Patents

Literature

101 results about "Tear tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tear tape, also known as tearstrip or tear-off ribbon, is a narrow adhesive tape used to open packaging. The backing is often a narrow oriented polymer such as polypropylene but other polymers, yarns, and filaments are also used. Many tear tapes use a pressure sensitive adhesive but others have a heat-activated adhesive system.

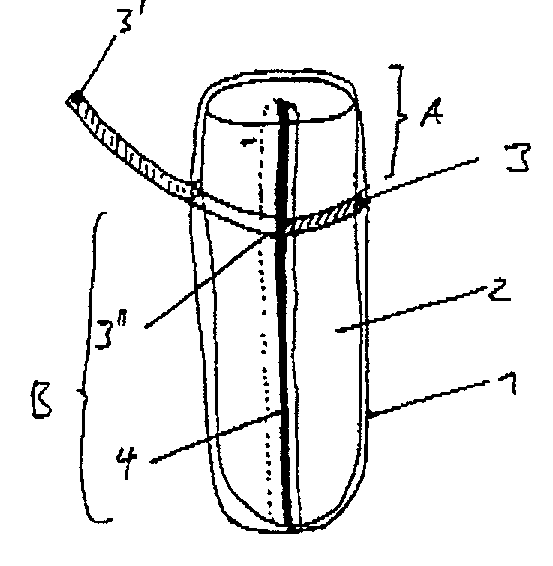

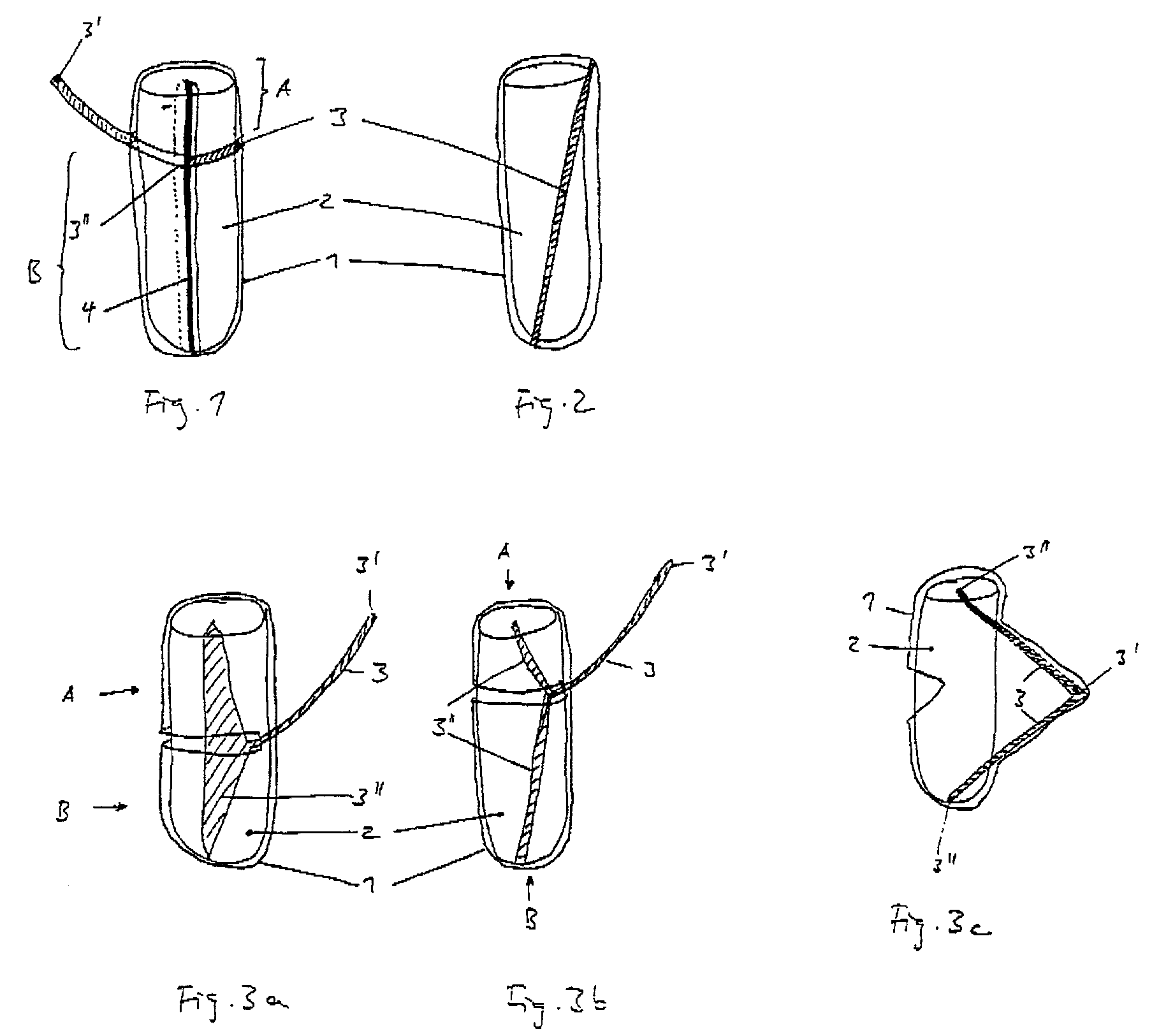

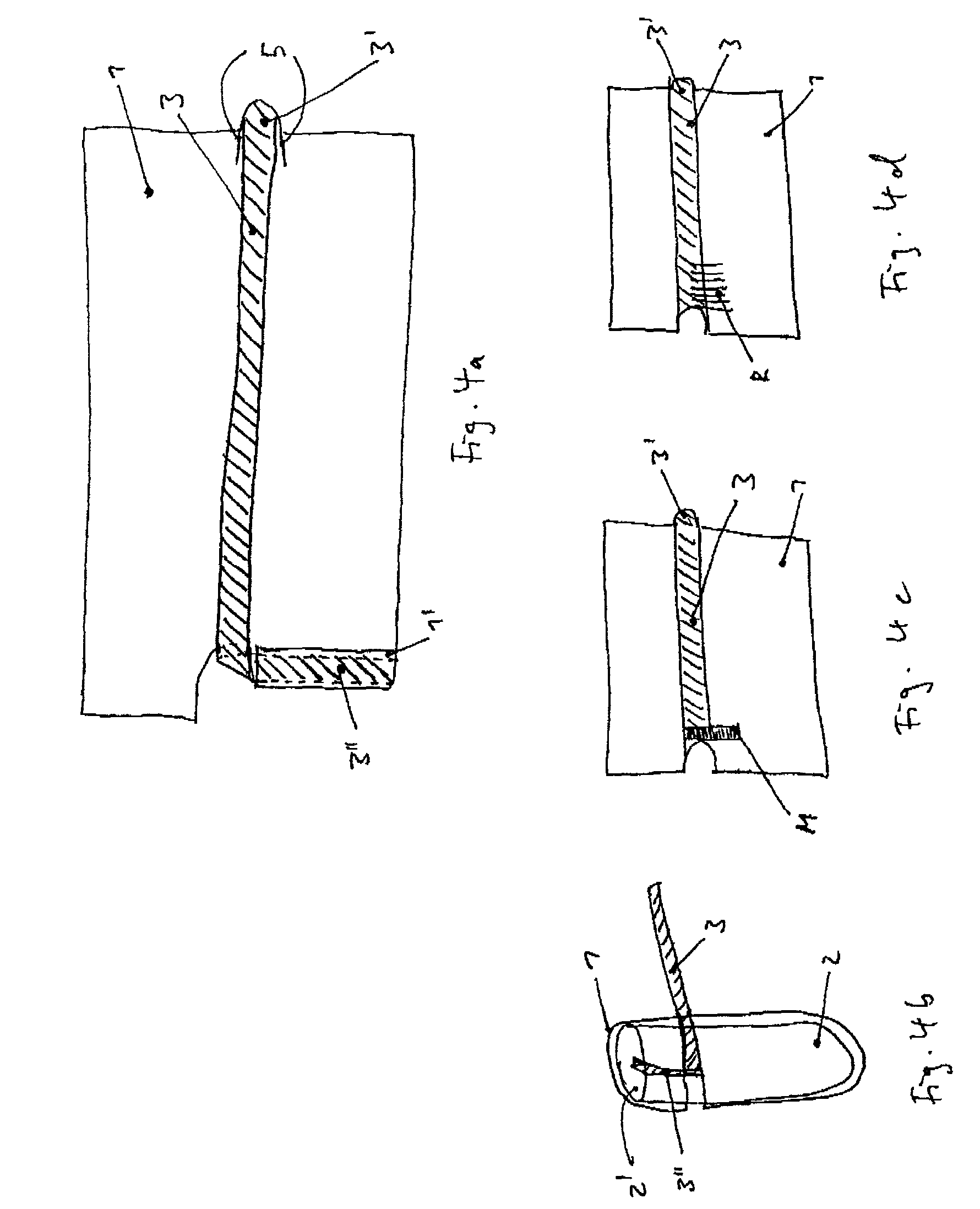

Tampon wrapper with opening means comprising stopper

The present invention relates to a wrapper for individually packaging absorbent articles for personal hygiene, especially tampons. The wrapper of the present invention is provided with an opening means comprising a tear tape and a stopper, the tear tape is used for opening the wrapper and the stopper prevents the wrapper from becoming separated into more than two segments of wrapper material upon being opened.

Owner:THE PROCTER & GAMBLE COMPANY

Manufacture technique of easy tear tape

InactiveCN101619199ANeat and beautiful appearanceEasy to useLiquid surface applicatorsFilm/foil adhesivesTear tapeEngineering

The invention relates to a manufacture technique of easy tear tape, comprising the following steps: 1) tricot grid cloth: using a tricot weft insertion machine to carry out full tricot weft insertion on the warp and weft to be knitted into mesh fabric; 2) thermal forming and finishing: carrying out thermal treatment on the mesh fabric and sizing treatment on a sizing machine by using a sizing agent; 3) compounding: using high temperature melt resin on the front and back faces, and carrying out direct film sprinkling treatment to obtain a three-layered structural film shape substrate; and 4) adhesive coating: directly coating pressure-sensitive adhesive on the substrate followed by drying, or pre-coating the pressure-sensitive adhesive on a mold release substrate and drying followed by being transferred to be compounded onto the three-layered substrate to obtain the adhesive tape with viscosity. The invention has the beneficial effects that the tape produced by the technique of the invention can be torn off transversely with slight force in use, can be directly torn off without special tools, and the transverse torn part is neat, so that the adhesive material looks neat and beautiful in appearance, the use is safe and convenient, the working efficiency is improved and task cost is reduced.

Owner:李俊辉 +1

Product packaging including digital data

InactiveUS20050153128A1Open efficientlyStampsAccessories for indicating/preventing prior/unwanted useDigital dataTear tape

Light sensitive materials applied in shipping materials, including security seals and tear tape, for authentication, discrimination and recognition of items.

Owner:VERIFICATION TECH INC

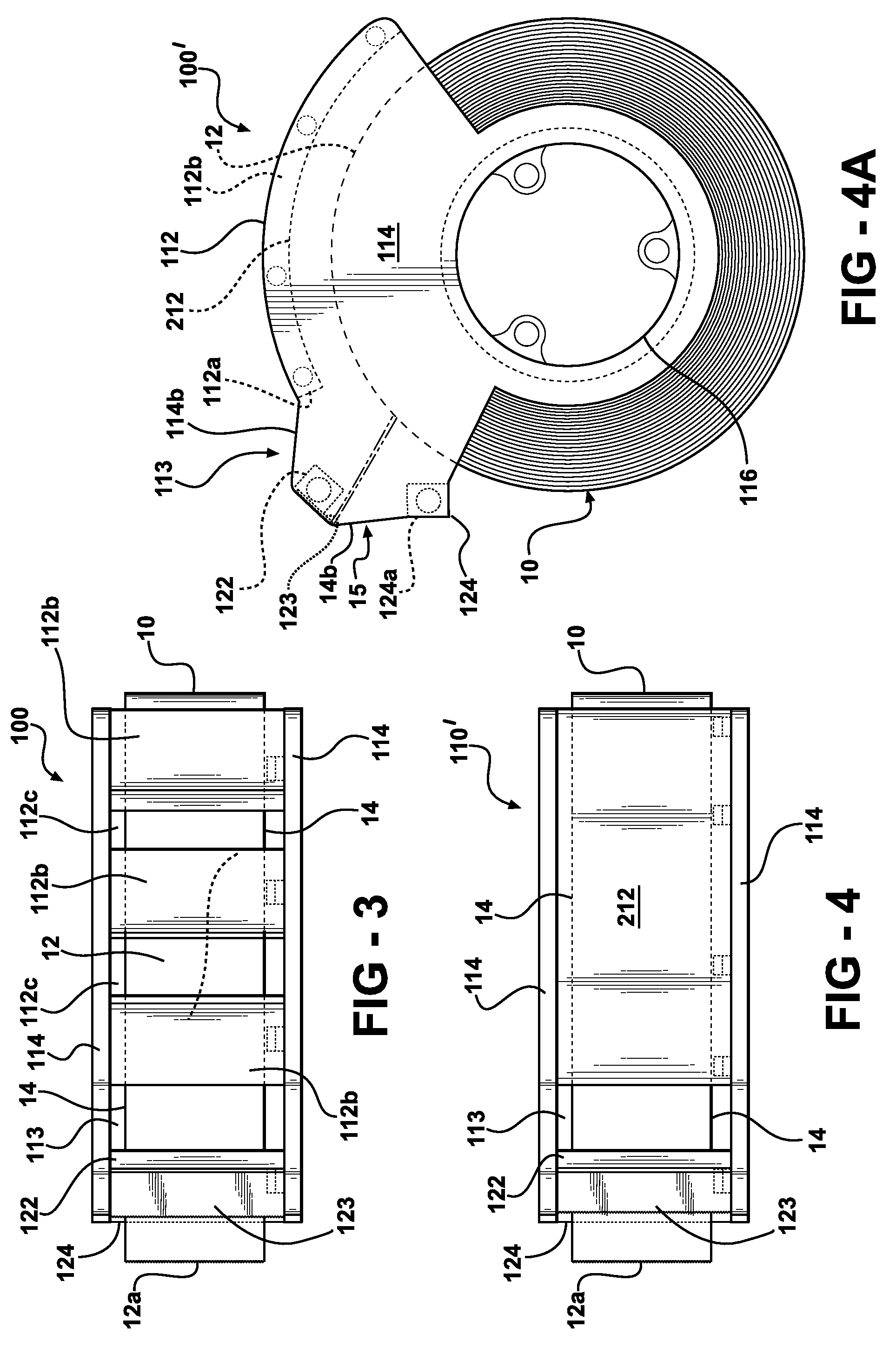

Duct Tape Dispenser With Holder

InactiveUS20080067211A1Easy to masterPrevents the tape from rolling awayPaperhangingRoof toolsTear tapeWall mount

A tape dispenser, useful for storing, dispensing, and cutting a roll of duct tape, or similar wide, heavy, hard-to-tear tape. The dispenser is formed in two axially-registered and rotationally-mated halves. The dispenser can also include a mating wall-mounted or shelf-mounted receptacle that releasably mounts the dispenser on a convenient surface, and that allows tape to be dispensed and torn with one hand from the receptacle-mounted dispenser.

Owner:WENICK IND

Product packaging including digital data

InactiveUS20030047610A1Write quicklySimple technologyStampsAccessories for indicating/preventing prior/unwanted useDigital dataTear tape

Light sensitive materials applied in shipping materials, including security seals and tear tape, for authentication, discrimination and recognition of items.

Owner:VERIFICATION TECH INC

Duct Tape Dispenser

A tape dispenser, useful for storing, dispensing, and cutting a roll of duct tape, or similar wide, heavy, hard-to-tear tape. The dispenser has a unique roll-surrounding structure with two sidewalls, a top wall axially extending between the sidewalls above the roll of tape, a spool support extending axially between the sidewalls and through the roll's spool, a retainer bar extending axially between the sidewalls, and an elevated cutting bar located above the top wall and the retainer bar and extending axially between the sidewalls. The dispenser is formed in two axially separable halves. The retainer and cutting bars help connect and strengthen the sidewalls, and are in turn reinforced by the sidewalls and the rest of the dispenser in their tape-retaining and cutting functions. The rigid, axially separable halves of the dispenser are preferably held together with a magnetic connection. The dispenser can also include a bracket that both removably stores the dispenser on the undersurface of a cabinet or the like, and that allows tape to be dispensed and torn with one hand from the bracket-mounted dispenser.

Owner:WENDY STEELE +1

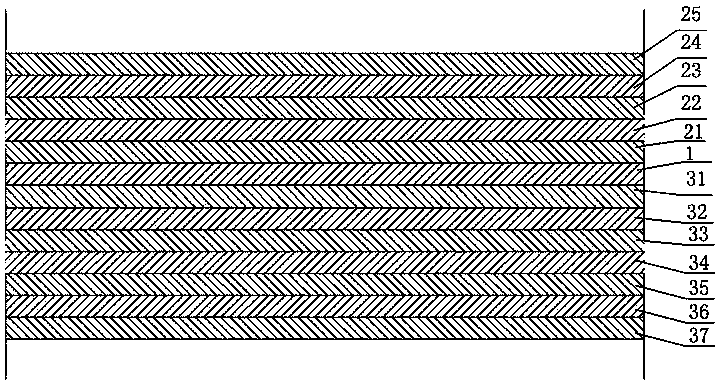

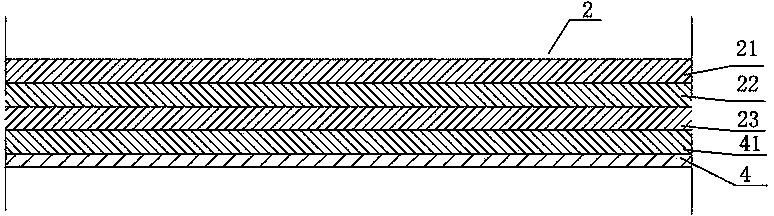

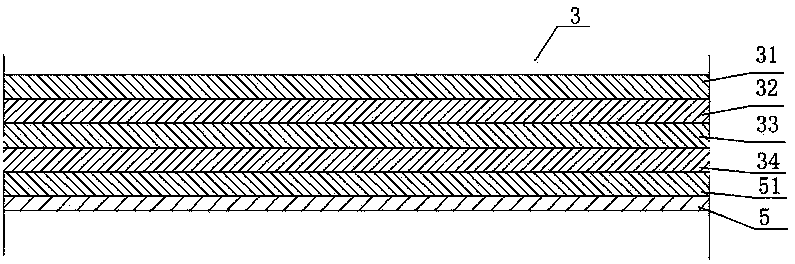

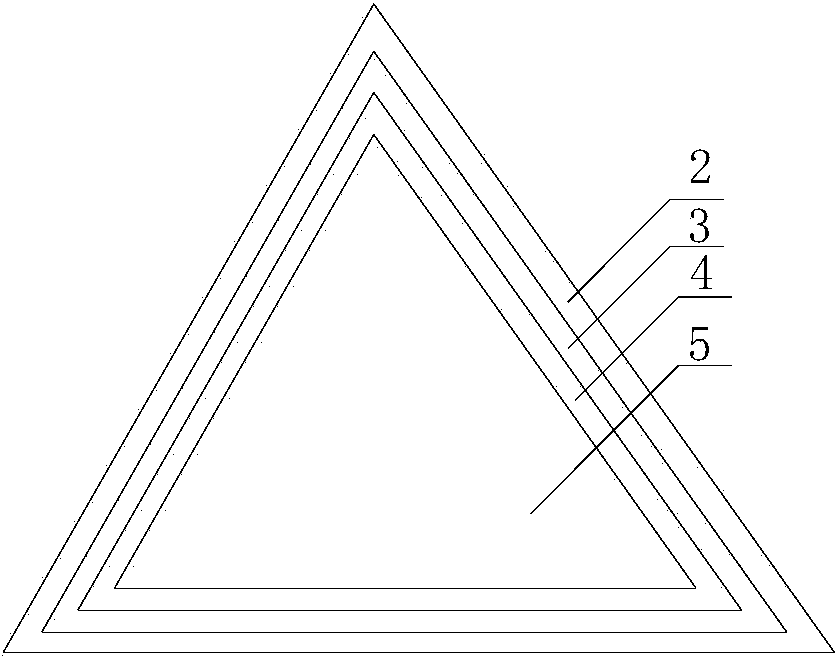

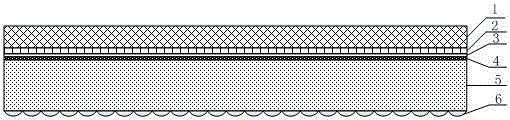

Laser fluorescent anti-fake tear tape with both sides in gold or silver stamping and manufacturing method thereof

ActiveCN103407686AHigh technology contentImprove anti-counterfeiting performanceFlexible coversWrappersPolyesterFluorescence

The invention relates to a laser fluorescent anti-fake tear tape with both sides in gold or silver stamping and a manufacturing method thereof. The laser fluorescent anti-fake tear tape comprises a polyethylene film, a gold face layer and a laser fluorescent face layer; the gold face layer and the laser fluorescent face layer are respectively composited on two sides of the polyethylene film; the gold face layer comprises a front stamping glue layer, a front aluminized layer, a gold-stripe ink layer, a front gloss oil protective layer and a pressure-sensitive adhesive layer; the laser fluorescent face layer comprises a back stamping glue layer, a red fluorescent layer, a laser film pressure layer, a back aluminized layer, a transparent character layer, a back gloss oil character-protective layer and a silicon oil layer arranged from inside to outside sequentially. Two rolls of PET polyester film are used as transfer film; the gold-stripe ink layer, the aluminized layers, the transparent character layer, the laser film pressure layer and the red fluorescent layer which are preprinted and coated on the PET polyester film are transferred to the front side and the back side of BOPP (biaxially-oriented polypropylene) film through the synchronous front-and-back side composite process, so that technological content and anti-fake performance of the anti-fake tear tape are improved.

