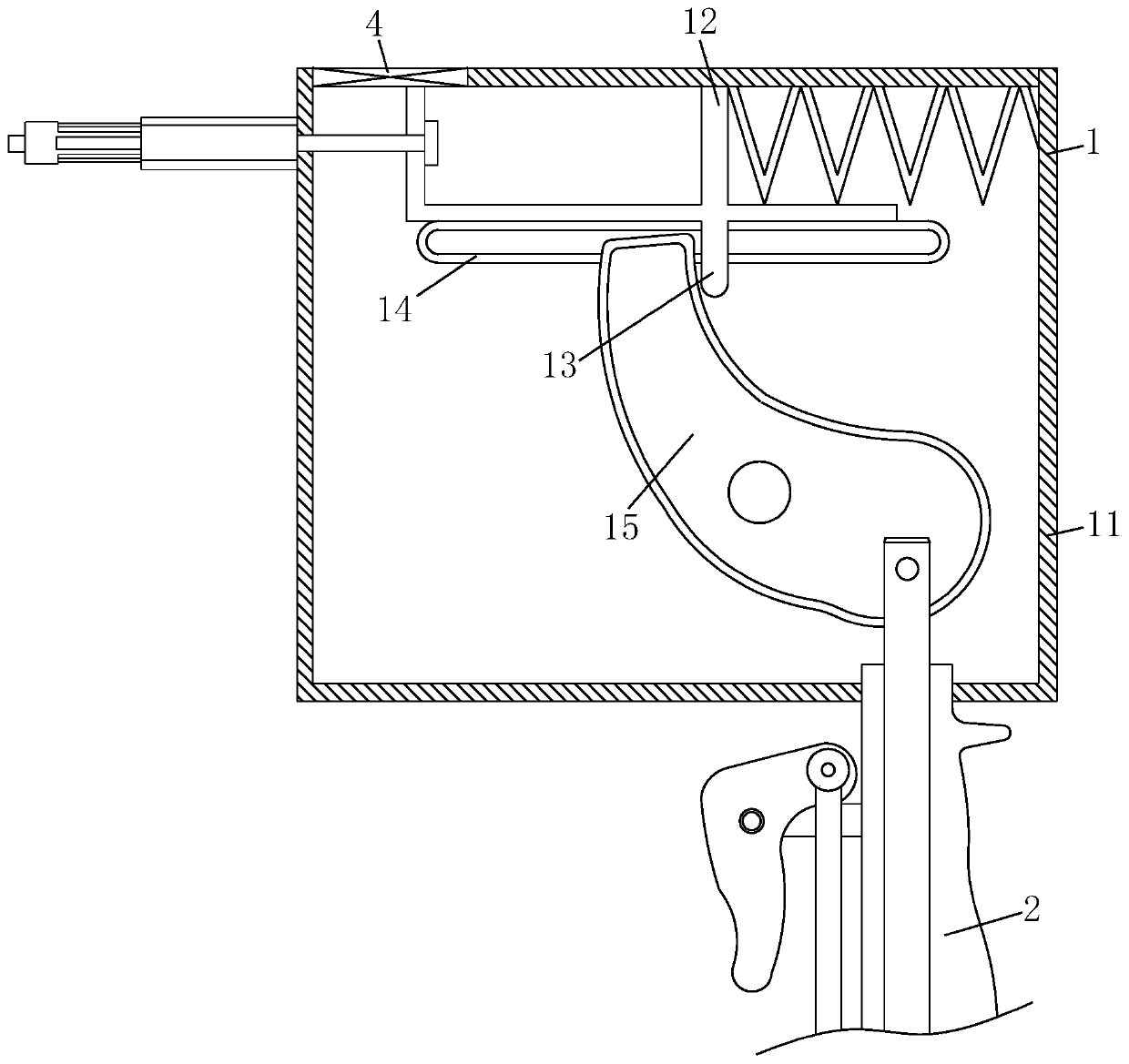

Small and skillful dual-handle hand riveter

The invention discloses to a small and skillful dual-handle hand riveter, which comprises a riveter seat, a rivet adjusting mechanism, a rivet gripping mechanism, two handles and a pull rod, wherein the rivet adjusting mechanism is arranged at the front end of the riveter seat, the rivet gripping mechanism is installed in the rivet adjusting mechanism, one end of one handle and one end of the other handle are respectively hinged with the two sides of the riveter seat, and the pull rod is movably inserted in the center hole of the riveter seat. The invention is characterized in that all or large part of the pull rod is provided with a rear part, and the pull rod, the fixing piece of a pull rod telescopic mechanism arranged at the end of the pull rod and connecting rods arranged on the two sides of the fixing piece and respectively hinged with the heads of the handles are arranged in the cavity of the riveter seat; and handle matching grooves are arranged on the two sides of the riveter seat. The invention has the advantages that since the length of the handles is shortened, all or large part of the pull rod is provided with the rear part, and the pull rod, the fixing piece of the pull rod telescopic mechanism arranged at the end of the pull rod and connecting rods arranged on the two sides of the fixing piece and respectively hinged with the heads of the handles are arranged in the cavity of the riveter seat, the gripping force and the stability of the hand riveter are greatly improved, the appearance is tidier and cleaner, the use is handy and ingenious, and the carrying, the packaging and the transportation are convenient.

Owner:余姚市嘉合工具厂 +1

Bearing dismounting tool

InactiveCN101786225AImprove disassembly efficiencyReduce labor intensityMetal working apparatusTube drawingHand riveter

The invention discloses a bearing dismounting tool which is characterized in that: a positioning cylinder is fixed on the cylinder body of a hand riveter cylinder, the cylinder shaft of the hand riveter cylinder extends to the positioning cylinder to be fixed with one end of a pull tube, the other end of the pull tube extends out of the positioning cylinder, the tube wall of the pull tube out of the positioning cylinder is provided with 3-8 openings along axial direction and in even circumferential distribution, and the center hole of the pull tube at the end has conical closing-in structure; a mandrel penetrates through the cylinder shaft of the hand riveter cylinder and extends to the pull tube to be in threaded fit with the pull tube, the conical end of the mandrel extends to the pull tube and is matched with the closing-in structure at the center hole end part of the pull tube in shape and size. The bearing dismounting tool has simple structure, easy assembly, low cost, light weight, overcomes site limits, not only has convenient and reliable operation and movement, but also has strong generality, can effectively improve the bearing dismounting efficiency and greatly reduces the labor intensity for operators.

Owner:力帆科技(集团)股份有限公司

Easy squeeze blind rivet gun

The invention relates to a device which uses a rivet, in particular to a hand riveter which is driven to achieve the riveting operation by a motor. According to the technical proposal which is provided by the invention, a rivet nozzle is fixedly arranged in a shell; the rivet nozzle is provided with a through hole where the rivet can be inserted; a hand riveting device is connected in the shell at one side of the rivet nozzle in a sliding way; the sliding direction of the hand riveting device is consistent to the axis line of the through hole; the shell is internally provided with a driving device and a control device thereof which drive the hand riveting device to slide forwards and backwards corresponding to the rivet nozzle. The invention has the advantages of compact structure, convenient application, strong force, and avoiding the hidden trouble which is possible to be brought by error operations.

Owner:孙延新

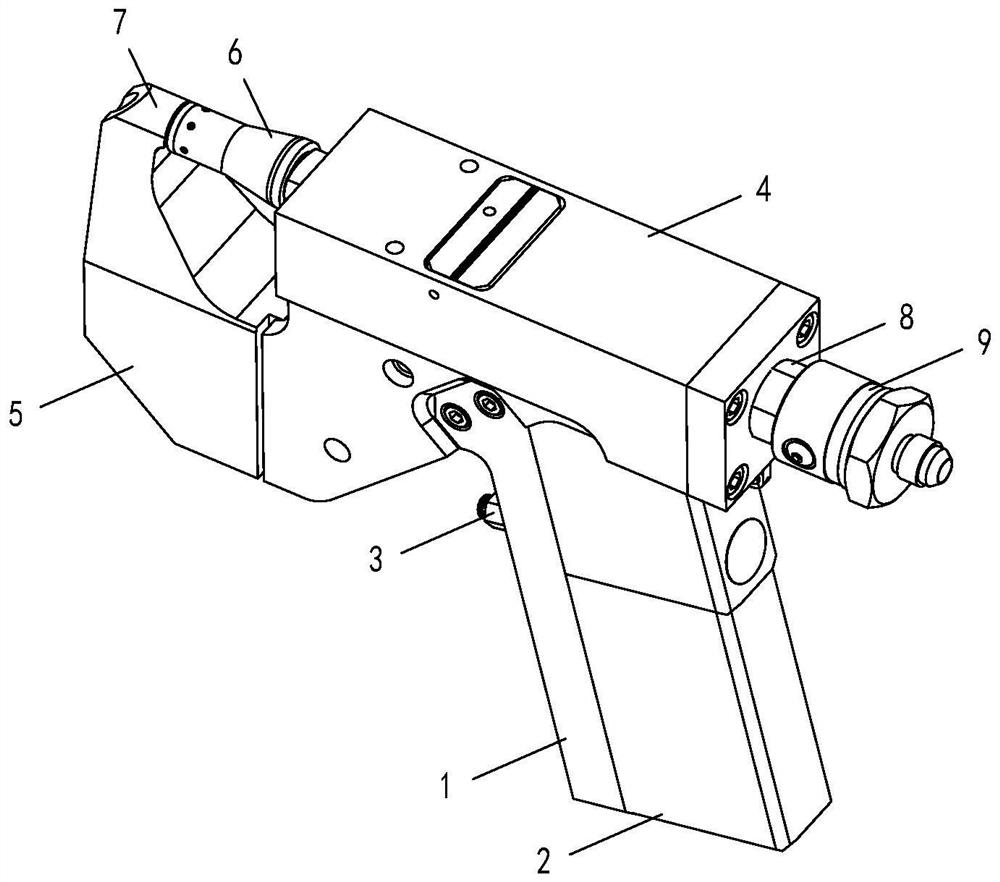

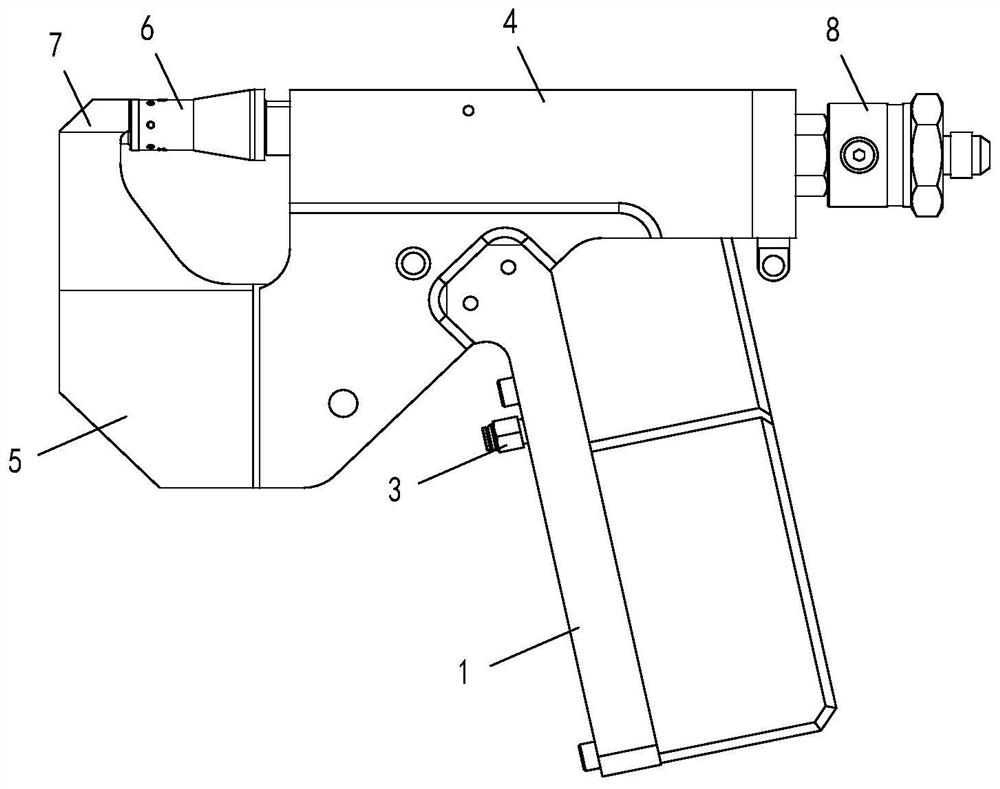

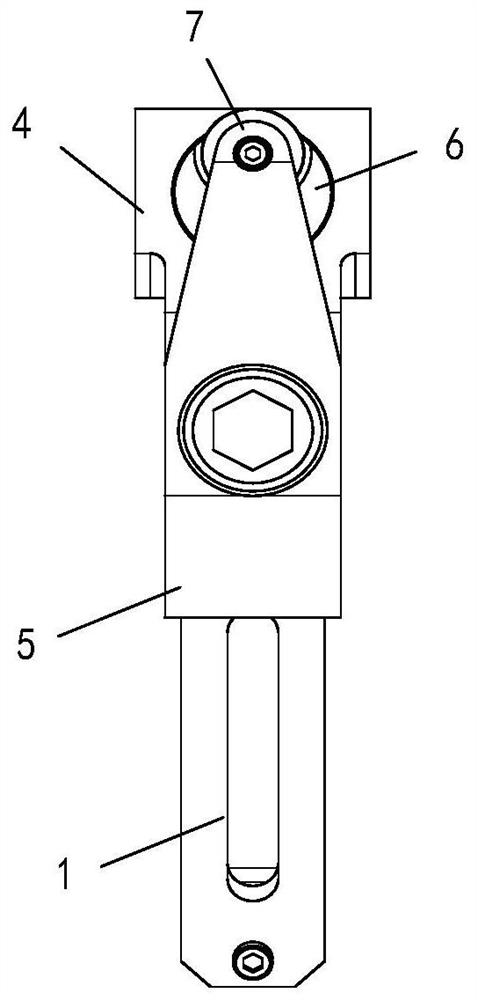

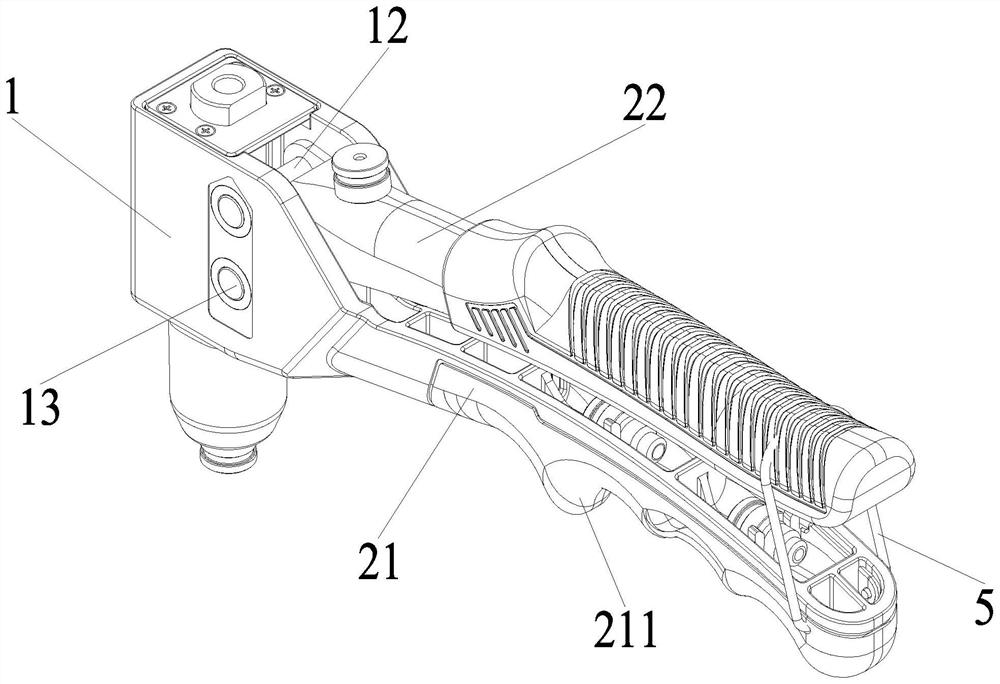

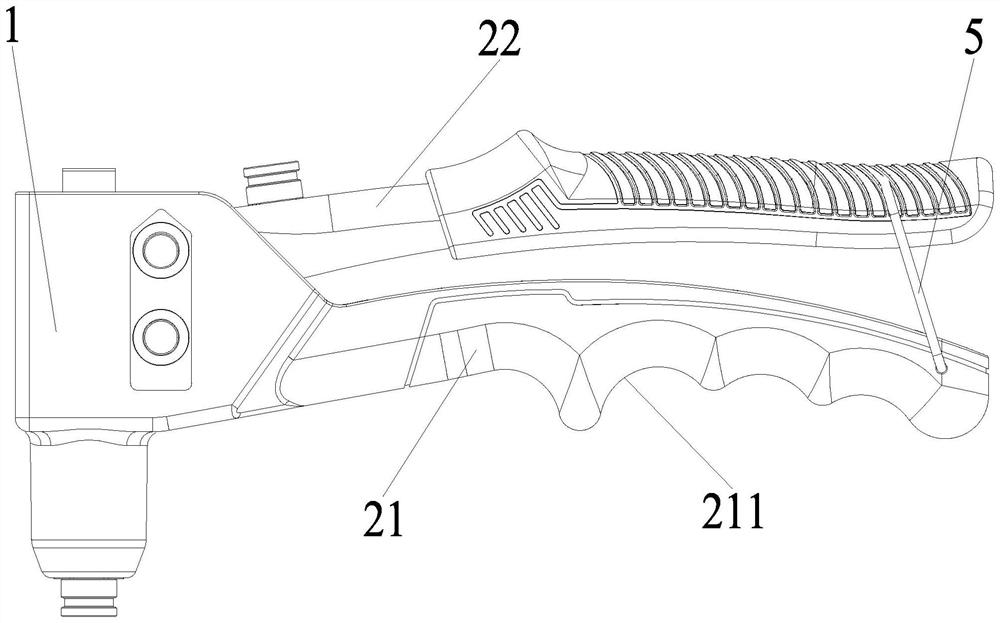

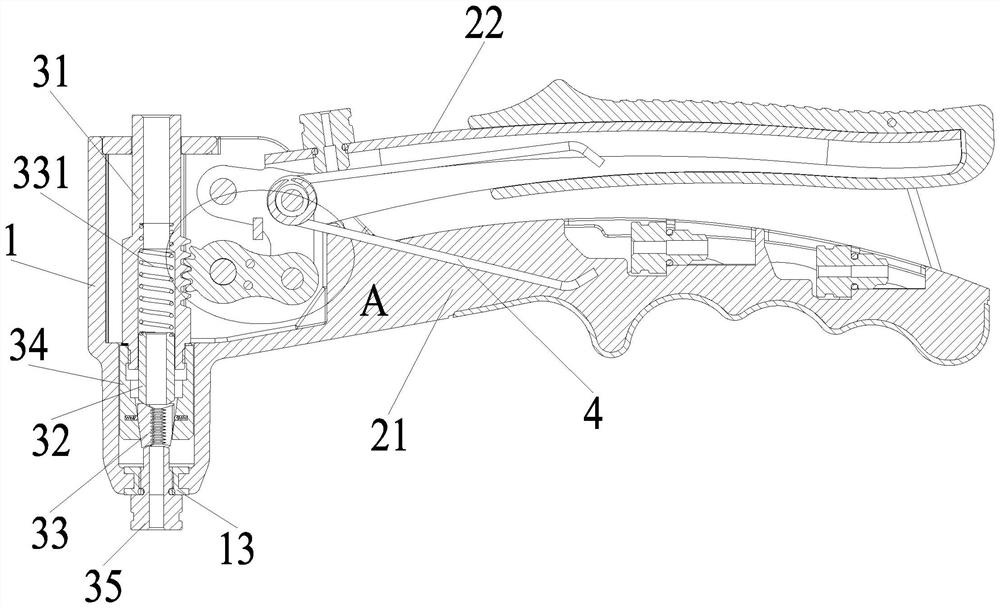

Single-handle hand riveter

The invention discloses a single-handle hand riveter. The hand riveter comprises a body, a handle, a pull rod, a grasping mechanism, a rivet adjusting mechanism, a first hinge pin, a second hinge pin, a third hinge pin and a linkage plate, wherein the rivet adjusting mechanism is matched with the front end of the body; the grasping mechanism is arranged in the chamber of the rivet adjusting mechanism; the tail of the grasping mechanism is matched with the pull rod; the first hinge pin is fixed on the body; the second hinge pin is fixed on the handle and is connected with the first hinge pin by the linkage plate; and the third hinge pin is fixed on the handle and is simultaneously connected on the pull rod fixedly. The single-handle hand riveter has the following advantages that the three hinge pins are adopted to be connected with the body, the handle and the pull rod, the second hinge pin fixed on the handle is connected with the first hinge pin fixed on the body by the linkage plate and the third hinge pin fixed on the handle is simultaneously fixed on the pull rod; and during riveting, the second hinge pin is driven by the linkage plate to approach the pull rod so that the moment is increased, thus further saving labor during use.

