Patents

Literature

80results about How to "Reduce overall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

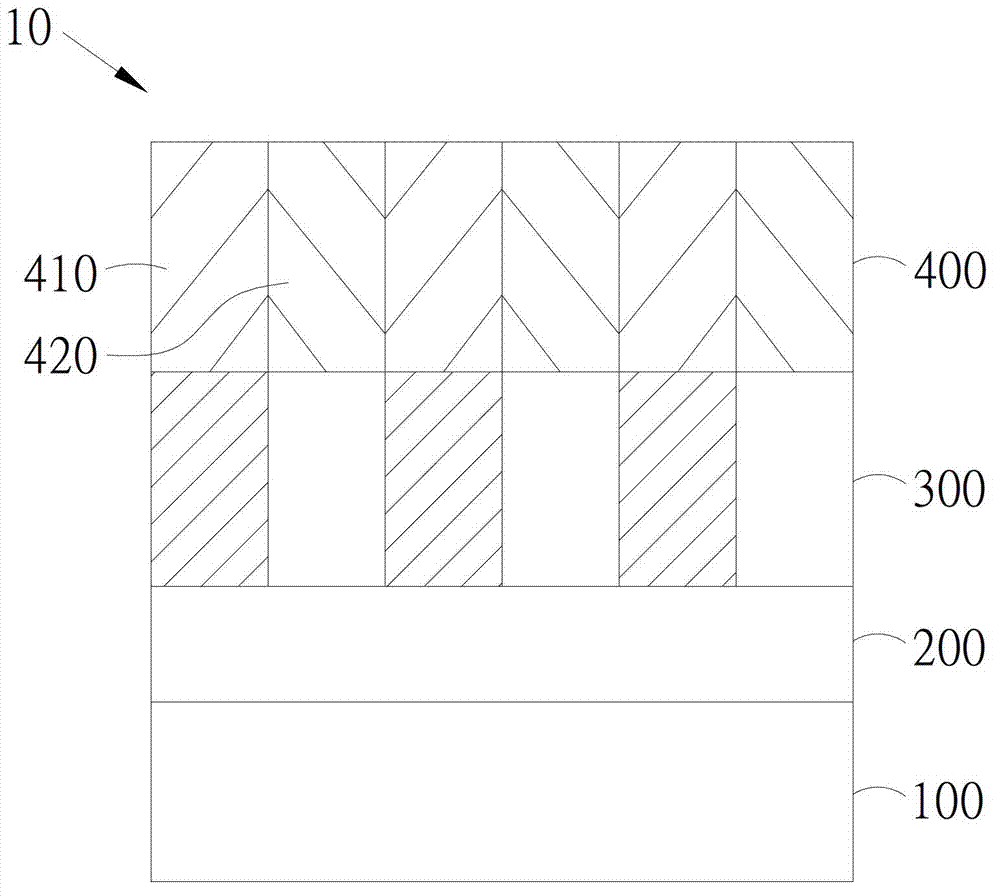

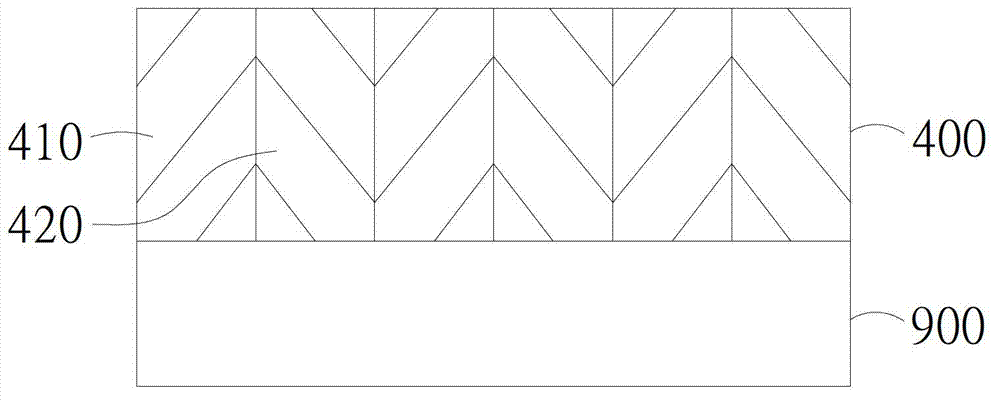

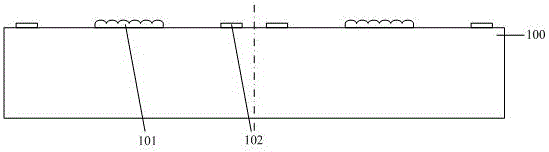

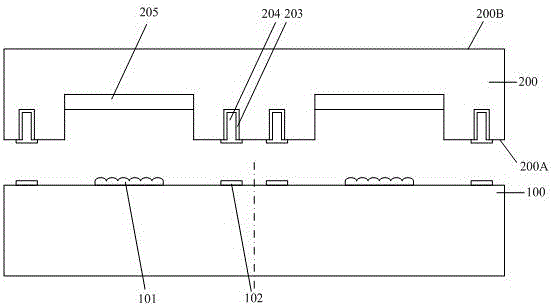

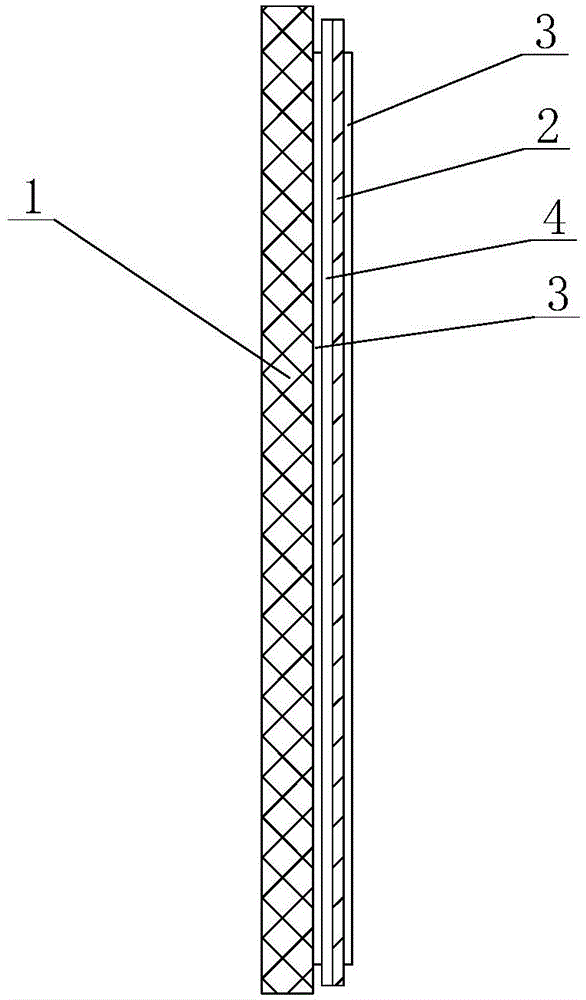

Light field modulation layer, backlight structure and display device

ActiveCN107193070AReduce overall thicknessReduce manufacturing costDiffraction gratingsPlanar/plate-like light guidesDisplay deviceGrating

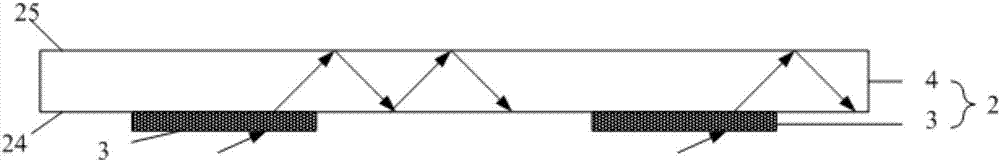

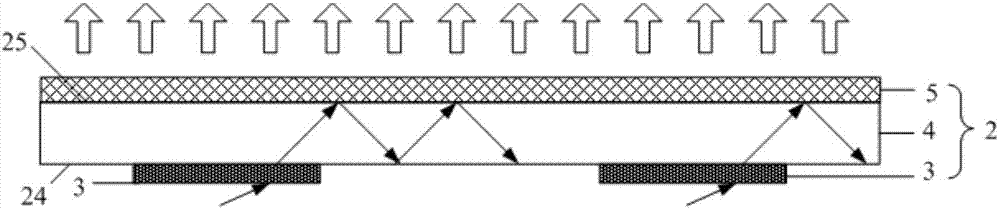

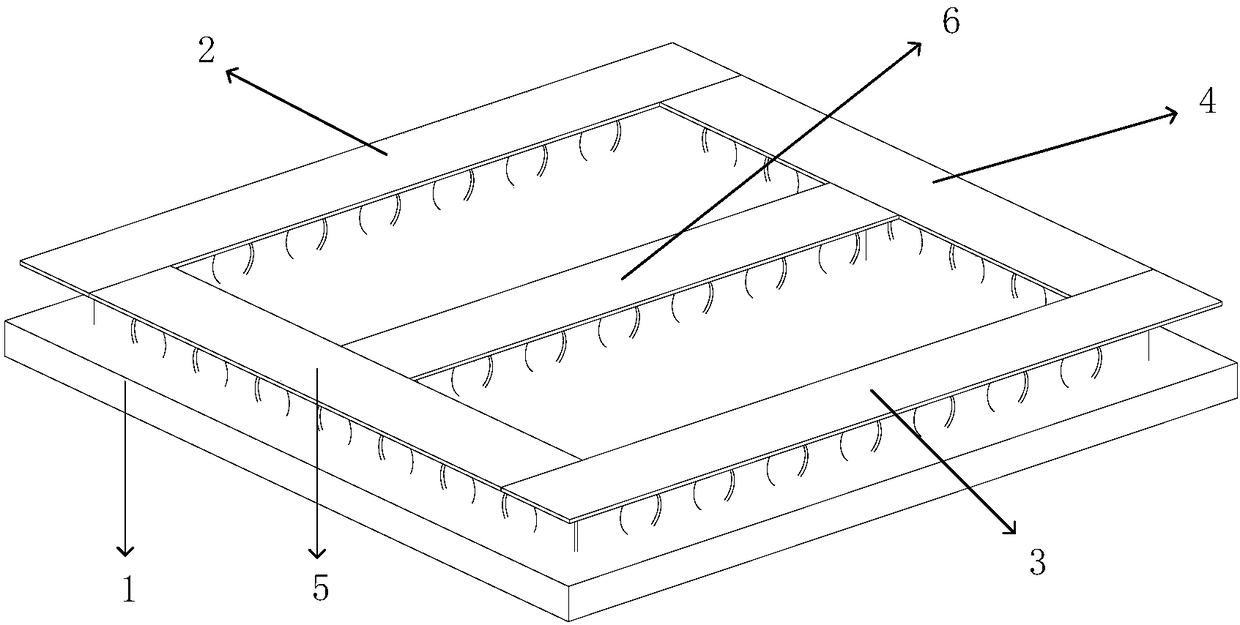

The invention discloses a light field modulation layer, a backlight structure and a display device. The energy and direction of light emitted from the light field modulation layer can be uniformly distributed, the thickness of the backlight structure is reduced, the number of LED used in the backlight structure is reduced, and the cost is lowered. The light field modulation comprises a waveguide layer and a grating structure, the waveguide layer is provided with a first surface and a second surface which are oppositely arranged, the grating structure is arranged on the first surface or the second surface of the waveguide layer, the grating structure is used for guiding the incident light on the grating structure into the waveguide layer and conducts total reflection propagation in the waveguide layer.

Owner:BOE TECH GRP CO LTD

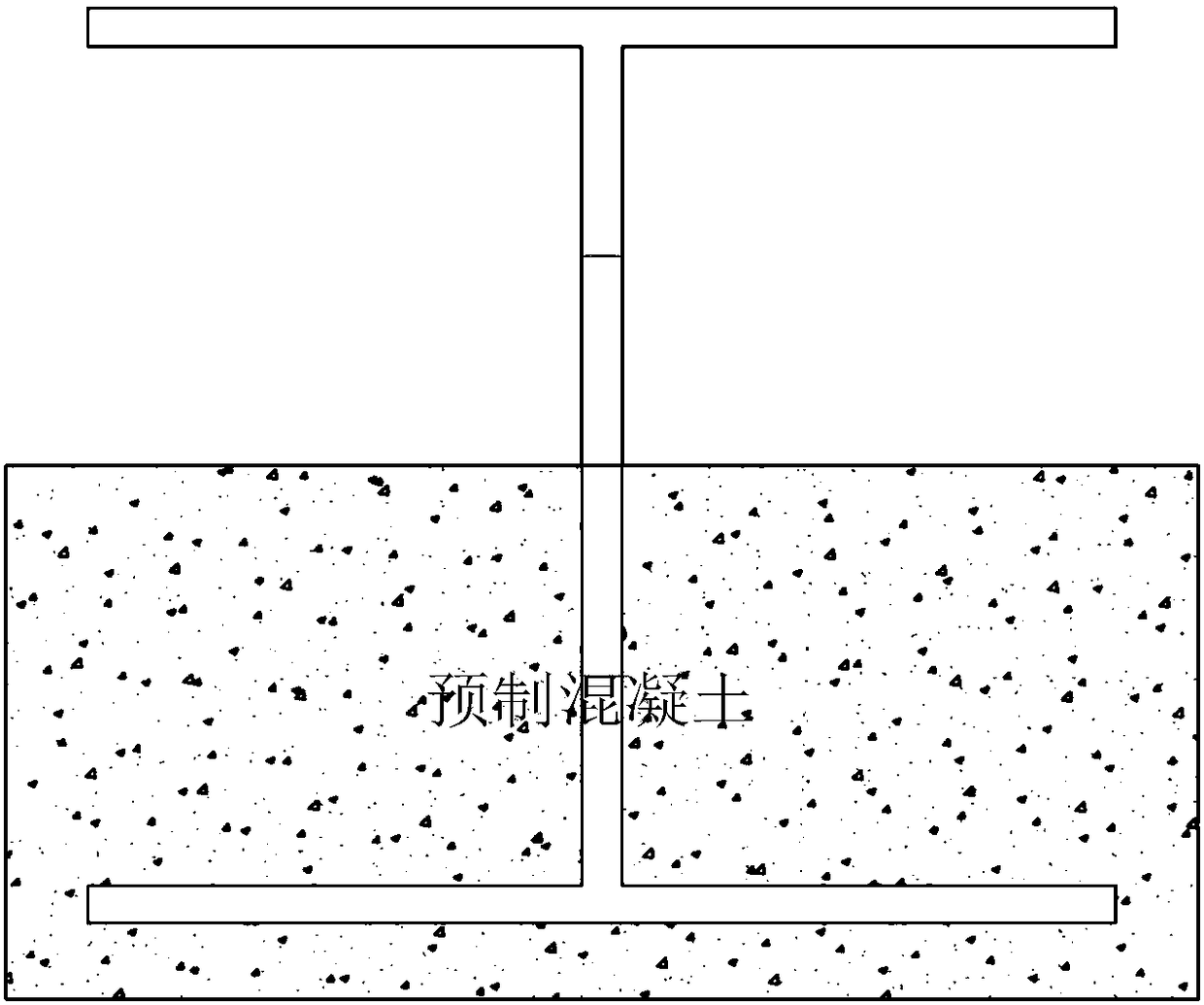

Fabricated invisible-beam floor plate

InactiveCN108385885AOvercoming construction techniquesReduce overall thicknessFloorsFloor plateRebar

The invention provides a fabricated invisible-beam floor plate, and belongs to the field of components of buildings. The invisible-beam floor plate is an integral module formed by beams whose web plates are provided with holes and a reinforced concrete floor plate, wherein the beams which are well prefabricated in a factory are firstly used as borders of the integral module of a beam plate; precast concrete is poured at the bottoms of the beams; afterwards, pipelines can be freely laid on precast concrete layers; the pipelines among different plate blocks pass through the holes of the web plates of the beams; lightweight concrete is poured after the laying is completed. According to the invisible-beam floor plate, through the integration of the beam plate, on the premise that the bearing capacity is not decreased, the integral thickness of the beam plate is decreased; the clear space of a building is improved; the space is arranged more flexibly; upper and lower flanges of the beams are all embedded in the concrete of the floor plate; on one hand, the local stableness of a component can be improved by the concrete reserved around the beams, and on the other hand, the fireproof andanticorrosive problems of a steel structural beam are relieved to a certain extent; the personalized layouts of the pipelines are facilitated by the ways that the web plates are provided with the holes and the floor plates are hierarchically poured, and the later maintenance and modification are convenient.

Owner:BEIJING UNIV OF TECH

Novel offset printing and hot stamping technique

InactiveCN103921542AReduce overall thicknessAvoid quality problemsBronze printingRotary lithographic machinesHot stampingUV curing

A novel offset printing and hot stamping technique sequentially includes: (1) feeding articles to be printed to printing color cells of an offset printing press sequentially and printing with ultraviolet curing ink, wherein one or more printing color cells are utilized to perform full oil printing, and positions, required to be hot stamped, on full oil printing surfaces are hollowed out; ink in required colors is printed on printed surfaces of the articles to be printed in a screening manner by one or more printing color cells of other printing color cells according to the color of alumite requiring hot stamping, a lining ink layer is formed, and the surface color of the surface of positions, required to be hot stamped, of the articles to be printed is enabled to be consistent with that of the alumite; (2) hot stamping alumite on the articles to be printed by a hot stamping machine to form a hot stamping pattern layer covering the lining ink layer. The novel offset printing and hot stamping technique is good in hot stamping effect and capable of effectively avoiding quality problem, caused by incomplete hot stamping, of products which are subjected to offset printing prior to hot stamping, product quality is guaranteed, and product percentage of pass is increased.