Owner:广州咏顺包装材料有限公司

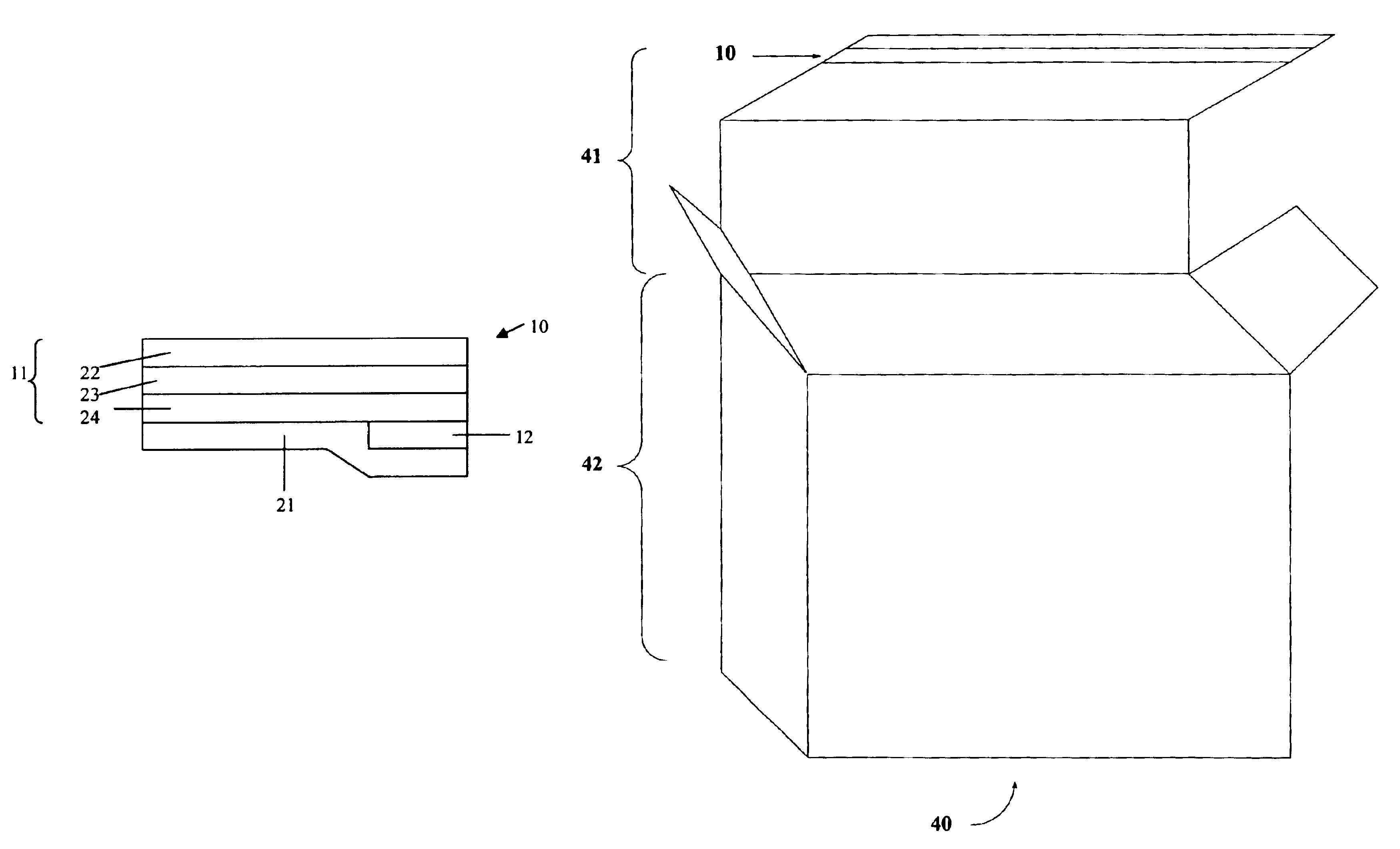

Moisture activated reinforcement string and tear opening tapes for corrugated and cartonstock containers