Owner:YUYAO TANGWEN TOOL CO LTD

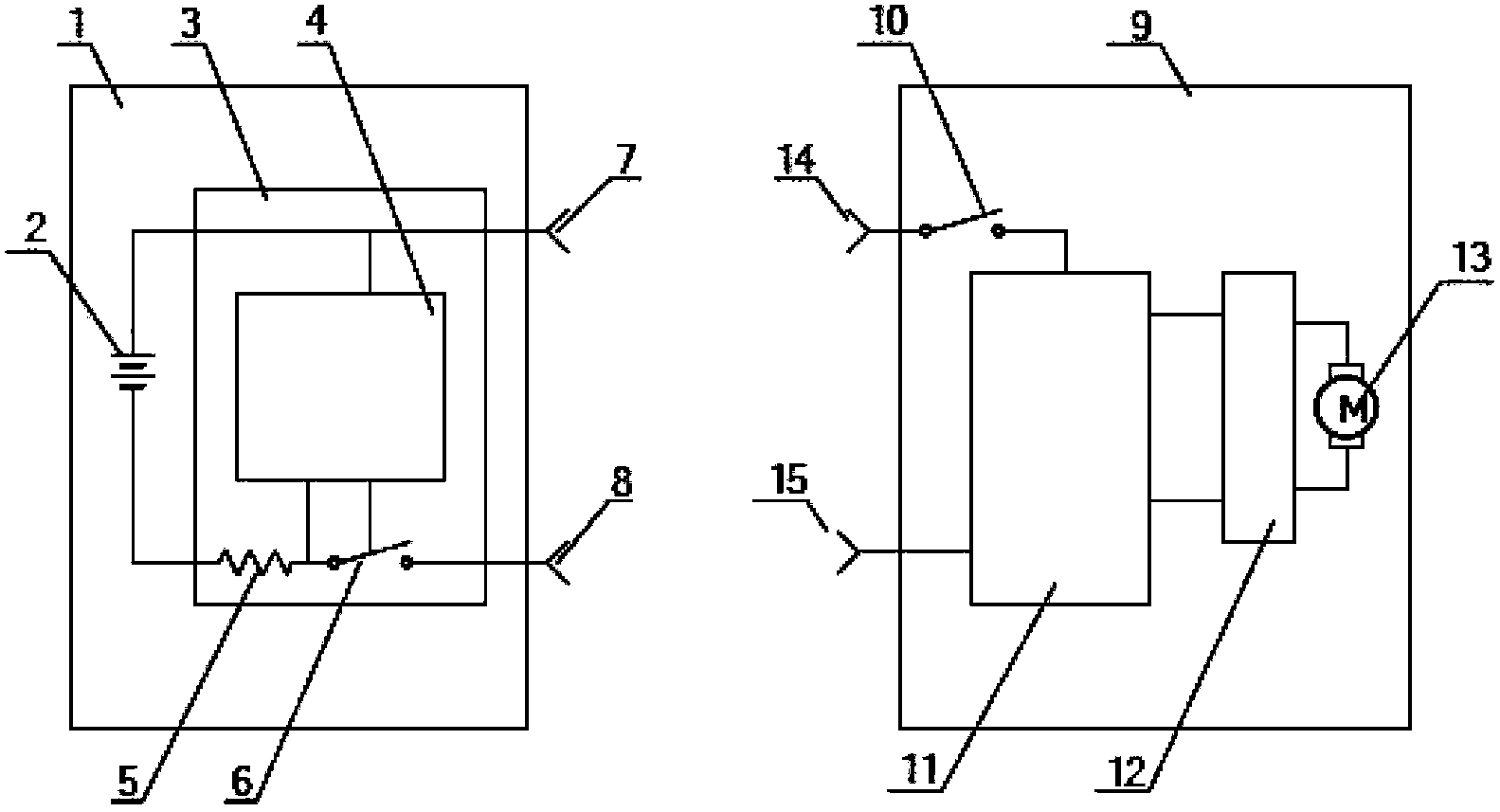

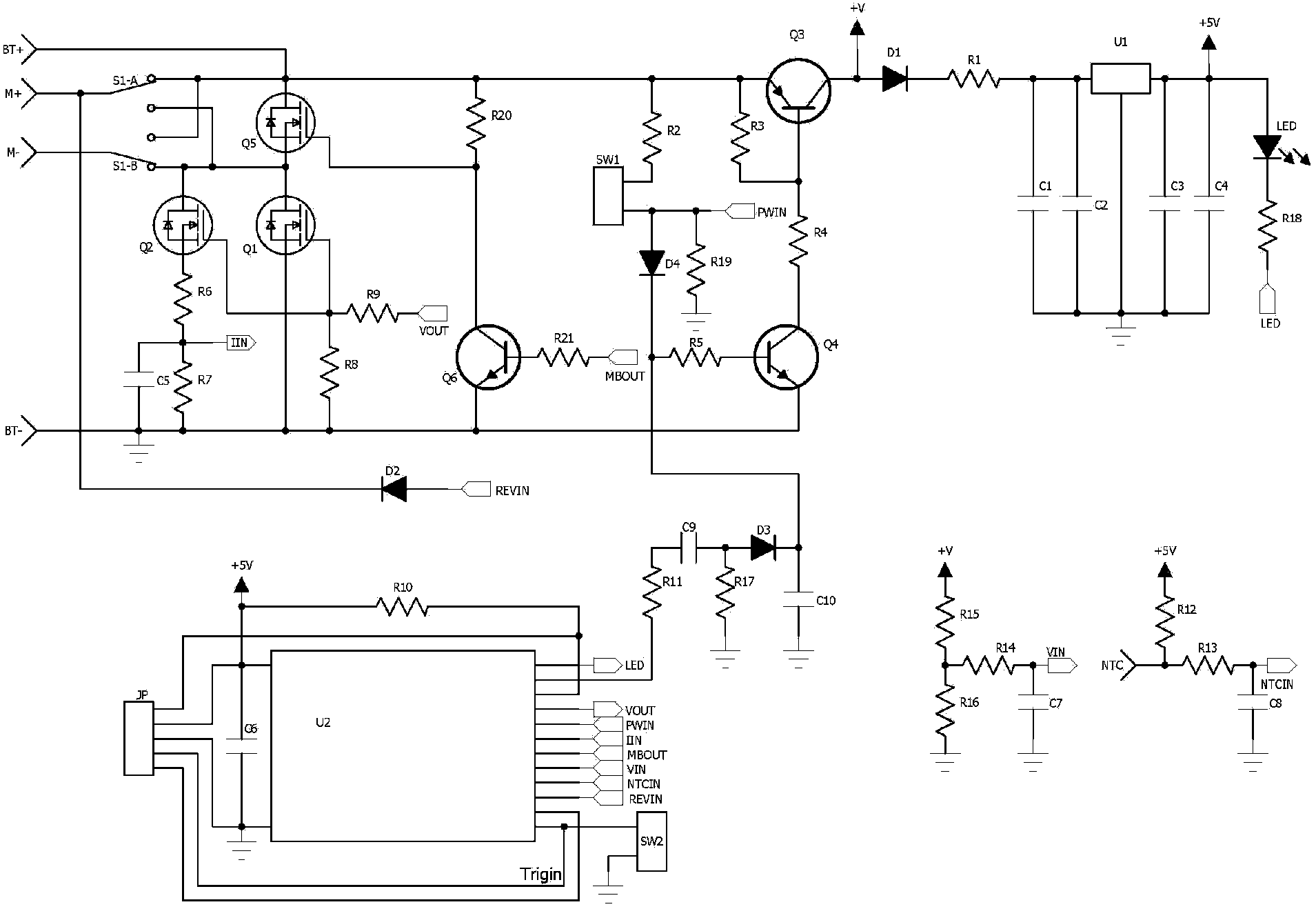

Li-ion hand riveter control and protection circuit

ActiveCN103567349AExtended service lifeEasy to useEmergency protective circuit arrangementsMicrocontrollerControl engineering

The invention discloses a li-ion hand riveter control and protection circuit. The li-ion hand riveter control and protection circuit comprises a hand riveter main control MCU (Micro Controller Unit) module and a hand riveter power control circuit module, a hand riveter temperature detection module, a hand riveter in-situ detection module, a hand riveter braking module and a hand riveter current detection module which are connected with the hand riveter main control MCU module; the hand riveter power control circuit module is connected with a positive pole output end of a lithium battery pack through a hand riveter master control switch; the hand riveter temperature detection module is connected with an NTC(Negative Temperature Coefficient) output end which is arranged inside the lithium battery pack through an NTC input end of a hand riveter; one end of the hand riveter braking module is connected with a hand riveter operating motor through a hand riveter motor reversing switch. The li-ion hand riveter control and protection circuit has the advantages of being long in service life, safe and convenient and efficient.

