Manufacturing method for lead-free sealing glass with transitional expansion coefficient

A technology of expansion coefficient and manufacturing method, applied in glass manufacturing equipment, glass molding, manufacturing tools and other directions, can solve the problems of increased difficulty, difficult product quality control, complicated sealing process, etc., and achieves low cost and simple sealing process. , The effect of easy control of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

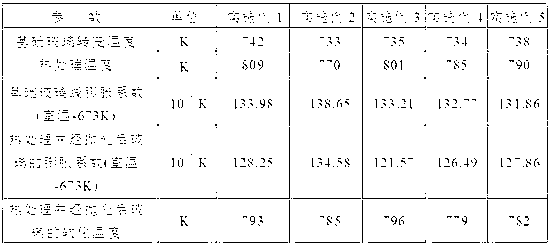

Examples

Embodiment 1

[0023] The parts by weight of raw materials used consist of:

[0024] 51.96 parts of quartz sand, 3.83 parts of aluminum hydroxide, 13.99 parts of bismuth trioxide, 2.16 parts of ferric oxide, 14.46 parts of sodium carbonate, 4.64 parts of sodium nitrate, 19.39 parts of potassium carbonate, 5.52 parts of potassium nitrate, 2.74 parts of magnesium oxide, 2.73 parts of calcium carbonate.

[0025] The specific steps of the manufacturing method are as follows:

[0026] (1) After mixing the above raw materials evenly, melt and homogenize them in a kiln at 1753K to obtain a glass melt;

[0027] (2) After the glass melt flows through the material channel to the working part, the temperature drops to 1423K, and then it is continuously cast on a cast iron mold with a temperature of 733K through a material guide pipe to obtain a basic glass with a thickness of 6cm, which is pulled by a cast iron crawler Enter the annealing kiln, anneal at 735K for 1.5h and then cool with the furnace; ...

Embodiment 2

[0031] The parts by weight of raw materials used consist of:

[0032] 50.56 parts of quartz sand, 3.73 parts of aluminum hydroxide, 13.61 parts of bismuth trioxide, 2.10 parts of ferric oxide, 14.07 parts of sodium carbonate, 4.51 parts of sodium nitrate, 18.87 parts of potassium carbonate, 5.37 parts of potassium nitrate, 2.66 parts of magnesium oxide, 5.24 parts of barium carbonate.

[0033] The specific steps of the manufacturing method are as follows:

[0034] (1) After mixing the above raw materials evenly, melt and homogenize them in a kiln at 1723K to obtain a glass melt;

[0035] (2) After the glass melt flows through the material channel to the working part, the temperature drops to 1373K, and then it is continuously cast on a cast iron mold with a temperature of 733K through a material guide pipe to obtain a basic glass with a thickness of 3cm, which is pulled by a cast iron crawler Enter the annealing kiln, anneal at 723 for 1.5h and then cool with the furnace;

...

Embodiment 3

[0039] The parts by weight of raw materials used consist of:

[0040] 51.61 parts of quartz sand, 3.81 parts of aluminum hydroxide, 13.90 parts of bismuth trioxide, 2.15 parts of ferric oxide, 14.37 parts of sodium carbonate, 4.61 parts of sodium nitrate, 19.26 parts of potassium carbonate, 5.48 parts of potassium nitrate, 2.72 parts of magnesium oxide, Zinc oxide 2.21 parts.

[0041] The specific steps of the manufacturing method are as follows:

[0042] (1) After mixing the above raw materials evenly, melt and homogenize them in a kiln at 1753K to obtain a glass melt;

[0043] (2) After the glass melt flows through the material channel to the working part, the temperature drops to 1423K, and then it is continuously cast on a cast iron mold with a temperature of 733K through a material guide pipe to obtain a basic glass with a thickness of 6cm, which is pulled by a cast iron crawler Enter the annealing kiln, anneal at 725K for 1.5h and then cool with the furnace;

[0044] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com