One-plate three-field ultrathin fuel cell bipolar plate and fuel cell stack

A fuel cell stack and fuel cell technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve the problem of vibration resistance, bending resistance and air tightness, sacrificial electrical conductivity, thermal conductivity, flow field plate combination Difficult problems, to achieve the effect of improving heat dissipation, shortening the path of heat transfer, and increasing the volume ratio power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

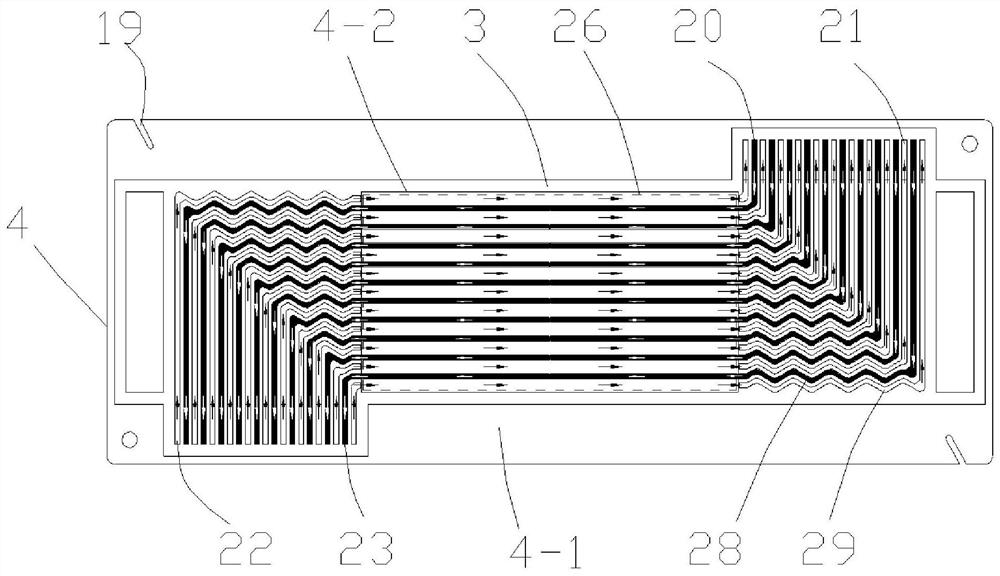

[0066] A one-plate three-field type ultra-thin fuel cell bipolar plate, the bipolar plate 4 includes a flow field plate 4-1, one side of the flow field plate 4-1 is an anode side, and the other side is a cathode side;

[0067] A fuel gas flow channel 28 and a cooling liquid flow channel 29 are arranged on the anode side of the flow field plate 4-1;

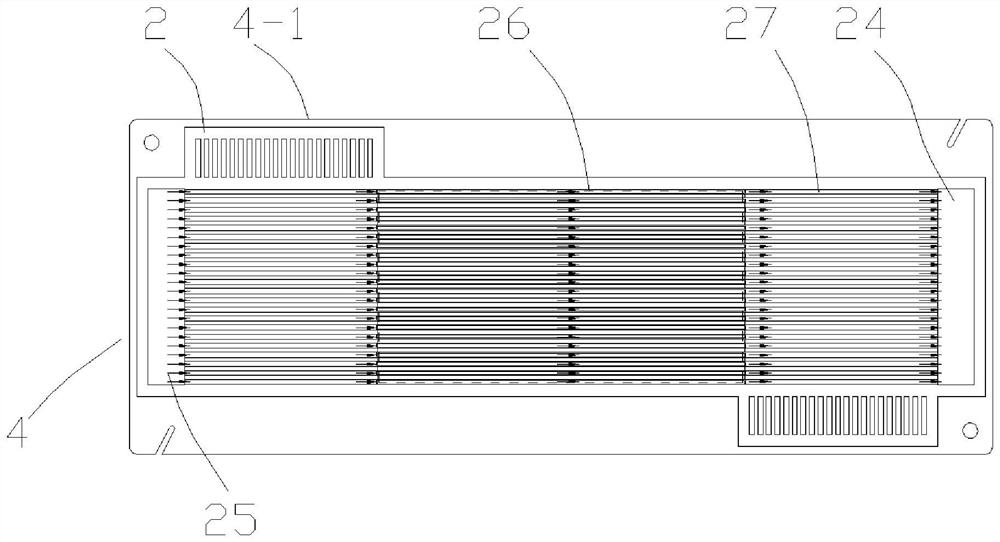

[0068] An oxidizing gas flow channel 27 is arranged on the cathode side of the flow field plate 4-1;

