Sealing method for carbon powder box

A technology of toner cartridges and seals, which is applied in the field of toner cartridge sealing, can solve problems such as complex processes and easily damaged toner cartridges, and achieve the effects of simplifying the sealing process, saving costs, and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

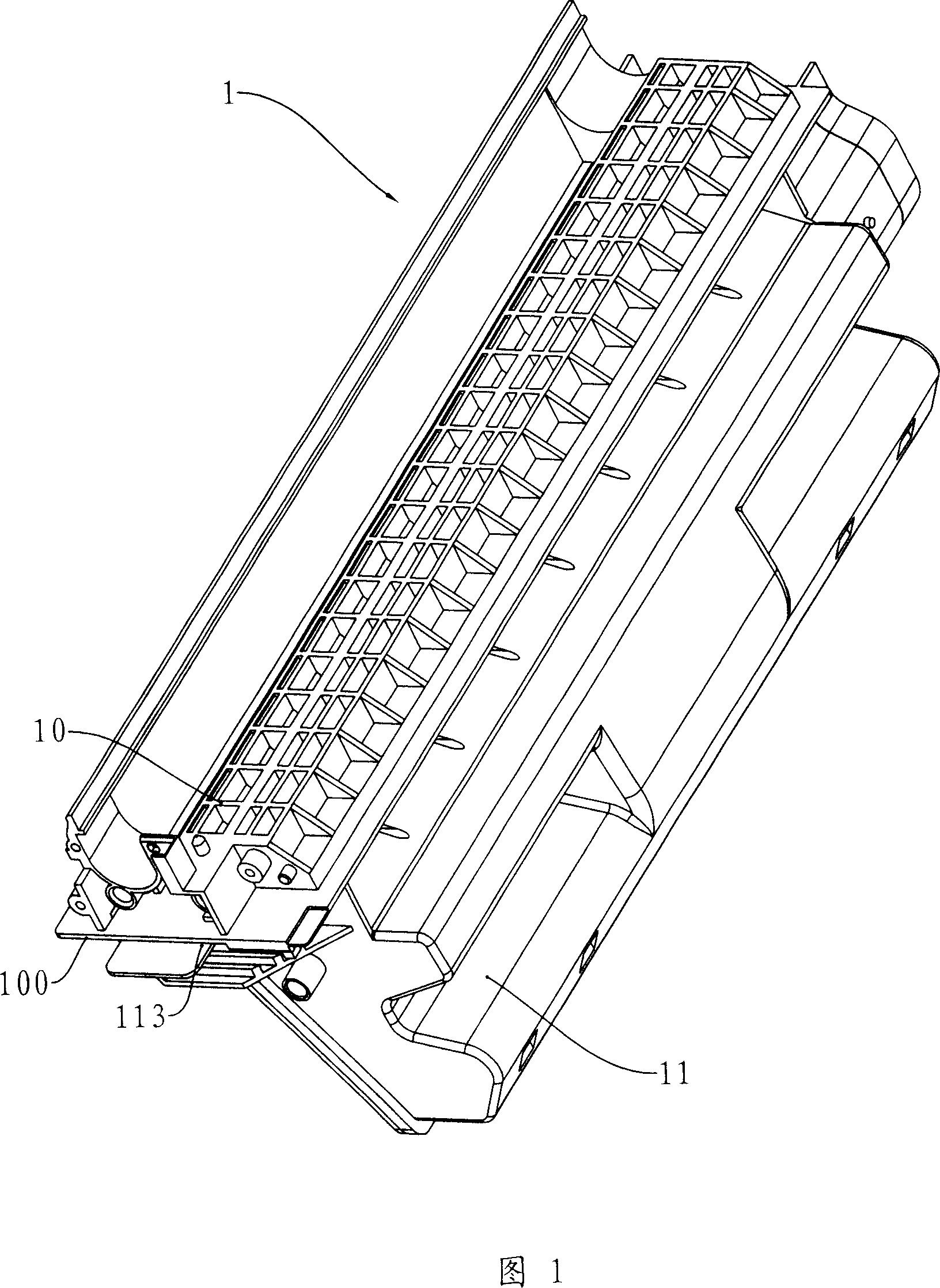

[0025] See Figure 1, Figure 1 is a typical recyclable toner box assembly 1, because in the process of recycling and regeneration of the toner box, the sealing process is essentially for the sealing of the toner box, and does not involve To the waste toner bin, therefore, for the sake of simplicity, only the powder bin assembly 1 of the toner cartridge is drawn in FIG. 1 , and the waste toner bin assembly of the toner cartridge is omitted. The powder bin assembly 1 includes a bottom frame 10 and a powder bin 11 fixed on the bottom frame 10 , and there is a certain gap between the powder bin 11 and the bottom frame 10 . The bottom frame 10 is usually called a developing frame, and the powder bin 11 is used to accommodate toner. There is a tear tape outlet 113 on the side of the junction between the developing frame and the bottom frame 10 .

