Patents

Literature

111results about How to "Simple sealing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

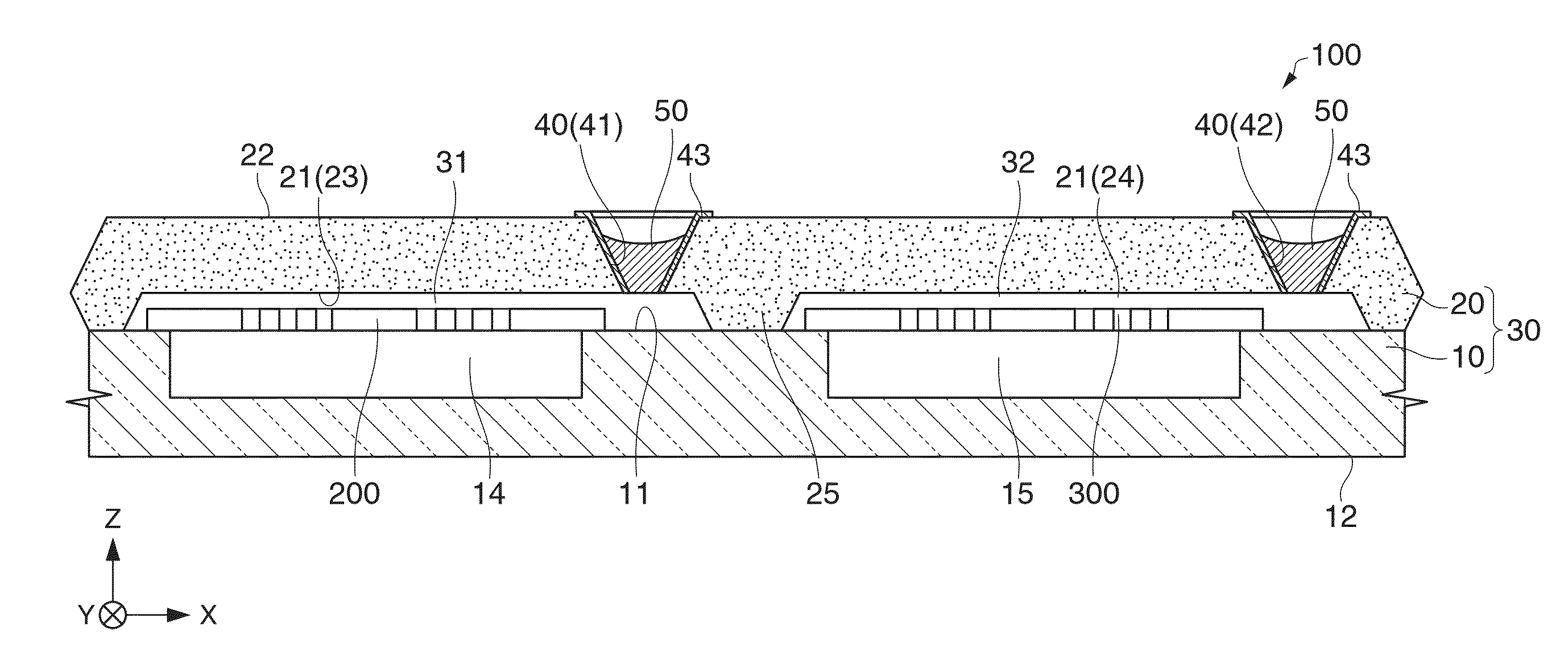

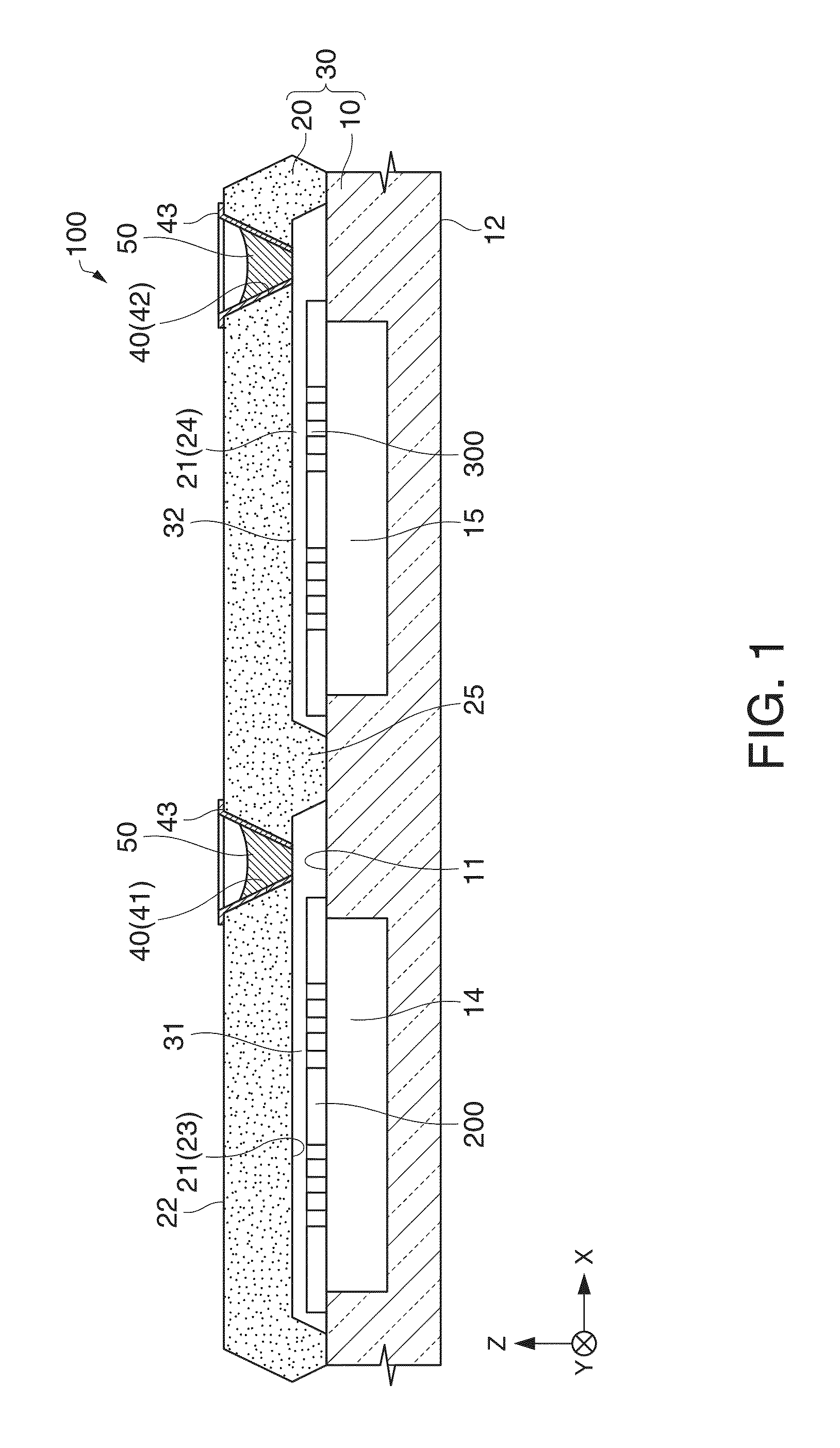

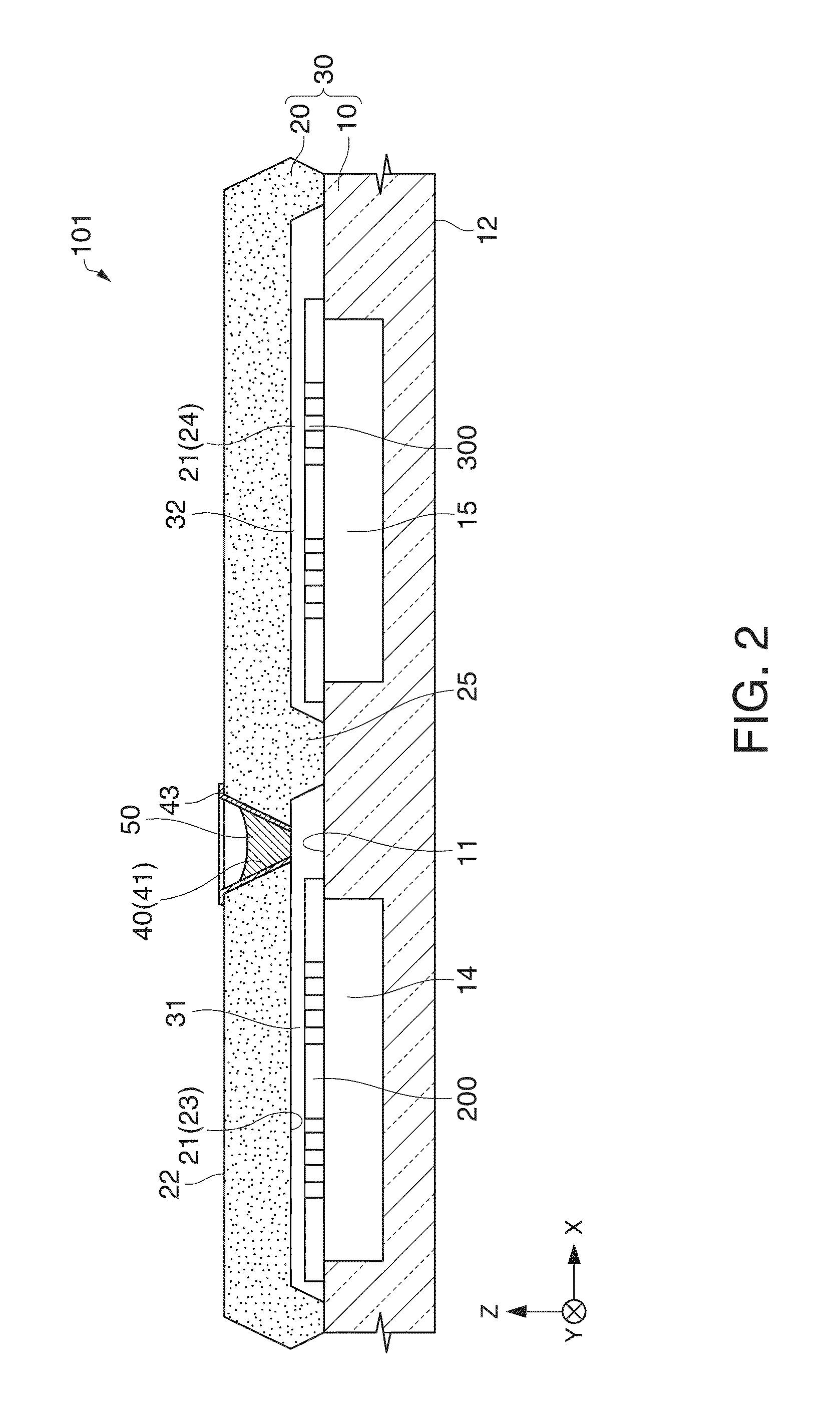

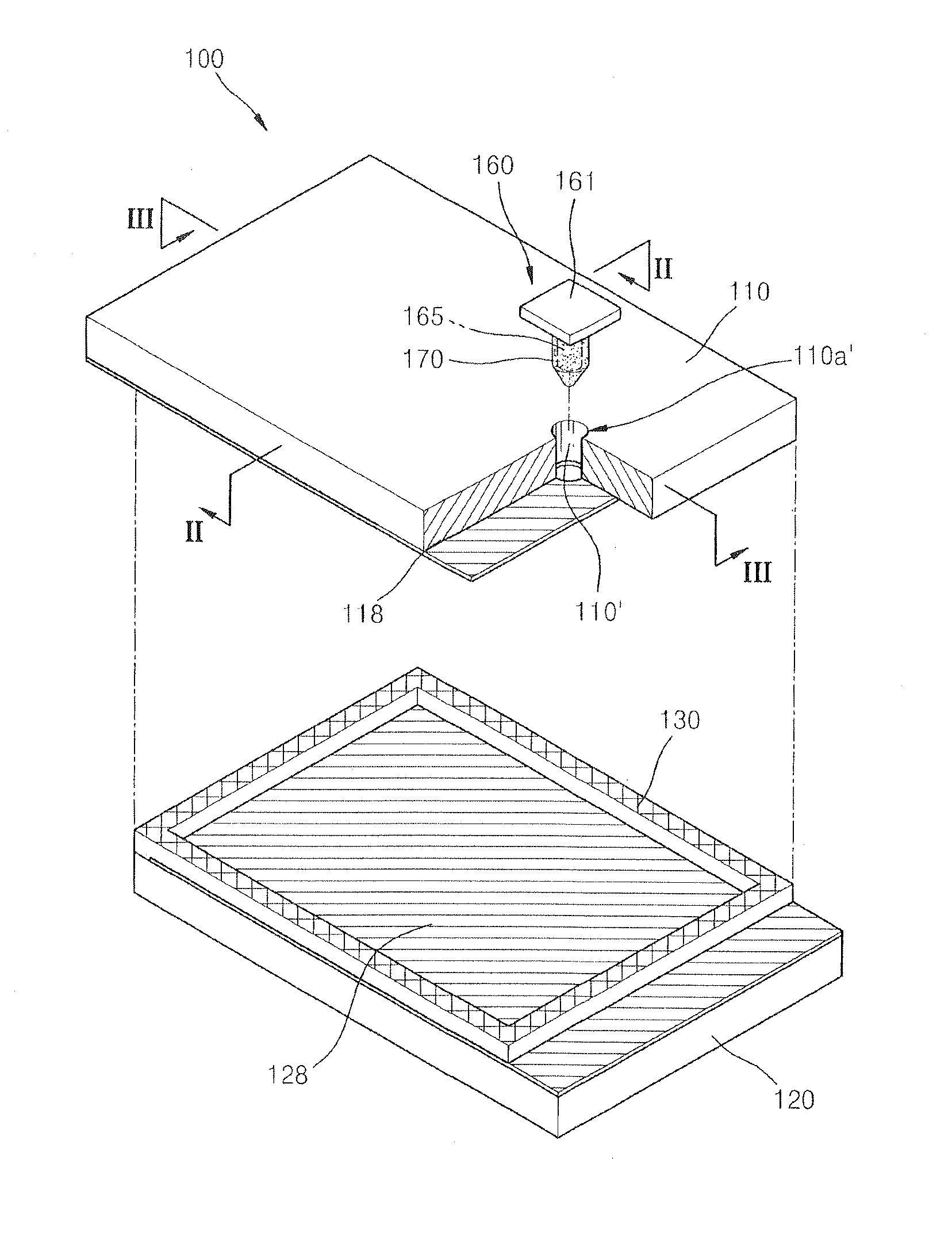

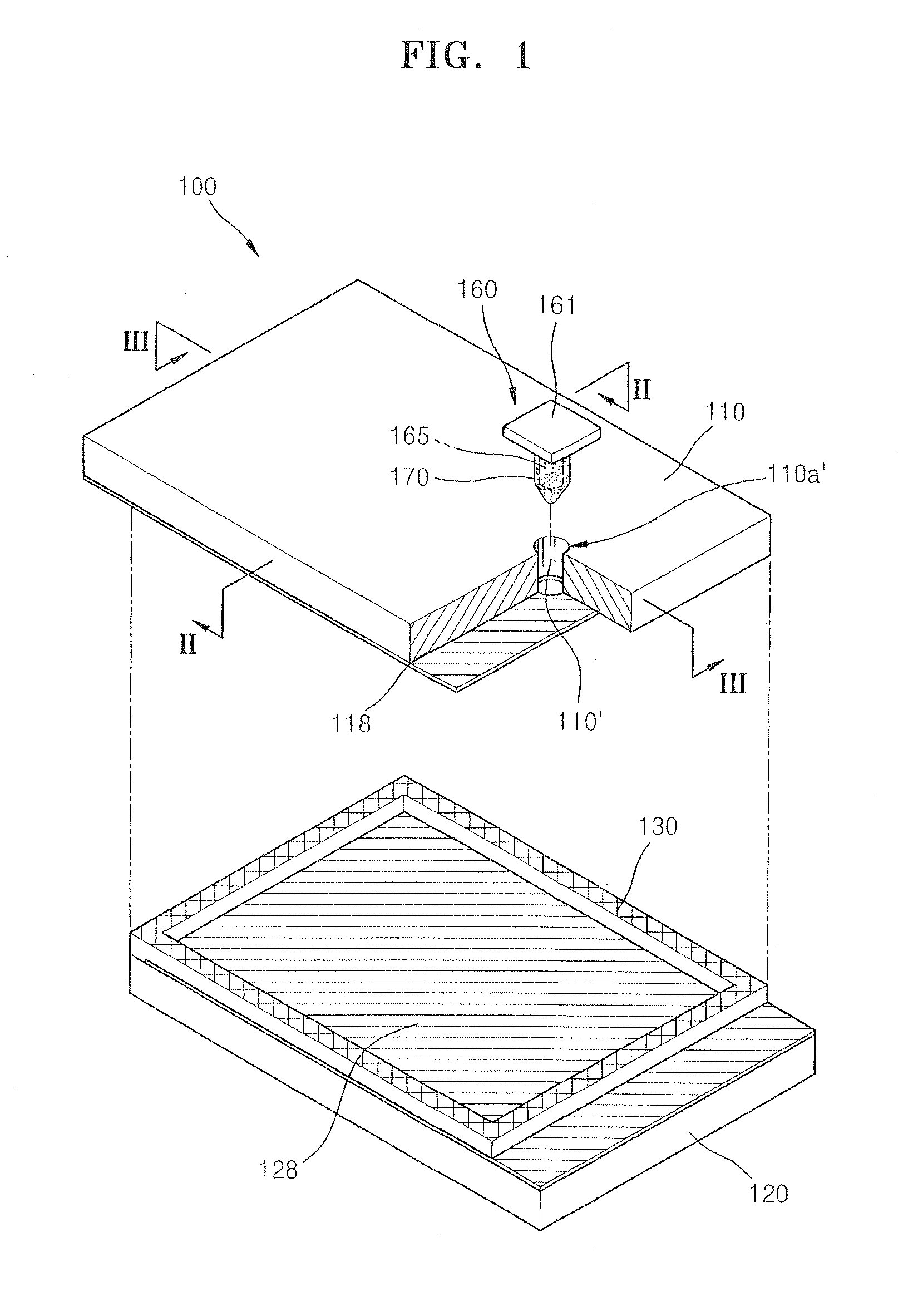

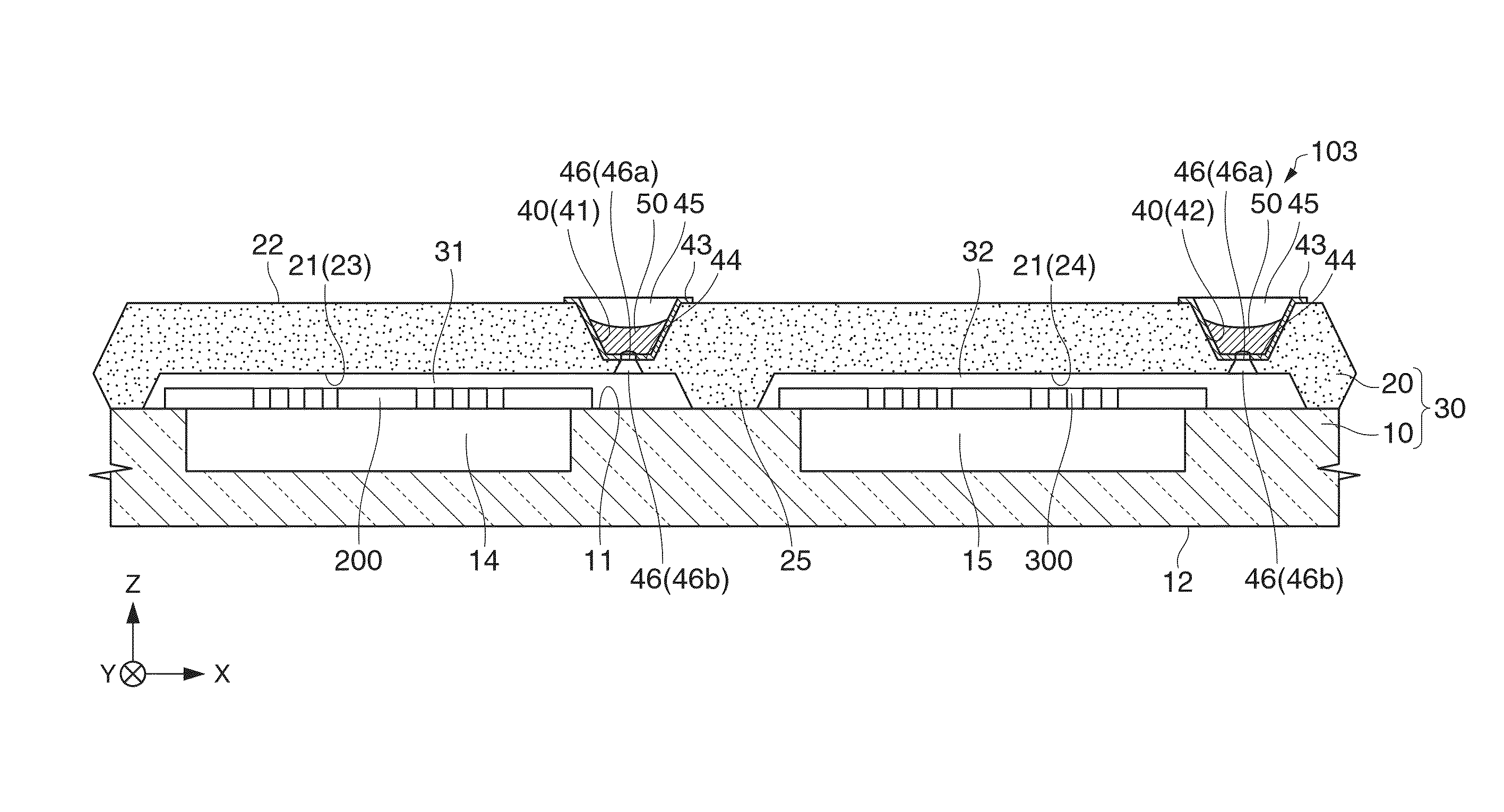

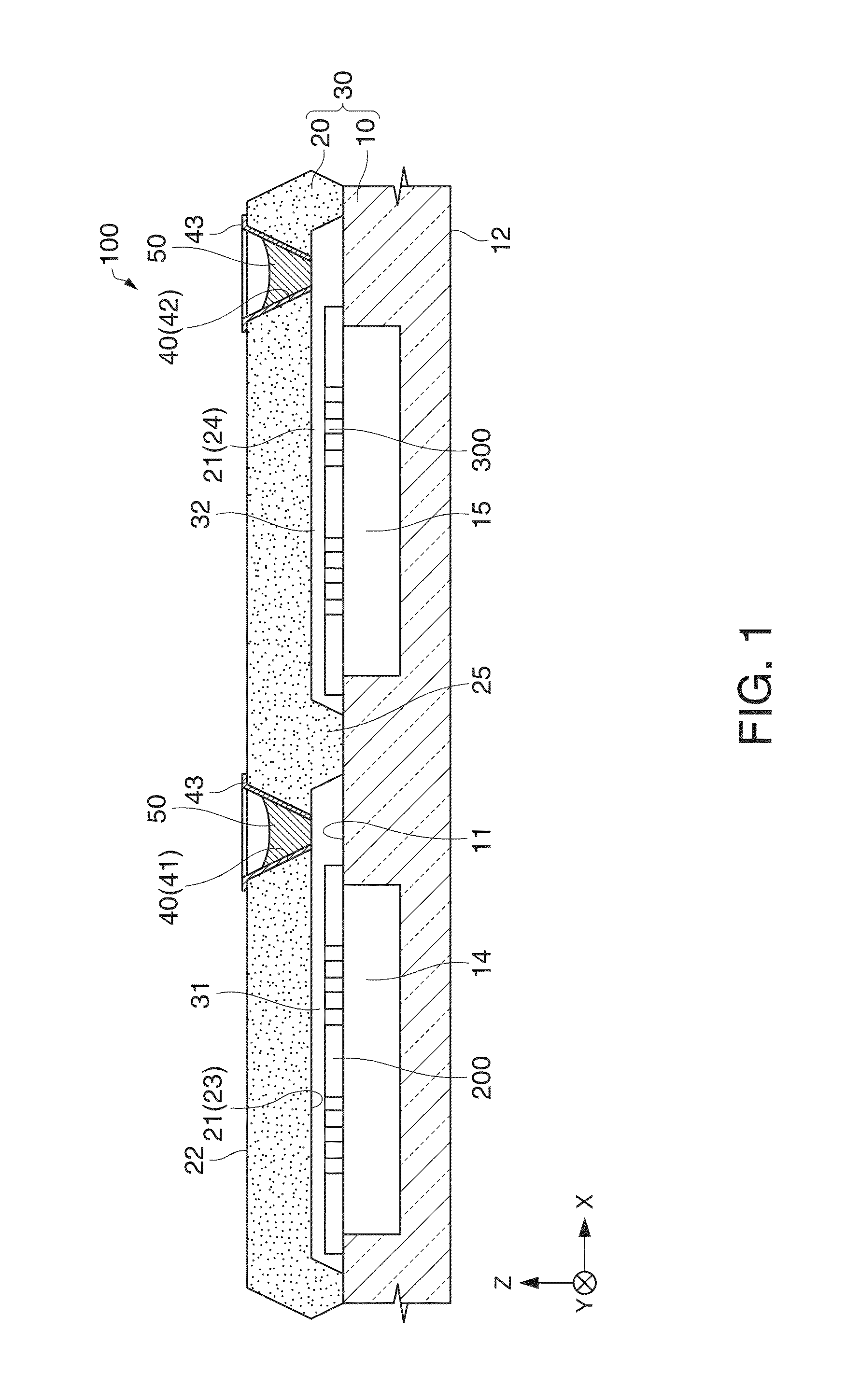

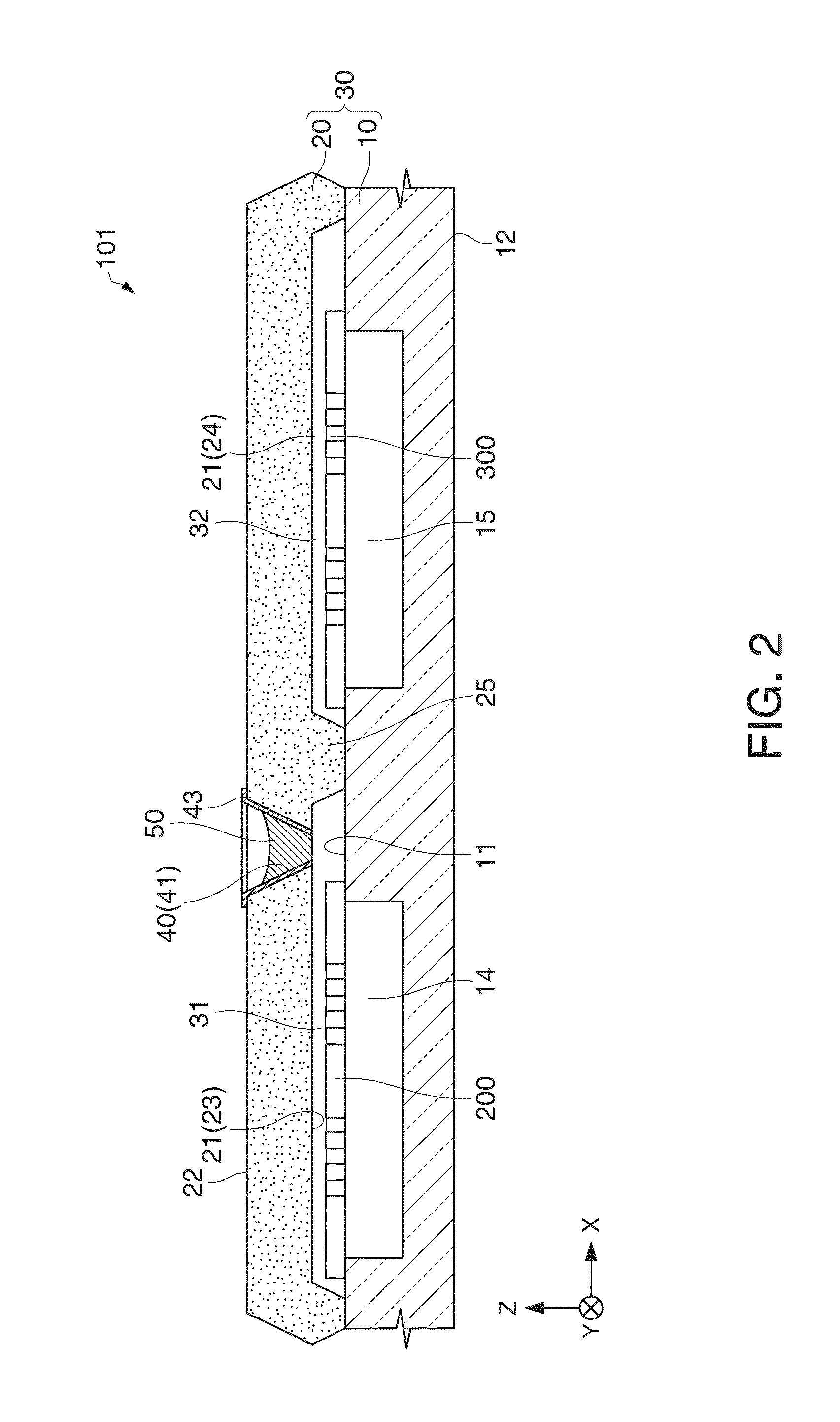

Electronic device and manufacturing method thereof, electronic apparatus, and moving body

ActiveUS20130265701A1Improve reliabilityManufacturing method can be providedWave amplification devicesDigital data processing detailsAtmospheric pressurePressure Atmosphere

An electronic device includes a substrate, a cover body which is placed on the substrate, a first cavity which is surrounded by the substrate and the cover body, and a second cavity which is surrounded by the substrate and the cover body, wherein an inner portion of the first cavity is sealed in a first air pressure atmosphere, and an inner portion of the second cavity is sealed in a second air pressure atmosphere which has a difference of air pressure with respect to the first air pressure atmosphere, a first through-hole, which communicates with the first cavity and is blocked by a seal member, is provided in at least one of the substrate and the cover body, and the first cavity and the second cavity are isolated from each other by a partition wall portion which is integrally provided to the cover body or the substrate.