Owner:ADALIS

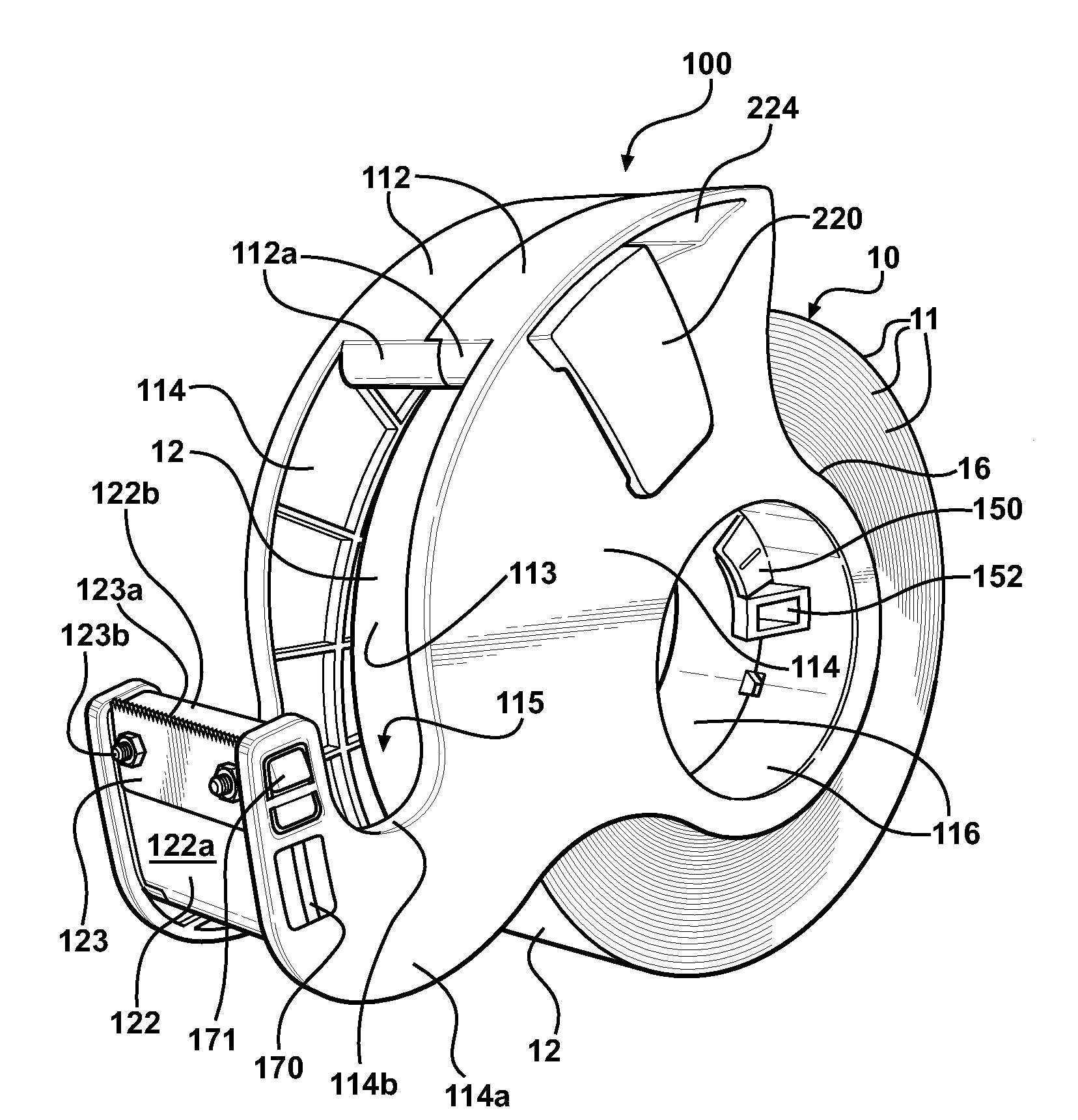

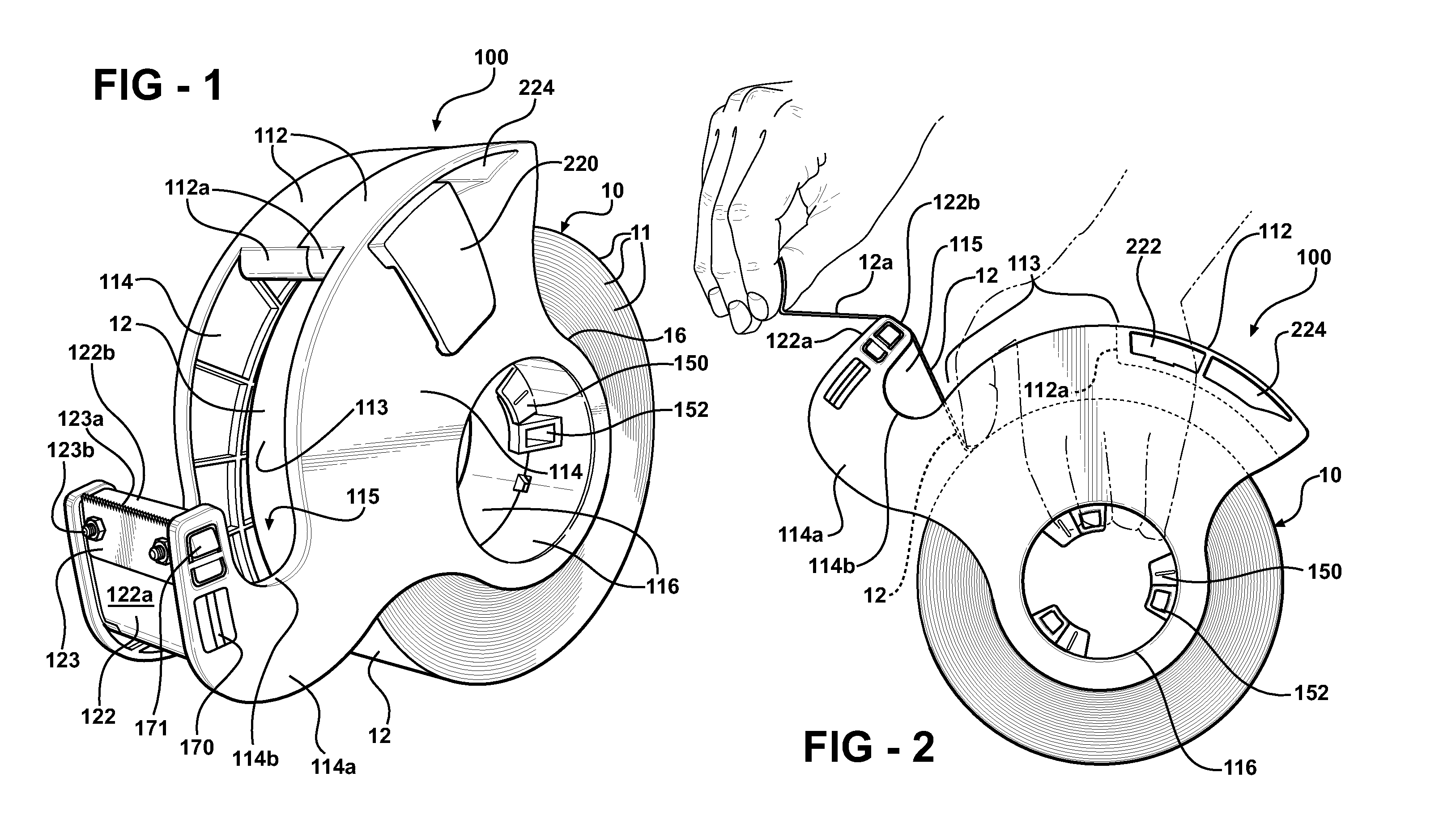

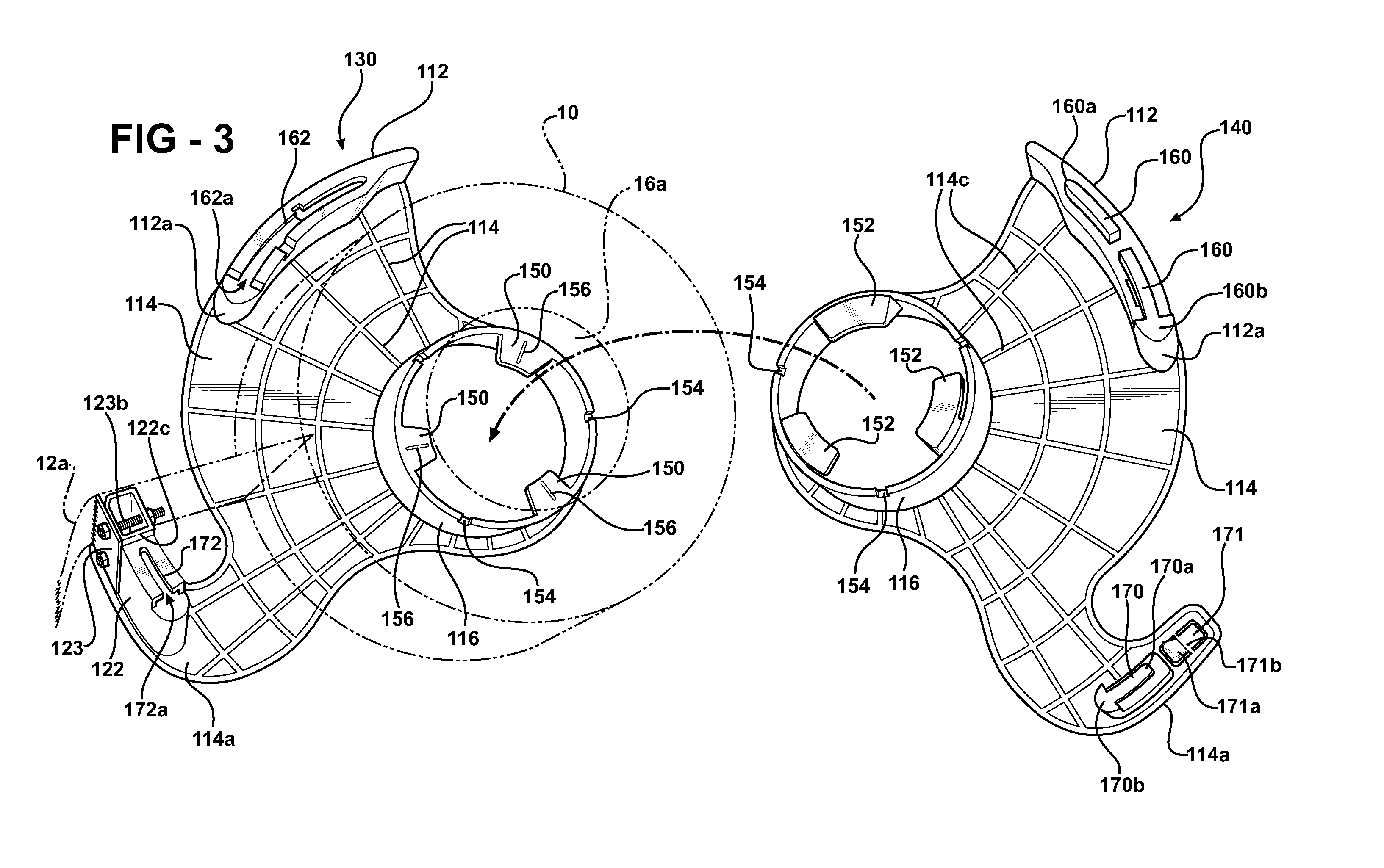

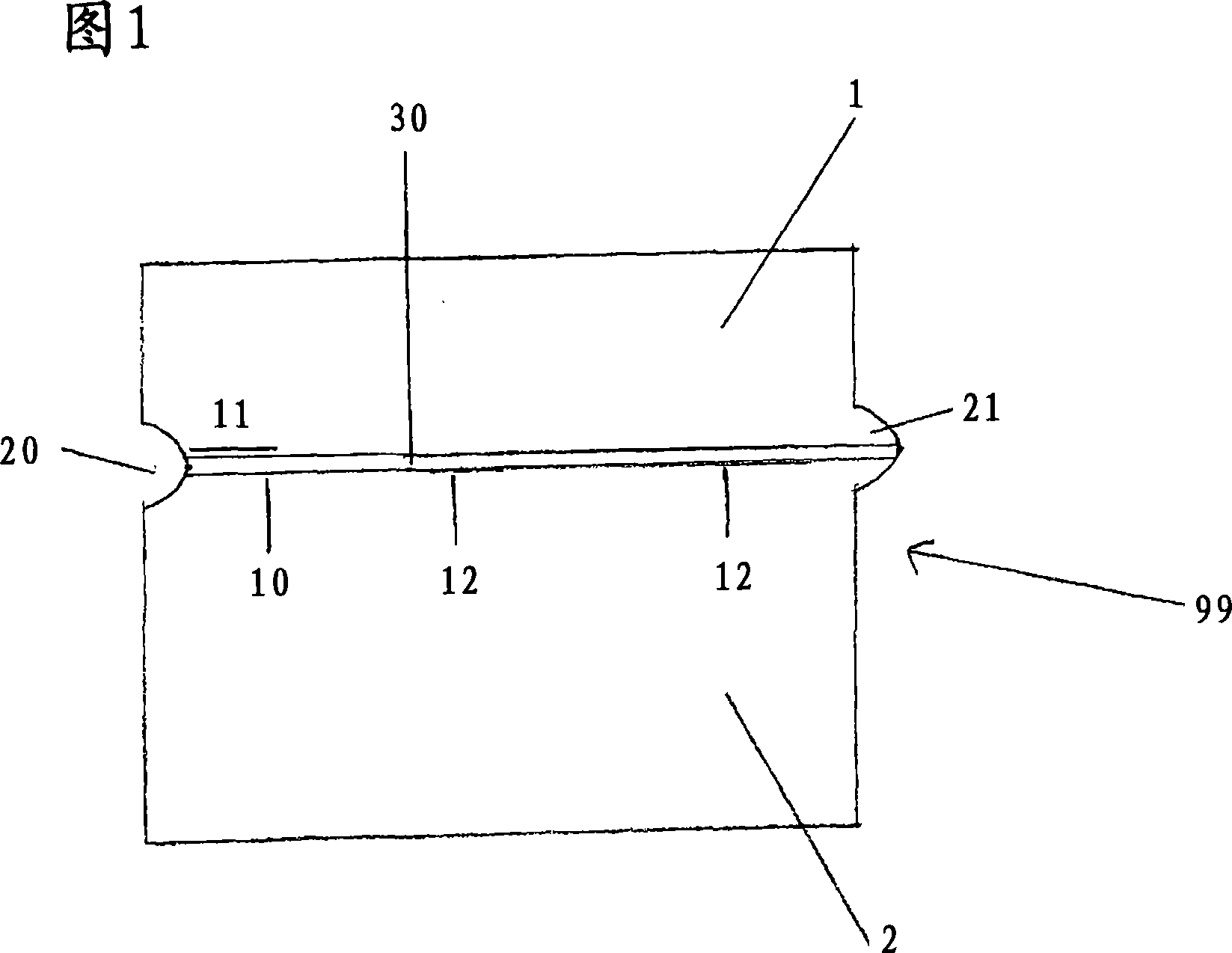

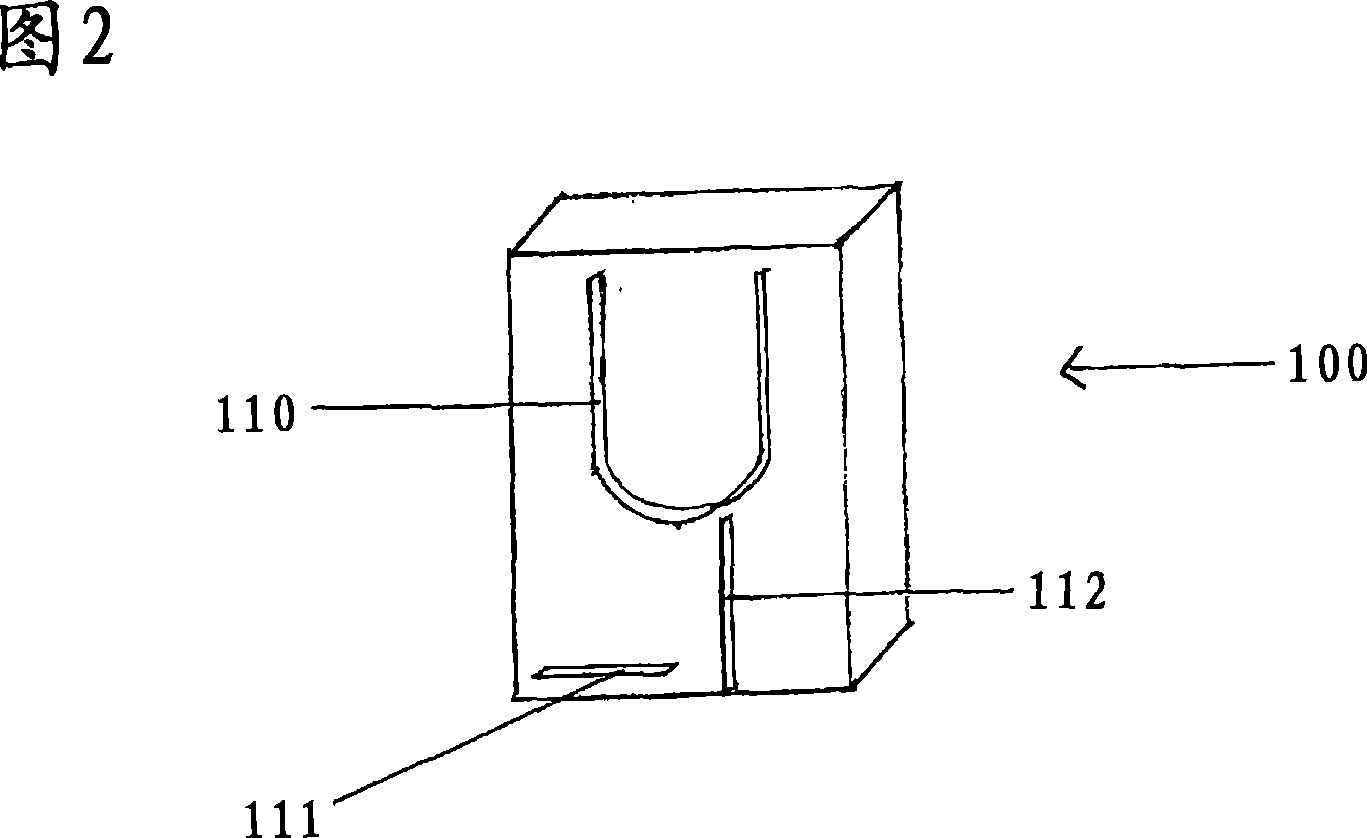

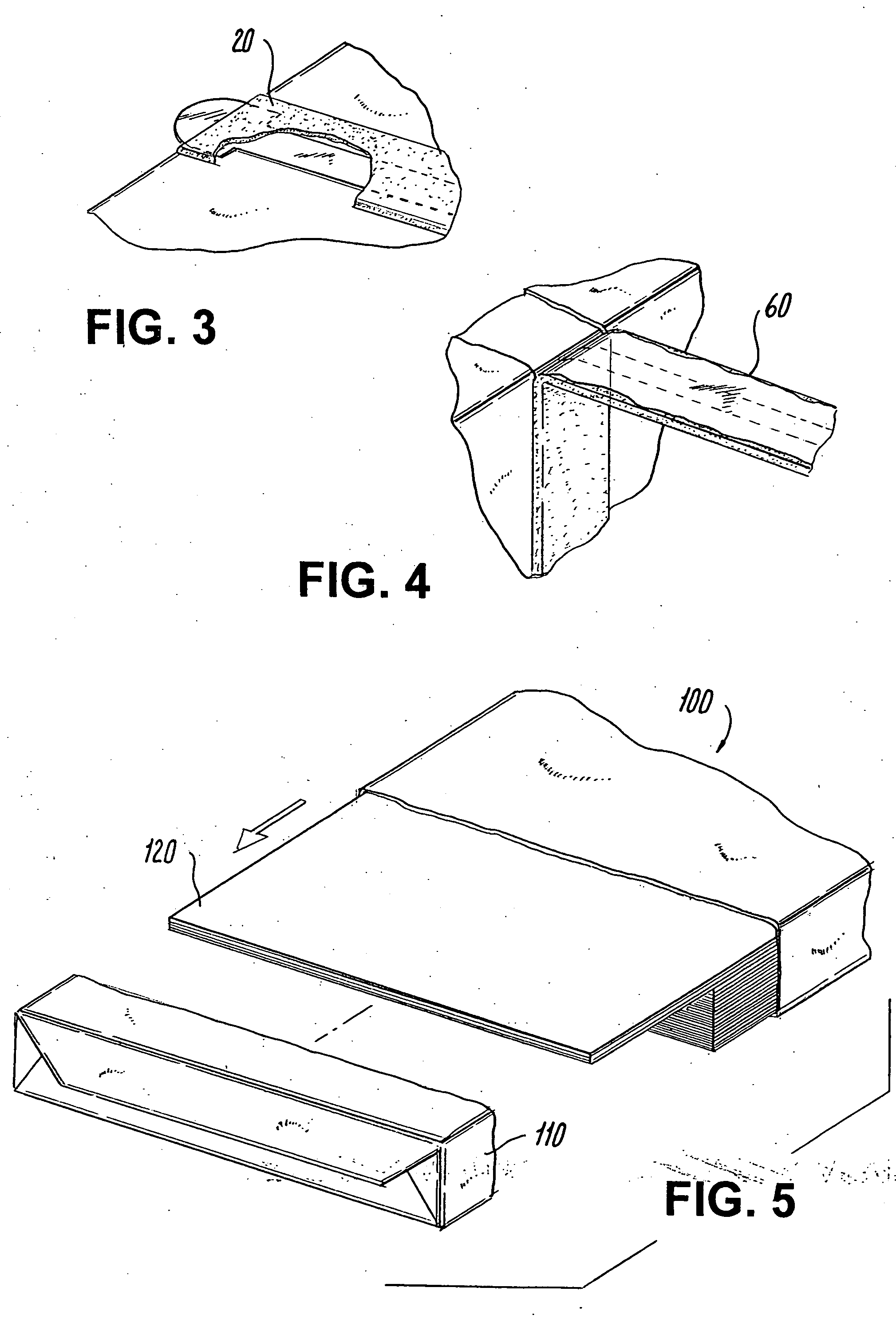

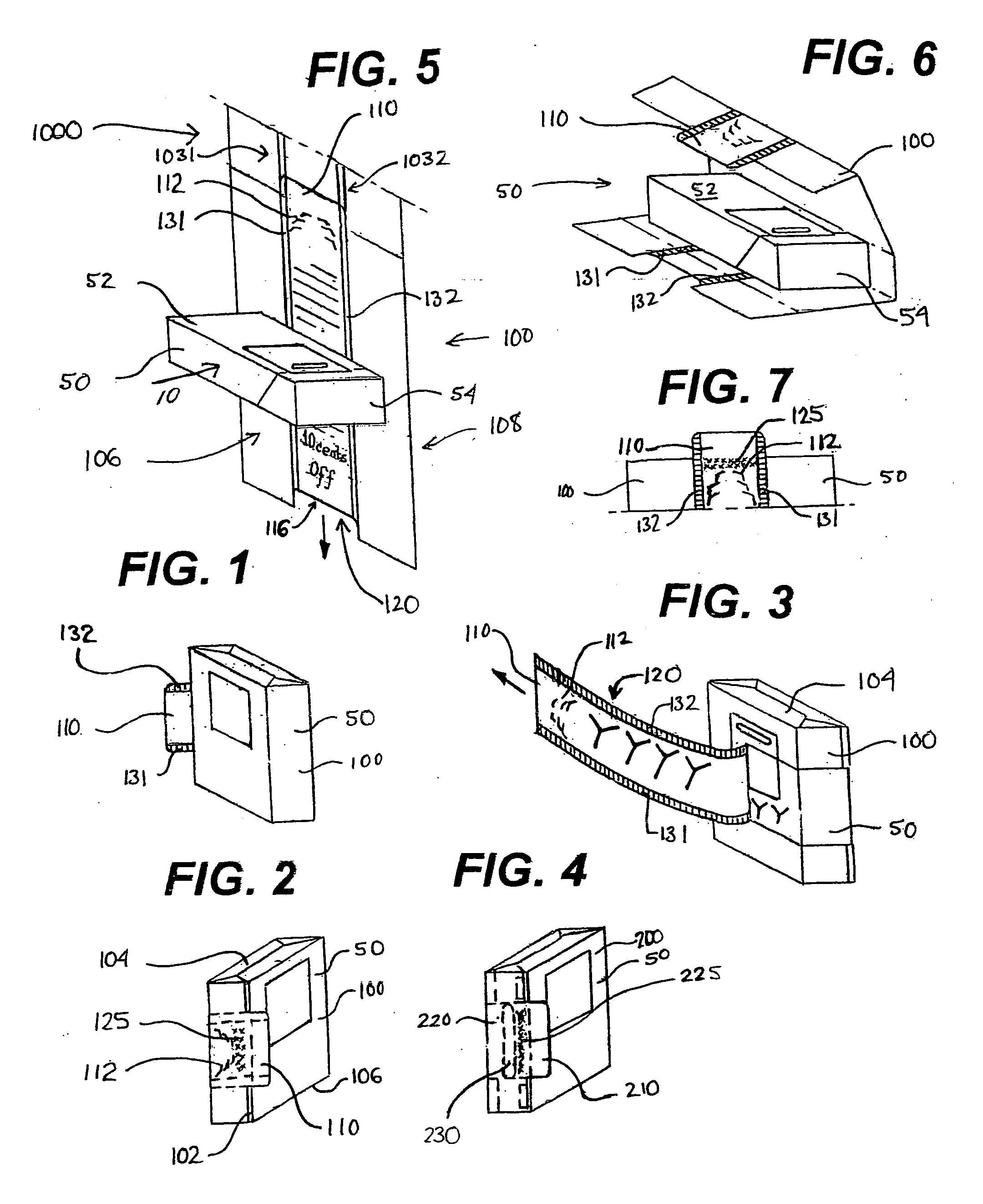

Easy opening of film wrapper

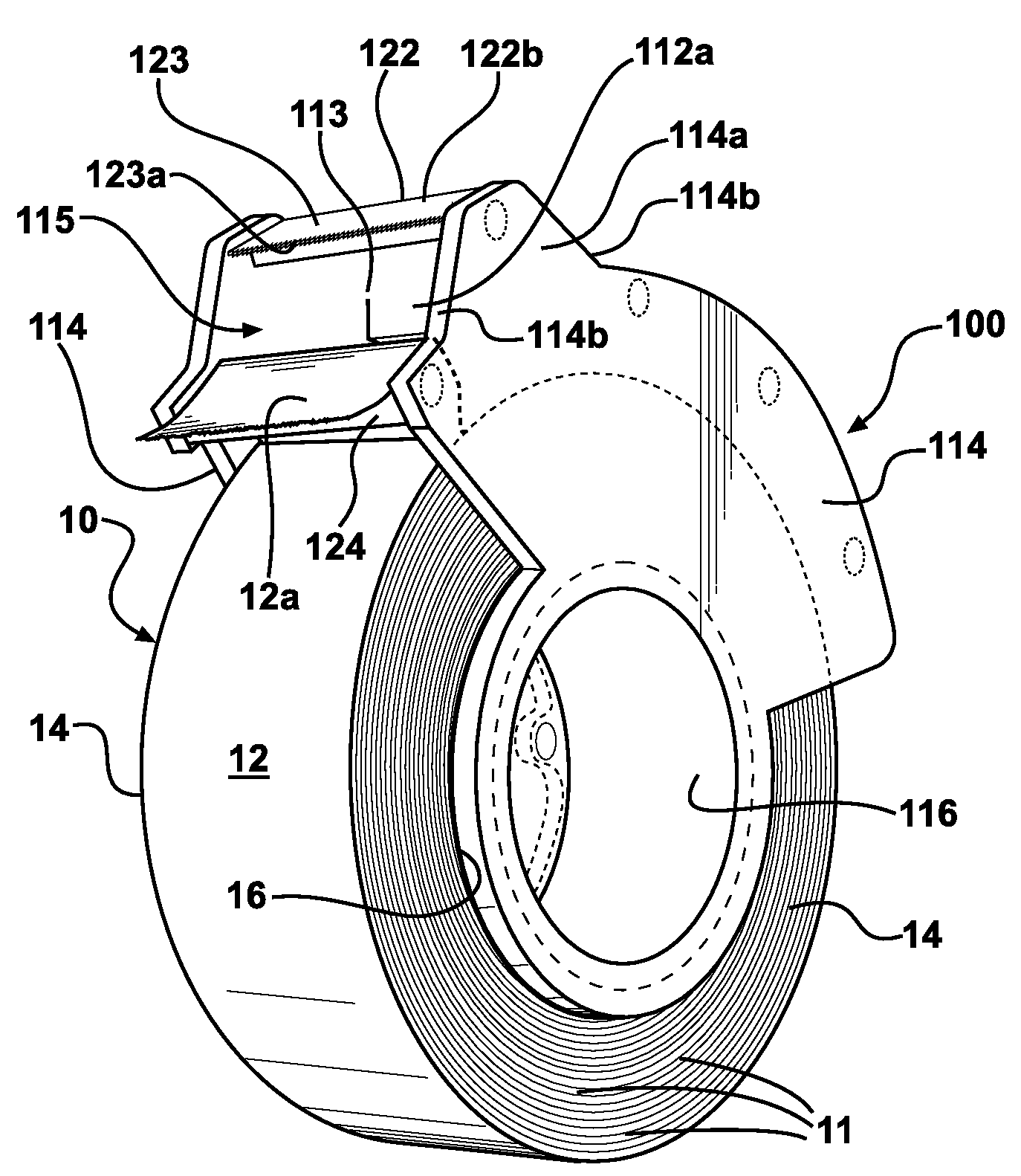

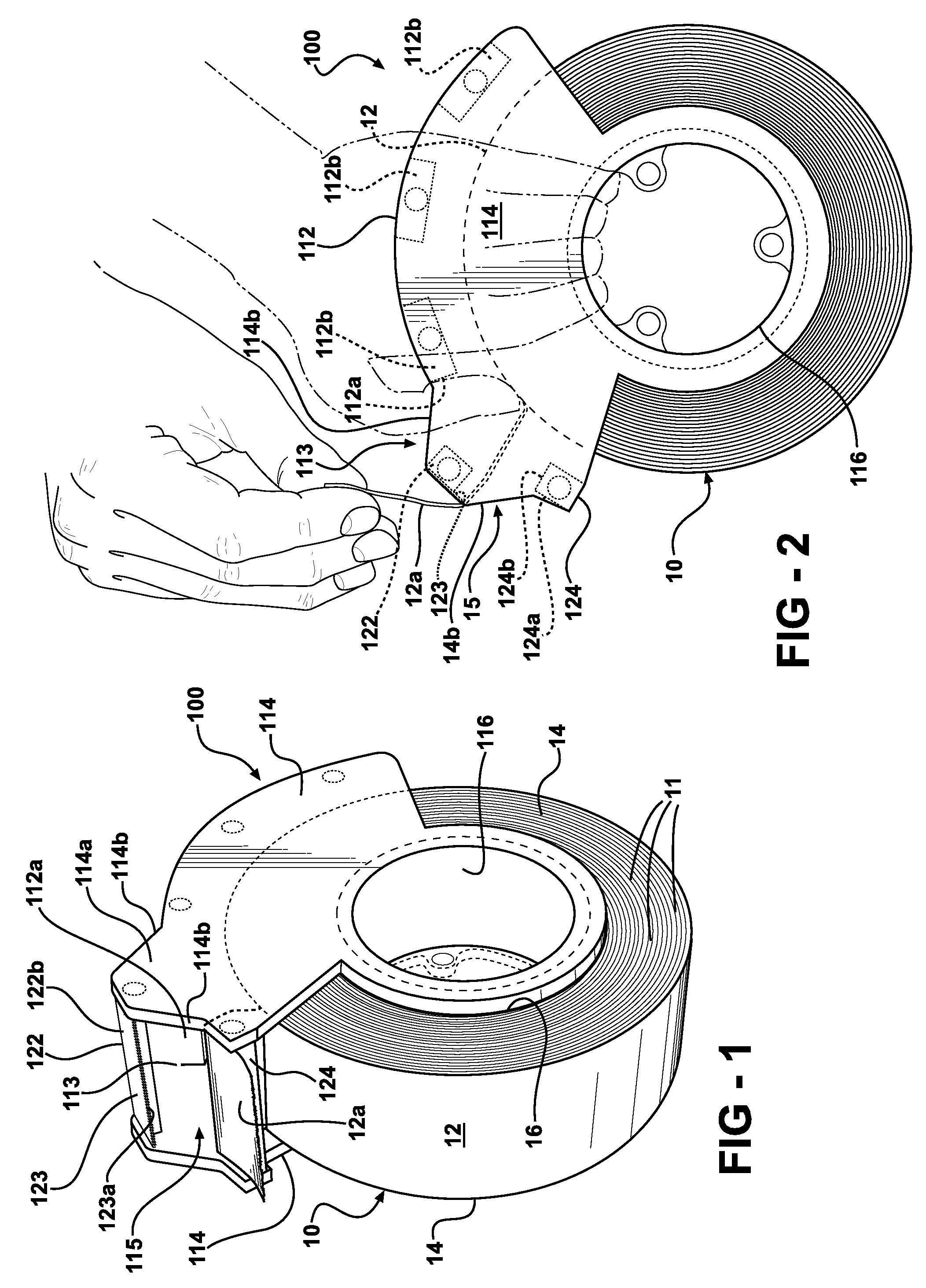

A film wrapper (99) comprises a tear tape (30) and at least one weakening line (10, 12) next to the tear tape (30) , the longitudinal axis of the at least one weakening line (10, 12) being substantially perpendicular to the tear tape (30) (perpendicular weakening lines (10, 12)) . An article is wrapped into the film wrapper. A multi- bladed knife (100) used for producing the film wrapper comprises a U-shaped or V-shaped first blade (110) and a second linear blade (112) parallel to the longitudinal axis of said first blade (110) and a third linear blade (111) perpendicular to the longitudinal axis of the first blade (110) .

Owner:PHILIP MORRIS PROD SA

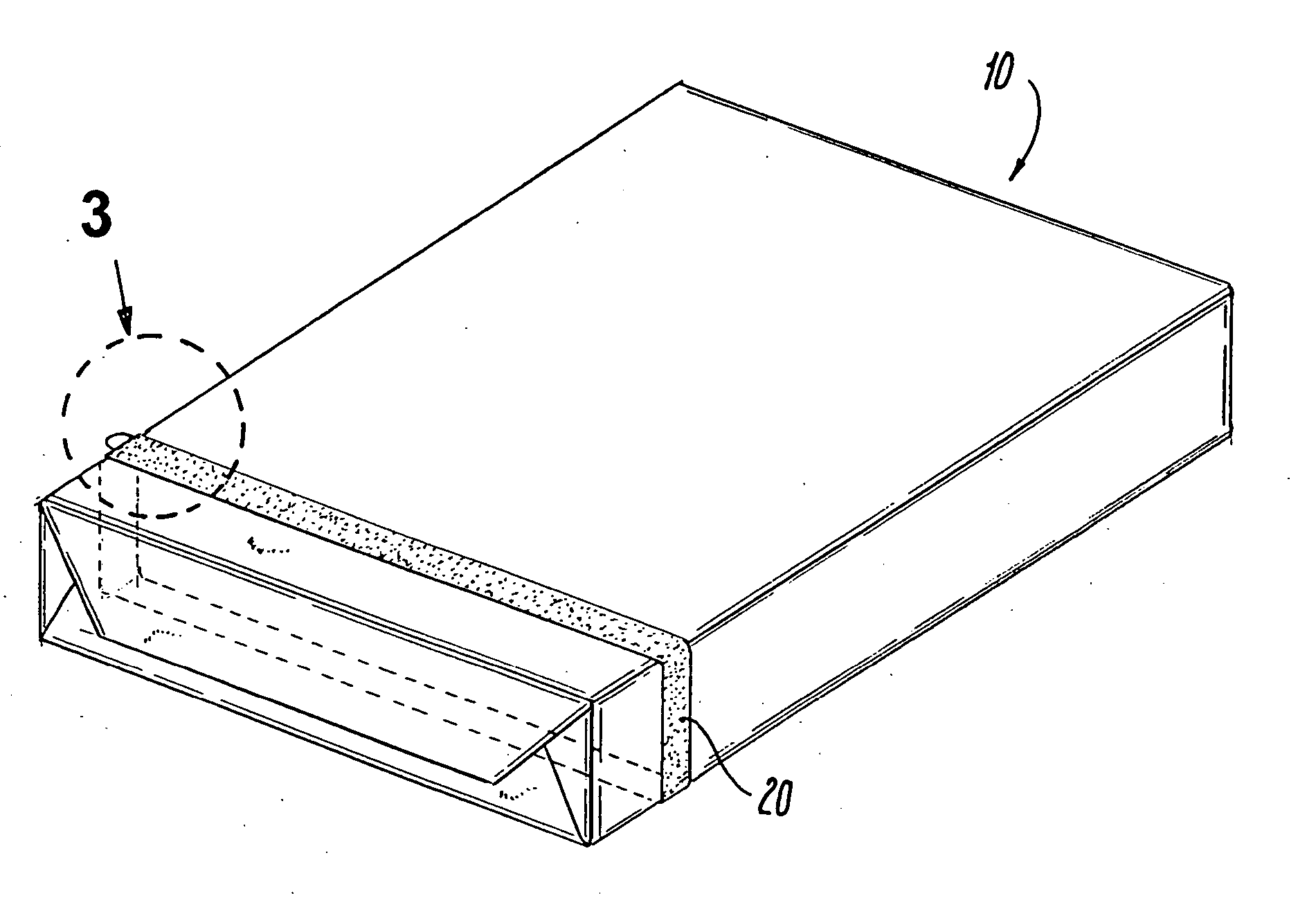

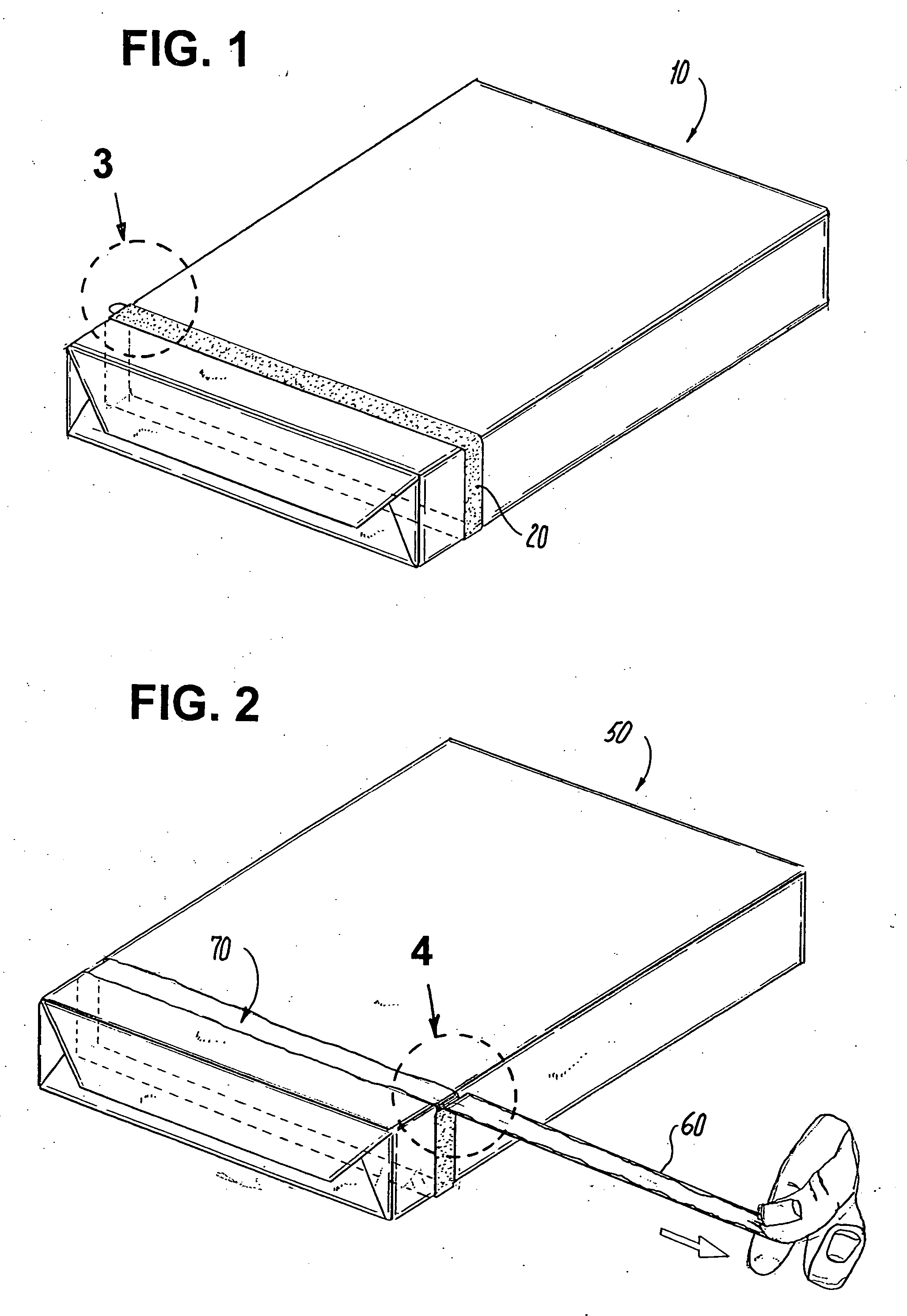

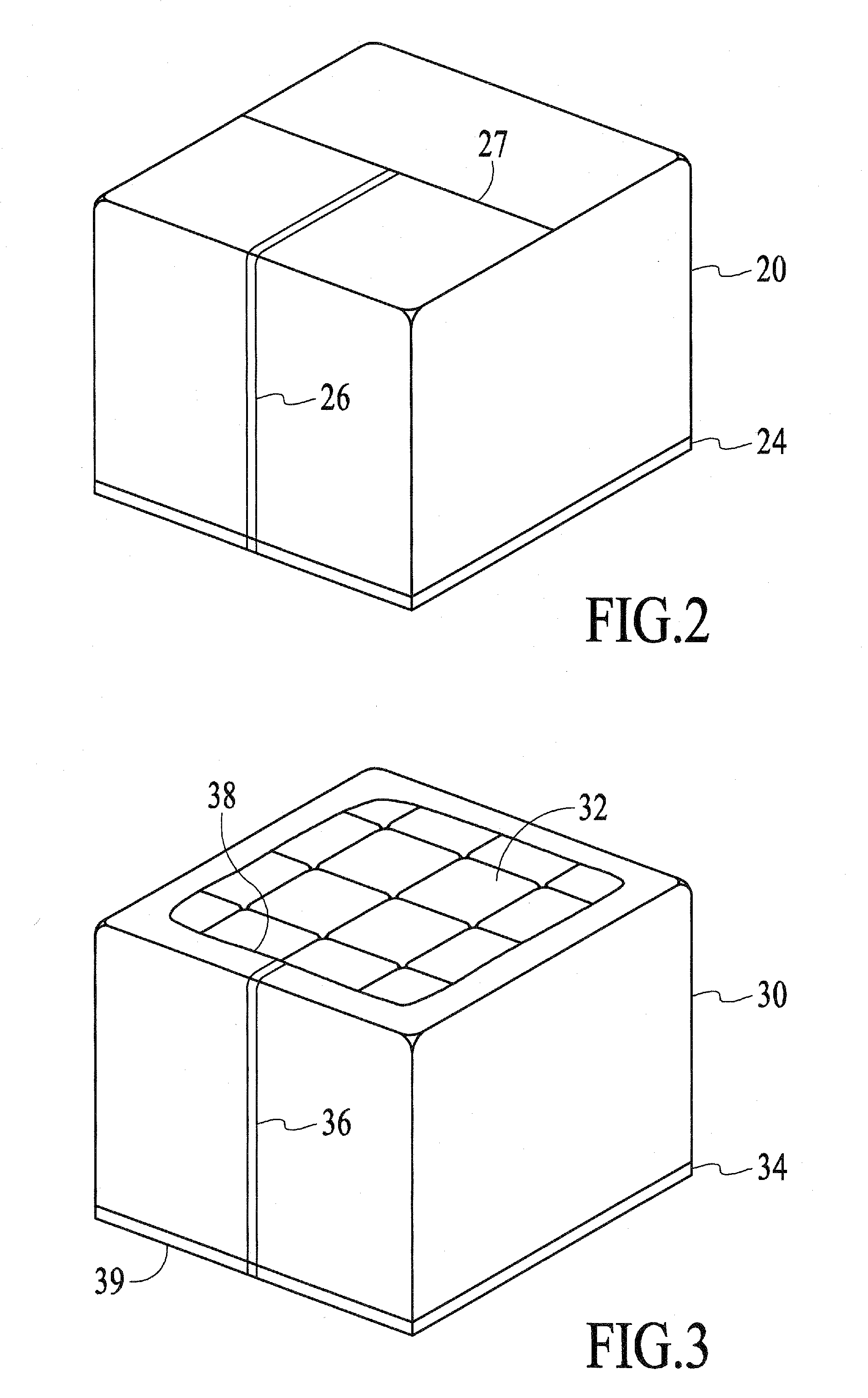

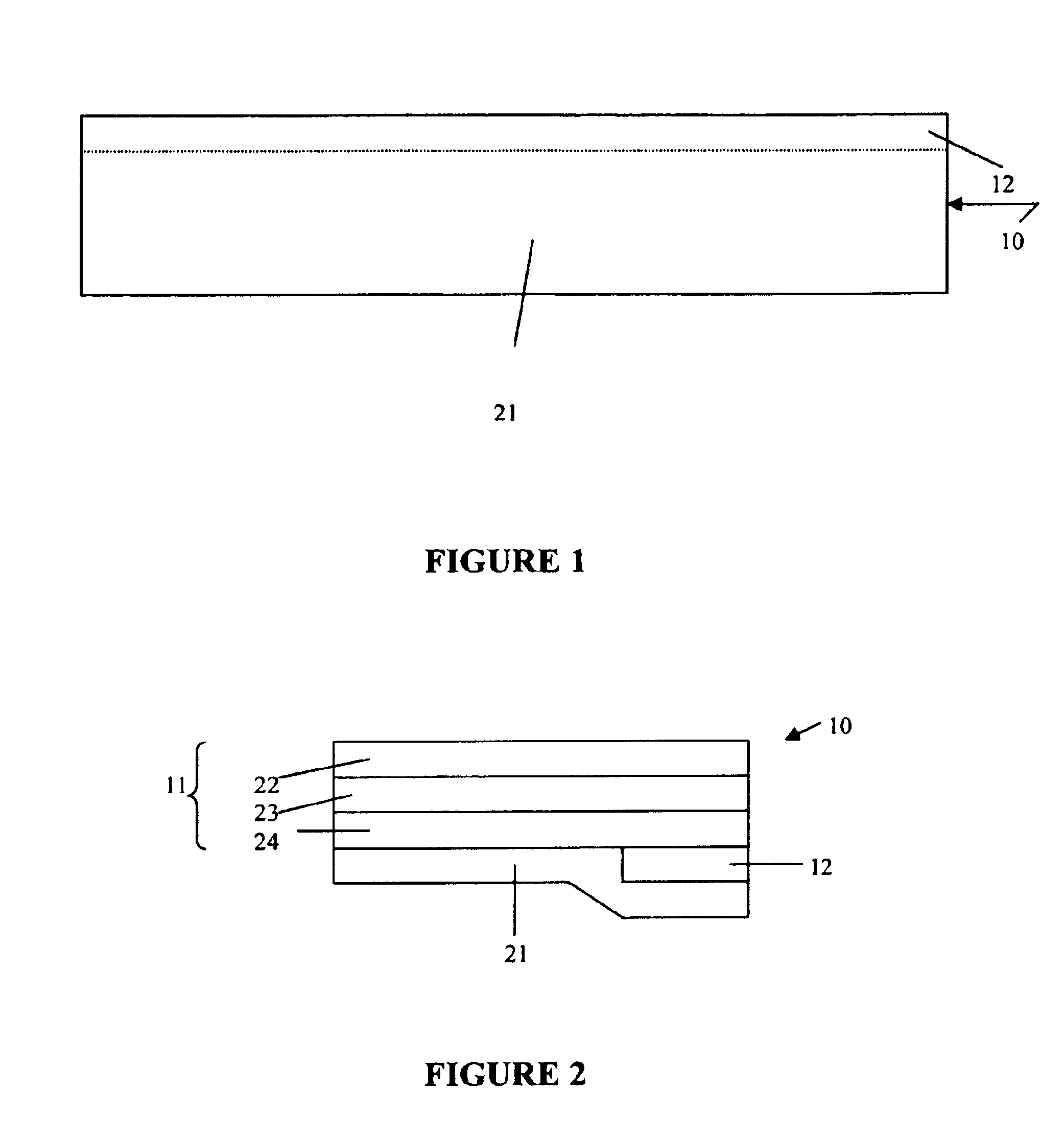

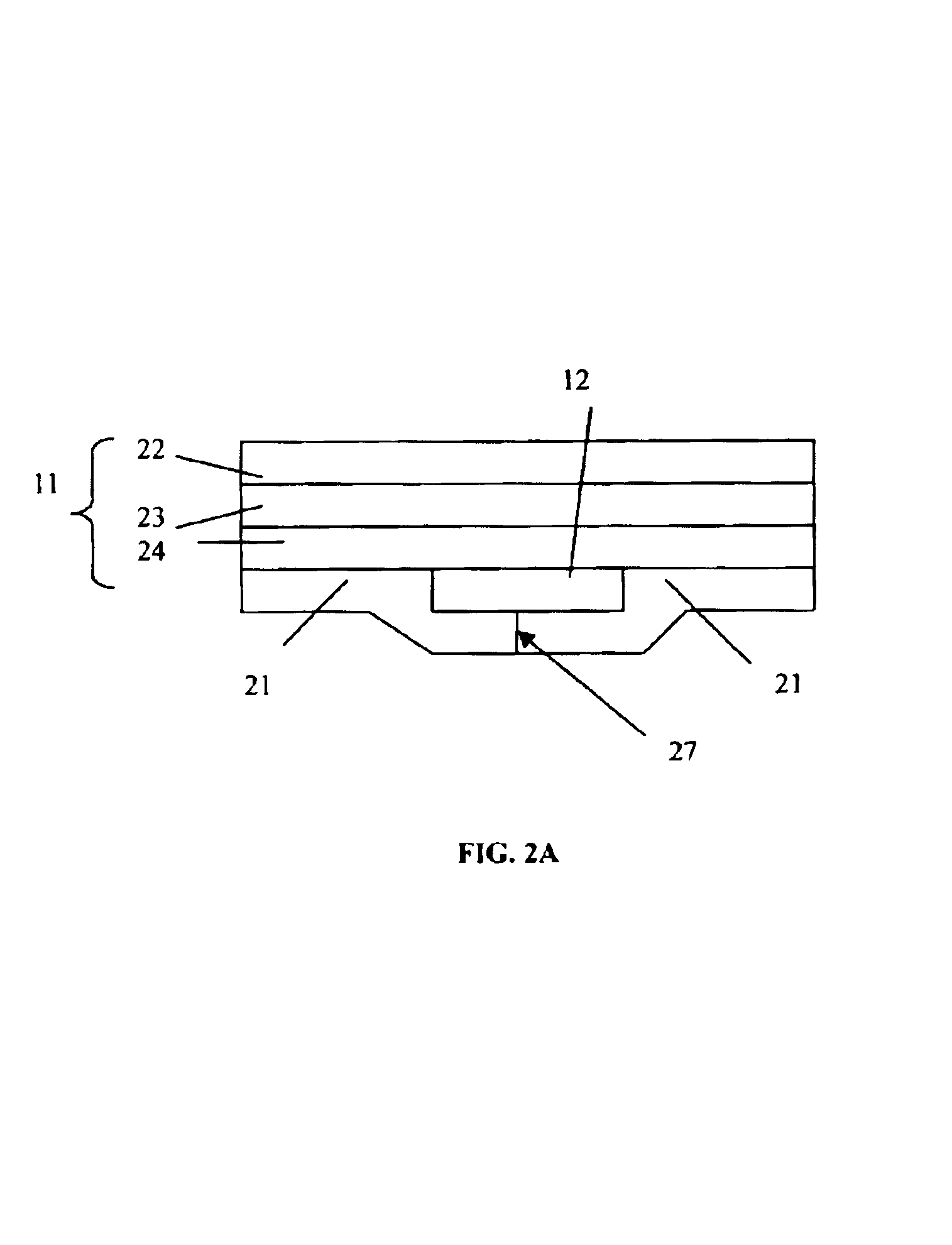

Ream wrap packaging with tear tapes

InactiveUS20050202191A1Prevents physical damage and scattering of loose partAvoid physical damagePaper article packagingWrappersEngineeringTear tape

A packaging for reams of cut paper involving tear tapes made of plastic or paper material inserted into the ream wrap. The tear tapes may be pulled to tear off and open one end of the wrapped ream, leaving the remaining packaging intact to serve as a storage and dispenser for partial reams of paper.