Owner:深圳欣旺达智能科技有限公司

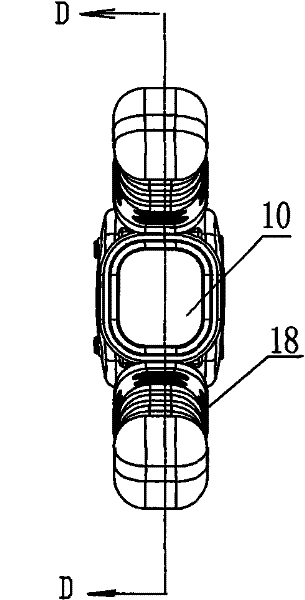

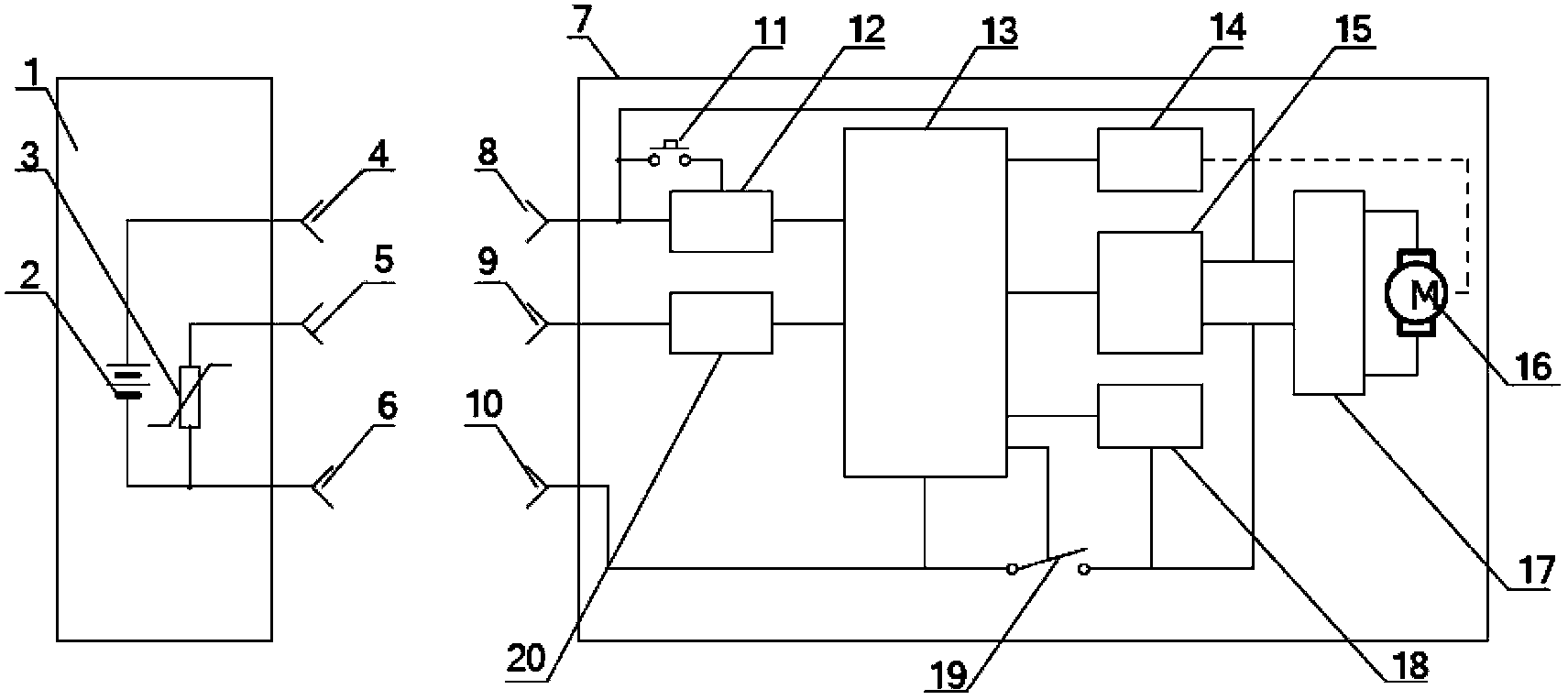

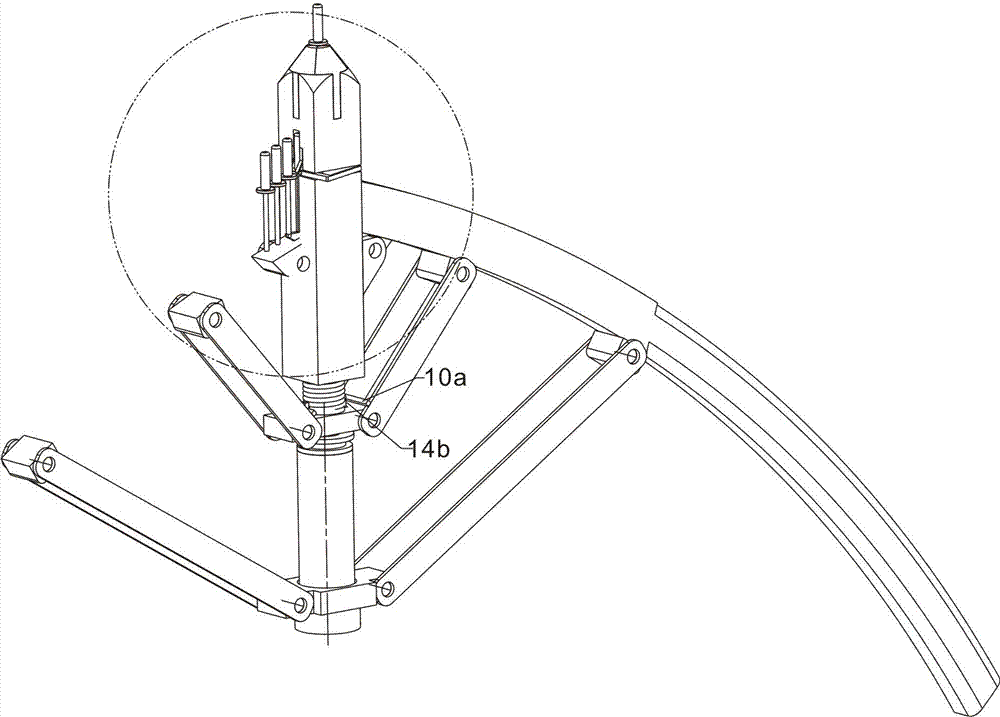

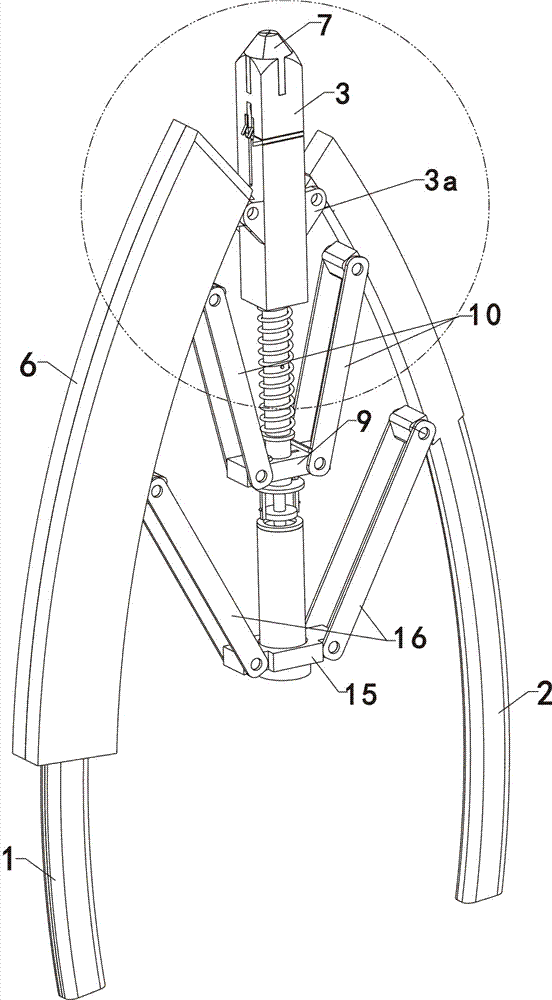

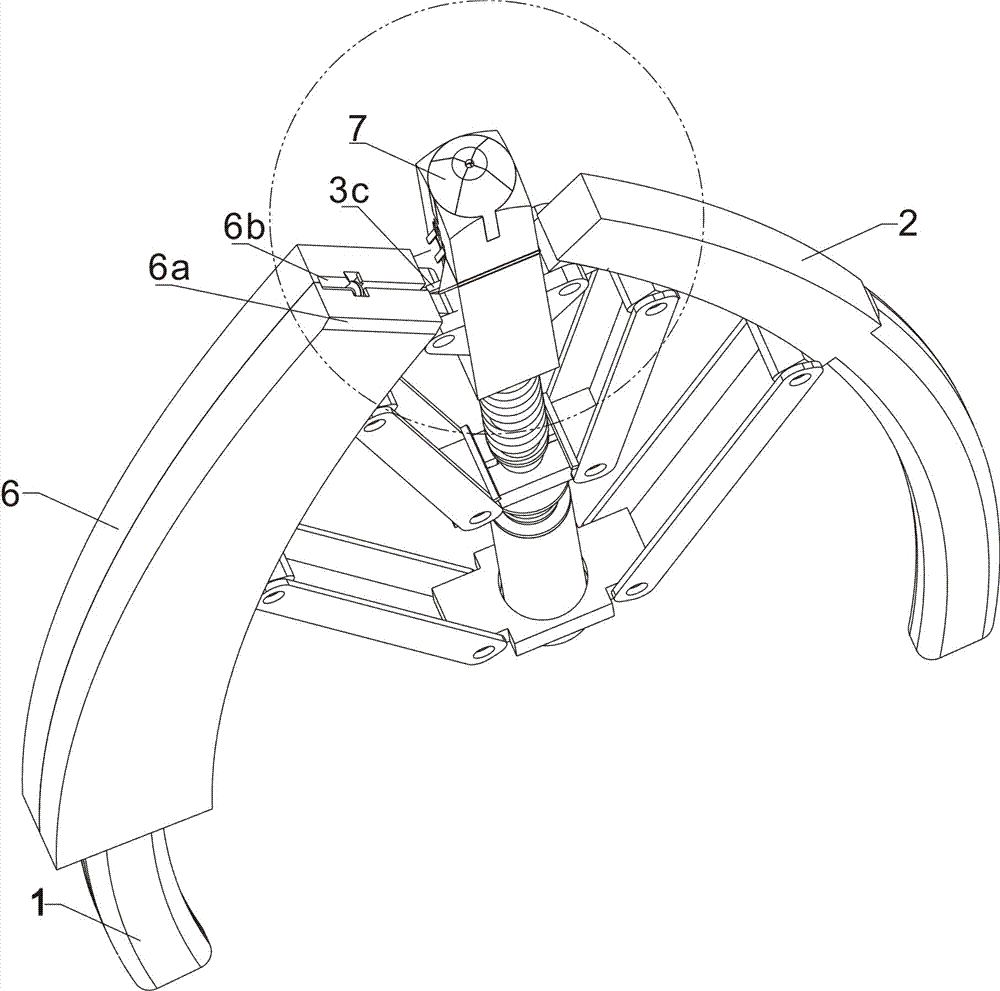

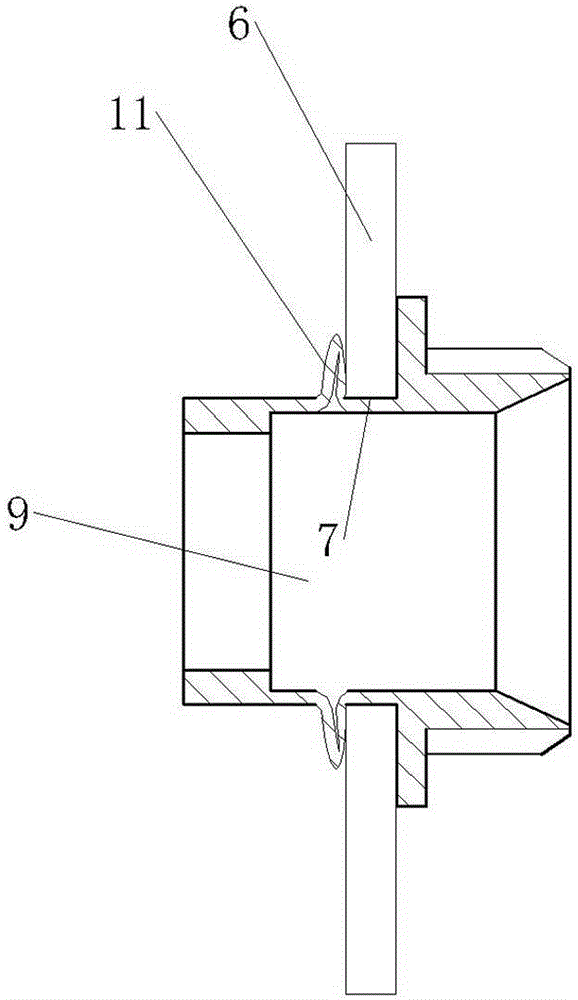

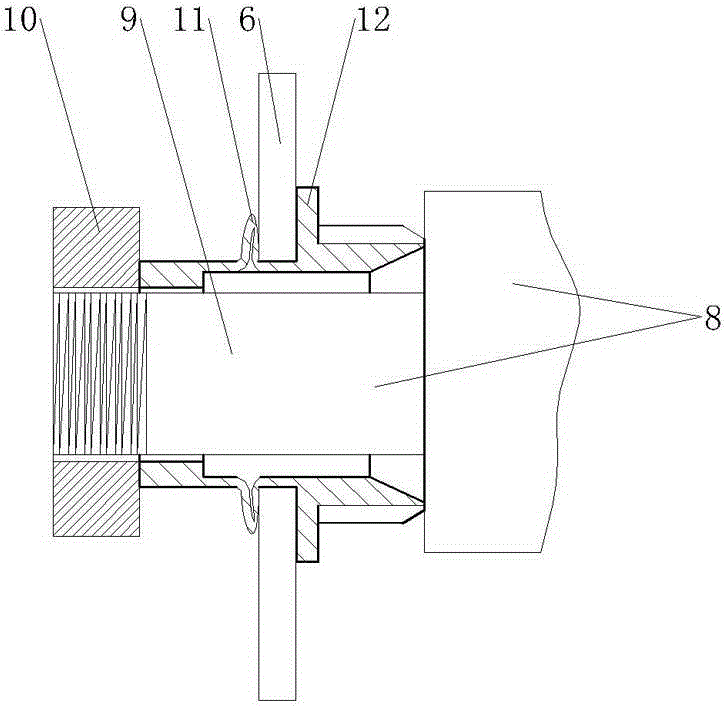

T type two spout hand riveter

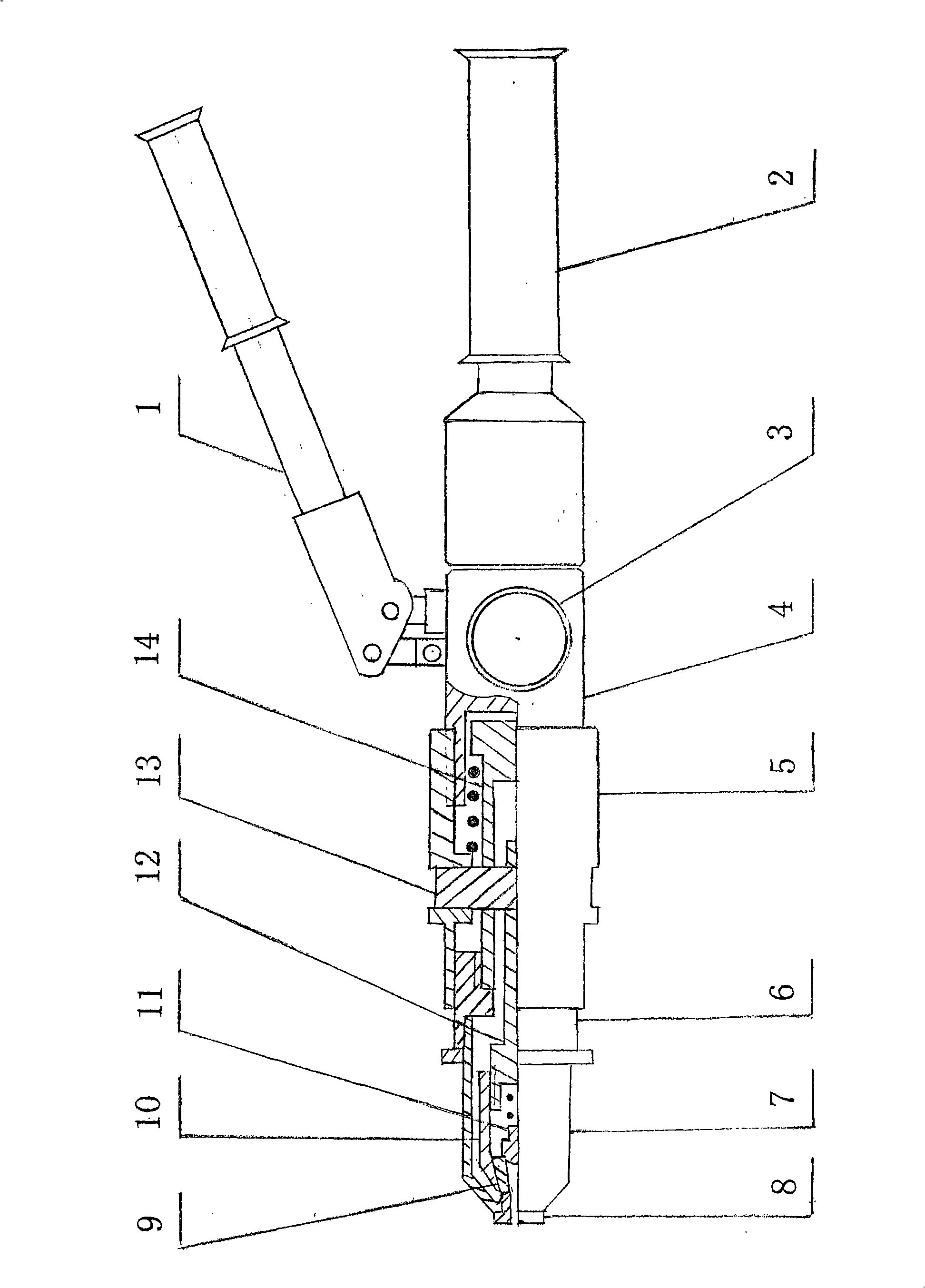

InactiveCN101602086AMake up for and solve the problem of using function limitationsMetal-working hand toolsPull forceHand riveter

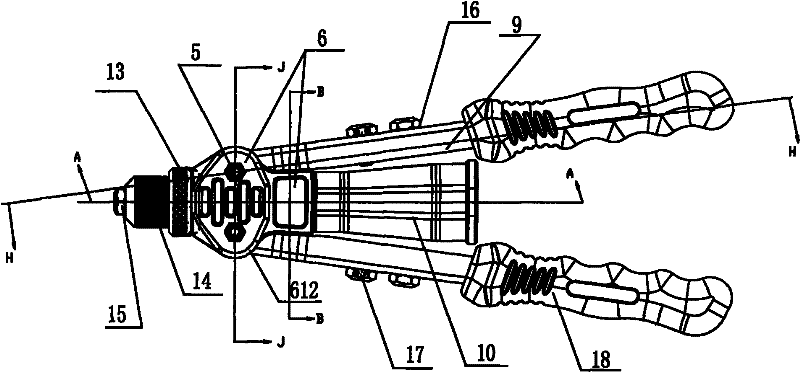

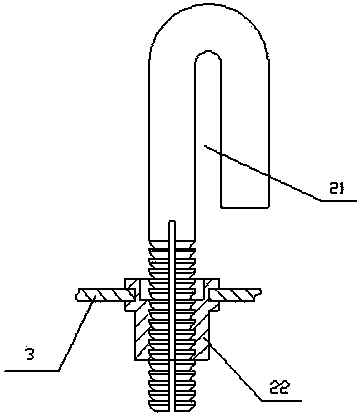

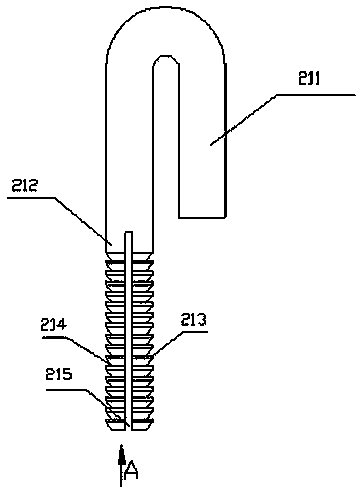

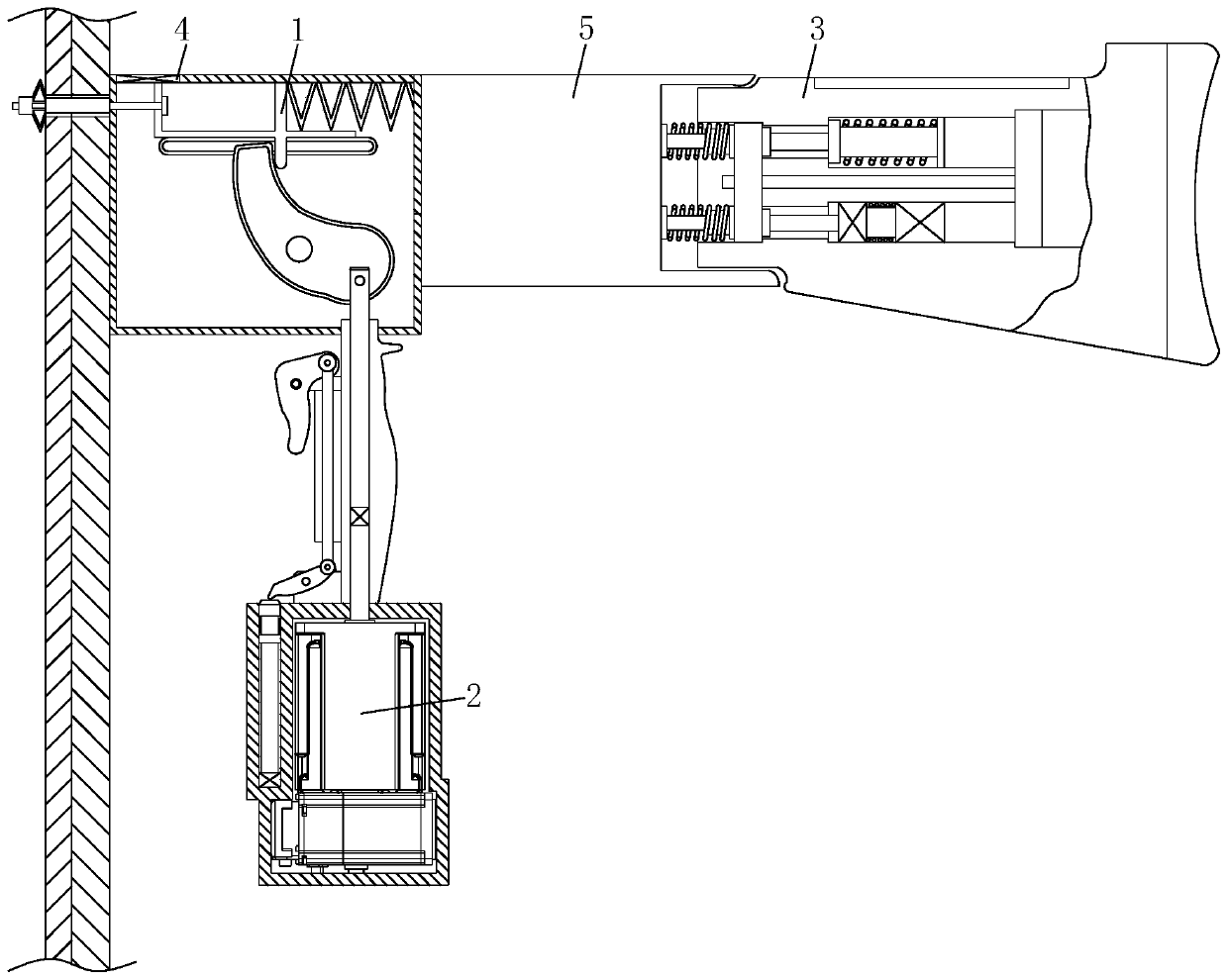

The invention discloses a T type two spout hand riveter. The riveter comprises a riveter seat, left and right handles which are positioned on both sides of the riveter seat and are hinged with the riveter seat, a lateral pull rod which is movably inserted in the riveter seat, a lateral pull rod stretching mechanism arranged between the lateral pull rod and the left and right handles, a regulating mechanism, and a blind rivet grasping mechanism in the regulating mechanism. The T type two spout hand riveter is characterized in that the inside of the riveter seat is also provided with a vertical pull rod, the lower end of the riveter seat at one end of the vertical pull rod is provided with the regulating mechanism, and the head of the vertical pull rod is provided with the blind rivet grasping mechanism; and a connecting part of the vertical pull rod and the lateral pull rod is provided with a vertical pull rod pulling mechanism which mainly comprises an L type connecting rod. The invention is the hand riveter, and is a rivet setting piler if a blind rivet nut grasping mechanism is used for substituting the blind rivet grasping mechanism. The action of the vertical pull rod pulling mechanism ensures that the lateral pulling force of the lateral pull rod is converted into vertical pulling force, which mainly solves the problem of the limitation of use function of the prior hand riveters.

Owner:袁建明

Hand riveter capable of realizing continuous riveting and riveting method

The invention provides a hand riveter capable of realizing continuous riveting and a riveting method. The hand riveter capable of realizing continuous riveting is characterized by comprising a left handle, a right handle, a riveter shell, an inner barrel and an outer barrel, wherein a rivet box used for storing rivets is formed in the left handle, and the upper end of the outer barrel corresponds to the inner part of the riveter shell; a moving opening is formed in the top of the riveter shell; the inner barrel is positioned in the outer barrel, and a rivet clamping component is arranged at the upper part of the inner barrel; the riveter shell is movably connected with the left handle and the right handle; a connecting block is arranged at the lower end of the outer barrel, and the left handle and the right handle are movably connected with the connecting block through connecting pieces respectively. The hand riveter capable of realizing continuous riveting has the advantages of novel design, compact structure, convenience in use, small size, easiness in carrying, etc. In the operation process, other energy and equipment are not needed, and only the left handle and the right handle need to be carried. Automatic and continuous riveting can be realized, the riveting efficiency is improved, and therefore the application range is wide.

Owner:张慧成

Manual hydraulic pressure strong pulling rivet gun

The invention belongs to a powerful hand riveter and particularly relates to a manually-operated hydraulic powerful riveter, which comprises a machine body, a push-and-pull switching device and a riveter head, and is characterized in that the machine body is a hydraulic machine body mainly composed of a fixed handle, a movable handle, an oil storage bag and an oil return valve. The push-and-pull switching device consists of a piston, a cylinder sleeve, a bar, a rigging screw and a connecting sleeve. The riveter head mainly comprises a clamping sleeve, a three-jaw, a top core and a riveter head sleeve. The hand riveter has the beneficial effects that the structure is unique; the riveting action is completed by using the reinforcement of the hydraulic machine body for the first time; the exerted force is strong; the use is convenient; the hand riveter can be used for large-diameter self-plugging rivets, particularly for the riveting of steel rivets; the riveting strength is enhanced; the scope of riveting application is expanded; no electricity or compressed air is needed for supplying power; the hand riveter is energy-saving, environment-friendly, and particularly suitable for use in operation places such as the field, high altitude, underwater, etc.

Owner:孟信芳

Hand riveter with integrated rivet-feeding and stapling mechanism

The invention relates to automatic rivet pulling equipment, in particular to a hand riveter with an integrated rivet-feeding and stapling mechanism of automatic riveting equipment. The hand riveter comprises a hand riveter body, a drive mechanism and a rivet group, wherein the hand riveter body and the drive mechanism are connected through a connecting body A; the connecting body A comprises an air cylinder body of the drive mechanism and an oil cylinder body of the hand riveter body; the oil cylinder body is matched with the hand riveter body; and the rivet group consists of a lower jaw part,an upper jaw part, a lower jaw insert, a rivet conveying elbow, a connecting block and a tension spring. The hand riveter has the advantages of reducing quantity of parts of the equipment, being simple in equipment assembly, improving safety performances and quality of the equipment, and being convenient for popularizing automatic and semi-automatic equipment.

Owner:LUOGE FASTENING SYST SHANGHAI CO LTD

Hand riveter capable of throwing away rivet cores

The invention discloses a hand riveter capable of throwing away rivet cores. The hand riveter is used for easily taking out the rivet cores in a riveter head in the riveting process. The hand riveter comprises handles, supporting rods and the riveter head, pull sleeves connected with clamping jaw seats are arranged on the rear portion of the riveter head, through holes are formed in the middles of the rear ends of the pull sleeves, the rear ends of the pull sleeves are connected with a piston sleeve pipe, and a piston rod is arranged in the piston sleeve pipe. The front end of the piston rod penetrates through the through holes in the rear ends of the pull sleeves and then enters the space between the two clamping jaw seats. The end, connected with the pull sleeves, of the piston sleeve pipe is open, and the other end of the piston sleeve pipe is closed. A cylindrical piston rod cap is arranged at one end of the piston rod, and a piston rod pin thinner than the piston rod cap is arranged at the other end of the piston rod. The piston rod cap faces the sealed side of the piston sleeve pipe, and the piston rod pin stretches to the position, between the two clamping claw seats, in the riveter head. If the rivet cores are adhered to multi-tooth clamping jaws in the riveting operation process and clamped in the riveter head, an operator holds the handles and swings the riveter head, the piston rod pin slides into the riveter head, and the rivet cores adhered to the multi-tooth clamping jaws can be jacked out.