Owner:SEIKO EPSON CORP

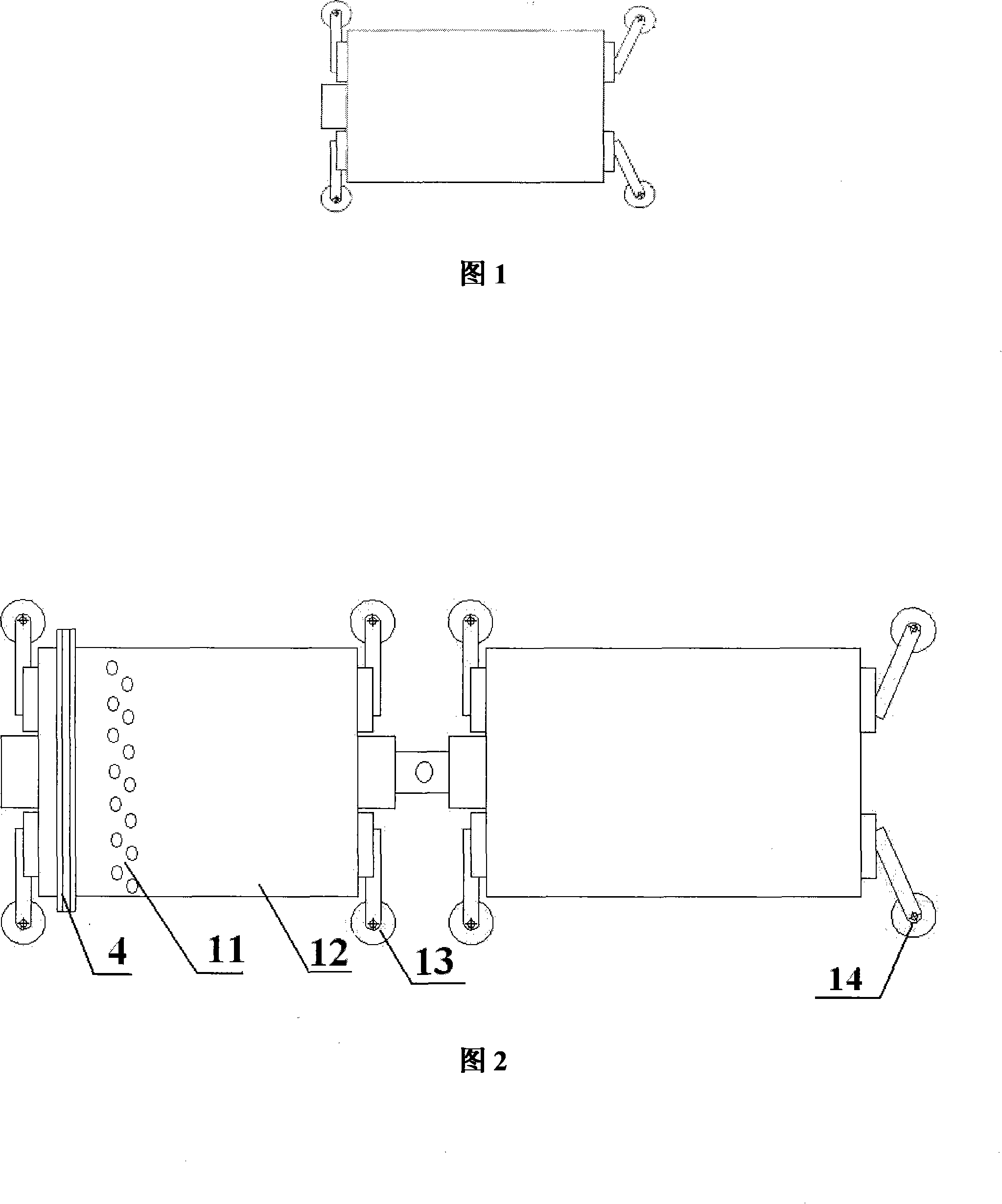

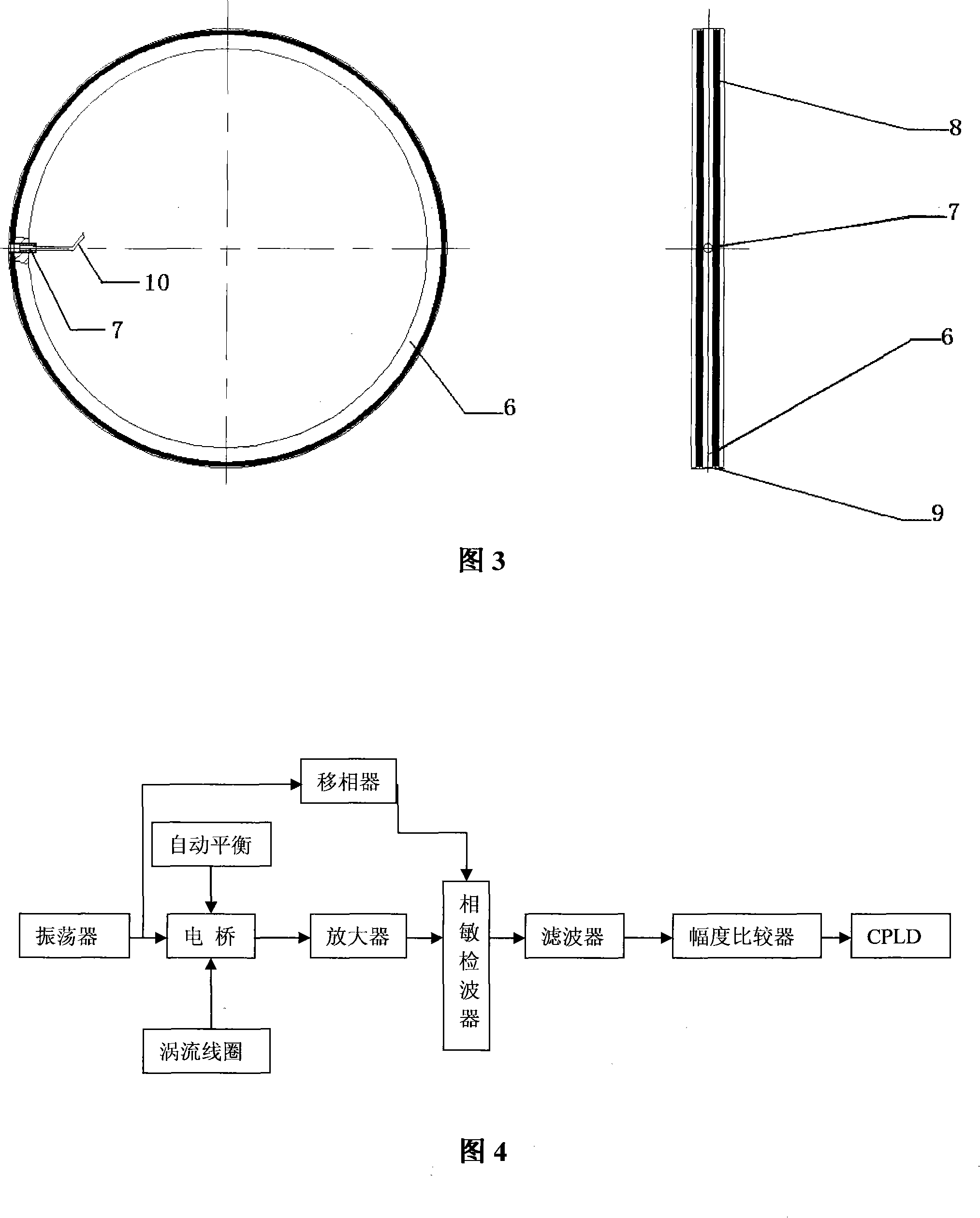

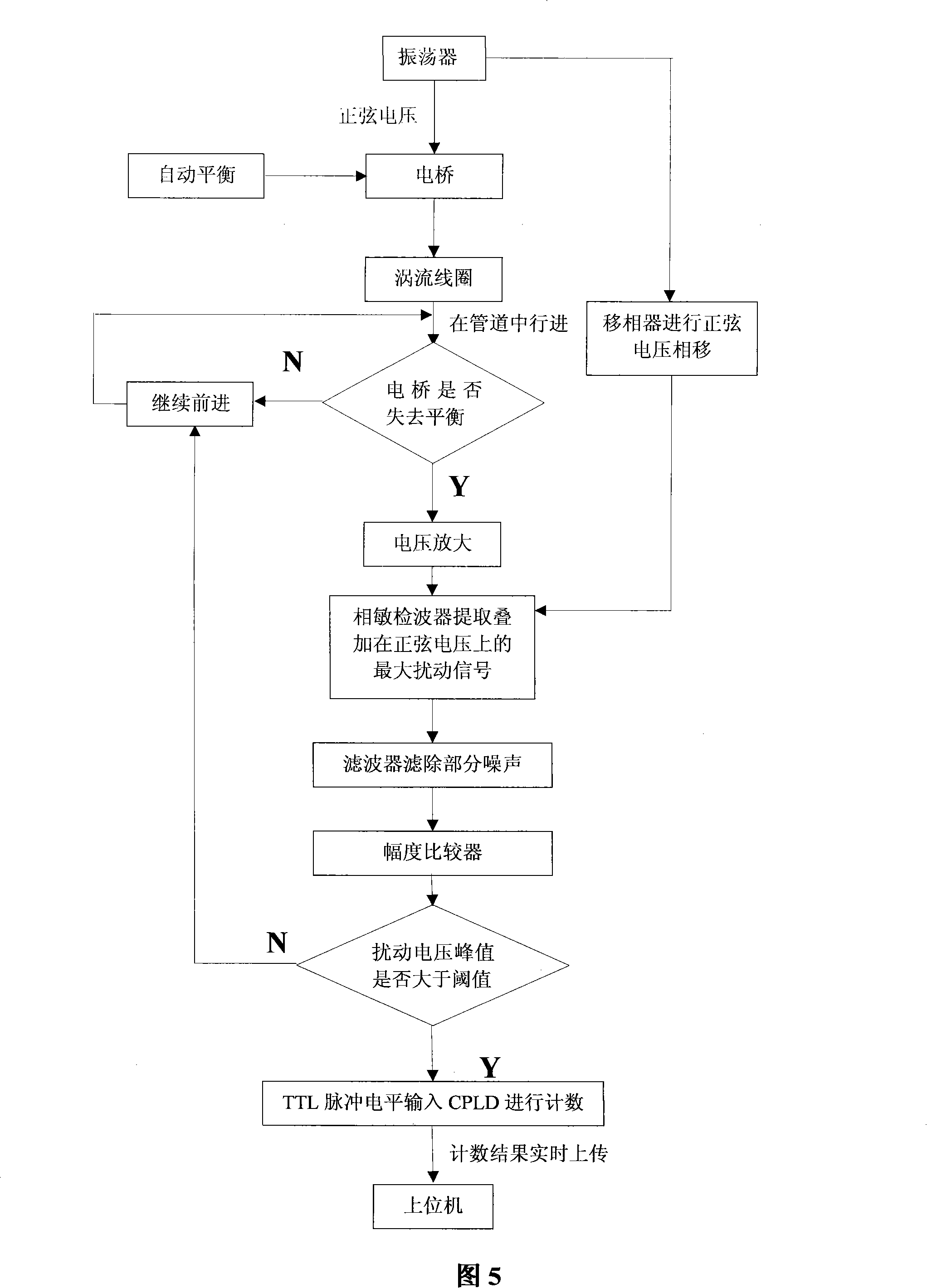

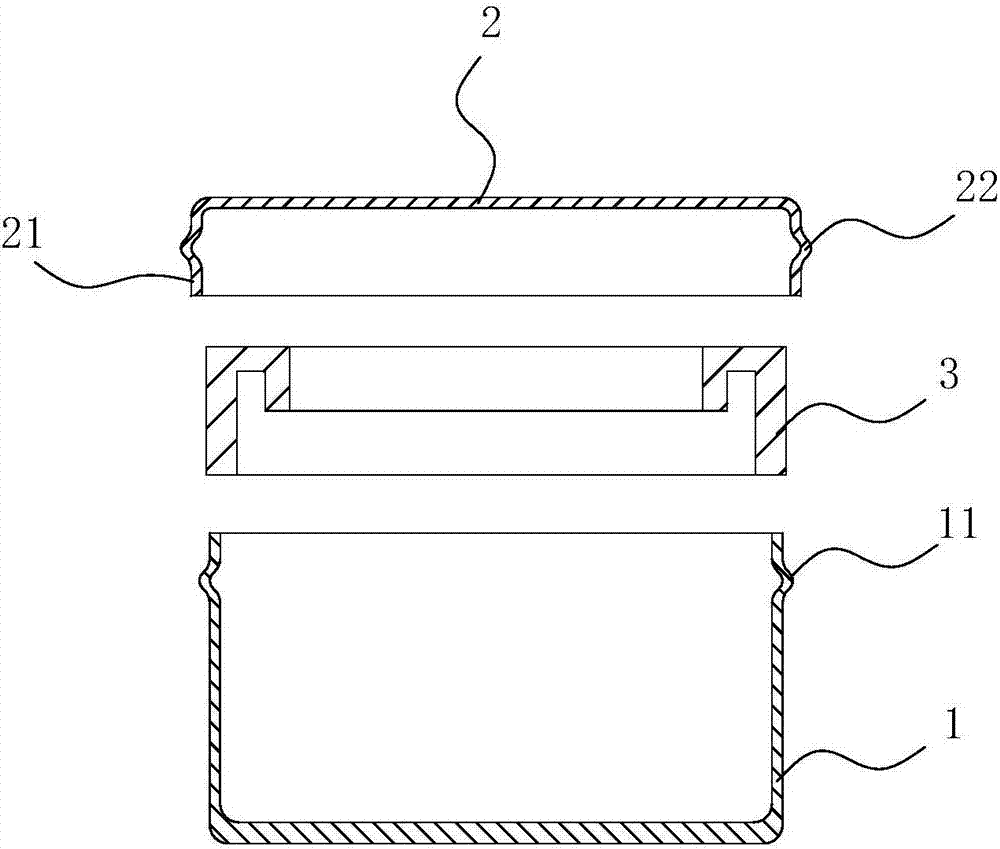

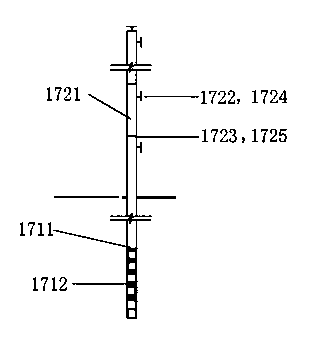

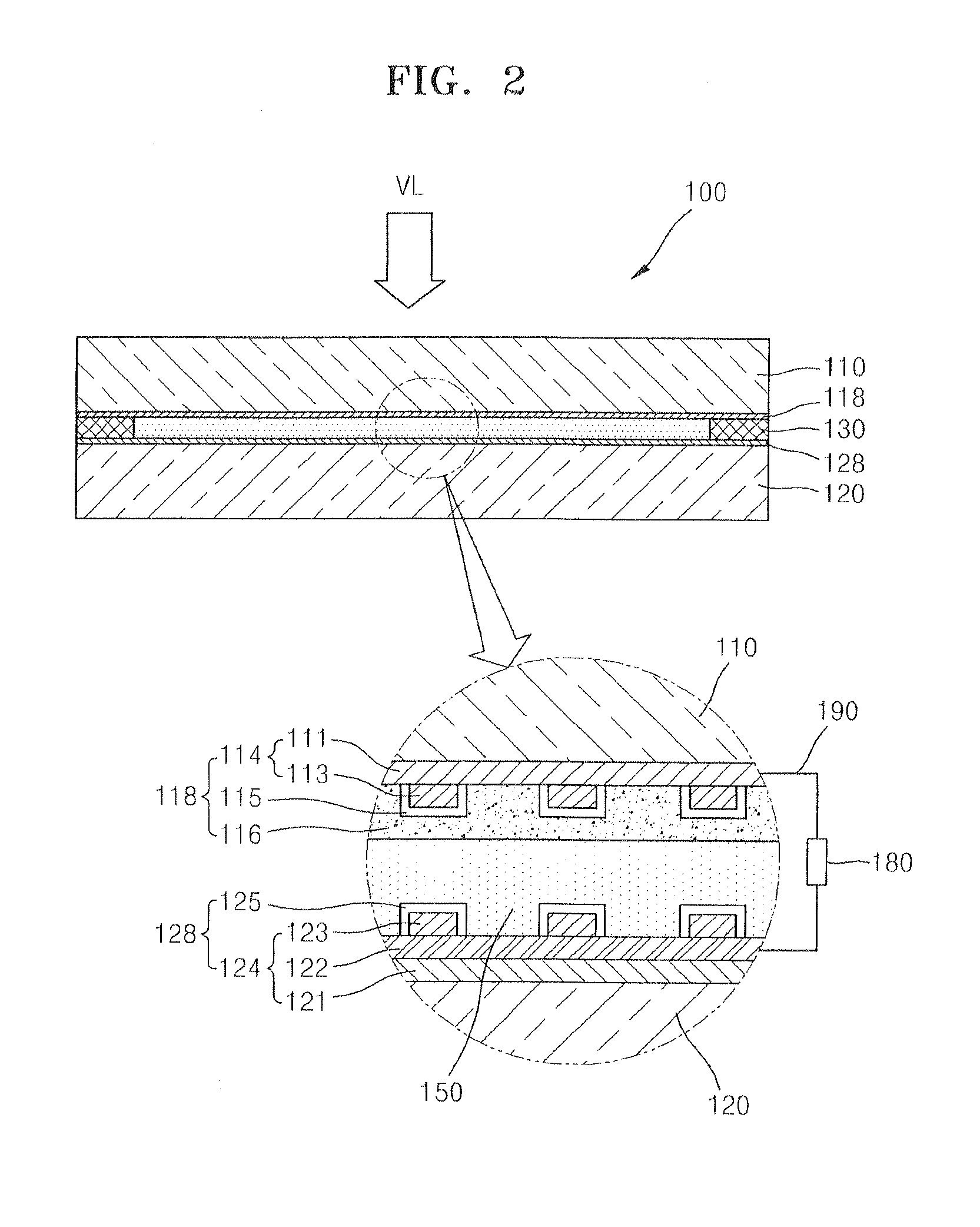

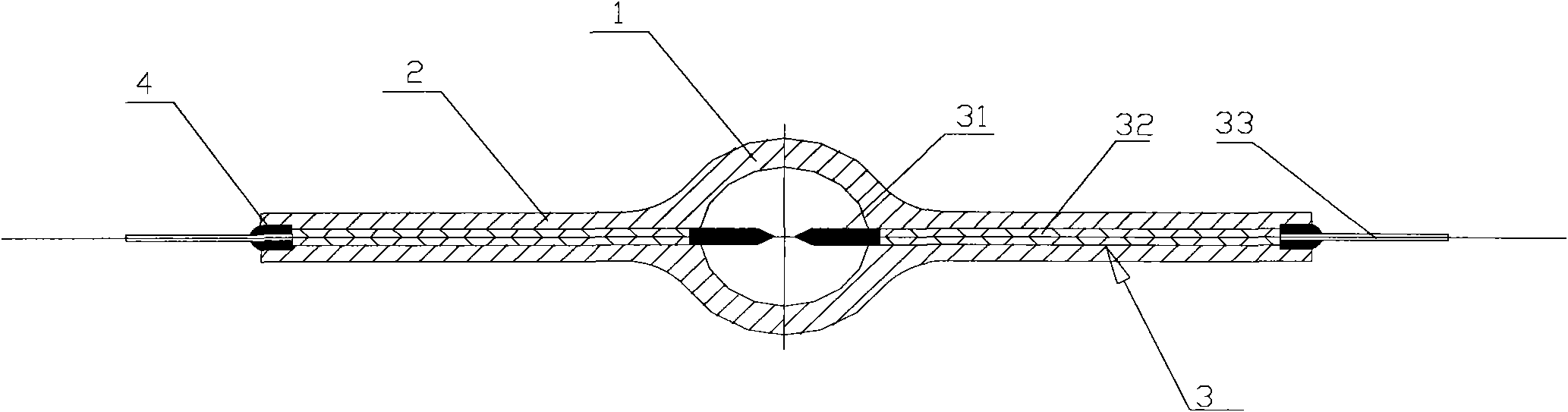

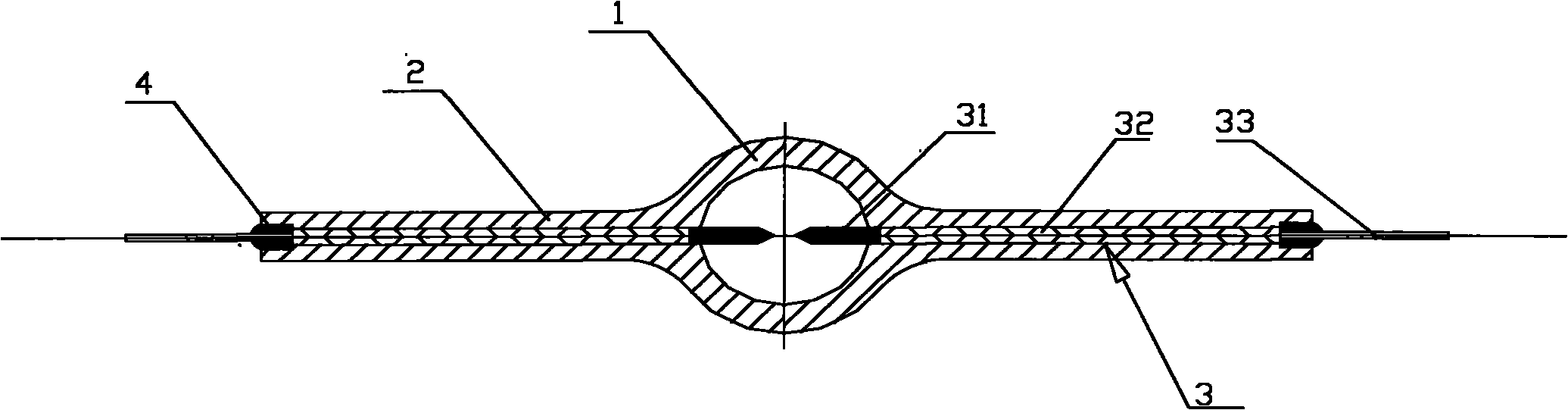

Long conveyance pipe defect positioning method and positioning system

ActiveCN101169225AAccurate seam countReduce in quantityPipeline systemsLocalization systemEddy current

The invention relates to a positioning method and a positioning system for a long-distance pipeline defect. In the method for locating defects of long-distance pipelines according to the present invention, a series of butt girth welds are formed in the long-distance pipelines during installation, and wheel-type odometers are used for mileage measurement and positioning in long-distance pipelines. When the wheel-type mileage While the meter is advancing and measuring the mileage in the long-distance pipeline, the eddy current testing device is used to detect when the butt girth weld has passed. This information is analyzed simultaneously with the mileage data of the wheel odometer to determine the pipeline defect s position. The long-distance pipeline defect location system of the present invention includes a wheel odometer and an eddy current detection device; the eddy current detection device includes an eddy current coil and an eddy current detection processing module connected with the eddy current coil. The positioning method and system of the invention can avoid the increase of the accumulative distance error of the wheel odometer, improve the positioning accuracy, and fully meet the positioning requirements.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

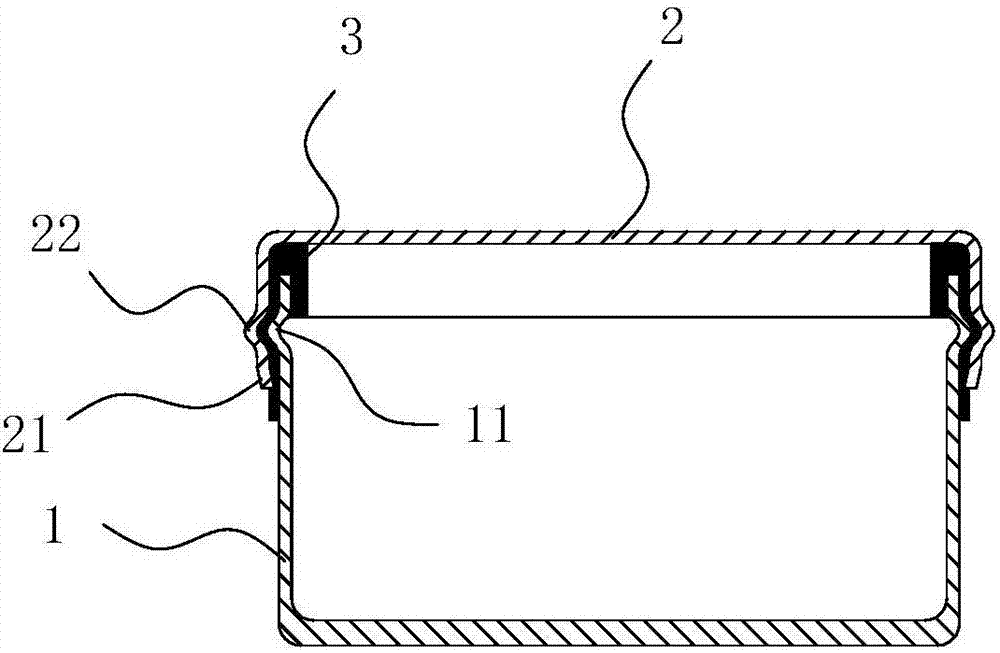

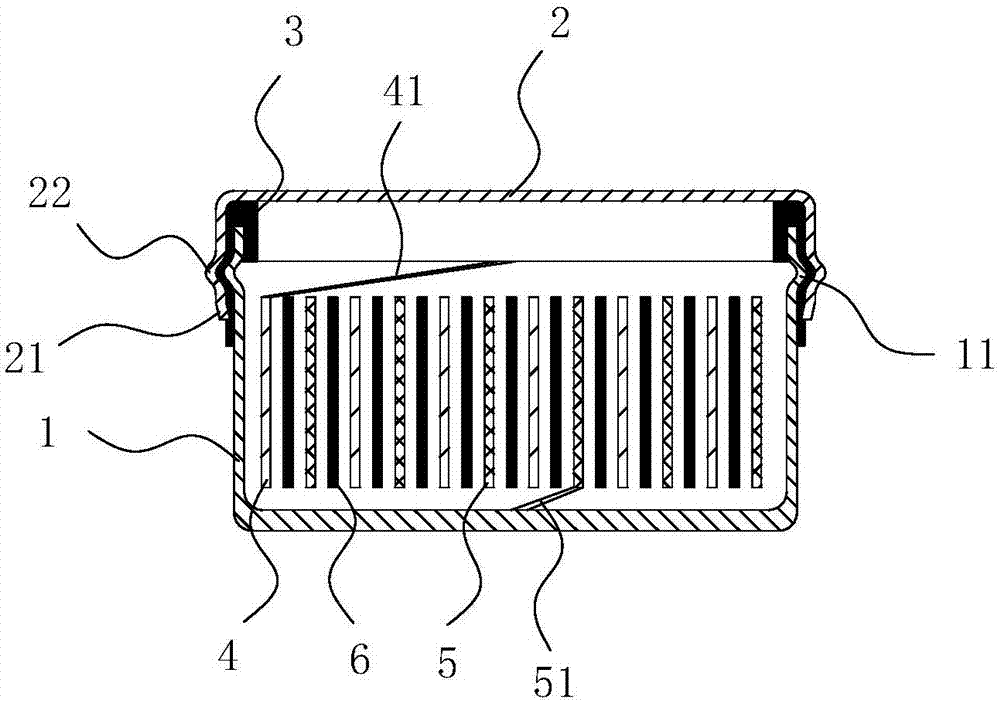

Rechargeable micro shell lithium ion battery structure and preparation method

InactiveCN107195807AIncrease capacitySimple structureFinal product manufactureSmall-sized cells cases/jacketsElectricityButton battery

The invention discloses a rechargeable micro shell lithium ion battery structure and a processing technology thereof. The battery comprises a sealing assembly and a winding body, wherein an electrolyte is arranged in the sealing assembly, and the winding body is soaked into the electrolyte; the sealing assembly consists of a shell, a cover cap and a seal ring, the shell and the cover cap are made of metal materials respectively, and the seal ring realizes insulation between the shell and the cover cap; the winding body is provided with a positive lug and a negative lug, the positive lug is electrically connected with the cover cap, and the negative lug is electrically connected with the shell. The disadvantage that disposable button cells in the current market cannot be recharged for utilization is abandoned, and a rechargeable micro shell lithium ion battery is creatively provided. The battery is simpler in structure, lower in cost and higher in space utilization rate.