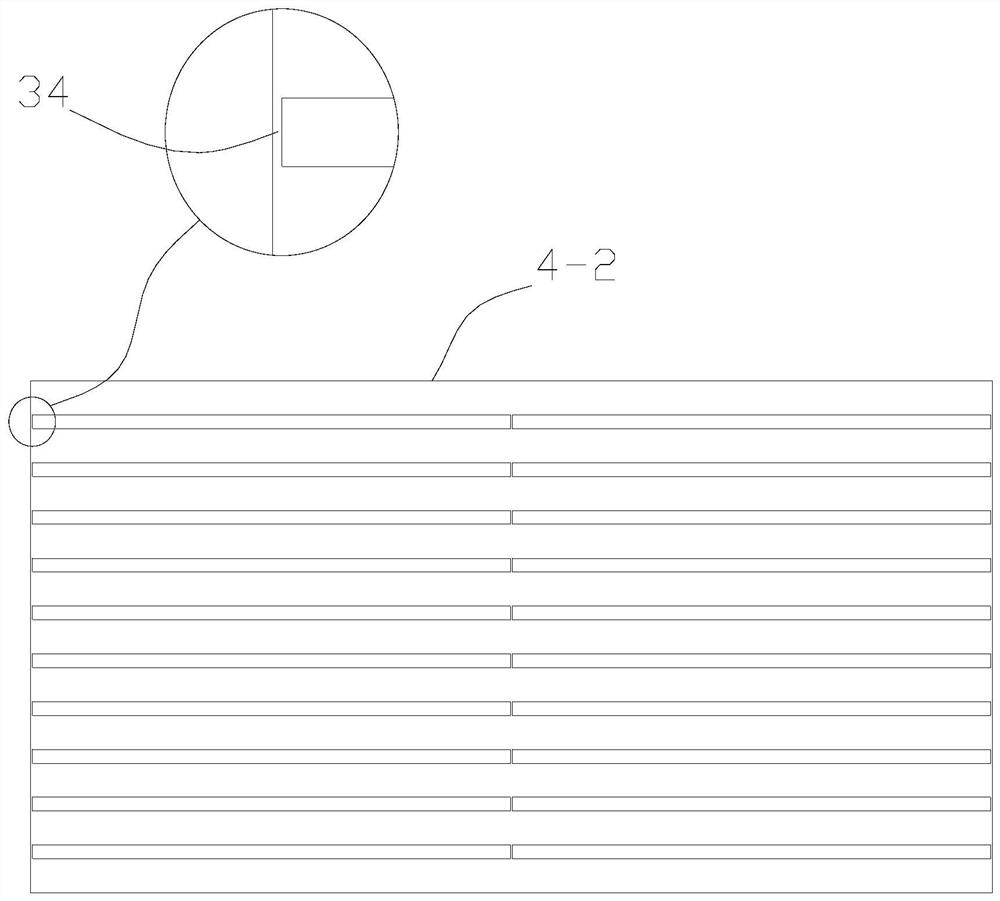

[0069] The bipolar plate 4 also includes a cover plate 4-2 placed on the anode side of the flow field plate 4-1 for separating the coolant flow channel 29 located in the active area from the fuel gas flow channel 28;

[0070] The anode side of the flow field plate 4-1 is used to closely cooperate with the anode seal 3 and the cover plate 4-2 to form a fuel gas flow field and a coolant flow field;

[0071] The cathode side of the flow field plate 4 - 1 is used to closely cooperate with the cathode seal 2 to form an oxidizing gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com