Owner:广西真龙彩印包装有限公司

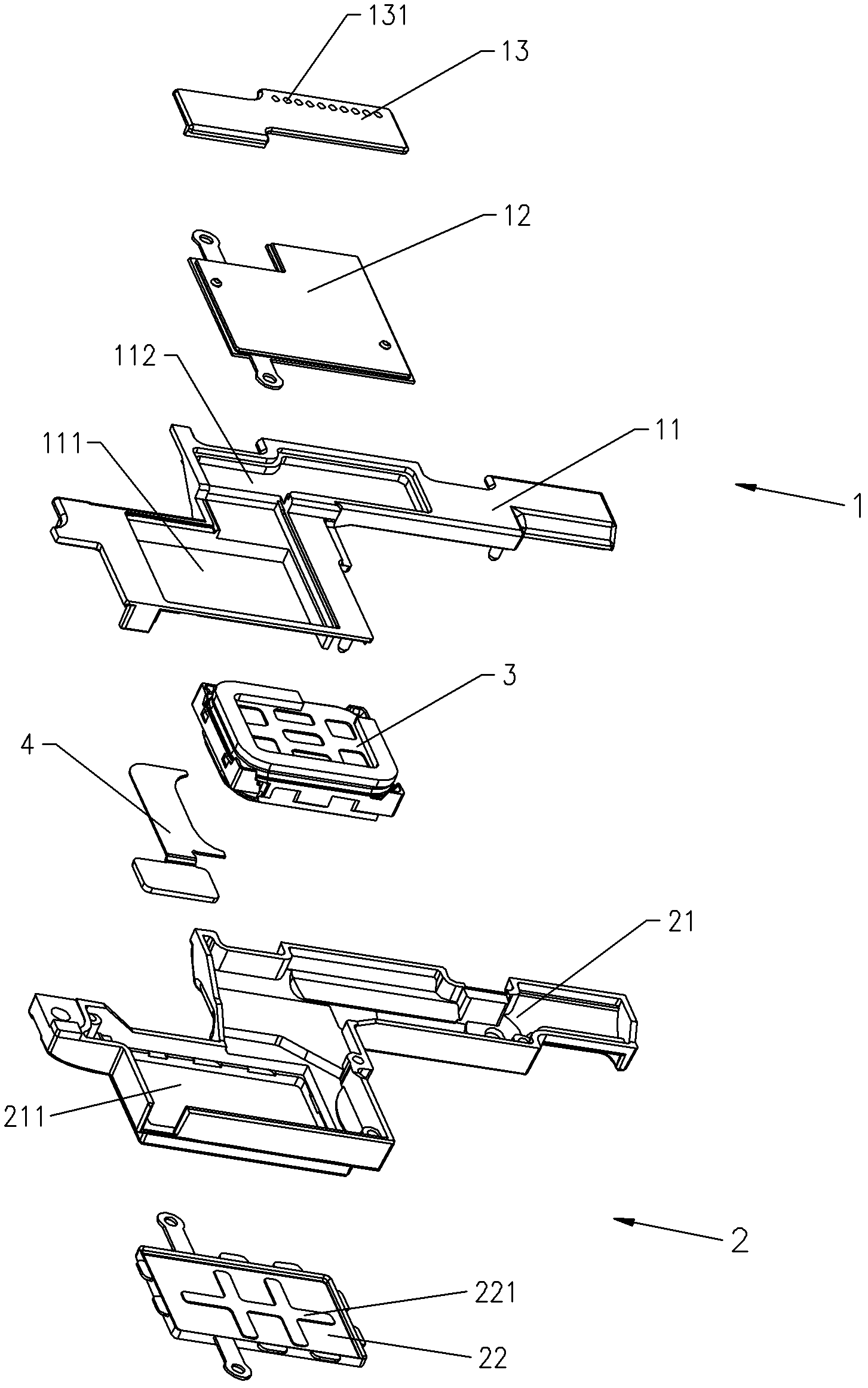

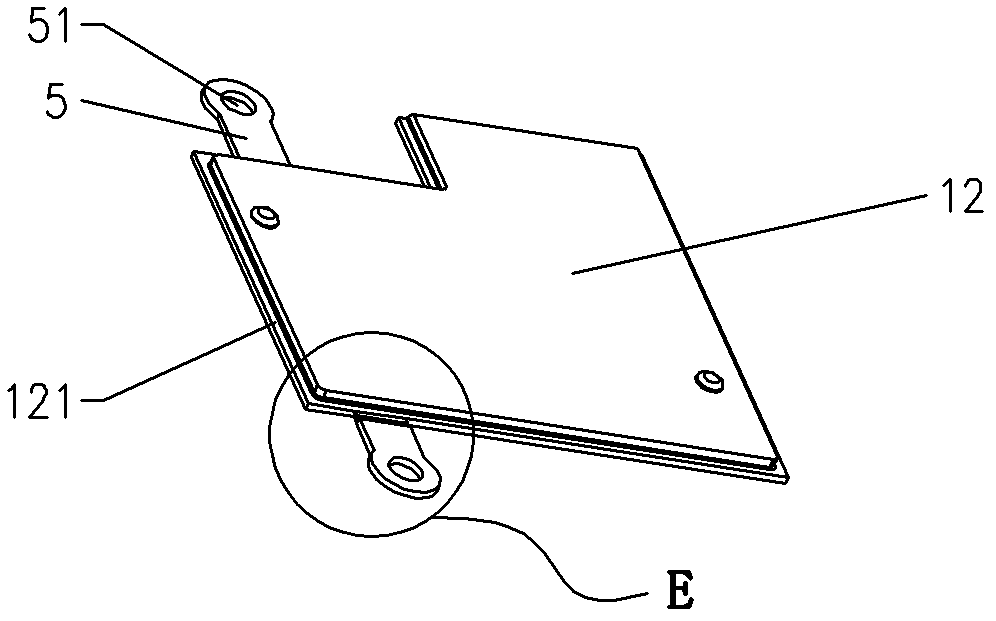

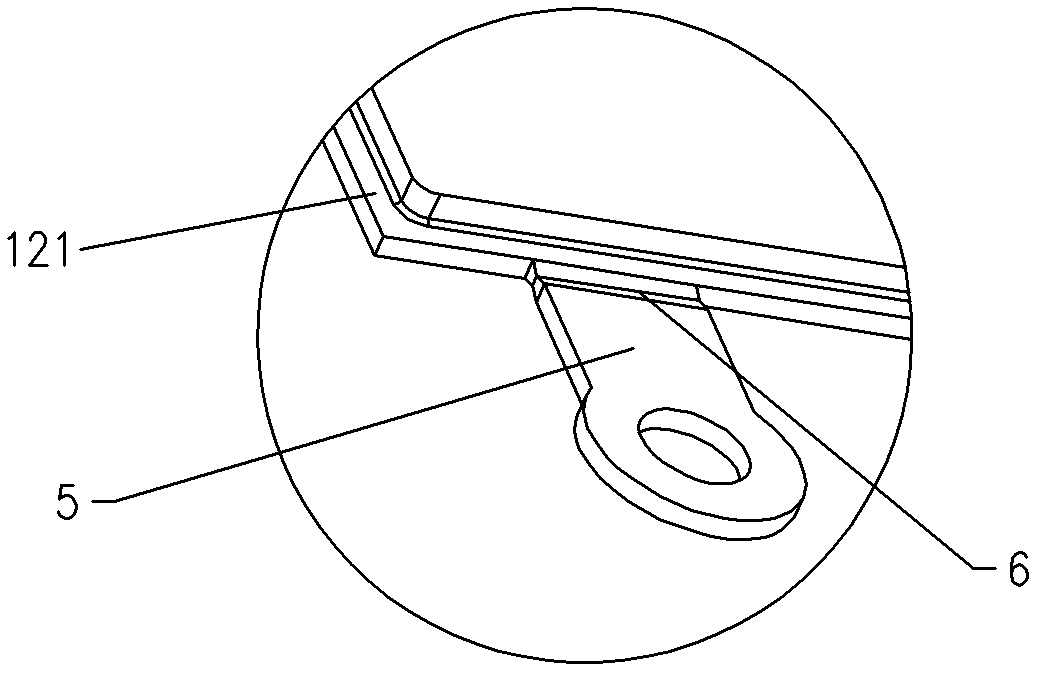

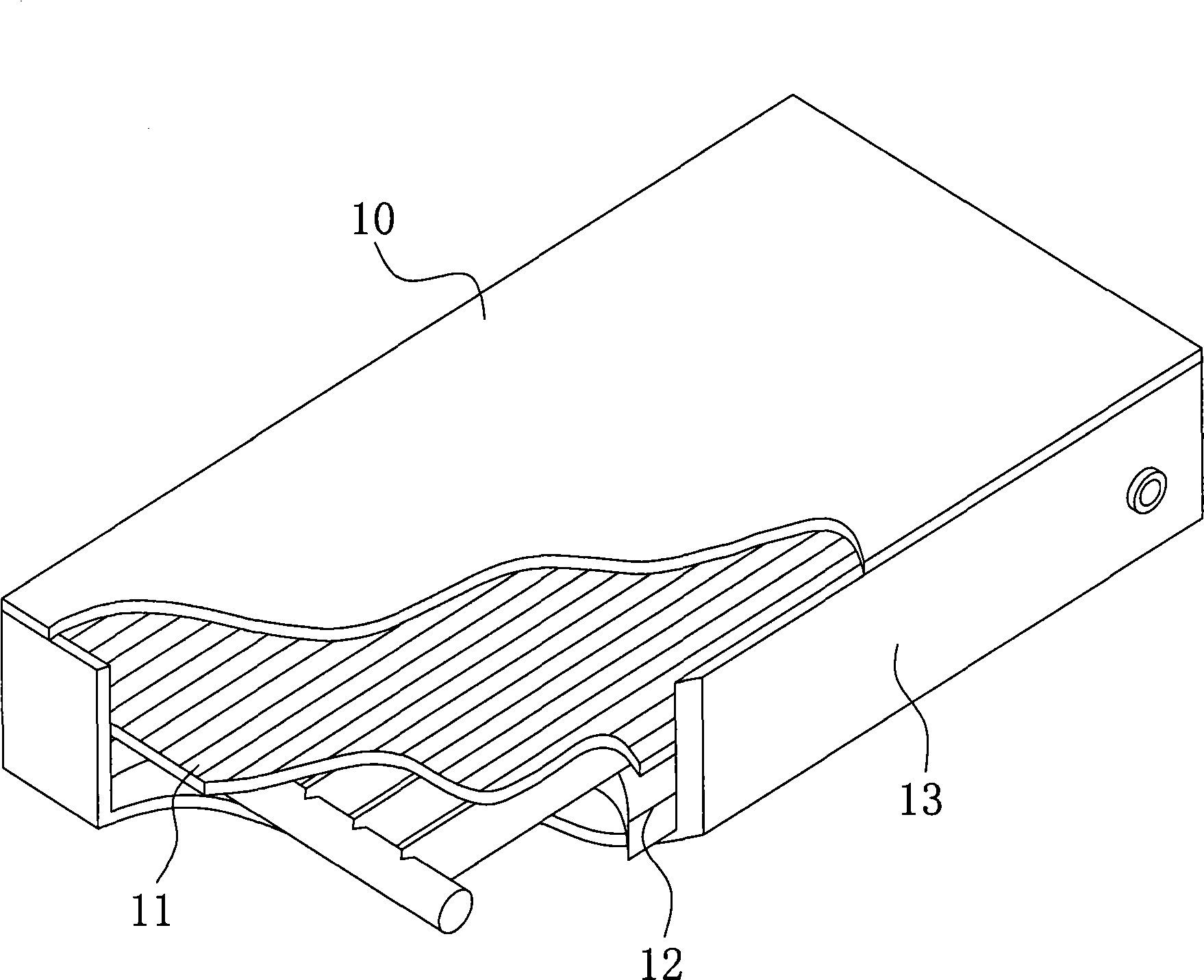

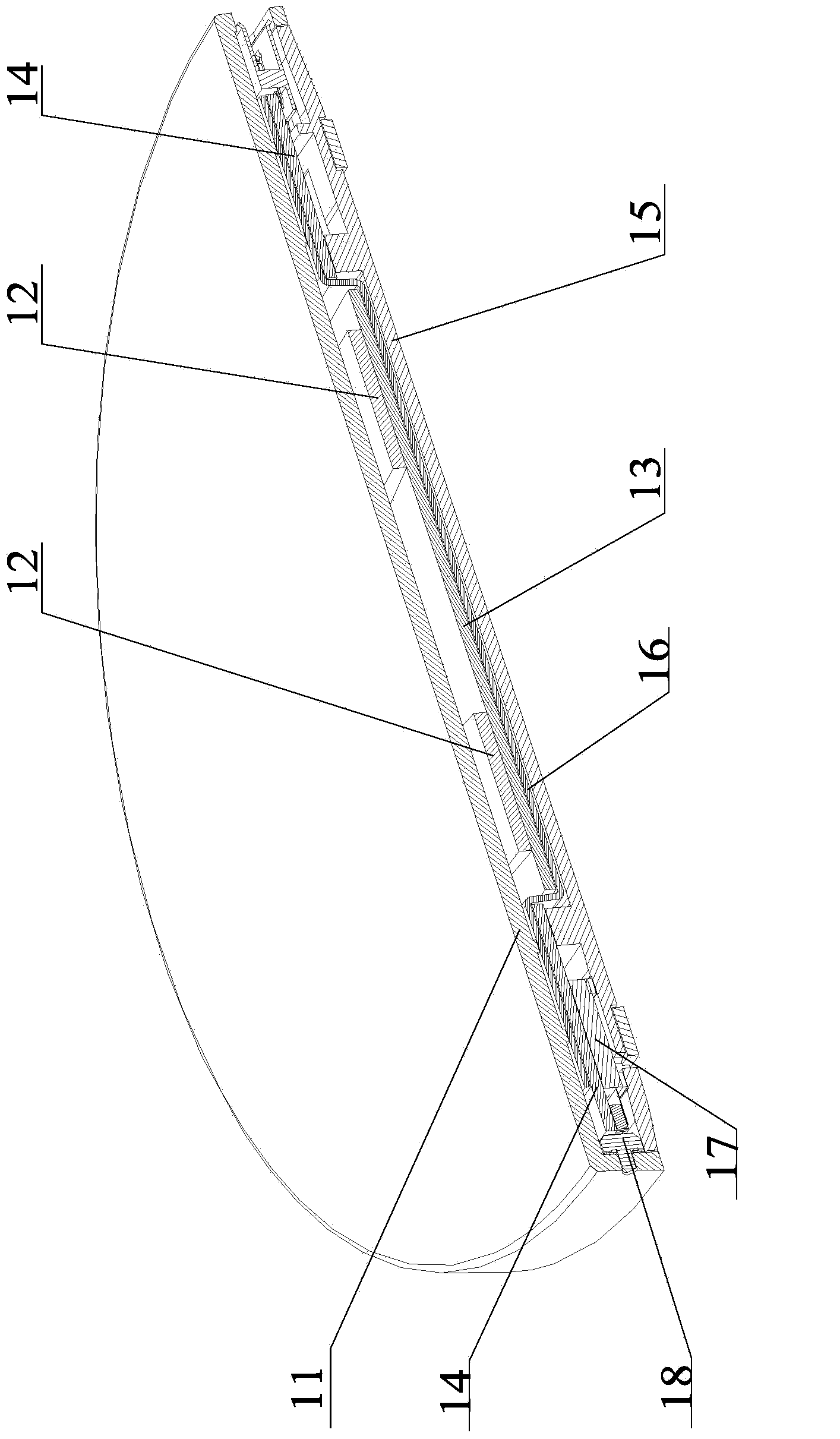

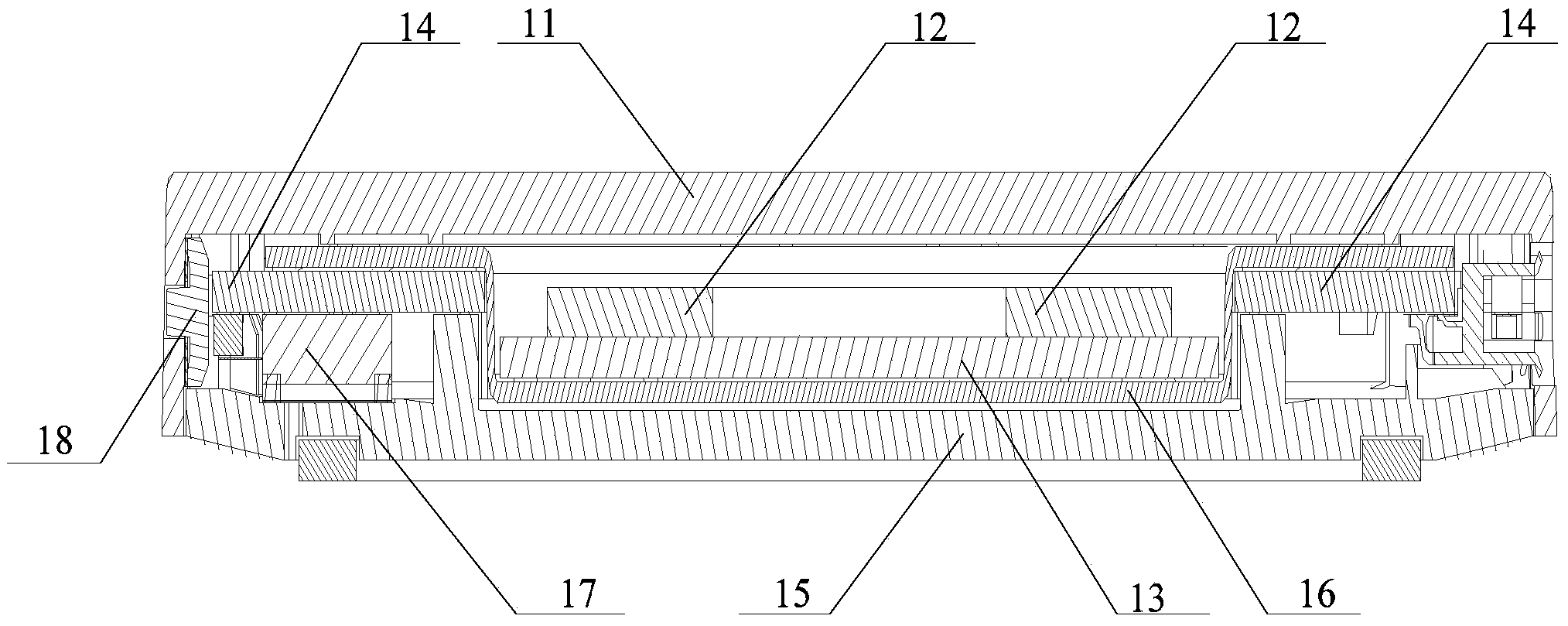

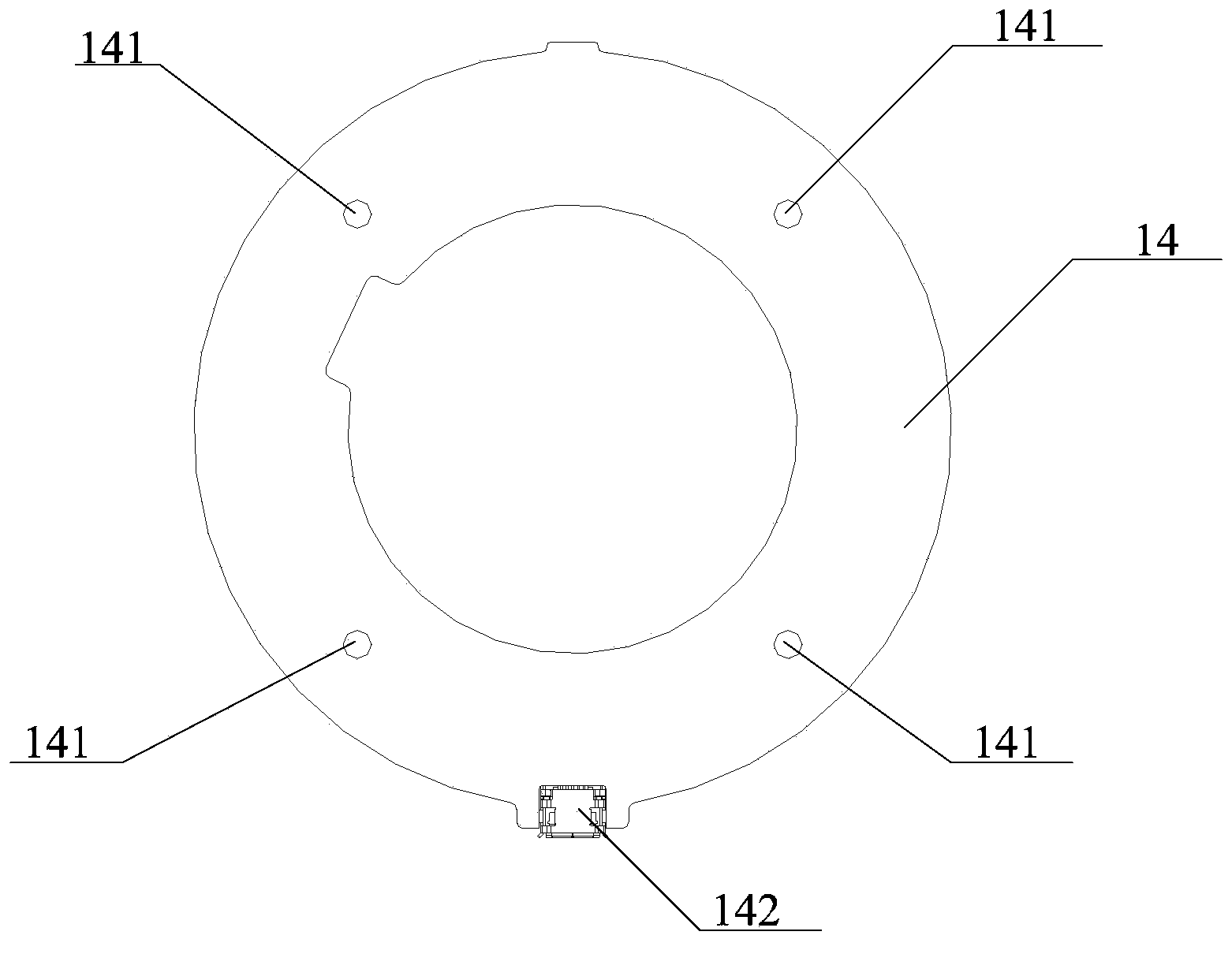

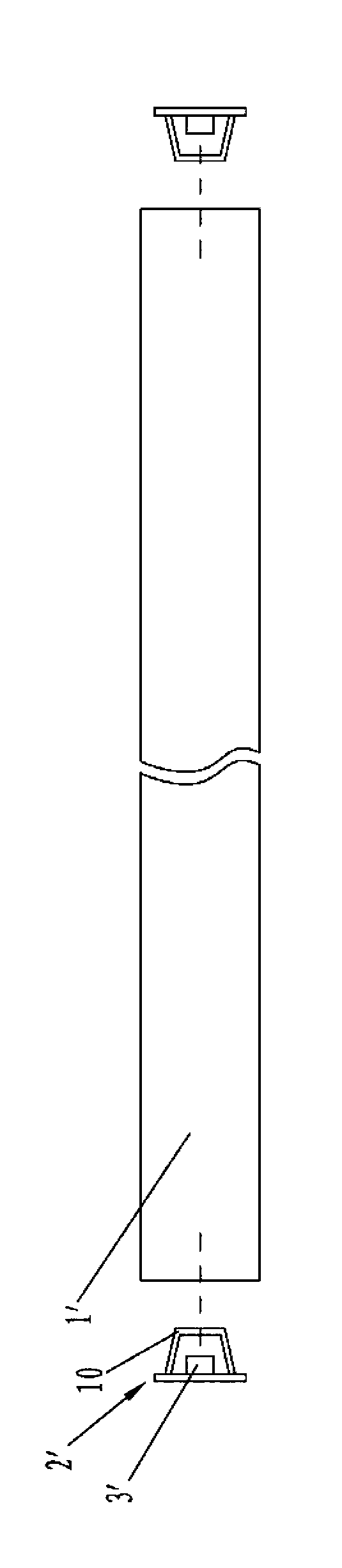

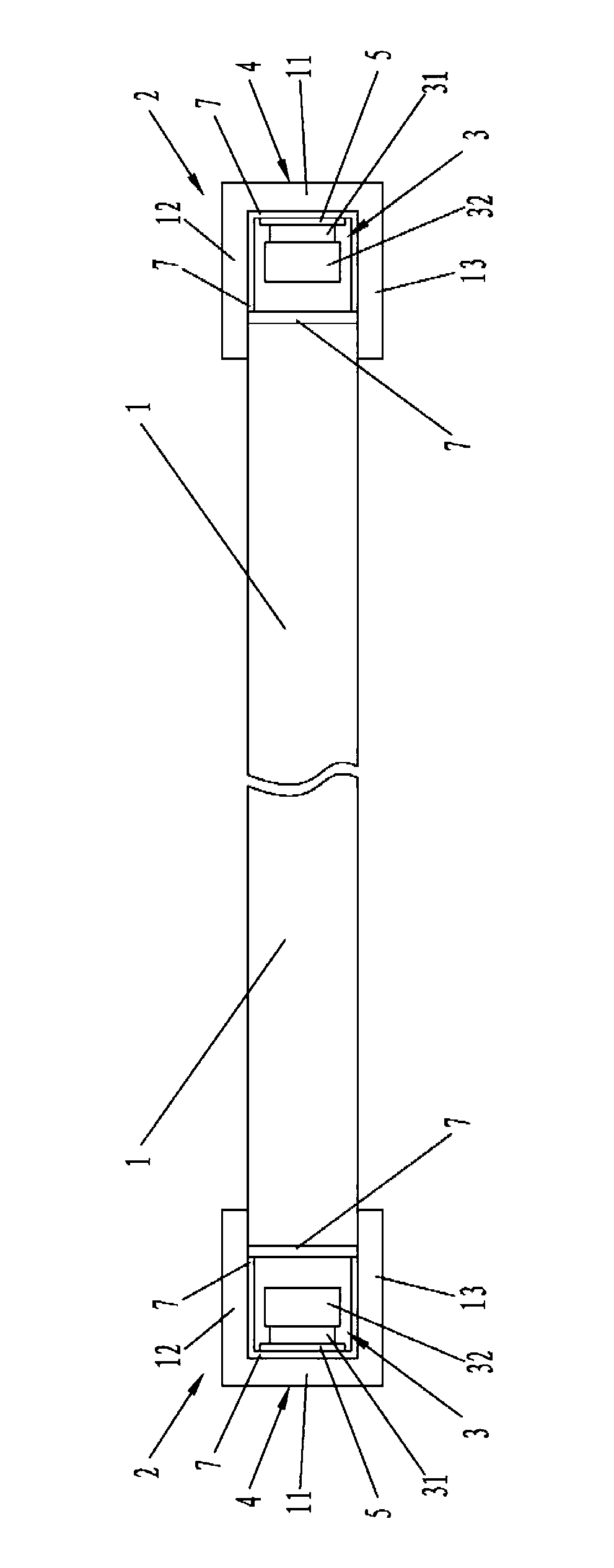

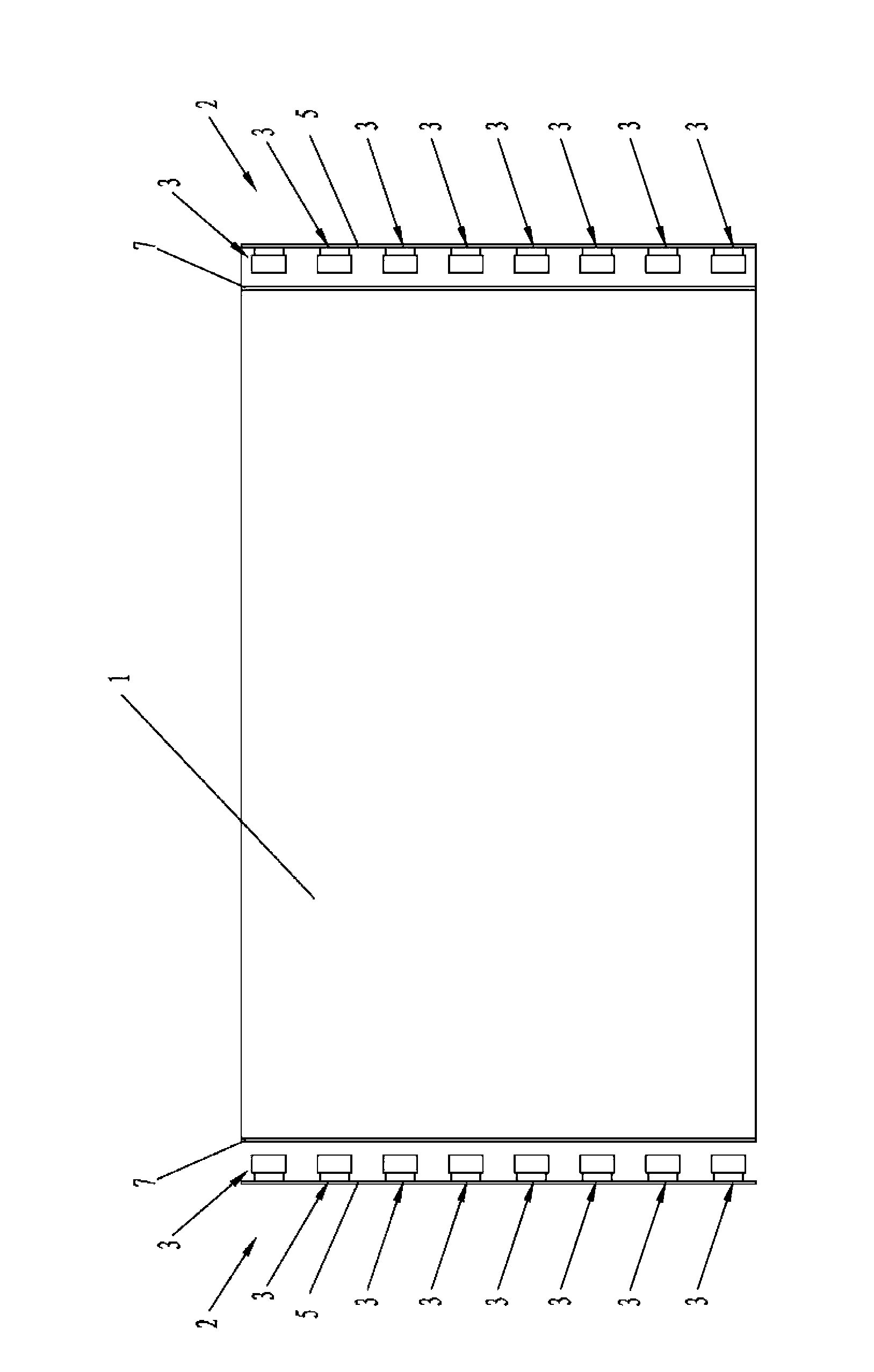

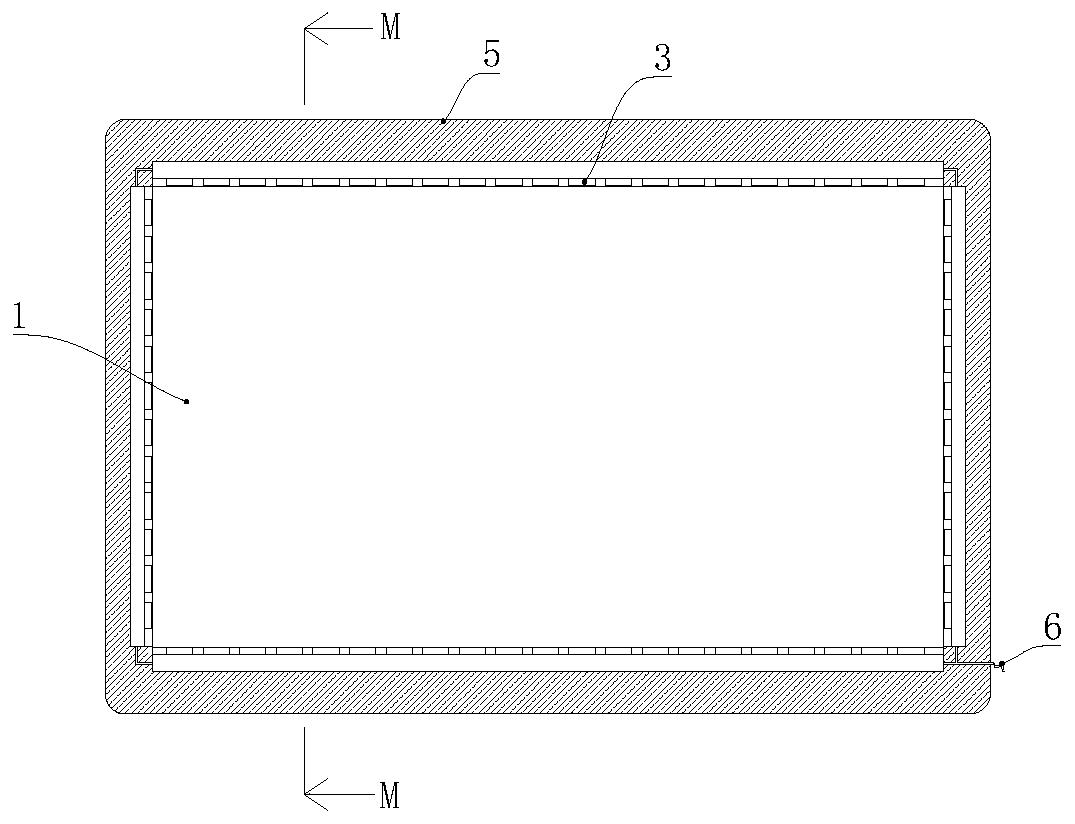

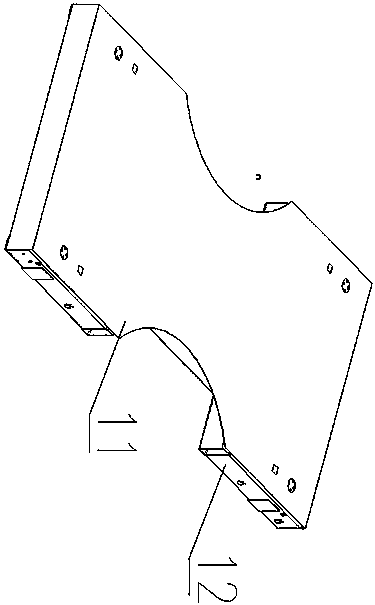

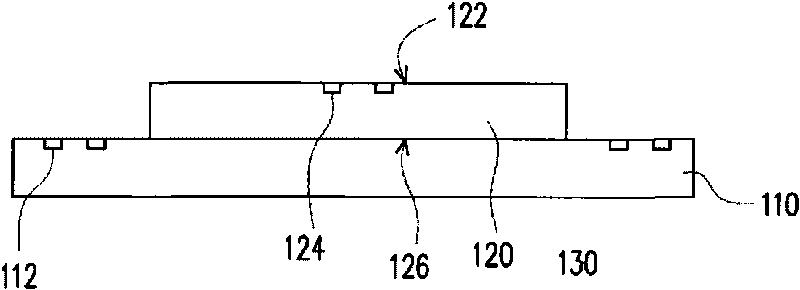

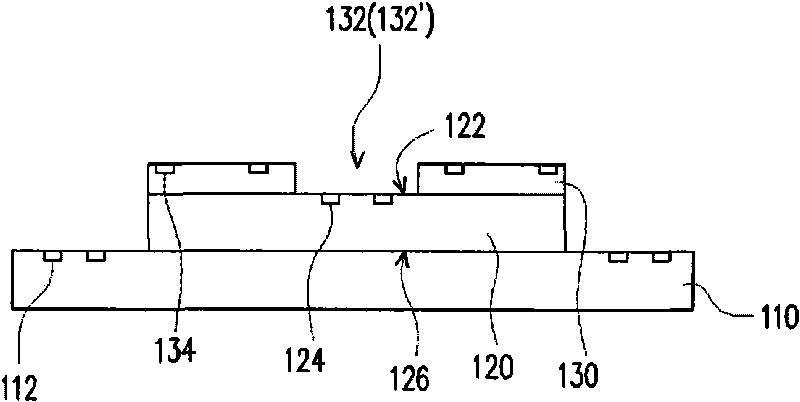

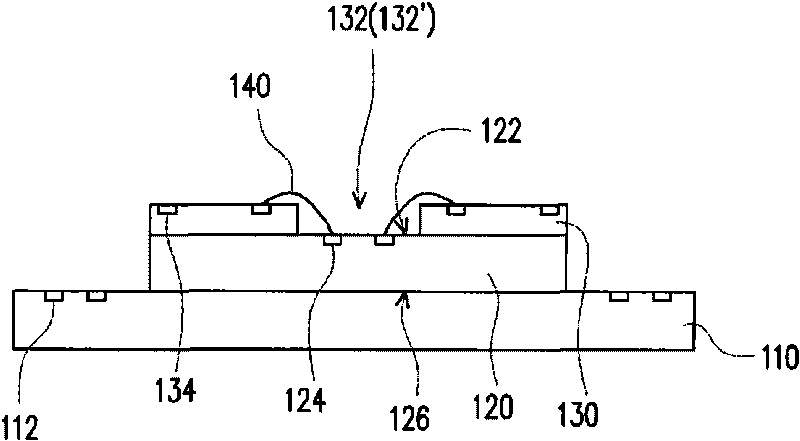

Miniature loudspeaker module and manufacturing method thereof

ActiveCN102523550AReduce overall thicknessAchieve thinningTransducer casings/cabinets/supportsLoudspeakerEngineering

The invention discloses a miniature loudspeaker module and a manufacturing method thereof. The miniature loudspeaker module comprises a loudspeaker unit and an outer casing, and the outer casing is used for holding and fixing the loudspeaker unit. The outer casing consists of an upper casing and a lower casing which are integrated, the space inside the outer casing includes a mounting portion for mounting the loudspeaker unit, each of the upper casing and the lower casing is provided with a body made of plastics, two mounting holes are arranged at the positions of the bodies corresponding to the mounting portion, inserts made of metal are arranged on the two mounting holes, the thickness of each insert is smaller than that of each body, the thickness of the module can be reduced by the above design and thinning of products is realized. In the manufacturing method of the miniature loudspeaker module, positioning parts are integrally formed on the upper insert and the lower insert which are made of metal, the upper insert and the lower insert are positioned on an injection mold accurately through the positioning parts, then the body of the upper casing combined with the periphery of the upper insert and the body of the lower casing combined with the periphery of the lower insert are formed by injection molding, thereby yield and production efficiency of products are improved.