Owner:EVE ENERGY CO LTD

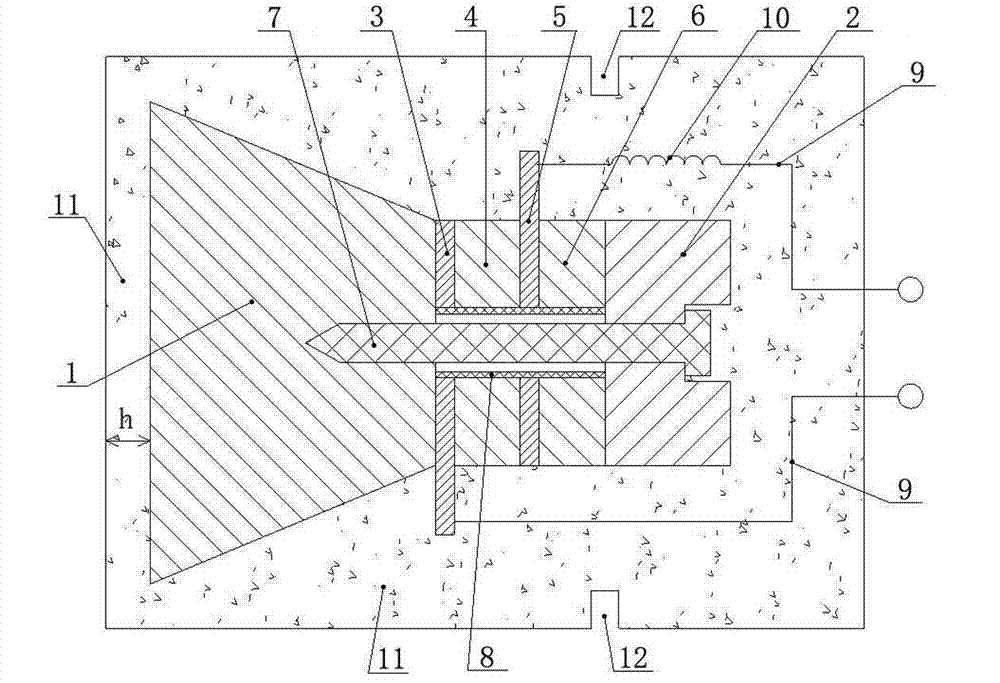

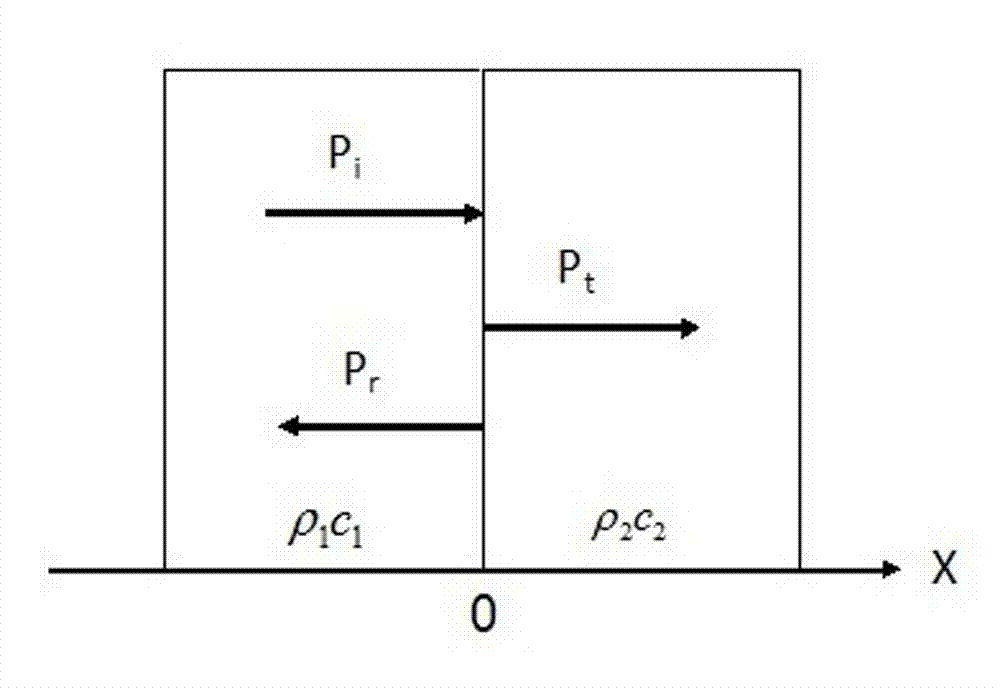

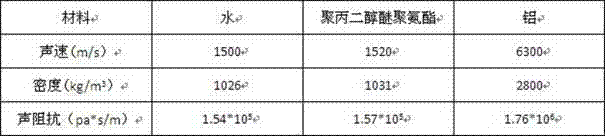

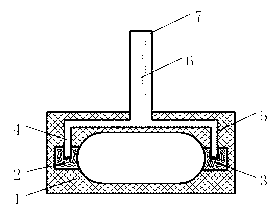

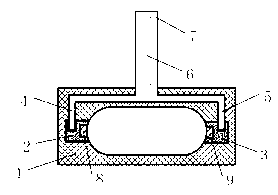

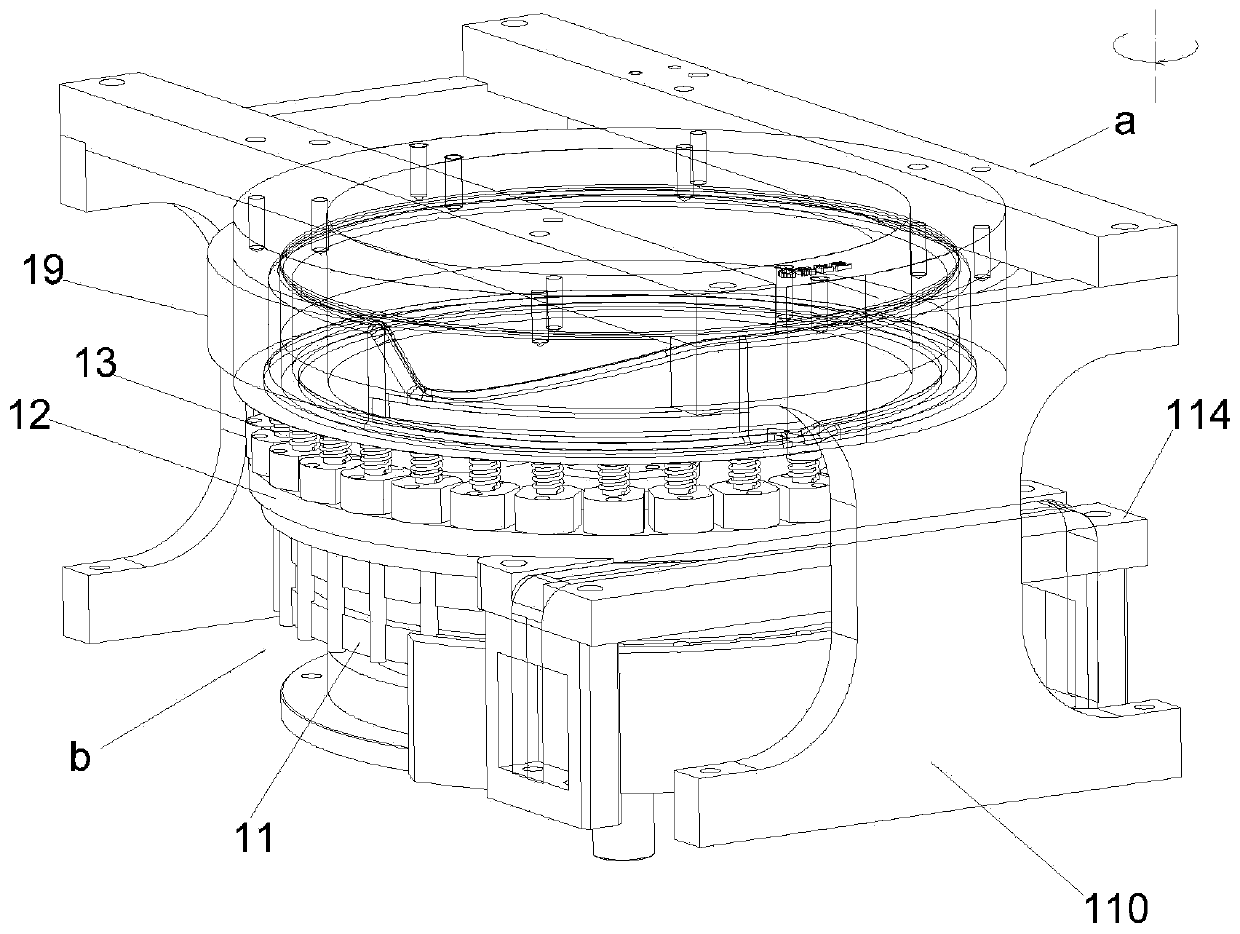

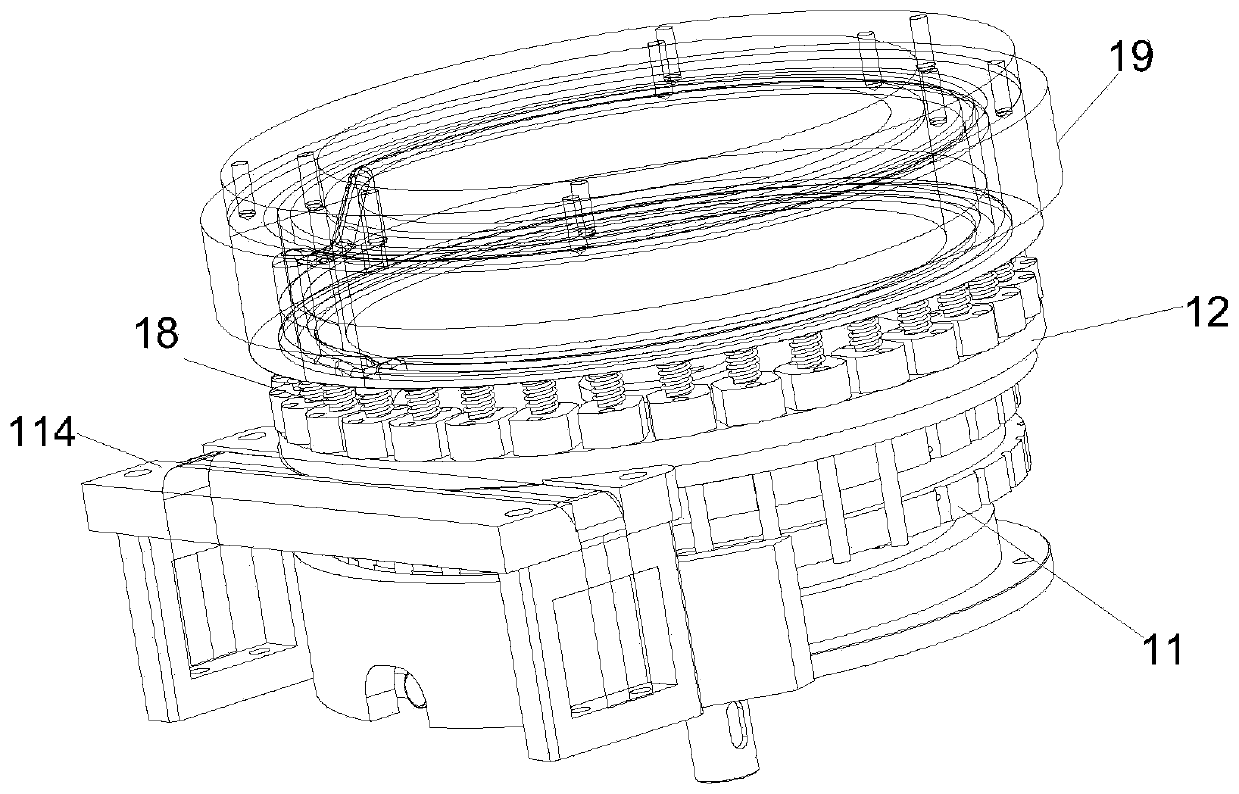

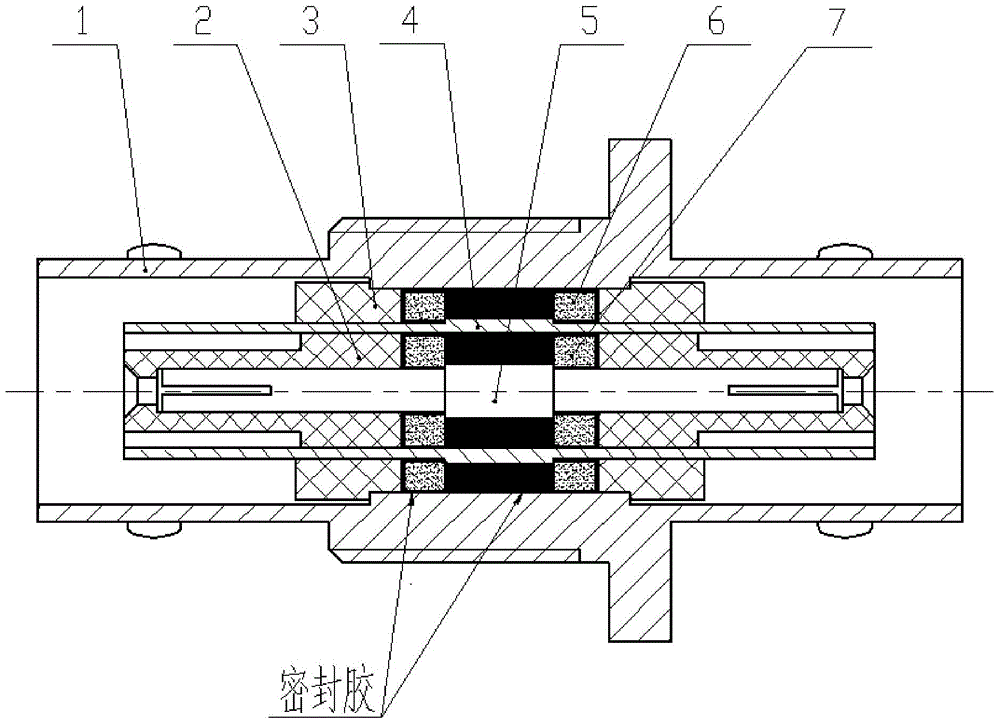

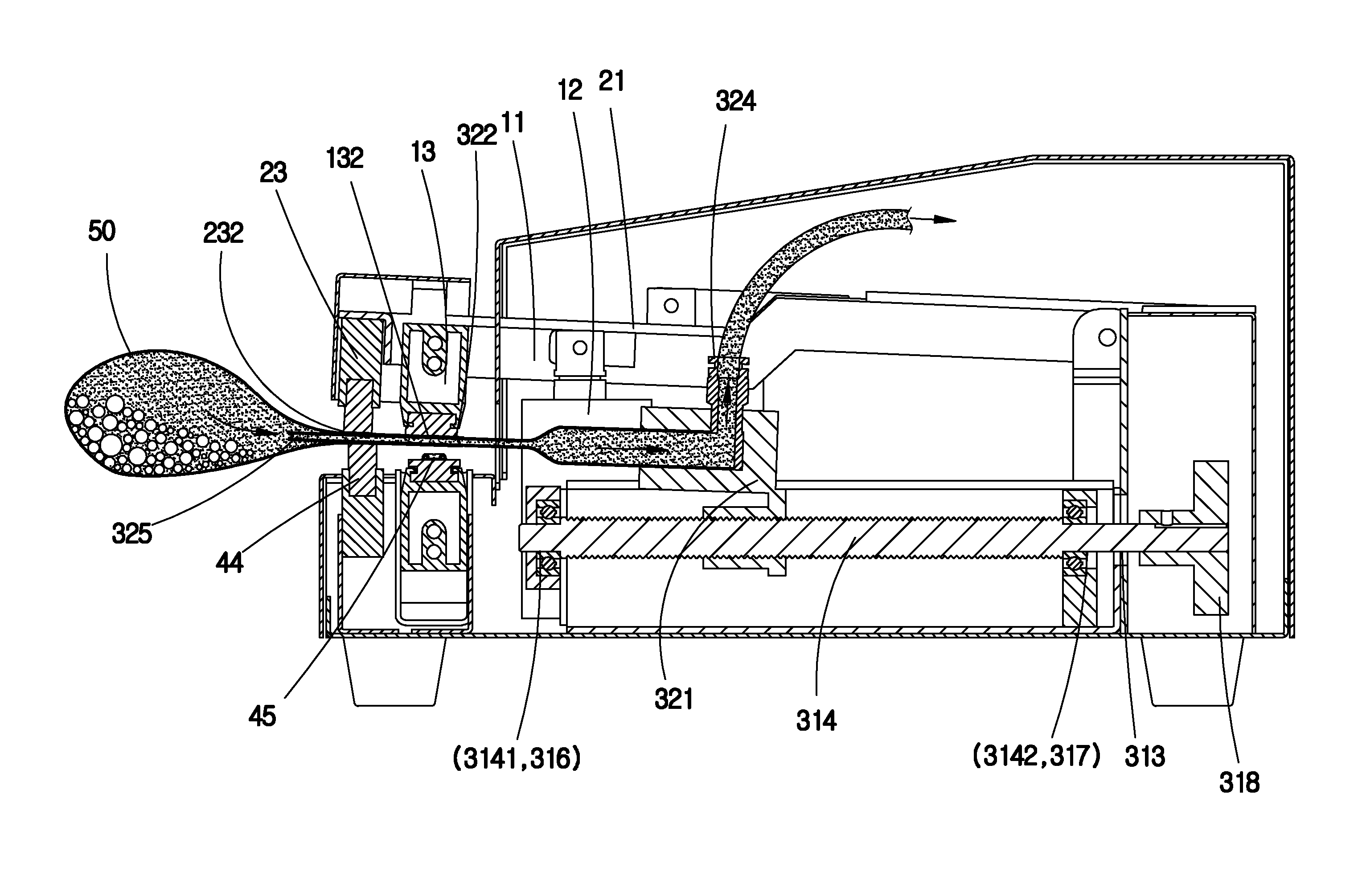

Watertight packaging type ultrasonic cleaning transducer

InactiveCN103041977ANo damageAchieving tightnessMechanical vibrations separationCleaning using liquidsEngineeringEnergy source

The invention relates to a watertight packaging type ultrasonic cleaning transducer which solves the problems of proneness to damage, difficulty in maintenance, low cleaning efficiency and the like of existing cleaning transducers. The transducer comprises a front cover plate, a rear cover plate, a positive electrode plate, a negative electrode plate, a first annular piezoelectric ceramic piece and a second annular piezoelectric ceramic piece, wherein the positive electrode plate, the negative electrode plate, the first annular piezoelectric ceramic piece and the second annular piezoelectric ceramic piece are locked between the front cover plate and the rear cover plate through a prestressing screw rod. The positive and negative electrode plates are connected with wires which are serially connected with a matching inductor. A sealing layer composed of poly propylene glycol ether polyurethane rubber is poured outside the integral structure, and the thickness h of the sealing layer packaged on the front end face of the front cover plate is one quarter of wavelength of sound waves given out by the transducer. The watertight packaging type ultrasonic cleaning transducer is reasonable in material selection, simple in sealing process, low in cost, high in reliability, easy to maintain and convenient for arraying, and further, the matching inductor is added, so that energy sources are saved, and cleaning efficiency is improved.