Owner:COATING EXCELLENCE INT

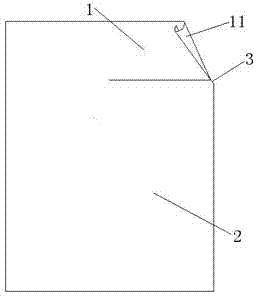

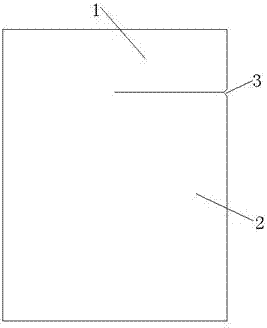

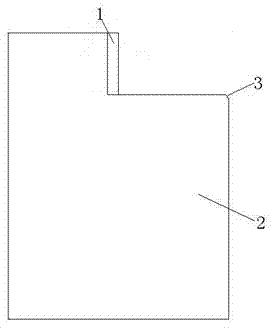

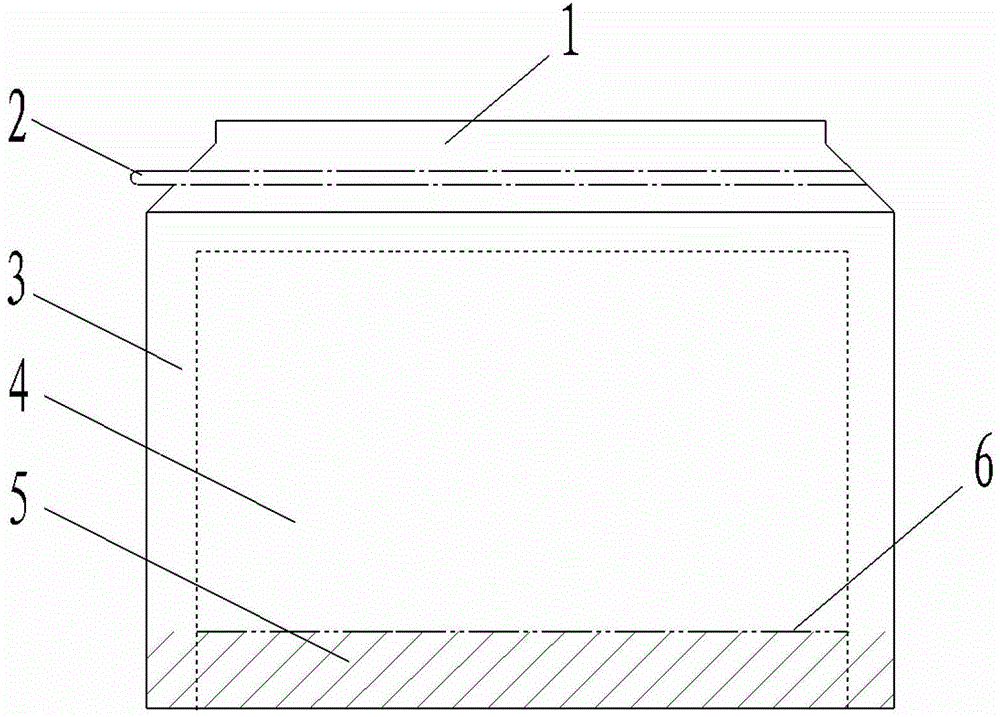

Food packaging bag

The invention discloses a food packaging bag. The food packaging bag comprises a bag body and a tear tape connected with the upper end of the bag body, the edges of the tear tape and the bag body, which are connected, are provided with a tear opening; the curly portion of the tear tape is arranged above the tear opening and is naturally curly; when the tear tape is torn along the tear opening, the curly portion can be horizontally rolled up along the boundary line of the bag body and the tear tape. The food packaging bag avoids the inconvenience existing when a packaging bag is torn open.

Owner:中山市聚达包装制品有限公司

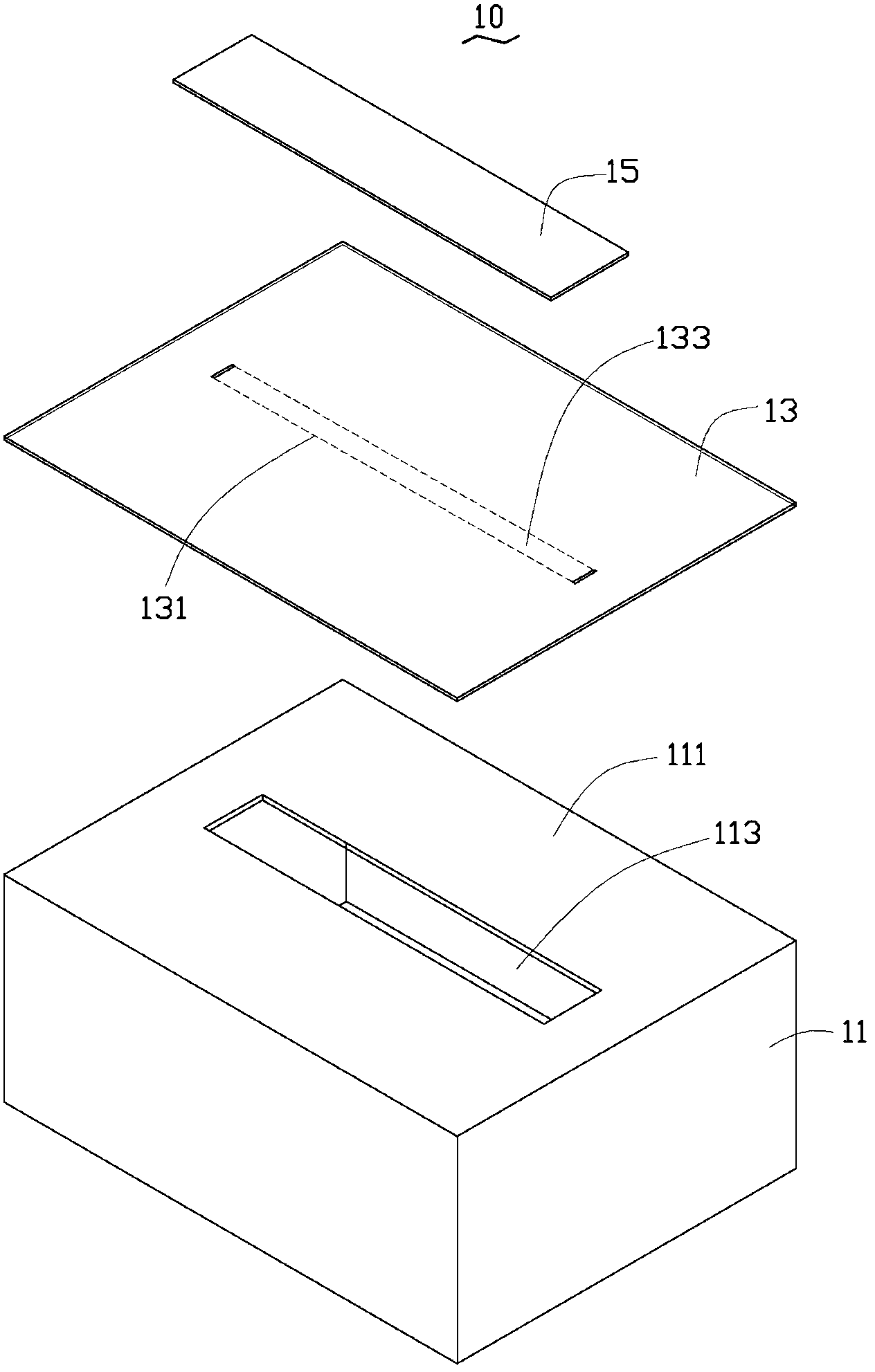

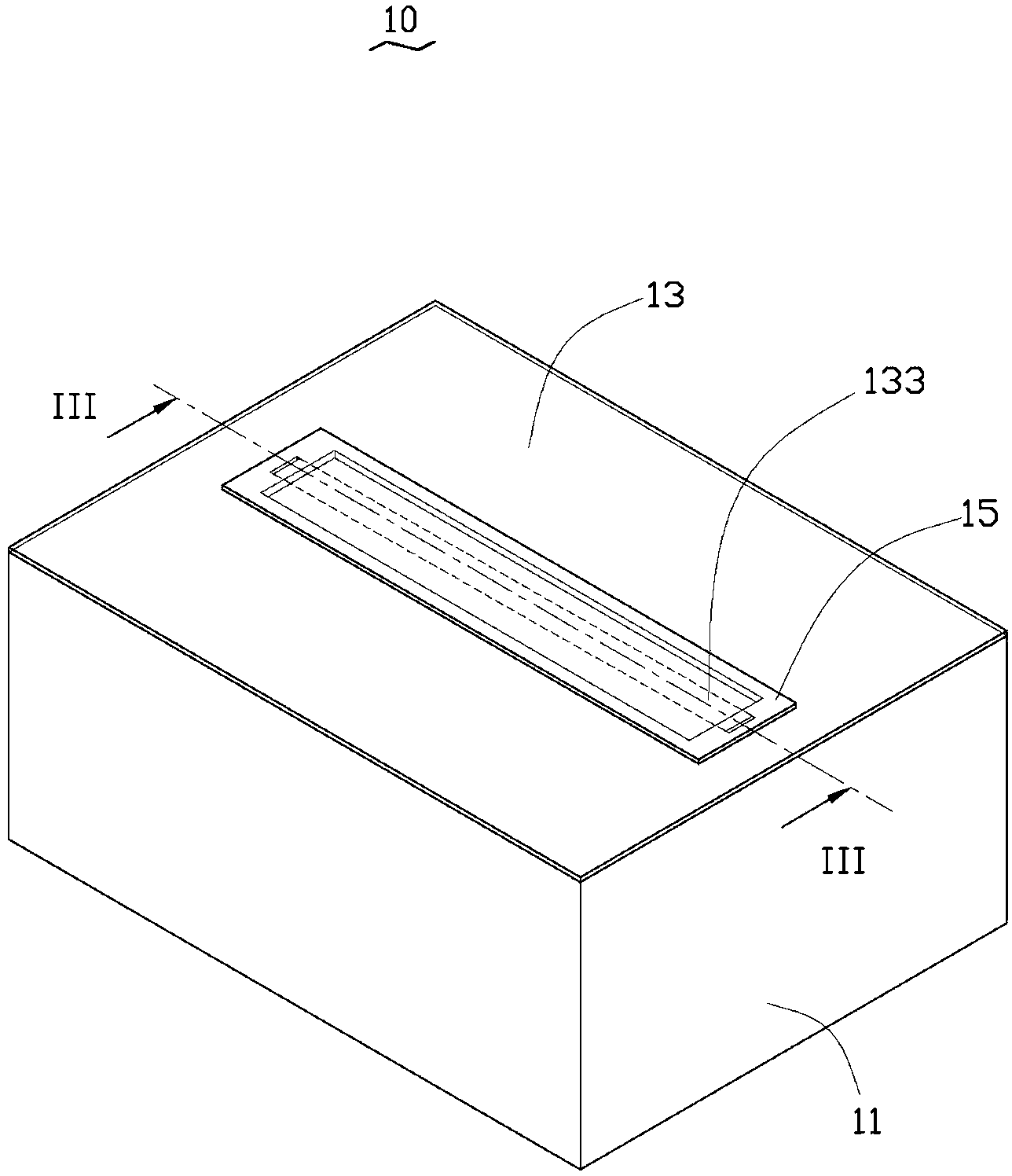

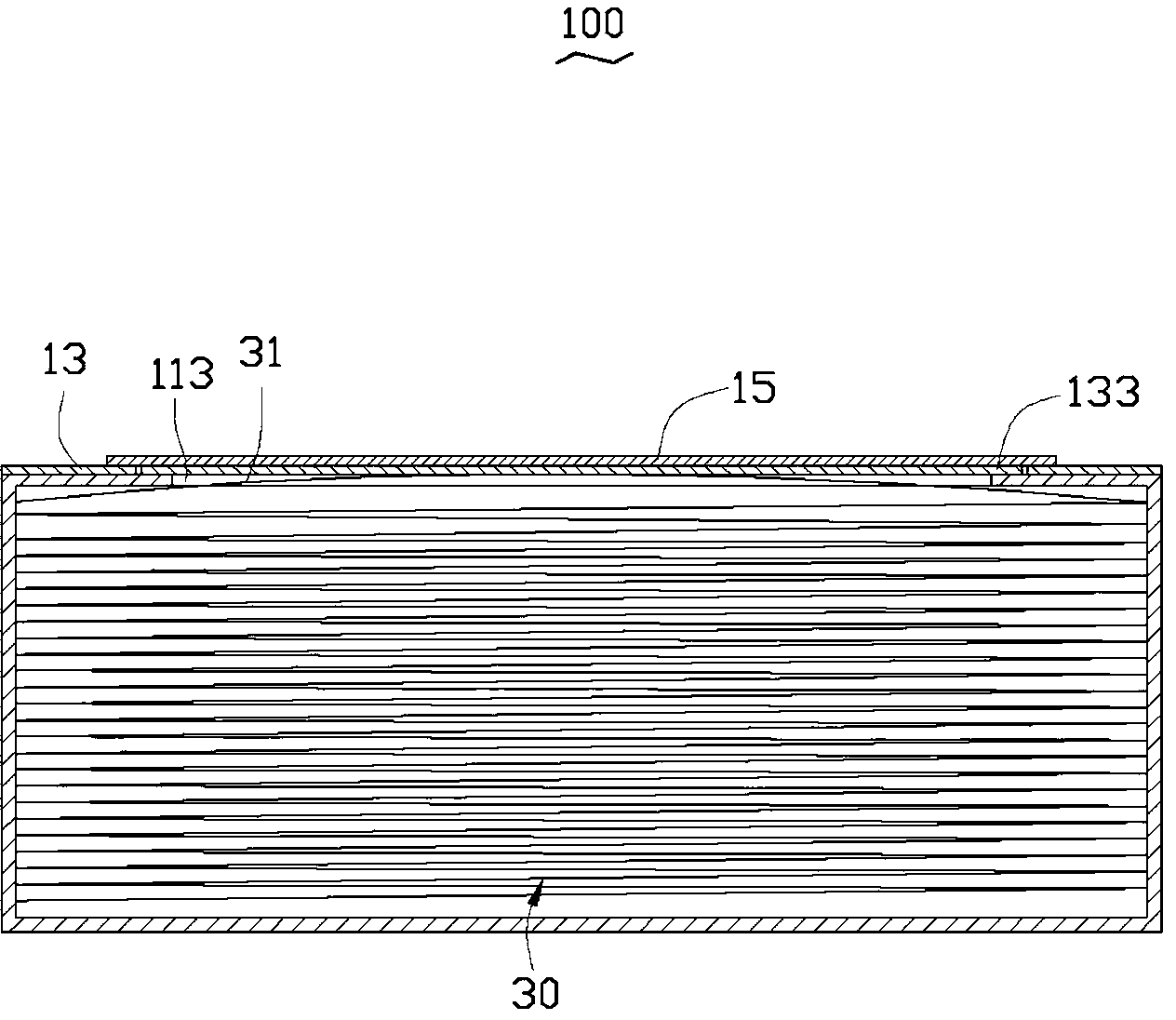

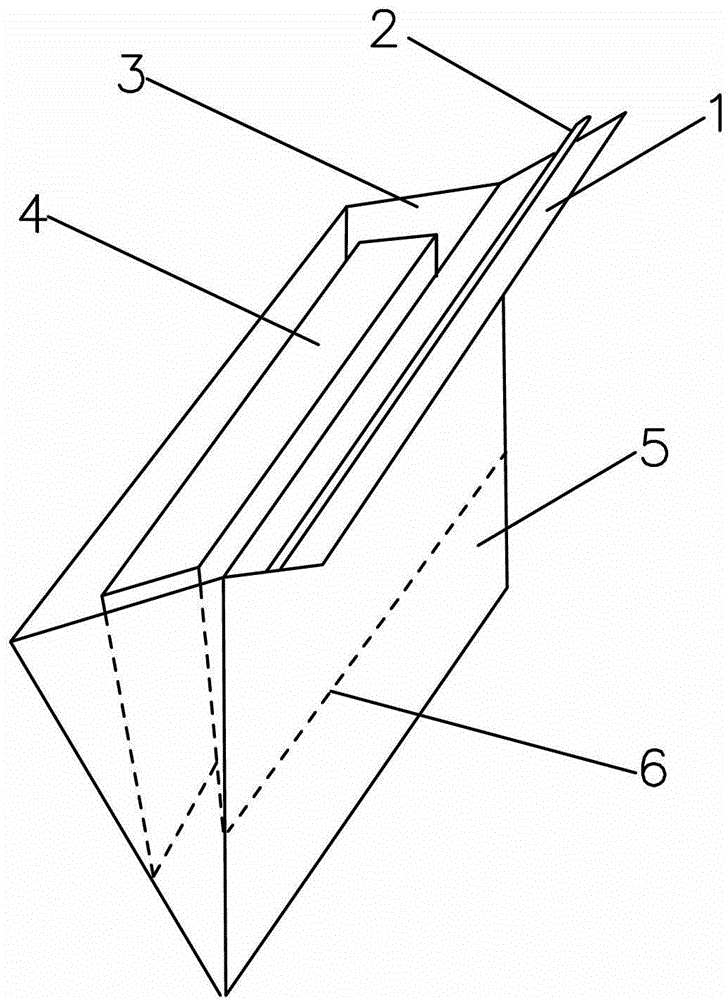

Tissue box and manufacturing method thereof

A tissue box comprises a body, wherein the body is used for containing a paper stack which is formed through a plurality of pieces of paper overlaid sequentially. The tissue box further comprises a tear tape and a paper-taking tape which is arranged on the body in a separable mode, wherein the paper-taking tape comprises an inner surface and an outer surface, wherein the outer surface is bonded to the tear tape, the inner surface is bonded to the nearest piece of paper in the body away from the paper-taking tape, the tear tape is used for tearing the paper-taking tape so as to enable the paper-taking tape to be separated from the body, and therefore the paper which is bonded to the paper-taking tape is pulled out from the inner portion of the body. The tissue box brings convenience to a user to pull out the first piece of paper. The invention further relates to a manufacturing method of the tissue box.

Owner:GOLD HONG YE PAPER

Product packaging including digital data

InactiveUS20070001011A1Open efficientlyAccessories for indicating/preventing prior/unwanted useRecord information storageDigital dataAdhesive belt

Light sensitive materials applied in shipping materials, including security seals and tear tape, for authentication, discrimination and recognition of items.

