Multilayer plane winding coil designing method suitable for double column magnetic core structure

A planar winding and design method technology, which is applied in coil manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of transformer leakage increase, manufacturing cost soaring, practical limitations, etc., to reduce the total thickness, The effect of reducing the total number of layers and reducing technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

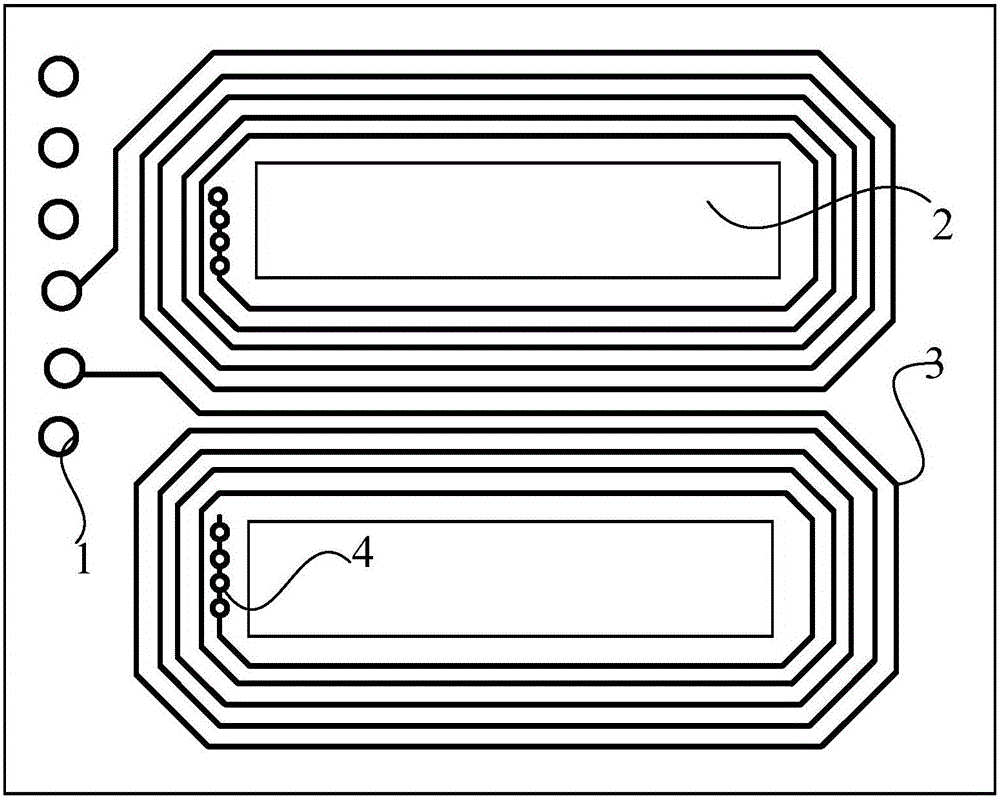

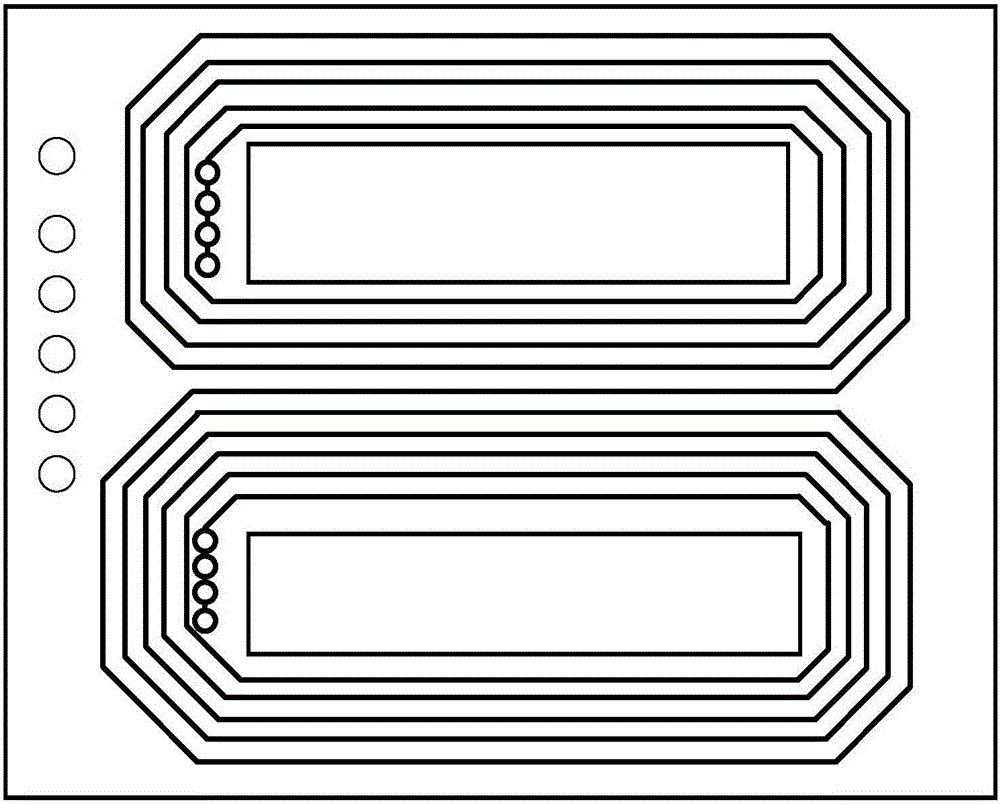

[0024] A method for designing a planar plate winding coil suitable for a double-column magnetic core structure, the method specifically includes the following steps:

[0025] Step 1: Open two parallel magnetic core post installation through holes on the PCB;