Owner:刘细宝

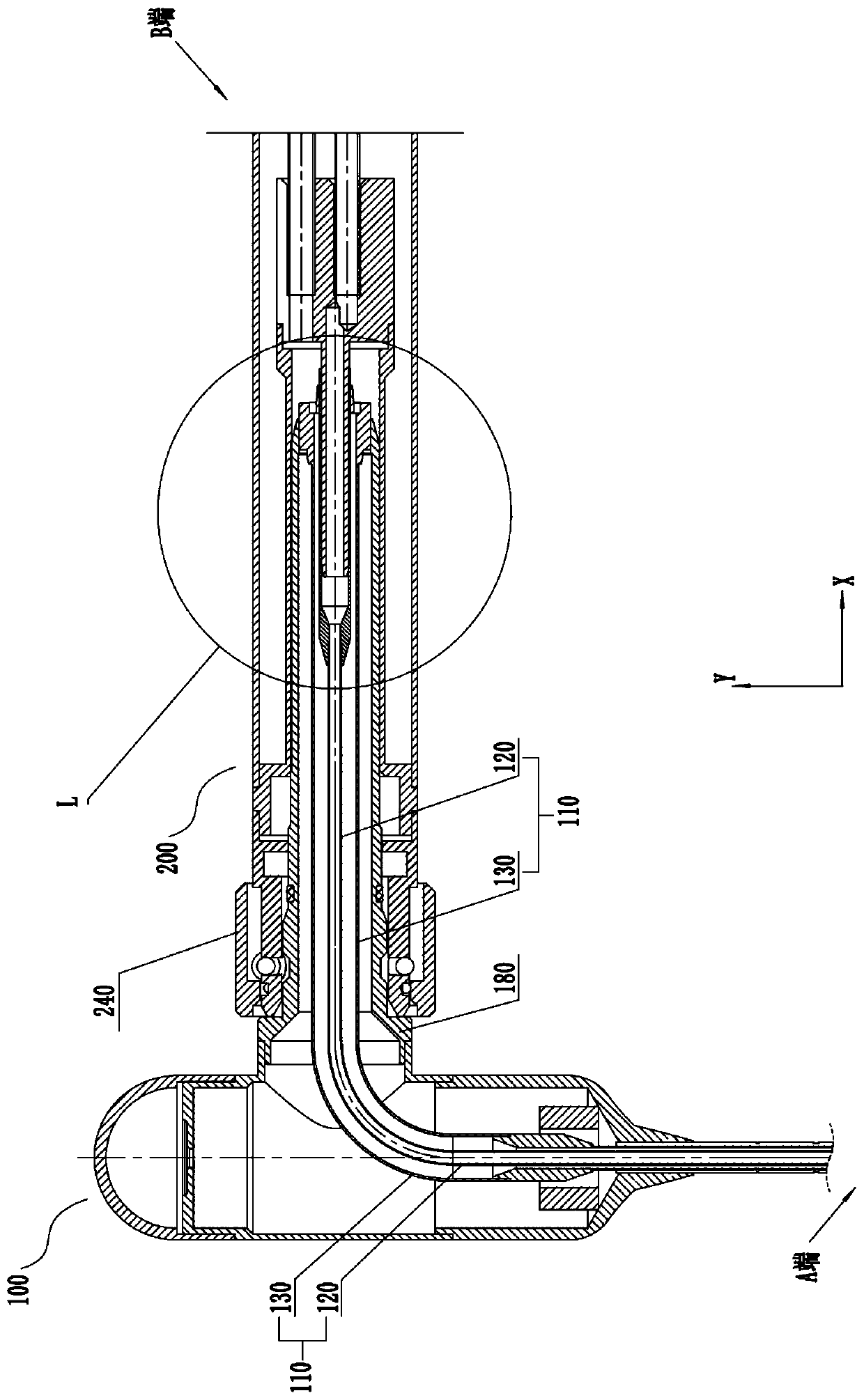

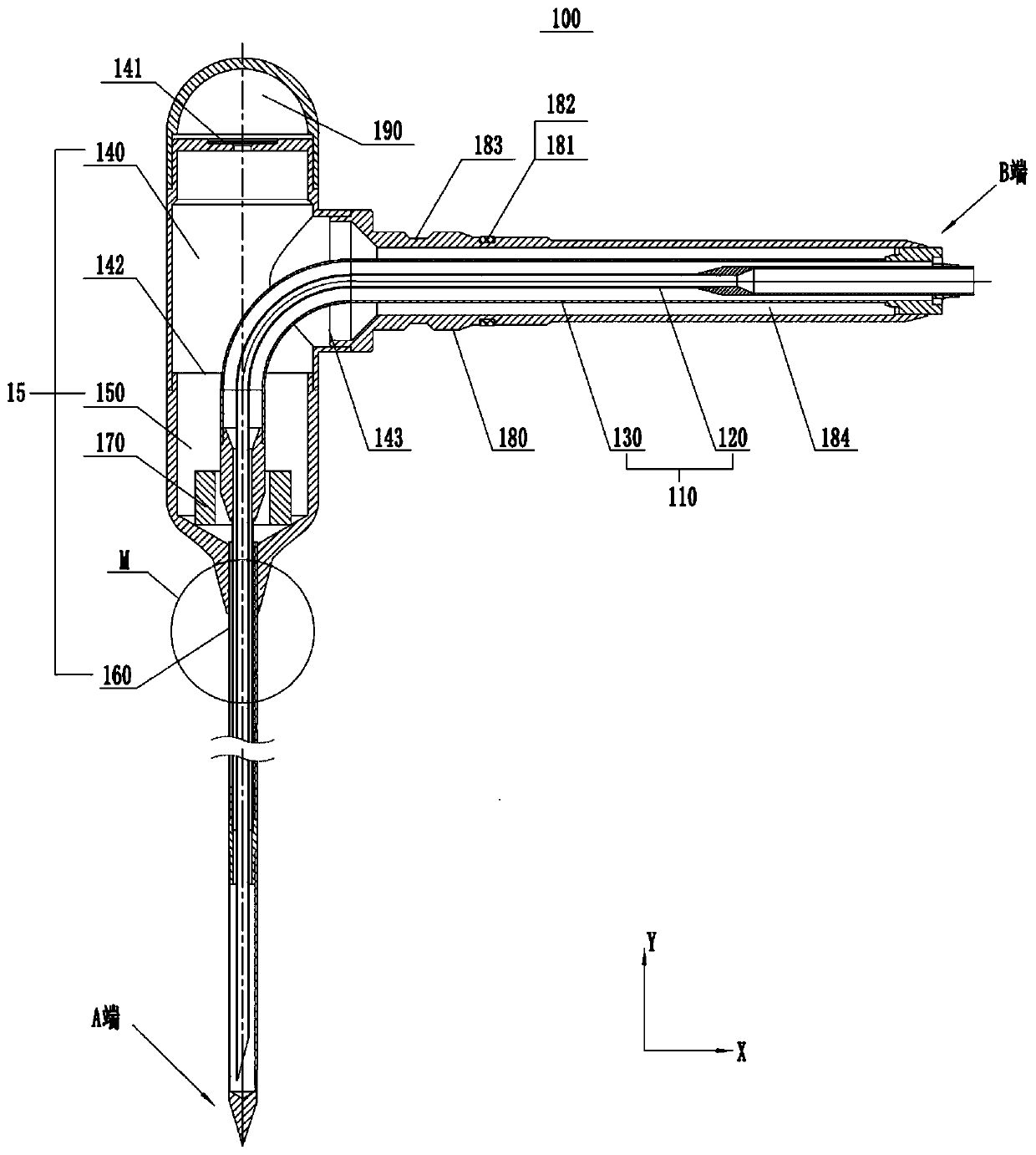

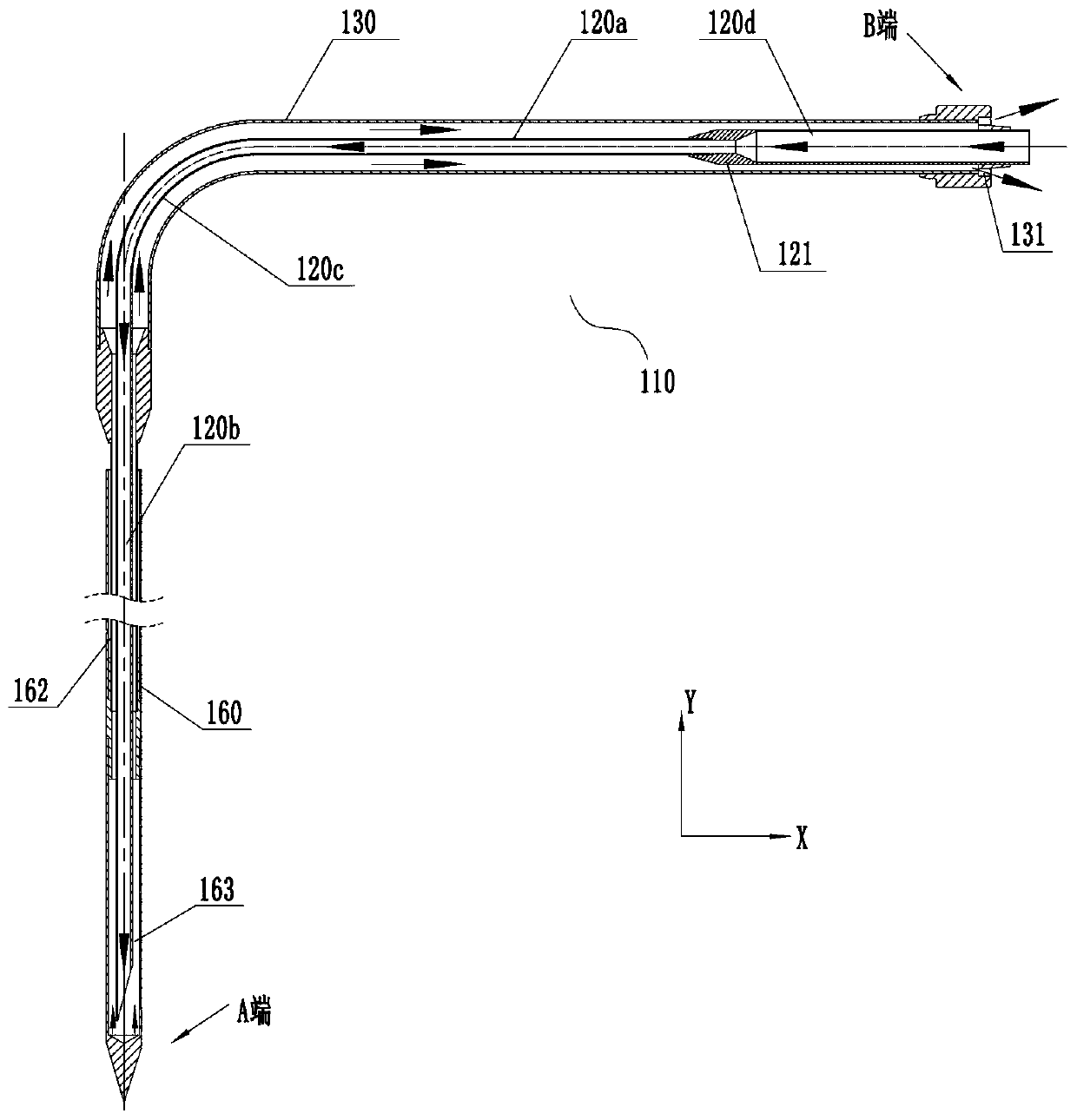

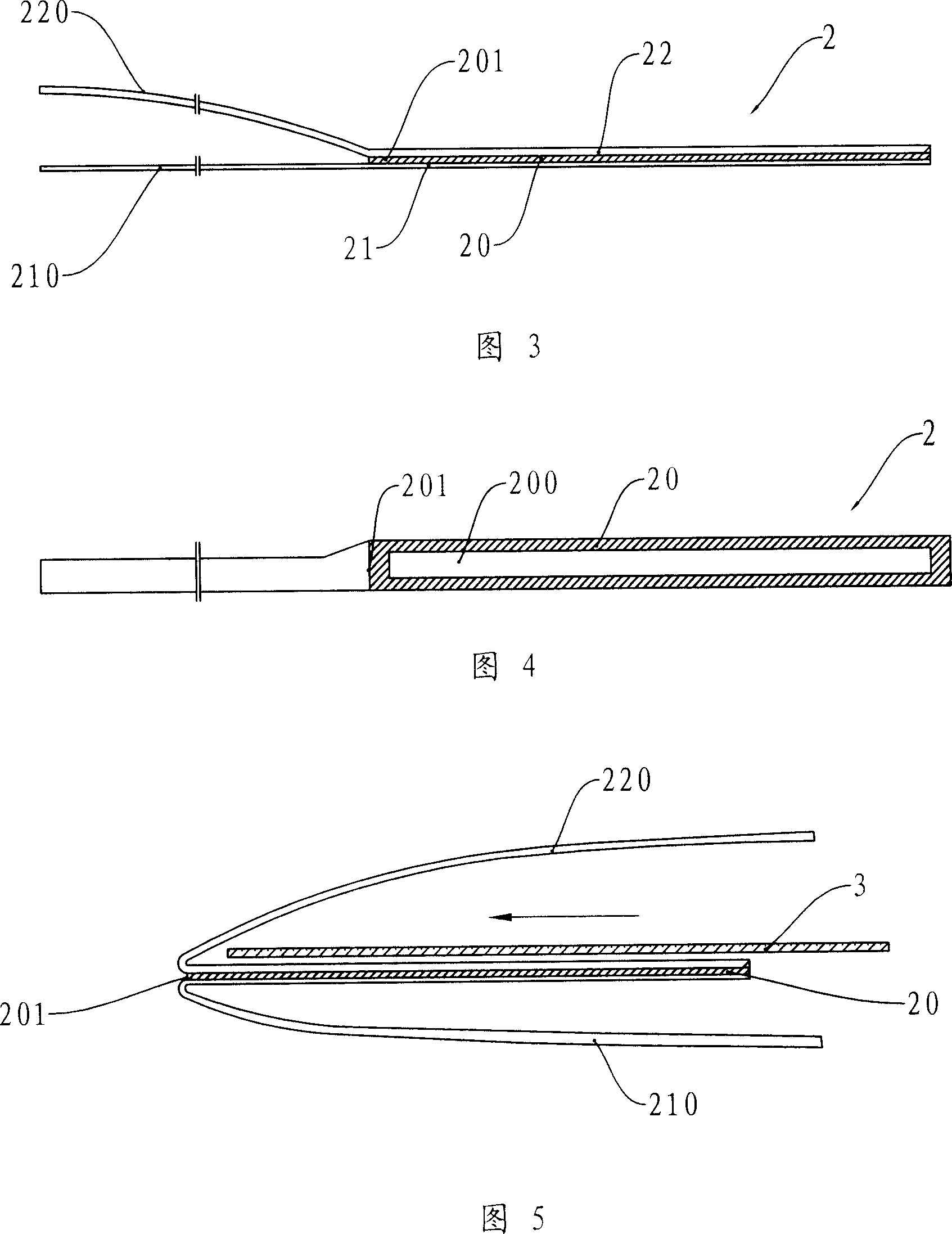

Hot and cold ablation needle

InactiveCN110575242AReduce disturbanceImprove treatment stabilitySurgical instruments for heatingSurgical instruments for coolingMedicineBiomedical engineering

The invention relates to the technical field of therapy, in particular to a hot and cold ablation needle. The hot and cold ablation needle is used for solving the technical problem that in the prior art, disturbance of a handle part of an ablation needle body can be immediately transmitted to a needle tip part of the ablation needle body, and consequently a patient is affected. The hot and cold ablation needle comprises a first flow inlet pipe assembly and a first backflow pipe assembly, the first flow inlet pipe assembly and the first backflow pipe assembly are constructed to be of bent pipestructures correspondingly, thus the extension directions of the first flow inlet pipe assembly and the first backflow pipe assembly are both changed, even if sudden disturbance or vibration acts on the handle part of the ablation needle body, the situation that acting force is immediately transmitted to the needle tip part of the ablation needle body, and consequently the patient is affected is avoided, therefore, through the bent pipe structures, disturbance of unstable factors such as disturbance to the needle tip part of the ablation needle body can be reduced, and thus the therapeutic stability of the ablation needle body is improved.

Owner:HYGEA MEDICAL TECH CO LTD

Organic sealing of bonded neodymium-iron-boron magnet and cathodic electrophoretic composite surface protection technology

InactiveCN101013628AThe sealing process is simpleEasy to operateInorganic material magnetismElectrophoretic coatingsDecanedioic acidChemistry

The invention relates to one compound surface protection technique to add Ferro-magnet organic sealing hole and cathode electrophoresis, which adopts relative buffer erosion oilchromium sulfonate for 0.2%-1.5%, dodecyl amine for 0.1%-1%, cyclohexadiene for0.2%-1.5%; oleic acid, decanedioic acid and octadecyl amine reaction for0.1%-0.5% impregnant or rapid fix impregnant, wherein, in vacuum condition, it processes sealing hles and then for electrophoresis coating compound surface.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Electrode device of electromagnetic flow meter

ActiveCN102840887ASimple preparation processSimplify the assembly processVolume/mass flow by electromagnetic flowmetersSignal conditioning circuitsHemt circuits

The invention discloses an electrode device of an electromagnetic flow meter. The electrode device of the electromagnetic flow meter comprises a measuring tube, a first electrode, a second electrode, a first lead, a second lead, a signal modulating circuit and a printed circuit board. The first electrode and the second electrode are respectively arranged on two sides of the inner wall of the measuring tube and a smooth surface is formed on the inner wall of the measuring tube. One ends of the first lead and the second lead are respectively connected with the first electrode and the second electrode, the other ends of the first lead and the second lead are connected with the signal modulating circuit, and the signal modulating circuit is arranged on the printed circuit board. The first electrode and the second electrode are made of electroconductive plastics and processed with an injection molding method. The measuring tube is made of insulation plastics and processed with the injection molding method. The electrode device of the electromagnetic flow meter is simple in manufacturing and assembling process and low in cost. The surface where electrodes contact with fluid is the smooth surface and on the same level with the inner wall of the measuring tube so that a measuring error caused by turbulent flow is reduced and higher measuring accuracy is obtained.

Owner:HANGZHOU ENGRID TECH

Method for forming composite material by matched mold

The invention discloses a method for forming a composite material by a matched mold, aiming to solve the problems that a composite material formed by an existing method is uneven in surface and insufficient in compactness. The method comprises the following steps: firstly, laying a prepreg layer of the composite material on the surface of an inner mold on a lower mold of a metal mold, and laying expansion rubber uniformly on the outer layer of the prepreg layer of the composite material; secondly, combining an outer mold with the outer layer of the expansion rubber, and combining the outer mold closely at the outer side of the outer mold by a mold combining ring, and covering the upper mold tightly, thereby obtaining the packaged mold; and thirdly, putting the packaged mold in the second step into a curing furnace, curing, then taking the mold out, cooling to room temperature, and demolding, thereby obtaining the formed composite material. The method is used for forming the composite material.

Owner:HARBIN FRP INST

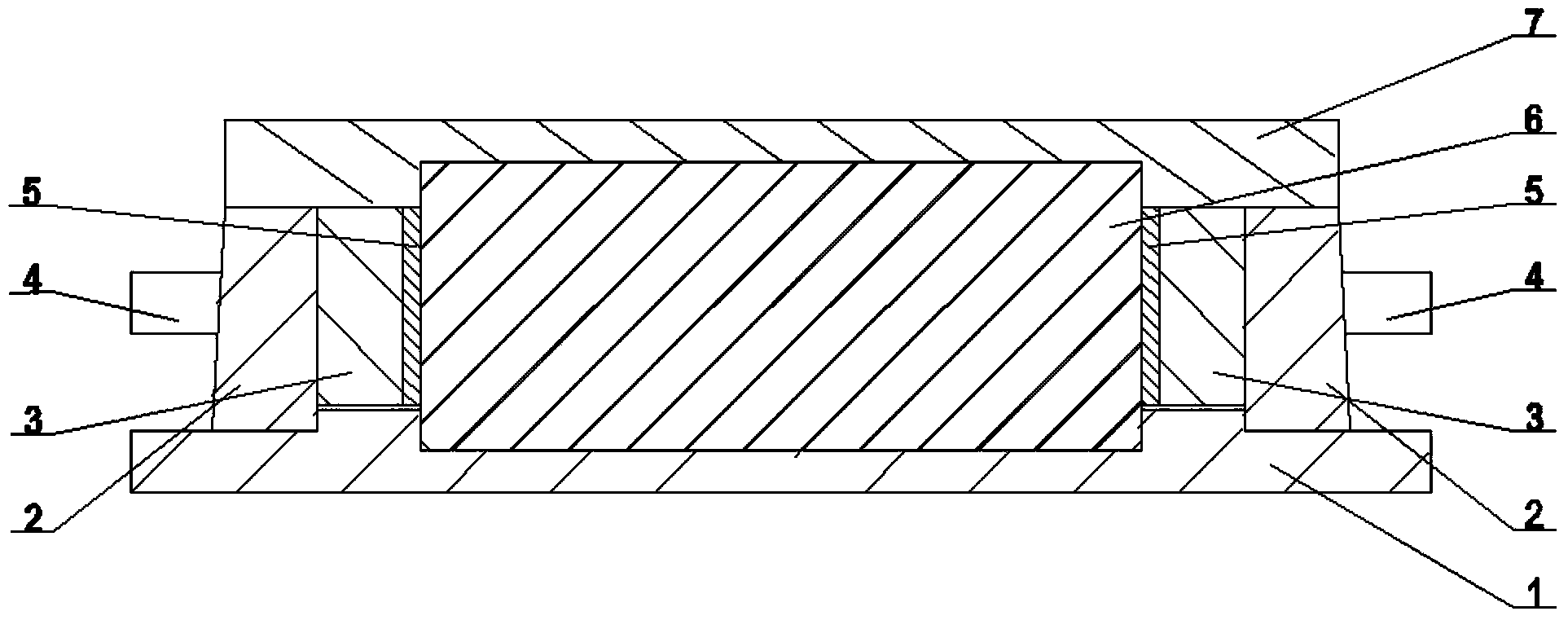

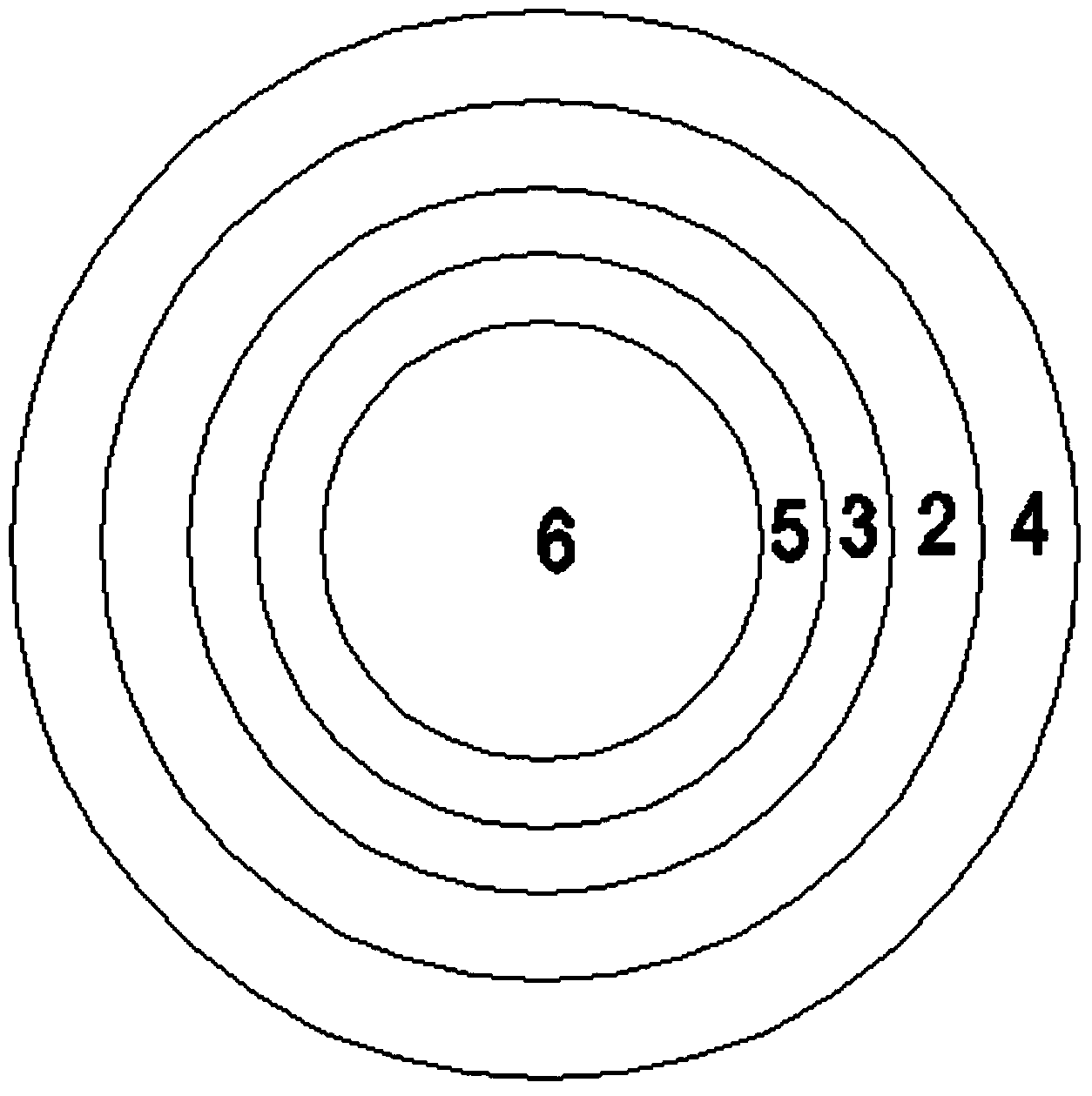

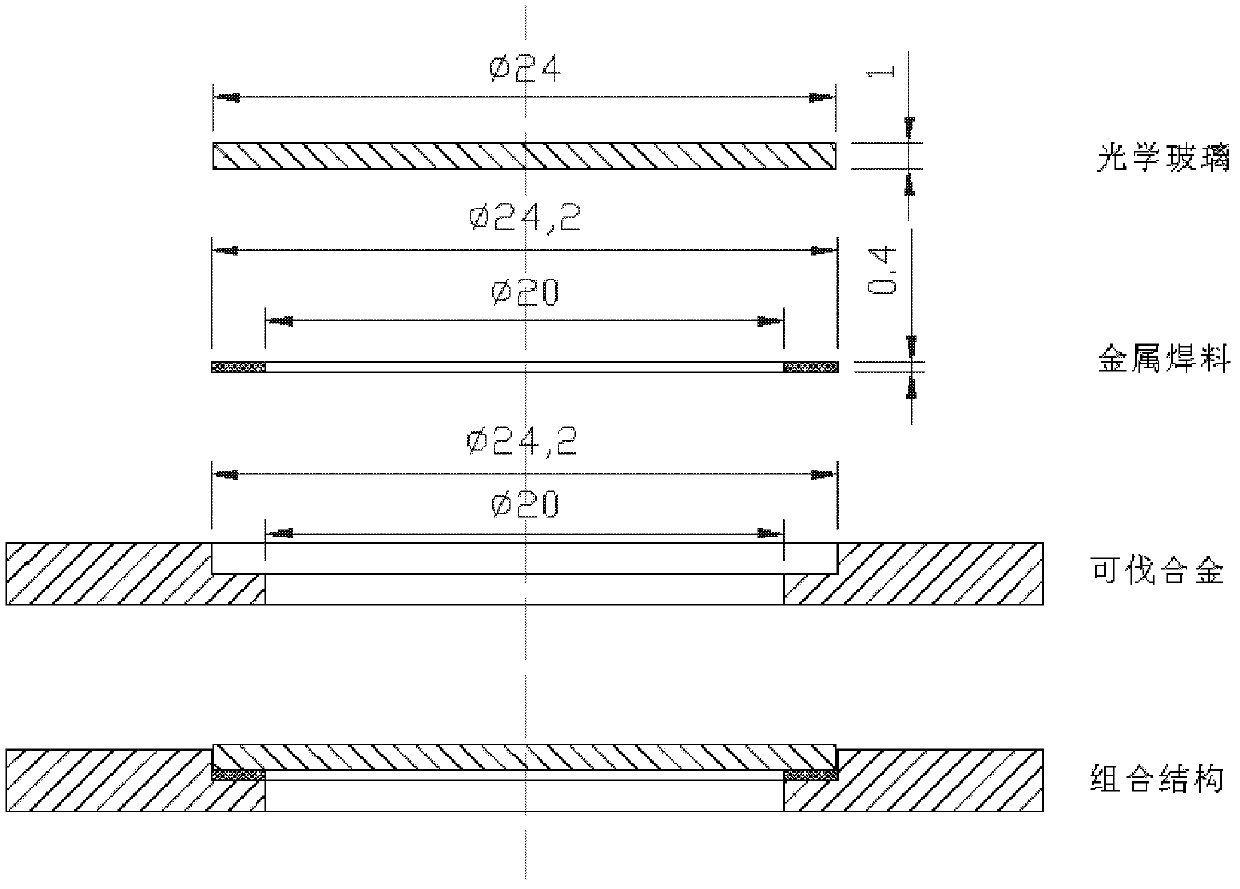

Hermetic seal method of optical glass and Kovar alloy

The invention discloses a hermetic seal technique of optical glass and Kovar alloy, belonging to the technical field of vacuum hermetic packaging. By using a Pb welding flux as a braze welding material, high-temperature treatment is carried out at certain temperature to finally implement welding between the two dissimilar materials (optical glass and Kovar alloy), thereby obtaining the packaging structural member formed by sealing a large-area optical window on a Kovar alloy pipe shell. The optical window structure sealed by the technique has the advantages of favorable mechanical strength, favorable air tightness, simple seal technique and high yield. The hermetic seal technique of optical glass and Kovar alloy is applicable to the fields of manufacturing of optical equipment and vacuum hermetic packaging of optical devices.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

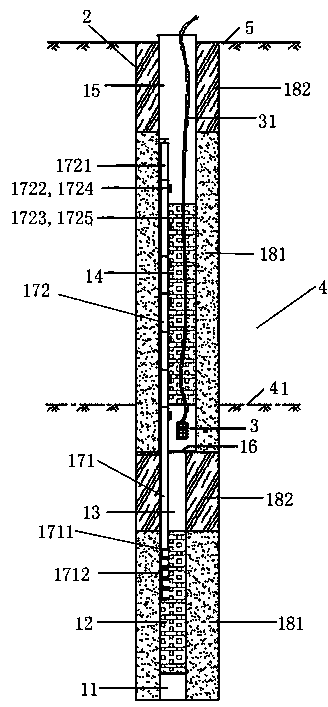

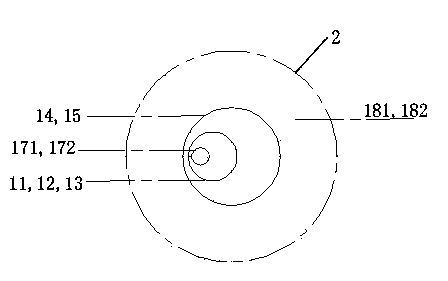

Tube well used for unwatering and pressure-reducing drainage and drainage method of tube well

The invention discloses a tube well used for unwatering and pressure-reducing drainage. The tube well comprises a well pipe comprising a precipitation tube, a pressure-reducing water filtering tube, a pressure-reducing well wall tube, an unwatering water filtering tube and an unwatering well wall tube which are sequentially arranged from bottom to top in a penetrating mode, and the joint of the pressure-reducing well wall tube and the unwatering water filtering tube forms a lower pressure-reducing well pipe and an upper unwatering well pipe through a seal board in a partitioning mode. The seal board is provided with a natural flow pipe comprising a water inlet pipe section and a water outlet pipe section, the water inlet pipe section is provided with a water inlet, the water outlet pipe section is sequentially provided with a plurality of water outlet pipe section bodies in the axial direction, each water outlet pipe section body is provided with a side wall water outlet and an upper water outlet, and the side wall water outlets and the upper water outlets are of opening and closing structures. The tube well simplifies drainage procedures, increases the drainage success probability, reduces engineering costs, accelerates the construction progress, increases the deep foundation pit excavation safety coefficient, and simplifies capping work. The invention further discloses a drainage method using the tube well.