Owner:VERIFICATION TECH INC

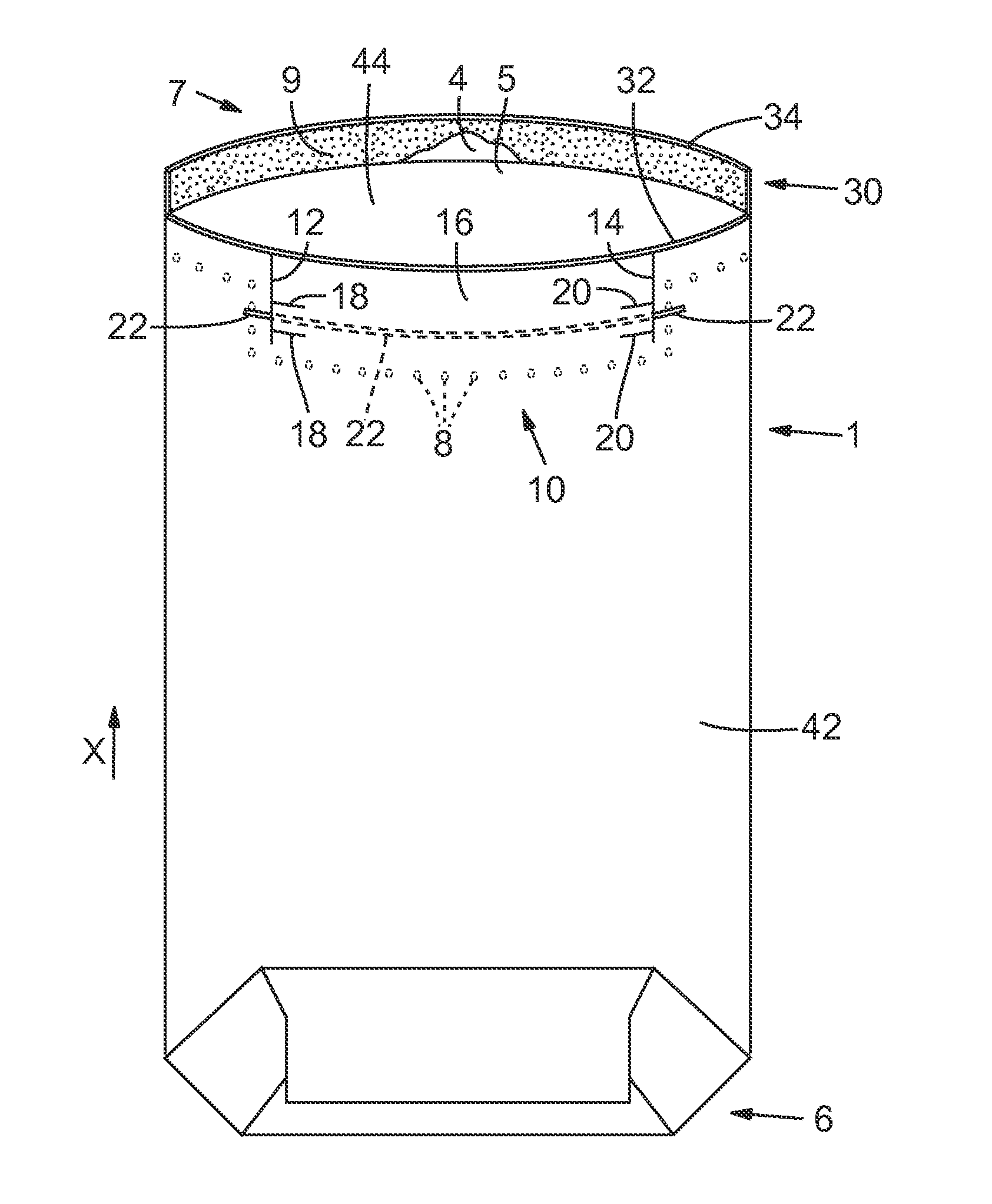

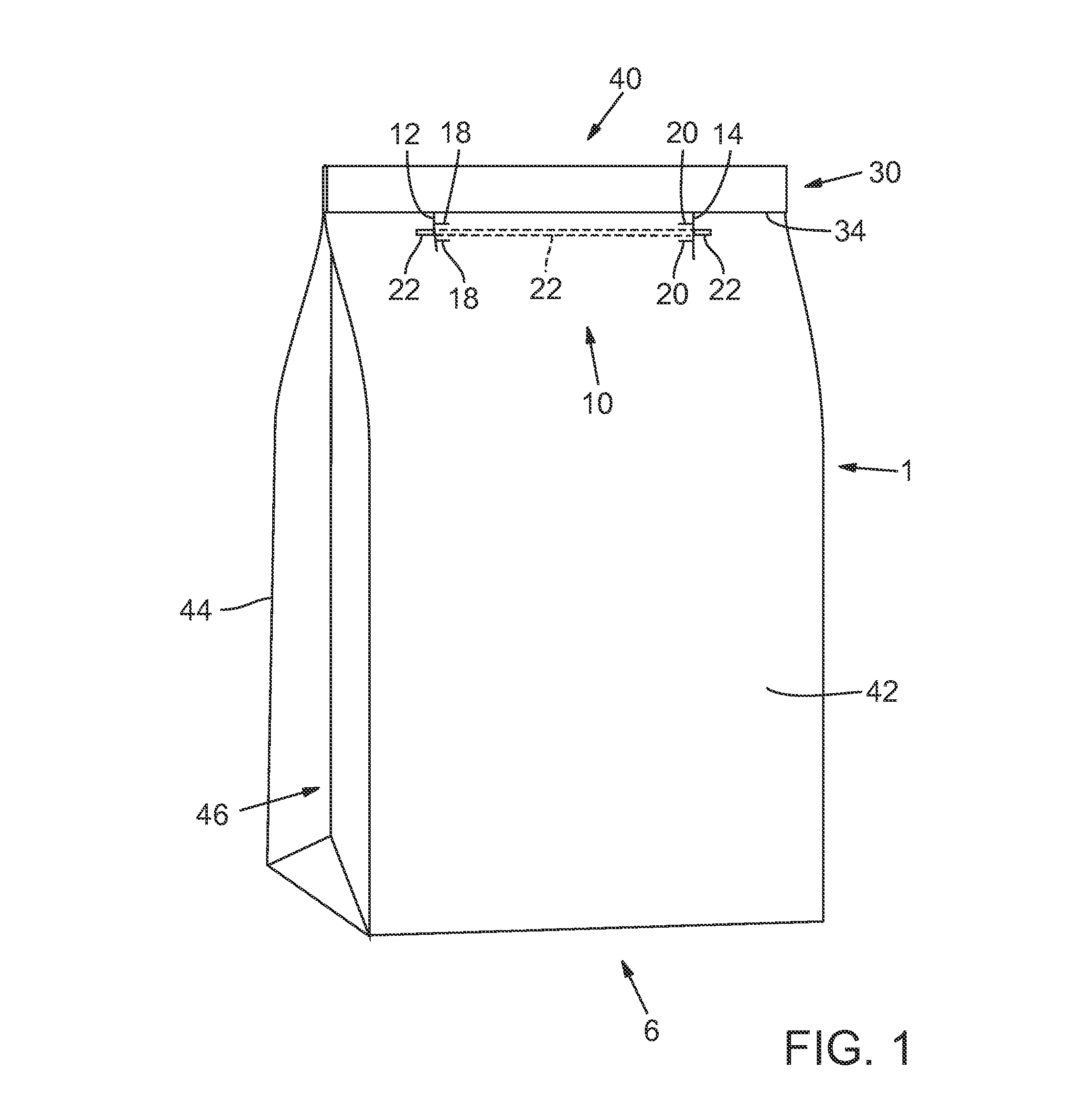

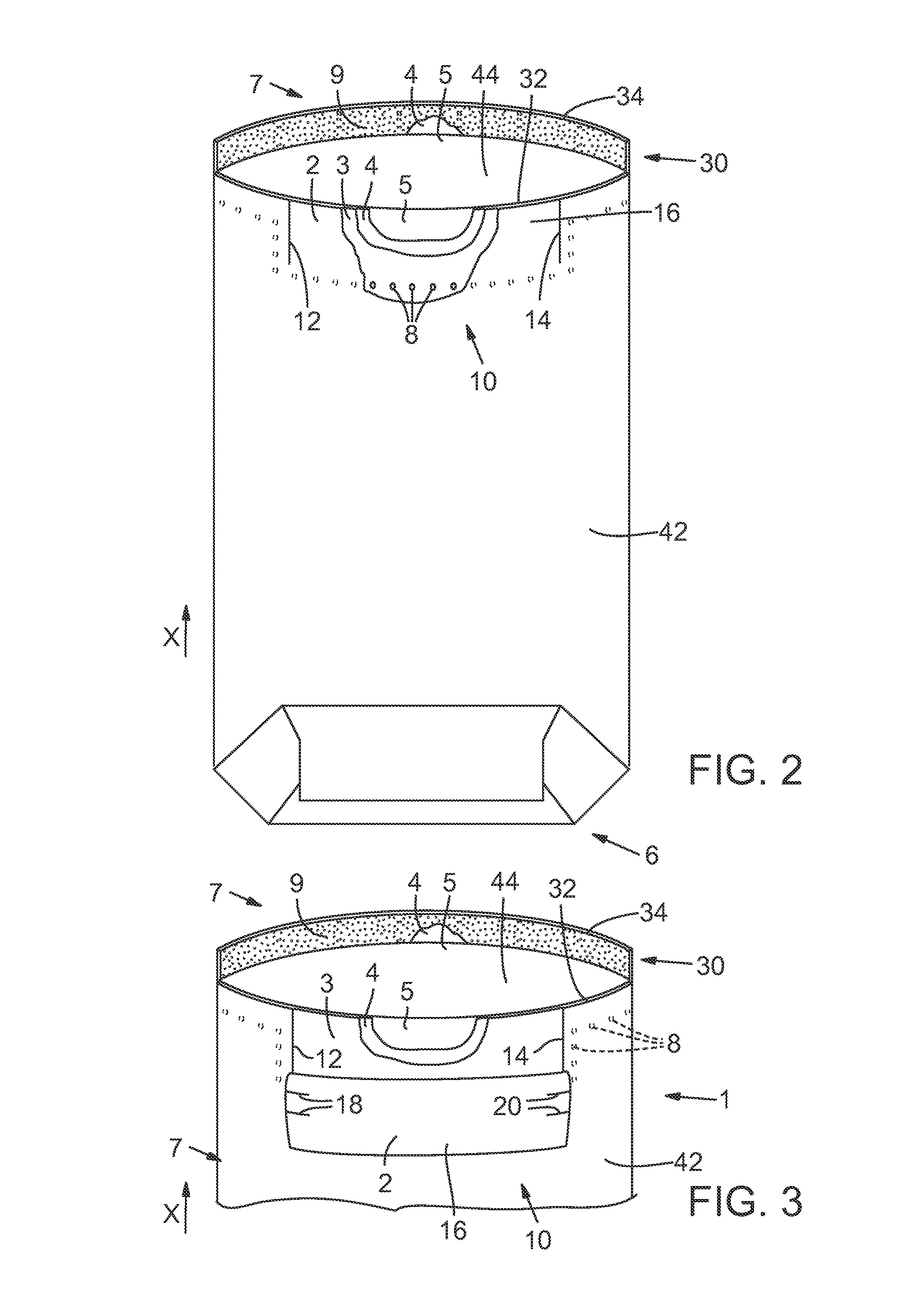

Easy Open Apparatus and Method for Multi-Ply Bags

An easy open apparatus for multi-wall bags and a method for making such bags are disclosed. The bag has a closed end and an open end and the rear panel is stepped relative to the upper edge of the front panel. A tear-tape strip is adhered to an inner surface of a flap formed in the outer layer of the front panel and extends partly across the panel with ends of the tear-tape exposed. To open the bag, the user grasps one exposed end of the tear-tape and pulls it outwardly away from the bag, thereby tearing the outer paper layer across the flap to form a “pocket” or “handle” that the user may grasp to tear the bag open.

Owner:STANDARD MULTIWALL BAG MFG +1

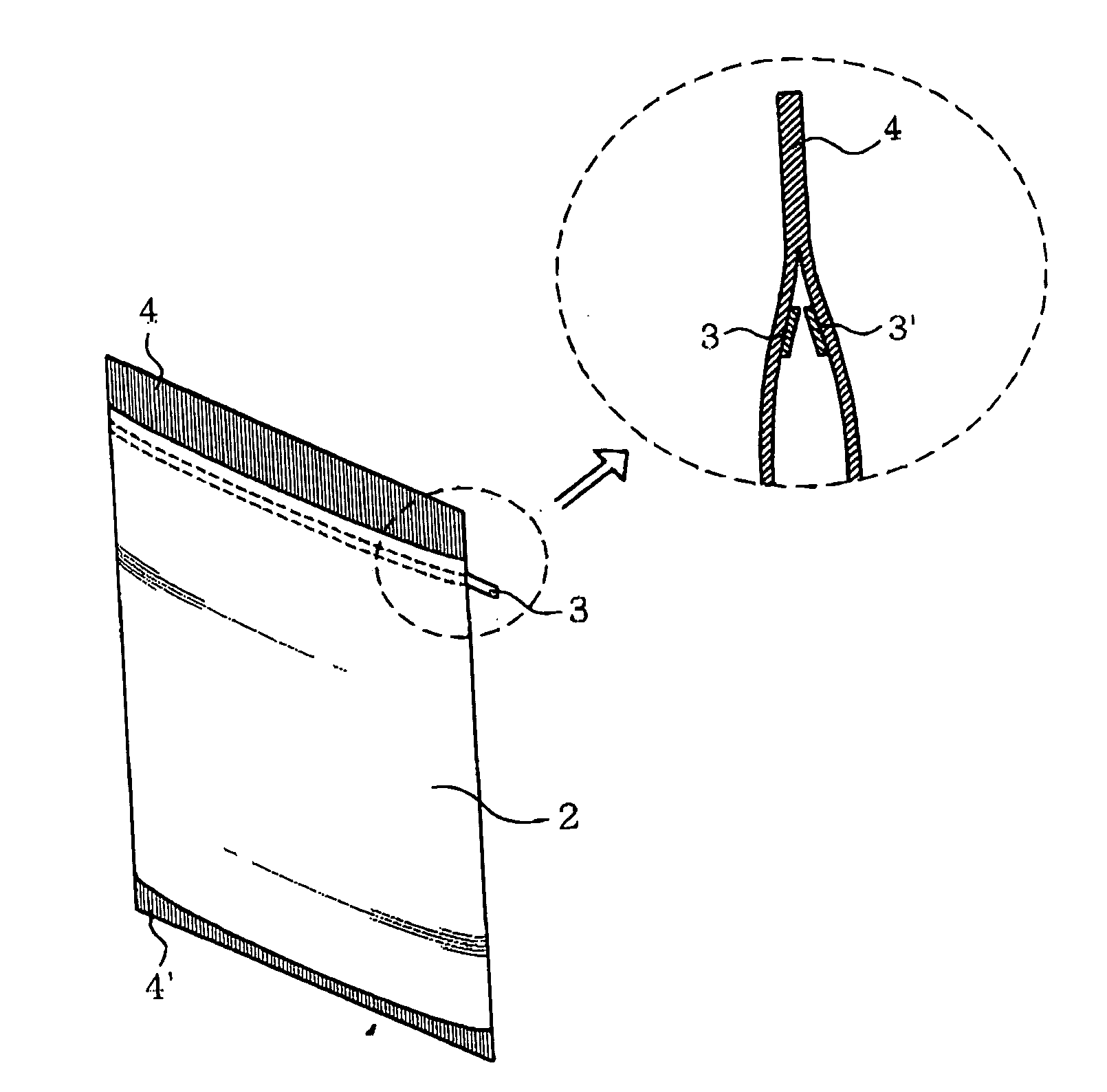

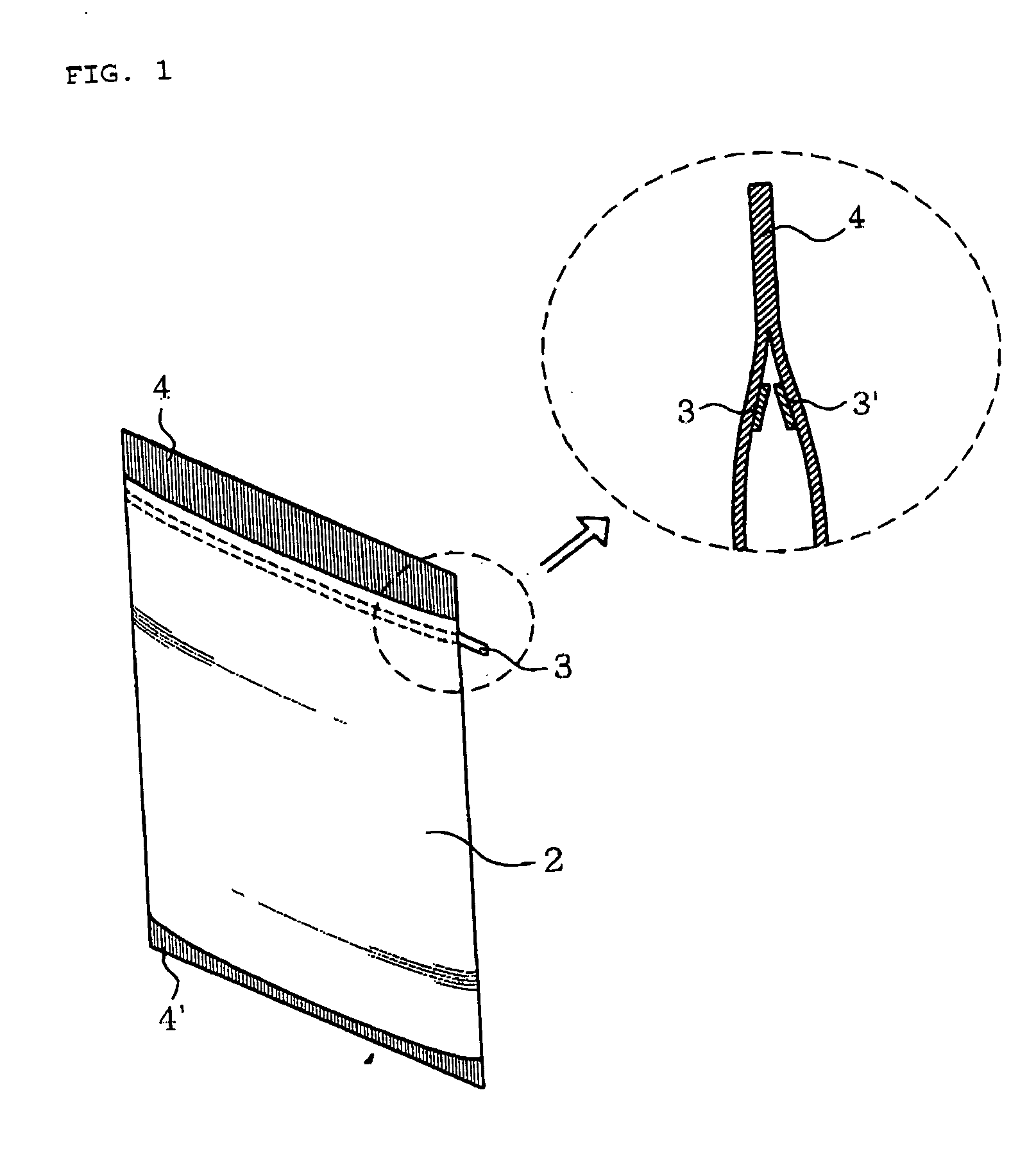

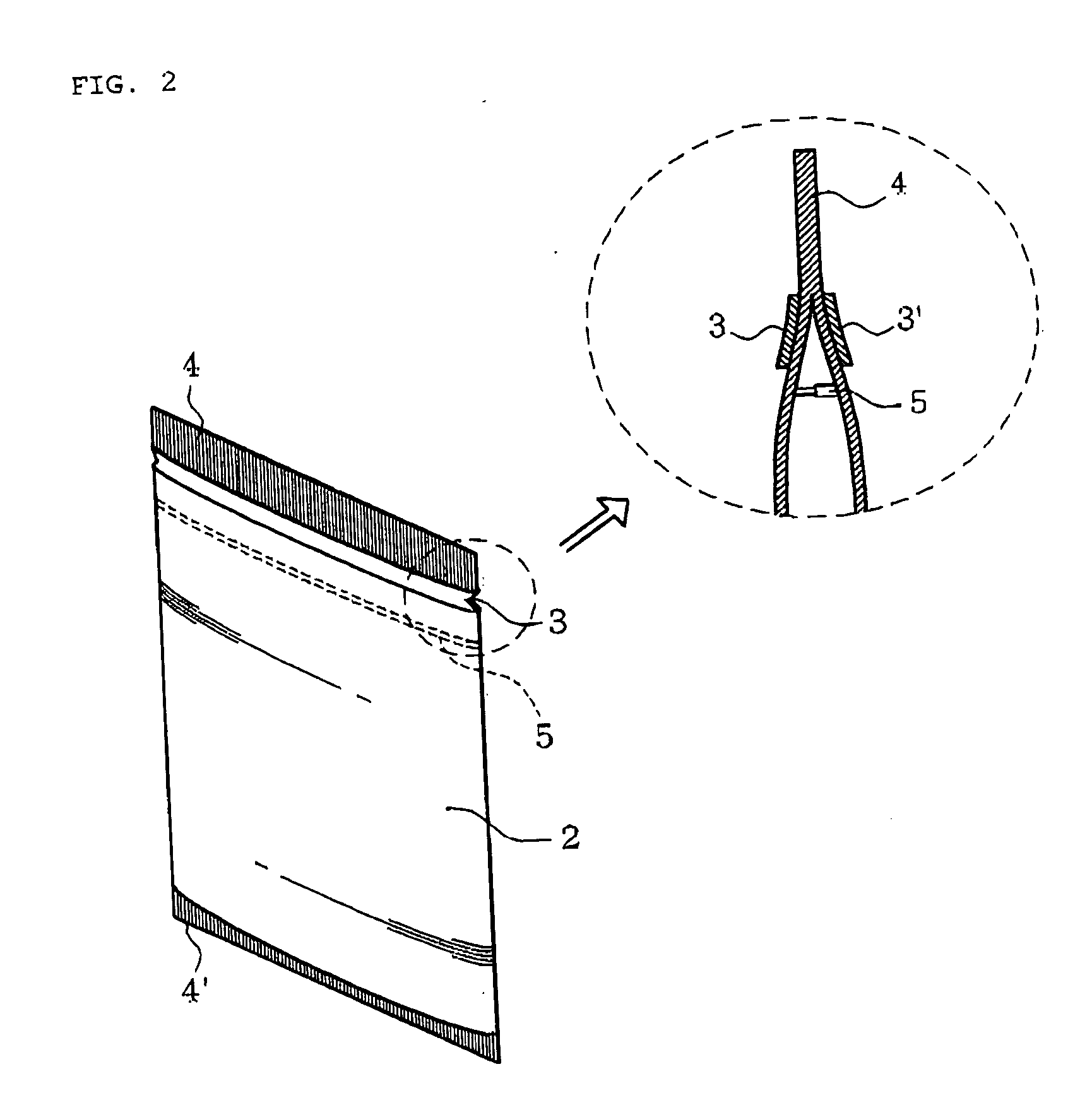

Plastic film bag with tear tapes

A plastic film bag, including a seam welded part, a plastic film bag body part, and a tear tape to open the plastic film bag, is disclosed. In the plastic film bag, the tear tape is made of a monodirectionally oriented polypropylene film and is attached to an outer surface of the plastic film bag at a predetermined position between the seam welded part and the plastic film bag body part. Because the plastic film bag of the present invention is realized such that the tear tape is attached to the outer surface of the plastic film bag using an adhesive, the tear tape does not compromise the function of sealing the package, but allows the package to be completely sealed, unlike a conventional tear tape attached to the inner surface of a plastic film bag.

Owner:KIM SUN CHANG

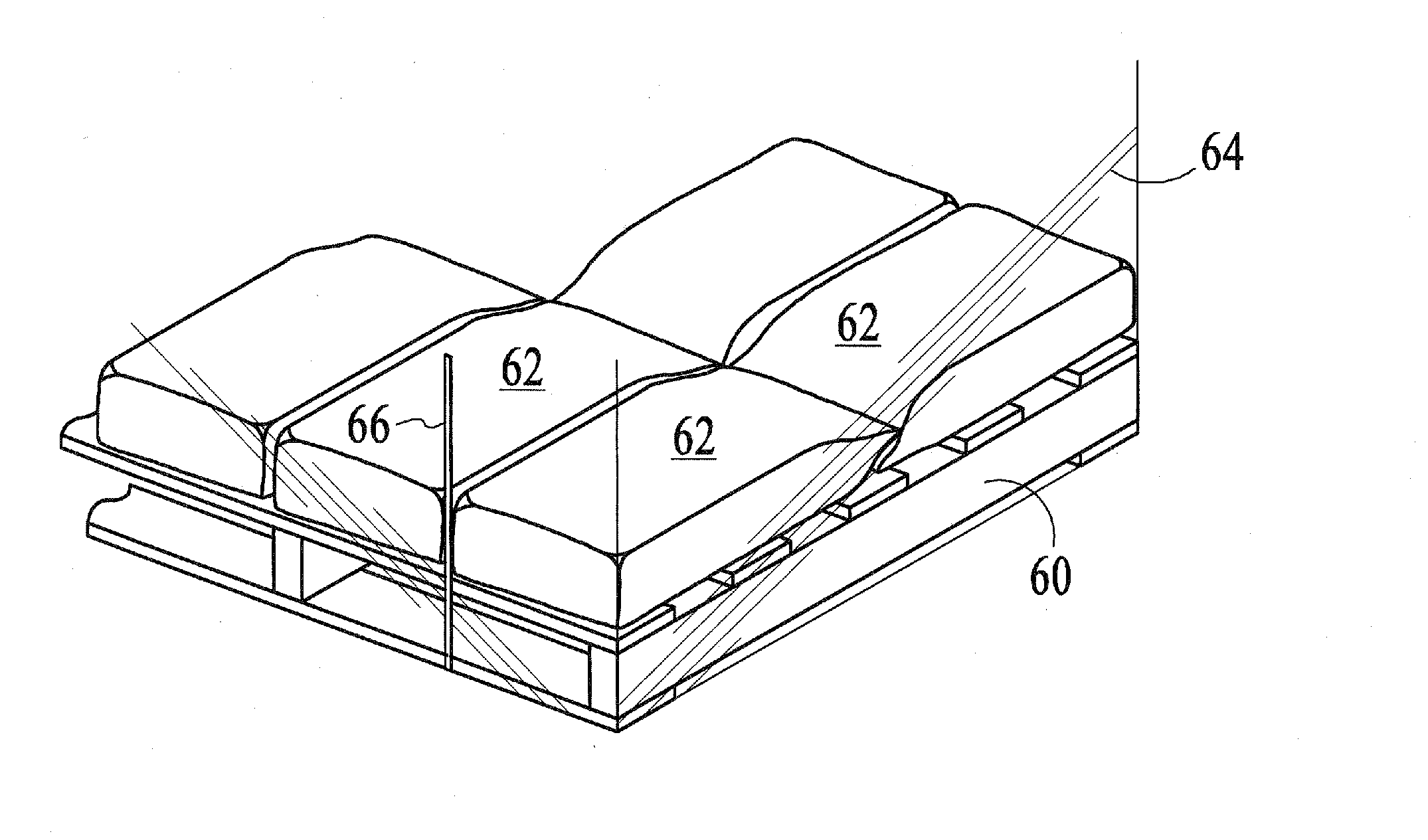

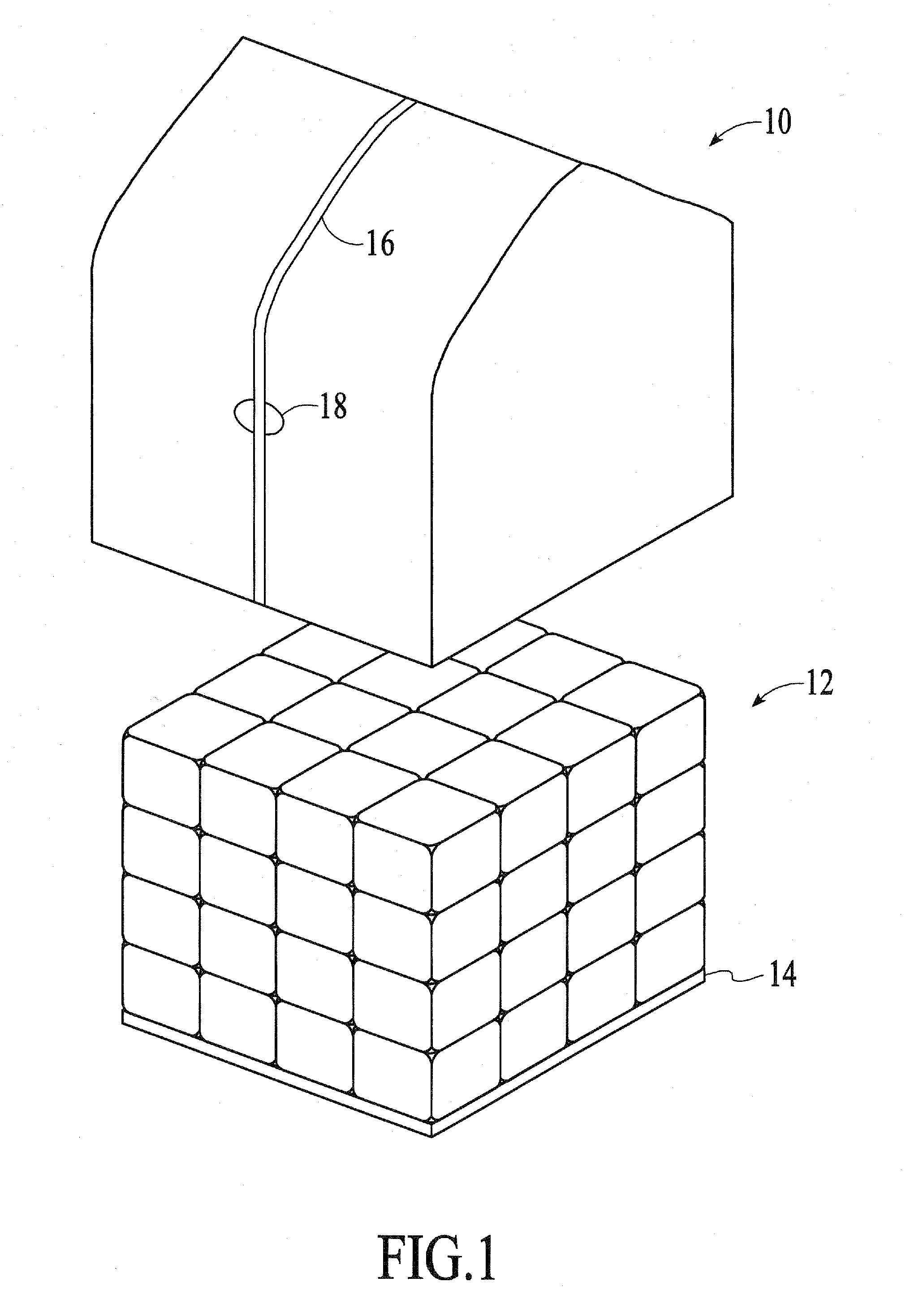

Pallet Hood Tear Tape

A packaging system for products on a pallet or slipsheet has a shrink hood or stretch hood with a tear tape for easy opening at the product use location without damaging the product. The tear tape may be a shearing tear tape to allow for cutting through the tough film of the hood or the tear tape may be aligned with laser perforations to cooperate with the tear tape.

