Miniature loudspeaker module and manufacturing method thereof

A technology of a miniature speaker and a manufacturing method, which is applied in the directions of sensors, transducer shells/cabinets/brackets, electrical components, etc., to achieve the effect of reducing the overall thickness and achieving thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

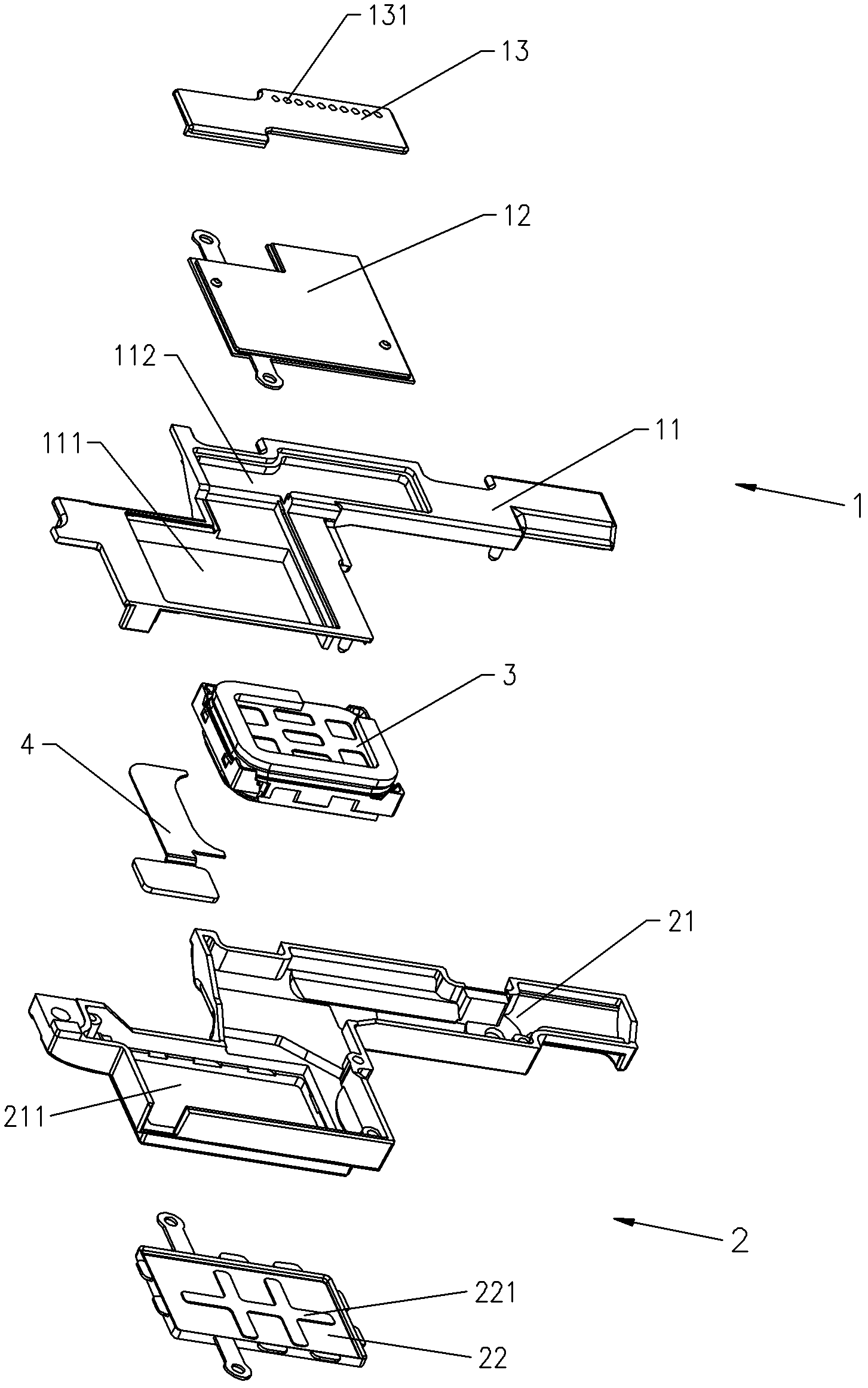

[0036] Such as figure 1 , Figure 9 and Figure 10 As shown, the micro-speaker module includes a speaker unit 3 and a casing for accommodating and fixing the speaker unit 3, and the casing is composed of an upper casing 1 and a lower casing 2 combined together. The micro-speaker module is also provided with a connecting piece 4, which electrically connects the micro-speaker module with an external electronic circuit.