Owner:ZHONGYIFENG CONSTR GRP

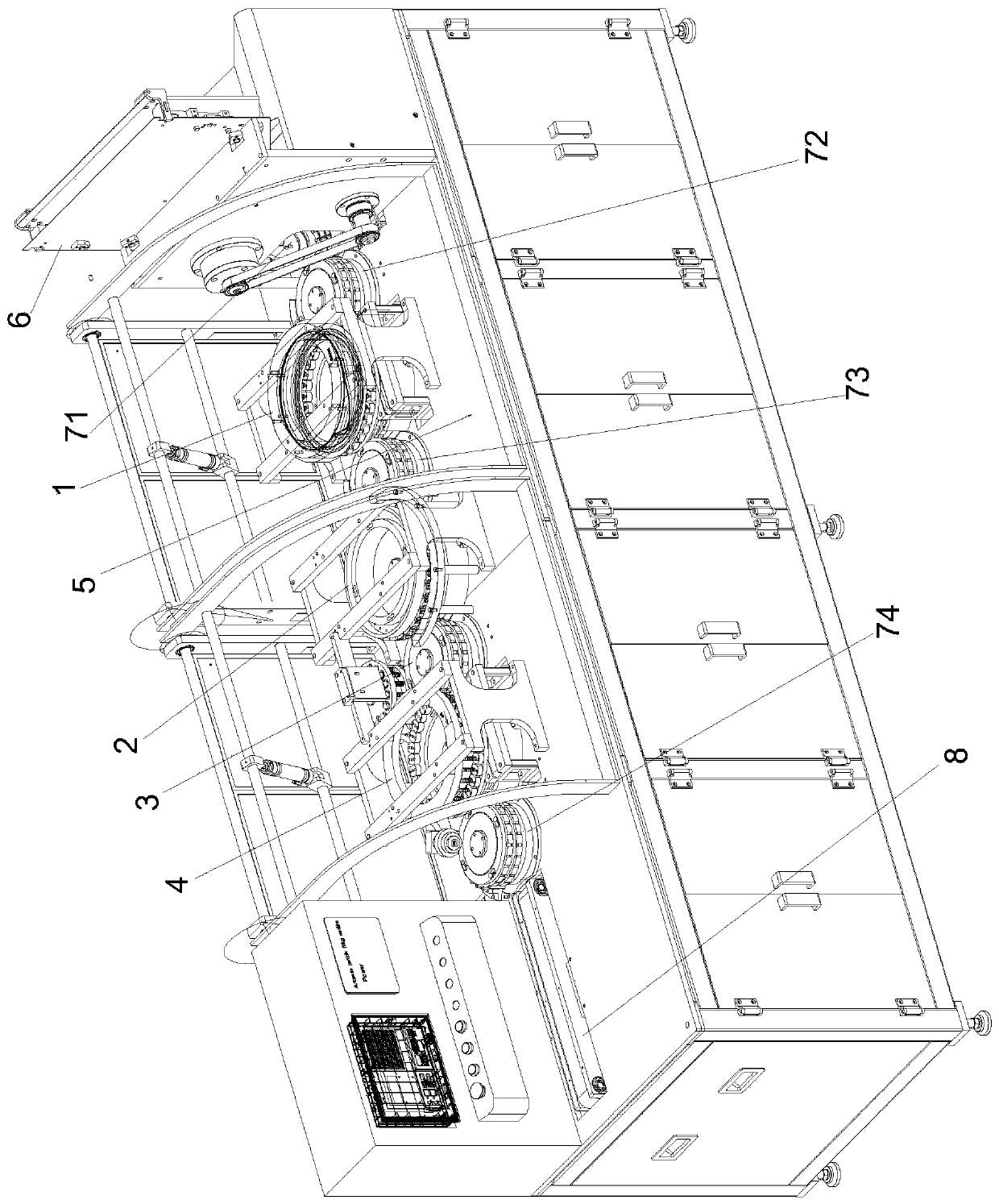

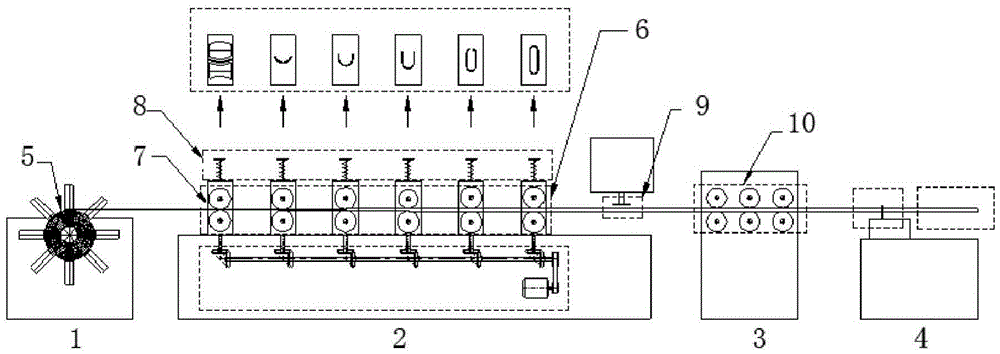

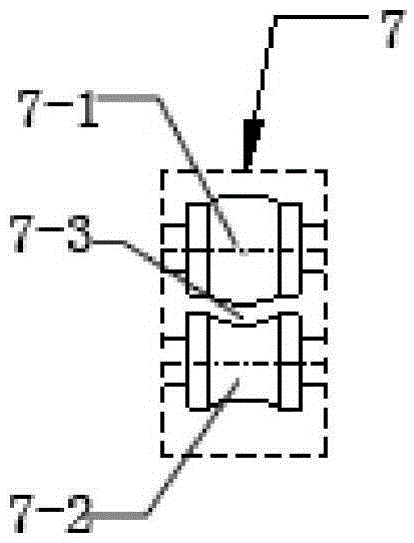

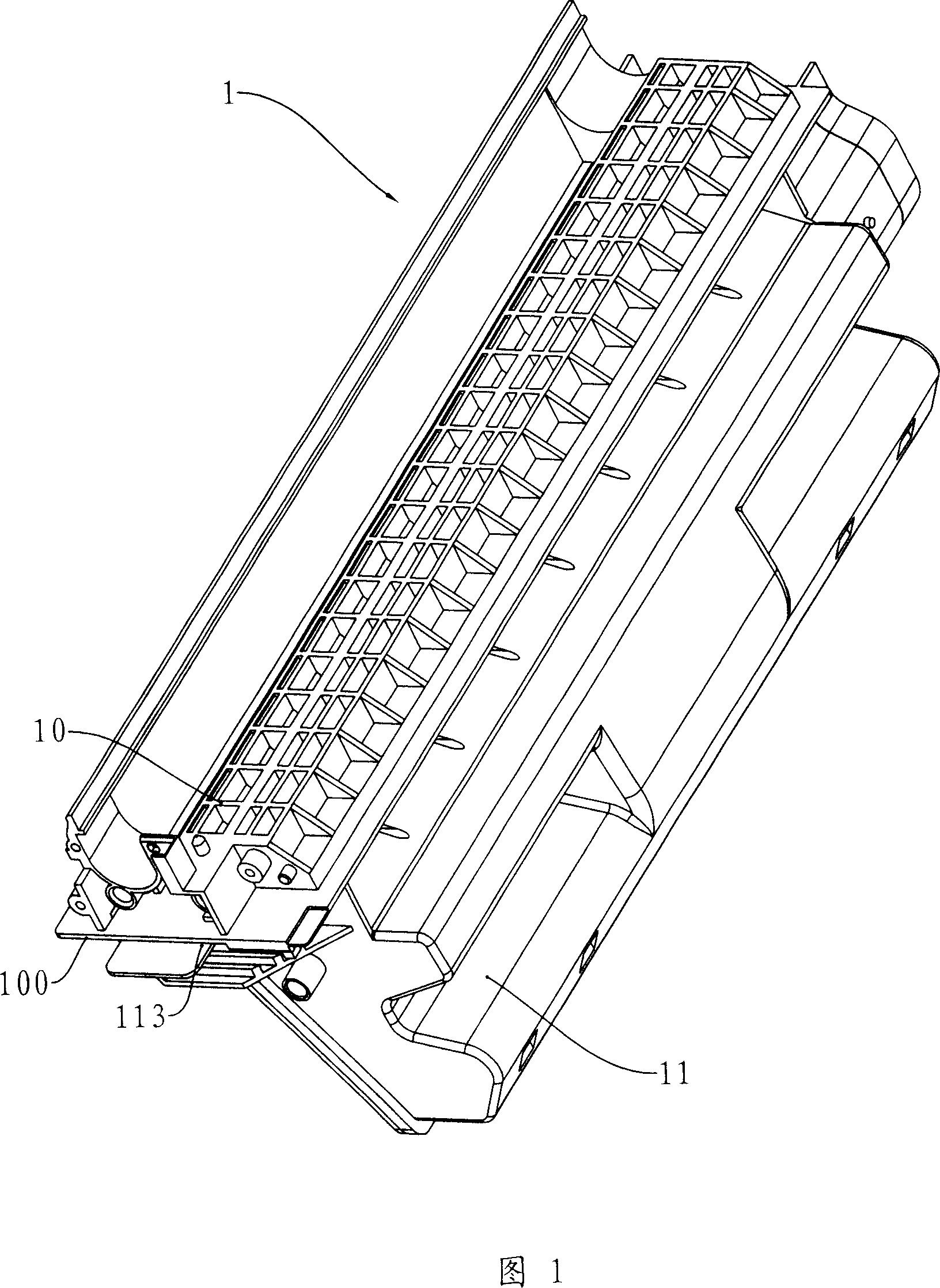

Improved particle continuous filling equipment

PendingCN110419768AGuaranteed uptimeEfficiencyCigarette manufactureTobacco devicesPunchingBurn cigarette

The invention provides improved particle continuous filling equipment, wherein in a priming section, a priming drum is utilized to drive cigarette blank pipes and an edge layer at the top end to synchronously rotate, a compound cam and compound punching needles above are matched, and by up-and-down movement of the compound punching needles, priming on the cigarette blank pipes is implemented; in afilling section, a filling drum is utilized to drive a feeding disk at the top end to rotate, a filling cam is matched with a plurality of moving pistons on the feeding disk, opening / closing of eachfilling through hole on a ring-shaped groove of the feeding disk is implemented, and filling is carried out in a filling working region where a separator is positioned; in a gluing section, glue dispensing rods and the cigarette pipes can be in contact at a meshing point under the press-against action of a gluing cam, a gluing wheel in a glue pool glues the glue dispensing rod; and in a sealing section, rotation of a sealing drum is utilized to drive sealing punching needles to be matched with a sealing cam above so as to implement up-and-down movement of the sealing punching needles and complete sealing on the glued cigarette pipes. According to the invention, higher efficient and high quality preparation of a particle heating non-burning cigarette product can be implemented, and cost isreduced.

Owner:CHINA TOBACCO ANHUI IND CO LTD

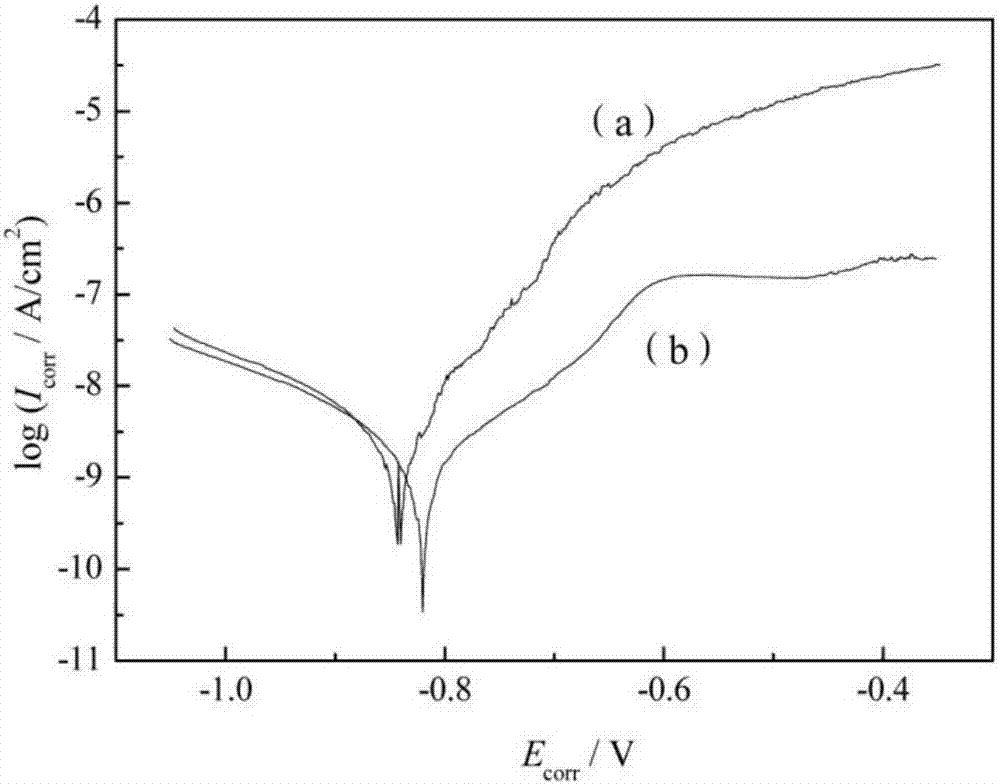

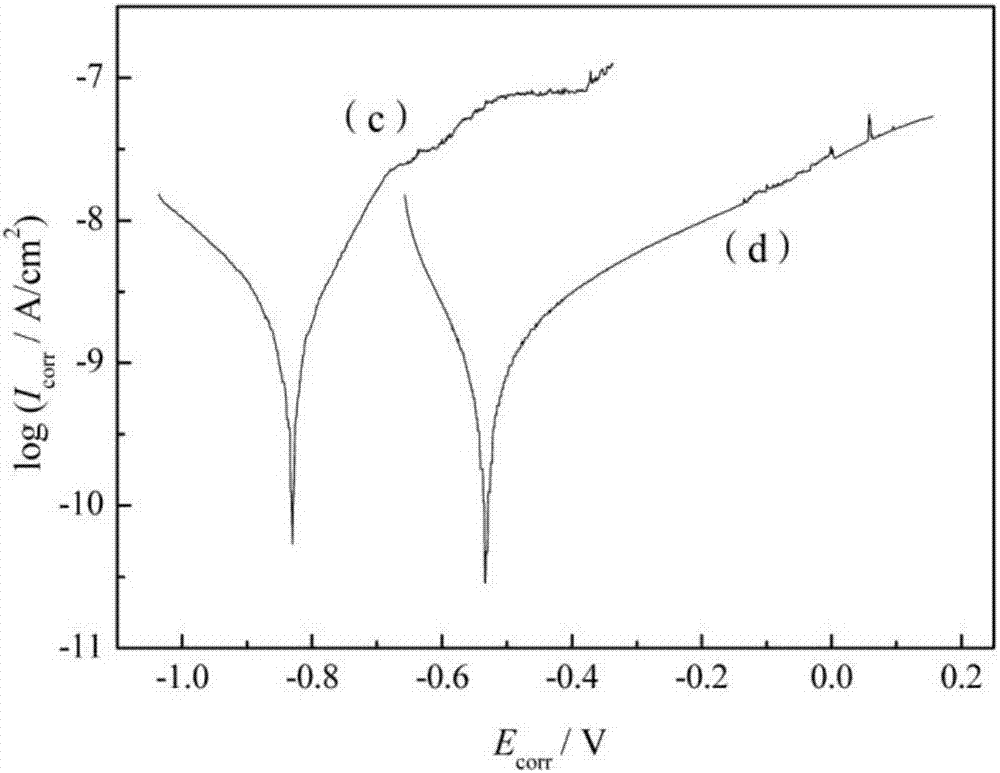

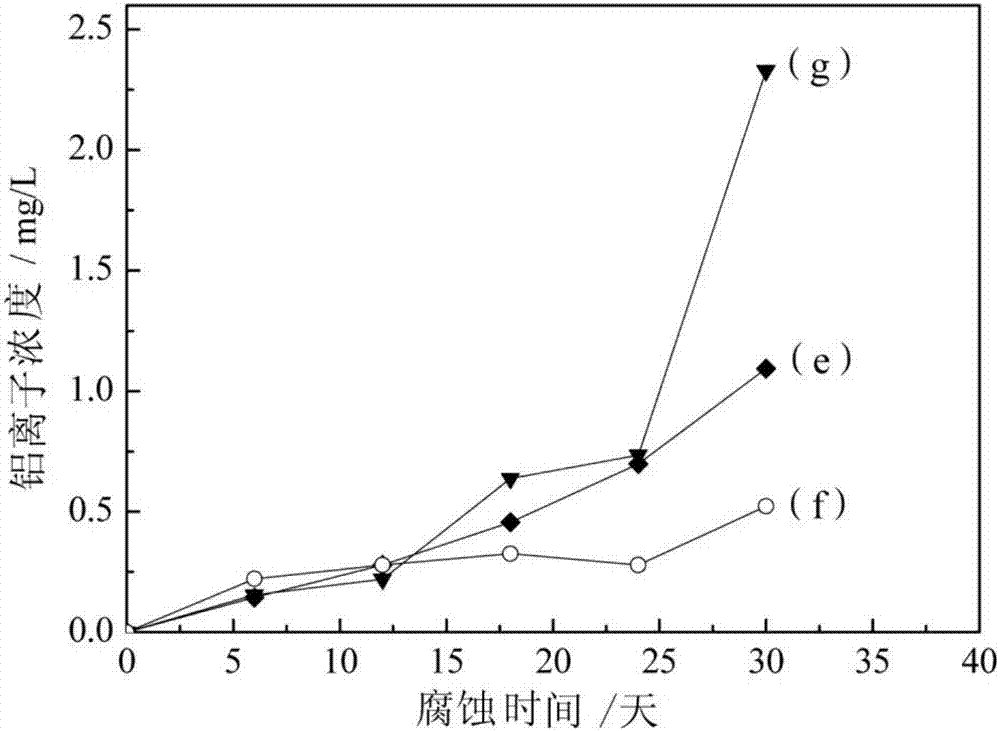

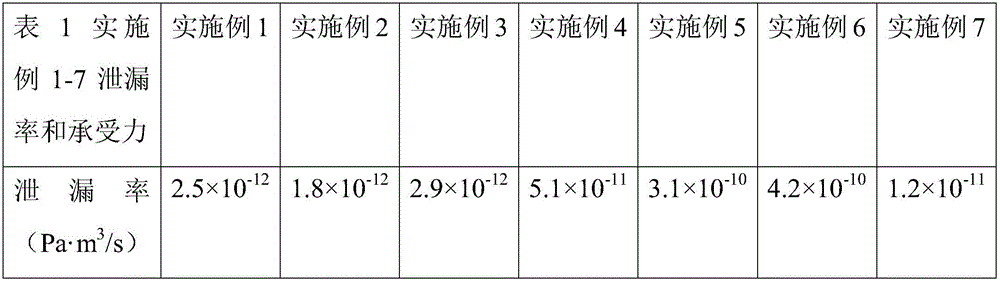

Treatment method for improving corrosion resistance of surface of aluminum alloy

ActiveCN106894071AImprove corrosion resistanceSimple sealing processAnodisationCellsElectrolysisSilicon

The invention belongs to the technical field of aluminum alloy surface corrosion resistance, and in particular, relates to a treatment method for improving corrosion resistance of the surface of an aluminum alloy. Through adjustment of an electrolyte ratio and electrolysis process parameters and use of aeration stirring, a formed ceramic oxide film has a more uniform and compact structure; and a titanium-silicon composite sol sealing method is adopted to fill an outer loose layer of the ceramic oxide film so as to further improve the Cl<-> ion infiltration capacity of the film layer. The method is simple, control is easy, the process is stable, and the method is particularly suitable for seawater corrosion resistance protection requirements of aluminum alloys in marine engineering environments.

Owner:STATE DEV & INVESTMENT +1

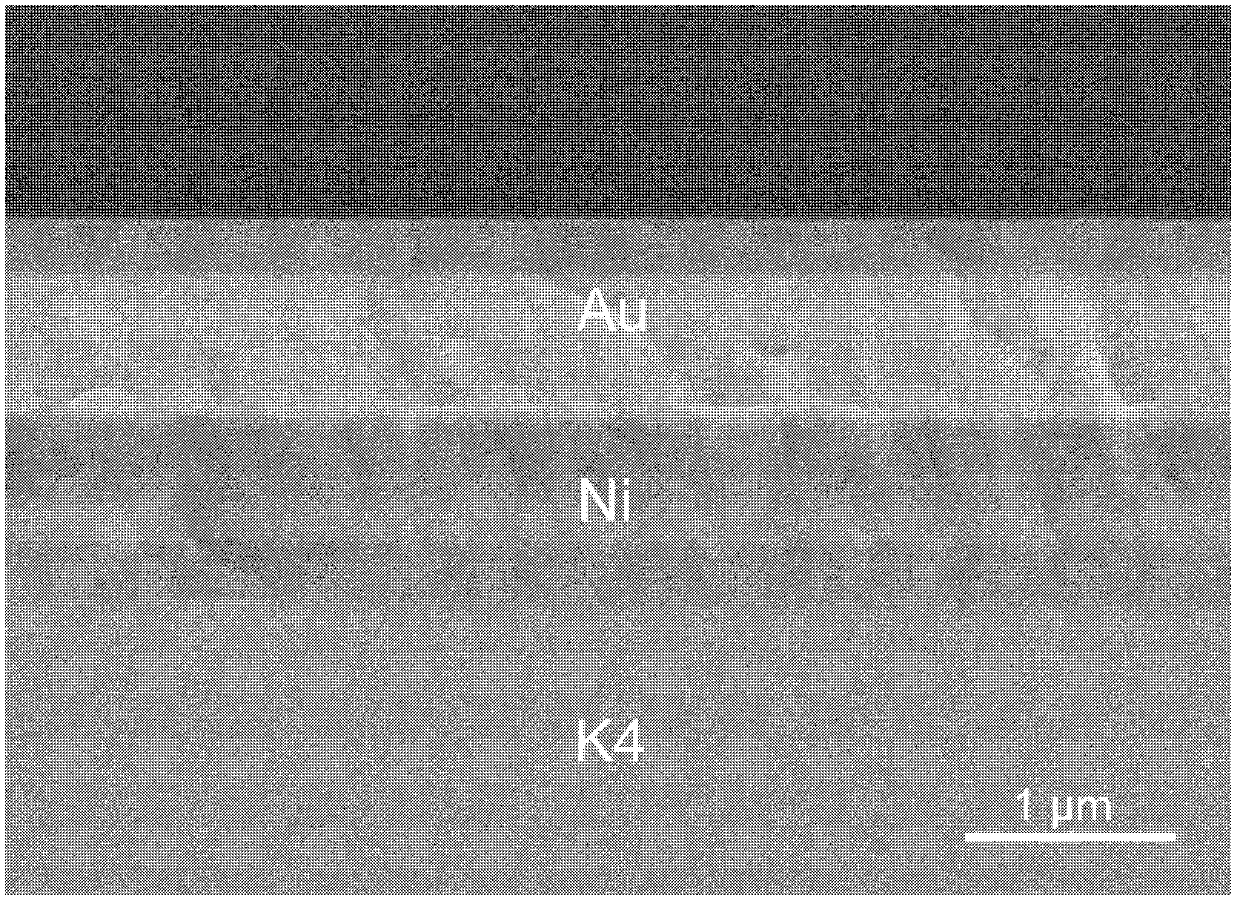

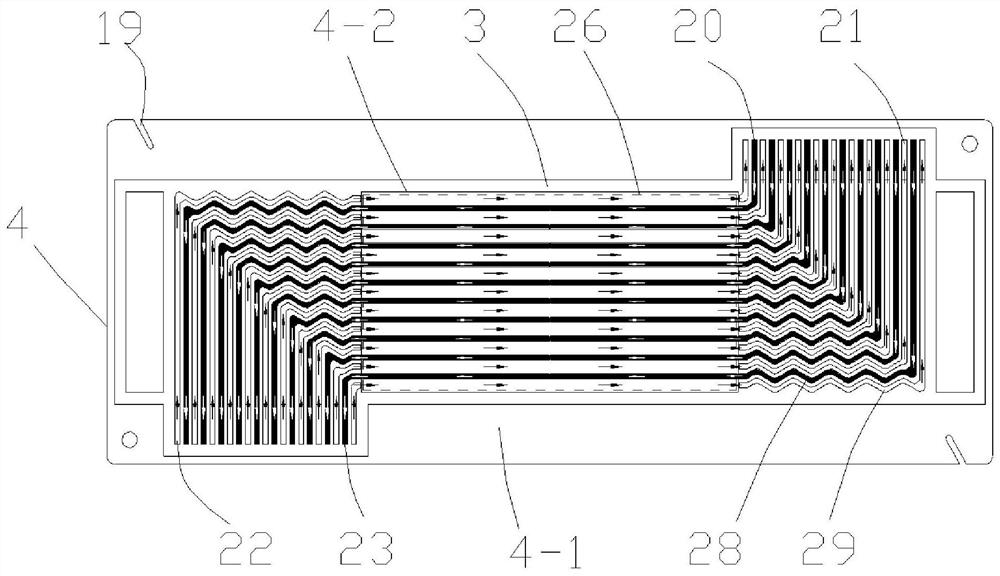

Photoelectric conversion device and manufacturing method thereof

InactiveUS20110220202A1Seal performance be improveSimplification of sealing processLight-sensitive devicesFinal product manufactureEngineeringPhotoelectric conversion

A photoelectric conversion device includes first and second substrates on which first and second electrodes are respectively formed, arranged to face each other, an electrolyte injected into a gap between the first and second substrates through an electrolyte injection hole formed in the first substrate, and an injection hole sealing member for sealing the electrolyte injection hole. The injection hole sealing member includes a cover portion for covering an entrance end of the electrolyte injection hole and an insertion portion extending from the cover portion along the electrolyte injection hole.