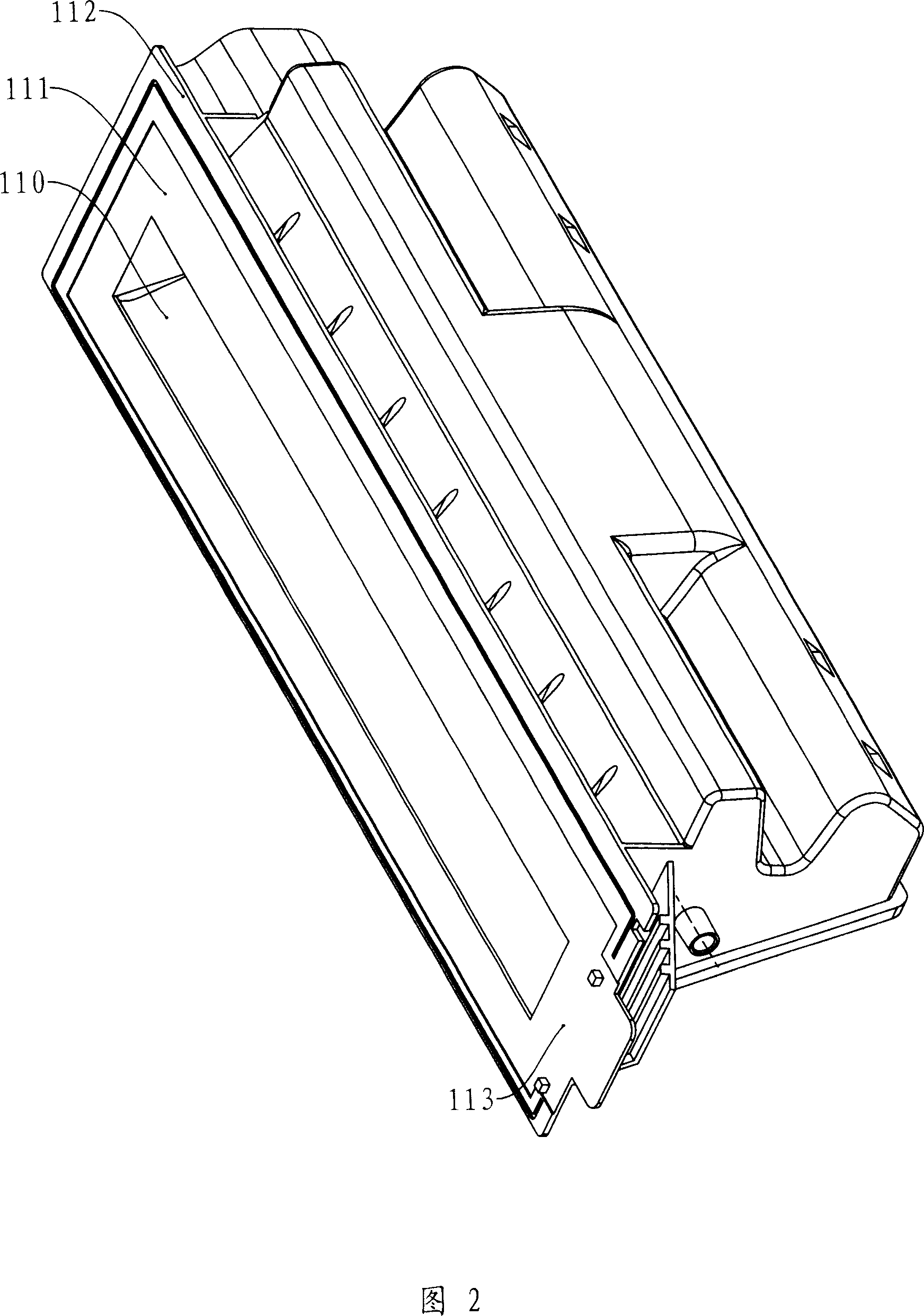

[0026] As shown in Figure 2, Figure 2 is a perspective view of the powder bin 11 with the development frame cut or unwelded, the powder bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com