Owner:STATE GRID CORP OF CHINA +1

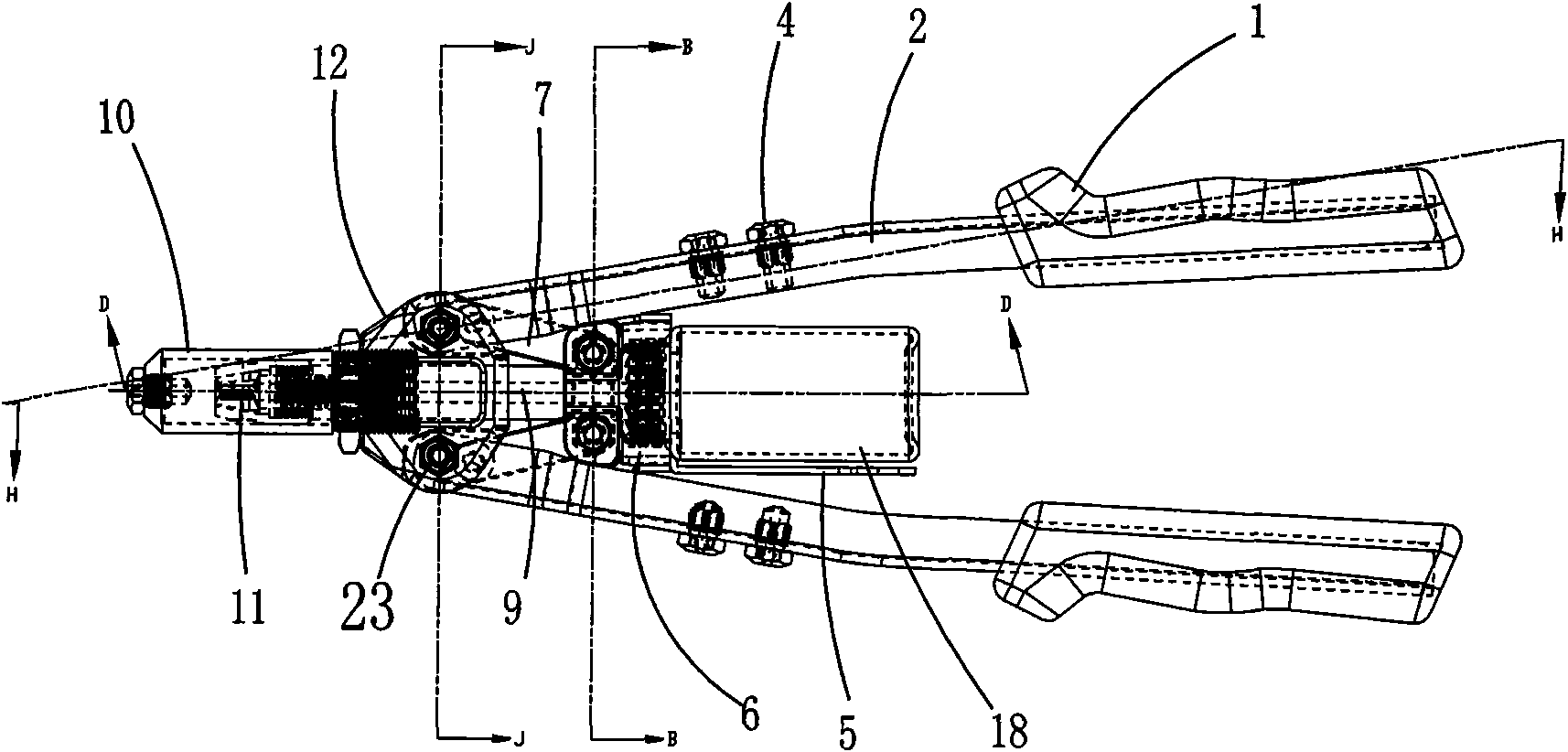

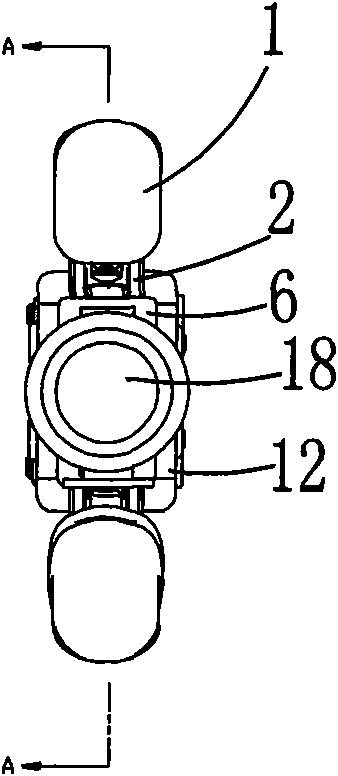

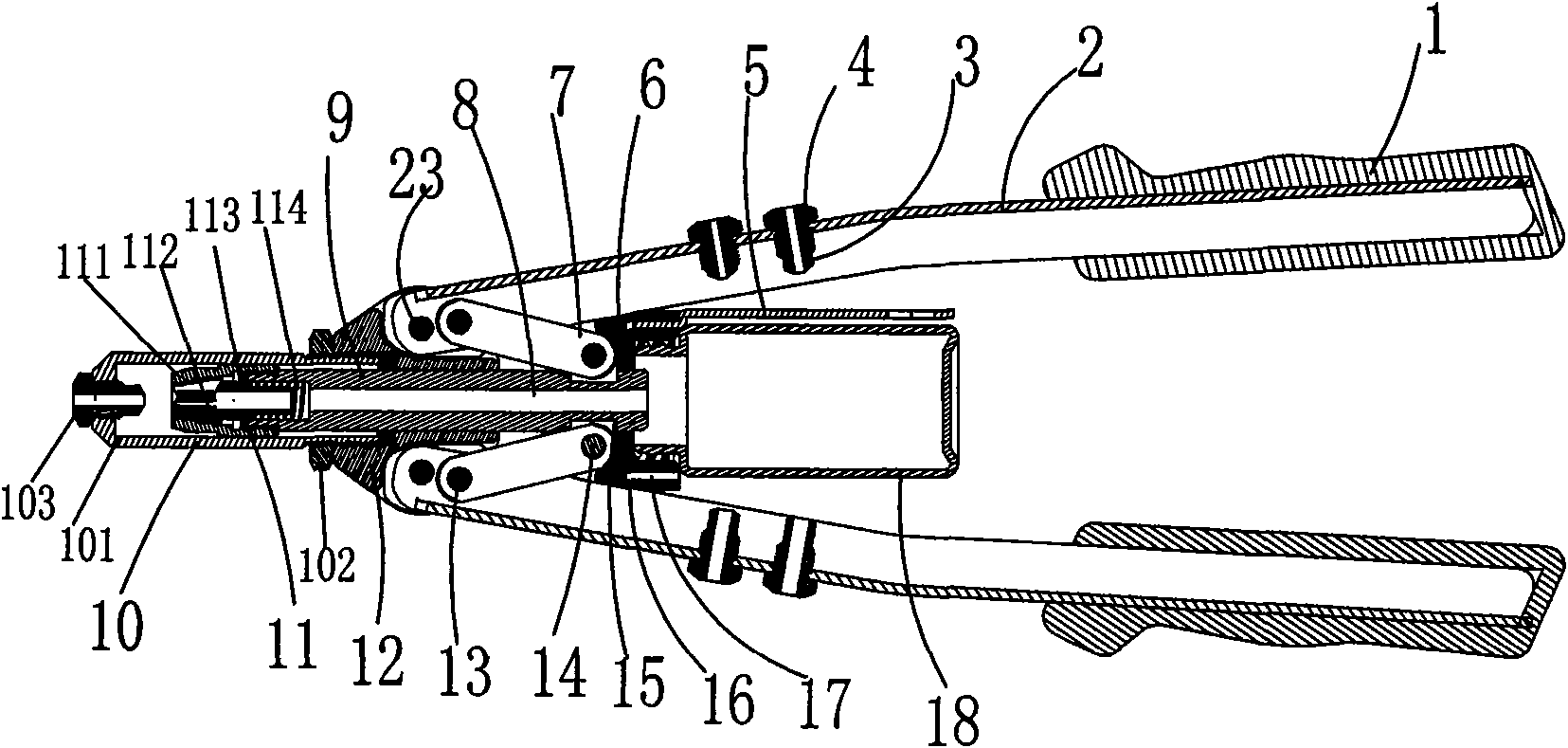

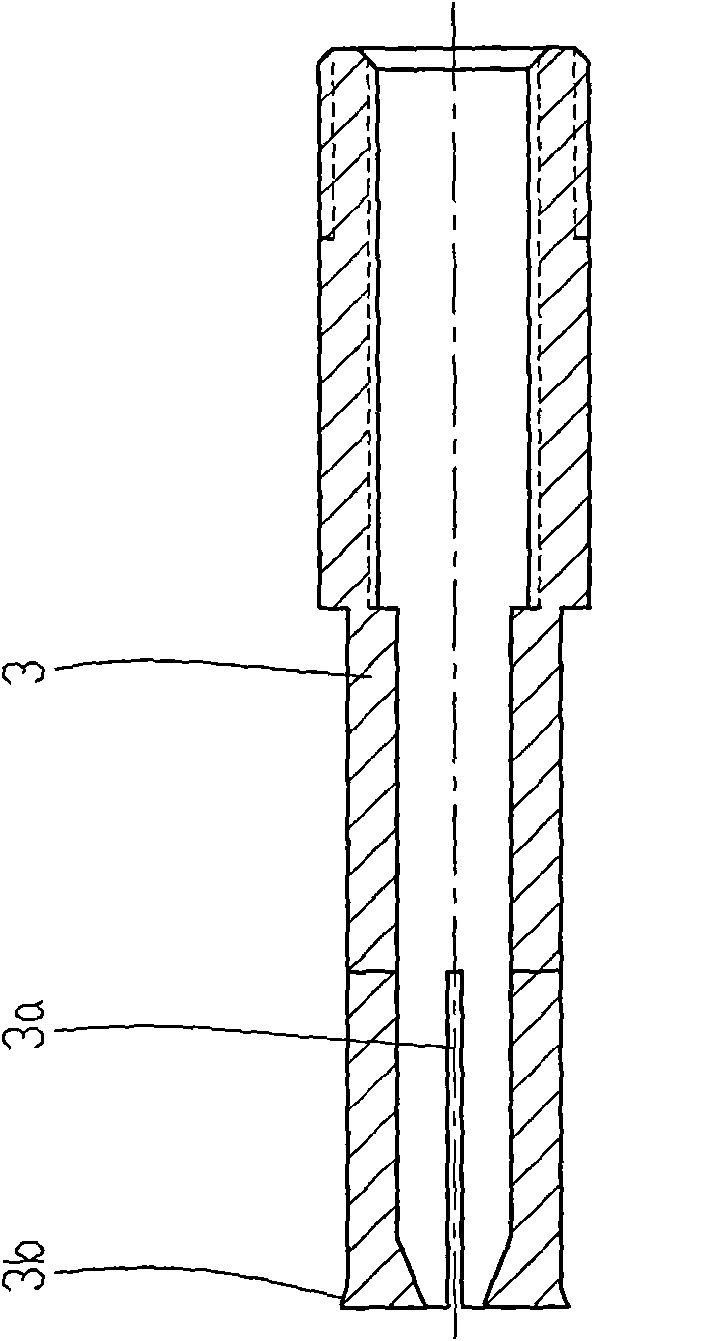

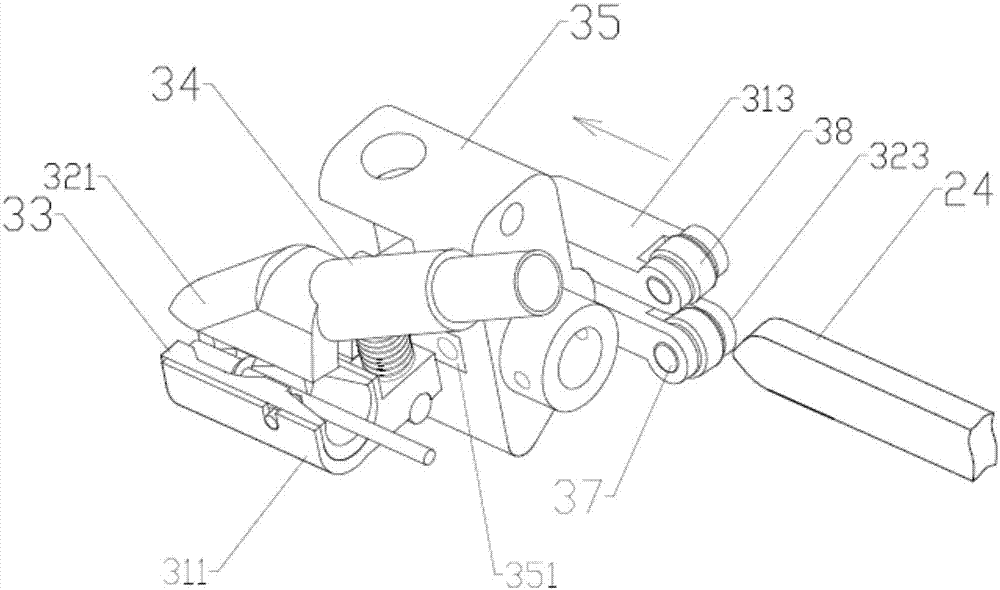

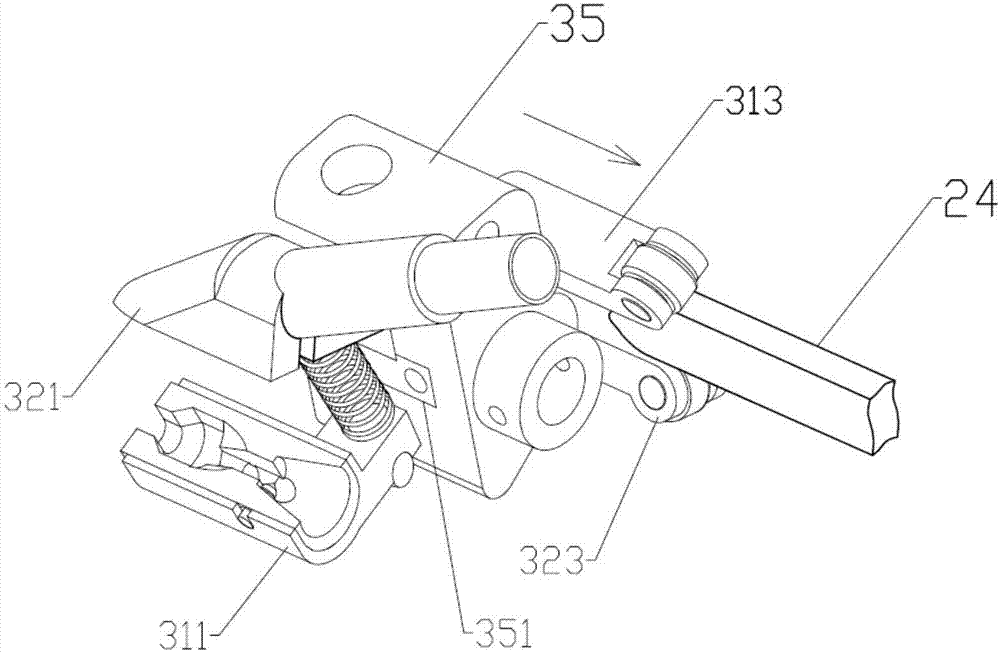

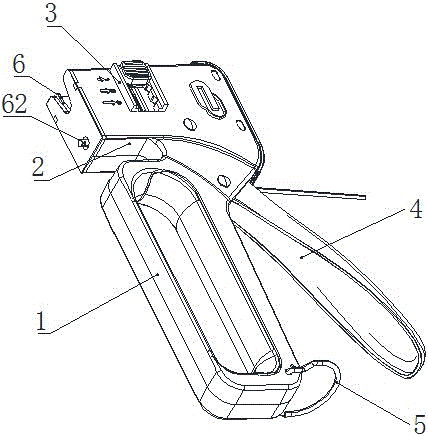

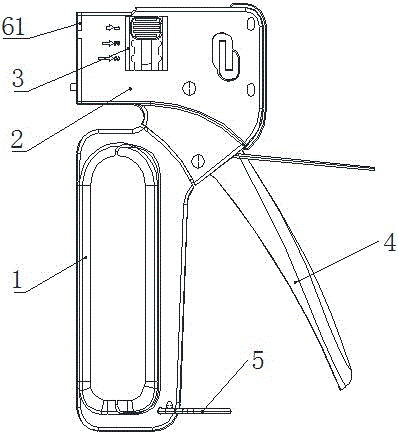

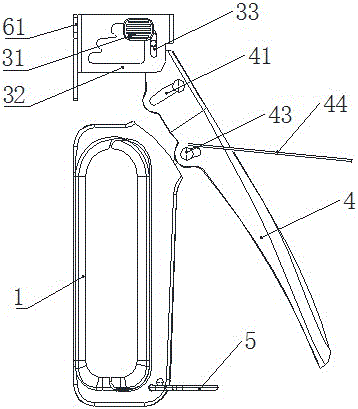

Small and skillful dual-handle hand riveter

The invention discloses to a small and skillful dual-handle hand riveter, which comprises a riveter seat, a rivet adjusting mechanism, a rivet gripping mechanism, two handles and a pull rod, wherein the rivet adjusting mechanism is arranged at the front end of the riveter seat, the rivet gripping mechanism is installed in the rivet adjusting mechanism, one end of one handle and one end of the other handle are respectively hinged with the two sides of the riveter seat, and the pull rod is movably inserted in the center hole of the riveter seat. The invention is characterized in that all or large part of the pull rod is provided with a rear part, and the pull rod, the fixing piece of a pull rod telescopic mechanism arranged at the end of the pull rod and connecting rods arranged on the two sides of the fixing piece and respectively hinged with the heads of the handles are arranged in the cavity of the riveter seat; and handle matching grooves are arranged on the two sides of the riveterseat. The invention has the advantages that since the length of the handles is shortened, all or large part of the pull rod is provided with the rear part, and the pull rod, the fixing piece of the pull rod telescopic mechanism arranged at the end of the pull rod and connecting rods arranged on the two sides of the fixing piece and respectively hinged with the heads of the handles are arranged inthe cavity of the riveter seat, the gripping force and the stability of the hand riveter are greatly improved, the appearance is tidier and cleaner, the use is handy and ingenious, and the carrying, the packaging and the transportation are convenient.

Owner:余姚市嘉合工具厂 +1

Riveting gun capable of throwing out the rivet core

The invention discloses a hand riveter capable of throwing away rivet cores. The hand riveter is used for easily taking out the rivet cores in a riveter head in the riveting process. The hand riveter comprises handles, supporting rods and the riveter head, pull sleeves connected with clamping jaw seats are arranged on the rear portion of the riveter head, through holes are formed in the middles of the rear ends of the pull sleeves, the rear ends of the pull sleeves are connected with a piston sleeve pipe, and a piston rod is arranged in the piston sleeve pipe. The front end of the piston rod penetrates through the through holes in the rear ends of the pull sleeves and then enters the space between the two clamping jaw seats. The end, connected with the pull sleeves, of the piston sleeve pipe is open, and the other end of the piston sleeve pipe is closed. A cylindrical piston rod cap is arranged at one end of the piston rod, and a piston rod pin thinner than the piston rod cap is arranged at the other end of the piston rod. The piston rod cap faces the sealed side of the piston sleeve pipe, and the piston rod pin stretches to the position, between the two clamping claw seats, in the riveter head. If the rivet cores are adhered to multi-tooth clamping jaws in the riveting operation process and clamped in the riveter head, an operator holds the handles and swings the riveter head, the piston rod pin slides into the riveter head, and the rivet cores adhered to the multi-tooth clamping jaws can be jacked out.