Owner:SAMSUNG SDI CO LTD

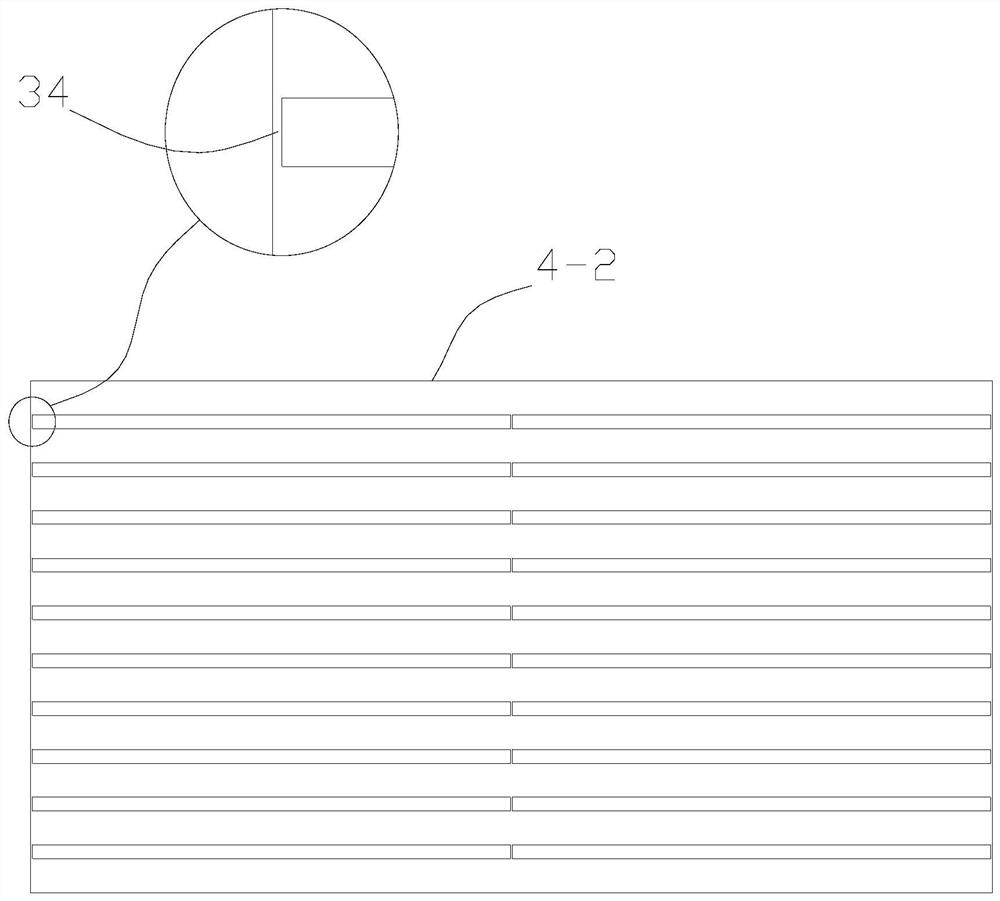

Method for manufacturing flat tubes

The invention relates to a method for manufacturing flat tubes. The method includes a coarse pressing forming phase, a dimensional fine pressing phase, a shell nosing phase and a welding sealing phase. Rolling is carried out by progressive dies of a plate pressing machine in the coarse pressing forming phase and the dimensional fine pressing phase, progressive drawing die sets are mounted on the plate pressing machine, at least three roller groups are arranged in each progressive drawing die set and synchronously rotate on the plate pressing machine in a linkage manner, each roller group comprises an upper roller and a lower roller which are oppositely arranged in the up-down direction, the upper rollers are provided with conical bosses which outwardly extend, radially inward conical grooves which are matched with the upper rollers are formed in the lower rollers, roller gaps for pressing and forming metal sheets are reserved between the conical bosses and the conical grooves, and pressures which are applied by the upper rollers and the lower rollers on the central metal sheets are 0.5-5 KG. The method has the advantages that the plate pressing machine coarsely presses and finely presses the metal sheets, then the metal sheets are formed by the aid of shell nosing working procedures and high-frequency welding, and accordingly the flat tubes can be quickly formed.

Owner:徐晓冰

Nd-Fe-B magnet inorganic sealing hole adhesion and cathode electrophoresis composite surface protection technique

InactiveCN101015858AThe sealing process is simpleEasy to operateInductances/transformers/magnets manufactureMagnetic materialsTetramineNeodymium iron boron

The invention relates to a method for adhering neodymium iron boron inorganic hole and cathode electrophoresis composite surface protection, wherein the invention uses inorganic hole agent of potassium metasilicate, liquid glass or lithium silicate whose modules are 3.3-5.4, 3.3 and 4.5, added with inhibitor additive as 0.5-2% hexamethylene tetramine, 0.2-1% bioquin and 0.5-3% sodium molybdatem, under vacuum condition to seal the holes of neodymium iron boron magnet, then processes composite surface protection of electrophoresis coat. The invention has simple operation and semi-automatic operation, to obtain uniform thickness and better insulation property.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

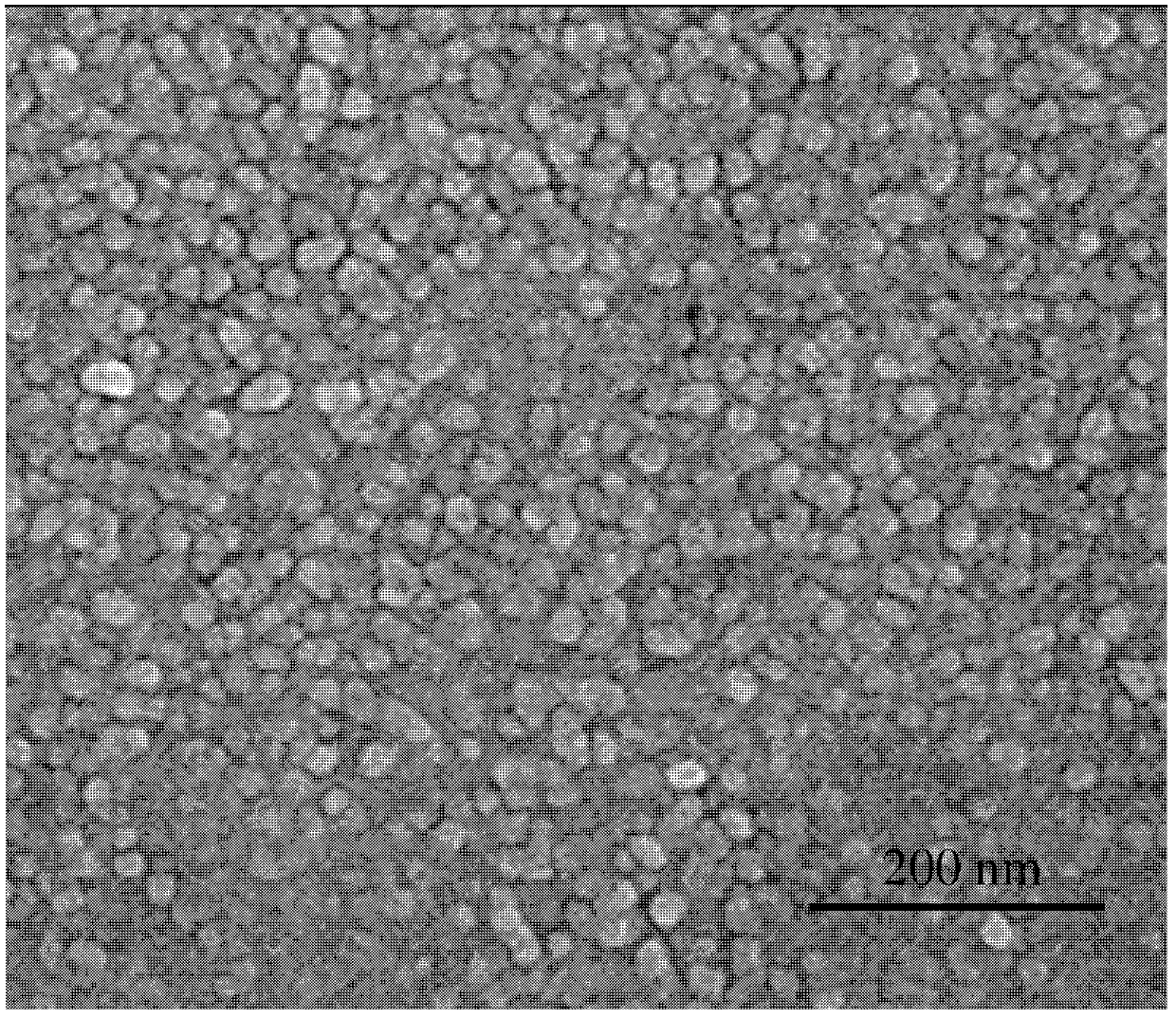

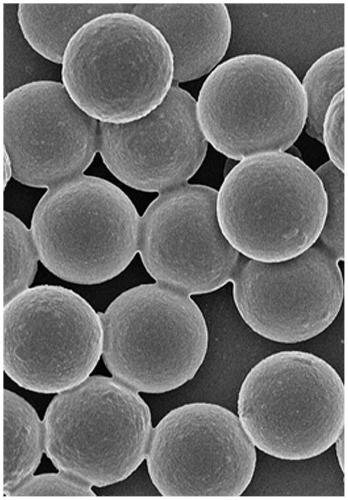

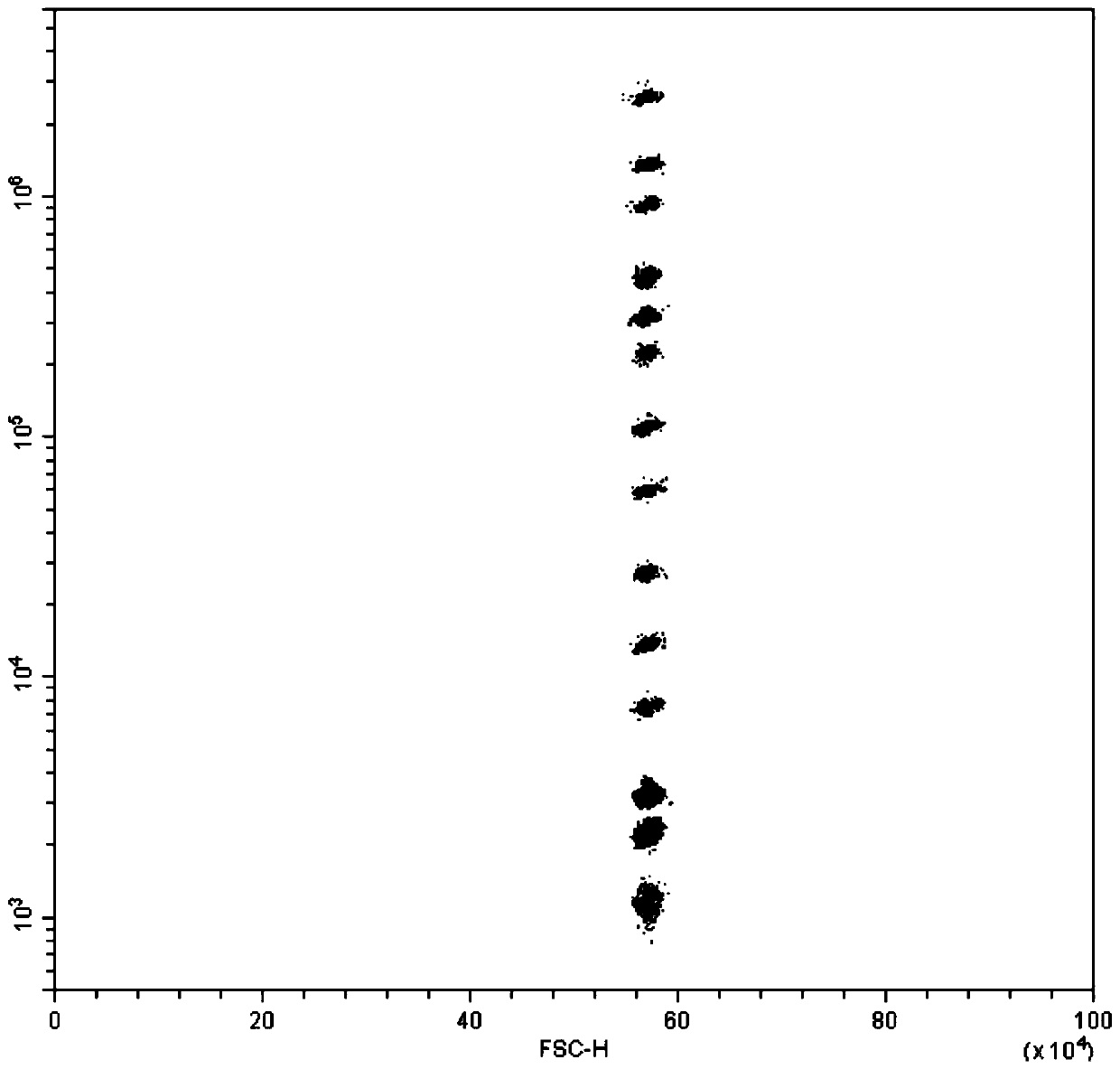

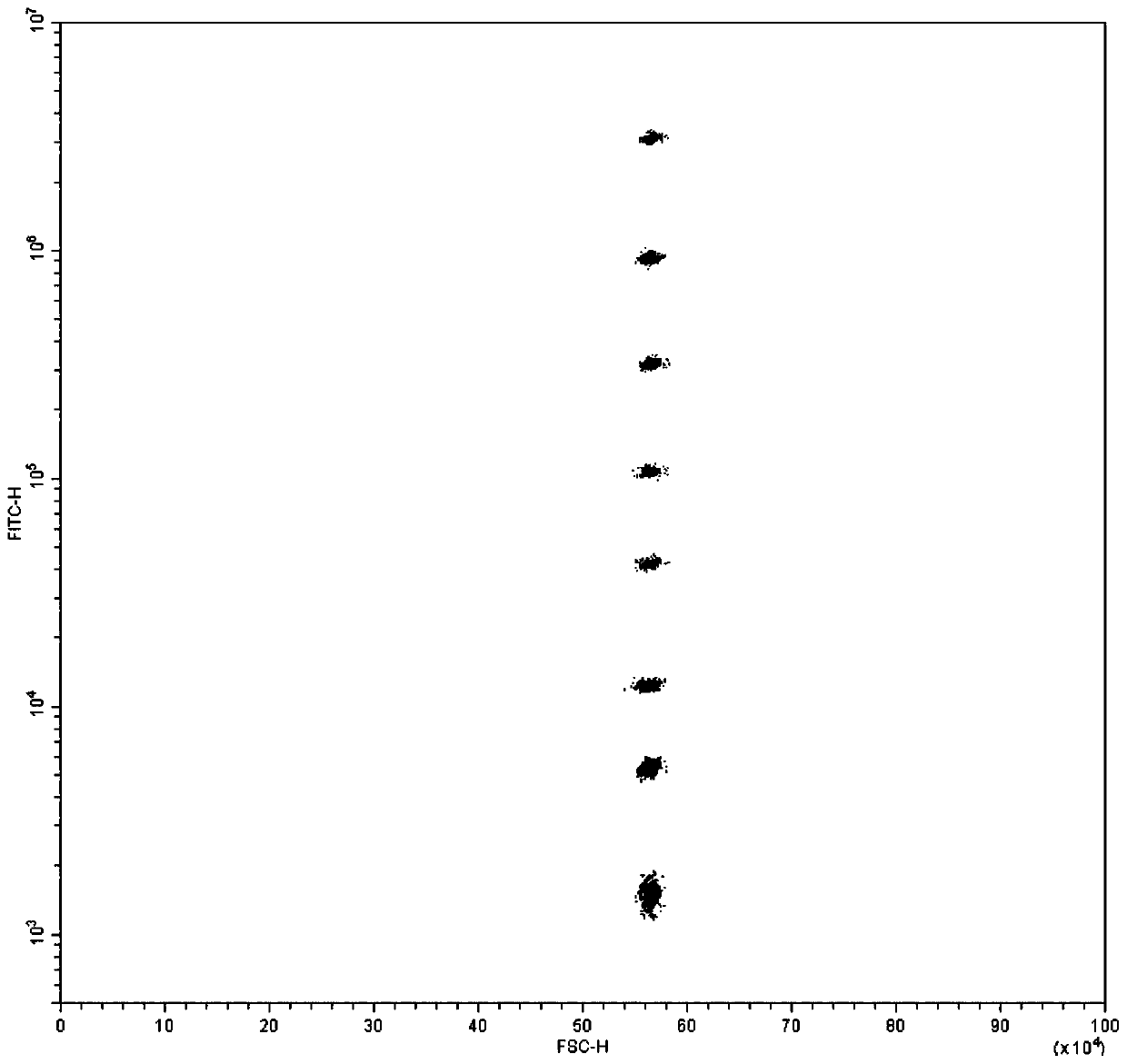

Magnetic fluorescent coding microsphere and preparation method thereof

ActiveCN111426659AReduce polarityIncrease polarityFluorescence/phosphorescenceMicrosphereMagnetite Nanoparticles

The invention relates to a magnetic fluorescent coding microsphere and a preparation method thereof. Firstly, during magnetic particle synthesis, medium-chain and short-chain fatty acids are used formodifying the surfaces of magnetic nanoparticles, so that the polarity of the surfaces of the magnetic nanoparticles is increased, the magnetic nanoparticles can be uniformly dispersed in a good solvent, and the particle size is more uniform; then, a two-step swelling method is adopted, which comprises the following steps: firstly, enabling magnetic nanoparticles to enter swelled polymer microspheres; enabling the fluorescent dye to enter the swollen polymer microspheres to form a 'magnetic particle core-fluorescent shell layer' structure, and reducing quenching and shielding effects of the magnetic particles on fluorescence to the greatest extent; then, by utilizing the swelling fading effect of the microspheres in a poor solvent, sealing cracks generated on the surfaces of the microspheres due to the swelling effect, avoiding leakage of magnetic nanoparticles and fluorescent dyes, greatly simplifying the sealing process, and obtaining the magnetic fluorescent coding microspheres withgood microsphere particle uniformity, good magnetic performance and good fluorescent performance.

Owner:深圳唯公生物科技有限公司

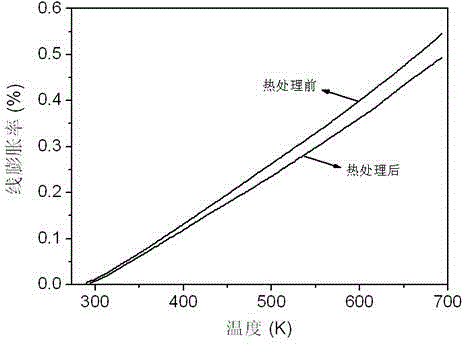

Process for carrying out low-temperature glass sealing after titanium alloy electrochemical oxidation

ActiveCN106757275AHigh bonding strengthGood processing consistencySurface reaction electrolytic coatingAir atmosphereThermal expansion

The invention discloses a process for carrying out low-temperature glass sealing after titanium alloy electrochemical oxidation. The process comprises the following steps that (1) a titanium alloy is subjected to conventional ungrease treatment; (2) low-temperature sealing glass with the softening temperature ranging from 430 DEG C to 460 DEG C, the sealing temperature ranging from 520 DEG C to 540 DEG C, the thermal expansion coefficient being 8.5-10.0*10<6> / (25-300 DEG C) and the specific resistance being larger than 10<14> omega.cm is selected and prepared into a glass blank according to a conventional method; (3) under the condition of 20 DEG C, a sulfuric acid solution with the concentration ranging from 150 g / L to 200 g / L is used as an electrolyte, the ungreased titanium alloy is used as an anode, a lead plate or a graphite plate is used as a cathode, and electrolytic oxidation is carried out; (4) inner conductor workpiece oxidation is carried out; and (5) glass sealing is carried out. According to the process, the glass sealing temperature range is narrowed, sintering is carried out under the air atmosphere, the sealing process is simple, the cost is low, and the procedure of the process is easy to control.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

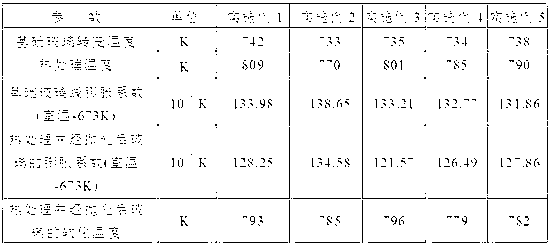

Double-coaxial connector bonded and sealed by ceramic matrix

ActiveCN104577459ANo damageImprove transmission qualityCoupling device detailsTwo-part coupling devicesElectrical conductorSealant

The invention provides a double-coaxial connector bonded and sealed by a ceramic matrix. The double-coaxial connector comprises an outer conductor, central conductor insulators, middle conductor insulators, a middle conductor, a central conductor, outer ceramic rings and inner ceramic rings, wherein the central conductor, the middle conductor and the outer conductor are three layers of coaxial contact pieces of the connector, are supported mutually by the inner ceramic rings and the outer ceramic rings and are filled with sealants for internal sealing. The two ends of the inner ceramic rings and the outer ceramic rings are insulated and isolated by the central conductor insulators and the middle conductor insulators. The double-coaxial connector with the sealing structure has the characteristics of light weight, excellent electric performance, simple sealing process and high sealing property.

Owner:杭州航天电子技术有限公司

Lead-free sealing glass with transitional expansion coefficient

Owner:QILU UNIV OF TECH

Manufacturing method for lead-free sealing glass with transitional expansion coefficient

ActiveCN103342451ASimple sealing processLow costGlass shaping apparatusAluminium hydroxideMixed materials

The invention relates to the field of glass new materials, and particularly discloses a manufacturing method for a lead-free sealing glass with a transitional expansion coefficient. The lead-free sealing glass is obtained by using quartz sand, aluminium hydroxide, bismuth trioxide, ferric oxide, sodium carbonate, potassium carbonate, magnesium oxide, calcium carbonate, barium carbonate and zinc oxide as raw materials and through the steps of mixing the above raw materials uniformly, melting the mixed materials and homogenizing to obtain a glass melt, then treating the glass melt by casting, annealing, cutting, buffing, polishing and performing heat treatment under a reduction atmosphere. The manufacturing method for the lead-free sealing glass with the transitional expansion coefficient overcomes various disadvantages in a conventional transitional sealing method, has the advantages of simple sealing process, low cost, easily controllable quality and the like, and is very suitable for situations that the cross section of a to-be-sealed device is in a circle structure.

Owner:SHANDONG KANGYOU GLASS MATERIAL CO LTD

Electronic device and manufacturing method thereof, electronic apparatus, and moving body

ActiveUS9247664B2Improve reliabilityManufacturing method can be providedTelevision system detailsWave amplification devicesAtmospheric pressurePressure Atmosphere