Owner:GOERTEK INC

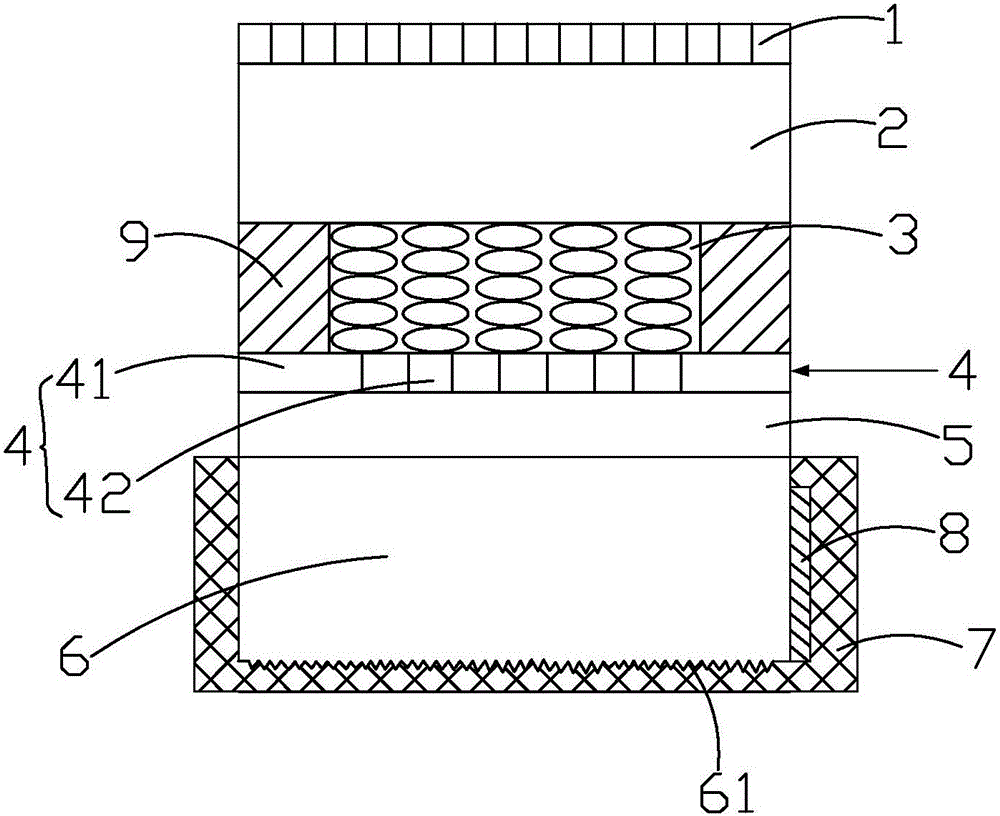

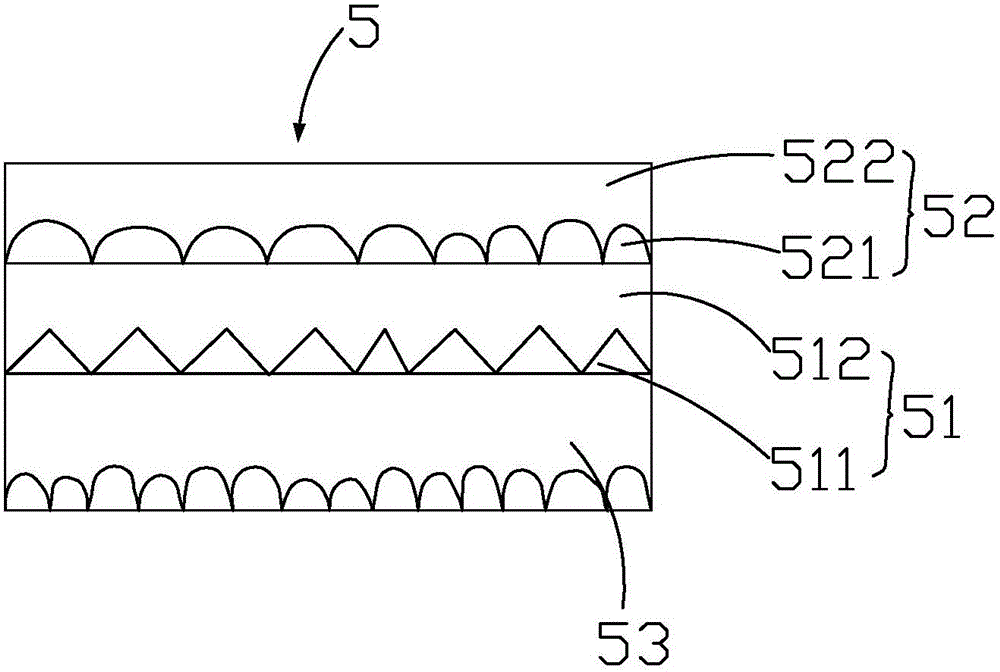

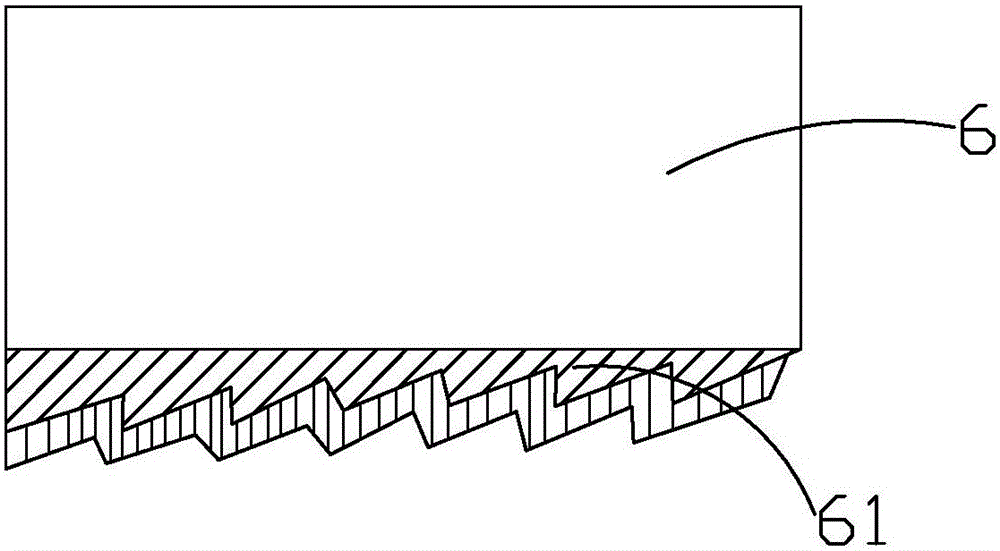

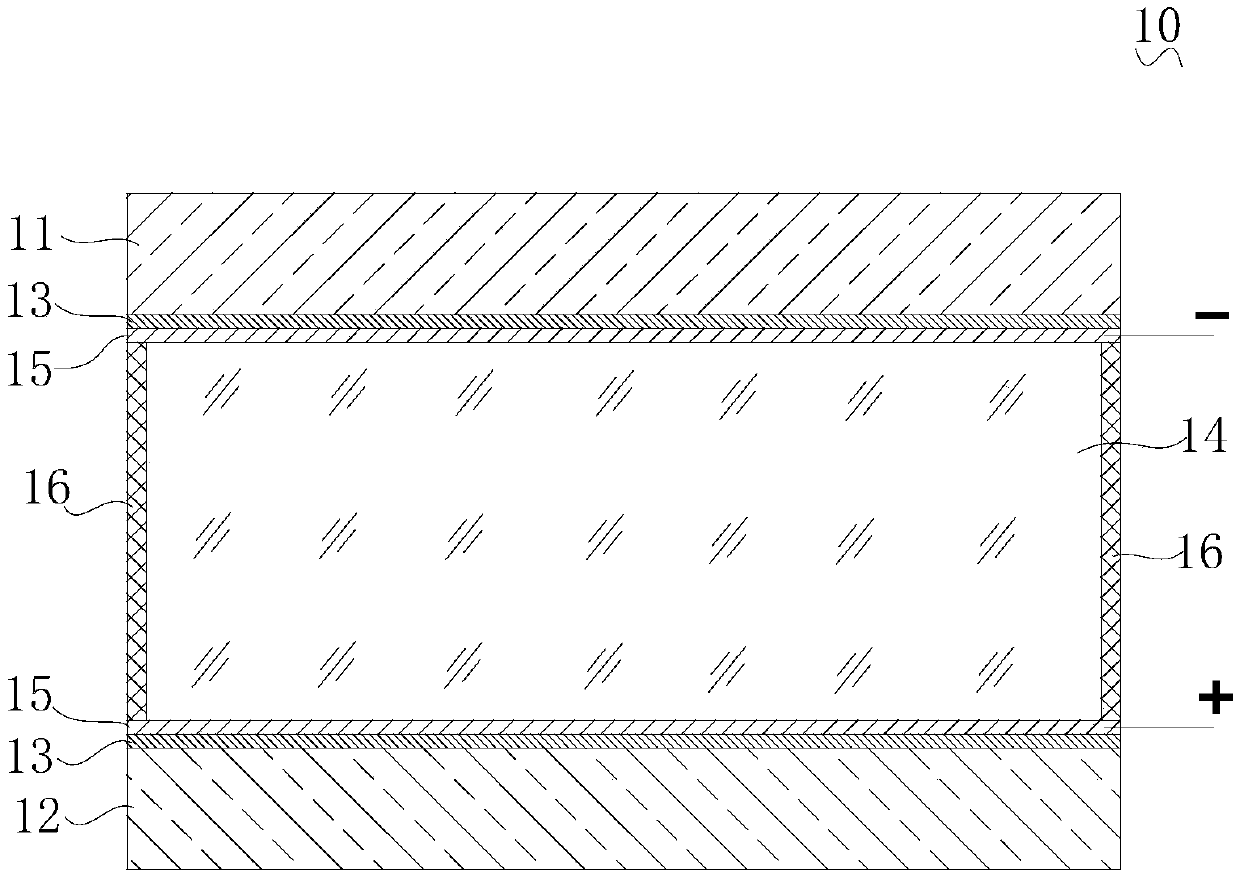

Liquid crystal display screen

PendingCN105807493AReduce overall thicknessReduce thicknessNon-linear opticsPolarizerLiquid-crystal display

The invention discloses a liquid crystal display screen. The liquid crystal display screen comprises an upper polaroid, an upper glass substrate, a liquid crystal layer, a metal wire grating polarizer, a composite optical layer and a lower glass substrate which are arranged in sequence from top to bottom, and further comprises a reflective sheet and a backlight source, wherein the backlight source is arranged on one side of the lower glass substrate; the reflective sheet coats the lower glass substrate and the backlight source; the top surface of the lower glass substrate is exposed out of the reflective sheet; the metal wire grating polarizer comprises a polarization substrate and a plurality of electrode strips which are formed on the polarization substrate through an etching process; the composite optical layer is used for adjusting light rays emitted from the upper surface of the lower glass substrate in order to form surface sources which are uniformly distributed. By adopting the liquid crystal display screen, a light guide plate of the liquid crystal display screen in the prior art is omitted, so that the overall thickness of the liquid crystal display screen is reduced greatly.

Owner:KUSN INFOVISION OPTOELECTRONICS

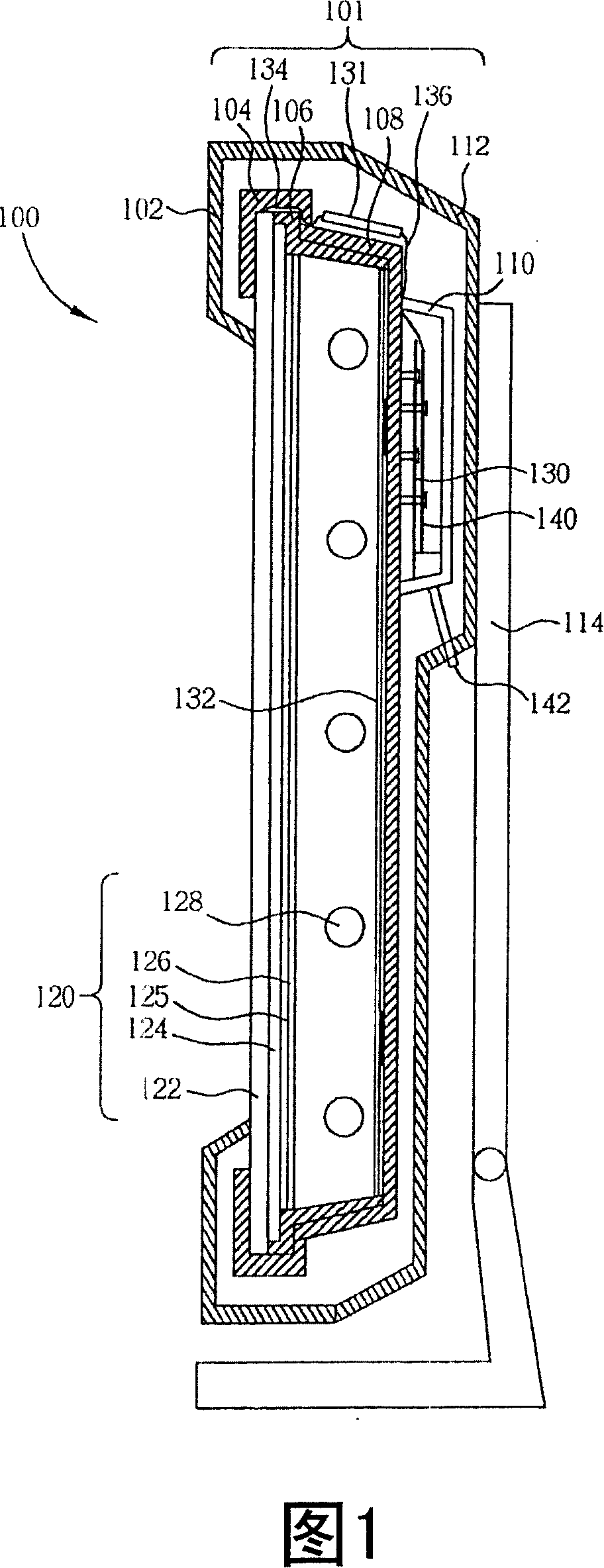

Liquid crystal display equipment

InactiveCN101666943AMeet the needs of brightness and color reproductionReduce overall thicknessElectric circuit arrangementsNon-linear opticsLiquid-crystal displayDirect illumination

The invention discloses liquid crystal display equipment. The equipment comprises a backboard, a side frame, an upper frame, a module frame, a liquid crystal screen, a circuit board of the liquid crystal screen and a direct illumination-type LED backlight, wherein the direct illumination-type LED backlight comprises a circuit board of an LED chip arranged on the bottom of the backboard, LED chipsarranged above the circuit board of the LED chip, an optical diaphragm arranged between the side frame and the upper frame as well as a drive and control circuit board and a drive and control electronic device of the LED chips; the drive and control circuit board is arranged inside the side frame or between the upper frame and the module frame; and the drive and control electronic device is arranged on the circuit board of the LED chip or integrated on the drive and control circuit board. The liquid crystal display equipment can reduce thickness, and achieves ultra-thin design.

Owner:BOE TECH GRP CO LTD

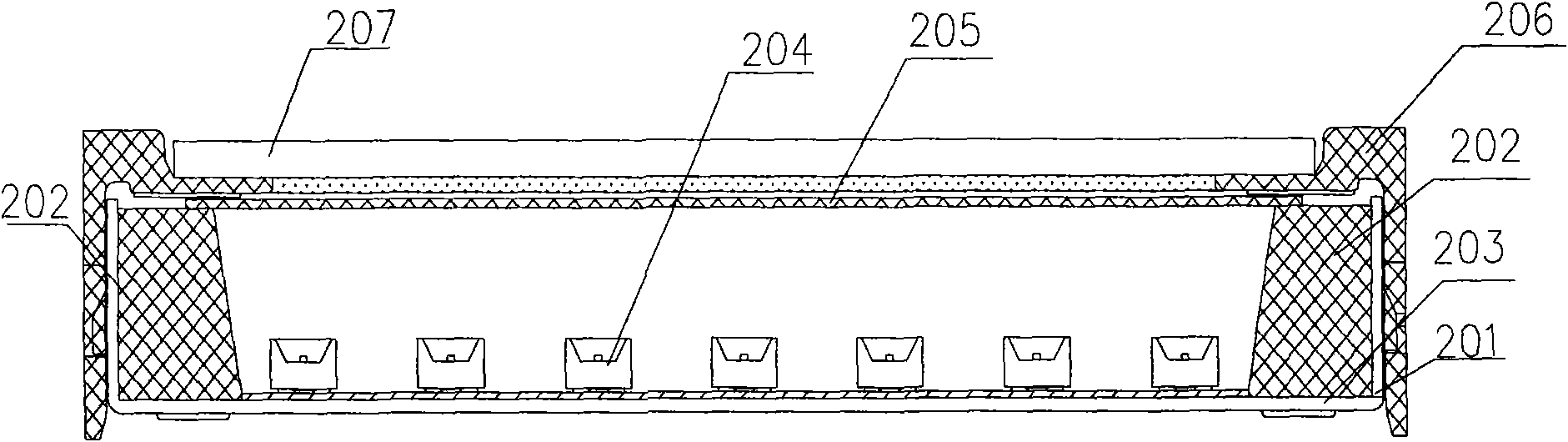

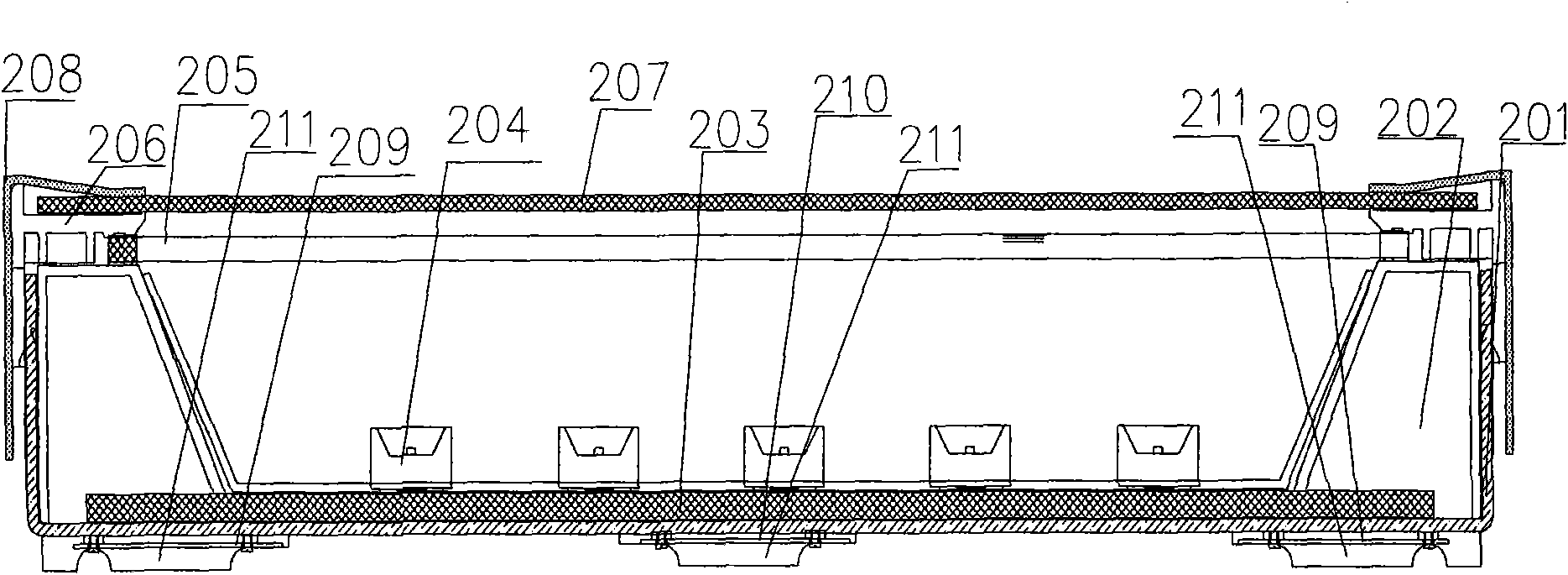

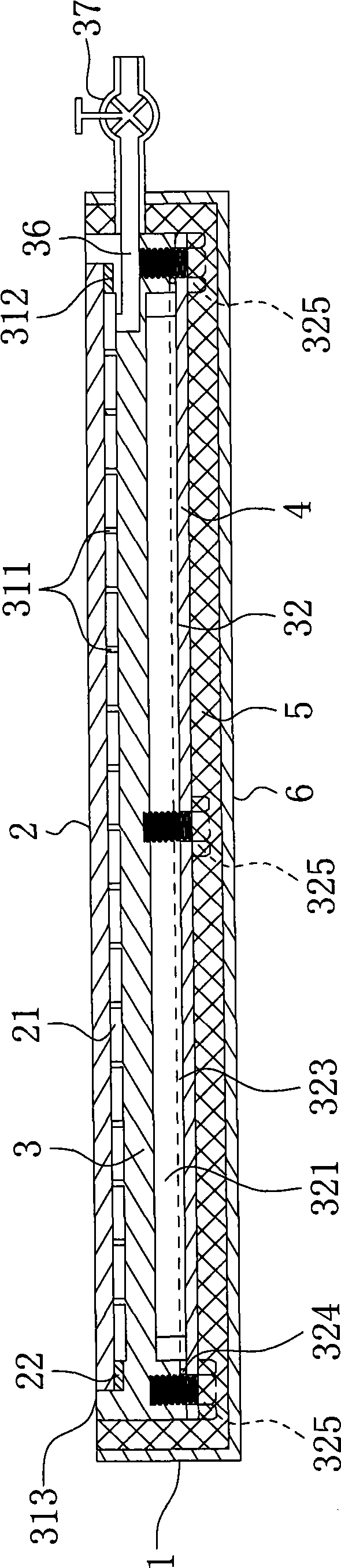

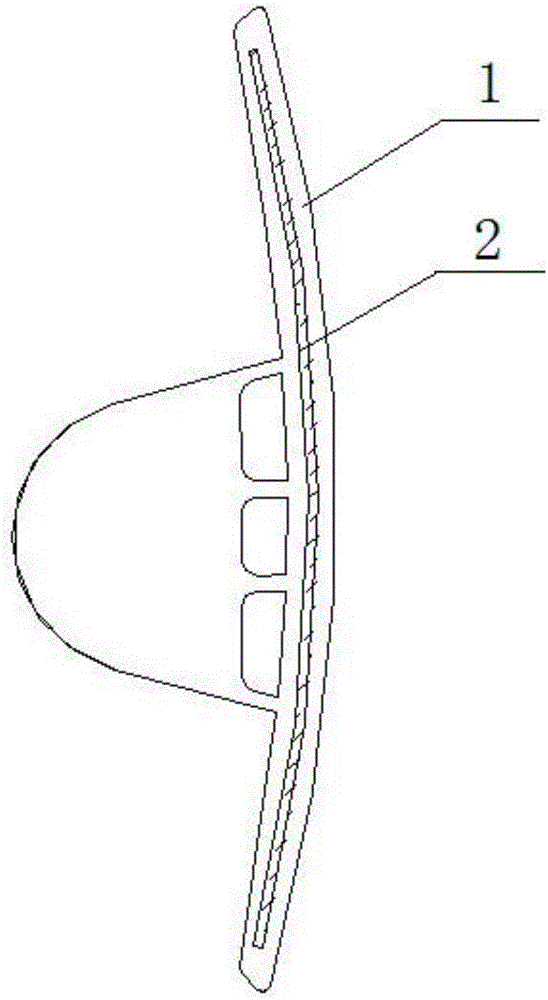

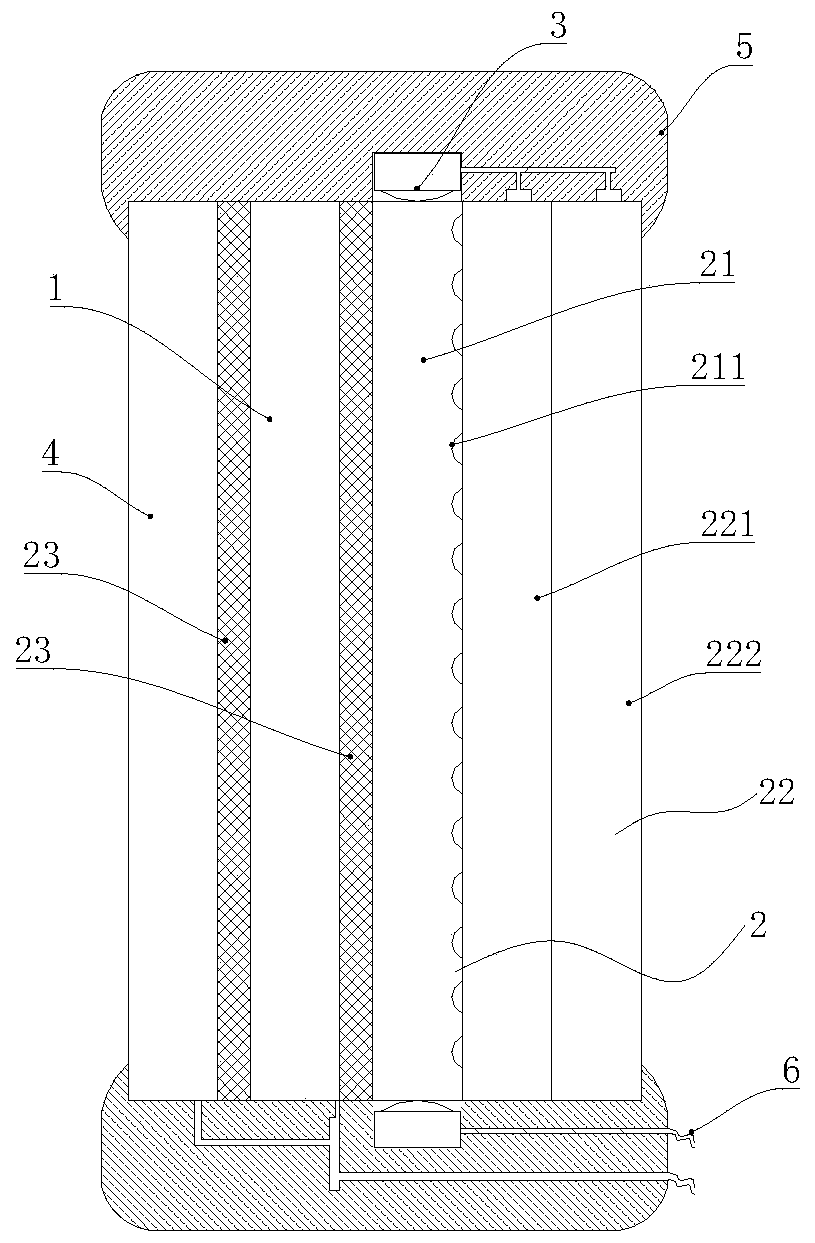

Plate type evacuated solar collector and solar energy heat collector

InactiveCN101509708AReduce overall thicknessImprove penetrationSolar heating energySolar heat devicesEngineeringVacuum state

The invention provides a flat-plate typed vacuum solar heat collector comprising a heat collecting plate, an upper cover, a supporting device, a lower cover and a heat-insulating layer, wherein the light can penetrate the upper cover which is arranged at a first side of the heat collecting plate; the supporting device is arranged between the upper cover and the heat collecting plate and comprises a plurality of supporting components; the heat collecting plate and the upper cover are divided by the supporting components; an internal space is arranged between the heat collecting plate and the upper cover; the internal space is in a vacuum state; the lower cover is arranged at a second side of the heat collecting plate; and the heat-insulating layer is arranged at the external side of the lower cover and the heat collecting plate.