Owner:STATE GRID CORP OF CHINA +1

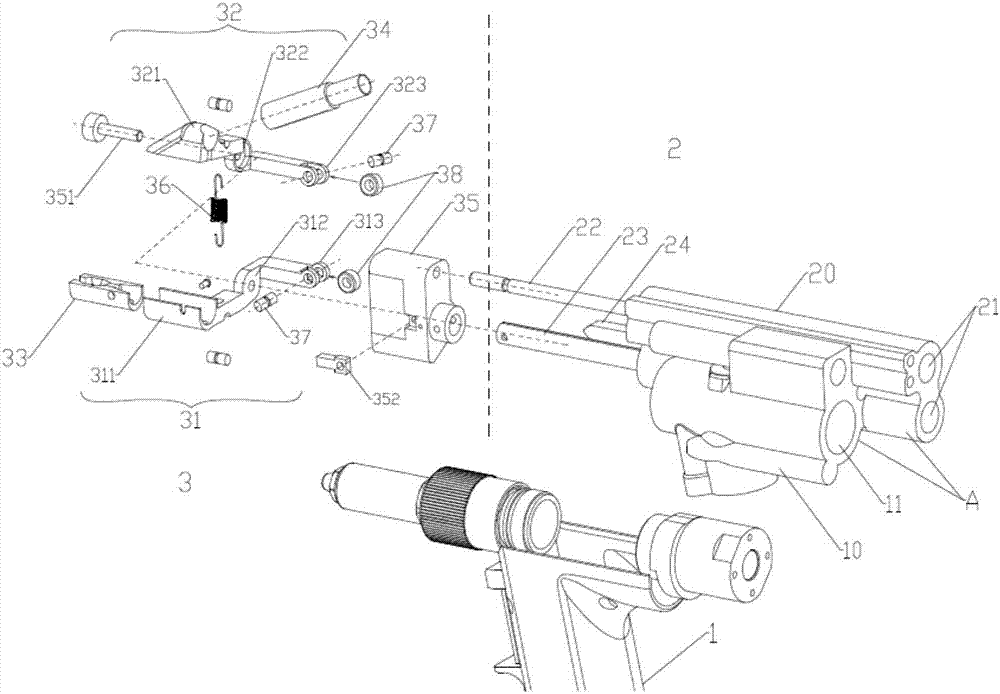

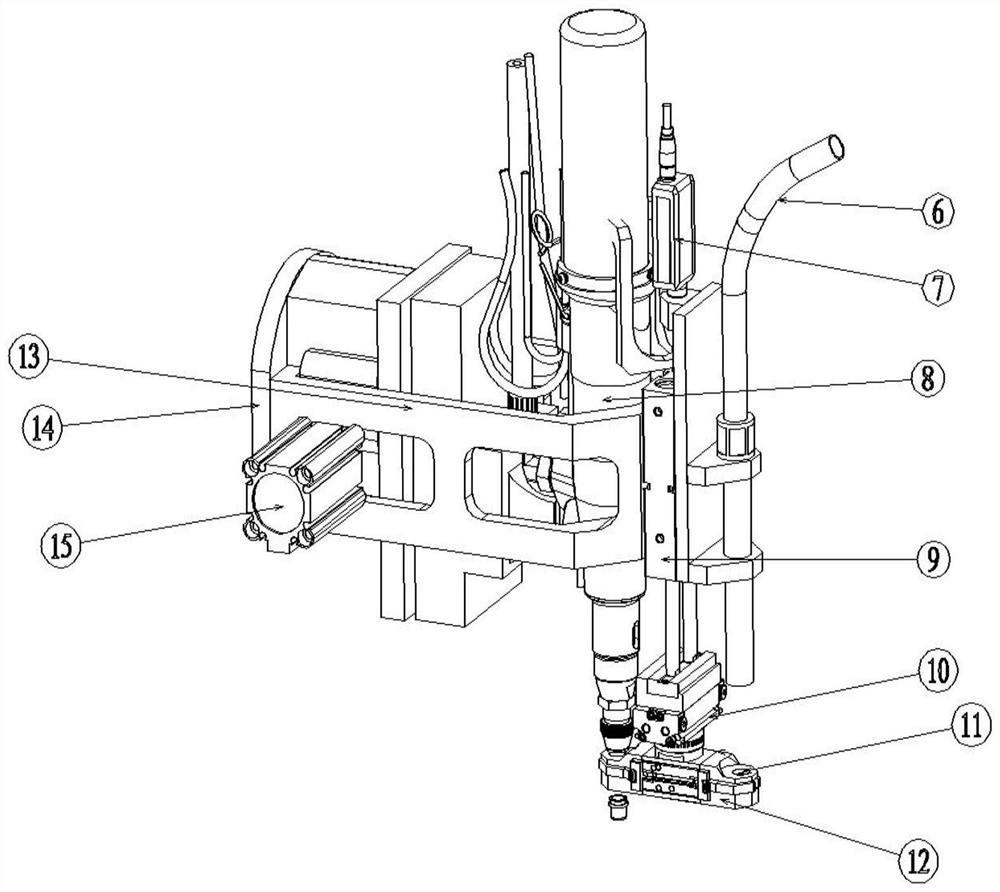

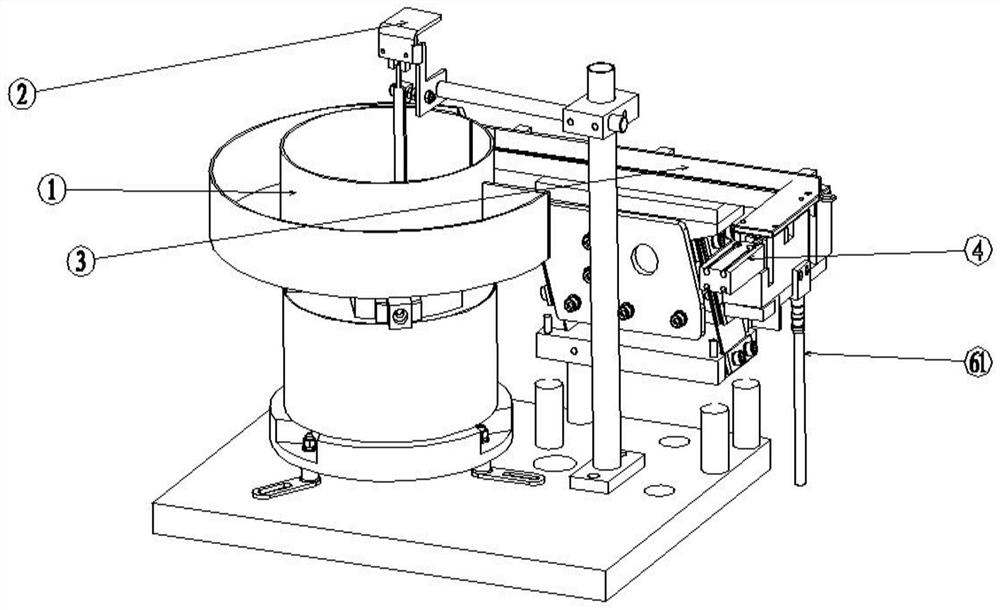

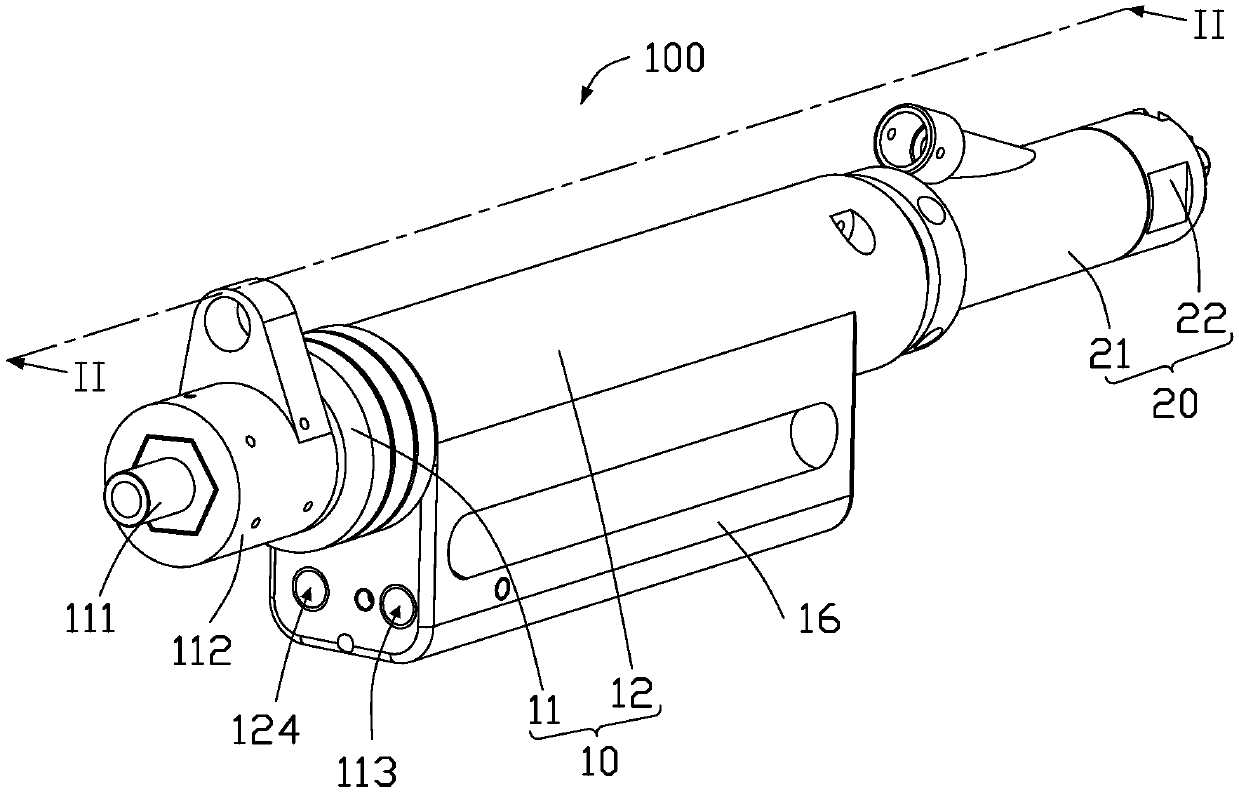

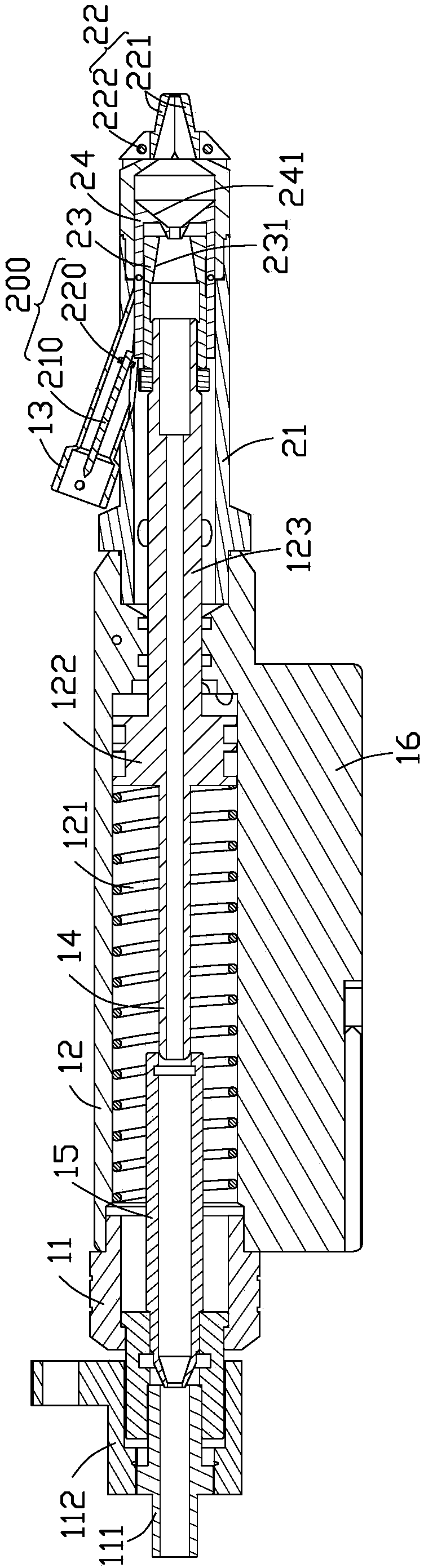

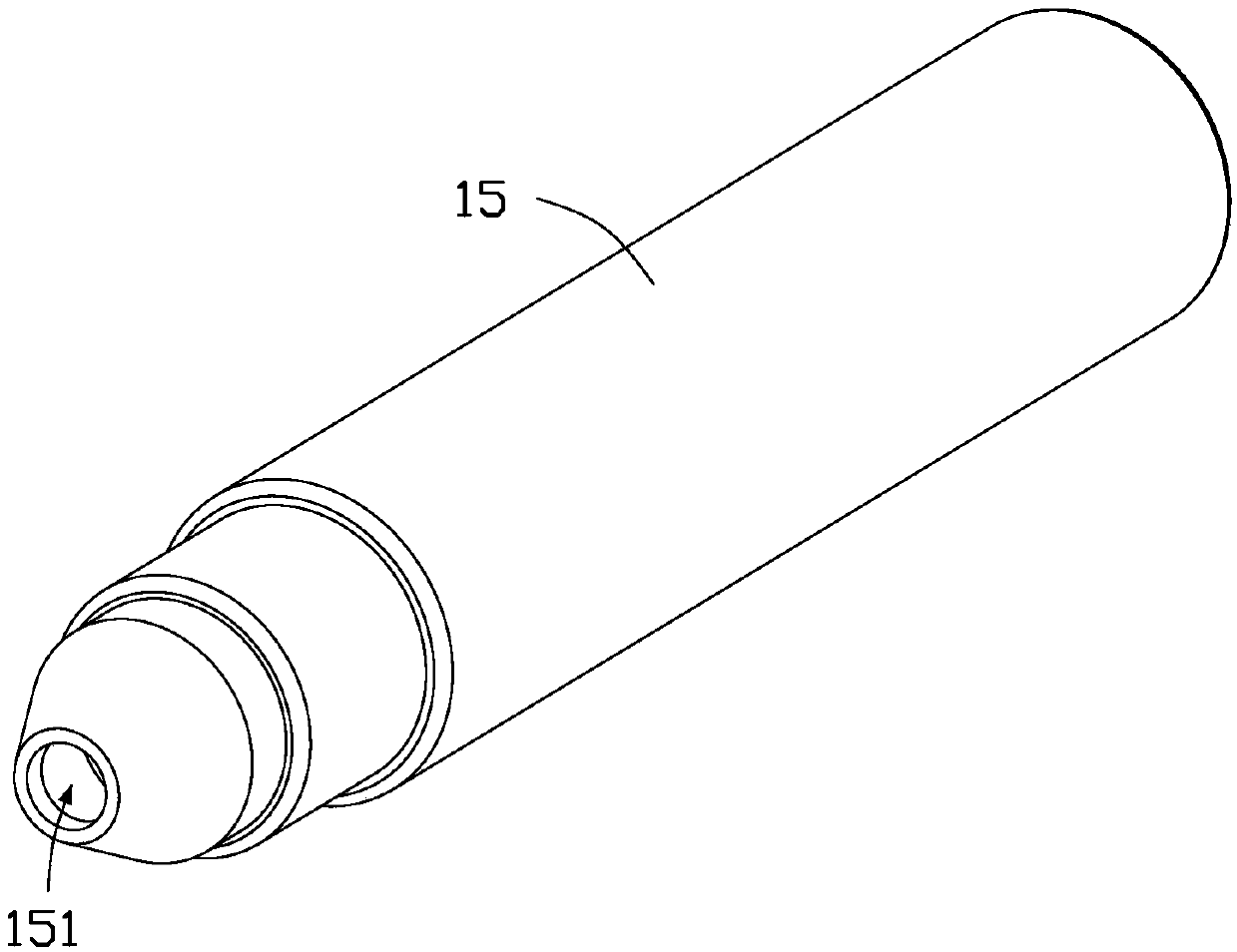

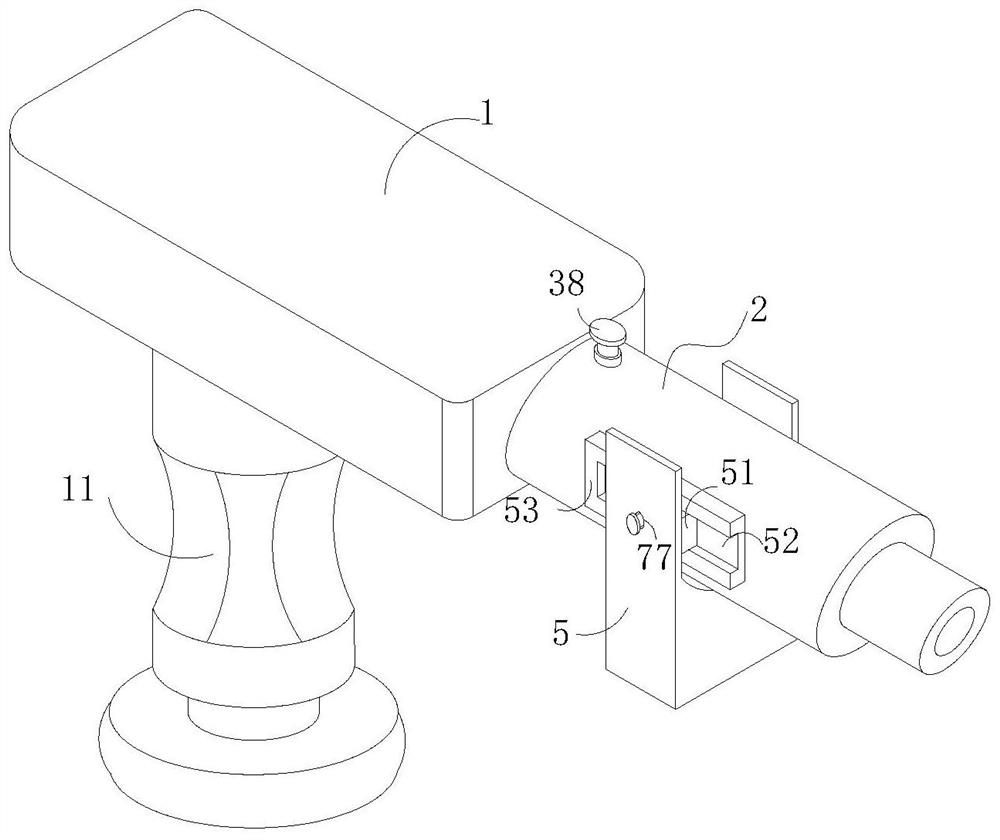

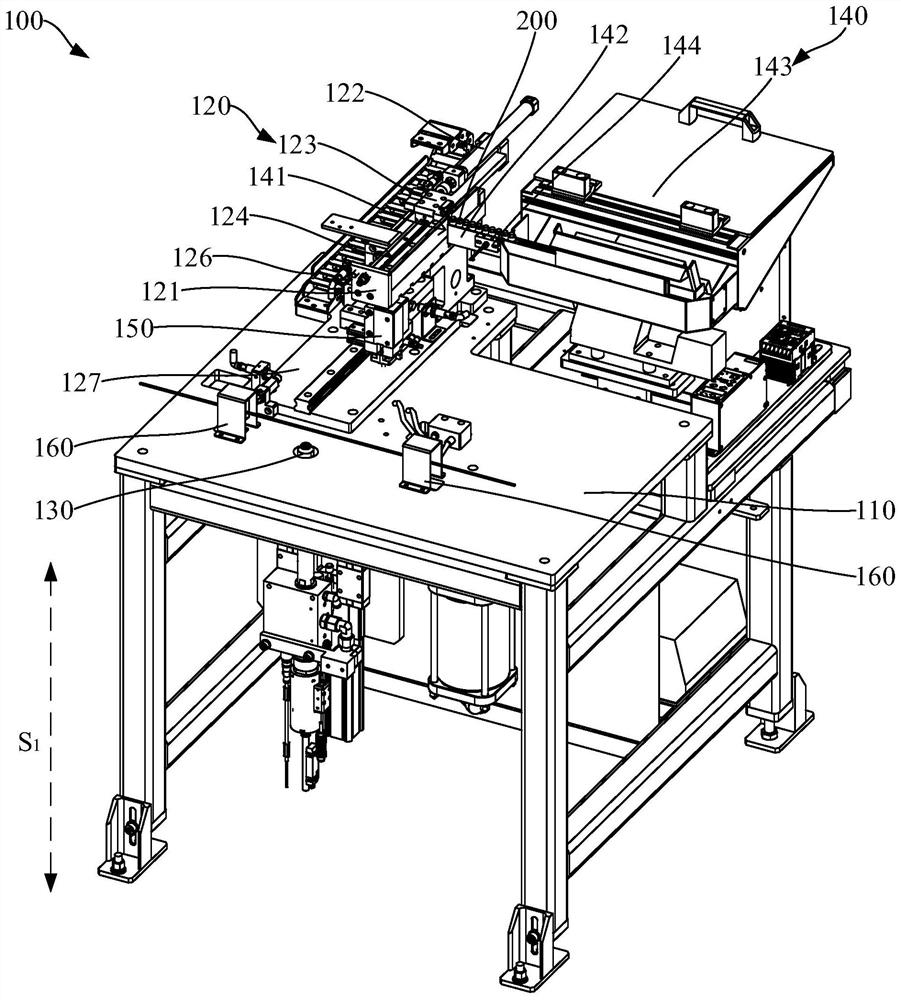

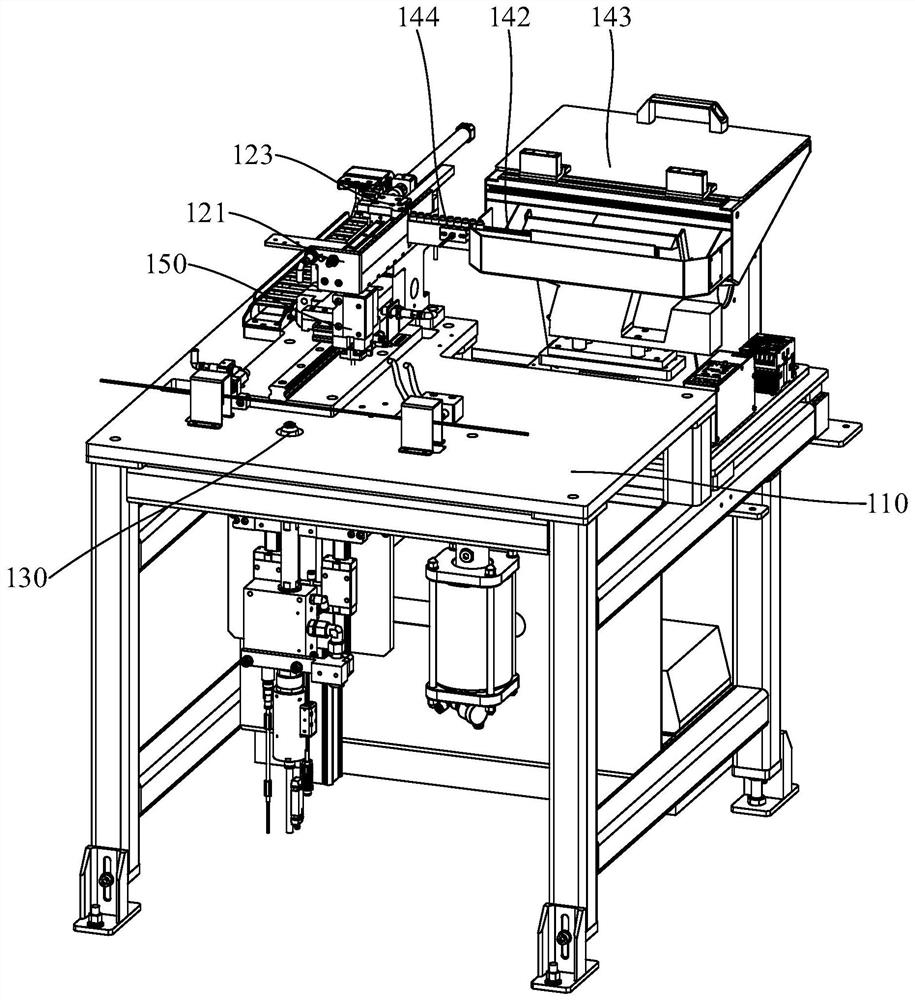

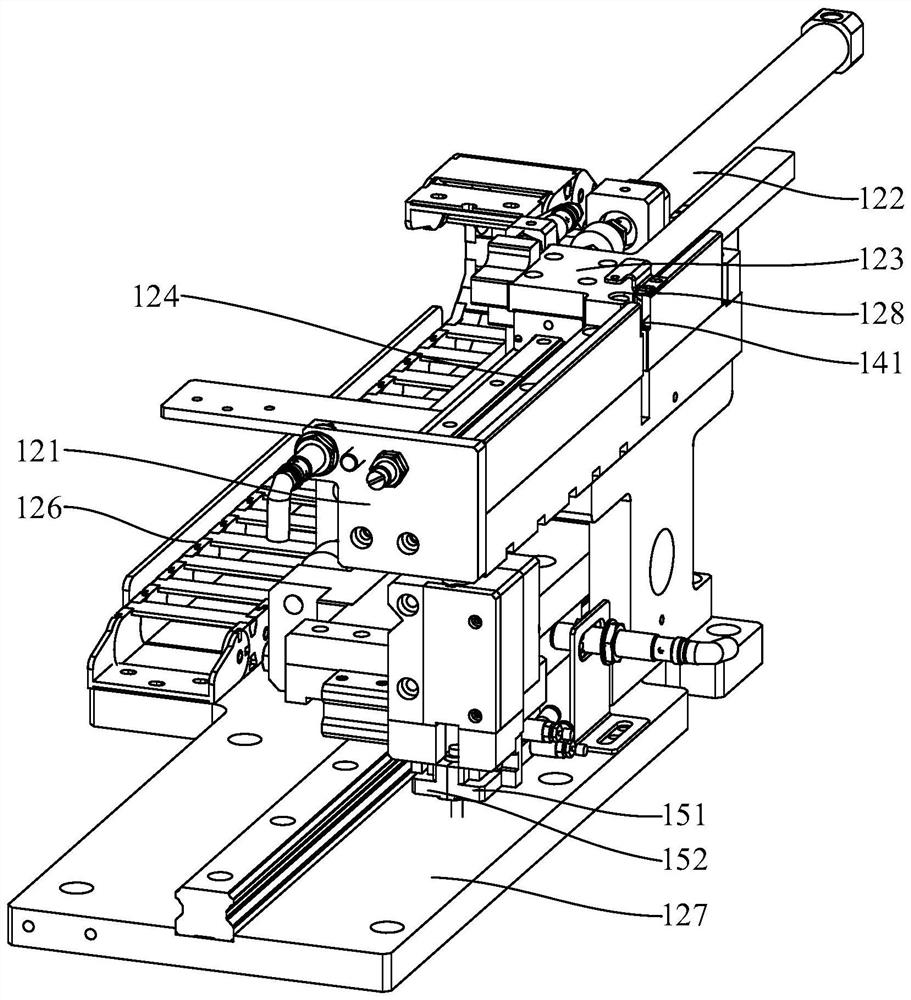

Automatic hand riveter and automatic hand riveting nut assembling machine

ActiveCN112475194AIncrease productivityImprove product qualityMetal working apparatusSoftware engineeringHand riveter

The invention discloses an automatic hand riveter and an automatic hand riveting nut assembling machine. The automatic hand riveter comprises a mounting rack, a feeding pipeline and a hand riveter body, the feeding pipeline extends in the vertical direction and is fixedly connected with the mounting rack, the hand riveter body extends in the vertical direction and is fixedly connected with the mounting rack, and the hand riveter further comprises a first structure and a second structure. The problems that the labor cost is high and the quality cannot be guaranteed through manual assembly can be solved.

