Rivet-pulling sealing method for lithium battery liquid injection seal

A lithium battery injection and sealing technology, applied in secondary batteries, battery pack parts, non-aqueous electrolyte batteries, etc. Practical significance, the effect of simplifying the sealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

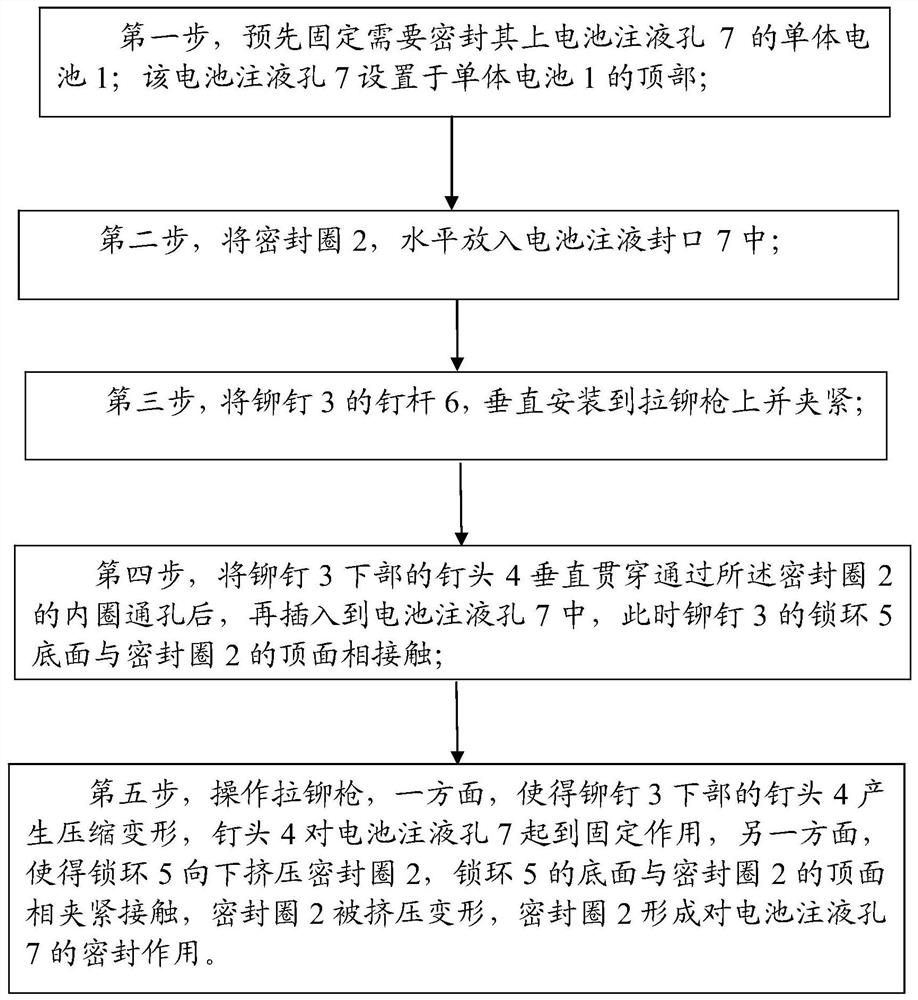

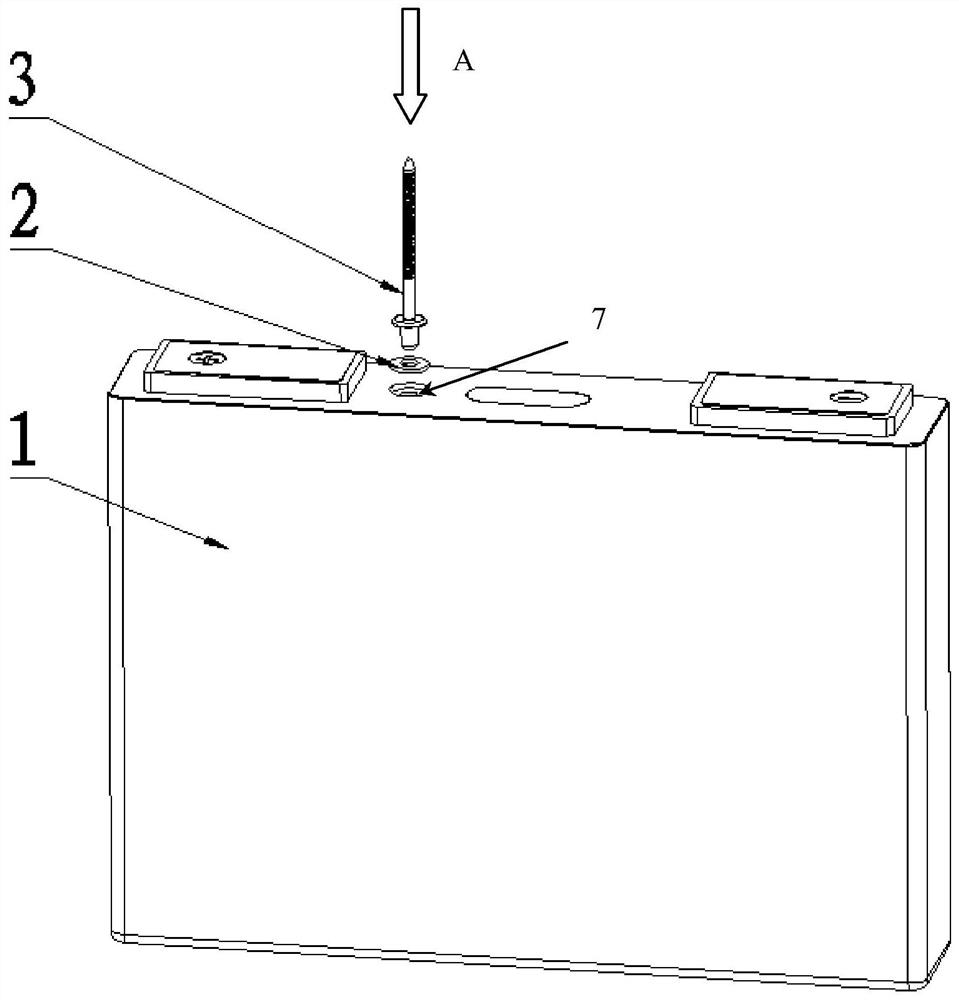

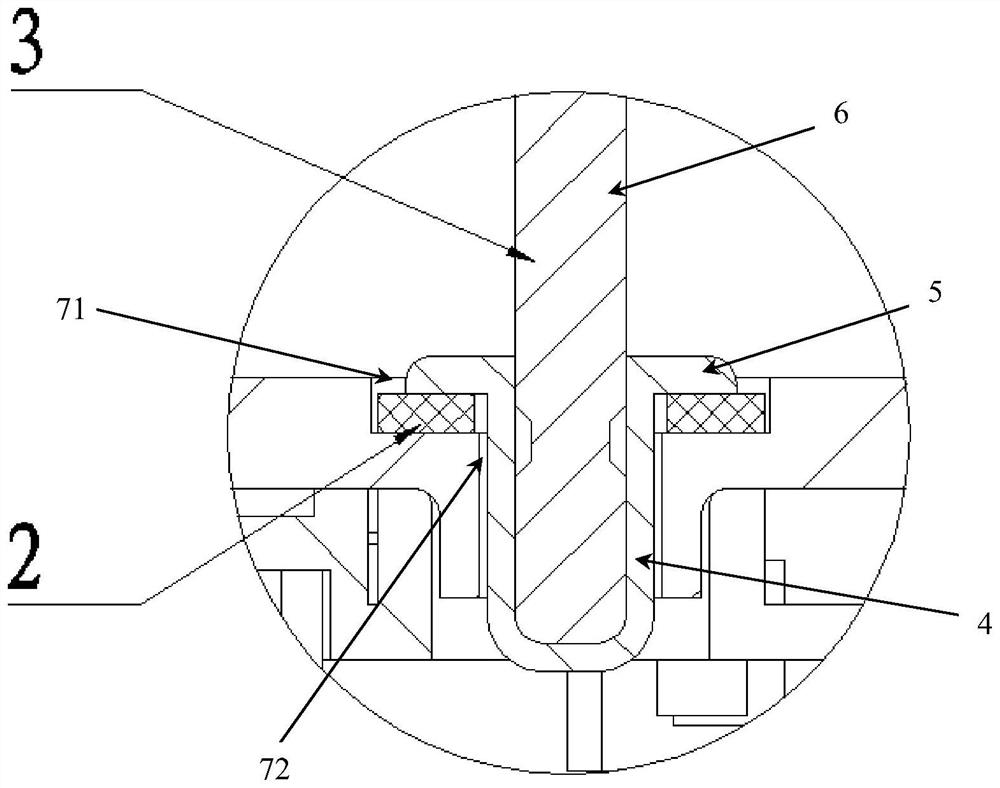

[0040] see Figure 1 to Figure 4 , the invention provides a blind riveting sealing method for liquid injection sealing of lithium batteries, comprising the following steps:

[0041] The first step is to pre-fix the single battery 1 that needs to be sealed with the battery liquid injection hole 7; the battery liquid injection hole 7 is set on the top of the single battery 1;

[0042] In the first step, the single battery 1 can be fixed vertically by existing clamps, and the battery liquid injection hole 7 faces upward.

[0043] In the second step, place the sealing ring 2 horizontally into the battery liquid injection seal 7;

[0044] In the third step, the nail rod 6 of the rivet 3 is vertically installed on the riveter and clamped;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com