Owner:DA-YEH UNIVERSITY

Three-dimensional display and manufacturing method thereof

ActiveCN102759804AReduce overall thicknessReduce manufacturing costNon-linear opticsOptical elementsLiquid-crystal displayLiquid crystal

The invention provides a three-dimensional display and a manufacturing method thereof, wherein the three-dimensional display comprises a display panel, a liquid crystal layer, an alignment layer and an adhesion layer; the liquid crystal layer is positioned at one side (opposite to the display panel) of the display panel; the alignment layer is formed by curable resin, and is positioned at the other side of the liquid crystal layer; the alignment layer is provided with a plurality of first and second alignment regions, wherein the first and second alignment regions are staggered with one another and are parallel with one another; liquid crystal on the first and second alignment regions respectively provides first phase delay and second phase delay, and the difference between the first phase delay and the second phase delay is gamma / 2; and the adhesion layer is configured between the display panel and the liquid crystal layer, the display panel is connected with the liquid crystal layer through the adhesion layer, the pencil hardness of the alignment layer is between 1B and 4H, and the adhesion force of the adhesion layer is 50-1500gf / 25mm. The three-dimensional display provided by the invention does not have a base material which is used for bearing the liquid crystal layer, so that the integral thickness can be lowered greatly, and the manufacturing cost is low.

Owner:BENQ MATERIALS +1

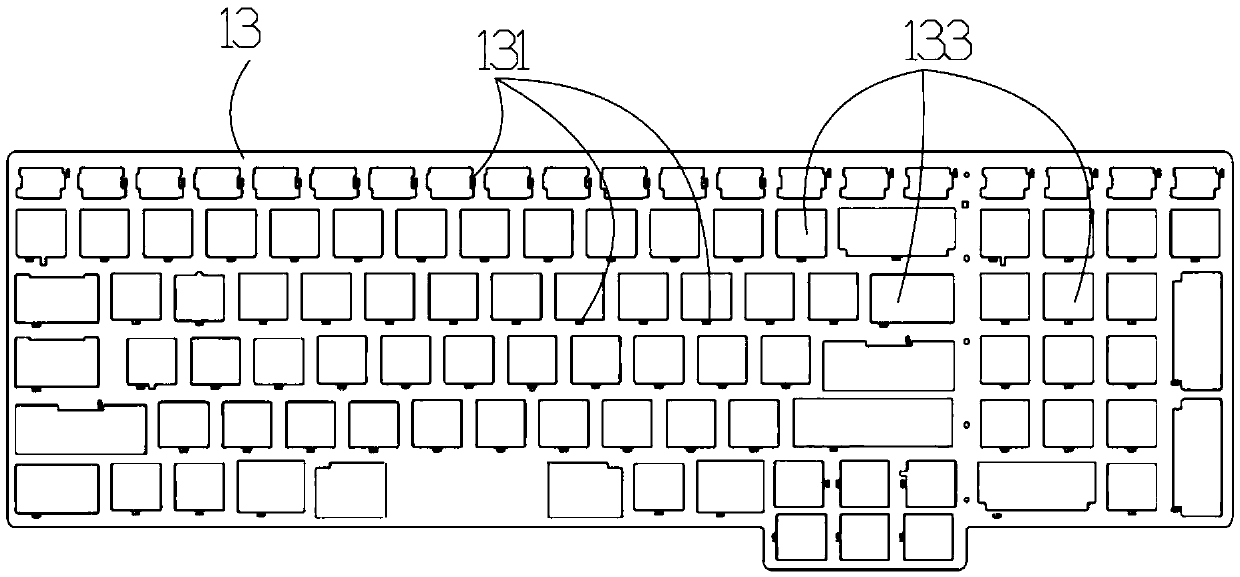

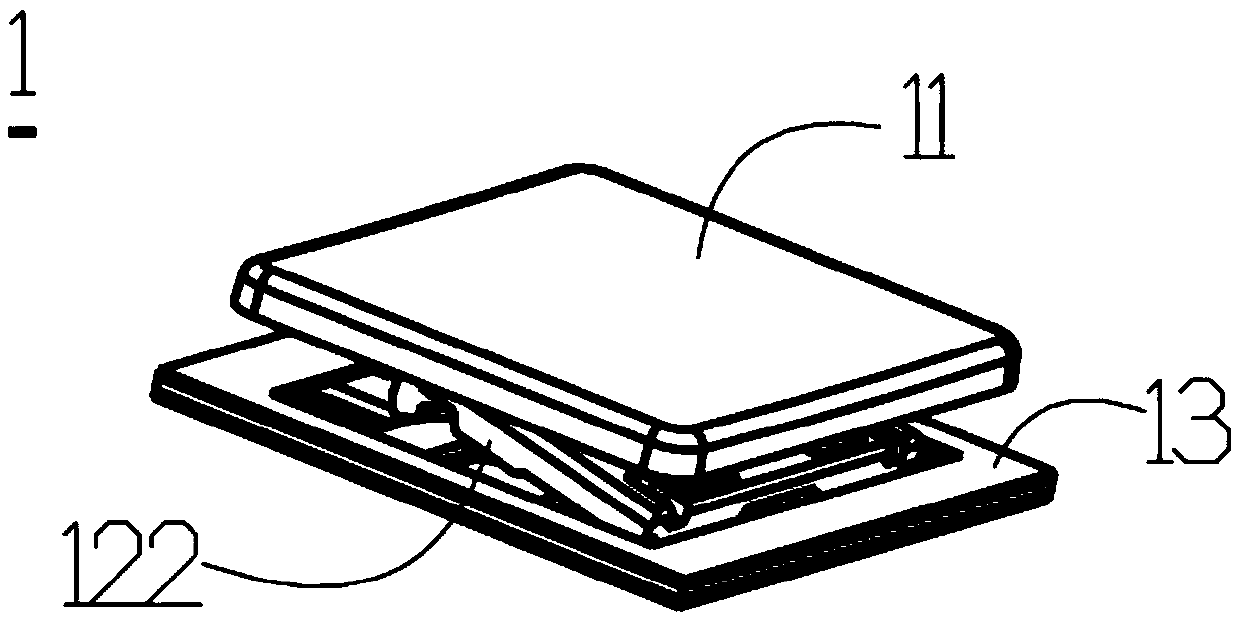

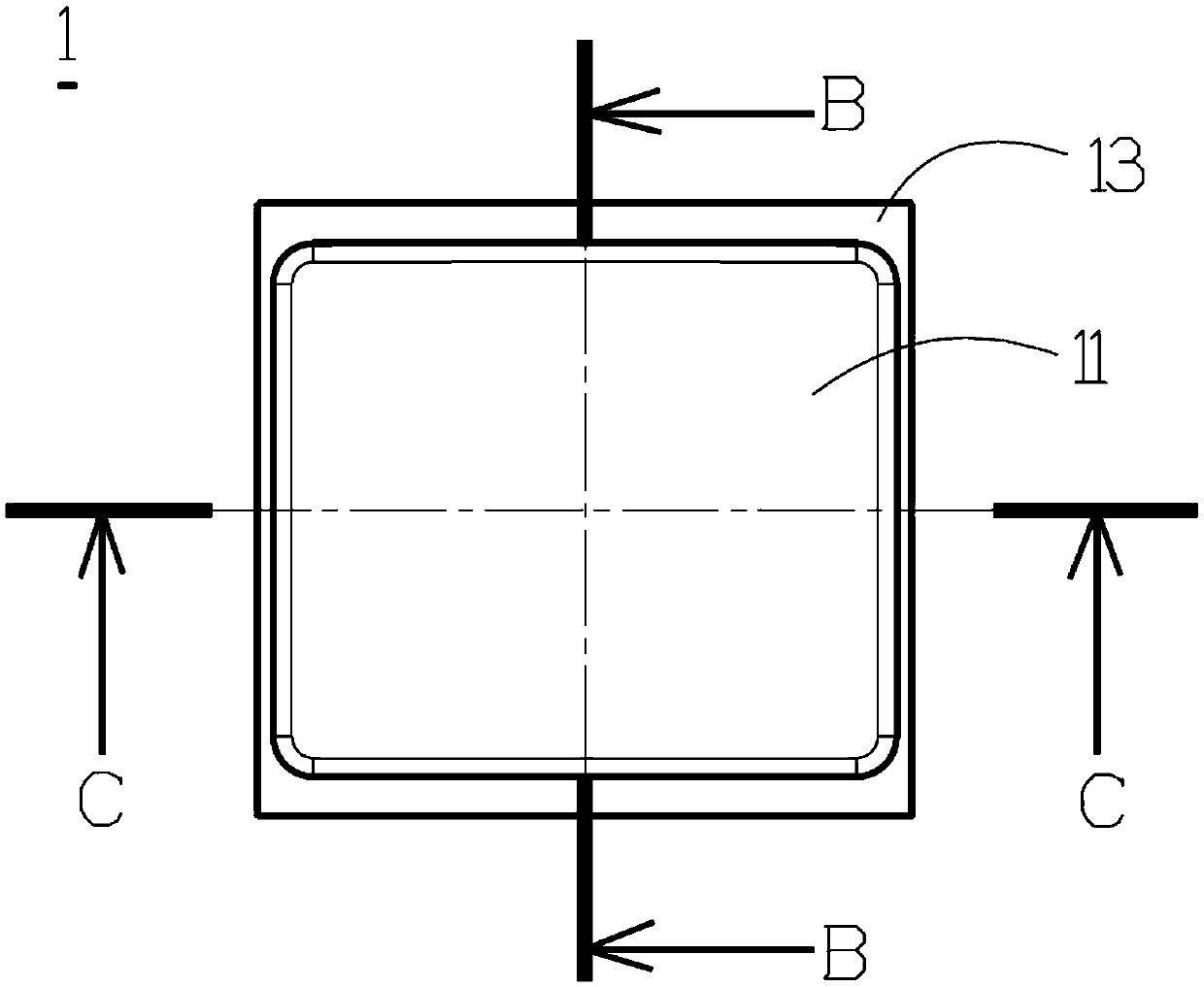

Light-emitting key

ActiveCN105513869AReduce overall thicknessReduce power consumptionLegendsElectric switchesLight sourceBrightness perception

The invention relates to a light-emitting key used in a light-emitting keyboard. A light source is arranged at a side under a light transmitting keycap; light rays emitted by the light source are emitted to a light transmitting area of the light transmitting keycap by a keycap connection mechanism or an elastic body of the light transmitting keycap through diffuse reflection or scattering. In this way, the light transmitting area of the light transmitting keycap can realize uniform light transmission, thus a backlight module is not required does not need to be arranged for the light-emitting keyboard, and the whole thickness of the light-emitting keyboard can be greatly reduced; in addition, arranging arrangement of a high-brightness light source is avoided, the light source electric energy consumption of the whole light-emitting keyboard can be greatly reduced, and a notebook computer using the light-emitting key is enabled to have longer battery endurance time.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

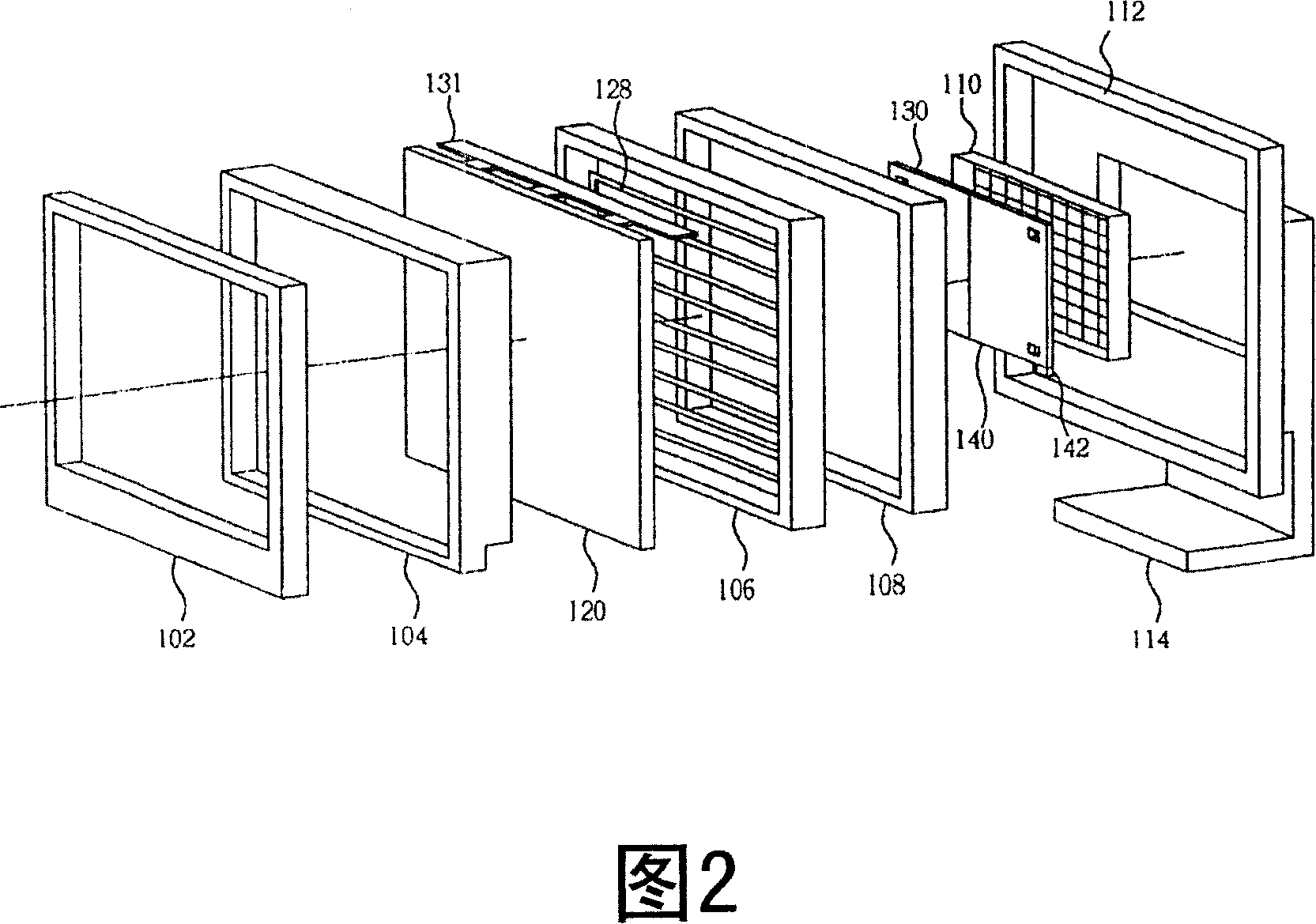

Display device

InactiveCN106556945AReduce overall thicknessReduce thicknessNon-linear opticsDisplay deviceComputer science

The invention relates to a display device used for double face display. The display device comprises two display panels and two backlight modules. The display device also comprises a pair of first frames which cooperate with each other to form an accommodating space, the accommodating space is used for accommodating the two backlight modules, the two backlight modules are arranged adjacently, the light extraction directions of the two backlight modules are opposite, and the two display panels are respectively arranged on the light extraction directions of the two backlight modules. With respect to the double face display device, the design of a support member connected with a pedestal is canceled, the two backlight modules are directly arranged in the accommodating space formed by the pair of first frames which cooperate with each other, and therefore the whole thickness of the double face display device can be greatly reduced.

Owner:QISDA SUZHOU +1

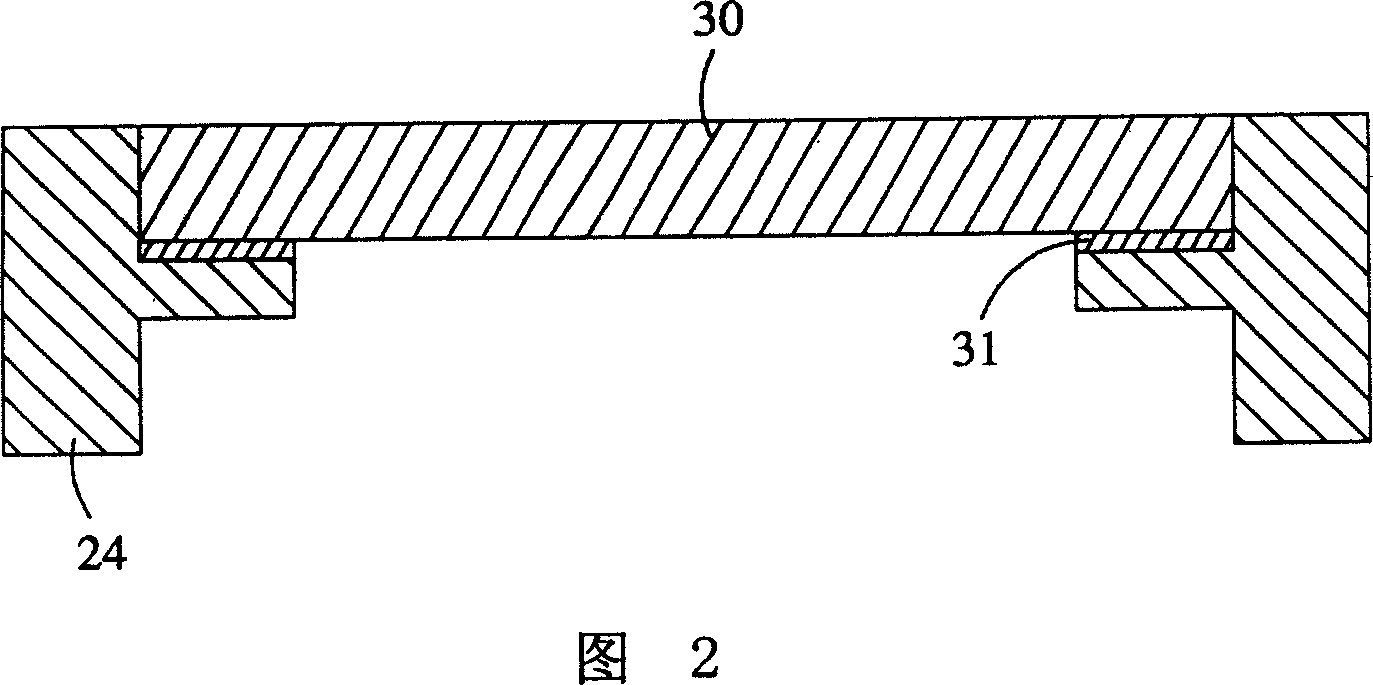

Wafer-level packaging method for CMOS image sensor

ActiveCN106024819AReduce overall thicknessImprove performanceSolid-state devicesRadiation controlled devicesCMOSImage sensor

Provided in the invention is a wafer-level packaging method for a CMOS image sensor. According to the method, a contact can be formed in a light-sensing surface of a chip by various ways of a ball grid array (BGA), a bump, and a lead; and assembling is carried out by silver paste connection, anisotropic conductive film (ACF) connection, pulse welding connection, ultrasonic connection, and solder ball thermal connection and the like. Therefore, the overall thickness after packaging is reduced effectively; and the image sensor performance is improved. The method is especially suitable for a high-pixel CMOS image sensor product and is also suitable for wafer-level packaging of a multi-camera module group product.

Owner:GALAXYCORE SHANGHAI

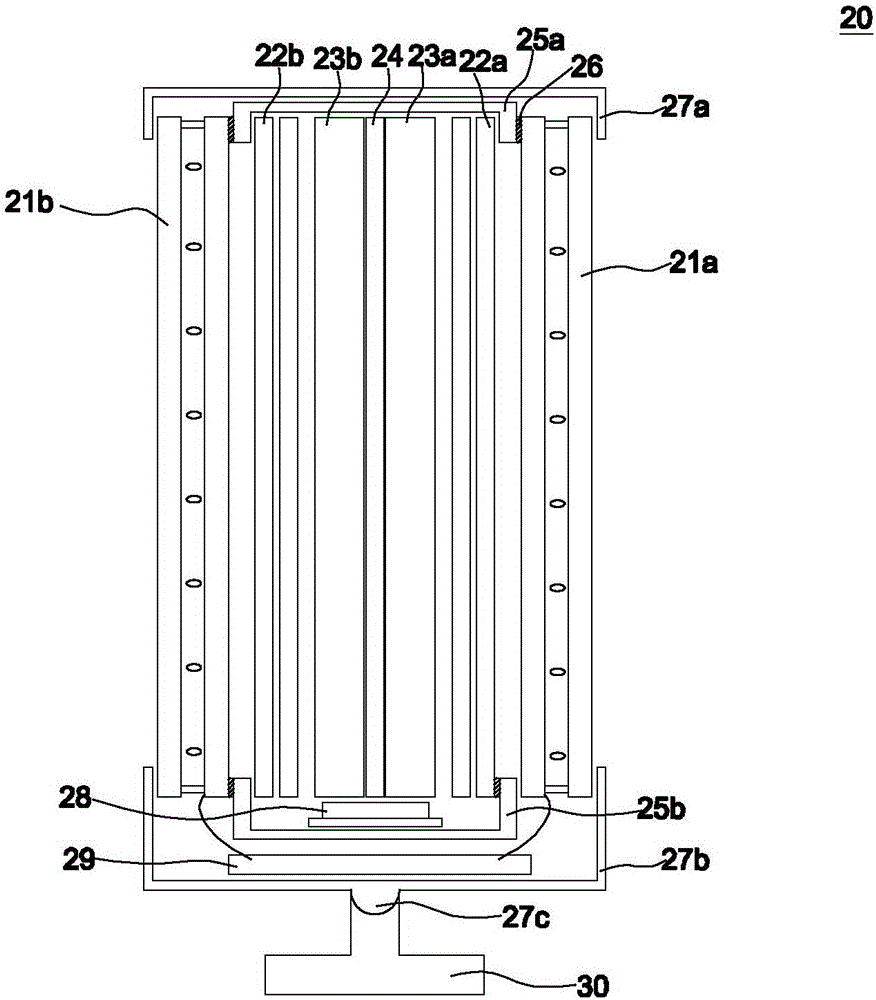

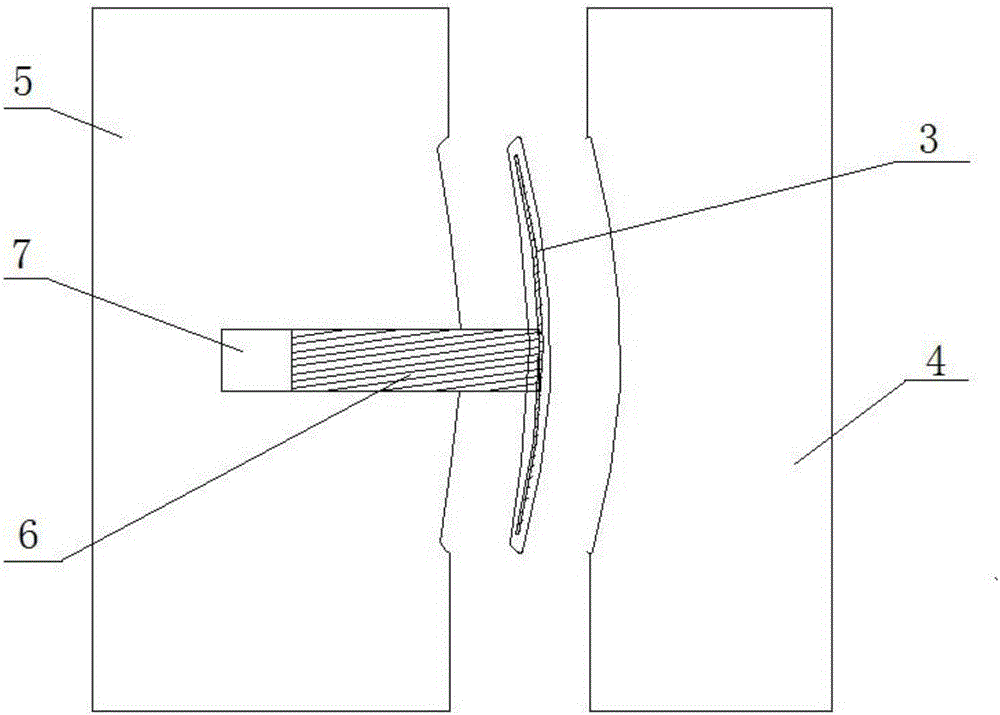

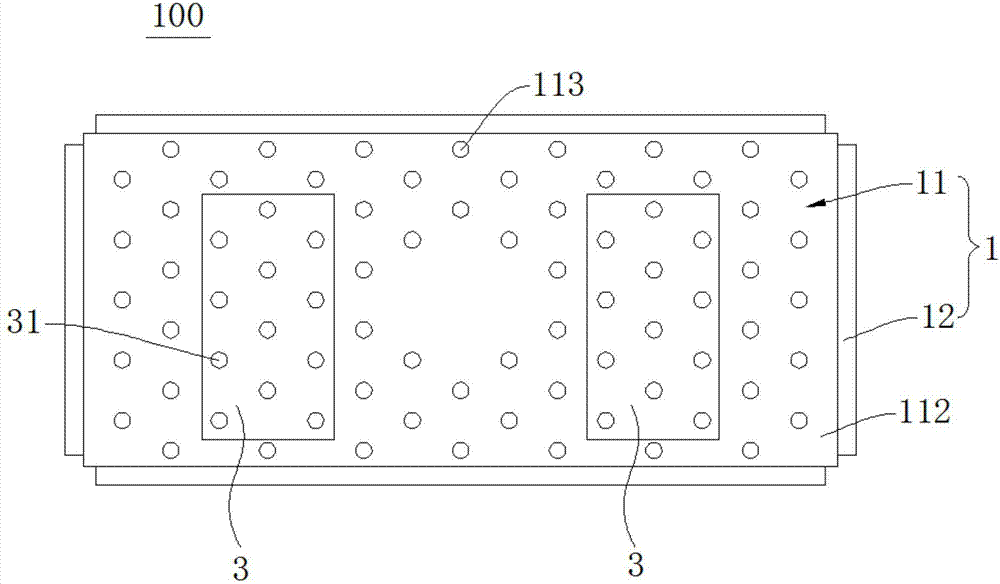

Wireless charger

InactiveCN103928969AReduce overall thicknessEasy to carryBatteries circuit arrangementsElectromagnetic wave systemPrinted circuit boardWireless

The invention discloses a wireless charger which is composed of an upper cover, a charging coil, a ferrite, a printed circuit board component and a lower cover. The charging coil is arranged on the ferrite, and the printed circuit board component is of a hollow structure so that the charging coil and the ferrite can be arranged in the hollow structure of the printed circuit board. The thickness of the final charger formed through combination is equal to the sum of the thickness of the upper cover, the thickness of the lower cover and the thickness of the printed circuit board component, the thicknesses of the traditional charging oil and the ferrite are omitted, the overall thickness of the wireless charger is greatly shortened, and the wireless charger is more convenient to carry.