Owner:南京睿维特紧固件设备有限公司

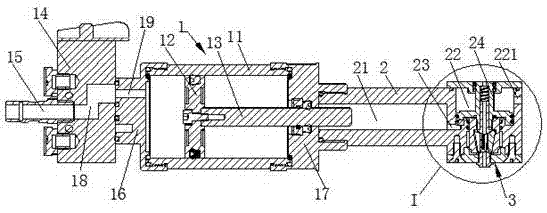

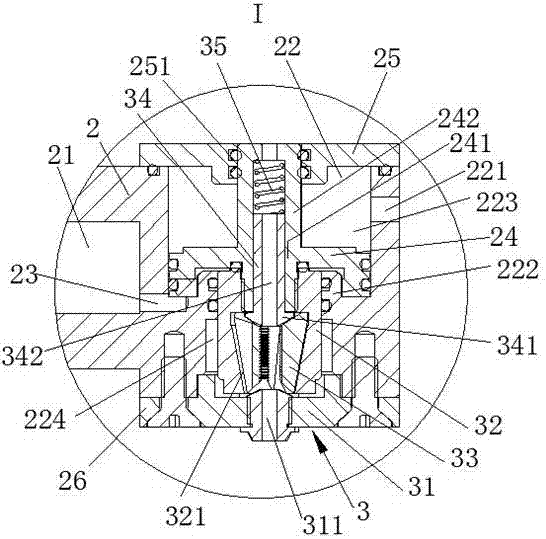

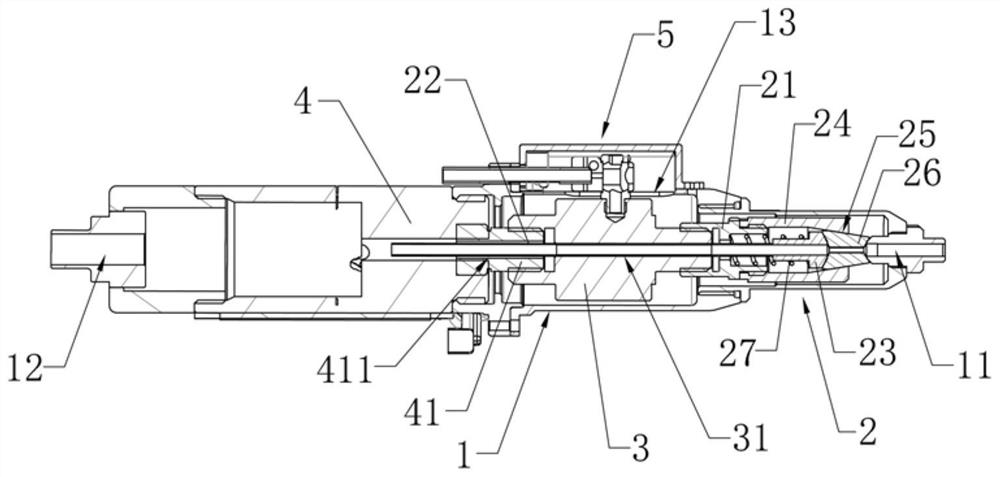

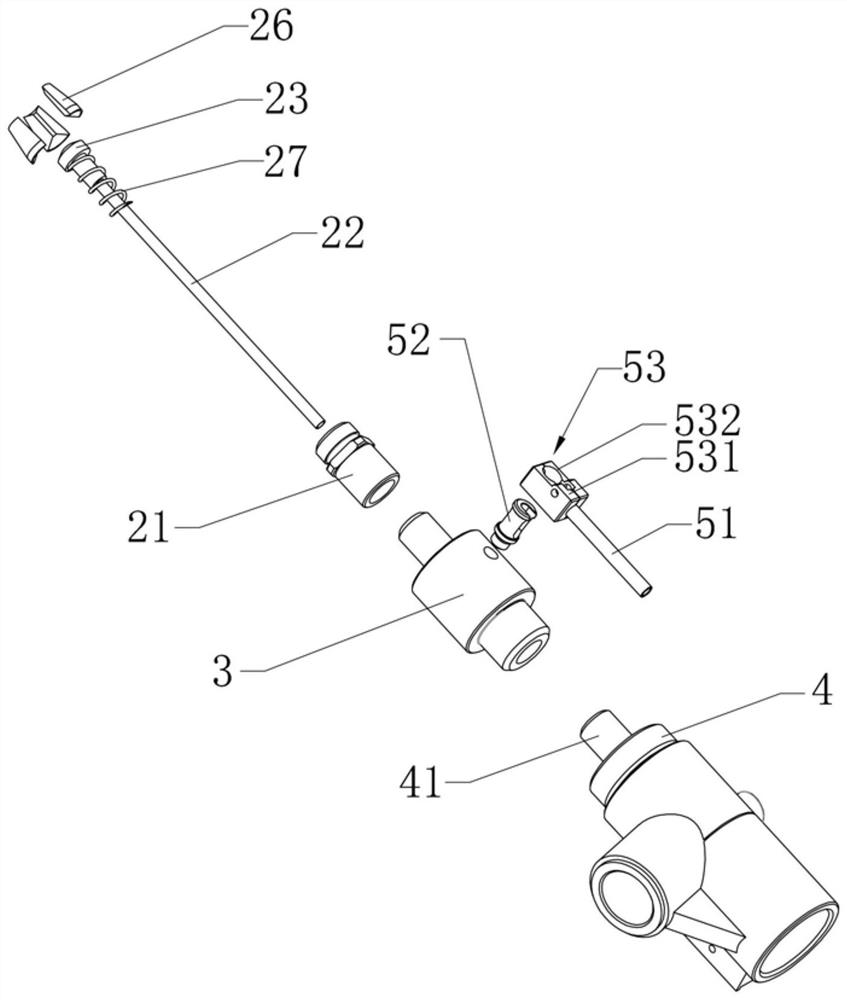

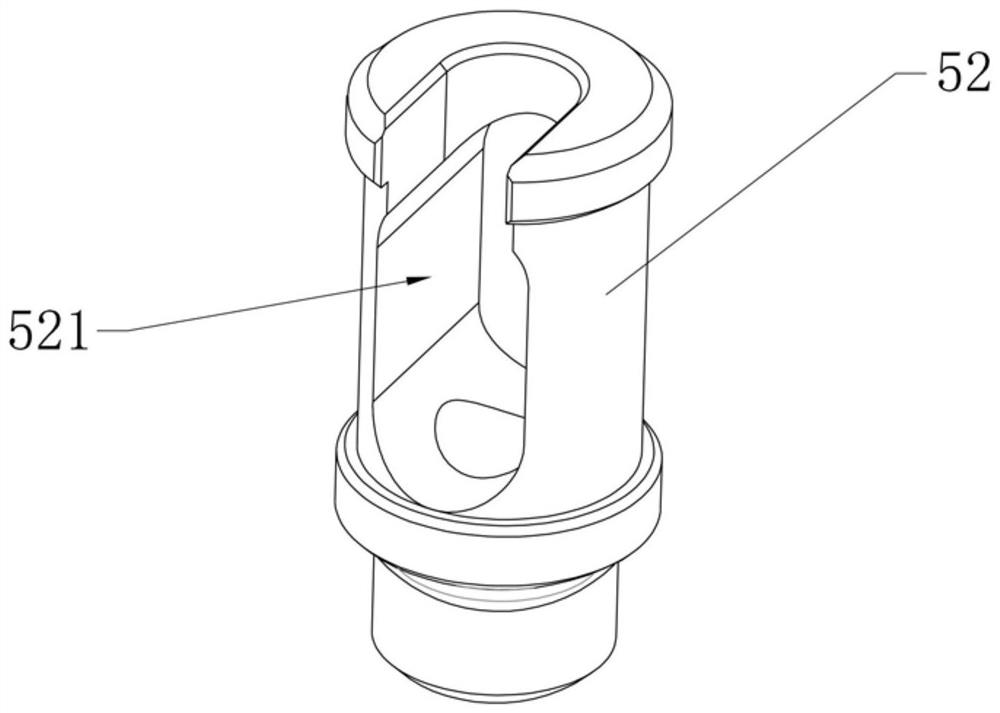

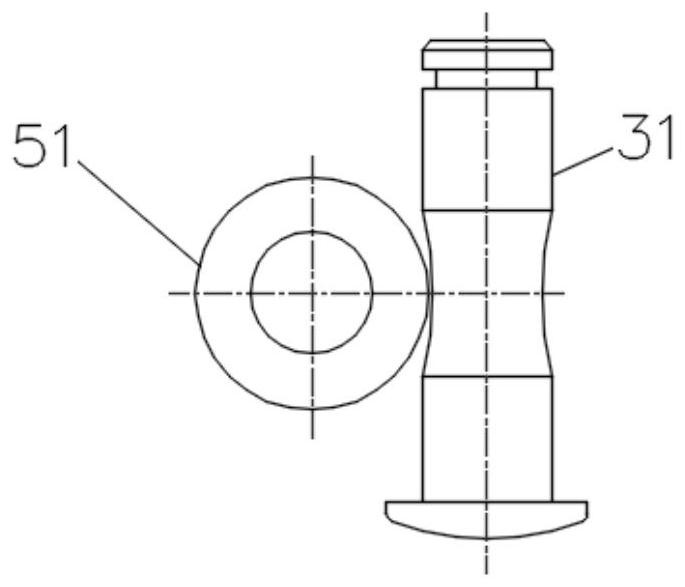

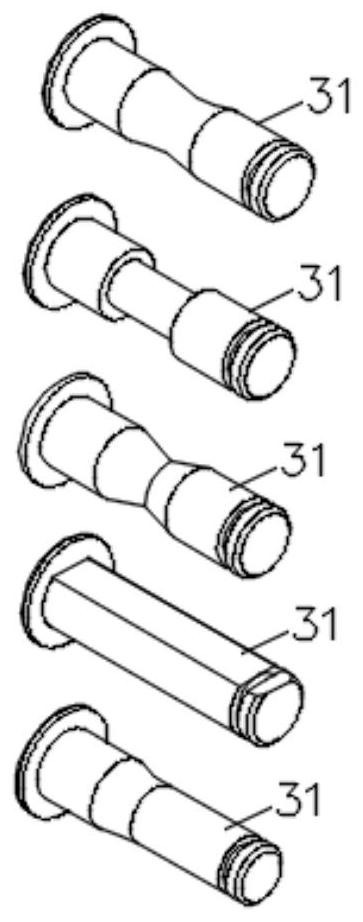

Hand riveter

The invention provides a hand riveter. The hand riveter comprises a gun body and a gun head. The gun body is axially provided with a negative-pressure air chamber and a hydraulic chamber which are incommunication. The gun head is detachably connected with the gun body and comprises a communication chamber communicating with the hydraulic chamber and a gun nozzle fixedly connected with the communication chamber. The side, close to the gun nozzle, in the communication chamber is coaxially provided with a clamping claw chamber. A conical top end is arranged on the clamping claw chamber, and a clamping claw part is formed by the conical top end and used for clamping a blind rivet. An elastic piece and a piston are arranged in the hydraulic chamber, one end of the elastic piece is connected with the negative-pressure air chamber, and the other end is connected with the piston. The clamping claw chamber is driven by the piston to axially move along the communication chamber. Since the automatic hand riveter is provided with the negative-pressure air chamber and the hydraulic chamber at the same time, under cooperation of the negative-pressure air chamber and the hydraulic chamber, automation of different stages such as rivet feeding, rivet pulling and rivet discharging of the hand riveter is achieved. The automatic hand riveter is high in riveting efficiency and speed; and manual blind rivet placement is not needed, rivet arranging and rivet feeding are finished at the same time, and accordingly the production efficiency is improved.

Owner:NANNING FUGUI PRECISION IND CO LTD

Pneumatic hand riveter

The invention relates to the field of hand riveters, in particular to a pneumatic hand riveter. The pneumatic hand riveter comprises a handle, a body and a riveter head, an external air pump is installed at one end of the body, a control element box is fixed to one side of the external air pump, and a circuit board for part control is installed in the control element box. A plurality of control buttons electrically connected with the circuit board are arranged on the outer wall of the control element box. The pneumatic hand riveter can solve the problems that due to the fact that the diameterof a rivet inlet hole in a riveter head of an existing pneumatic hand riveter is fixed, one pneumatic hand riveter can only be matched with rivets of one specification for use, meanwhile, when the existing pneumatic hand riveter works, the function of automatically discharging rivet rods of the rivets out of the riveter head after one-time riveting of the rivets is completed is not achieved, the rivet locking phenomenon is prone to appearing, due to the fact that the interior of the rivet inlet hole in the riveter head of the pneumatic hand riveter is lack of a cleaning component, the pneumatic hand riveter is extremely prone to being blocked during ash entering, and use is affected.

Owner:东莞市毅帆五金模具有限公司

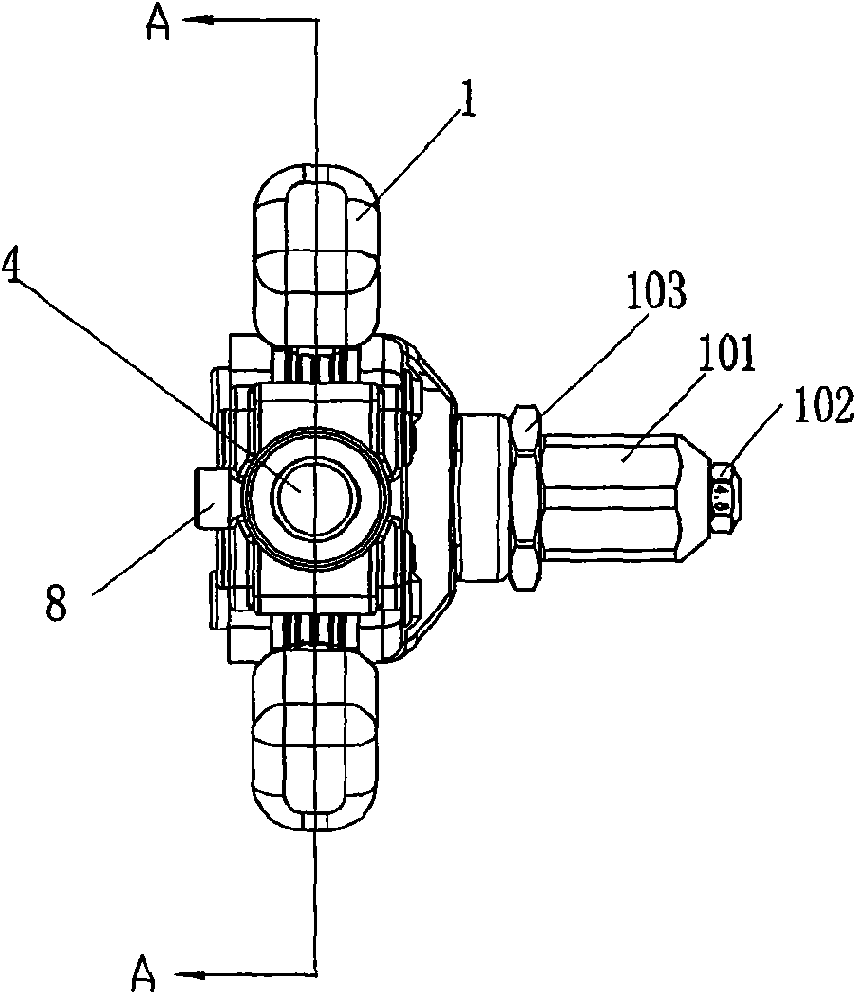

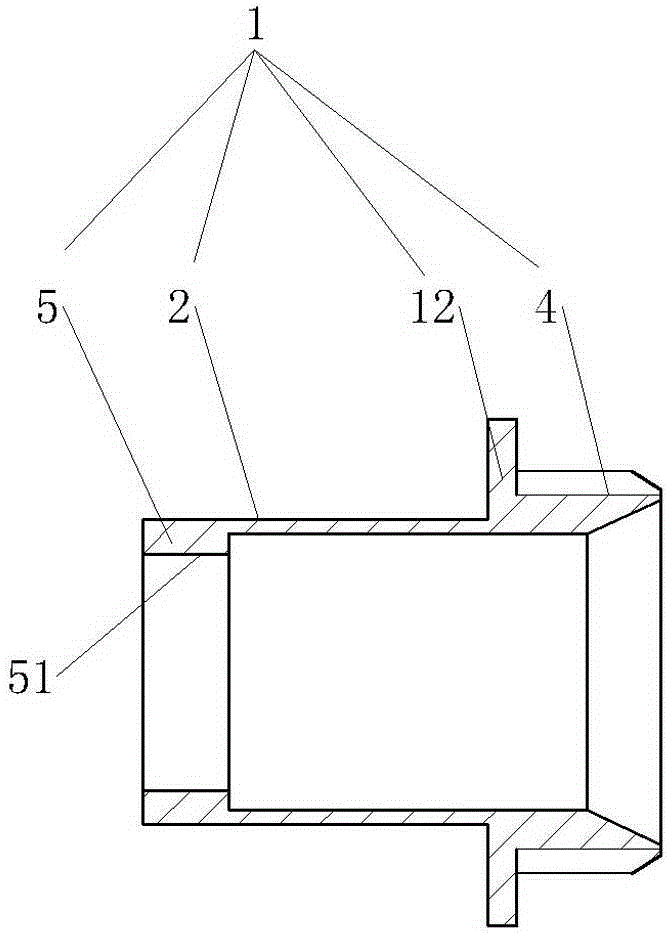

Rivet nut, method for processing waterproof joint on processed lamp shell and pressing block used in method

ActiveCN105156447ASmall caliberShorten the lengthElectric circuit arrangementsNutsHand riveterLamp shell

The invention discloses a method for processing a waterproof joint on a processed lamp shell, which comprises the following steps: 1. arranging a through hole in the shell; 2. inserting a deformation part of the rivet nut into the through hole; 3. enabling a hand riveter to be inserted into an inner hole in the rivet nut from one end of a threaded connection part and to penetrate through one end of the deformation part, and fixedly connecting the pressing block to the end part of the hand riveter; 4. starting the hand riveter to pull the pressing block backwards so as to promote the pressing block to compact the deformation part, so that the deformation part bulges outwards to clamp the shell around the through hole between the bulge and the rivet nut compaction disk; and 5. mounting other waterproof components. The invention also discloses a rivet nut and a pressing block adopted in the method. By using the method and device, the rivet nut can have smaller caliber and smaller length, can have larger internal diameter than the traditional rivet nut under the condition of the same external diameter, and can penetrate through more wires, so that the lamp shell is more beautiful.