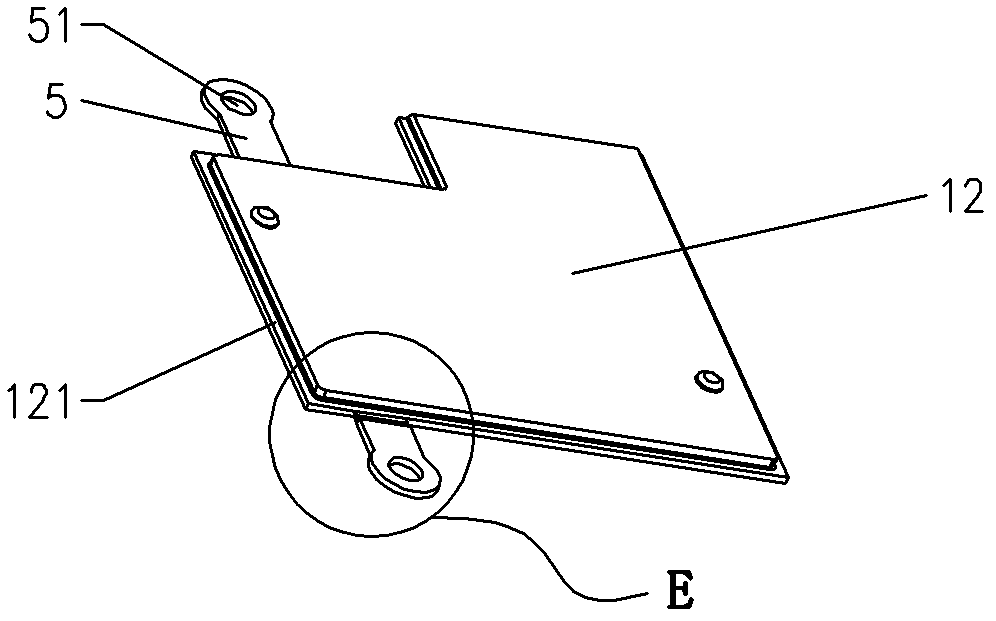

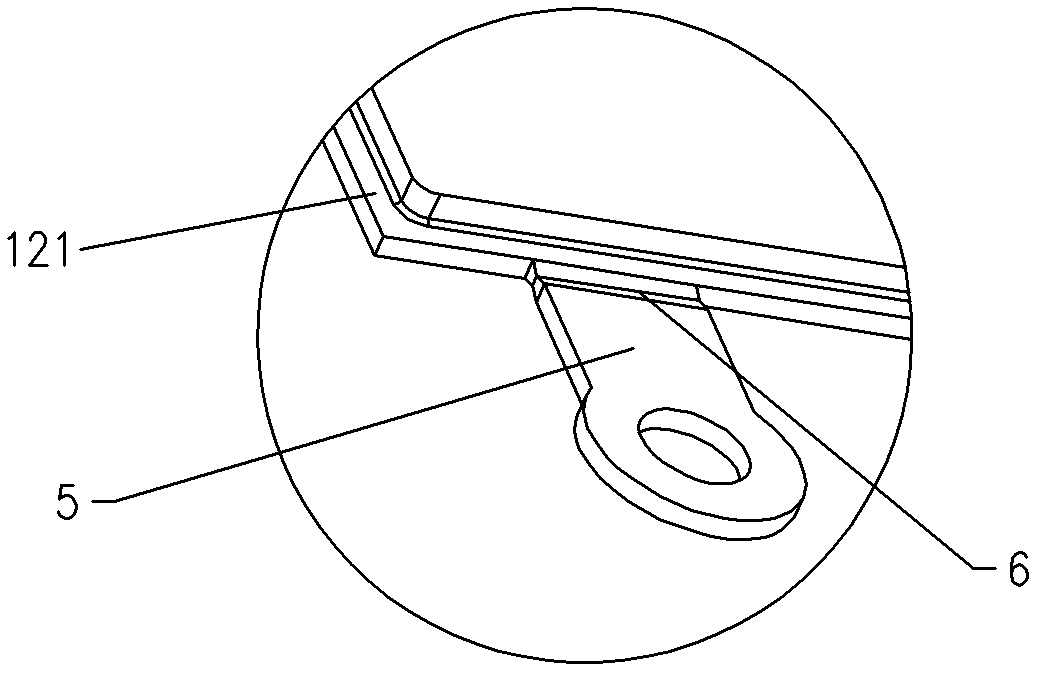

[0037] The space inside the housing includes a mounting portion A for mounting the speaker unit 3 . The upper case 1 includes an upper case body 11 made of plastic material, a first mounting hole 111 is provided at a position corresponding to the mounting part A on the upper case body 11, and a metal material is provided on the first mounting hole 111. The upper insert 12 is formed, and the thickness of the upper insert 12 is smaller than the thickness of the upper housing body part 11 . The lower housing 2 includes a lower housing body part 21 made of plast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com