Owner:SHANDONG GETTOP ACOUSTIC

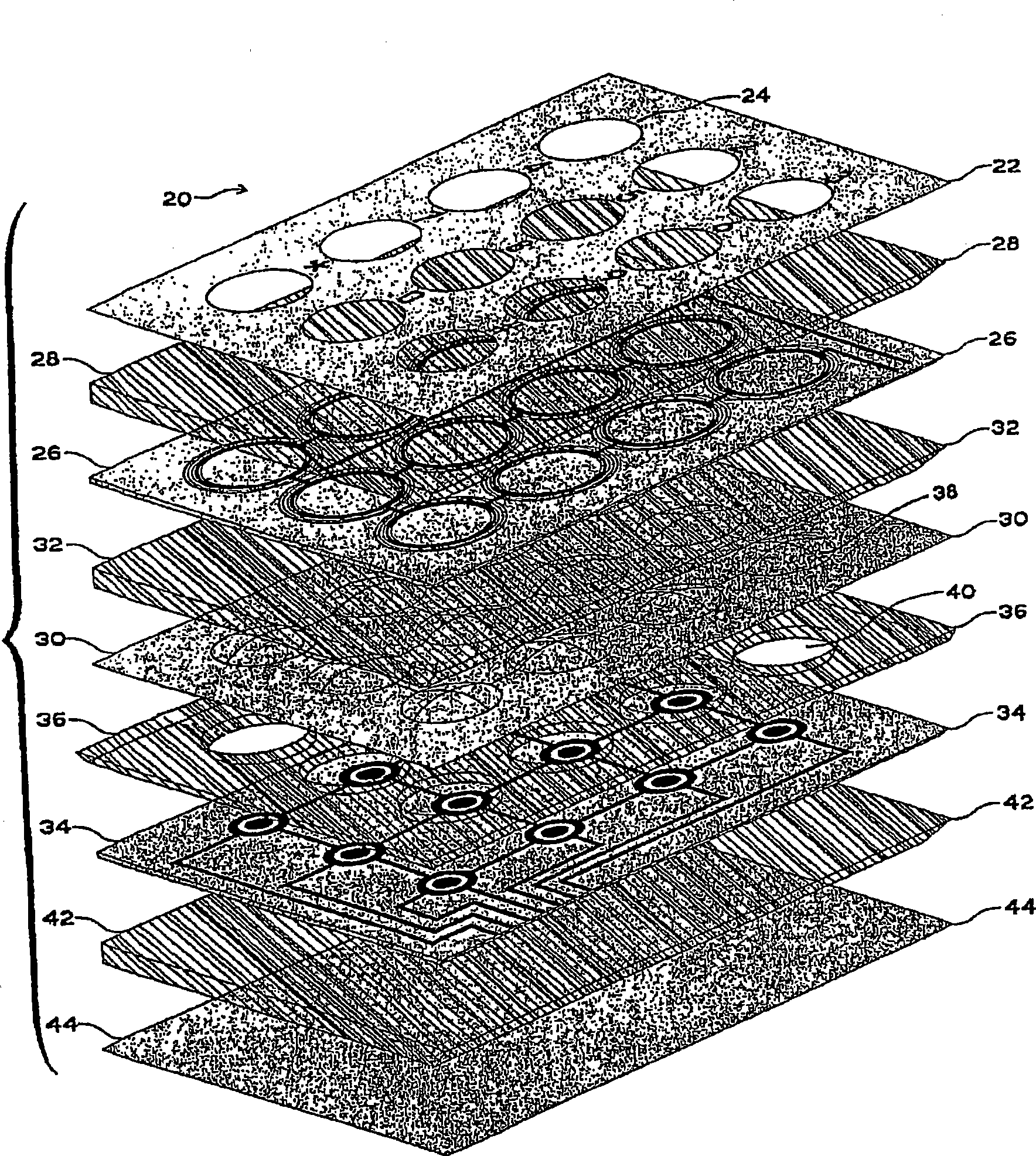

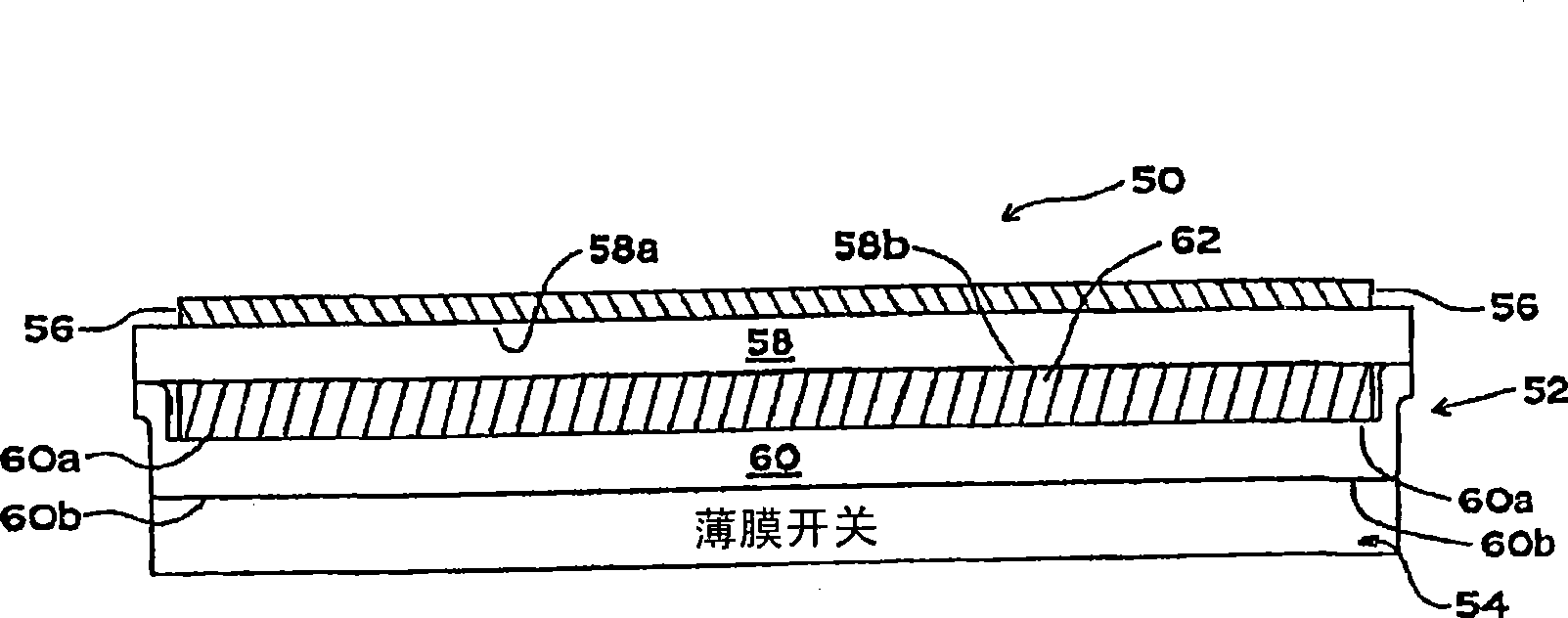

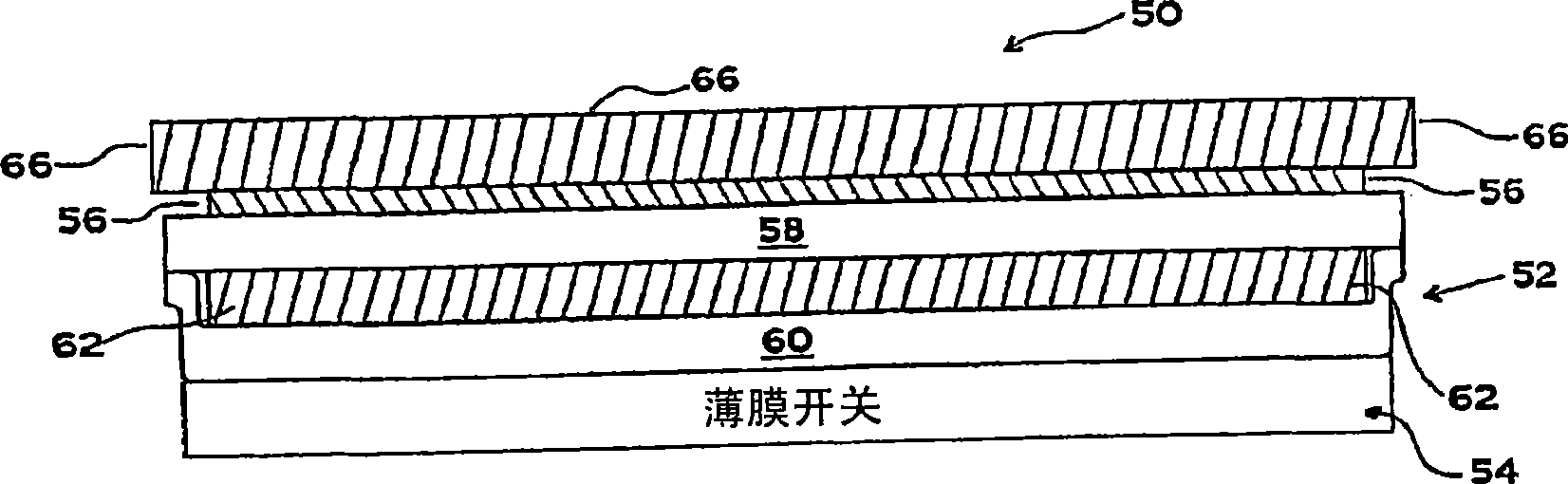

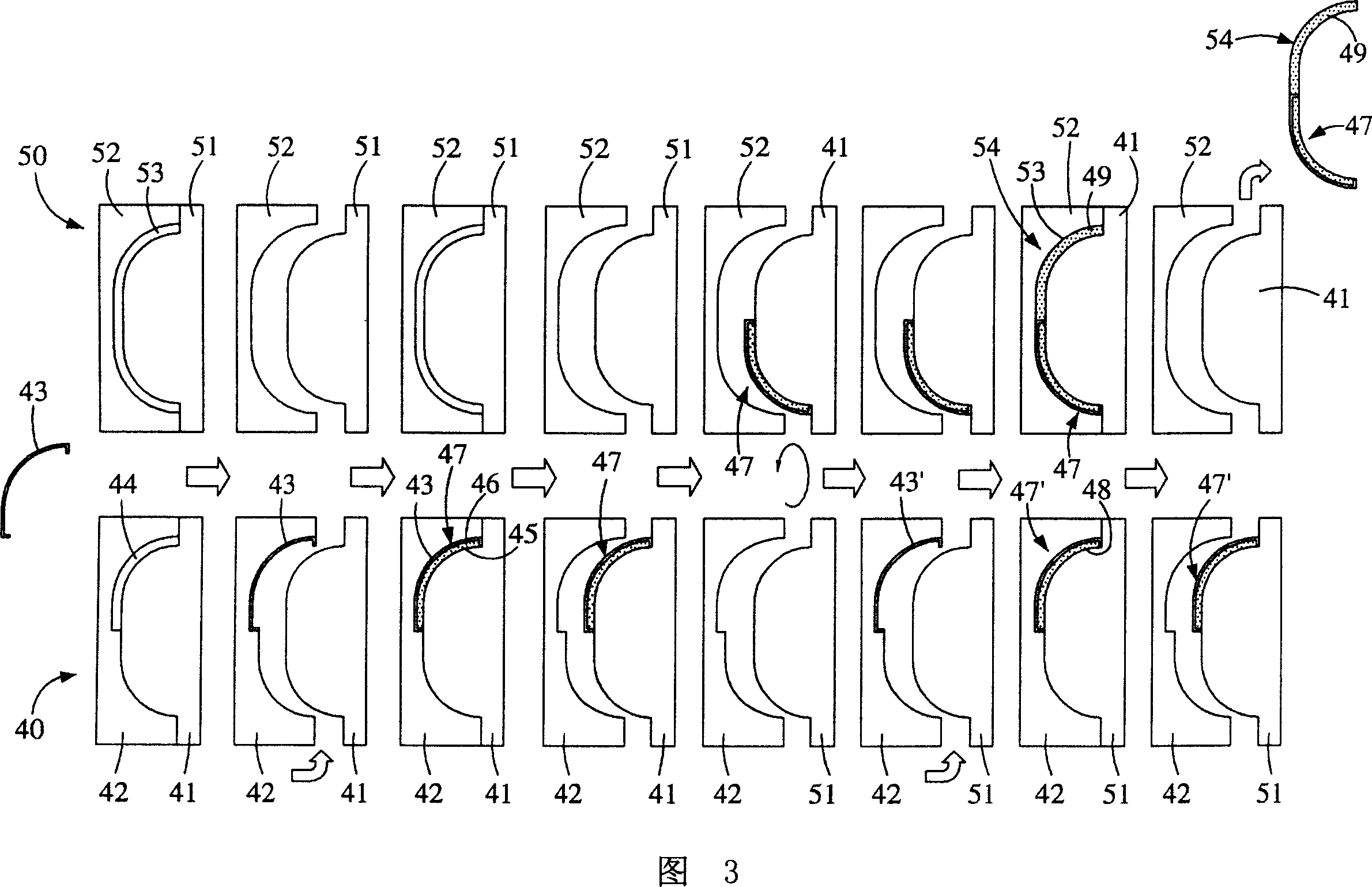

Electroluminescent lamp membrane switch

ActiveCN101490776AReduce overall thicknessReduce processing time and production costsLegendsElectric switchesCapacitanceMembrane switch

A combined monolithic electroluminescent lamp (52) and membrane switch (50) is manufactured by continuous printing. Graphic indicia (56) are imprinted on a deformable substrate (66). An electroluminescent lamp (52) is imprinted on the graphic indicia layer (56) and a membrane switch (50) is formed on the lamp. The monolithic switch (50) has a layer (120) for sensing switch actuation by means including resistance change, capacitance change, or magnetic field change.

Owner:2461729 ONTARIO

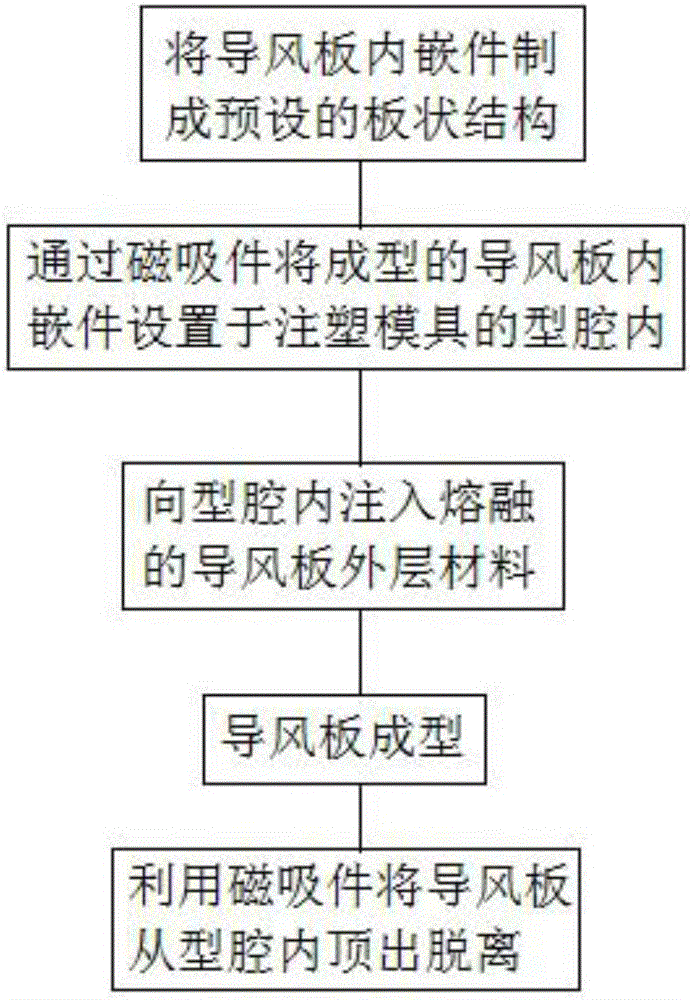

Air guide plate, injection mold and molding method

ActiveCN106003565AReduce overall thicknessSmall sizeAir-flow control membersEngineeringAluminium alloy

The invention provides an air guide plate, an injection mold and a molding method. The method comprises the following steps: a molded air guide plate insert is positioned in a molding cavity of the injection mold through a magnetic sucking piece; and a molten air guide plate outer-layer material is injected in the molding cavity, so that the outer-layer material wraps the air guide plate insert to form the air guide plate. The air guide plate adopts a sandwich layer embedding form to replace a double-layer structure form of a conventional aluminum alloy air guide plate, can only occupy less internal space of the air guide plate under the condition of guaranteeing strength and deformation resistance of the air guide plate, reduces the whole thickness of the air guide plate, and reduces the shape volume of the air guide plate.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

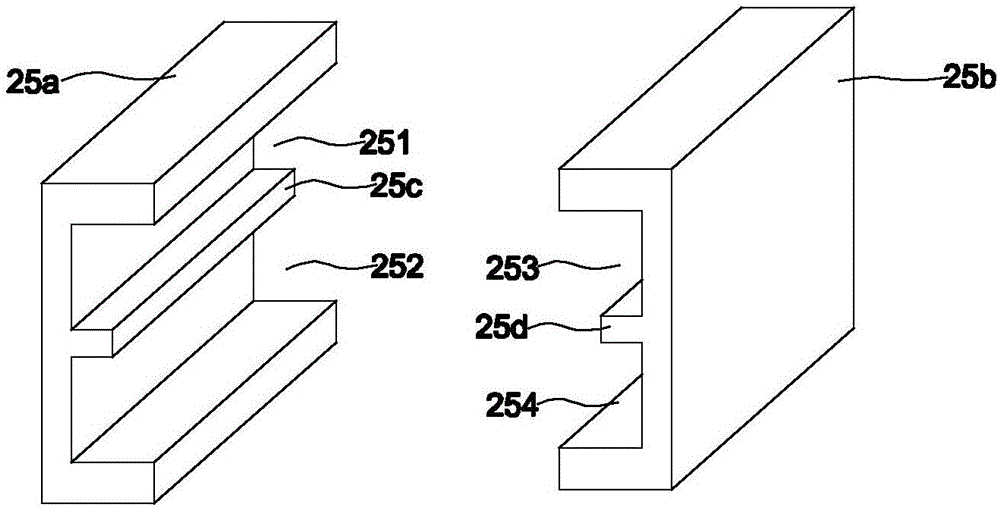

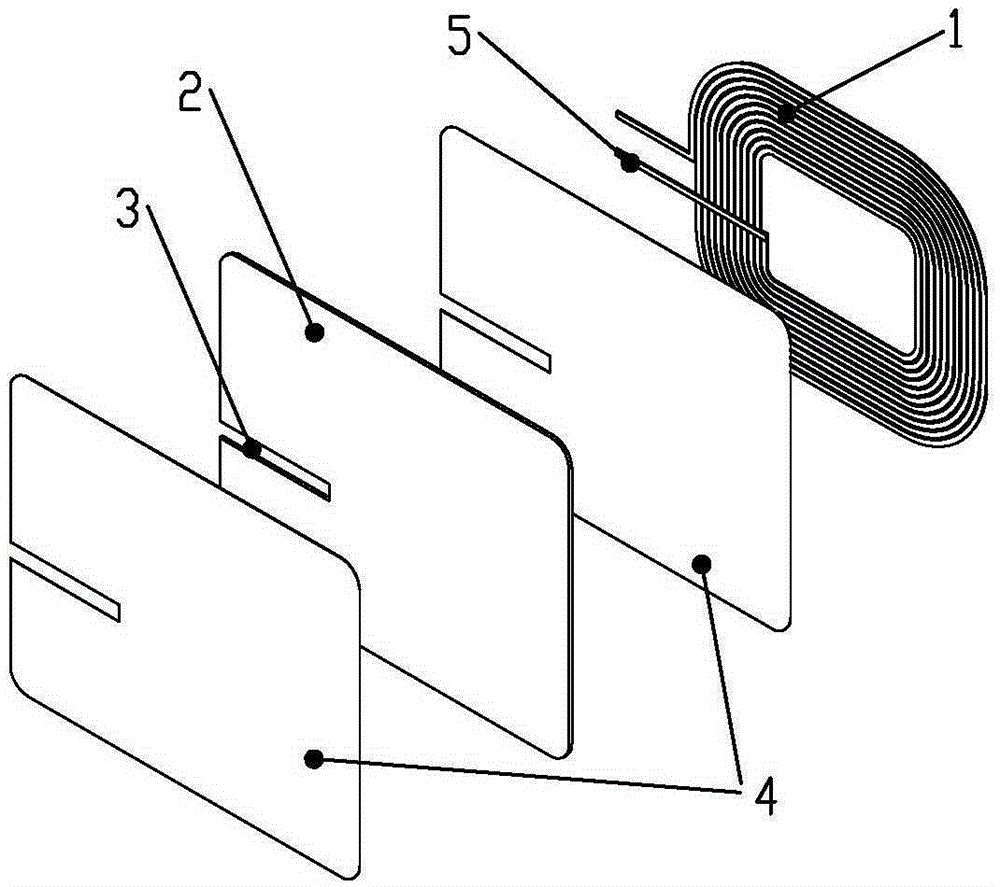

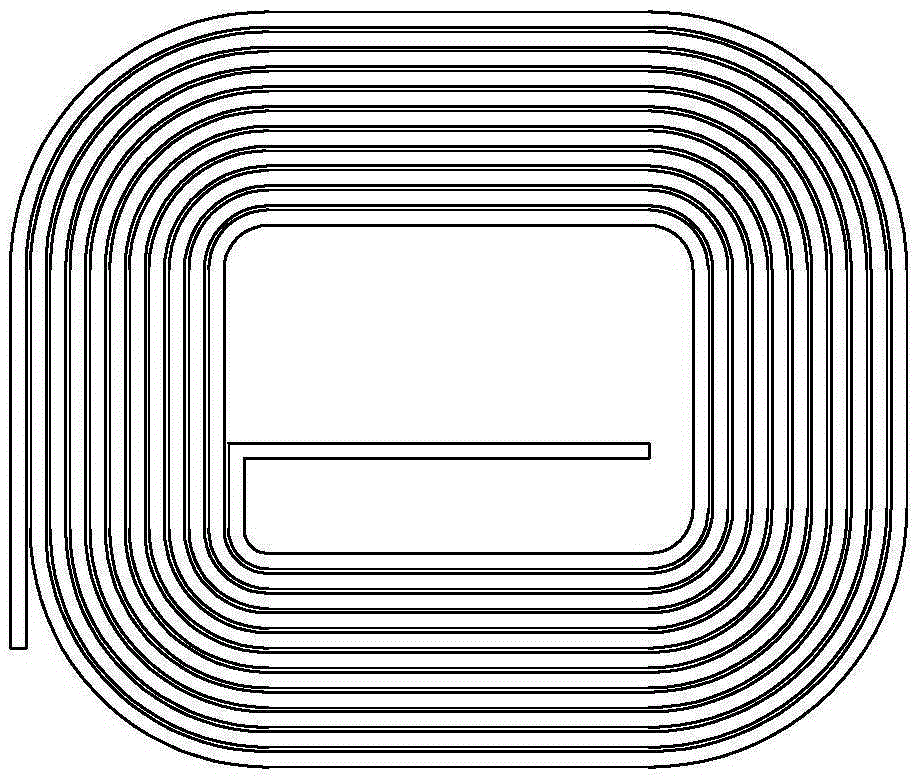

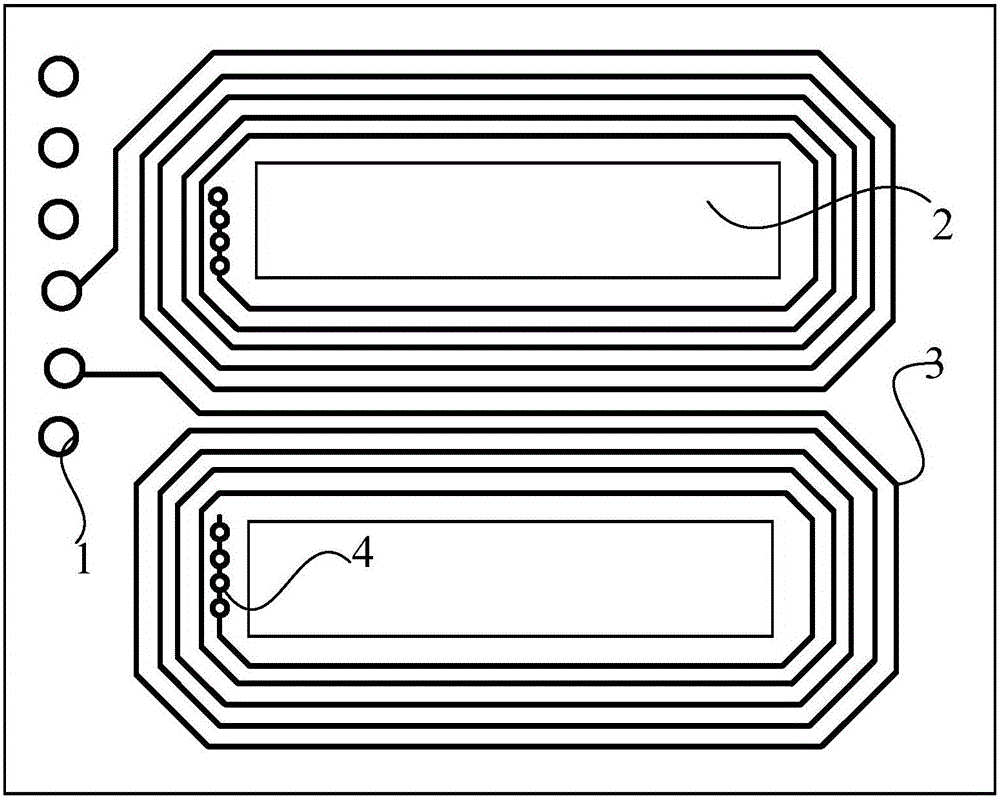

Wireless charging receiver end and manufacturing method thereof

InactiveCN105429309AReduce overall thicknessLarge diameterTransformersCircuit arrangementsCopper foilInductive charging

The invention discloses a wireless charging receiver end a manufacturing method thereof. The wireless charging receiver end comprises a receiving coil and a magnetic shielding sheet, wherein the lead section of the receiving coil is non-circular and the magnetic shielding sheet is arranged under the receiving coil. The wireless charging receiver end is characterized in that the magnetic shielding sheet is provided with at least one groove and an inner outgoing line of the receiving coil is arranged on the surface of the receiving coil in a folded way and is mounted in the at least one groove. With adoption of the structure and the manufacturing process of the product, the thickness of the coil can be reduced by the thickness of one copper foil layer; since the overall thickness of the coil is reduced largely, the thickness of single copper foil layer can be increased properly and further the diameter of the coil can be increased; therefore, the inner resistance of the coil can be lowered and the loss can be reduced.