Owner:ZHEJIANG RRR OPTOELECTRONICS TECH

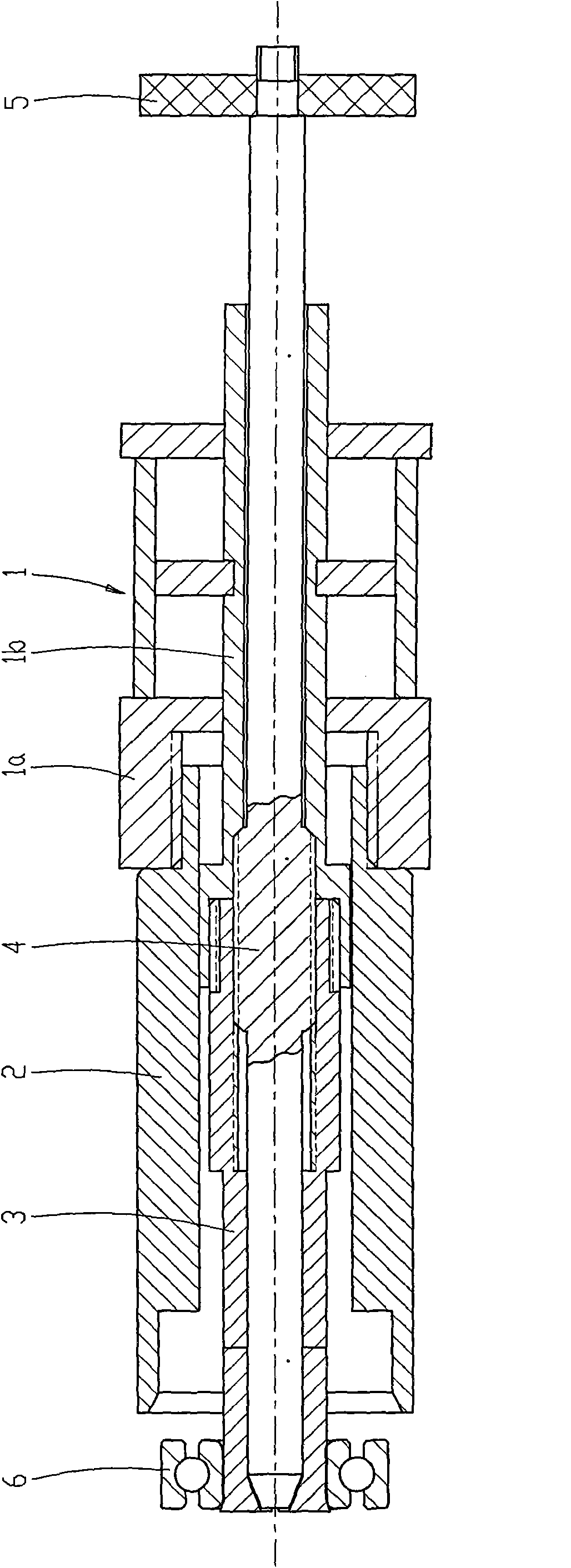

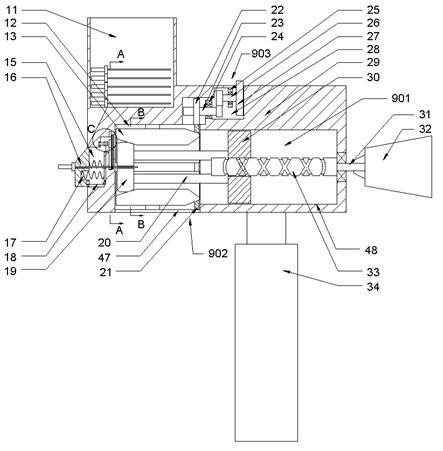

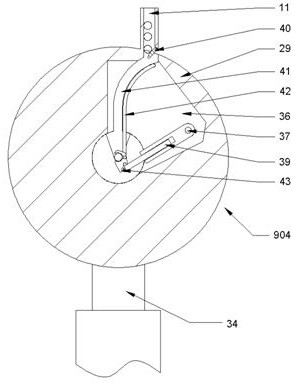

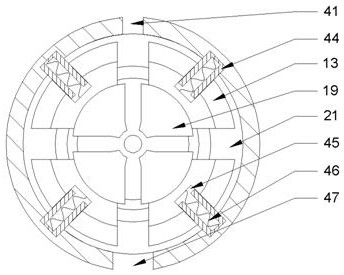

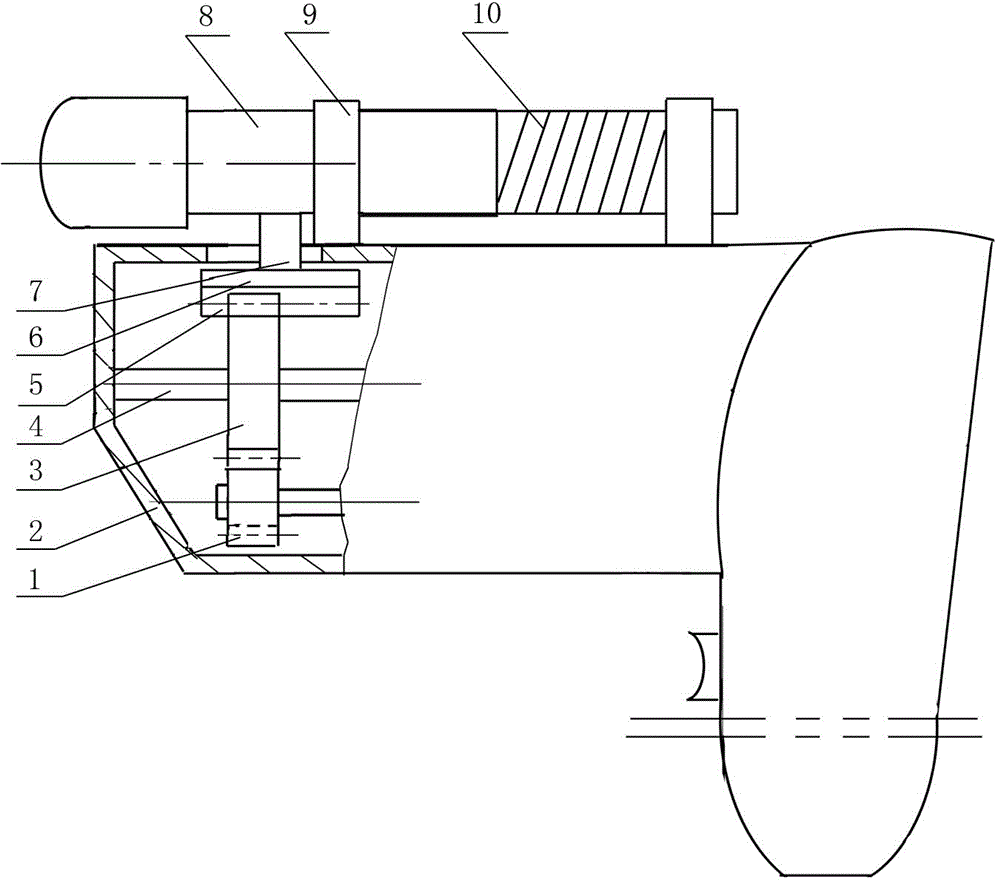

Ultrashort-head pneumatic hand riveter

The invention relates to an ultrashort-head pneumatic hand riveter. The ultrashort-head pneumatic hand riveter comprises an air cylinder, an oil cylinder body and a hand riveter head, wherein the air cylinder comprises an air cylinder body, an air cylinder piston and a piston ejection rod, the hand riveter head comprises a rivet head seat, an oil cylinder piston push rod, at least three tapered clamping jaws, a reset push rod and a reset spring, the oil cylinder piston push rod is fixedly connected with an oil cylinder piston, a tapered containing cavity which is used for containing the clamping jaws is formed in the oil cylinder piston push rod, the clamping jaws are located in the tapered containing cavity, the inner wall of the tapered containing cavity is an inclined plane and is matched with the tapered outer side surfaces of the clamping jaws, a piston hole is formed in the oil cylinder piston, the reset spring is located in the piston hole, one end of the reset push rod extends into the piston hole and is abutted with the reset spring, the other end of the reset push rod extends into the tapered containing cavity, the clamping jaws can be driven to separate by virtue of the extension of the reset push rod, the rivet head seat is fixed to a radial mounting hole, a rivet stem extension hole is formed in the rivet head seat, and the rivet stem extension hole communicates with the tapered containing cavity. The hand riveter has the advantage of compact structure of the rivet head and can be applied in areas with small riveting space.

Owner:CHANGZHOU HUBOLA JINCHUANG TRAFFIC EQUIP

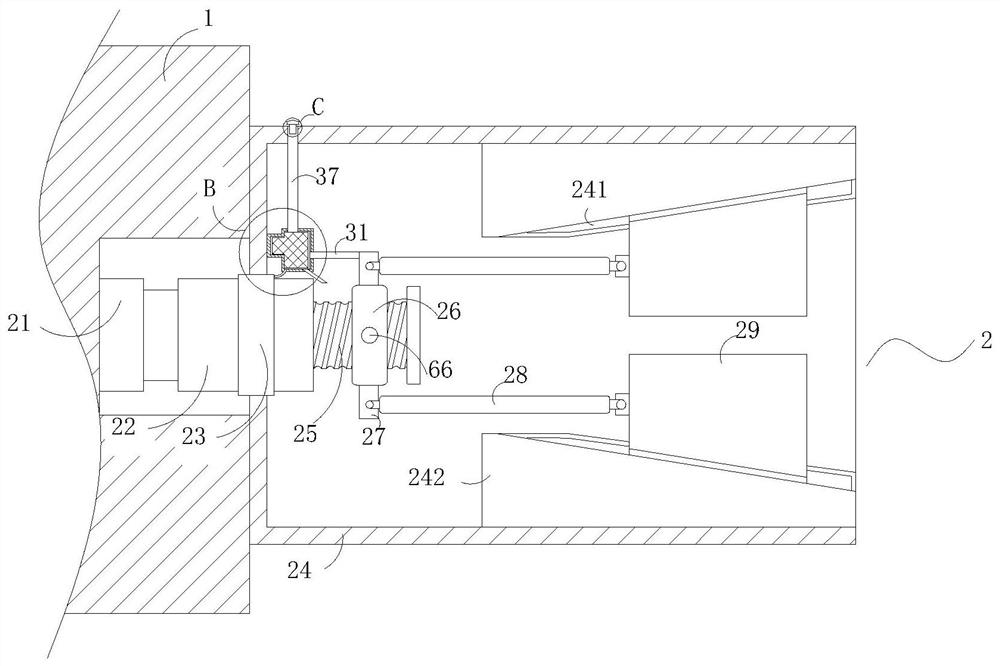

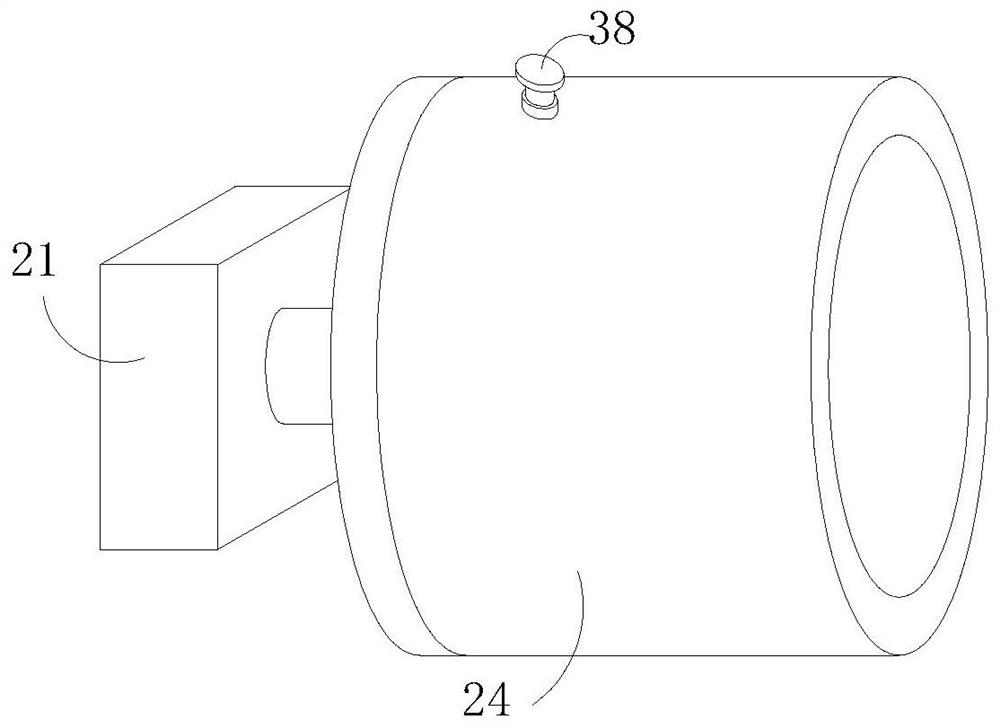

Hand riveter device connected with manual drill and capable of automatically loading rivets

InactiveCN112775386AFree from manual replacementFast riveting workReciprocating motionClassical mechanics

The invention relates to the technical field of rivets, in particular to a hand riveter device connected with a manual drill and capable of automatically loading rivets. According to the hand riveter device connected with the manual drill and capable of automatically loading the rivets, the defects that tools carried by existing rivet pulling operation are various, the number of times of replacing the tools in construction of workers is increased, labor hours are wasted, the workers need to repeatedly load the rivets by themselves in the using process, the labor intensity of the workers is increased, and therefore continuous, fast and efficient rivet pulling operation can not be achieved are overcome. The hand riveter device connected with the manual drill and capable of automatically loading the rivets comprises a rivet pulling gun, wherein a reciprocating device capable of doing reciprocating motion is arranged on the rivet pulling gun, a clamping device for pulling a rivet core is arranged on the left side of the reciprocating device, a rivet installing device for automatically installing rivets is arranged on the right side of the clamping device, the rivet installing device further comprises a rivet taking claw, and a rotating rod is hinged to the rivet taking claw.

Owner:义乌市培致贸易有限公司

Direct-current electric hand riveter

PendingCN113618013ATighten and clamp wellGood riveting effectEngine lubricationCurrent electricReciprocating motion

The invention relates to the technical field of hand riveters, in particular to a direct-current electric hand riveter. The direct-current electric hand riveter comprises a riveter body, a handheld part is fixedly connected to the bottom of the riveter body, a rivet pulling mechanism is fixedly connected to the right end of the riveter body, a lubricating assembly and a fixing hole are sequentially arranged in the rivet pulling mechanism from left to right, a waste core clamp is movably connected to the lower portion of the rivet pulling mechanism, an anti-clamping assembly is arranged between the rivet pulling mechanism and the waste core clamp, the anti-clamping assembly is arranged at the bottom of the rivet pulling mechanism, a clamping assembly is arranged at the movable joint of the rivet pulling mechanism and the waste core clamp, a motor rotates forwards and backwards once to drive a screw cylinder to reciprocate leftwards and rightwards once, so that a transmission rod pulls a riveting block to move leftwards and rightwards once. Due to the inclined arrangement of a T-shaped groove, when the two groups of riveting blocks move leftwards, the distance is reduced, so that a rivet is clamped and continuously pulled to move, a core rod of the rivet drives a rivet head to expand so as to plug a hole, meanwhile, the thinnest part of the core rod of the rivet is necked so as to be snapped, so that the rivet pulling action is completed.

Owner:刘海林

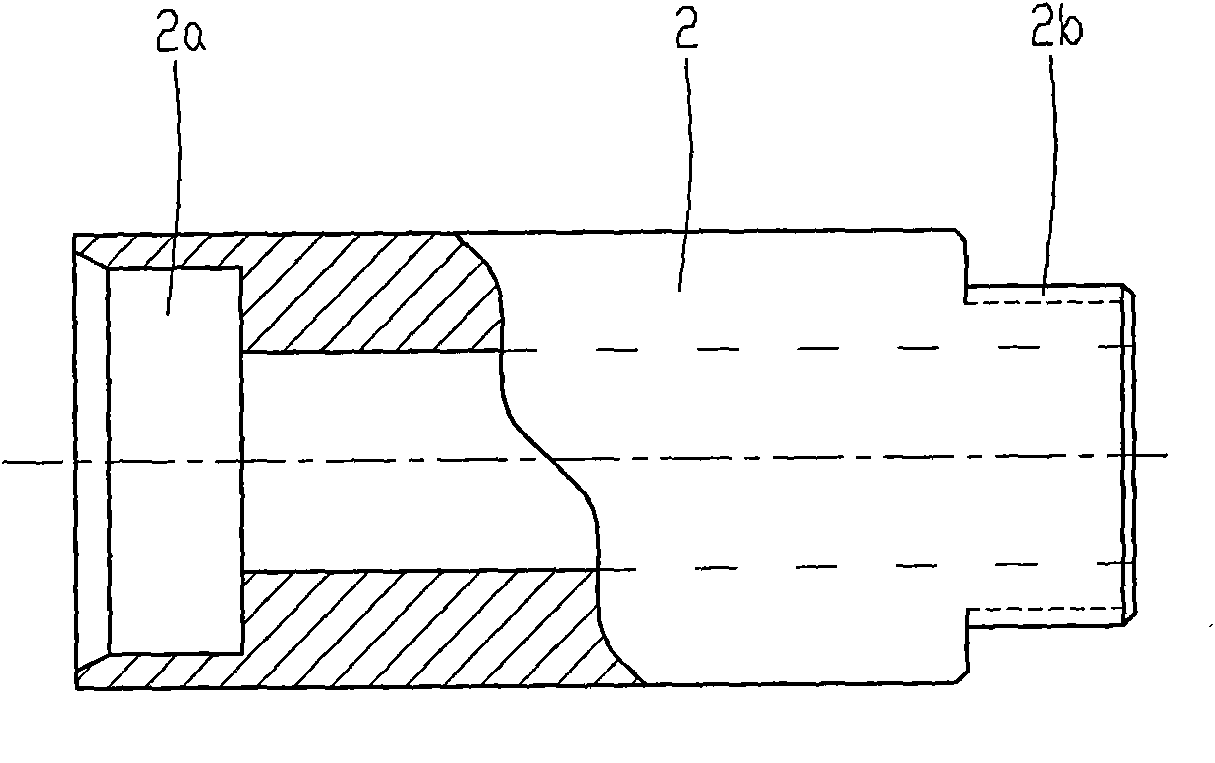

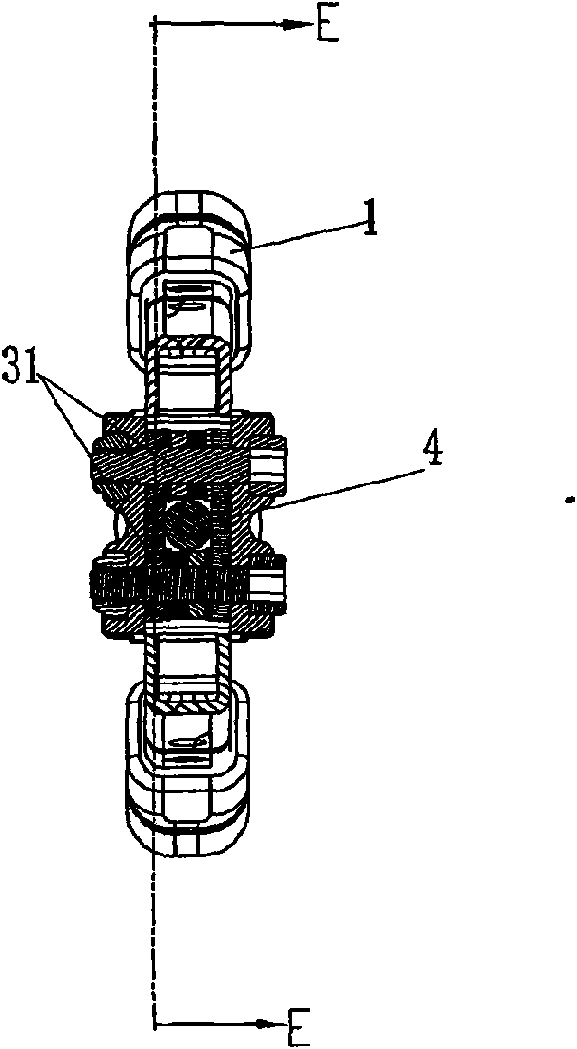

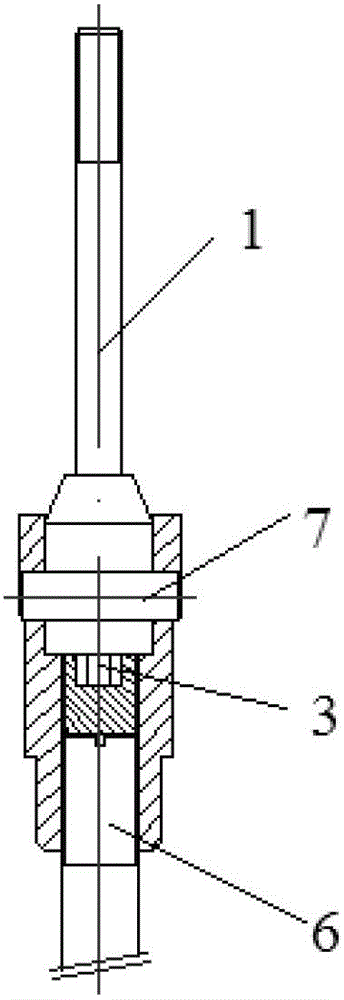

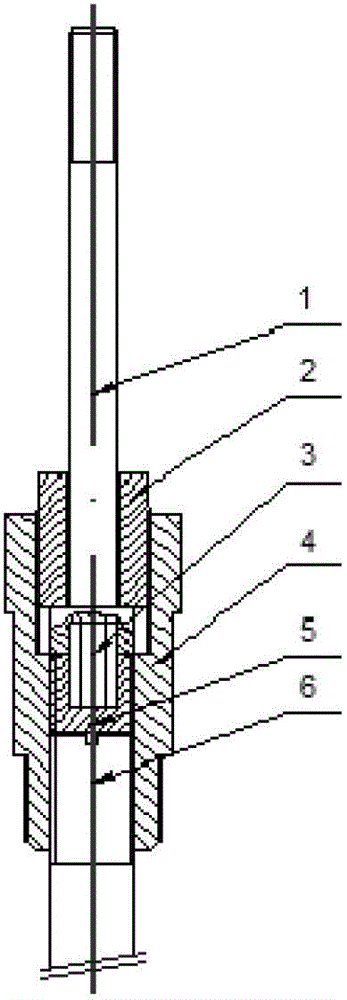

Coupler for hand riveter

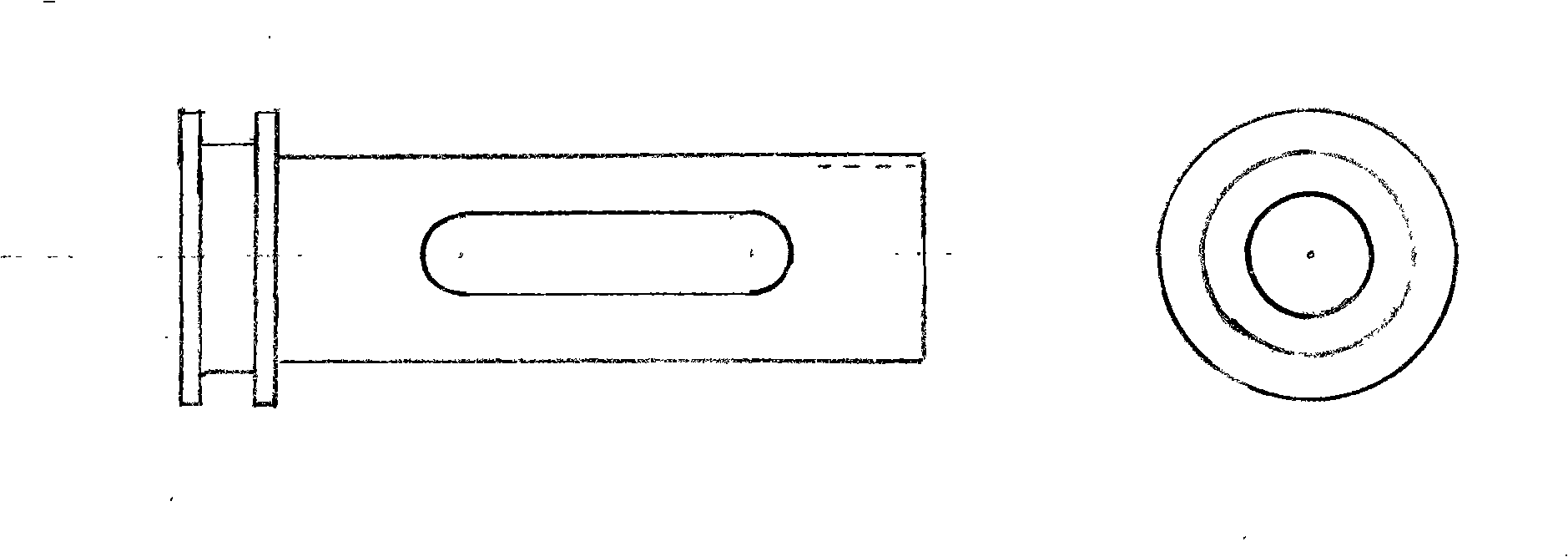

InactiveCN104028690AQuality improvementReduce breakageCouplings for rigid shaftsHand riveterEngineering

The invention relates to a coupler for a hand riveter. The coupler for the hand riveter comprises a rivet pulling head, a connecting shaft, a connecting shaft sleeve and an output shaft, and further comprises a rivet pulling head pressing block and a head supporting screw, wherein the connecting shaft sleeve is arranged on the output shaft, the head supporting screw is arranged on the connecting shaft sleeve and abuts against the output shaft, the connecting shaft is connected with the rivet pulling head and the heat supporting screw respectively, and the rivet pulling head pressing block presses the rivet pulling head. Compared with the prior art, the coupler for the hand riveter has the advantages of being reliable in quality, low in cost, convenient to maintain and the like.