[0026] Step 2: A plurality of metallized hole pads are provided on the outer edge of the PCB board;

[0027] Step 3: The first and last ends of the series winding on the whole board are drawn from two of the metallized hole pads on the PCB;

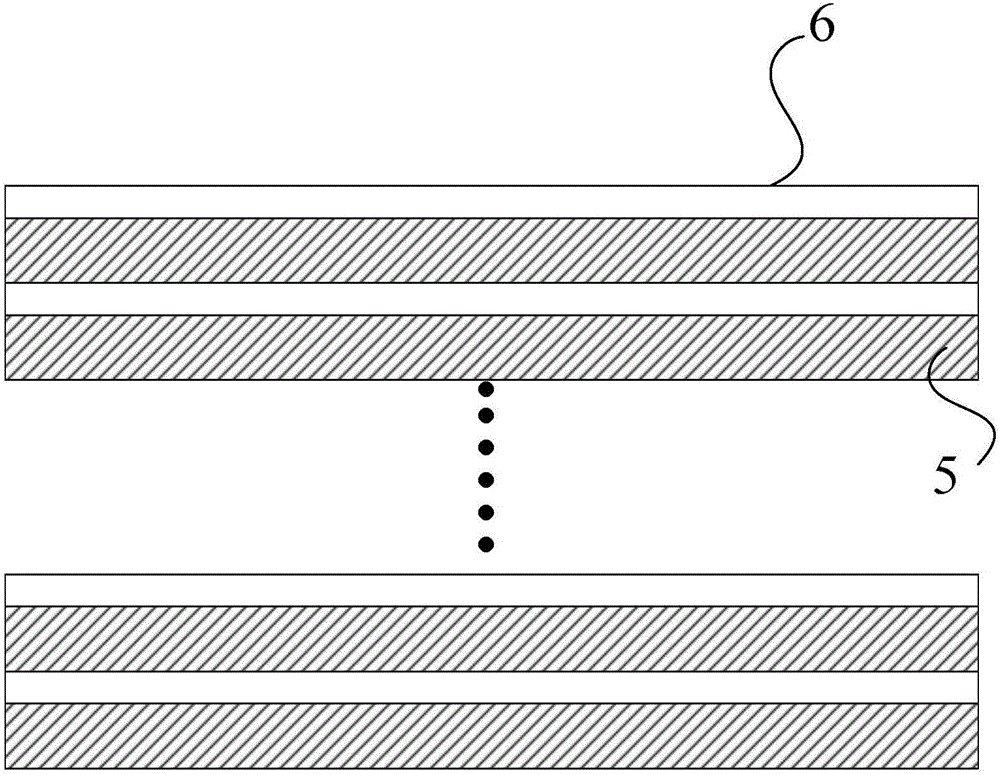

[0028] Step 4: Use the double-sided copper-clad substrate to route wires and form four windings around the two stem holes; the edge of each stem hole passes through multiple copper-faced wiring via holes, so that the cladding around the same stem hole Copper traces form a "double-layer series winding" with the same winding direction; two "double-layer series windings" around different core columns are connected in series in the opposite direction to form a full-board winding with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com