Owner:麦格磁电科技(珠海)有限公司

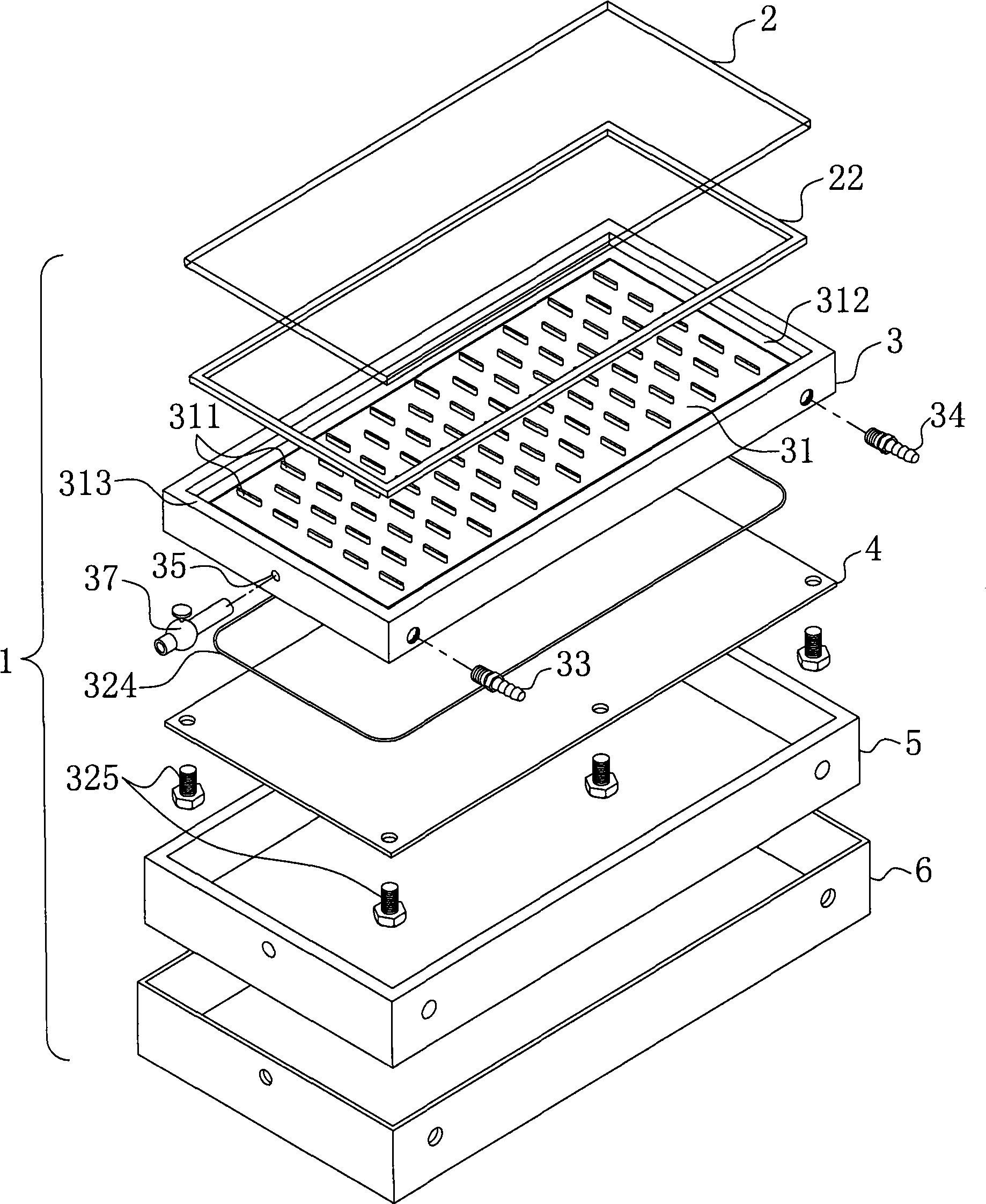

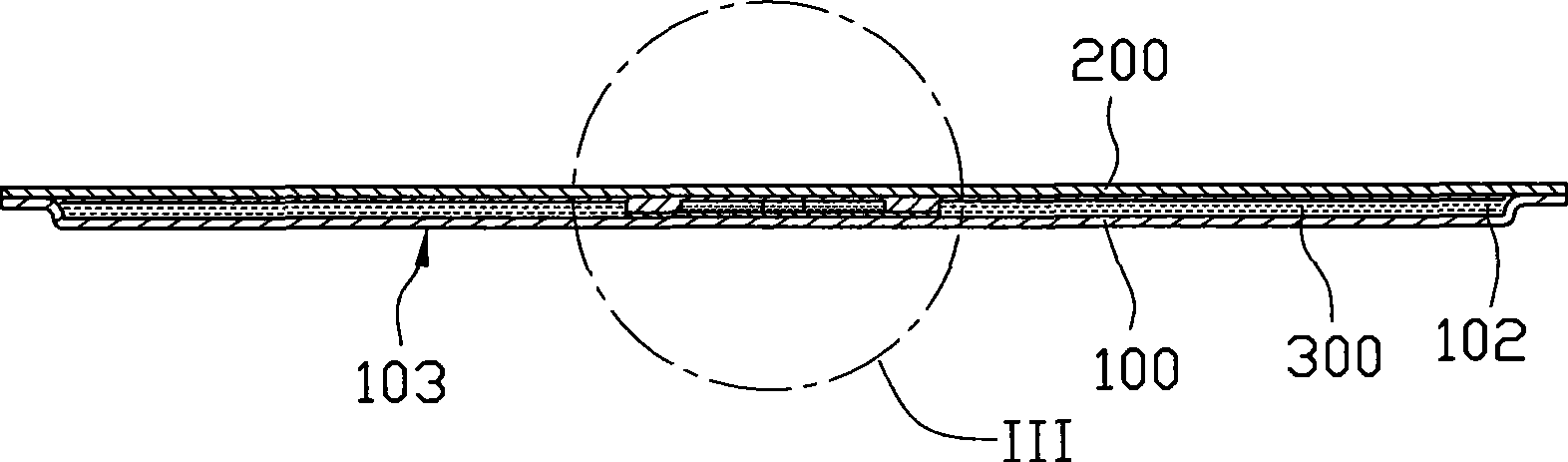

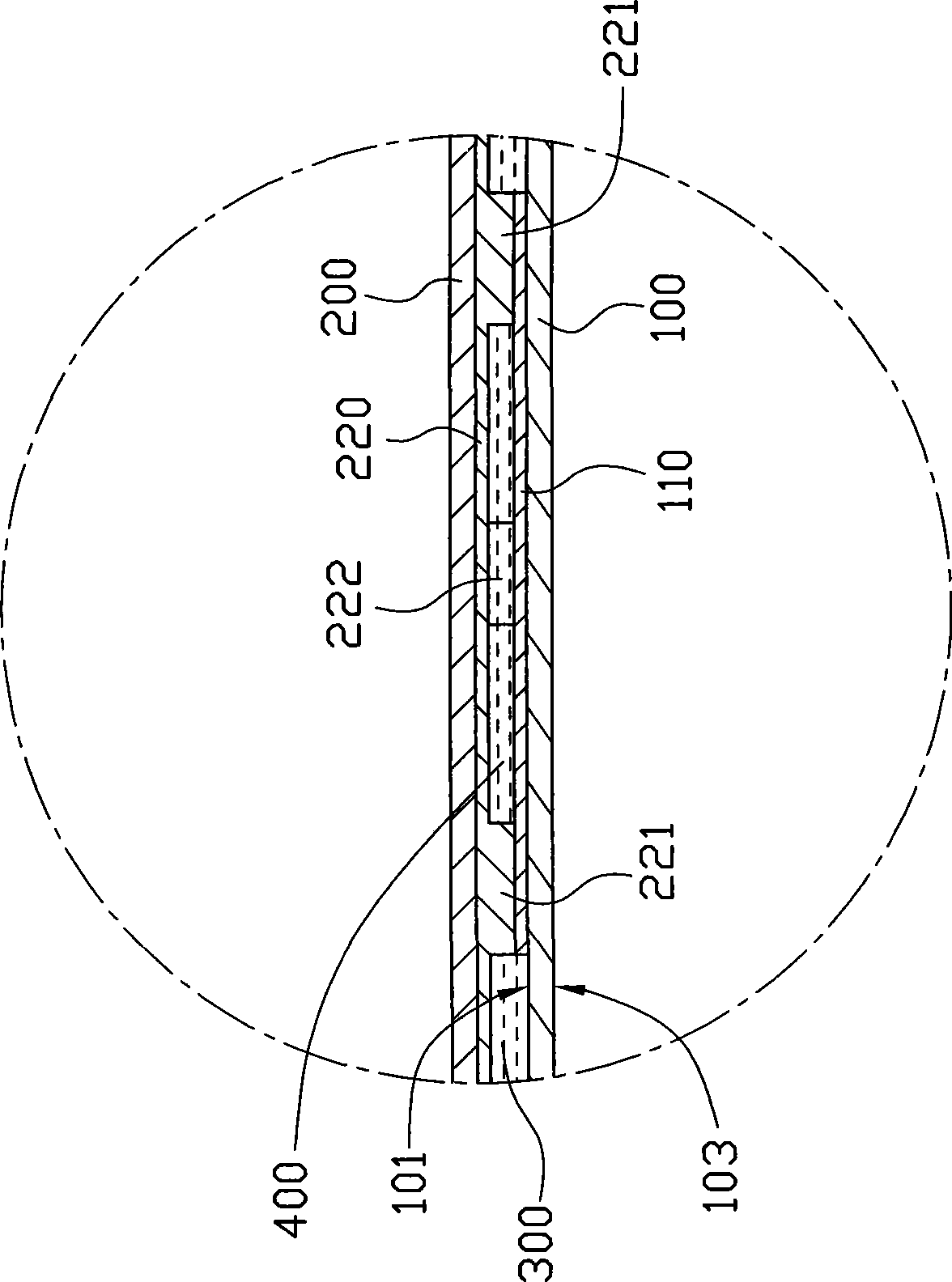

Temperature equalization board

InactiveCN101472442AReduce overall thicknessReduce resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringEqualization

Owner:FU ZHUN PRECISION IND SHENZHEN +1

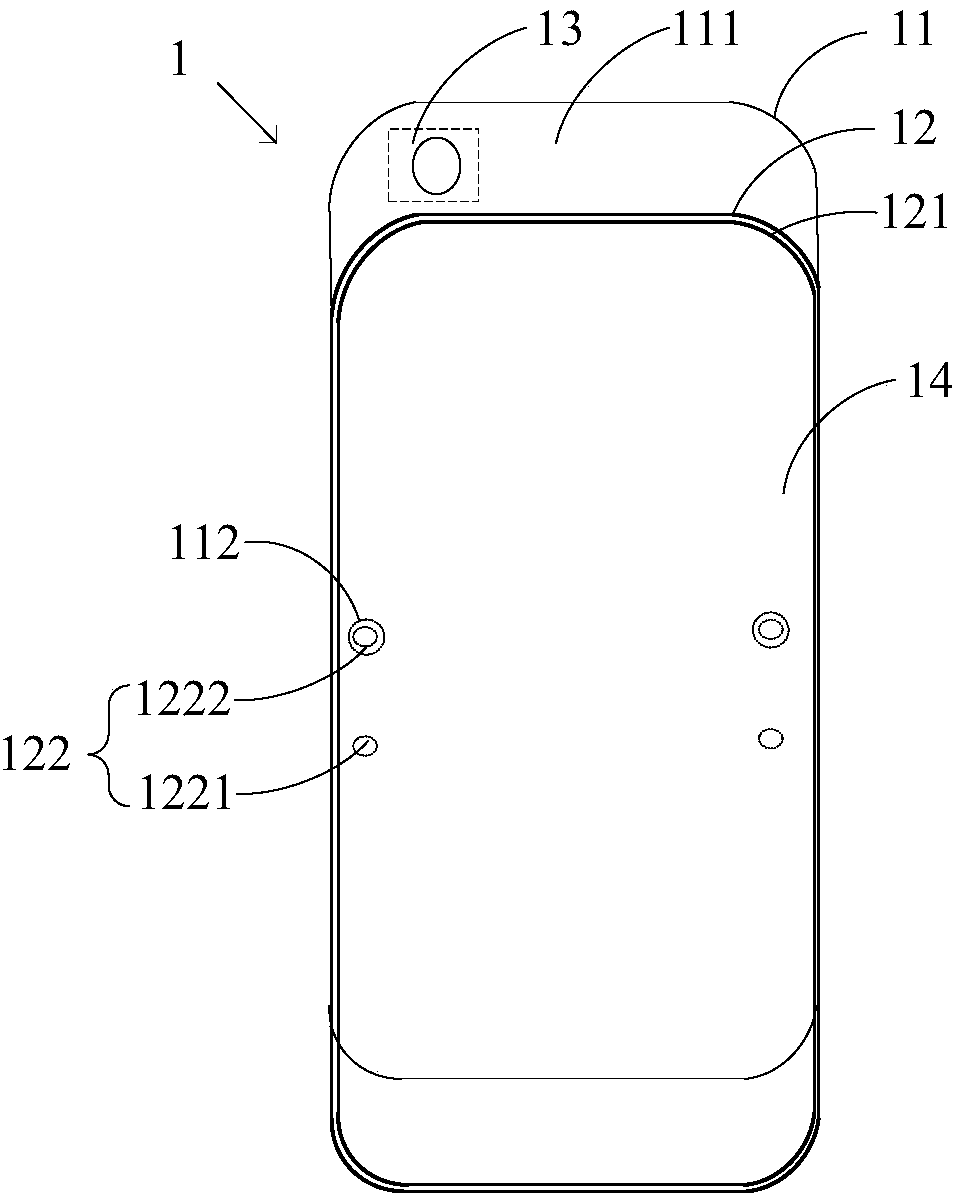

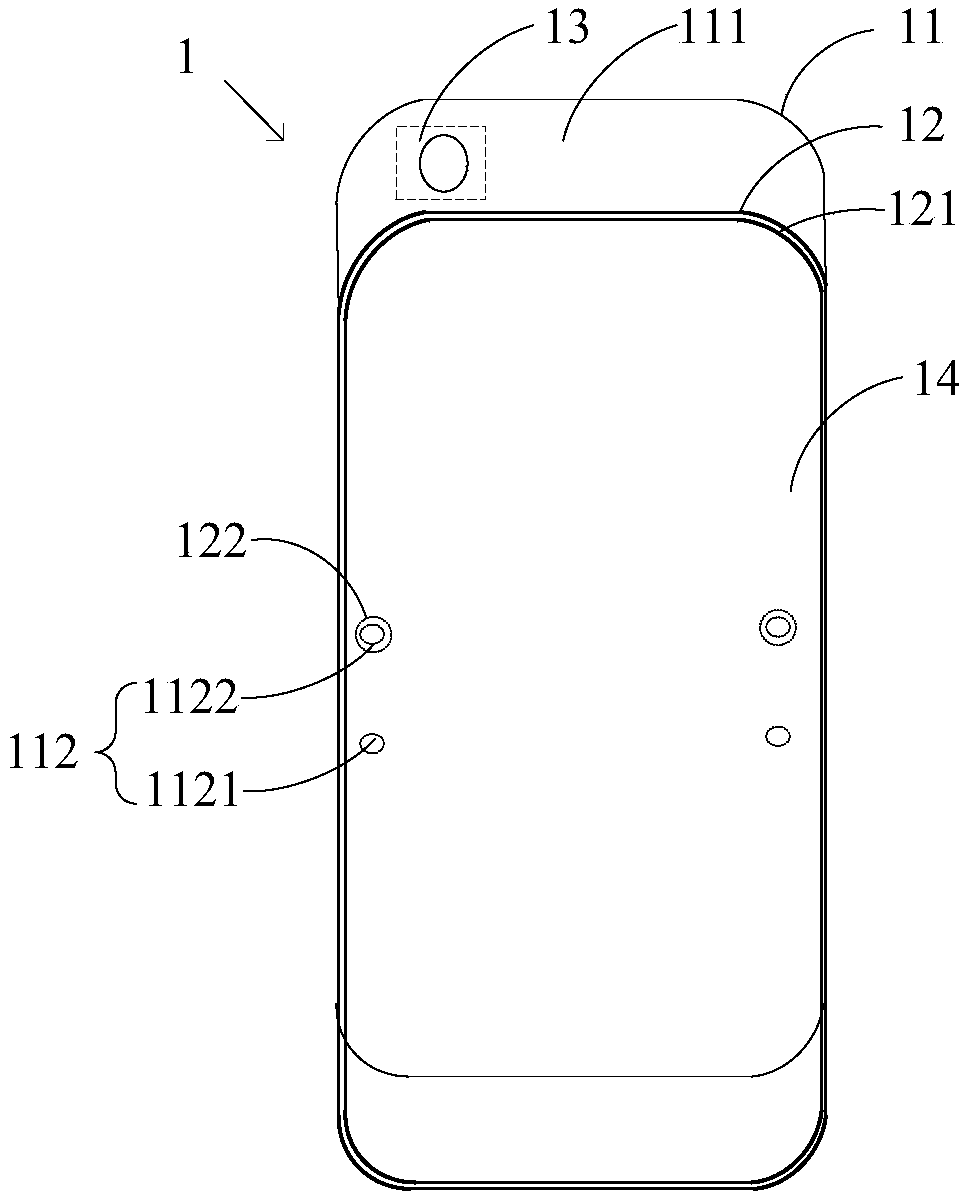

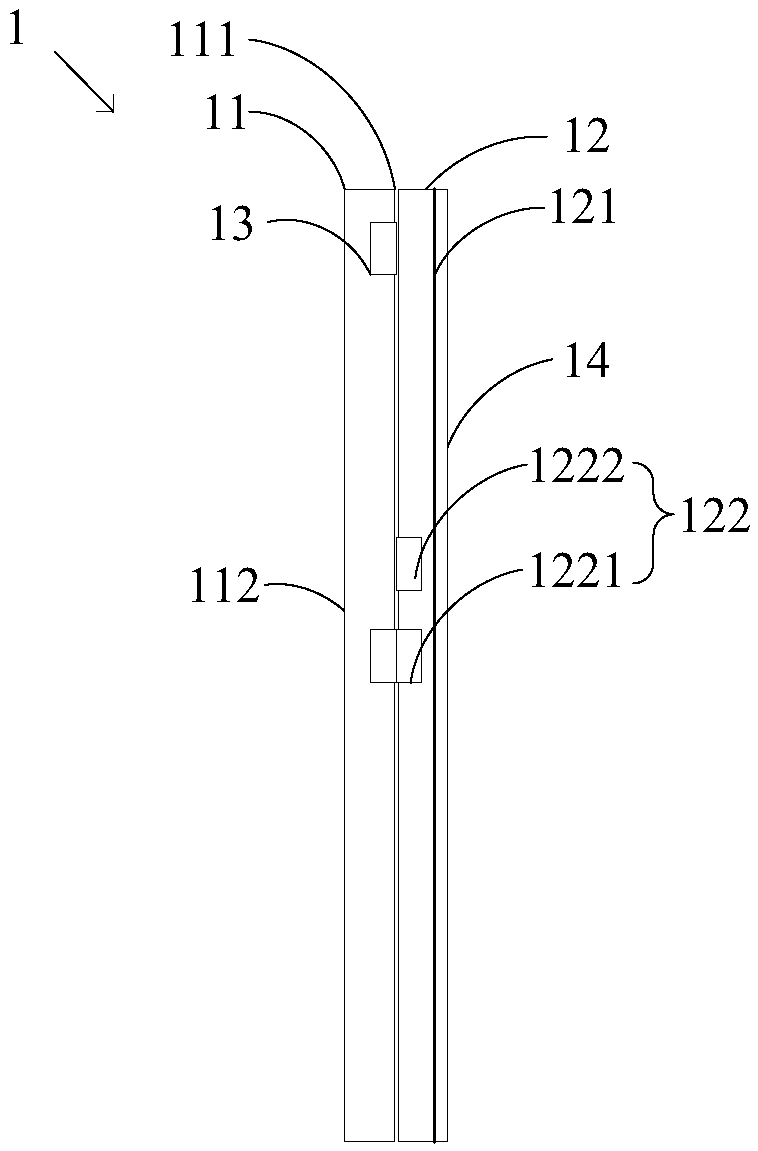

Electronic equipment

PendingCN108337422AReduce complexityReduce overall thicknessTelevision system detailsDigital data processing detailsEngineeringElectric equipment

The invention relates to electronic equipment. The electronic equipment comprises a camera assembly, a screen assembly, a first main body and a second main body; the first main body is in sliding connection with the second main body; a first magnetic assembly is arranged on the first main body, a second magnetic assembly is correspondingly arranged on the second main body, and the first magnetic assembly cooperates with the second magnetic assembly, so that the first main body and the second main body can relatively slide between the first cooperation position and the second cooperation position. By the above structure, the camera assembly arranged on the first main body can be selectively protruded or hidden in the second main body provided with the screen assembly; the complex degree ofa sliding structure is reduced through actuation sliding of a magnetic piece; the integral thickness of the first main body and the second main body is reduced, so that the light performance of the electronic equipment is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

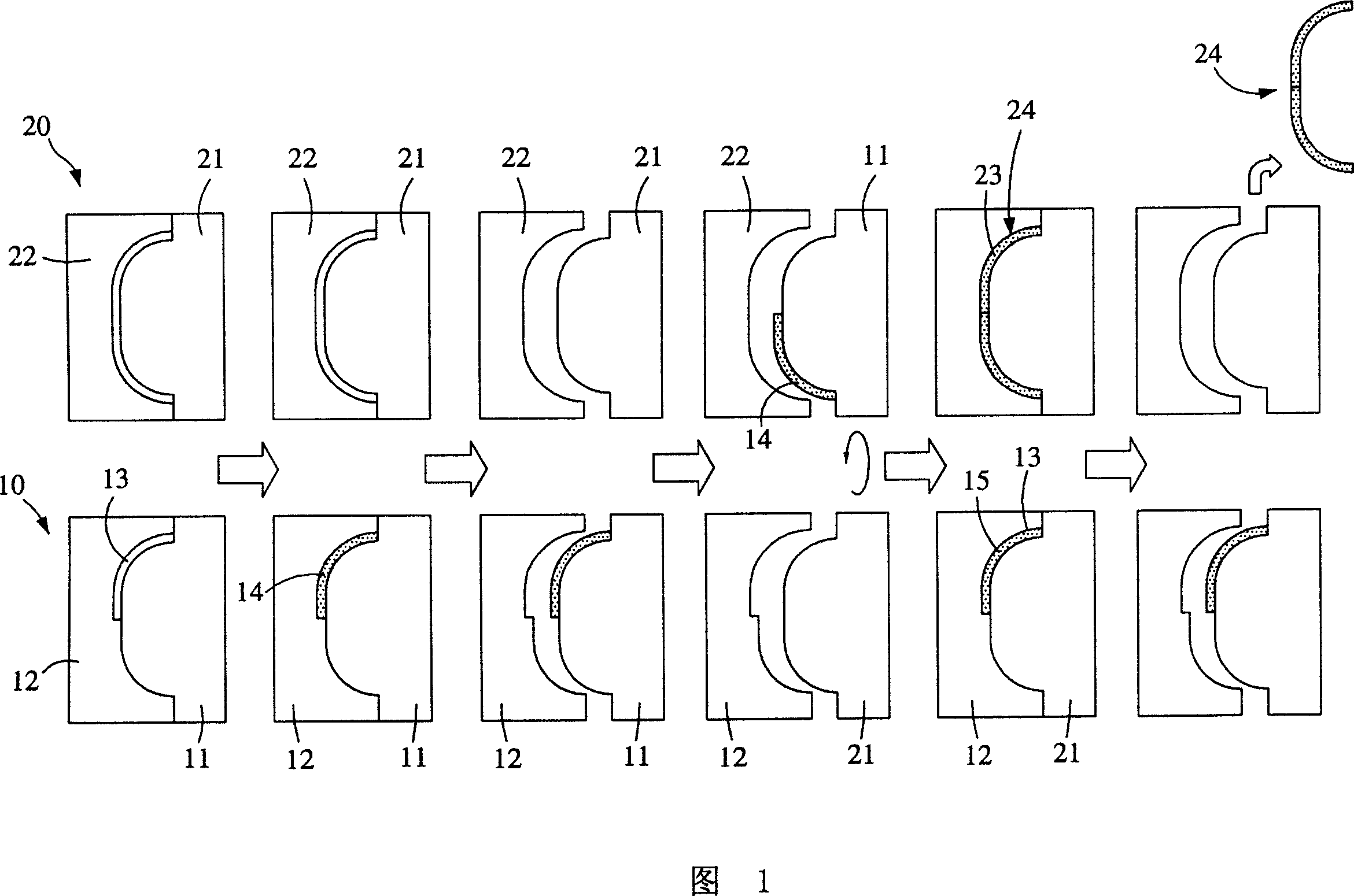

Hand-held type communication device front casing manufacturing method

InactiveCN101104302AReduce overall thicknessSimplify the assembly processDomestic articlesEngineeringHand held

The invention discloses a hand-held communication device front casing manufacturing method. The steps are that: at least a patterned film is disposed into a first female mould; plastic is poured into a first male mould and the first female mould and then the plastic is jetted to be molded into an embryo which is firmly combined with the film to form a window glass; the first male mould and a second male mould are rotated and replaced after the moulds are opened so as to make the window glass move with the first male mould; another film is disposed in the first female mould and at the same time the mould is closed so that the plastic can be poured into the moulds; the plastic is jetted and forms a first front casing in the first male mould and the first female mould, and another window glass is formed in the second male mould and the first female mould, then the front casing is taken out. Compared with prior art, the method is dispensed with the making process of the back-adhesive area and the adhibitting process. With the invention, the thickness of the whole body can be reduced and the assemblage can be simplified.