Owner:SHANGHAI ANDELAI AUTO PARTS

Hand riveter

Owner:ZHEJIANG EXCELLENT IND

Hand riveter with tension detection function

The invention relates to the technical field of automatic riveting guns, in particular to a hand riveter with a tension detection function, the hand riveter comprises a riveter body, a rivet clamping mechanism, a tension detector and a driving mechanism, one end of the riveter body is provided with a muzzle, and the rivet clamping mechanism, the tension detector and the driving mechanism are sequentially arranged in the direction, away from the muzzle, of the riveter body; the driving mechanism is provided with a telescopic rod, one end of the tension detector is connected with the nail clamping mechanism, and the other end of the tension detector is connected with the telescopic rod; and a nail feeding through hole is formed in the middle of the tension detector. The hand riveter is simple and compact in structural design, tension monitoring can be achieved through the hand riveter, tension monitoring is accurate and instant, an operator can conveniently control tension within a reasonable range, and therefore the riveting quality and efficiency are improved.

Owner:DONGGUAN SWIFT AUTOMATION EQUIP CO LTD

Hand riveter

The invention discloses a hand riveter, and relates to the field of manual tools. The riveter comprises a first handle, a second handle and a clamping and snapping mechanism, wherein the second handlecan rotate relative to the first handle around a pivot shaft, the second handle is separated by the pivot shaft into a force applying end and a warping end, and the warping end is connected to the clamping and snapping mechanism through a connecting shaft; when the force applying end of the second handle is rotated and opened relative to the first handle, the warping end of the second handle drives the clamping and snapping mechanism to move in a rivet feeding direction; and when the force applying end of the second handle is rotated and closed relative to the first handle, the warping end ofthe second handle drives the clamping and snapping mechanism to move in a pull riveting direction. By means of the reasonable arrangement, the hand riveter is labor-saving and comfortable in holding.

Owner:HANGZHOU UNITED TOOLS CO LTD +1

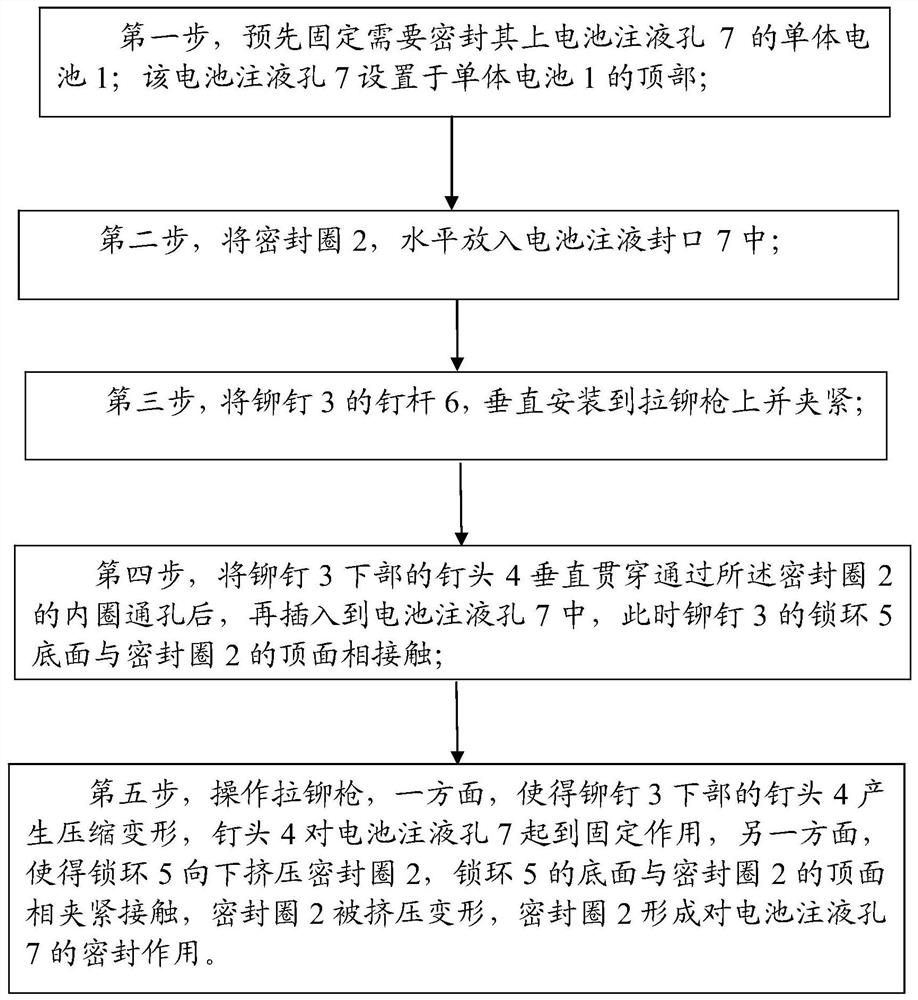

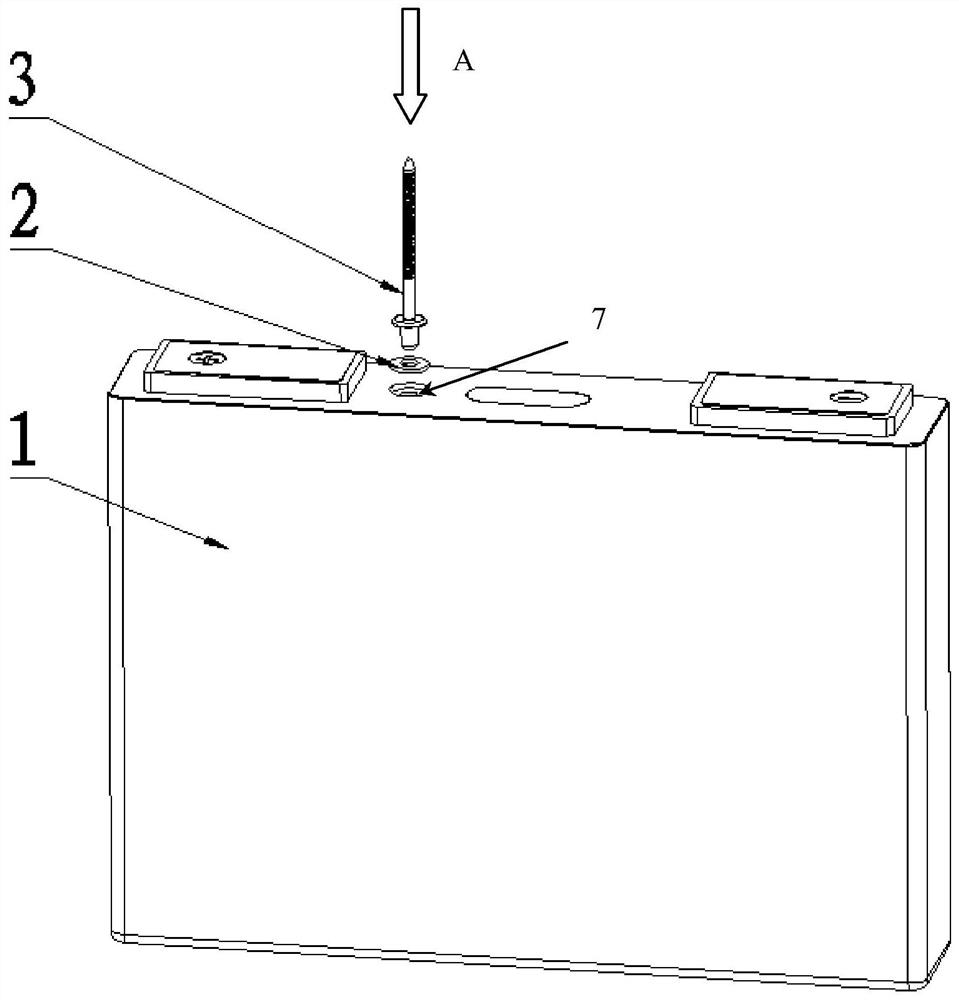

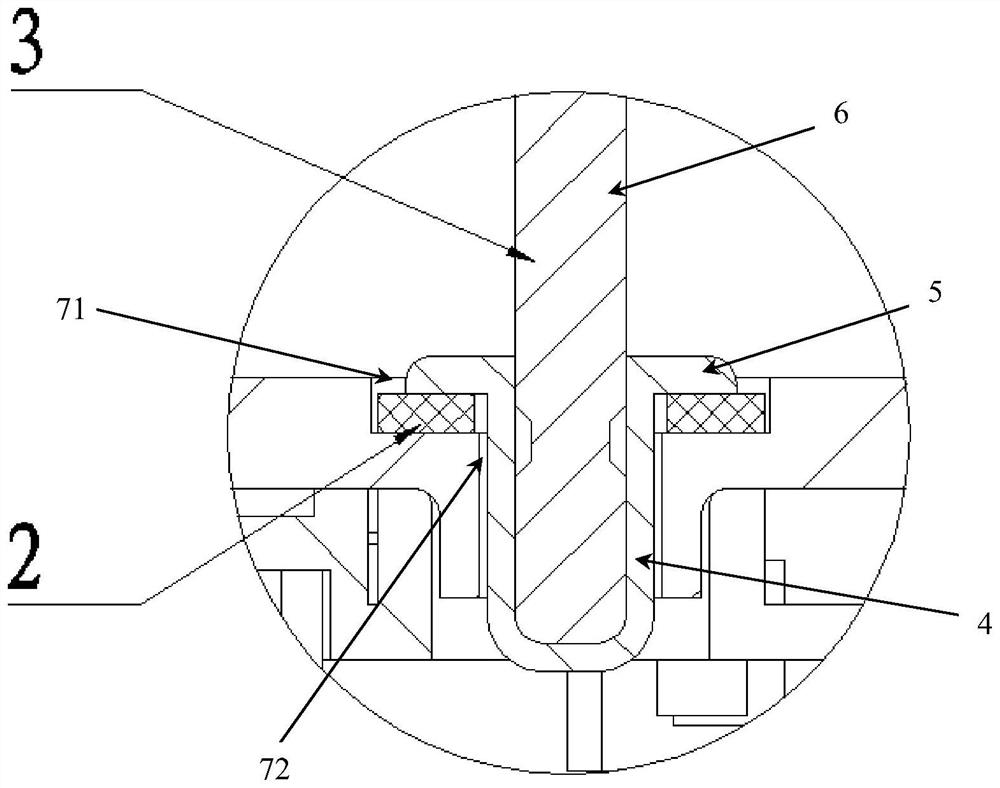

Rivet-pulling sealing method for lithium battery liquid injection seal

PendingCN113793974AReduce variablesGuaranteed tightnessFinal product manufactureCell component detailsHand riveterEngineering

The invention discloses a rivet-pulling sealing method for a lithium battery liquid injection seal. The method comprises the following steps: 1, fixing a single battery of which a battery liquid injection hole needs to be sealed in advance, wherein the battery liquid injection hole is formed in the top of the single battery; 2, horizontally putting a sealing ring into the battery liquid injection seal; 3, vertically installing the rivet rod of a rivet on a hand riveter, and clamping; 4, enabling a rivet head on the lower portion of the rivet to vertically penetrate through the inner ring through hole of the sealing ring, and then inserting the rivet head into the battery liquid injection hole to make the bottom face of a locking ring of the rivet in contact with the top face of the sealing ring; and 5, operating the hand riveter, so as to make the nail head fix the battery liquid injection hole, and make the sealing ring seal the battery liquid injection hole. The sealing process of the battery liquid injection hole can be simplified, so that the variable in the battery production process is reduced, the sealing performance of the battery is ensured, the production stability, safety and reliability of the battery are improved, and the overall manufacturing cost of the battery is reduced.

Owner:LISHEN (QINGDAO) NEW ENERGY CO LTD

Transmission structure of blind rivet gun

The invention discloses a transmission structure of a blind rivet gun. The transmission structure of the blind rivet gun comprises an outer shell of an electric hand drill, a speed reduction gear of the electric hand drill, a hand riveter pushing rod above the outer shell and two fixing frames for fixing the hand riveter pushing rod. A long shaft is arranged in the outer shell, and a large gear meshed with the speed reduction gear is arranged on the long shaft; a short shaft provided with a connecting plate is arranged at the fitting position of the hand riveter pushing rod; and the large gear is meshed with a transmission rack fixed to the connecting plate. The integral structure is simple, reasonable and reliable; flexibility and convenience are achieved. The blind rivet gun can shoot rivets easily and is stable in motion, so that moving parts of the blind rivet gun are not vulnerable to abrasion. If the blind rivet gun part is removed, the structure can also serve as an electric hand drill. According to the transmission structure of the blind rivet gun, the mode that an existing hand riveter must be operated by both hands, which causes inconvenience is changed, and single-person single-hand operation is achieved; the transmission structure is reliable in performance, and the working efficiency can be greatly improved; the riveting speed is high, and the structure is safe and reliable; and meanwhile the installing quality is improved.

Owner:STATE GRID CORP OF CHINA +1

Hand riveter

The invention discloses a hand riveter which comprises a shell with a built-in riveting structure and a handle, the handle comprises a first handle and a second handle which can relatively rotate, the shell and the first handle are plastic parts, the shell and the first handle are integrally formed, and the second handle is in transmission connection with the riveting structure. And a pressing mechanism is arranged in the rivet pulling structure. The hand riveter is made of plastic, so that the weight of the hand riveter can be reduced, the applicable crowd range can be expanded, and the cost can be reduced; according to the pressing mechanism, the capability of clamping the pulling rivet by the clamping jaw can be improved, the pulling rivet is prevented from falling off, sliding friction between the clamping jaw and the limiting sleeve is converted into rolling friction, and abrasion between the clamping jaw and the limiting sleeve is reduced.

Owner:HANGZHOU GREAT STAR IND CO LTD

Automatic rivet pulling device

PendingCN114713758AImprove plugging qualityImprove leak detection efficiencyHand riveterIndustrial engineering

The invention relates to an automatic rivet pulling device. The automatic rivet pulling device comprises a working platform, a riveting device and a riveting device, the feeding mechanism comprises a feeding seat, a first driving part and a feeding clamp, the feeding seat is movably connected with the working platform, a feeding groove is formed in the feeding seat, a penetrating hole is formed in the bottom wall of the feeding groove, and rivets can penetrate through the penetrating hole; the hand riveter is arranged on the working platform, and a muzzle of the hand riveter is opposite to the through hole in the height direction of the automatic rivet pulling device; and the feeding mechanism is provided with a feeding port. According to the automatic rivet pulling device, in the working process, an original plugging technology is replaced with a rivet pulling mode, the plugging quality is improved, and then the reliability of a test result is improved. Meanwhile, the automatic rivet pulling mode is beneficial to improving the working efficiency, so that the sealing performance detection efficiency is improved.

Owner:UPTON AUTOMATION SYST (GUANGZHOU) CO LTD

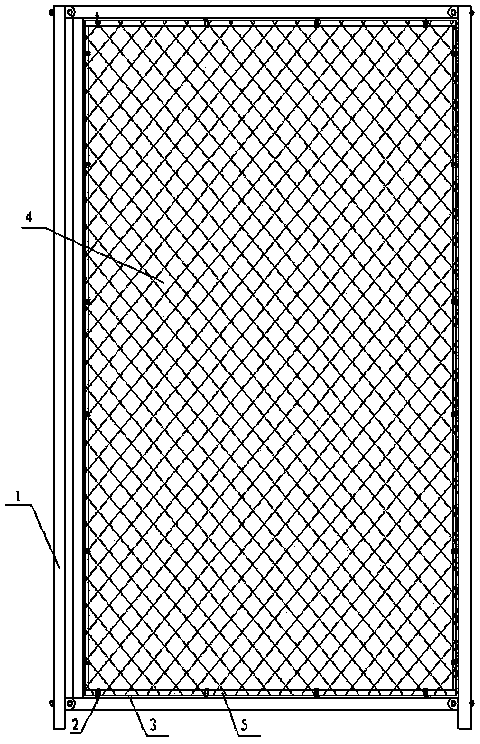

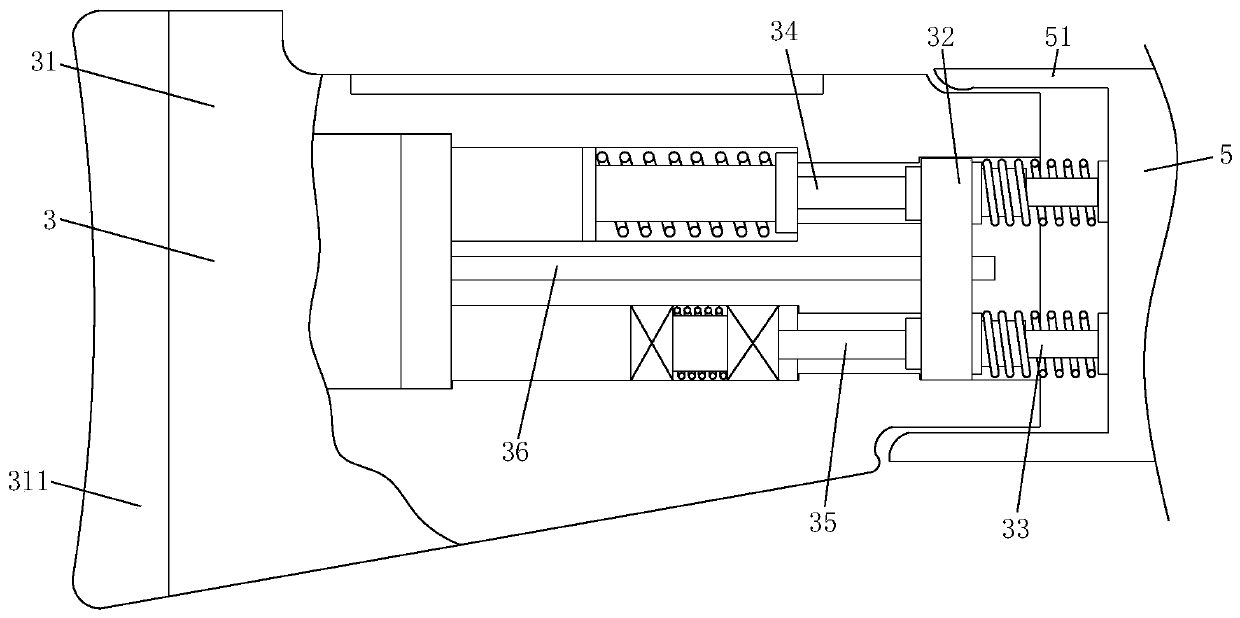

Mounting method of engineering surrounding net, and drag hook device, hand riveter and calipers device required by mounting method

The invention provides a mounting method of an engineering surrounding net and a drag hook device, a hand riveter and a calipers device required by the mounting method. The mounting method includes setting embedded parts; mounting upright columns; assembling the surrounding net; and fixing the surrounding net to the upright columns. The surrounding net comprises a frame, a net dragging support, a net and the drag hook device. Steps for assembling the surrounding net include arranging the net dragging support on the periphery of the net so that the net can be spread; then connecting one end of the drag hook device to the net dragging support; and fixing the other end of the drag hook device to the frame. The mounting method is simple in operation, consumed parts are fewer, the engineering surrounding net can be manually and quickly mounted in a field, accordingly, construction efficiency of the engineering surrounding net is greatly improved, and cost is lowered.

Owner:ZHEJIANG KANGMINGTE SPORTING GOODS

Direct-current electric hand riveter

InactiveCN111069515AFacilitate automatic riveting operationStable jobCurrent electricClassical mechanics

The invention relates to the field of plate machining, in particular to a direct-current electric hand riveter. The hand riveter comprises a rivet pulling assembly, a driving assembly and a cushioningassembly, wherein a clamping mechanism is arranged on one side of a top of the rivet pulling assembly, the driving assembly is arranged at a bottom of the rivet pulling assembly, a connecting arm isfixedly connected to the other side of the rivet pulling assembly, a wrapping sleeve is fixedly connected to one side of the connecting arm, the cushioning assembly located on one side of the connecting arm is sleeved with the wrapping sleeve, and a rivet is clamped in the clamping mechanism. A tensioning block is arranged and used in combination with a deflection cam, an air cylinder is connectedwith a common rechargeable lithium battery, a trigger is pulled to enable the air cylinder to work, a connecting shaft is installed at an output end of the air cylinder, the deflection cam is pulleddownwards, and one side of a top of the deflection cam and a limiting suspension plate are pressed and poked, so that the rivet is tensioned through the tensioning block, automatic rivet pulling operation on the rivet is advantageously performed, consumed huge external force needed by manual force application is avoided, manpower is saved, work is stable, and non-directionality of force applied bythe manual external force during rivet pulling is prevented.

Owner:雍小龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com