Owner:THE CLOROX CO

Rice dumpling and preparation process thereof

The invention discloses a rice dumpling which, from inside to outside, sequentially comprises a dumpling body, an inner plastic film, a dumpling leaf and an outer plastic film. The invention also discloses a preparation process of the rice dumpling, which comprises the following steps of hermetically wrapping the dumpling leaf between the inner plastic film and the outer plastic film, taking the cooked dumpling body, attaching the inner plastic film of the dumpling leaf to the dumpling body, folding, and sealing so as to obtain the rice dumpling. According to the invention, through pre-wrapping the dumpling leaf between food-grade plastic films with an easily-torn tape, the dumpling leaf is kept in a clean state; no poaching process is required to be performed, so that the delicate fragrance of the dumpling leaf is kept more completely, and before the rice dumpling is eaten, through a short-term reheating process, the delicate fragrance of the dumpling leaf is emitted; and when the rice dumpling is eaten, an operation of removing the easily-torn tapes is only required to be performed, thereby not only realizing the easy stripping of the dumpling leaf, but also keeping the delicate fragrance of the dumpling leaf well, so that the dumpling leaf is kept in a clean state, and the rice dumpling is eaten more conveniently; and the whole technological process can achieve automated production.

Owner:ZHEJIANG WUFANGZHAI INDAL

Films for envelopment of packages and methods of making thereof

Owner:PHILIP MORRIS USA INC

Moistureproof express delivery packaging bag easy to open

InactiveCN103144852AFree from harmWith waterproof and moisture-proof effectEnvelopesShock-sensitive articlesEngineeringTear tape

The invention discloses a moistureproof express delivery packaging bag easy to open, which comprises a packaging bag main body, wherein the packaging bag main body comprises an outer bag and a moistureproof inner bag arranged in the outer bag; an upper sealing bolt is arranged at the upper part of the outer bag; an easy tear tape with an unseal line is arranged on the upper sealing bolt; a gluing area is arranged at the area of the inner side of the outer bag, at the bottom of the outer bag; an interval breaking line is arranged around the moistureproof inner bag close to the bottom of the moistureproof inner bag; and the distance from the interval breaking line to the bottom of the moistureproof inner bag is the same as the height of the gluing area of the outer bag. With the adoption of the mode, the packaging bag has waterproof and moistureproof effects, protects documents mounted in the packaging bag against rain and water, and is simple and convenient to unseal.

Owner:SUZHOU VOCATIONAL UNIV

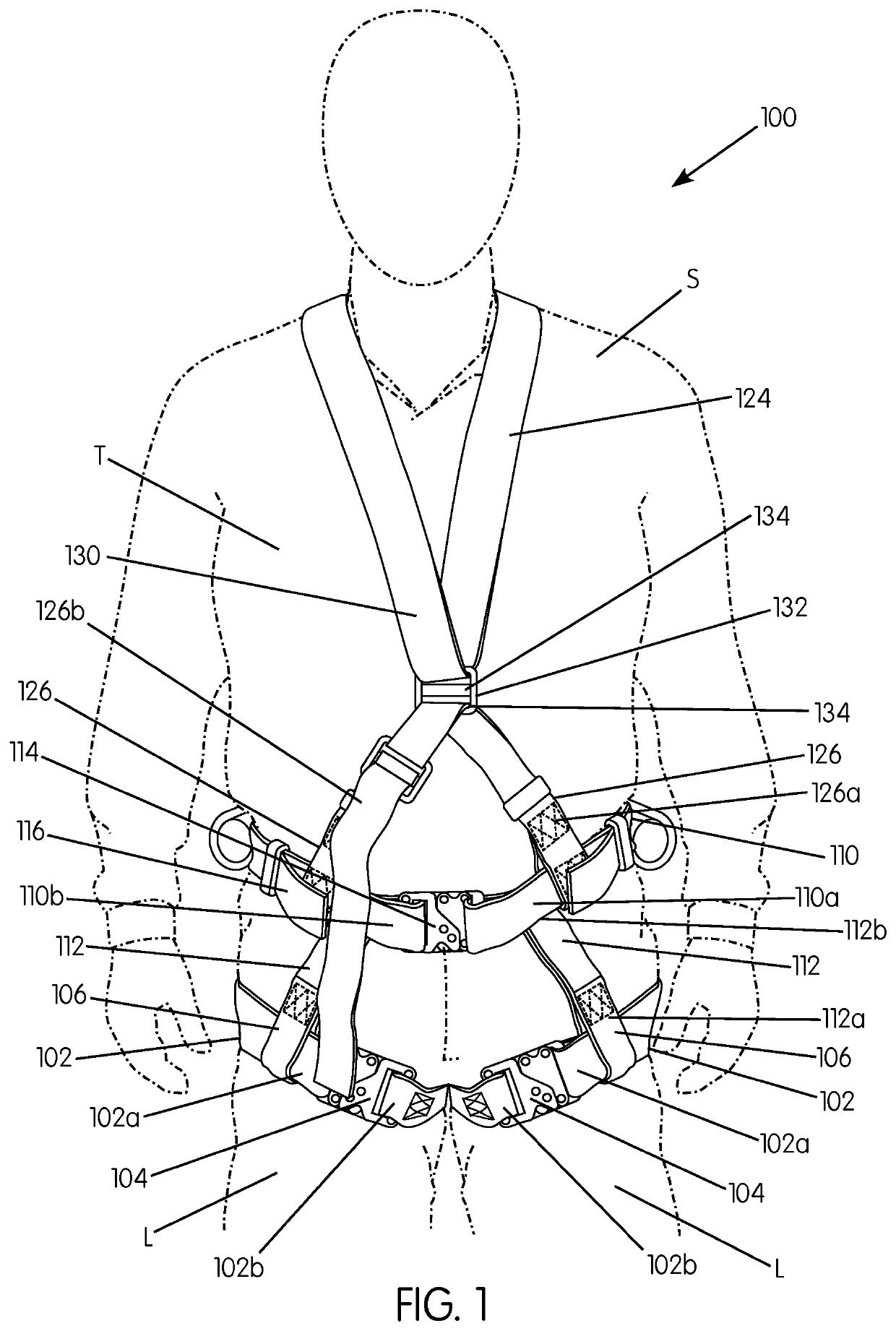

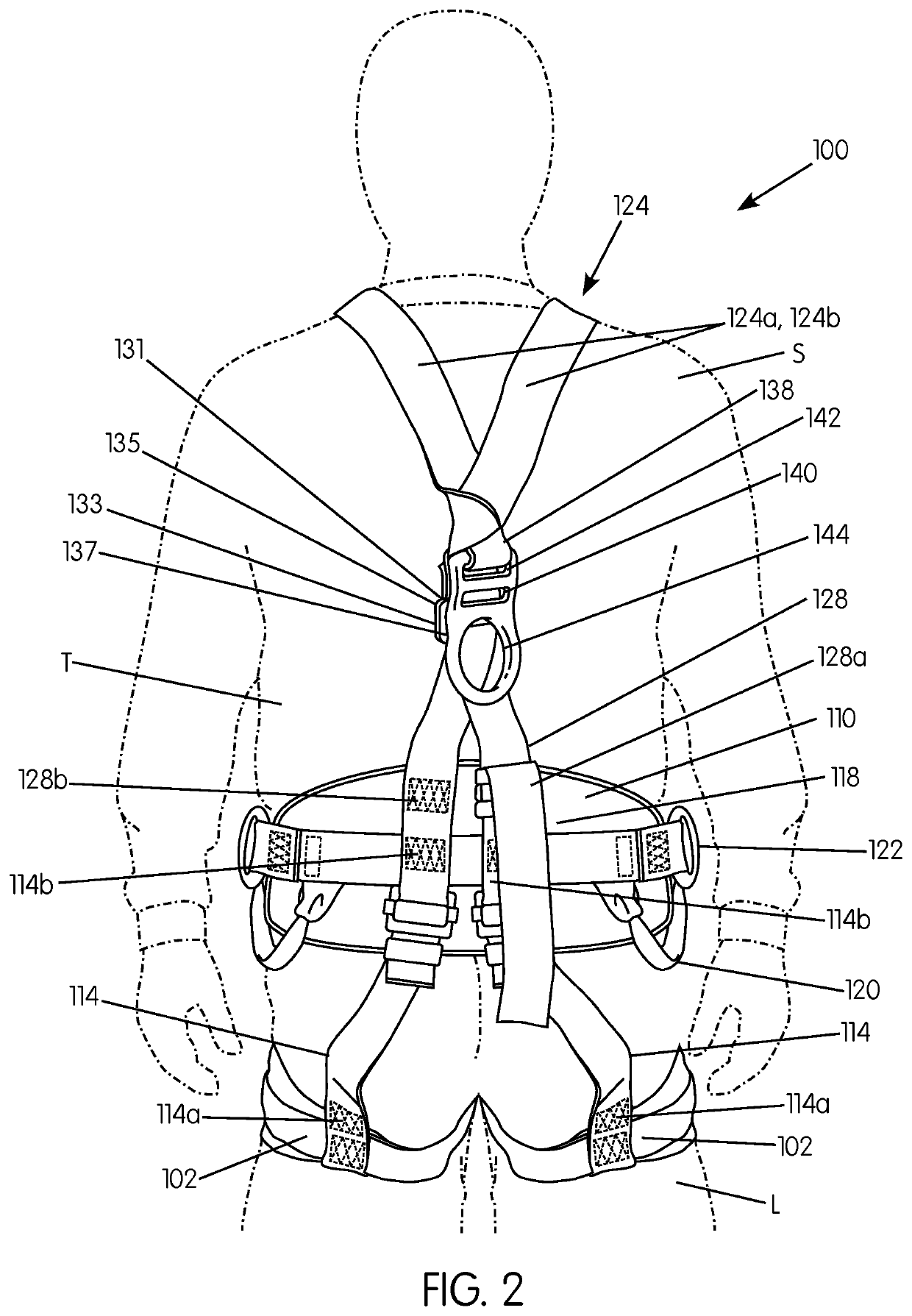

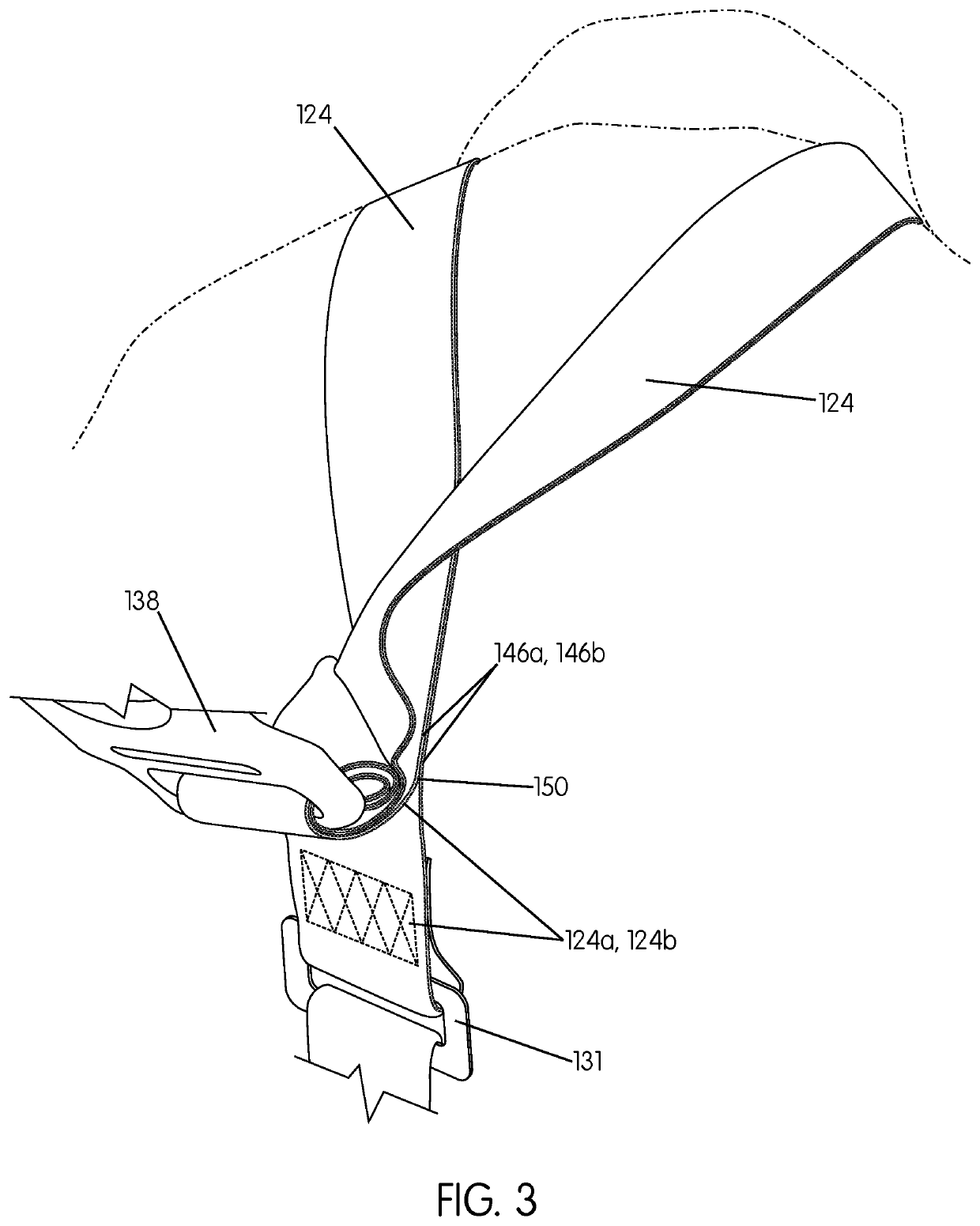

Harness with structural tear tape

ActiveUS10702723B2Easily and effectively worn by the userWithout compromising the user's ability to moveSafety beltsBuilding rescueEnergy absorptionEngineering

A harness configured for being removably attachable to a body of a user has an optional pair of leg straps, an optional belt strap, and a shoulder strap. The shoulder strap has a front portion attached to a front end of each leg strap and a rear portion attached to a rear end of each leg strap. At least a portion of the shoulder strap has an energy absorbing element formed integrally therein having a tearable webbing material with at least two bound, load-bearing webbing components configured to tear from one another.

Owner:MSA TECH

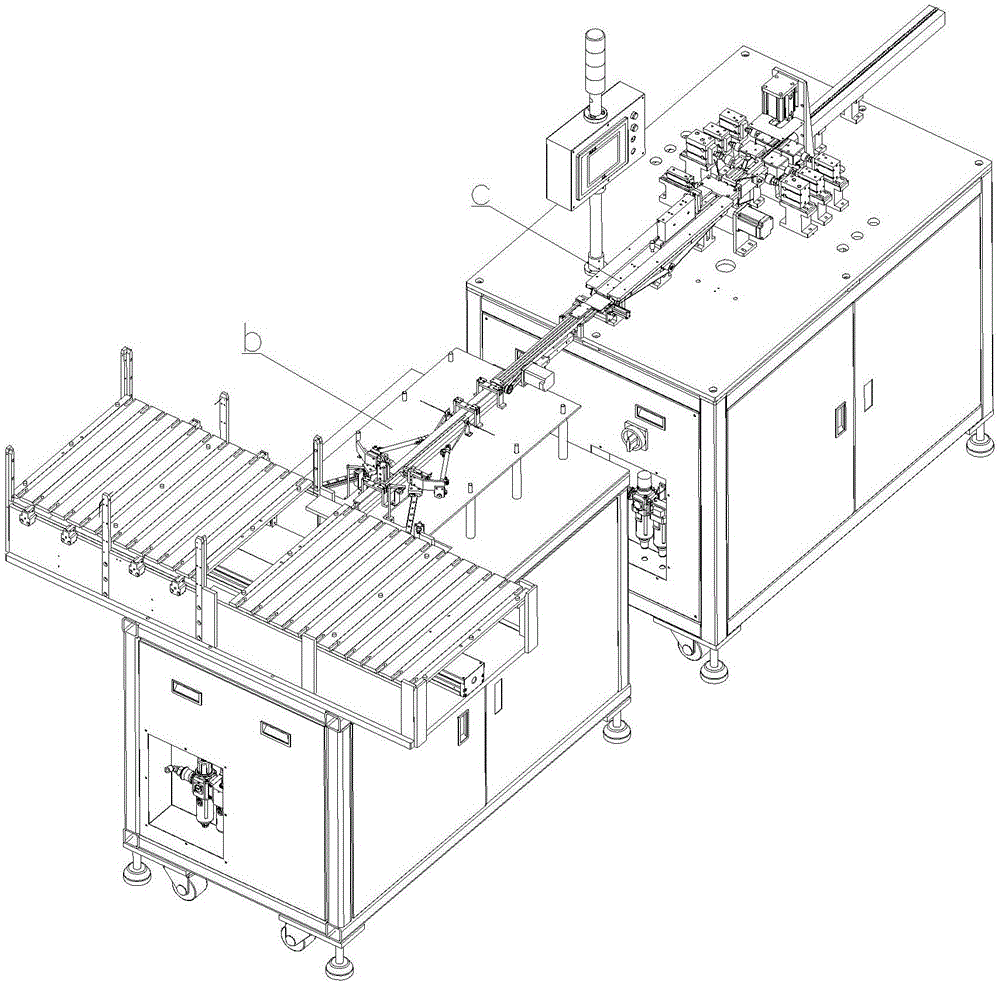

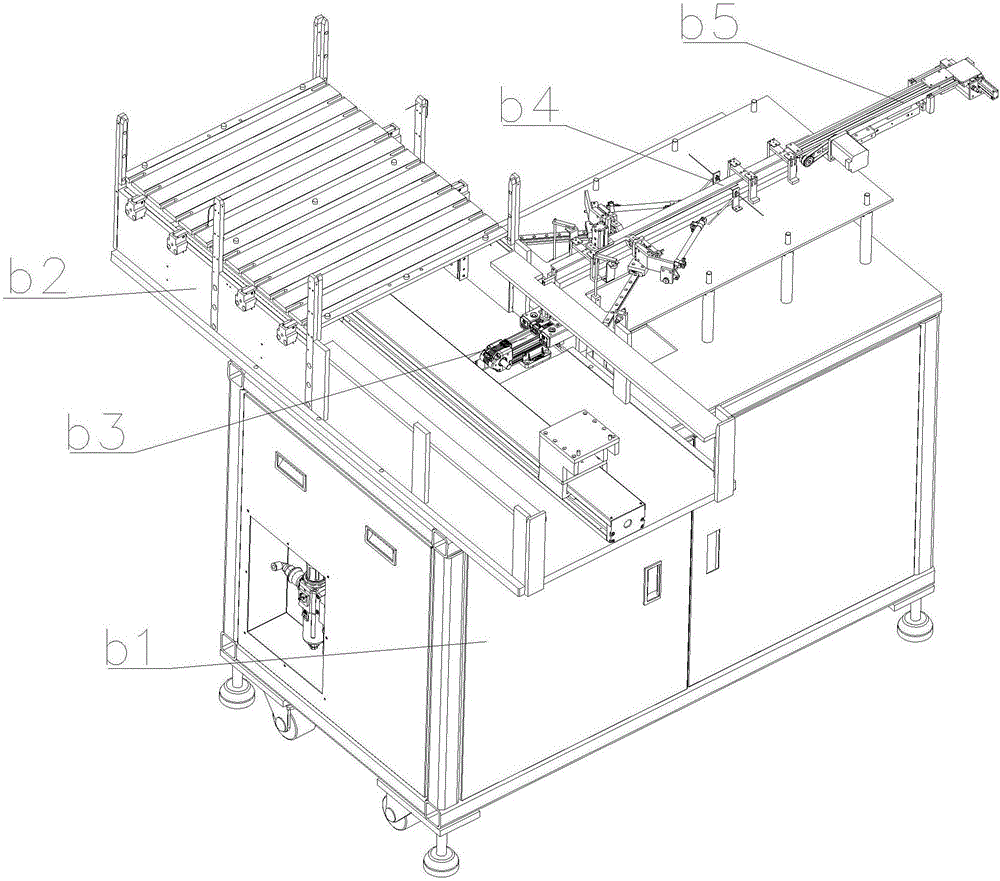

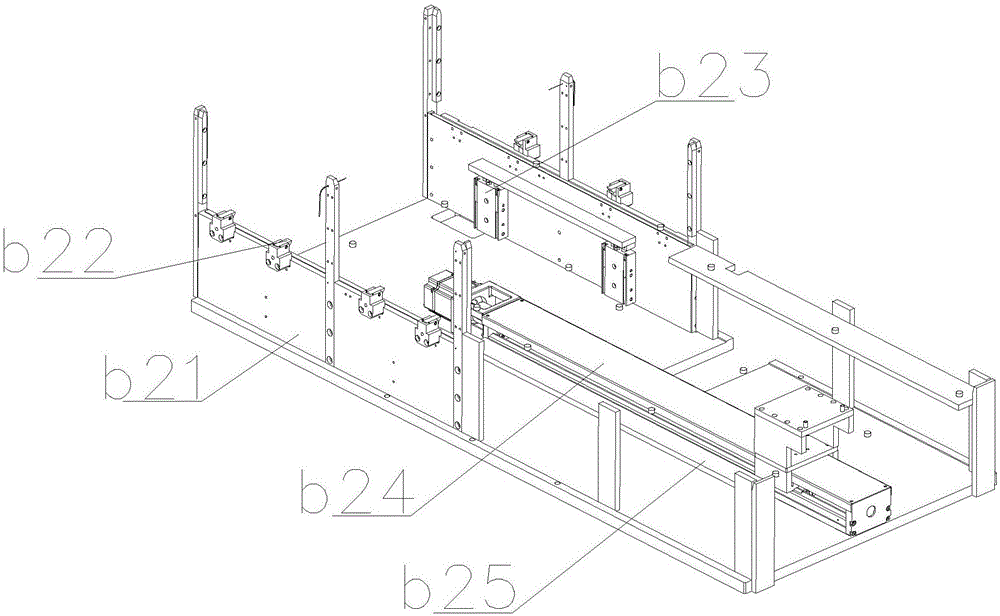

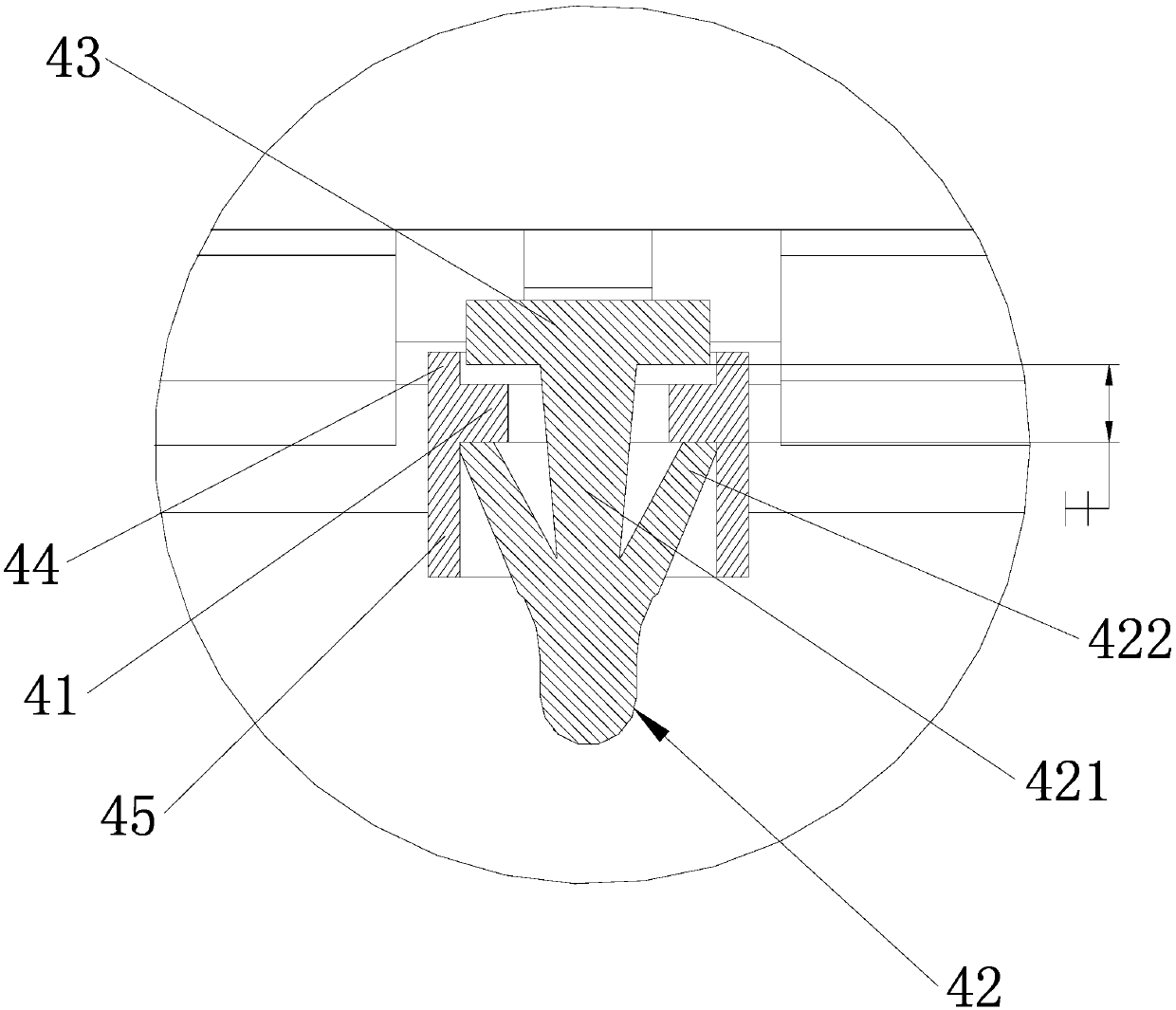

Stripping, bending and forming integrated equipment for electronic component tape

The invention discloses stripping, bending and forming integrated equipment for electronic component tape. The stripping, bending and forming integrated equipment comprises a tape tearing portion for tearing tape on electronic components off and a bending portion for bending pins of the electronic components. The bending portion is located on the material output side of the tape tearing portion. A tape-tearing feeding portion for feeding materials bonded with the tape is arranged on one side of a tape tearing workbench. The lower portion of a tape-tearing execution portion and the lower portion of the tape-tearing feeding portion are provided with a tape-tearing material transfer portion for transferring the materials on the tape-tearing feeding portion to the tape-tearing execution portion. The bending workbench is provided with a bending control portion for controlling the working state of bending equipment and a bending grouped conveying portion for conveying the materials in a grouped manner. By the adoption of the stripping, bending and forming integrated equipment for the electronic component tape, the tape on the electronic components can be torn off from the two sides, meanwhile quantitative conveying of the component materials and the two-time bending and shearing work of the pins can be completed continuously and automatically, the actions are continuous, the efficiency is high, and damage to the components is avoided.