Owner:SEIKO EPSON CORP

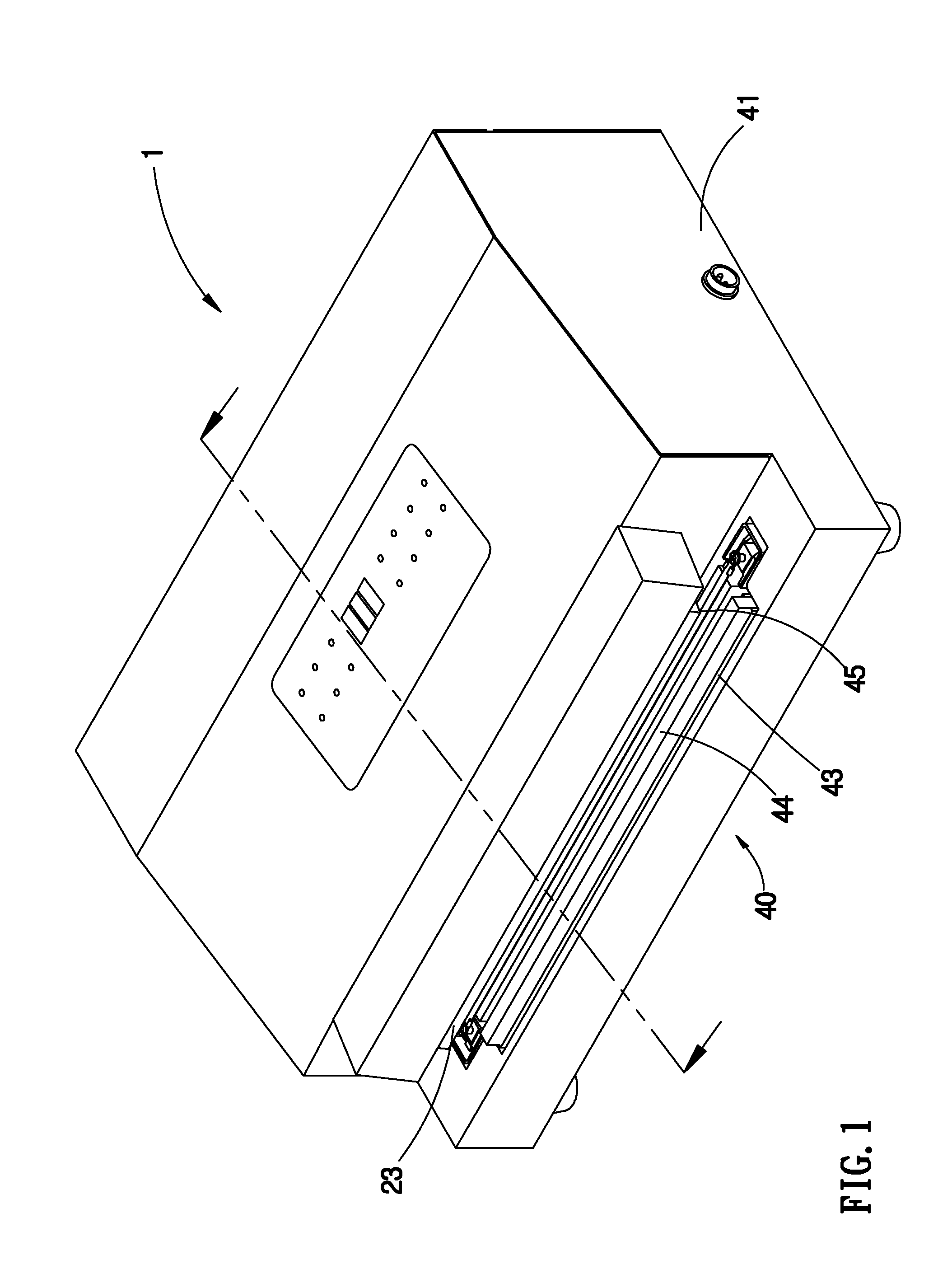

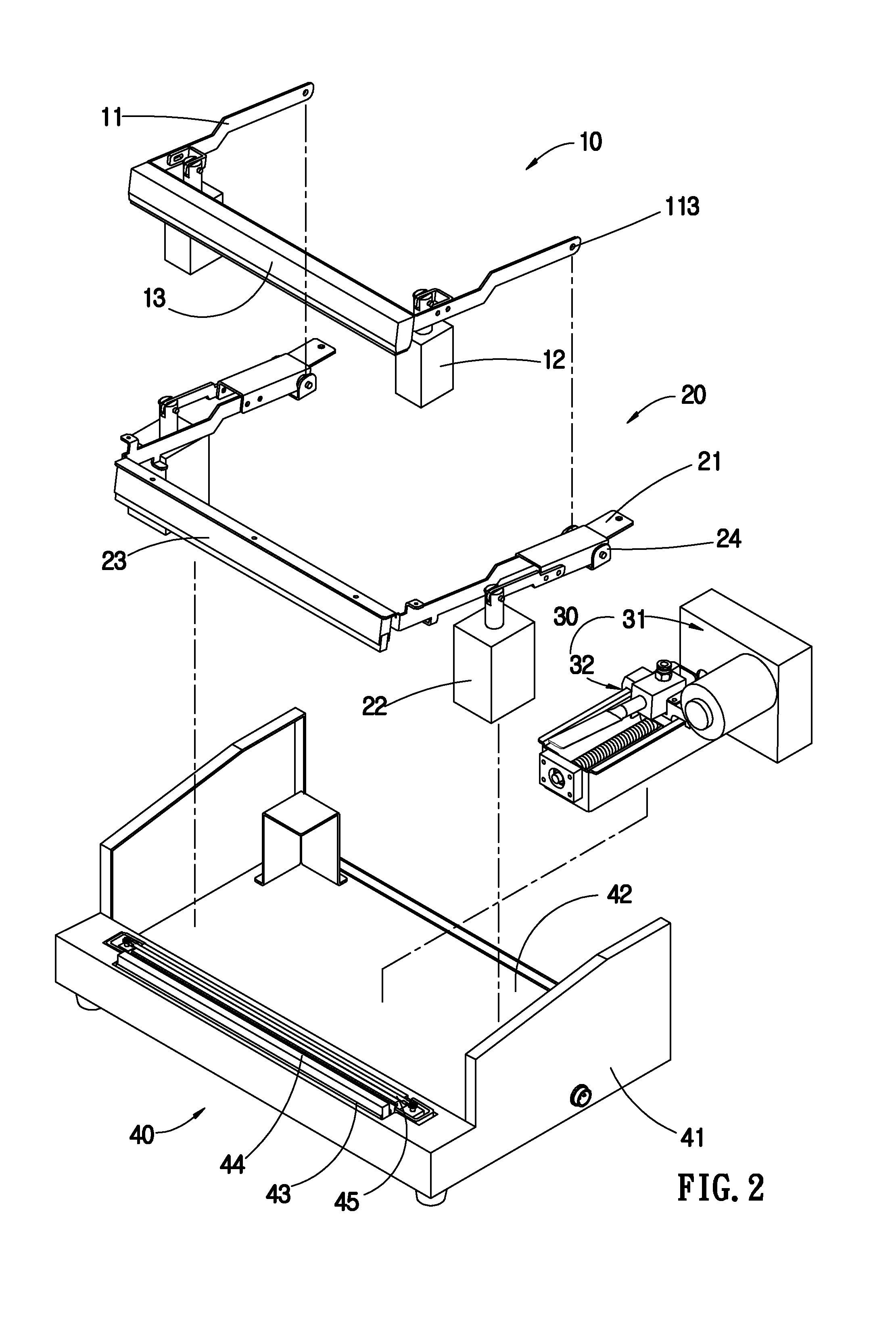

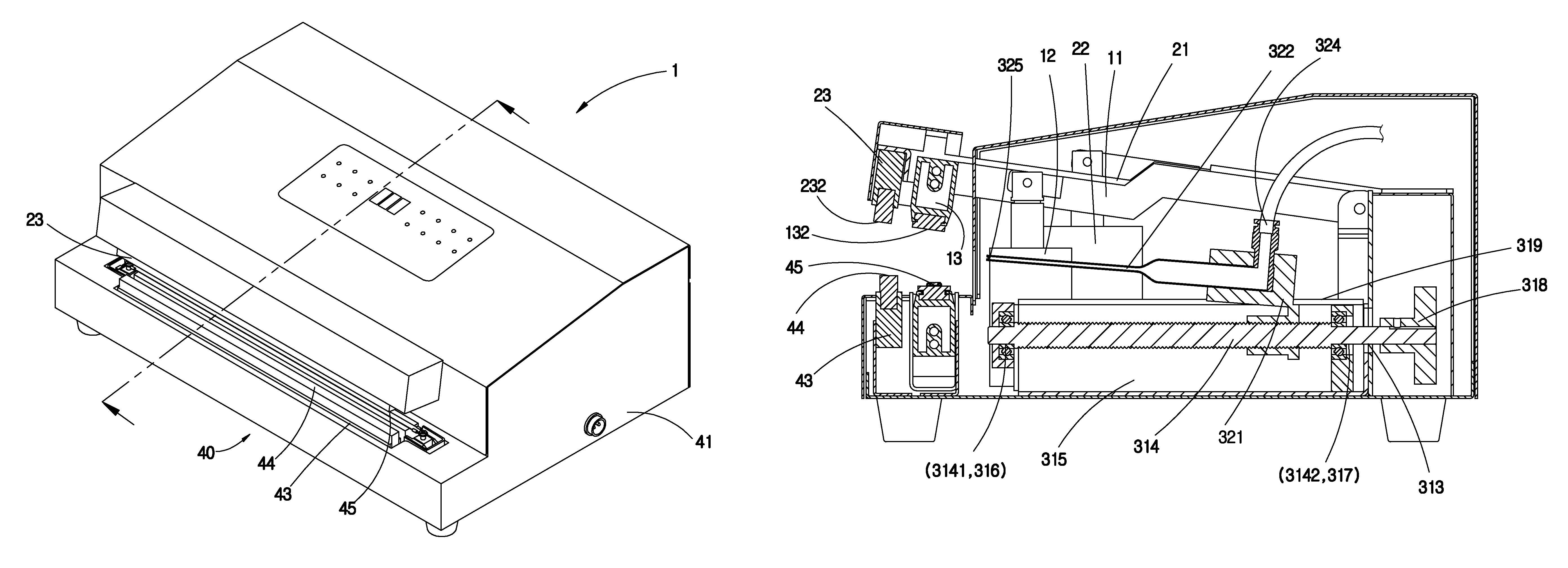

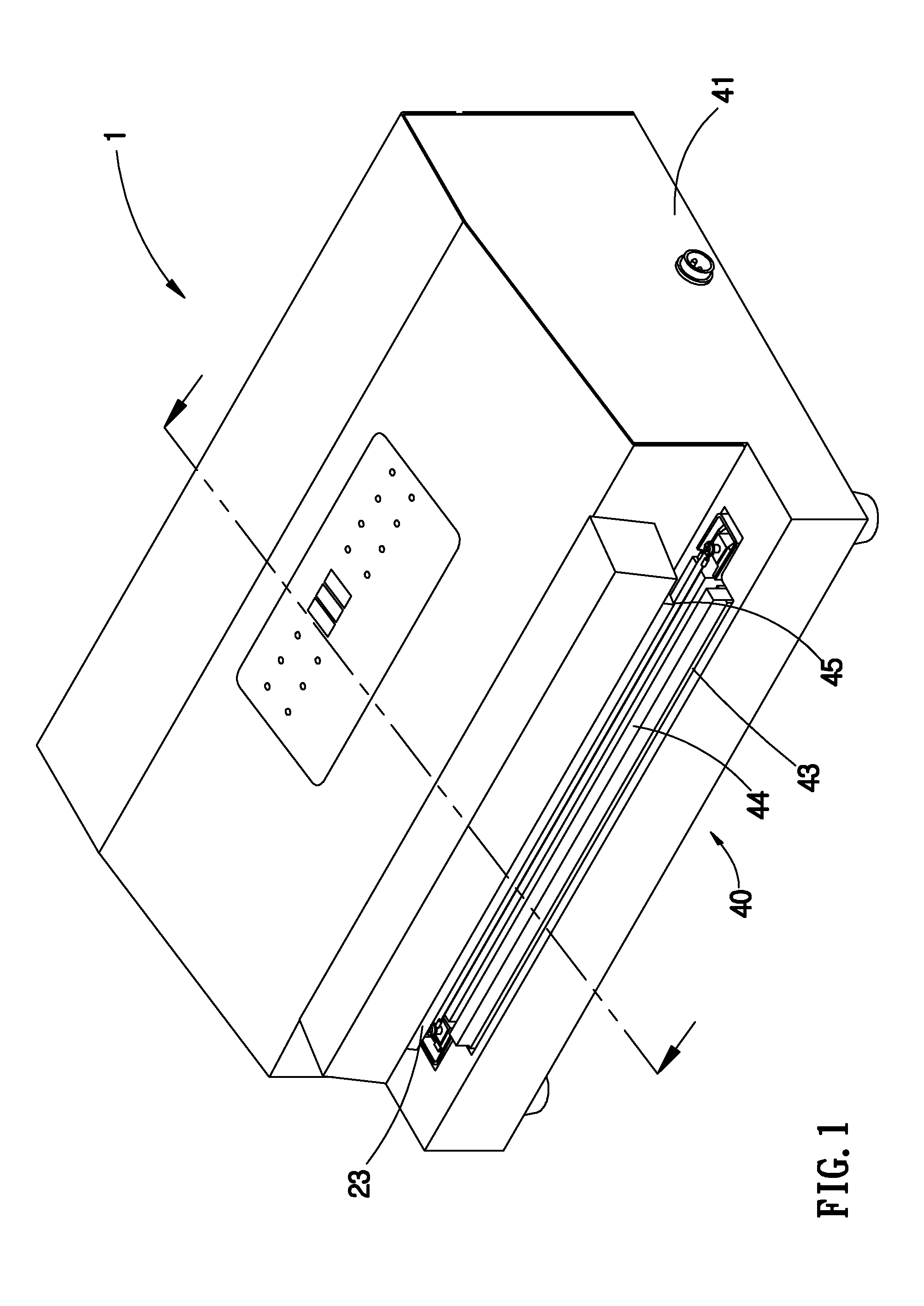

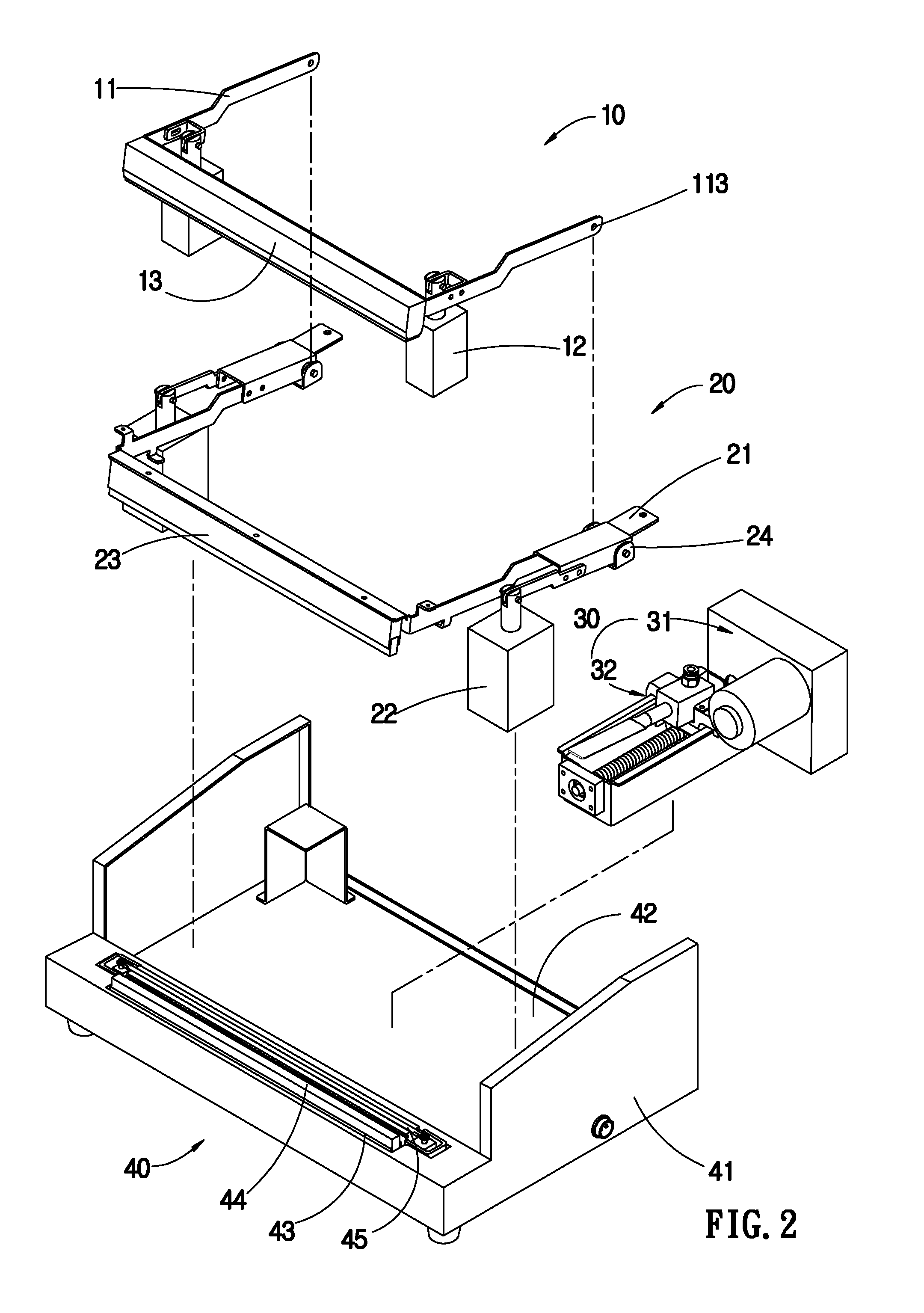

Vacuum sealing machine

ActiveUS20140102051A1Simple sealing processIsolating air excellentlyPackaging under vacuum/special atmosphereElectromagnetElectrical and Electronics engineering

A vacuum sealing machine contains a sealing unit including a first connecting rod, two first electromagnets, and a first press member, the first connecting rod having two fixing pieces and two first apertures, and the first press member having a first adhering face; a pressing unit including a second connecting rod, two second electromagnets, a second press member, and two connection mounts, the second connecting rod having two pull bars, a plurality of second apertures, and two support tabs to support the first connecting rod, and the second press member having a second adhering face; an air exhausting unit including a transmission device and a drawing device; the body having a holder in which a receiving room is formed so as to receive the sealing unit, the pressing unit, and the air exhausting unit; the receiving room having a seat, the seat having the barrier strip and a heating strip.

Owner:HUANG MAO SEN

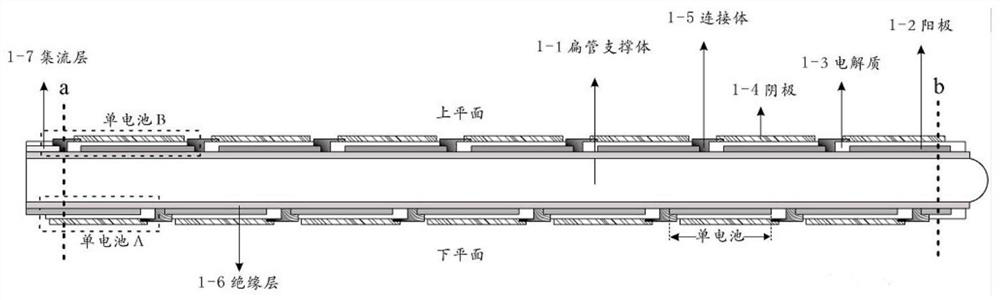

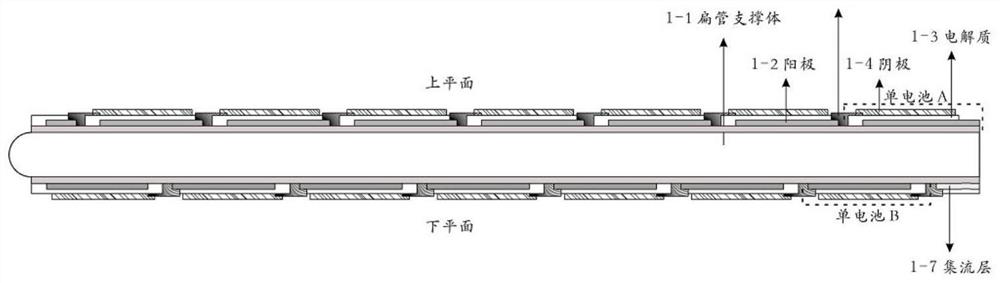

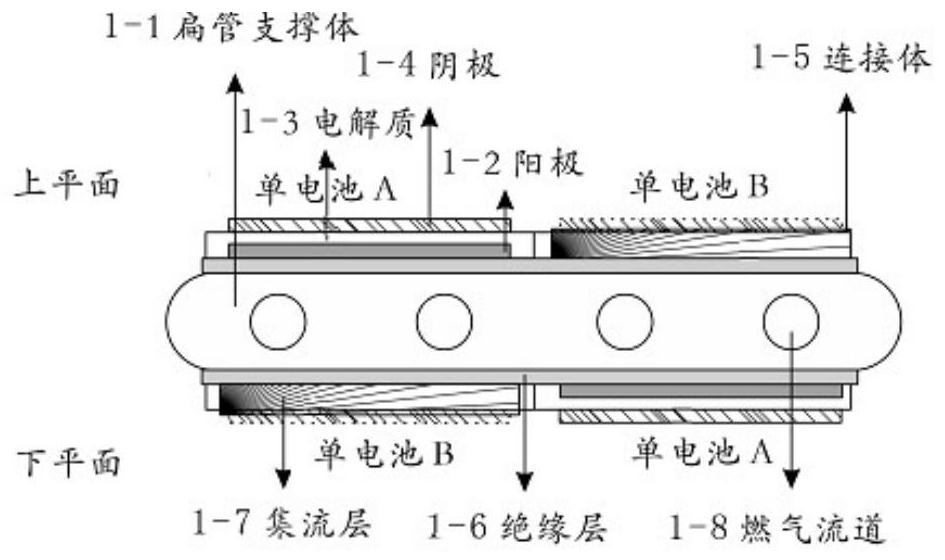

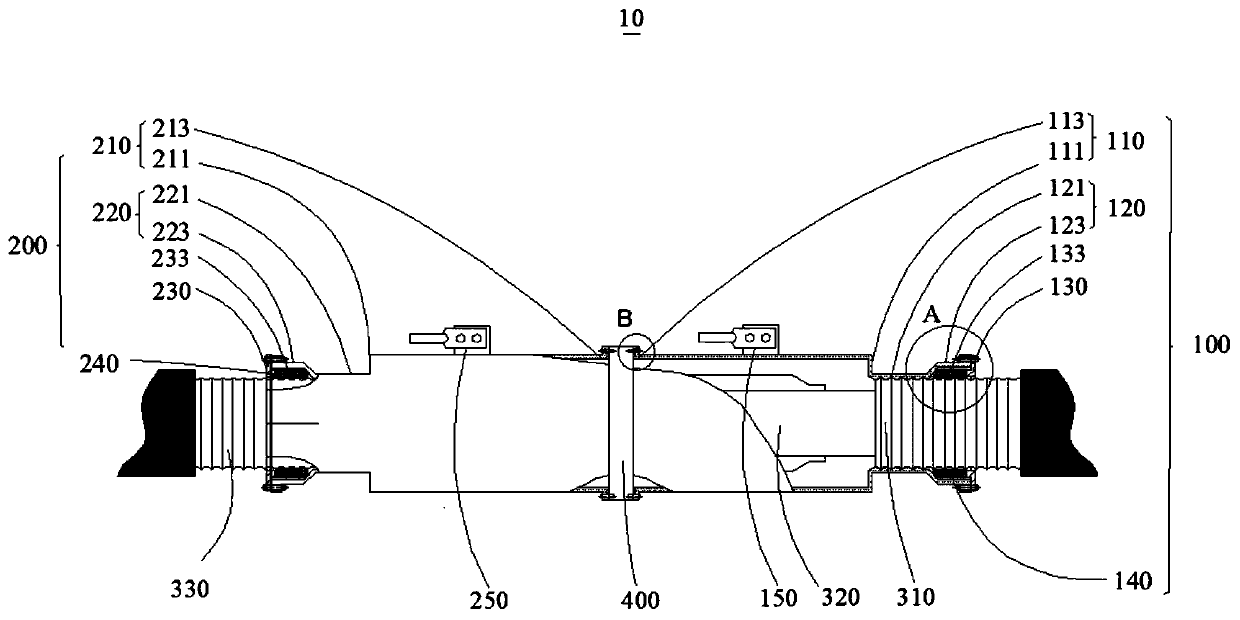

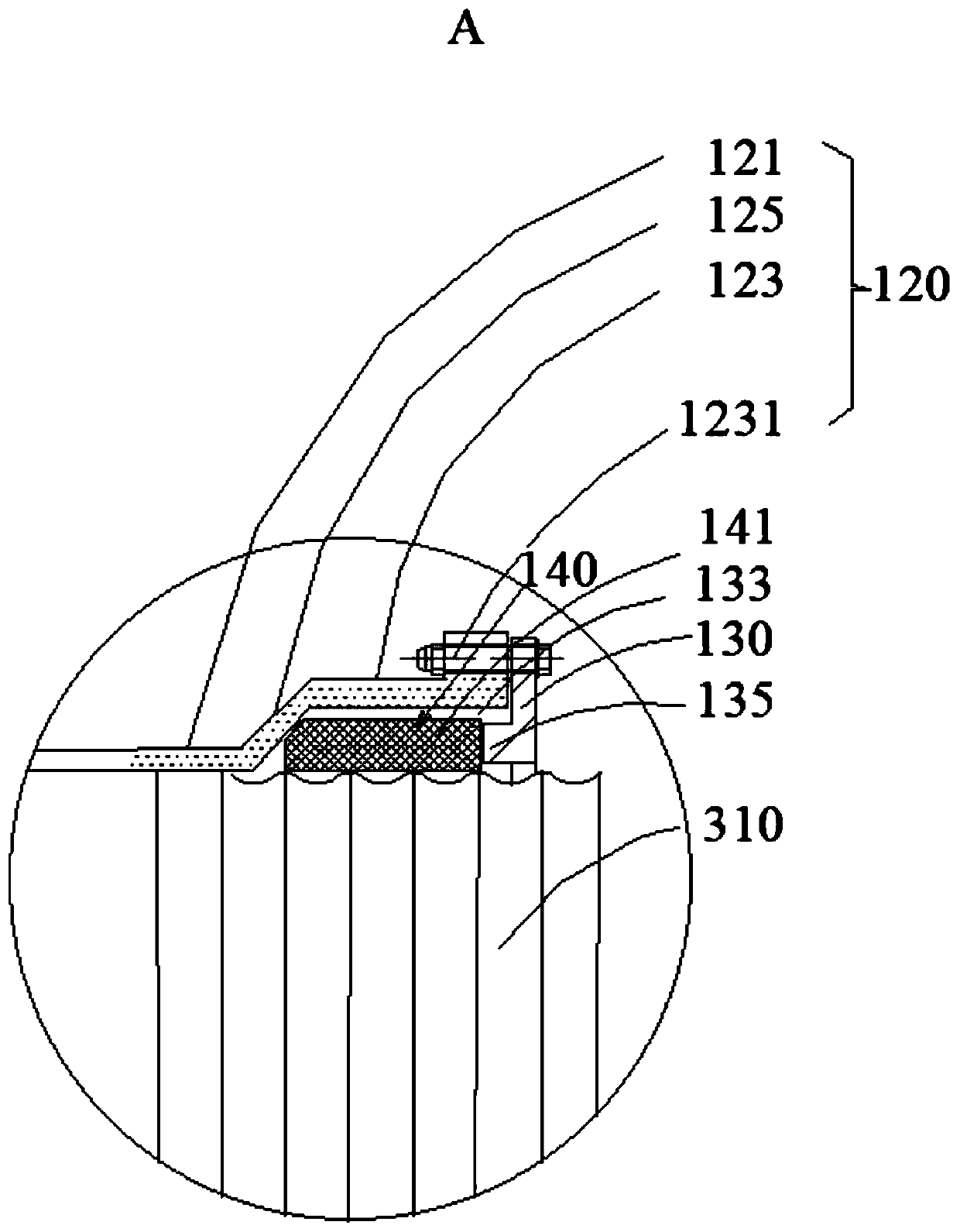

Self-sealing metal flat tube supported solid oxide fuel cell/electrolytic tank structure

PendingCN113948730AImprove efficiencyQuick start strategyFuel cell heat exchangeFinal product manufactureFuel cellsElectrical battery

The invention provides a self-sealing metal flat tube supported solid oxide fuel cell / electrolytic cell and a cell stack structure thereof. The structure comprises an insulating layer and a flat tube supporting body prepared from a metal material; the insulating layer covers the two planes of the flat tube supporting body; a battery pack is distributed on the insulating layer and is formed by connecting a plurality of single batteries in series through connectors to form a U shape; and the current collecting layer of the first single battery and the current collecting layer of the last single battery in the battery pack are both positioned at the opening end and are respectively used for leading in and leading out current. According to the design of the metal flat tube supporting body and the insulating layer provided by the invention, the flat tube supporting body is made of metal with high thermal conductivity, low cost and high strength, so that the starting rate of the cell can be remarkably improved, the cycle starting times can be increased, and a feasible scheme is provided for a high-efficiency, high-stability and quick-starting strategy of the fuel cell.

