Low-cost anti-warping simulation skating rink board structure and processing method thereof

A low-cost, anti-warping technology, applied in skating, sports accessories, bundling of skis, etc., can solve the problems of large thickness, increase the production cost of artificial ice boards, hinder the rapid promotion of artificial ice boards, etc., and achieve simple processing technology. , The effect of protecting athletes' joints and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

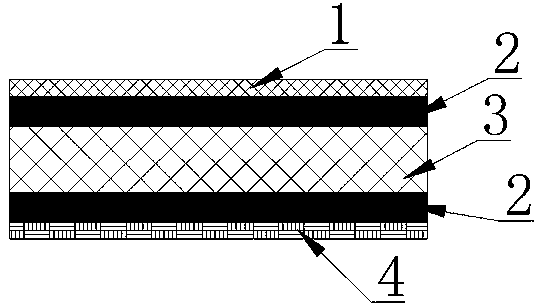

Embodiment 1

[0025] Extrude PTFE-modified high-density polyethylene sheet, carbon fiber-reinforced polypropylene sheet, micro-foamed polyethylene plastic sheet, carbon fiber-reinforced polyolefin sheet, and PTFE-modified high-density polyethylene in sequence The sheets are put into the mold one by one to close the mold, the mold cavity is vacuumed at -0.05~-0.1MPa, heated and pressurized at 80-260°C for 0.5-2h, then cooled and taken out.

Embodiment 2

[0027] Sequentially extrude PTFE-modified high-density polyethylene material into sheet, hot-melt adhesive film, glass fiber reinforced polypropylene sheet, hot-melt adhesive film, polyethylene plastic sheet, hot-melt adhesive film, glass-reinforced polyolefin Sheet material, hot melt adhesive film, polytetrafluoroethylene modified high-density polyethylene extruded sheet material are placed in the mold in turn to close the mold, heated and pressurized at 80-260°C for 0.5-2h, then cooled and taken out.

Embodiment 3

[0029] Put the ultra-high molecular weight polyethylene sheet, carbon fiber reinforced polypropylene sheet, micro-foamed polyethylene plastic sheet, carbon fiber reinforced polyolefin sheet, and polytetrafluoroethylene modified high-density polyethylene extruded sheet into the Close the mold in the mold, vacuumize the mold cavity at -0.05~-0.1MPa, heat and pressurize at 80-260℃ for 0.5-2h, then cool and take it out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com