Owner:金动力智能科技(深圳)有限公司

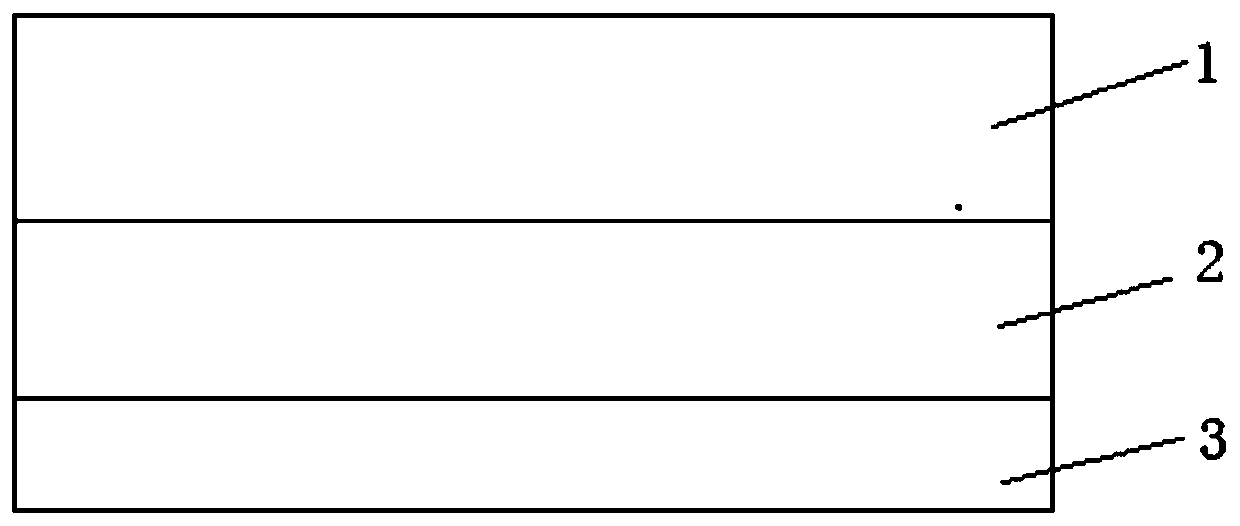

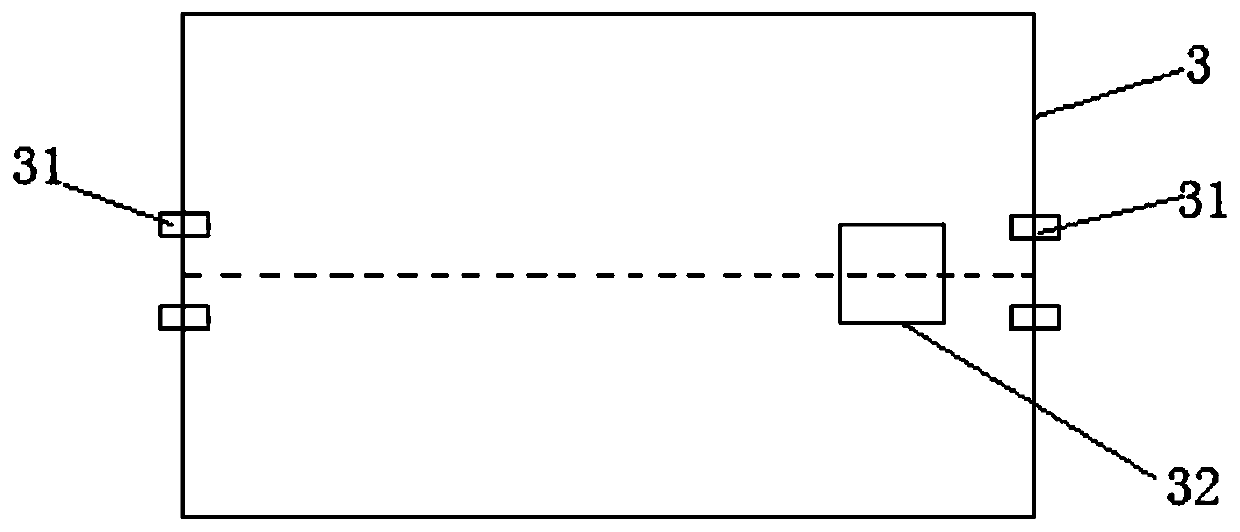

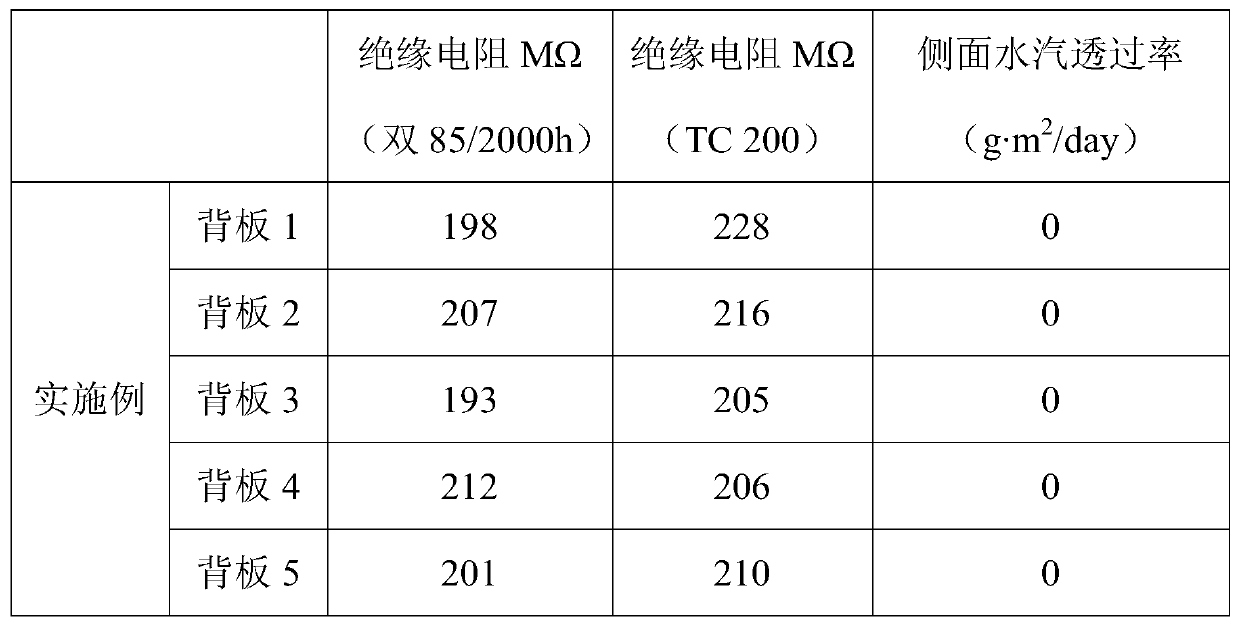

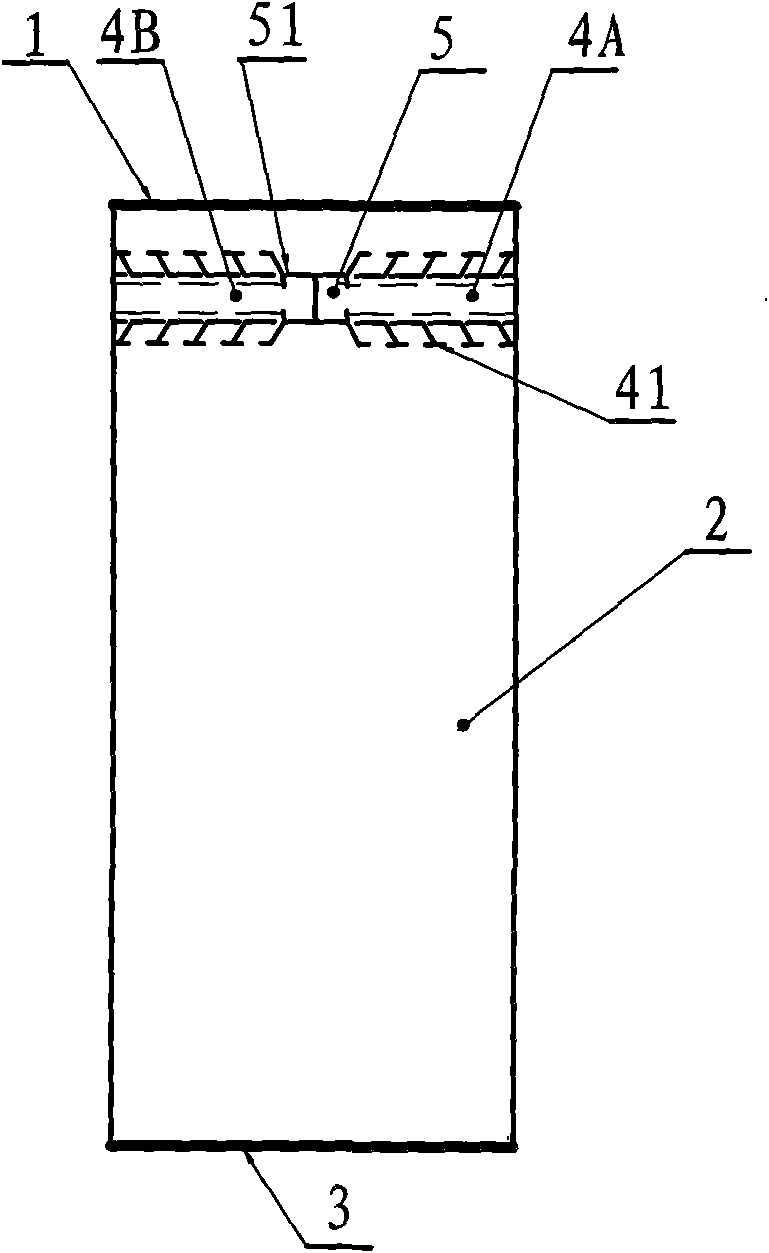

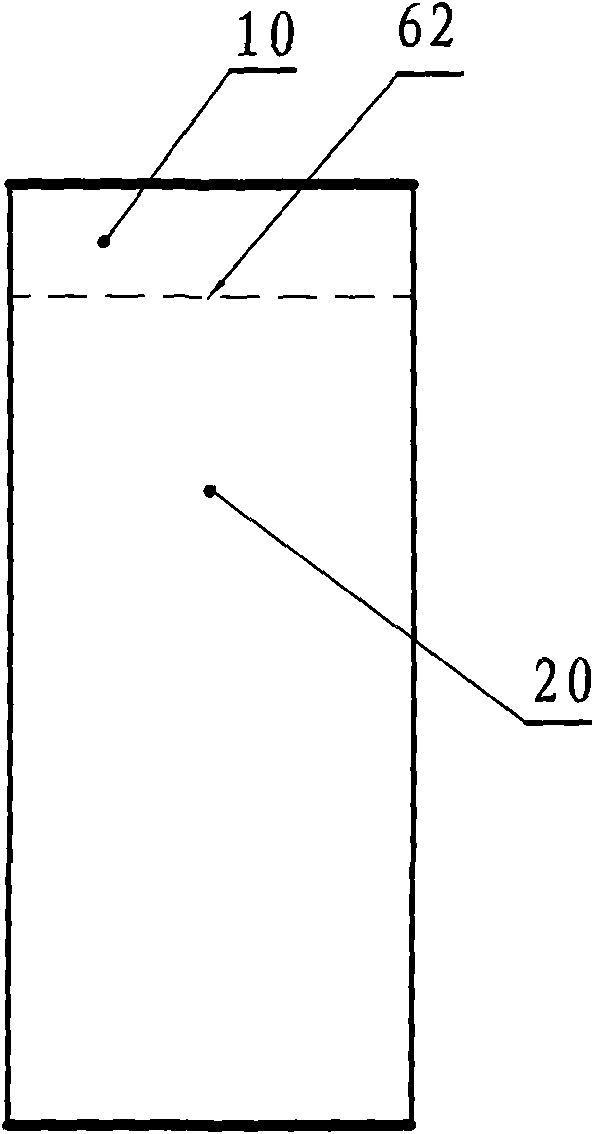

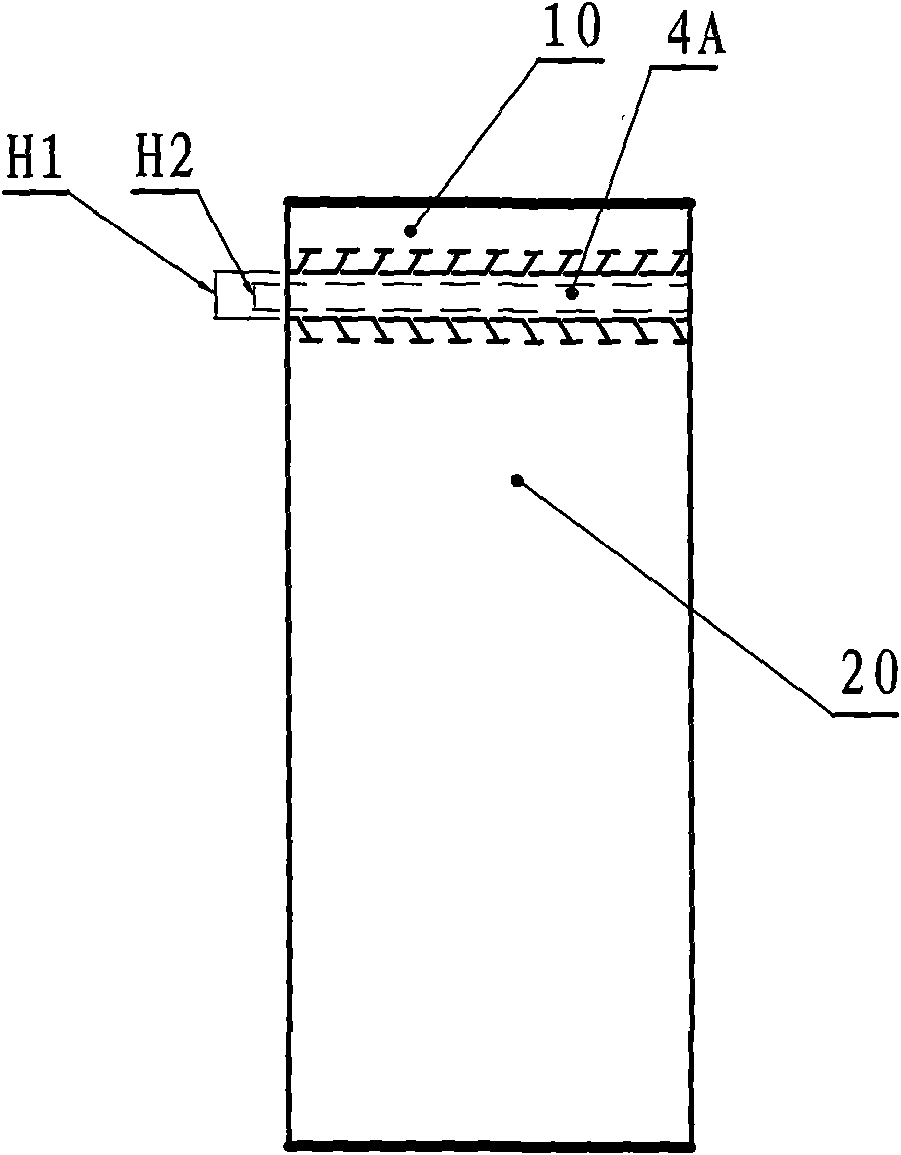

Repairing tape for photovoltaic module backboard, and bonding process and application thereof

PendingCN110055008AImprove water resistanceImprove insulation performanceFinal product manufacturePhotovoltaic energy generationWeather resistanceBonding process

The invention discloses a repairing tape for a photovoltaic module backboard, and a bonding process and application thereof. The repairing tape for the photovoltaic module backboard comprises a substrate layer, a functional adhesive layer and a release material layer which are sequentially arranged from top to bottom, wherein the substrate layer and the functional adhesive layer are of an integralwhole-surface structure, the release material layer is a two-section type release material layer, and each section of the two-section type release material layer is provided with a tear tape. The repairing tape is used for repairing a solar battery backboard, and has high insulation, low water vapor permeation rate and high weather resistance; the bonding process is simple, the bonding efficiencyis high, and the repairing tape is especially suitable for on-site repairing of the photovoltaic module backboard.

Owner:CYBRID TECHNOLOGIES INC

Disposable anti-fake paper packaging box

Owner:HUCAIS PRINTING

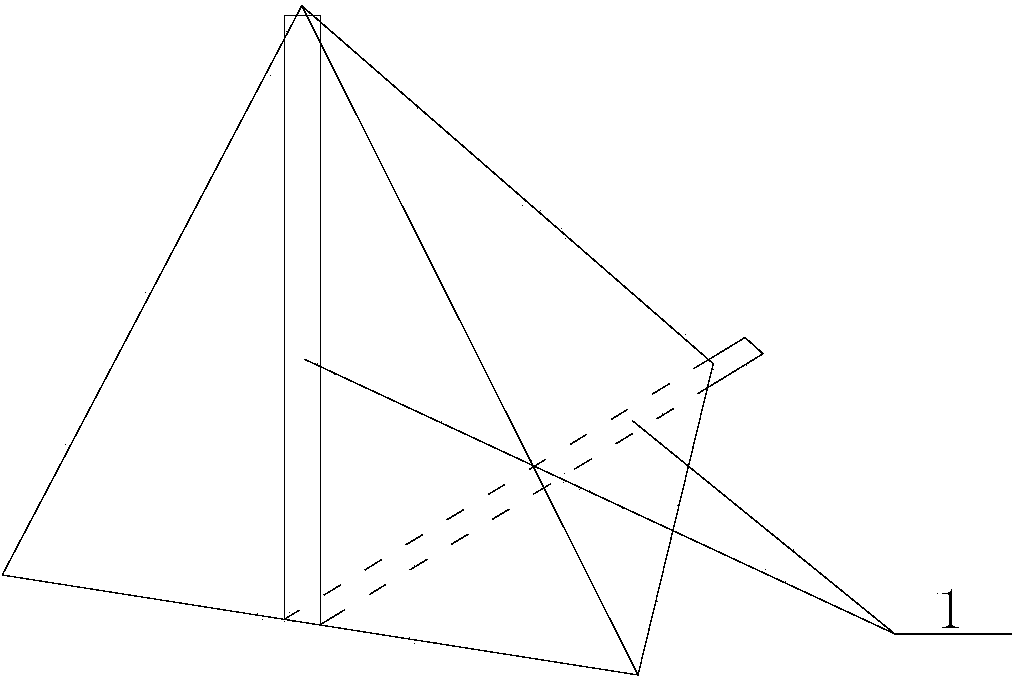

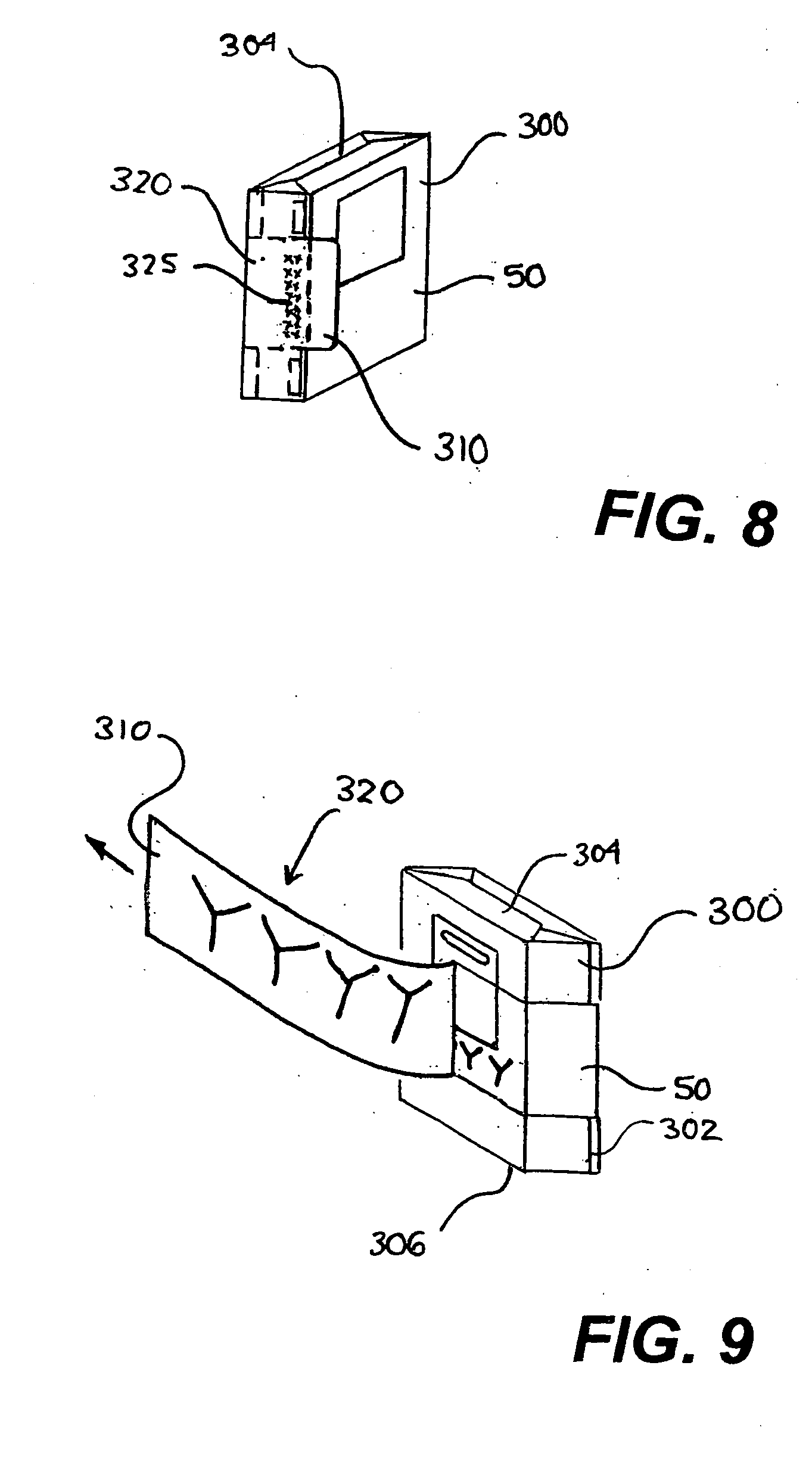

Tear tape applicator for ream wrap and other packaging materials

ActiveUS7849904B2Easy to openPrevents physical damage and scattering of loose partMechanical working/deformationLamination ancillary operationsEngineeringTear tape

Owner:COATING EXCELLENCE INT

Laser dynamic anti-counterfeiting tear tape for cigarette and production technology thereof

The invention discloses a laser dynamic anti-counterfeiting tear tape for a cigarette and a production technology thereof. The anti-counterfeiting tear tape comprises a base film layer, and a coating layer, an information layer, an adhesive layer, a thickening medium layer and a grating layer, which are sequentially arranged on the base film layer. The production technology comprises a holographic plate making step, a film coating step, a mould pressing step, an adhesive applying compounding and peeling step, a concave grating roller customizing step and a UV mould pressing step. The laser dynamic anti-counterfeiting tear tape for the cigarette, produced by the technology, not only has the holographic laser effect of a common tear tape for the cigarette, but also can move left and right with the angle of view, and accordingly, radar information on the anti-counterfeiting tear tape also represents a dynamic movement effect. The radar information impressed on the information layer in a staggered manner is unique and unduplicated. The grating layer adopts the UV adhesive mould pressing technology, and is fine in structure, high in line number and difficult to copy. The whole structure is cooperative to each other and reliable in anti-counterfeiting performance, and meanwhile, increases the packaging visual effect of the cigarette and a sales promotion function.