Owner:XI AN JIAOTONG UNIV

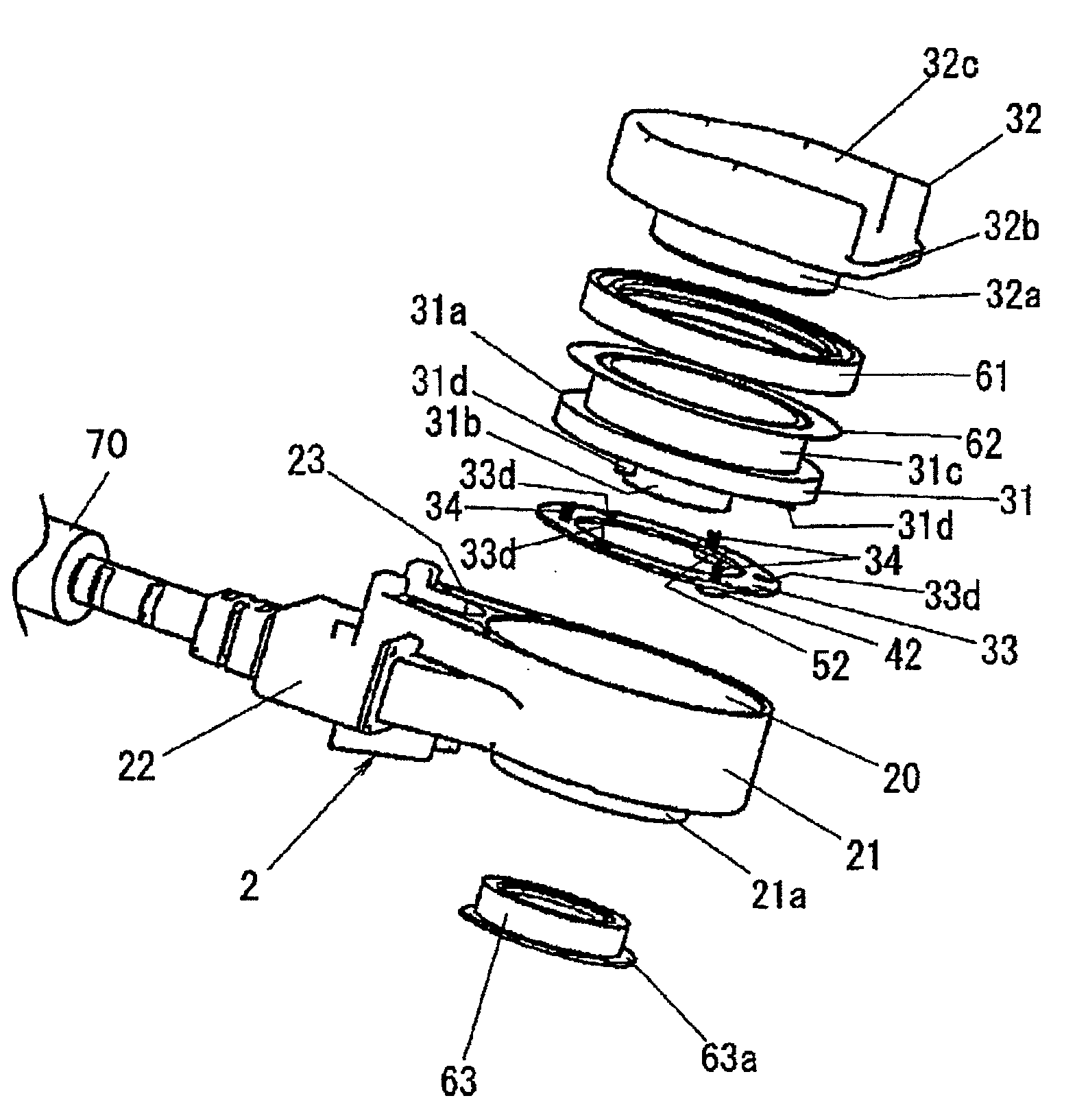

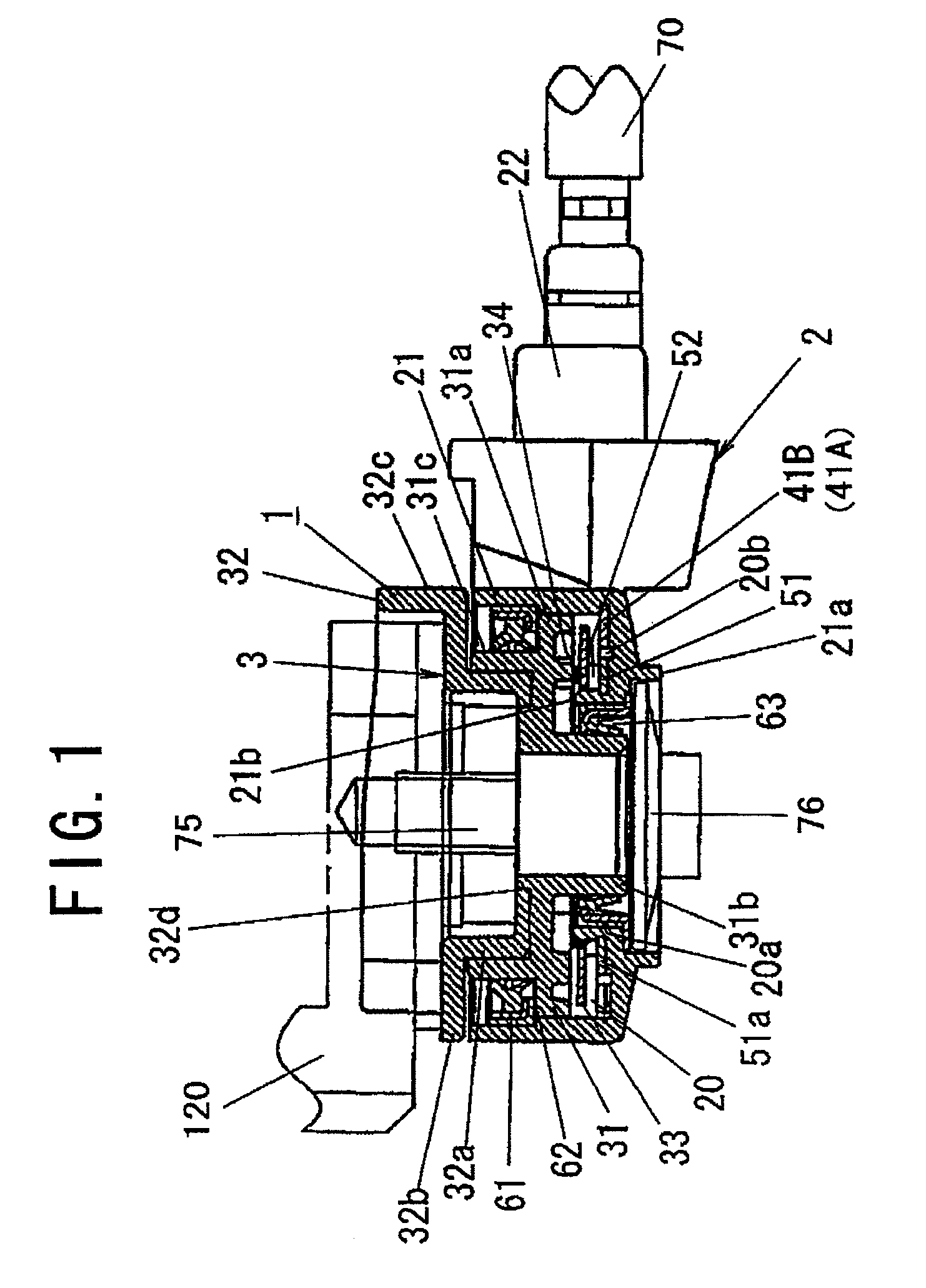

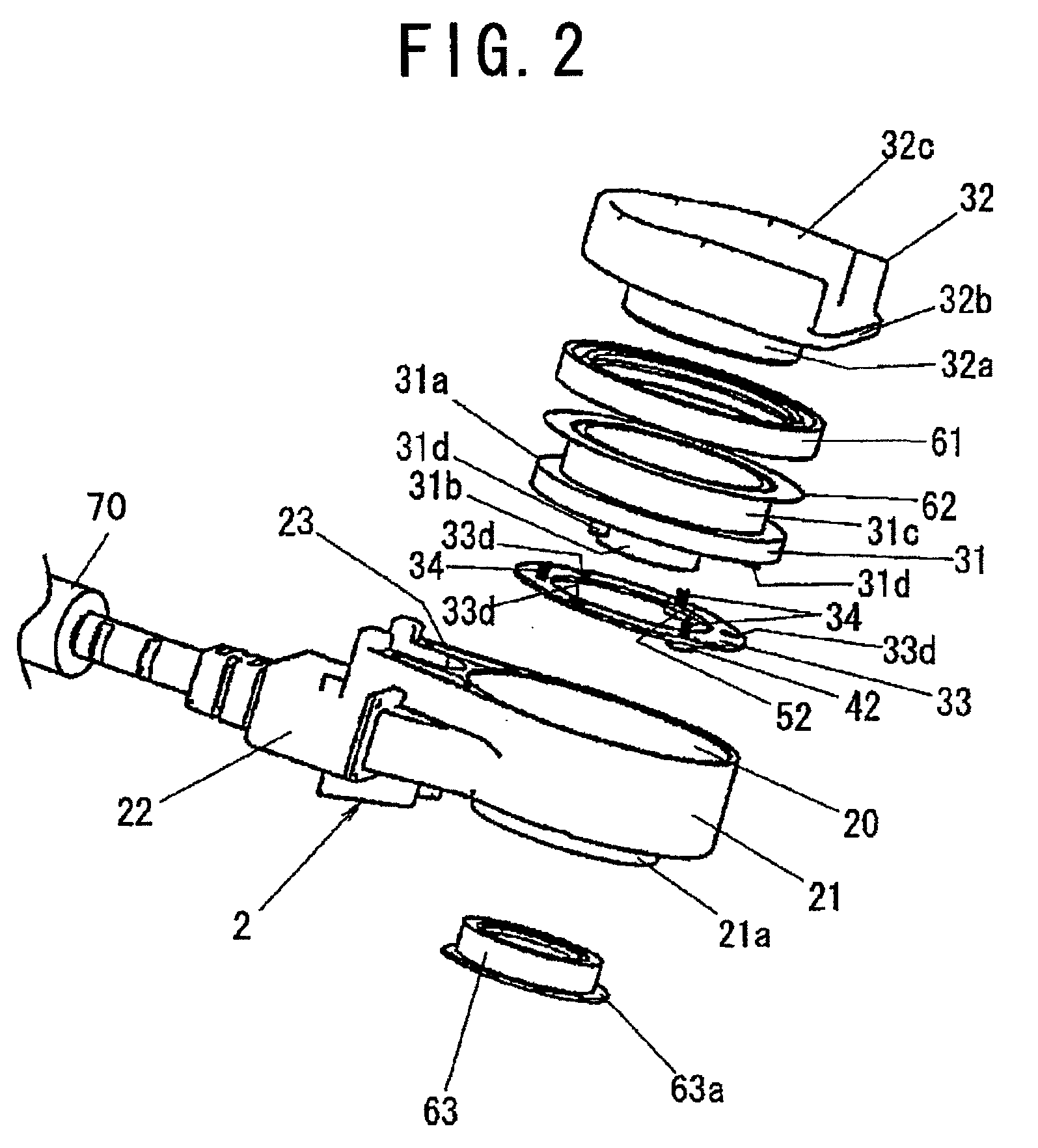

Rotary switch

InactiveUS20080073197A1Good adhesionLow costCycle standsCoupling device detailsRotary switchEngineering

A rotary switch, which is used to detect a state of a stand with respect to a body of a motorcycle, for example, comprises a housing having a ring-shaped outer wall so that an annular recess is formed; a rotor which is rotatably supported on the housing around a center axis of the annular recess; a plurality of stationary contacts each having a circular arc shape and provided on a bottom face of the annular recess; a moving contact which is provided on the rotor and is connected and disconnected with the stationary contacts following to rotation of the rotor with respect to the housing; and a cable draw-out portion from which an electric cable including a plurality of inner cables respectively connected to at least the stationary terminals is drawn out from the housing. The rotor has a U-shaped joint which holds an end portion of the stand pivotally mounted on the body, so that the rotor rotates corresponding to rotation of the stand with respect to the stationary portion.

Owner:MATSUSHITA ELECTRIC WORKS LTD

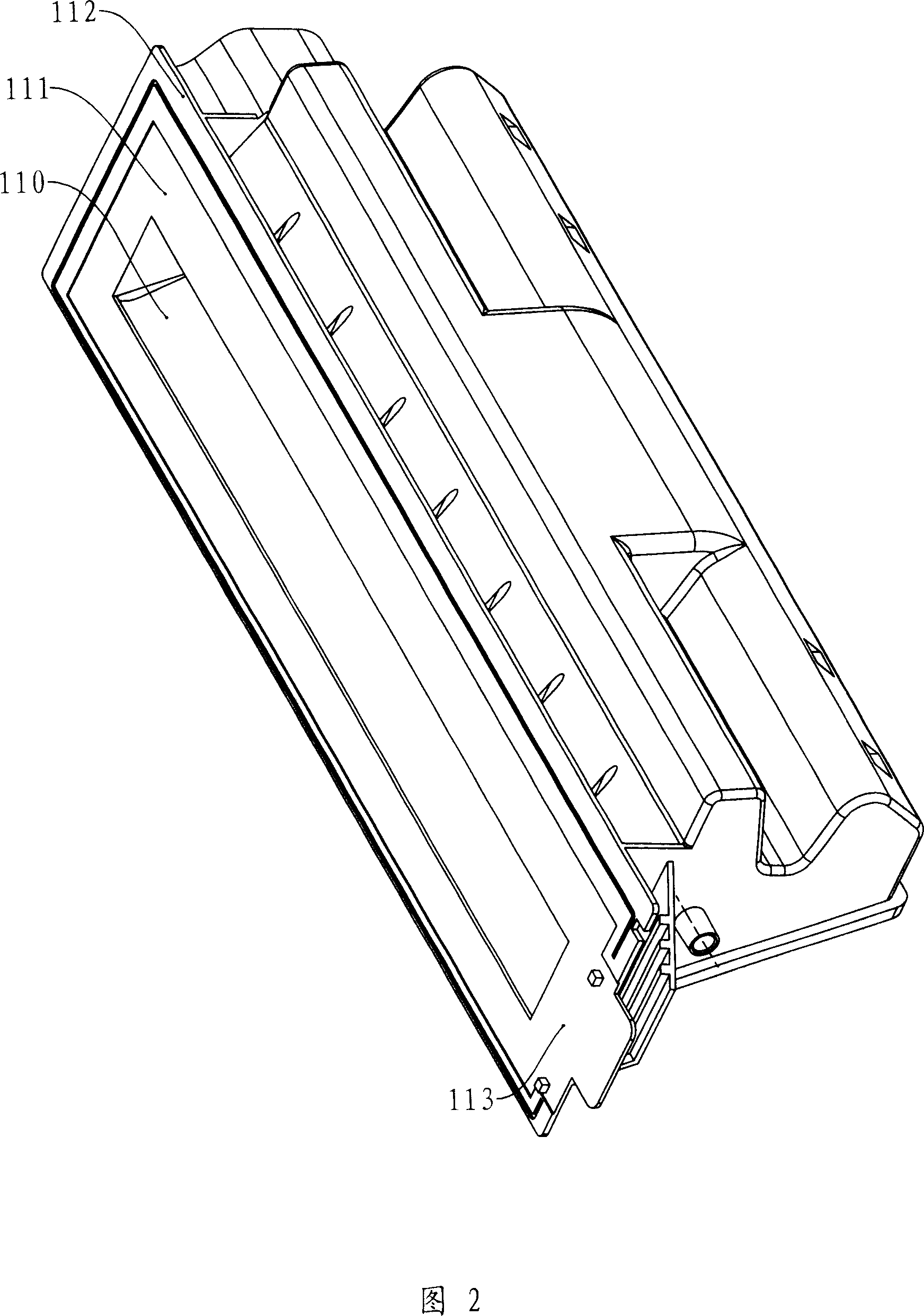

Sealing method for carbon powder box

The invention relates to sealing method of carbon powder box, the carbon powder box includes a power storehouse housing the carbon powder; the power storehouse possesses a meal outlet which can be sealed by sealing strip, the surface of meal outlet and the surface of tearing band export located at the side of the meal outlet are intersected. The seal element possesses adhesive layer and the first stripping layer and the second stripping layer which is located at the side of the adhesive layer, a opening which is basically anastomotic with the meal outlet is set at middle of the adhesive layer, the first tearing band and the second tearing band are separately extended from the zigzag ends of the first stripping layer and the second stripping layer. The methods contain: the zigzag ends of the seal element is inserted into the top of the meal outlet from the tearing band export; the first stripping layer is extracted from the tearing band export by the first tearing band which is near the surface of meal outlet and inlet, all-around of the adhesive layer and meal outlet is bonded seal. The process of resealing is simplified, the cost is saved, and the damage of carbon powder box resolution in current technique is also avoided.

Owner:ZHUHAI TIANWEI TECH DEV CO LTD

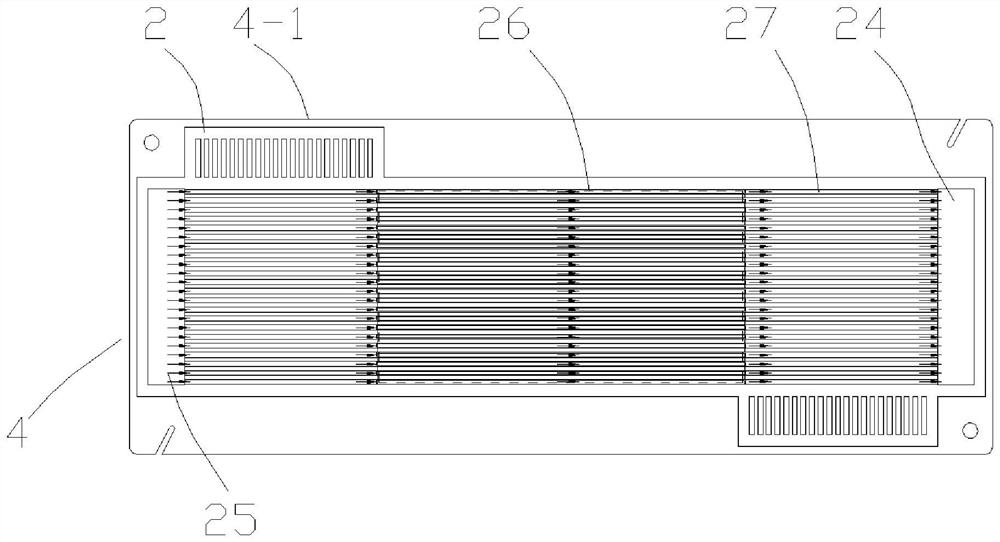

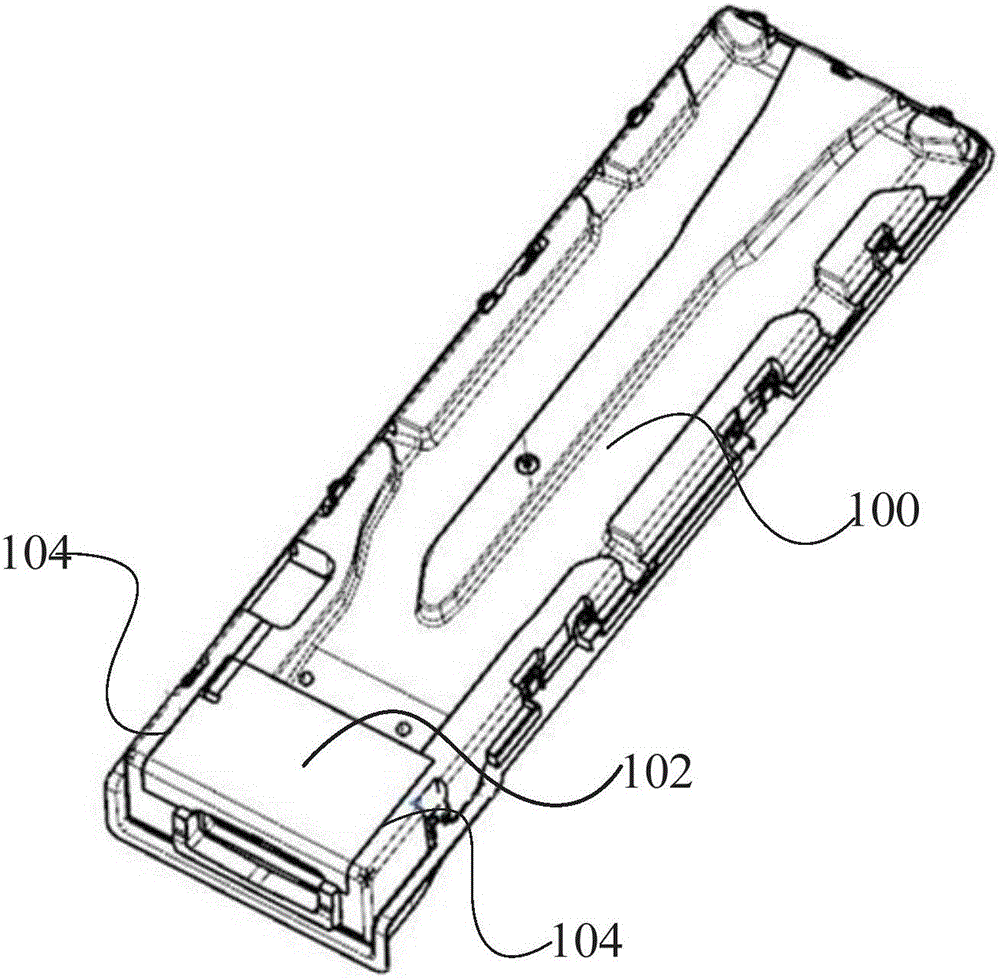

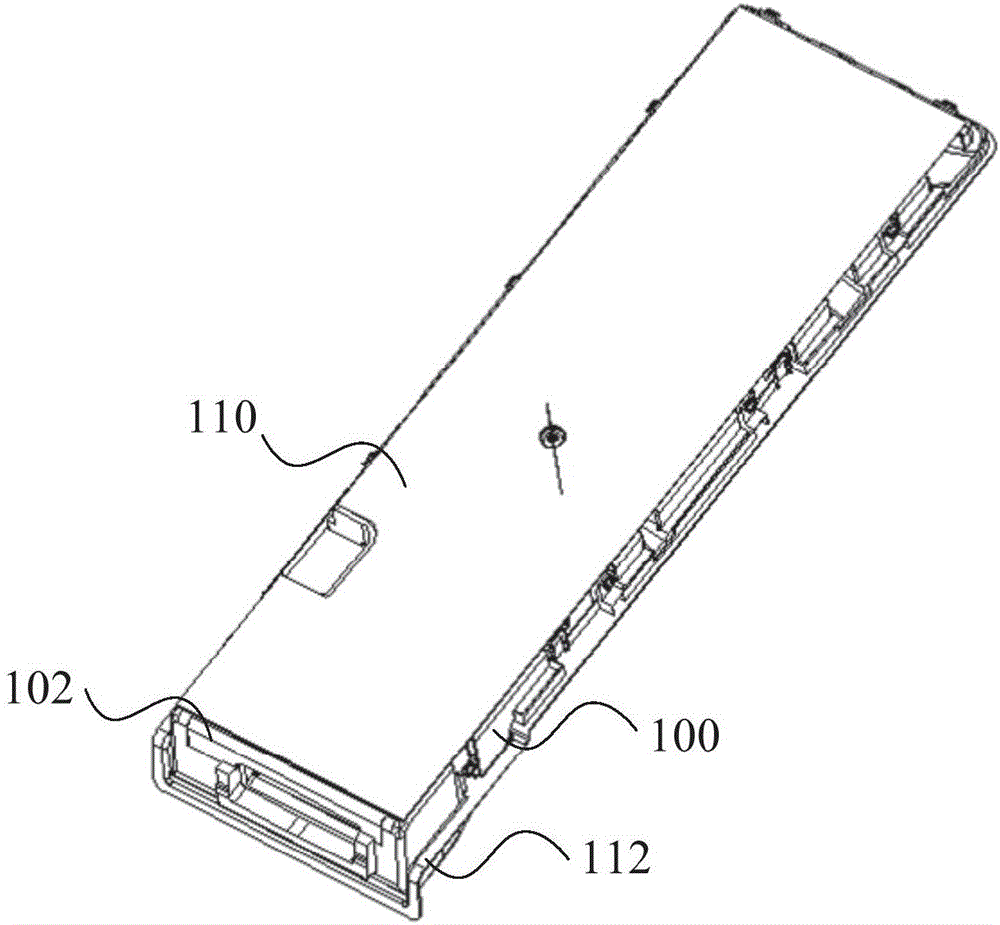

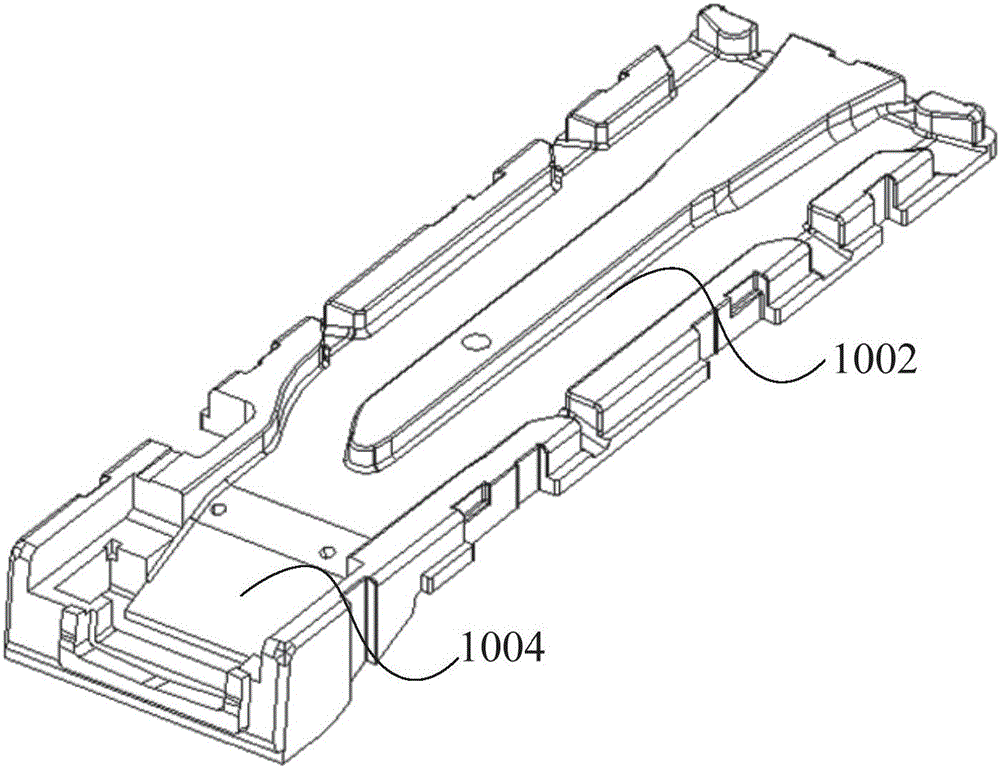

One-plate three-field ultrathin fuel cell bipolar plate and fuel cell stack

PendingCN112768720ASimple sealing processReduce overall thicknessCollectors/separatorsPhysicsEngineering

The invention relates to a one-plate three-field ultrathin fuel cell bipolar plate and a fuel cell stack. The bipolar plate comprises a flow field plate, one side of the flow field plate is an anode side, and the other side of the flow field plate is a cathode side; a fuel gas flow channel and a cooling liquid flow channel are arranged on the anode side of the flow field plate; an oxidizing gas flow channel is arranged on the cathode side of the flow field plate; the bipolar plate further comprises a cover plate which is arranged on the anode side of the flow field plate and used for separating the cooling liquid flow channel and the fuel gas flow channel located in the active area; the anode side of the flow field plate is used for being tightly matched with an anode sealing piece and the cover plate to form a fuel gas flow field and a cooling liquid flow field; and the cathode side of the flow field plate is used for being tightly matched with a cathode sealing piece to form an oxidizing gas flow field. The three flow fields are concentrated on one plate, so that the thickness of the bipolar plate can be greatly reduced, the volume of a galvanic pile is greatly reduced, and the volumetric specific power density of the galvanic pile is improved.

Owner:TONGJI UNIV

Vacuum sealing machine

ActiveUS9327854B2Simple sealing processIsolating air excellentlyPackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereElectromagnetElectrical and Electronics engineering

A vacuum sealing machine contains a sealing unit including a first connecting rod, two first electromagnets, and a first press member, the first connecting rod having two fixing pieces and two first apertures, and the first press member having a first adhering face; a pressing unit including a second connecting rod, two second electromagnets, a second press member, and two connection mounts, the second connecting rod having two pull bars, a plurality of second apertures, and two support tabs to support the first connecting rod, and the second press member having a second adhering face; an air exhausting unit including a transmission device and a drawing device; the body having a holder in which a receiving room is formed so as to receive the sealing unit, the pressing unit, and the air exhausting unit; the receiving room having a seat, the seat having the barrier strip and a heating strip.

Owner:HUANG MAO SEN

Cable intermediate joint protection shell

The invention relates to a cable intermediate joint protection shell; the cable intermediate joint protection shell comprises a first sealing assembly and a second sealing assembly, wherein the firstsealing assembly and the second sealing assembly are the same in structure. The first sealing assembly is in sealing connection with the second sealing assembly. The connecting pipe of the first sealing assembly is provided with an internal thread, wherein the internal thread is used for being matched with the external thread of a metal sheath of a first cable. The two ends of the cable intermediate joint protection shell can be stably connected with the metal sheath of the first cable and the metal sheath of a second cable, the contact area is large, and the conduction resistance is small. Afastening flange of the first sealing assembly is used for sleeving the metal sheath of the first cable and is arranged at one end, far away from the connecting pipe, of the sealing shell, and the fastening flange is connected with a second flange end in a bolt mode, so that a sealing cavity is formed among the sealing shell and the fastening flange and the metal sheath of the first cable; and thesealing cavity is used for filling a sealing element. The sealing process is simple, and is not limited by the technical level of operating workers during on-site installation.

Owner:SHENZHEN POWER SUPPLY BUREAU

Ceramic projection lamp

InactiveCN101882558AReduced electrode heatingRaise the cold junction temperatureProjectorsHigh-pressure discharge lampsMaterials scienceElectrode

The invention discloses a ceramic projection lamp, which comprises a discharge chamber, electrode pipes placed at two ends of the discharge chamber and electrode components entering the discharge chamber through the electrode pipes, wherein the discharge chamber and the electrode pipes are made of a transparent material; the electrode components and the electrode pipes are airtightly sealed by solder; and mercury is filled in the discharge chamber; each electrode pipe comprises an inner pipe section and a welded groove, which are connected; the inner pipe section is close to the discharge chamber, the welded groove is positioned at the position of the end face, the inside diameter of the welded groove is greater than that of the inner pipe section, and the welded groove and the discharge chamber are airtightly sealed by the solder. The ceramic projection lamp has high illumination efficiency and good sealing effect.

Owner:CHAOZHOU ORILITE LIGHTING

Air flue structure and refrigerator

ActiveCN106152689ASimple production processIncrease productivityLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

The invention provides an air flue structure used for a refrigerator. The air flue structure comprises a first air flue cover body, a second air flue cover body and a sealing plate, wherein the second air flue cover body is matched with the first air flue cover body during installation and is provided with matching lines, the matching lines and the upper surface of the second air flue cover body are located on the same plane, and the sealing plate is located above the second air flue cover body and is installed on the first air flue cover body. According to the technical scheme, the matching lines of the first air flue cover body and the second air flue cover body are arranged on the plane where the upper surface of the second air flue cover body is located and are directly sealed by the sealing plate, and therefore the process and the material of independent sealing are eliminated, the production efficiency is improved, and the production cost is saved; and the sealing plate is used for direct sealing, and therefore the contact area is increased, and the sealing effect is improved.

Owner:HEFEI HUALING CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com