Flexible-rigid circuit board and manufacturing method

A circuit board production, soft and hard combination technology, applied in the direction of multi-layer circuit manufacturing, printed circuit components, printed circuit structure connection, etc. Plate thickness and other issues, to achieve the effect of reducing the overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The rigid-flex circuit board and the manufacturing method of the rigid-flex circuit board provided by the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0023] The manufacturing method of the rigid-flex circuit board 100 provided by the embodiment of the present invention includes the steps of:

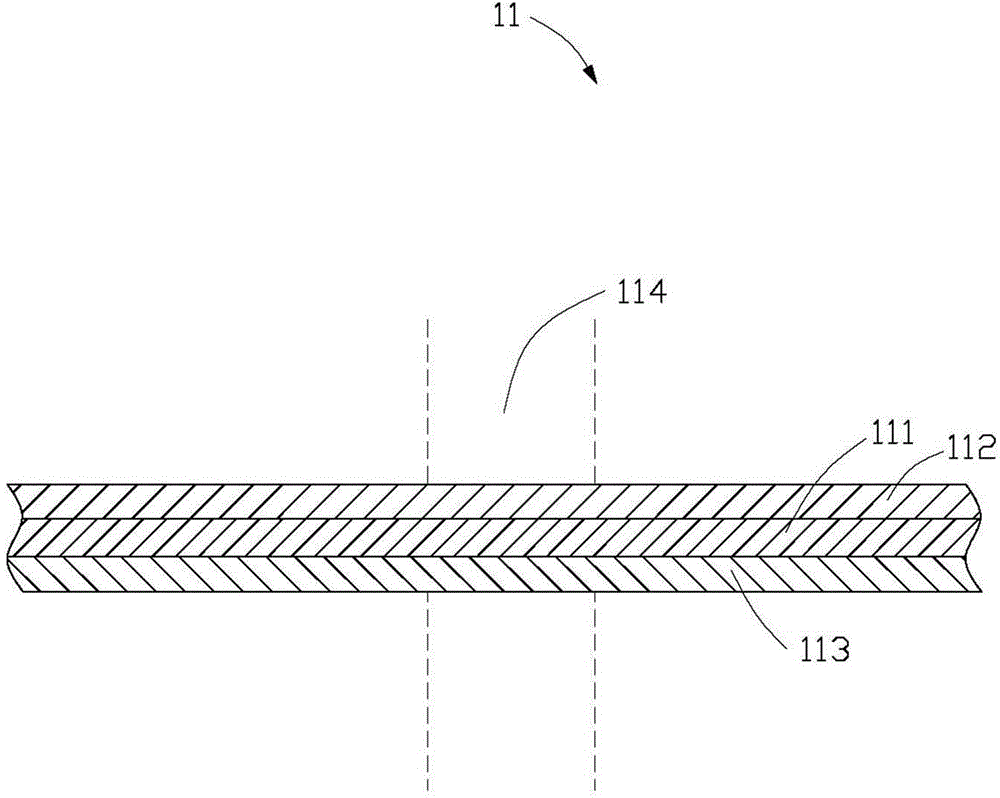

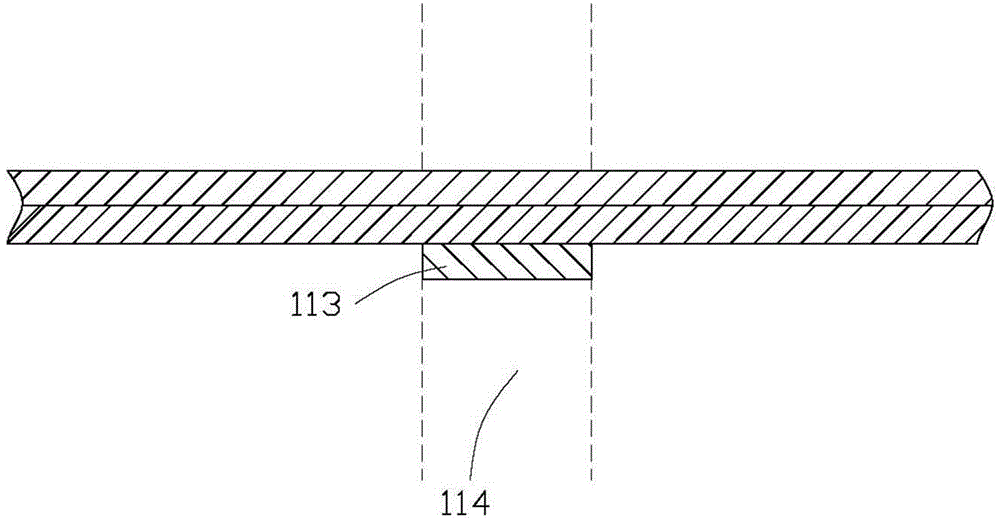

[0024] For the first step, see figure 1 , providing a first rigid substrate 11.

[0025] The first rigid substrate 11 can be a multi-layer board, a double-sided board or a single-sided board. In this embodiment, the first rigid substrate 11 is a double-sided copper-clad substrate. The first rigid substrate 11 includes a first dielectric layer 111 , a first copper foil layer 112 and a second copper foil layer 113 . The first dielectric layer 111 can be made of epoxy glass fiber cloth, phenolic resin or the like. The first copper foil layer 112 and the second copper foil layer 113 are located on oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com