Owner:ARIMA COMM CORP LTD

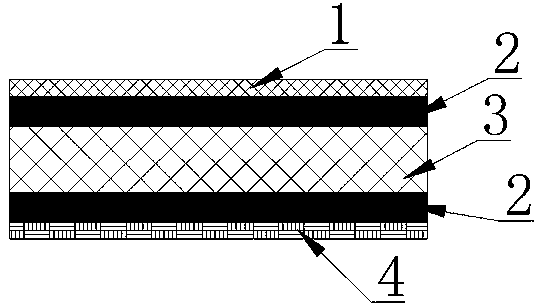

Flexible-rigid circuit board and manufacturing method

ActiveCN105451442AReduce overall thicknessReduce thicknessPrinted circuits structural associationsMultilayer circuit manufacturePrinted circuit boardDielectric layer

The invention relates to a flexible-rigid circuit board comprising first and second rigid circuit boards and a flexible circuit board. The first rigid circuit board comprises a first adhesive layer, and a first outer line layer and a first dielectric layer which are on the two sides of the first adhesive layer. The flexible circuit board comprises a third adhesive layer, first and second inner line layers adhered to the two sides of the third adhesive layer respectively, and second and fourth dielectric layers covering the first and second inner line layers respectively. The first adhesive layer glues the first and second adhesive layers. The first rigid circuit board has a first open area provided with a first groove. The second dielectric layer is exposed from the first groove. The second rigid circuit board comprises a second adhesive layer, and a second outer line layer and a third dielectric layer which are on the two sides of the second adhesive layer. The second adhesive layer glues the third and fourth dielectric layers. The second rigid circuit board has a second open area which corresponds to the first open area and is provided with a second groove. The fourth dielectric layer is exposed from the second groove. All the line layers are electrically connected through conductive via holes. The invention further relates to a flexible-rigid circuit board manufacturing method.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

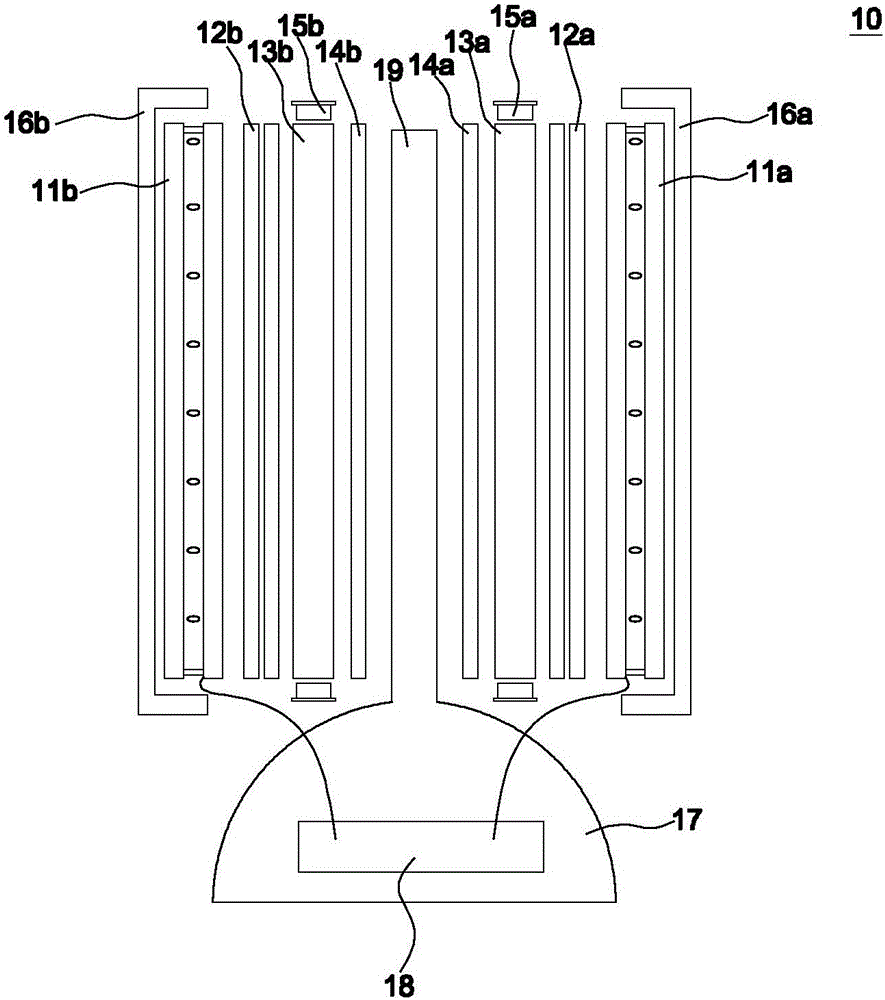

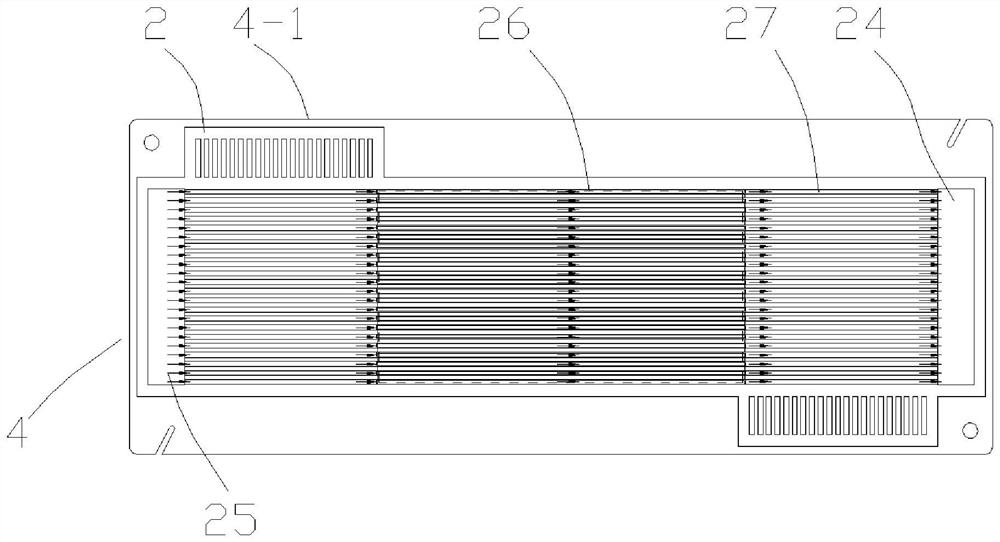

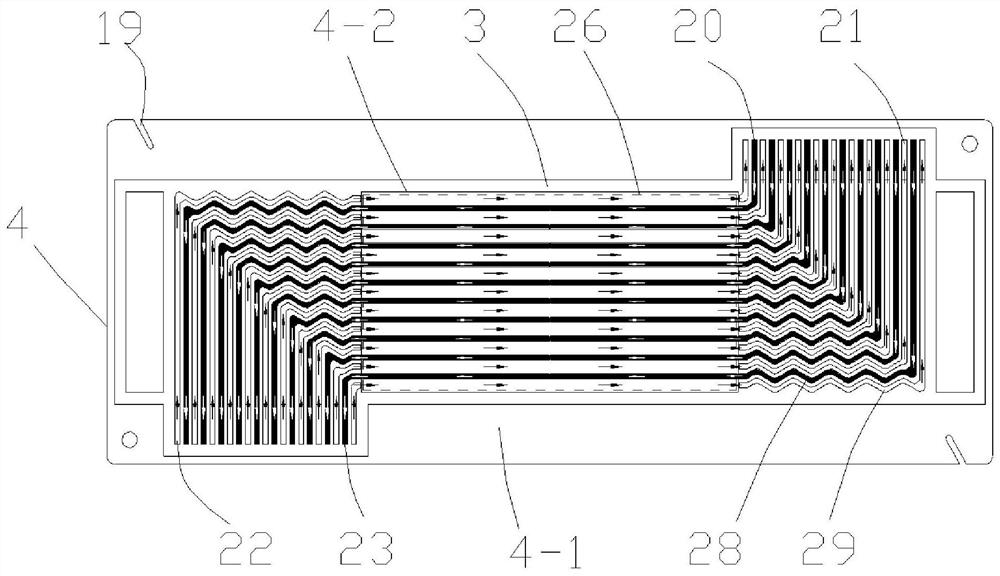

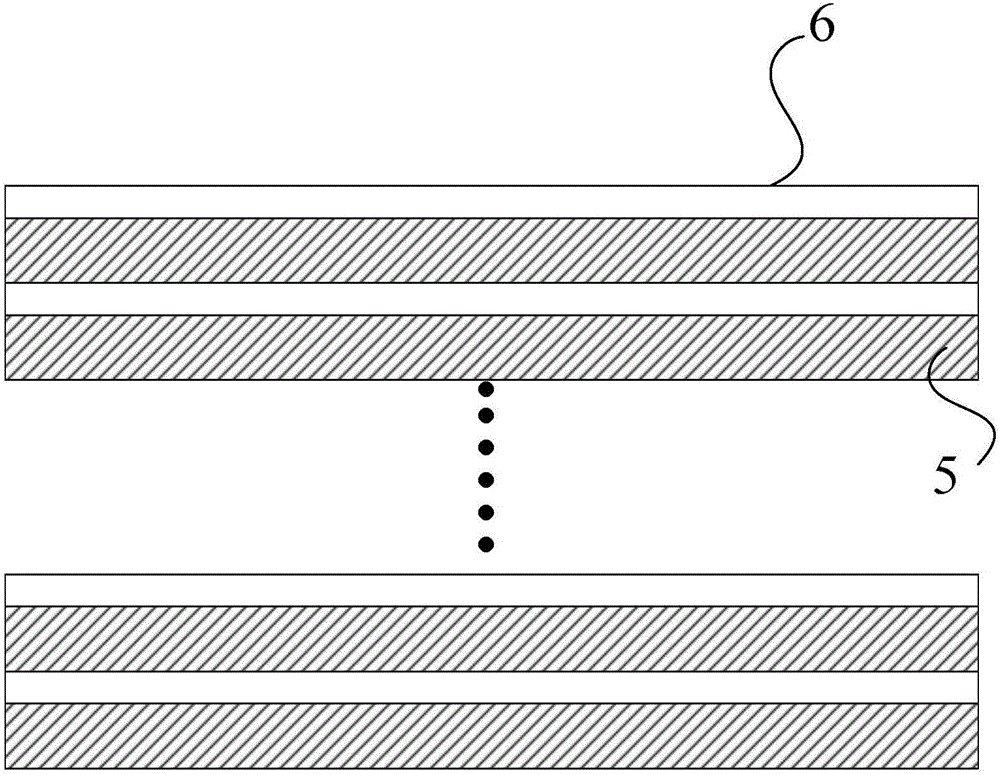

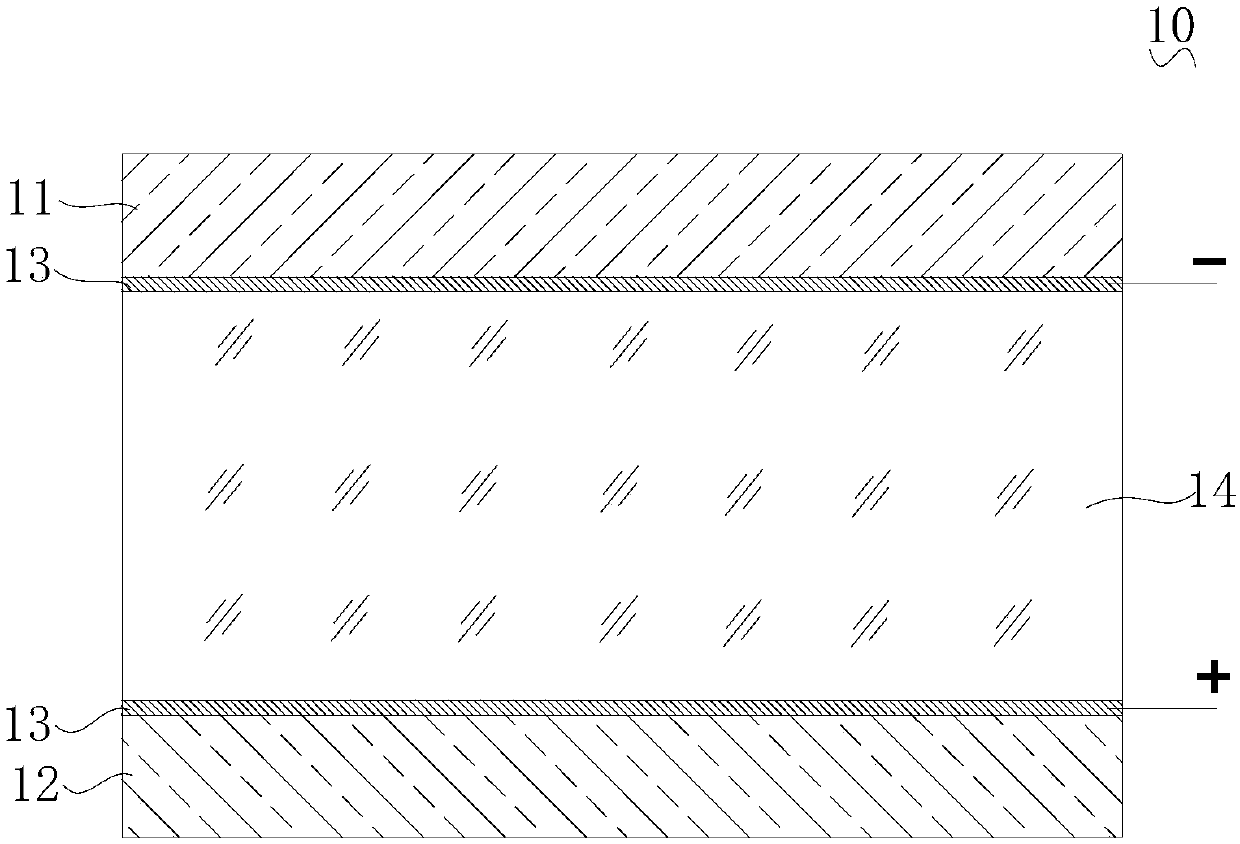

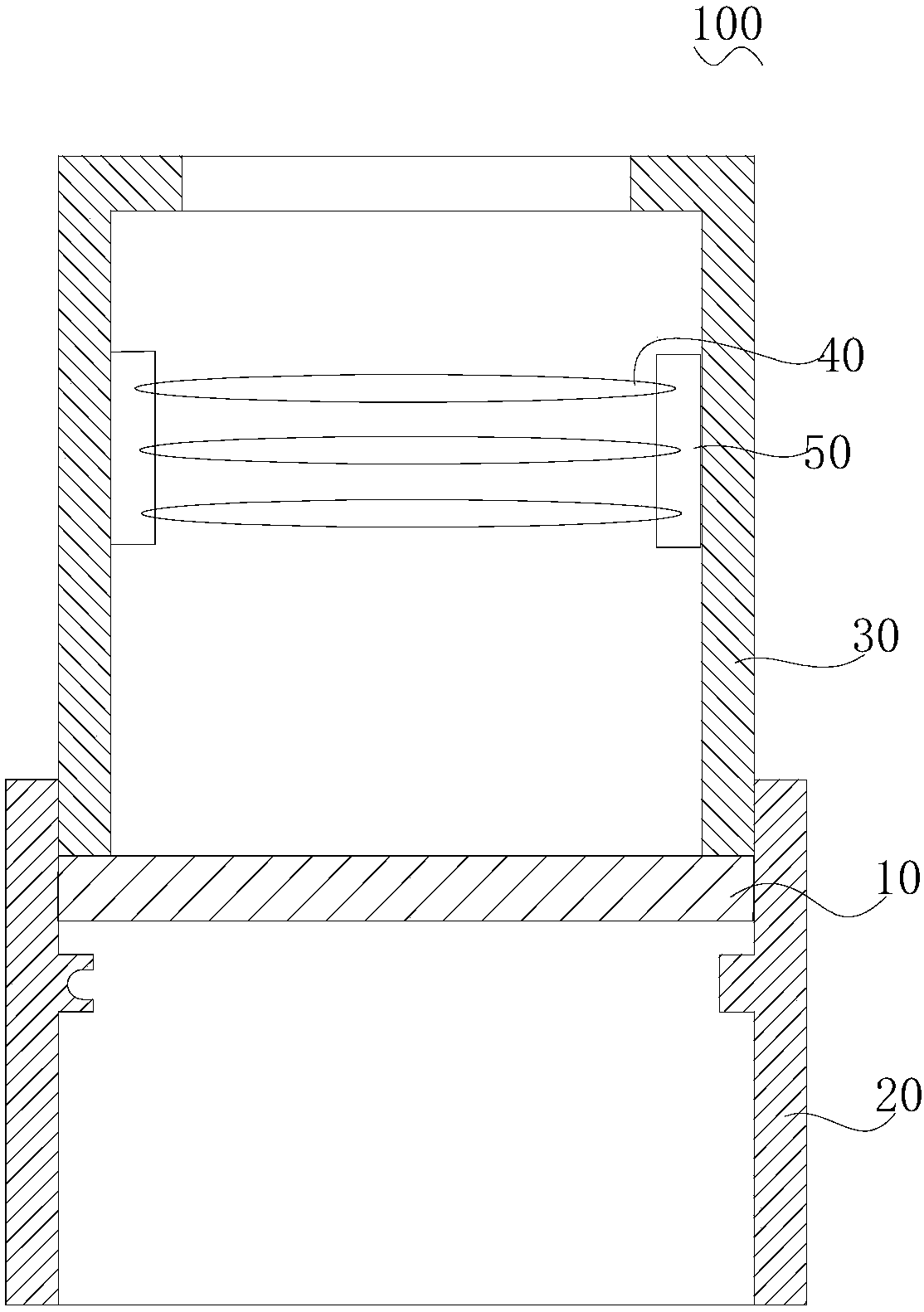

One-plate three-field ultrathin fuel cell bipolar plate and fuel cell stack

PendingCN112768720ASimple sealing processReduce overall thicknessCollectors/separatorsPhysicsEngineering

The invention relates to a one-plate three-field ultrathin fuel cell bipolar plate and a fuel cell stack. The bipolar plate comprises a flow field plate, one side of the flow field plate is an anode side, and the other side of the flow field plate is a cathode side; a fuel gas flow channel and a cooling liquid flow channel are arranged on the anode side of the flow field plate; an oxidizing gas flow channel is arranged on the cathode side of the flow field plate; the bipolar plate further comprises a cover plate which is arranged on the anode side of the flow field plate and used for separating the cooling liquid flow channel and the fuel gas flow channel located in the active area; the anode side of the flow field plate is used for being tightly matched with an anode sealing piece and the cover plate to form a fuel gas flow field and a cooling liquid flow field; and the cathode side of the flow field plate is used for being tightly matched with a cathode sealing piece to form an oxidizing gas flow field. The three flow fields are concentrated on one plate, so that the thickness of the bipolar plate can be greatly reduced, the volume of a galvanic pile is greatly reduced, and the volumetric specific power density of the galvanic pile is improved.

Owner:TONGJI UNIV

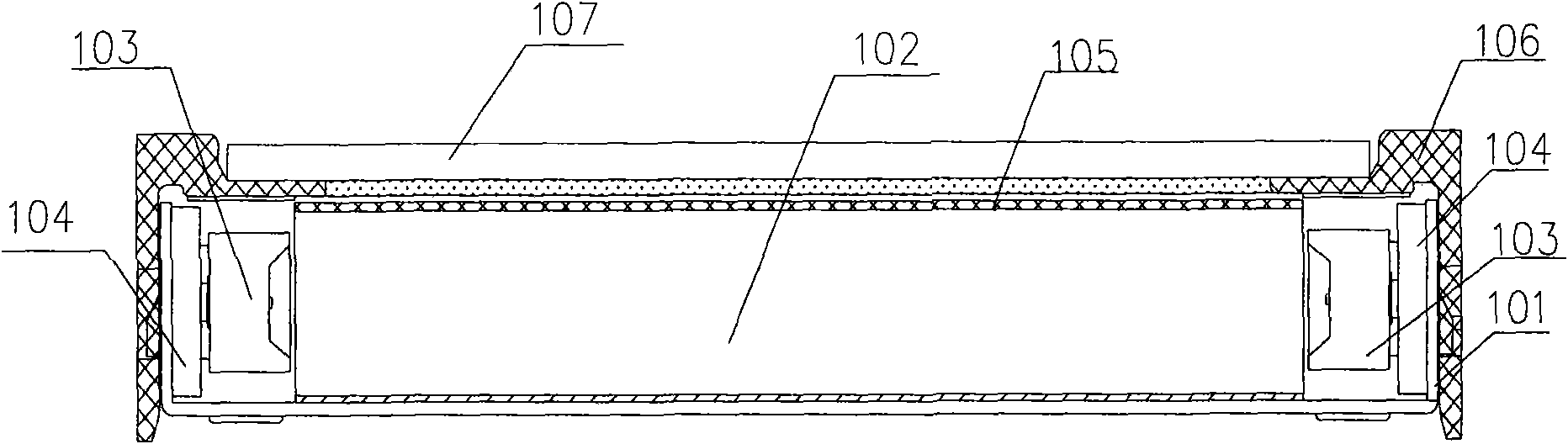

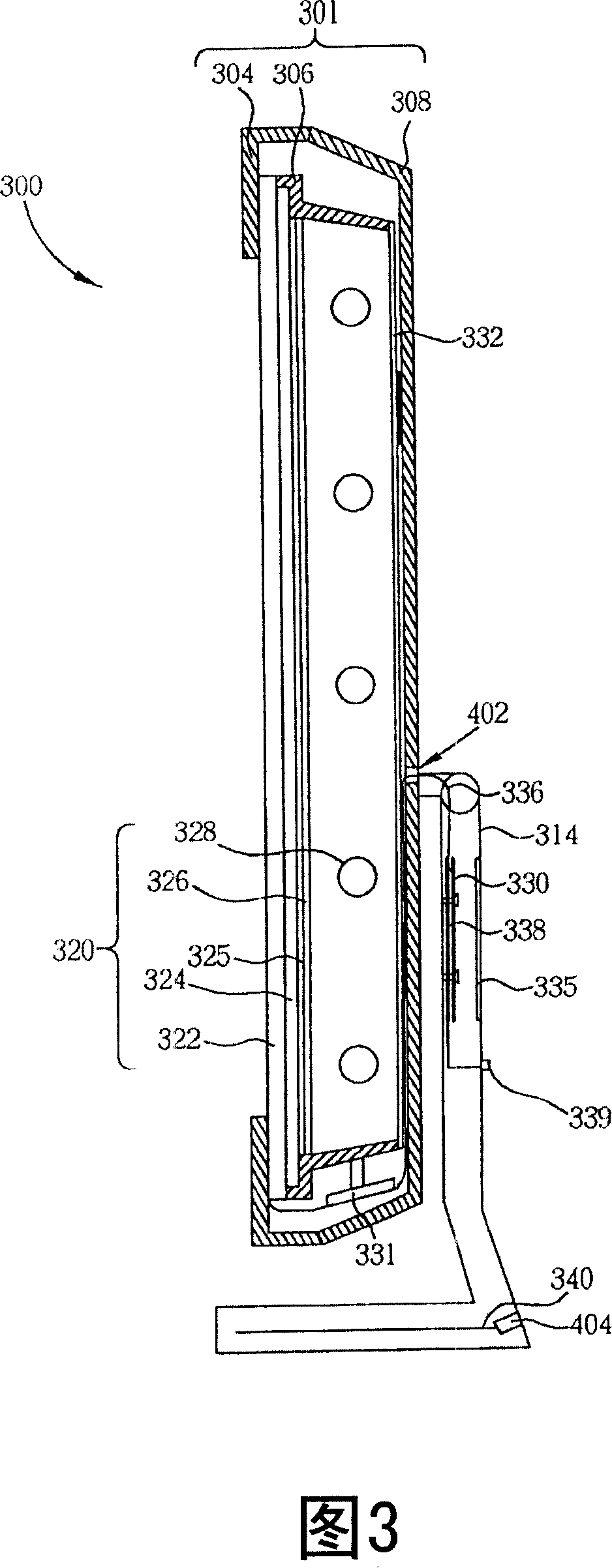

Backlight module and display device using same

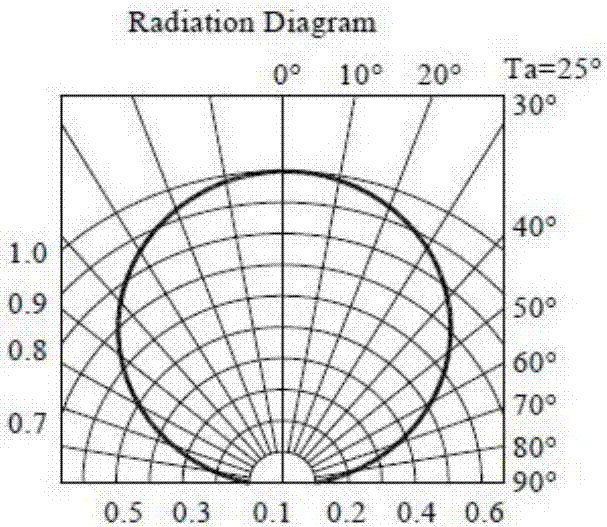

ActiveCN103017023AReduce overall thicknessLow costPoint-like light sourceLight fasteningsEntrance angleLight guide

The invention provides a backlight module and a display device using the same. The backlight module comprises a light guide plate and a light source device; the light source device comprises an LED (Light-Emitting Diode) chip of which the light extraction surface is directly towards the lateral surface of the light guide plate. The display device using the backlight module, which is provided by the invention, comprises the backlight module. According to the light source device in the backlight module provided by the invention, due to the cancel of a lamp cavity, the size can be greatly reduced, so that the thickness of the backlight module can further be correspondingly reduced. Due to the cancel of the lamp cavity, a light emitting angle of the light source device can further be increased and light emitted by each surface of the LED chip can enter the light guide plate from the lateral surface, so that a light entrance angle of the light which enters the light guide plate is greatly increased, and thus, light entrance spots are avoided and brightness of the backlight module is further promoted. The display device using the backlight module, which is provided by the invention, adopts the backlight module provided by the invention, so that the overall thickness of the display device can be reduced, the cost can be further reduced and the display quality of the display device is greatly improved.

Owner:BOE TECH GRP CO LTD +1

Transparent display device

The invention discloses a transparent display device. The transparent display device comprises a transparent liquid crystal screen and a backlight module arranged on the incident surface of the transparent liquid crystal screen, the backlight module comprises a transparent light guide plate and a dimming film parallel to the transparent light guide plate. The dimming film is in full-fit connectionwith the dot surface of the transparent light guide plate; the transparent liquid crystal screen is completely attached to the light-emitting surface of the transparent light guide plate; a light source is arranged on the edge of the transparent light guide plate, a plurality of transparent liquid crystal screens are sequentially and completely attached to the same transparent light guide plate,the dimming film comprises a white dimming film and a black dimming film, the rough surface of the white dimming film is completely attached to the mirror surface of the black dimming film, and the mirror surface of the white dimming film is completely attached to the dot surface of the transparent light guide plate. According to the display device at any time, transparent and non-transparent display of the display device can be switched at any time, and screen information can be displayed more clearly.

Owner:合肥泰沃达智能装备有限公司

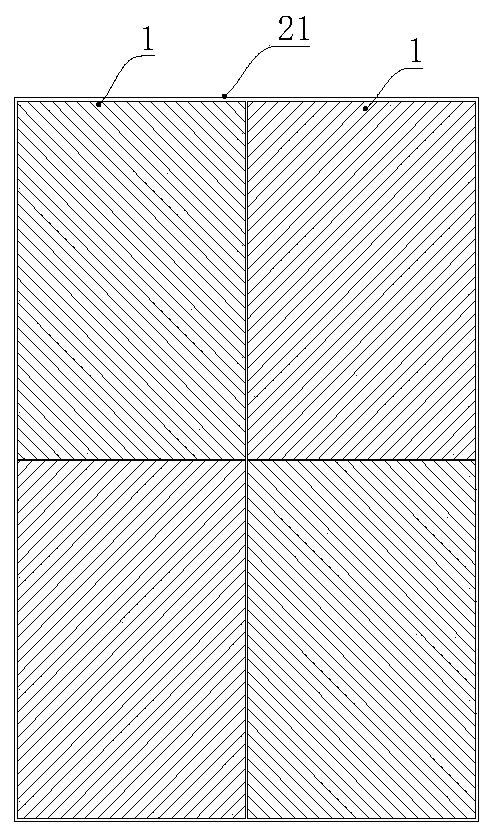

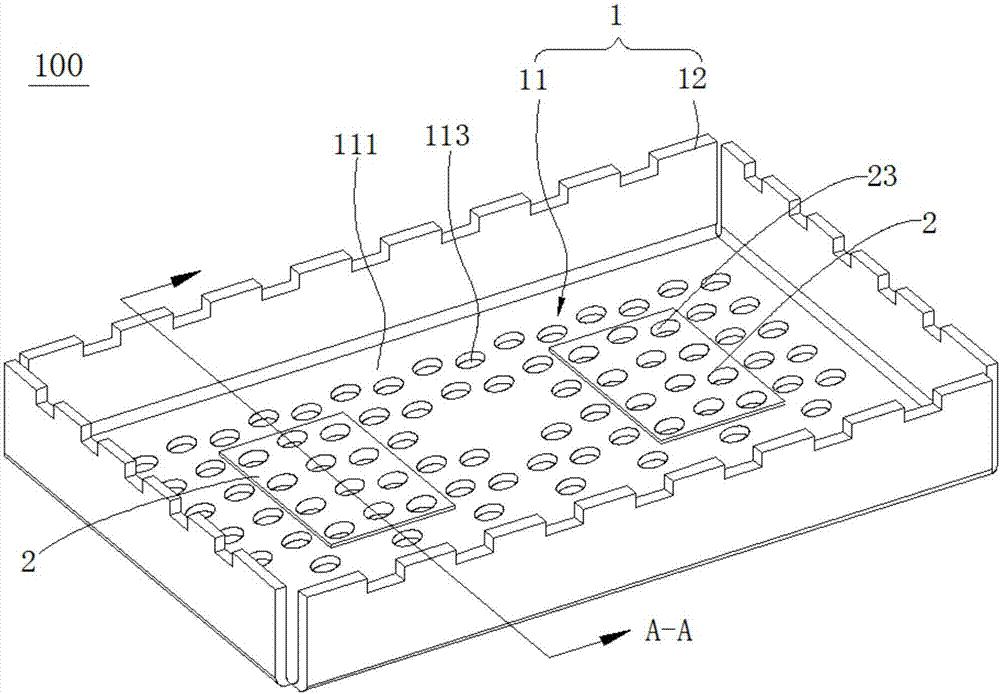

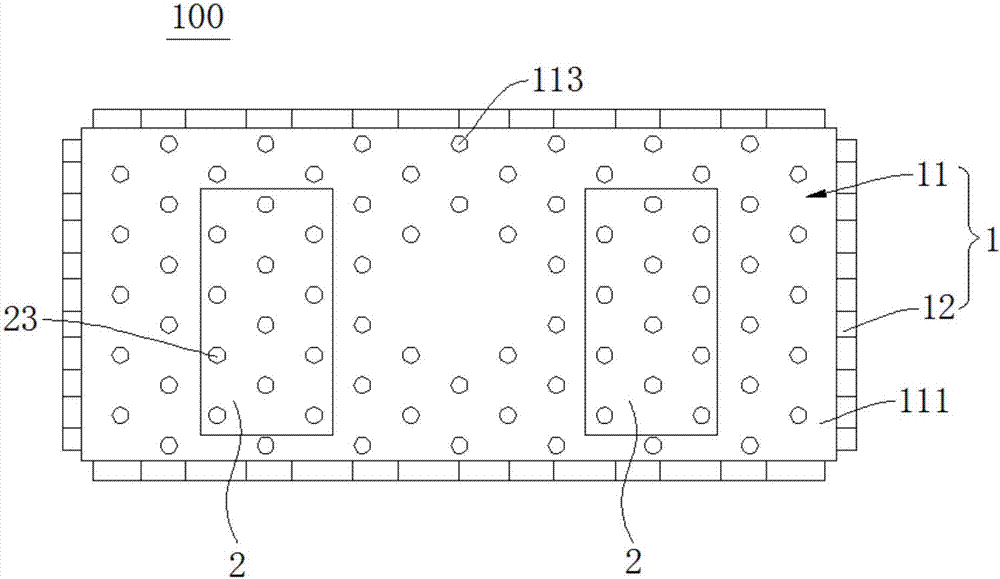

Low-cost anti-warping simulation skating rink board structure and processing method thereof

PendingCN109771930AIncreased bending stiffnessReduce overall thicknessSki bindingsWater-skiingSurface functionAdverse effect

The invention relates to the field of sports product processing, and particularly discloses a low-cost anti-warping simulation skating rink board structure and a processing method thereof. The low-cost anti-warping simulation skating rink board structure comprises a board body and is characterized in that the board body is sequentially formed by hot melting compositing of a surface function material layer with a low friction coefficient, a high-rigidity fiber-reinforced thermoplastic composite layer, a low-cost thermoplastic polymer material sandwiched layer, a high-rigidity fiber-reinforced thermoplastic composite material layer and a bottom face function layer from top to bottom. The structure is simple, the processing technology is simple, the processing precision is high, the processing cost is low, one-time molding is performed, no secondary machining is needed, the adverse effect caused by simulation ice board warping on the skating rink motion smoothness is effectively reduced,joints of a sportsman are protected, and the motion fatigue is lowered.

Owner:TAISHAN SPORTS IND GRP +1

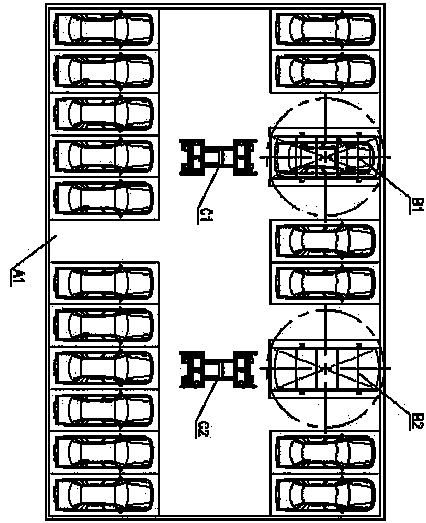

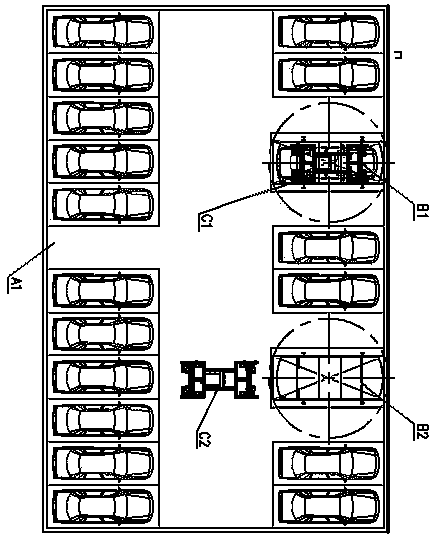

Novel intelligent three-dimensional garage AGV carrying trolley

The invention discloses a novel intelligent three-dimensional garage AGV carrying trolley. The novel intelligent three-dimensional garage AGV carrying trolley comprises a travelling main frame capableof moving longitudinally, a transverse-moving assembly capable of realizing moving transversely, an upper jacking mechanism for jacking a vehicle-carrying plate, a lower jacking mechanism for switching longitudinal movement and transverse movement, and a laser system which moves transversely for guiding positioning and deviation rectifying. Compared with tradition carrying equipment, the AGV carrying trolley has the characteristics that the structure is simple, operation is stable, the load capacity is large, the thickness is small, and the requirement for the civil engineering ground is low;and the AGV carrying trolley and the matched vehicle-carrying plate can jointly achieve the function of mounting of a charging pile, and the AGV carrying trolley is suitable for the field of vehiclecarrying of intelligent three-dimensional garages.

Owner:SHENZHEN DINGTAI INTELLIGENT PARKING SYST CO LTD

Cooling device and electronic equipment

PendingCN107135598AReduce overall thicknessCooling ApplicableMagnetic/electric field screeningPrinted circuit aspectsPrinted circuit boardEngineering

The invention provides a cooling device and electronic equipment. The cooling device is used for being arranged on a printed circuit board so as to cool an electronic component arranged on the printed circuit board, and the cooling device comprises a supporting mechanism, and a first heat transfer part, wherein the supporting mechanism comprises a slablike body and a connecting part arranged at the edge of the body, the body and the connecting part form an internal space for containing the electronic component, the supporting mechanism can be connected with the printed circuit board through the connecting part, the body has a first surface and a second surface, the first surface and the second surface are oppositely arranged, the first surface faces the electronic component when the supporting mechanism is connected to the printed circuit board, the first heat transfer part is arranged on the first surface and is arranged corresponding to the electronic component, the first heat transfer part is in contact with the electronic component when the supporting mechanism is connected to the printed circuit board, and the thickness of the first heat transfer part is 2-15 mils. The cooling device is suitable for cooling the electronic equipment which needs to be light and thin.

Owner:TIANJIN LAIRD TECH LTD

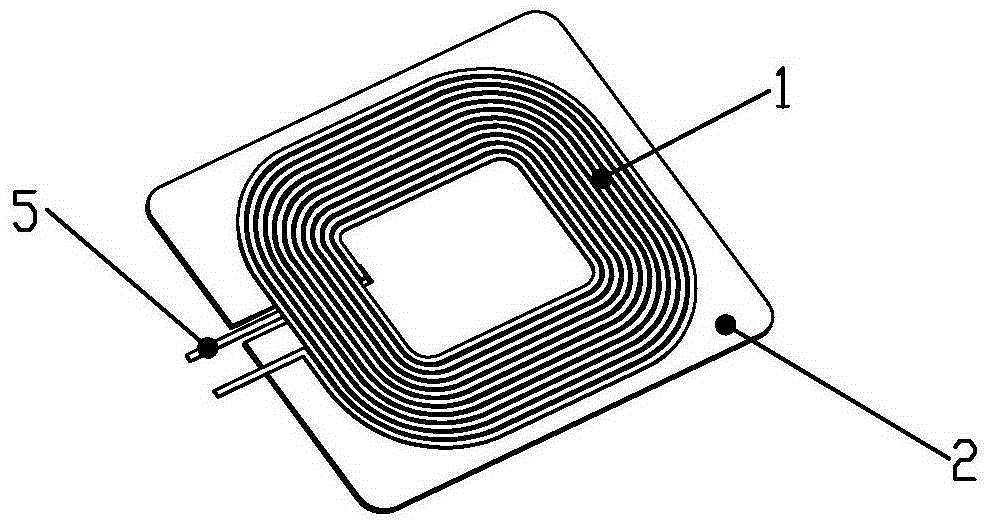

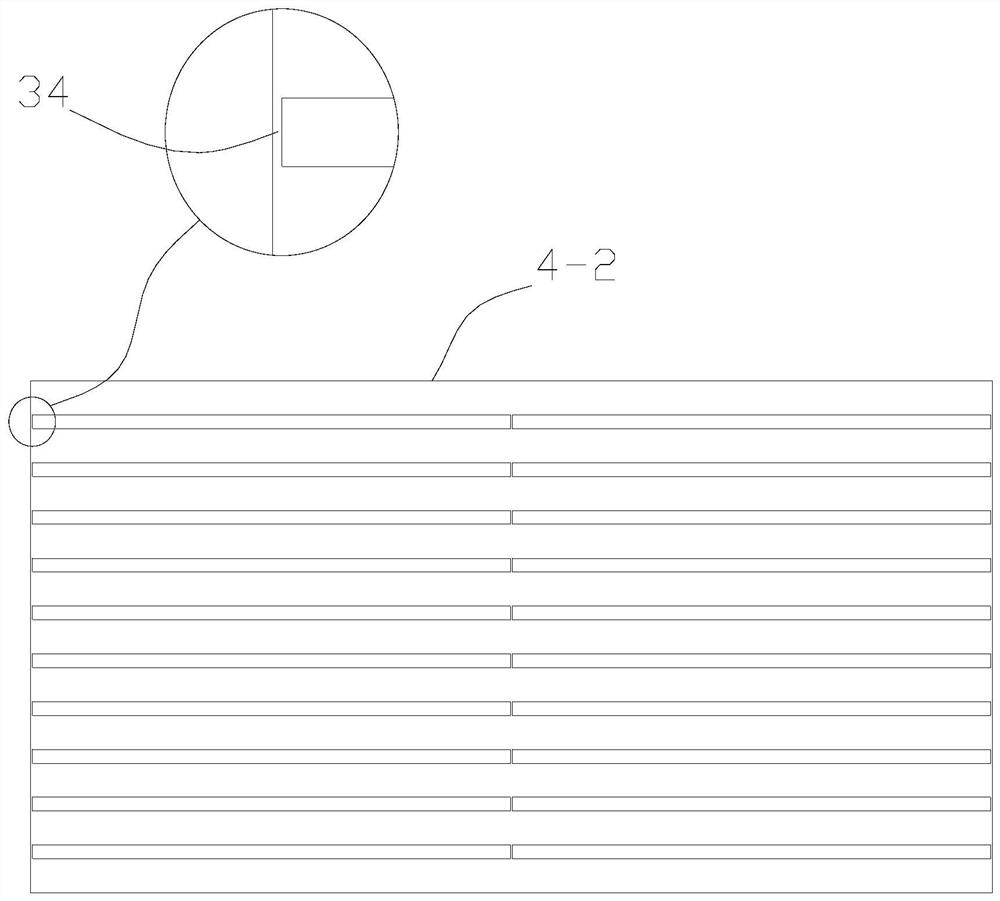

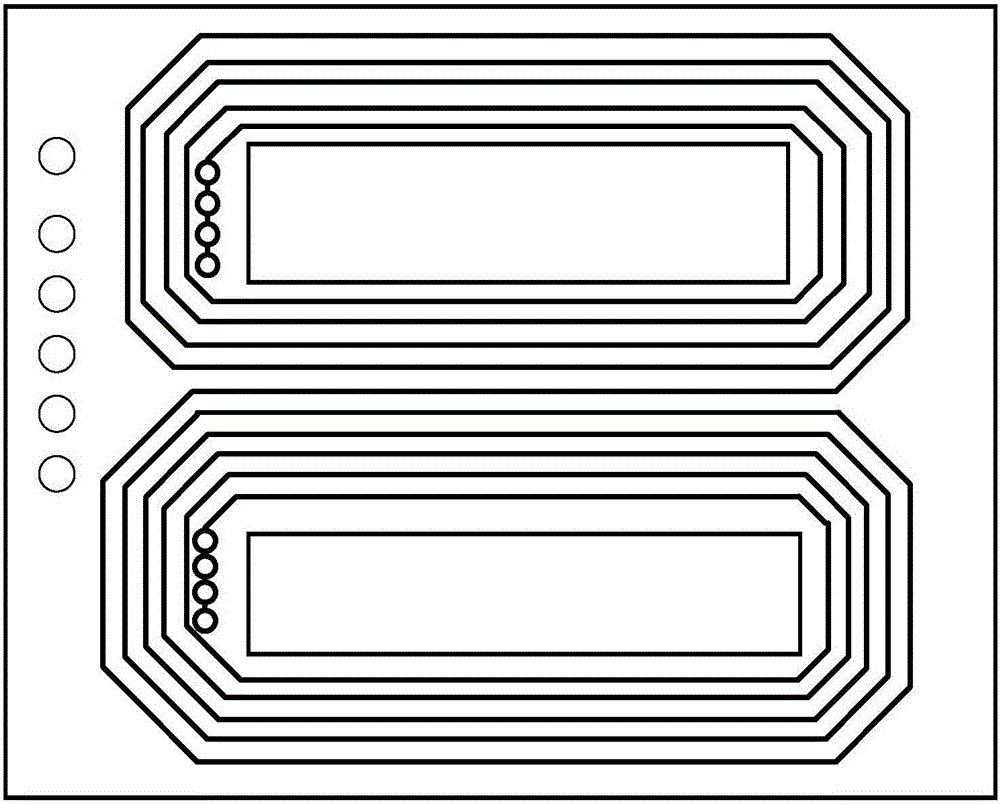

Multilayer plane winding coil designing method suitable for double column magnetic core structure

InactiveCN106067372AReduce the total number of layersReduce overall thicknessCoils manufactureMagnetic coreElectrical and Electronics engineering

The invention discloses a multilayer plane winding coil designing method suitable for double column magnetic core structure. The method comprises the following steps: installing through holes and a plurality of metalized hole welding plates on two parallel magnetic core columns of a PCB; drawing the head end and the tail end of windings in series connection on the whole board from two of the metalized hole welding plates of the PCB; using double-face copper-clad base materials for going wires and forming four windings around the two core column holes; obtaining a multilayer plane winding coil in such a manner that the edges of each core column hole are provided with going wires and through holes through multiple copper faces to make the copper clad going wires around the same core column form double layer series connection windings wrapped in the same direction; and lastly, providing an insulation layer between two adjacent PCBs; and providing insulation layers both at the top and the bottom of the multilayer plane winding coil of the double column magnetic core structure. In the invention, the technical limitation of the single-column winding of a planar transformer is changed, and under the same winding current-carrying density, winding coils are two times as many and winding inductance is four times as much as those of the single-layer board.

Owner:浙江求缺科技有限公司

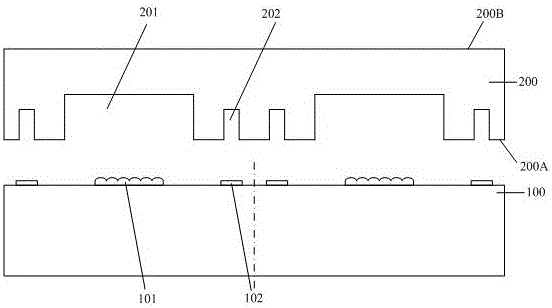

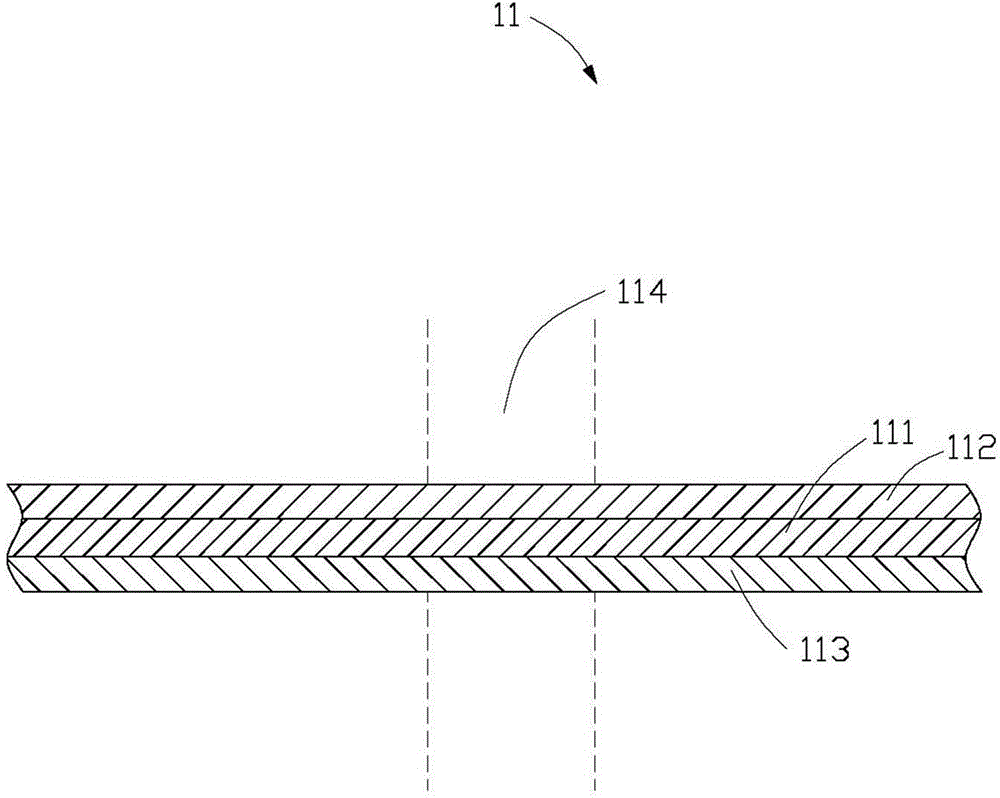

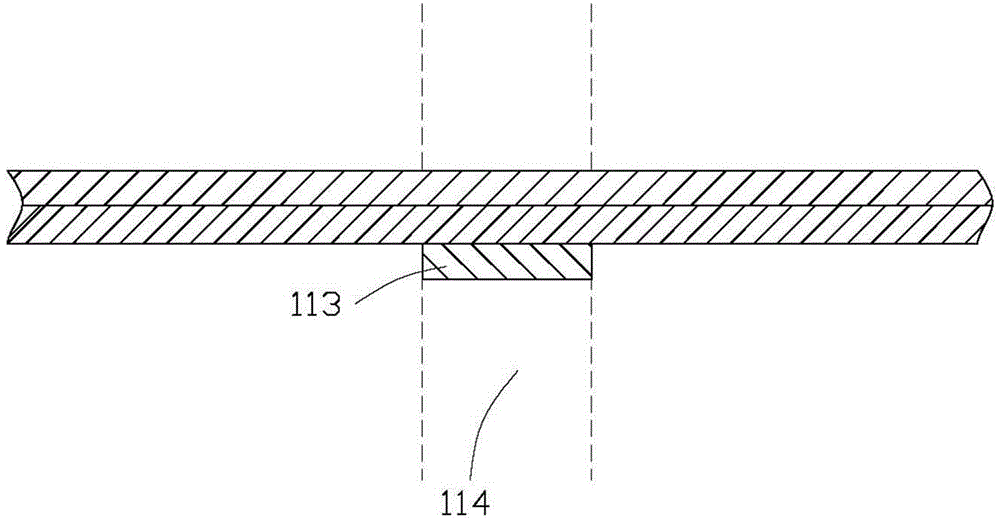

Multi-point touch screen with single-layer film and production method thereof

InactiveCN104156115AReduce overall thicknessReduce processInput/output processes for data processingTotal thicknessFilm structure

The invention discloses a multi-point touch screen with single-layer film. The multi-point touch screen with the single-layer film comprises a glass covering plate and PET film, wherein an indium tin oxide conducting circuit is etched on one surface of the glass covering plate, the surface of the glass covering plate etched with the indium tin oxide conducting circuit adheres to one surface of the PET film through optical cement, and an indium tin oxide conducting circuit is etched on the other surface of the PET film. According to the multi-point touch screen with the single-layer film, the circuits are printed and etched on the tempered glass covering plate and a functional piece of a single-layer film structure at the same time, then the single-layer film is attached onto the tempered glass covering plate, therefore, an existing double-layer film structure is replaced, and the multi-point functional piece is obtained, the total thickness of the touch screen is decreased. Meanwhile, production procedures are simplified, so that production cost is reduced.

Owner:无锡宇宁智能科技有限公司

Multi-chip packaging structure and manufacturing method thereof

ActiveCN101740552AReduce height and lengthReduce overall thicknessSemiconductor/solid-state device detailsSolid-state devicesEngineeringRelay

The invention discloses a multi-chip packaging structure which comprises a loader, a first chip, a relay circuit base board, a plurality of first bonding wires, a plurality of second bonding wires, a second chip, a plurality of third bonding wires, and a bonding layer. The first chip is arranged on the loader. The relay circuit base board is arranged on the first chip. The first bonding wire is electrically connected between the first chip and the relay circuit base board. The second bonding wire is electrically connected between the relay circuit base board and the loader. The second chip is arranged on the loader and is stacked with the first chip. The third bonding wire is electrically connected between the second chip and the loader. The bonding layer is adhered between the first chip and the second chip. Besides, the invention provides a manufacturing method for the multi-chip packaging structure.

Owner:CHIPMOS TECH INC

Display device

InactiveCN101150941AReduce overall thicknessSolve the heavyInstrument housingRack/frame constructionImaging SignalImage signal

A display device comprises a display panel assembly and a supporting assembly for supporting the display panel assembly. The supporting assembly is provided with an analog and digital signal control device, a connector plate for connecting input image signals and a power supply control device.

Owner:INNOLUX CORP

Optical filterer, lens module and imaging module

InactiveCN107608157AReduce overall thicknessSimple structureCamera filtersNon-linear opticsCamera lensElectric field

The invention discloses an optical filterer. The optical filterer comprises a first lens, a second lens and a transparent light guide medium. The first lens and the second lens are arranged oppositelyto each other in a spaced mode, and the two opposite surfaces of the first lens and the second lens are both provided with high-reflective film layers. The light guide medium is arranged between thehigh-reflective film layers, and the refractive index of the light guide medium can be changed under the effect of an external electric field to change the wavelength of light passing through the optical filter. The invention further discloses a lens module and an imaging module. In the optical filterer, the refractive index of the light guide medium can be changed to change the wavelength of thetransmitted light of the optical filter by changing the external electric field instead of relatively moving the first and second lenses, a space for meeting the movement requirements of the first lens or the second lens and an actuator for driving the lenses to move do not need to be arranged on the optical filterer, and the optical filter is small in overall thickness and simple in structure.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com