Owner:绍兴京华激光材料科技有限公司

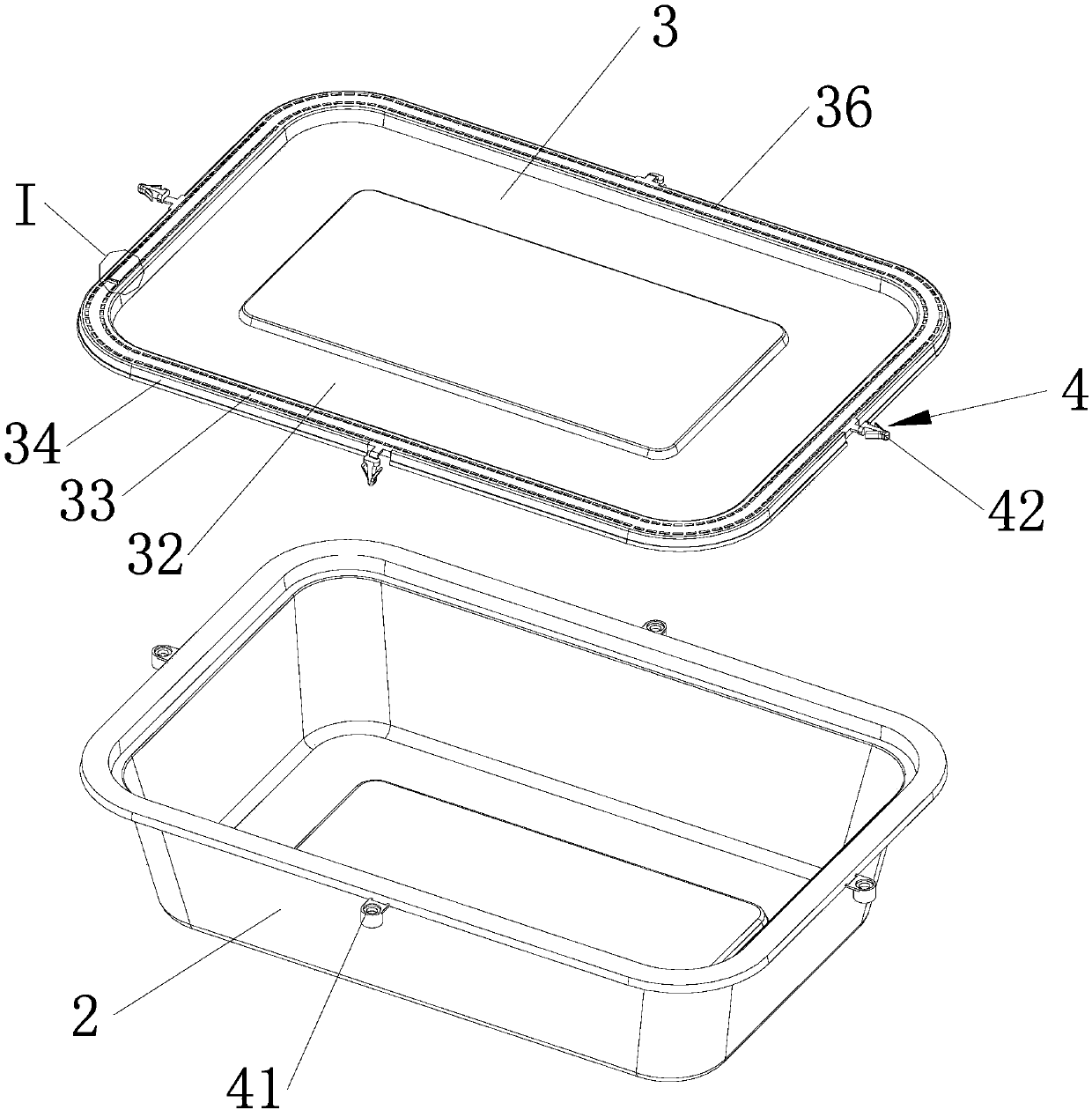

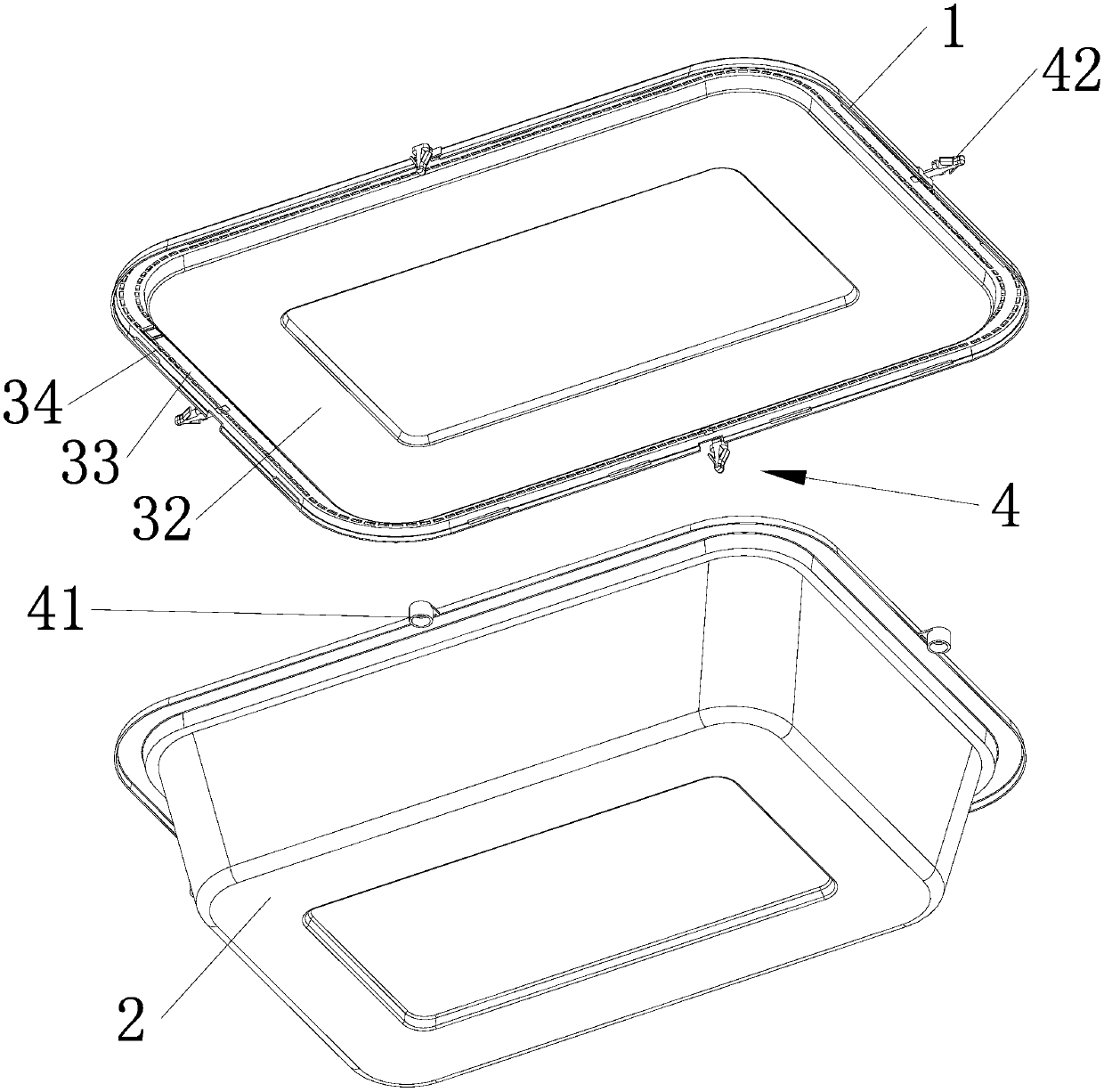

Opening-prevention fast food box capable of being opened rapidly

An opening-prevention fast food box capable of being opened rapidly comprises a bottom box body and a box cover. The box cover is divided into a box cover main body, a tearing strip and an outer edgewhich are integrally formed from inside to outside. The tearing strip is connected through plastic bones or thin walls at the joint of the box cover main body and the outer edge. A tearing handle is arranged at one end of the tearing strip. Thus, when a user is going to open the box cover, a user pinches the tearing handle and pulls the tearing strip outwards, the two sides of the tearing strip are torn off along the plastic bones or the thin walls at the moment, the box cover main body can be opened until the whole tearing strip is torn down, and the user can eat food in the food box; and thus people can use the fast food box more conveniently through the mode that the box cover is opened by tearing off the tearing strip.

Owner:ZHUHAI CITY QIRUN ELECTRONICS CO LTD

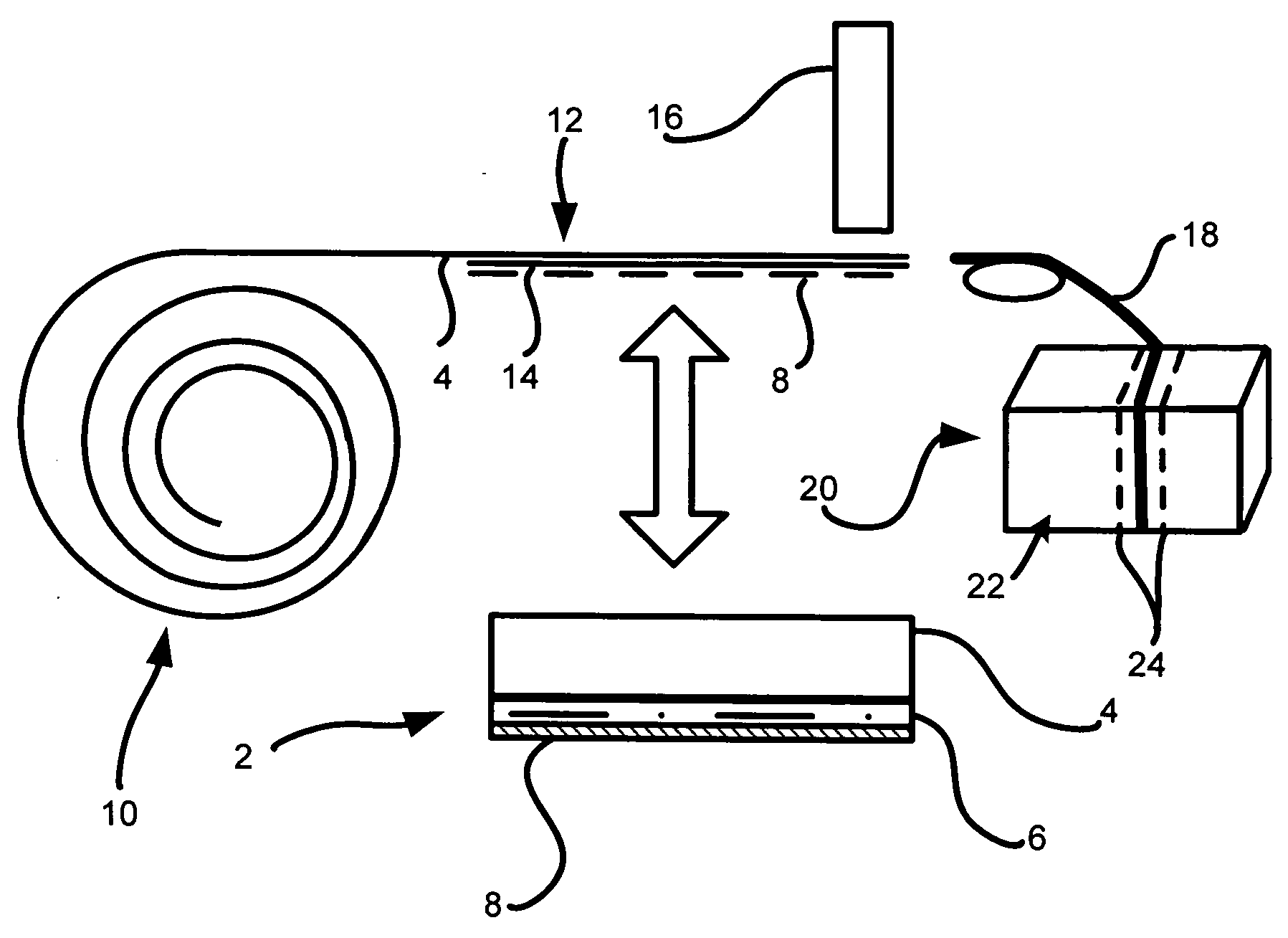

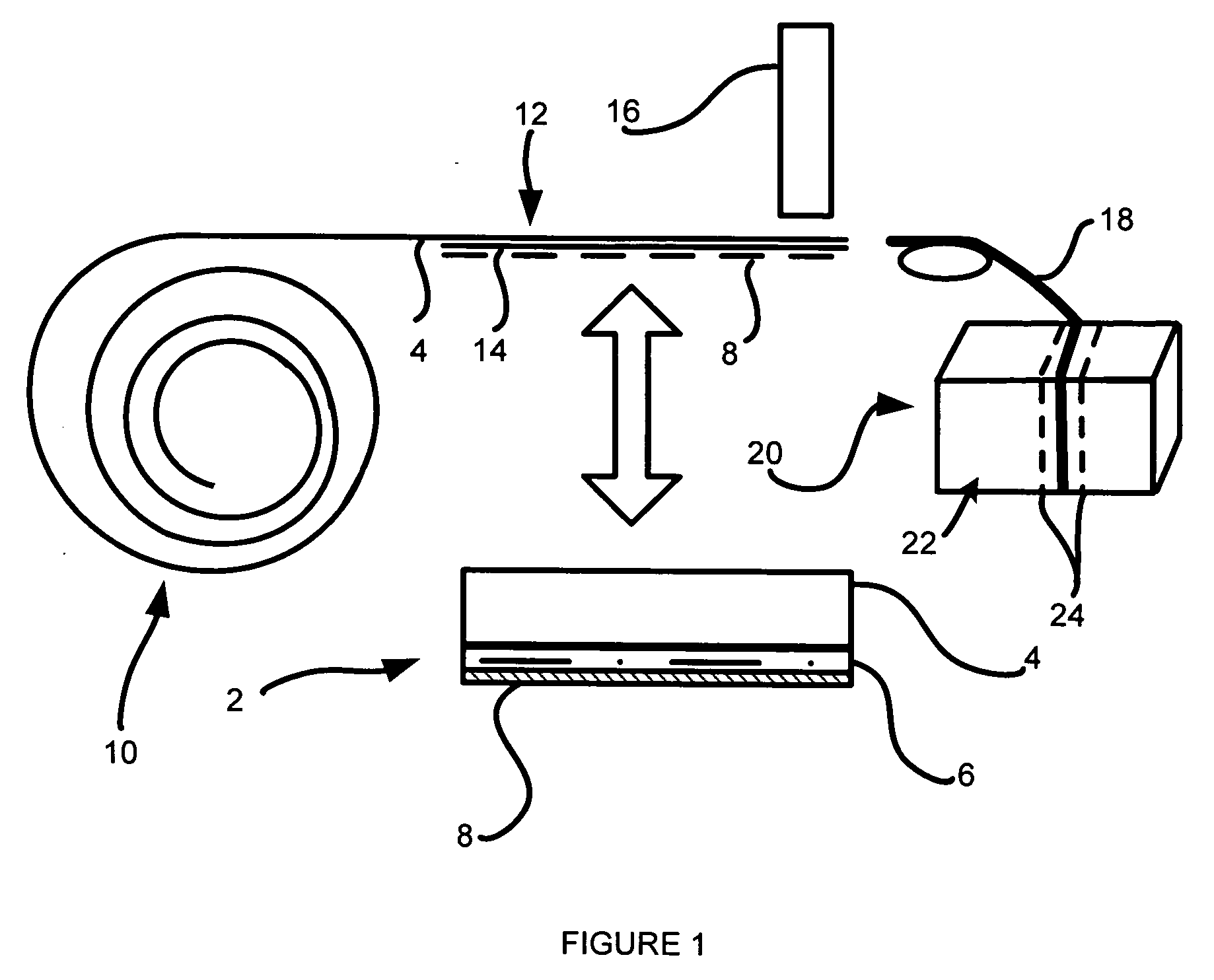

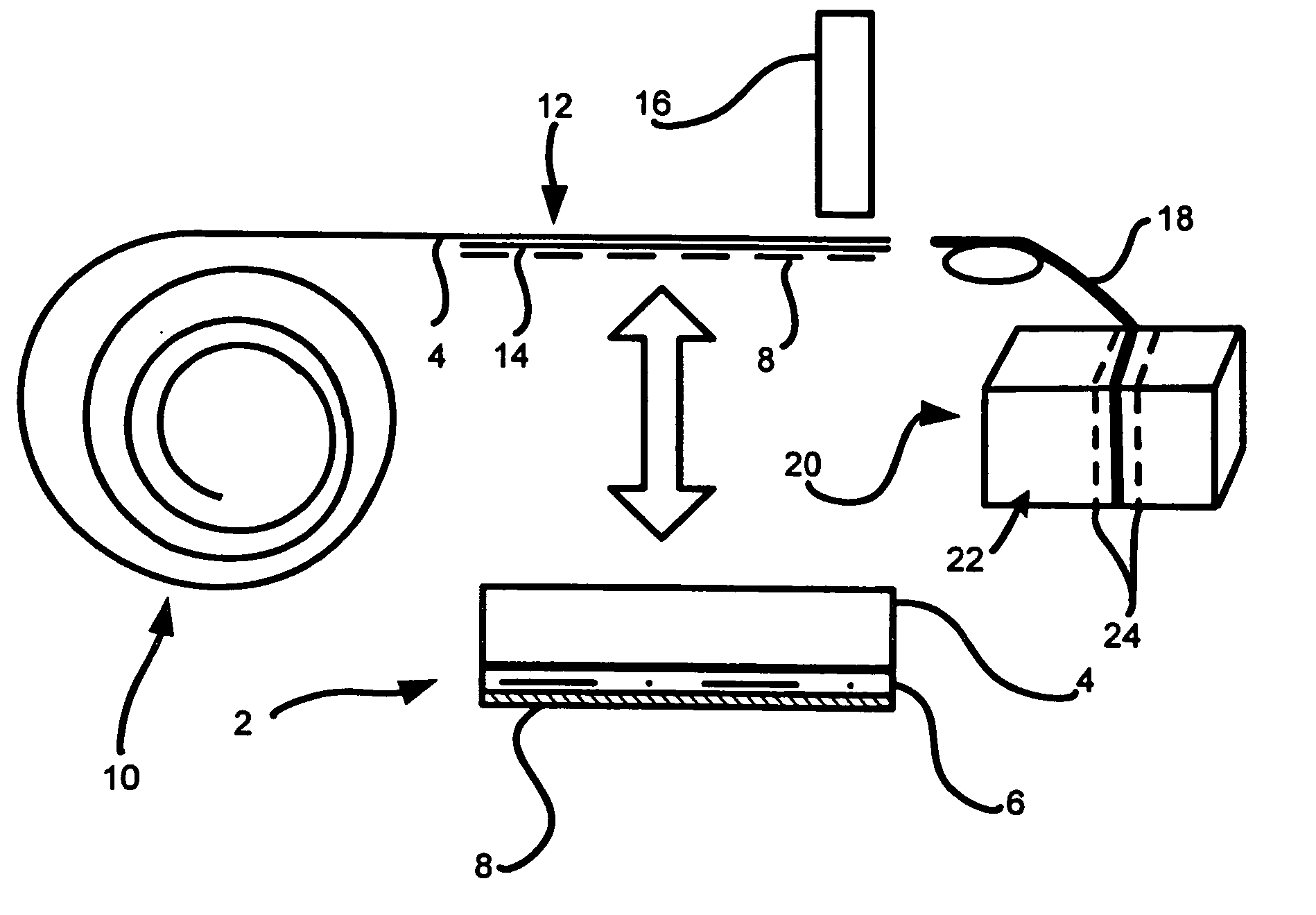

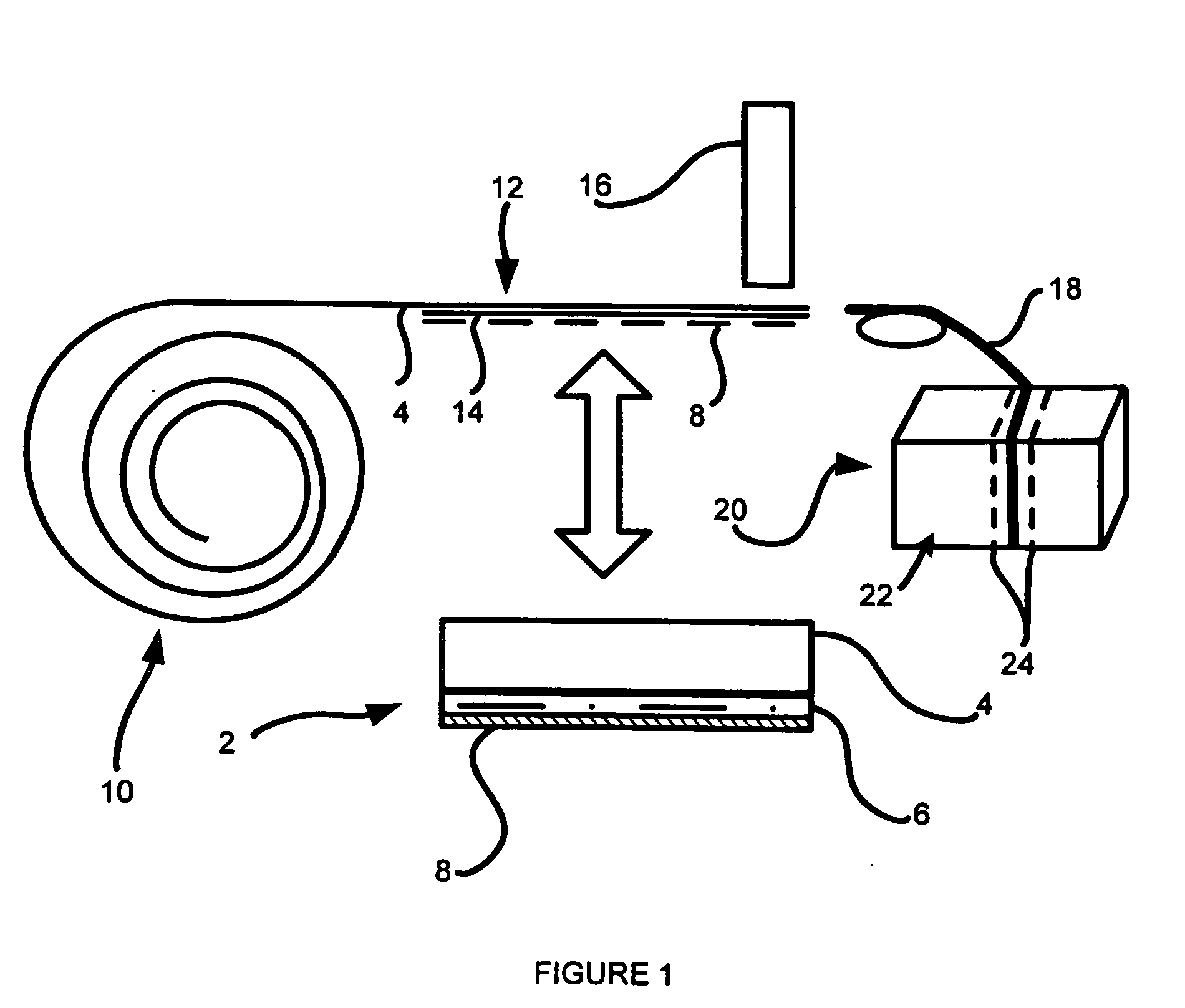

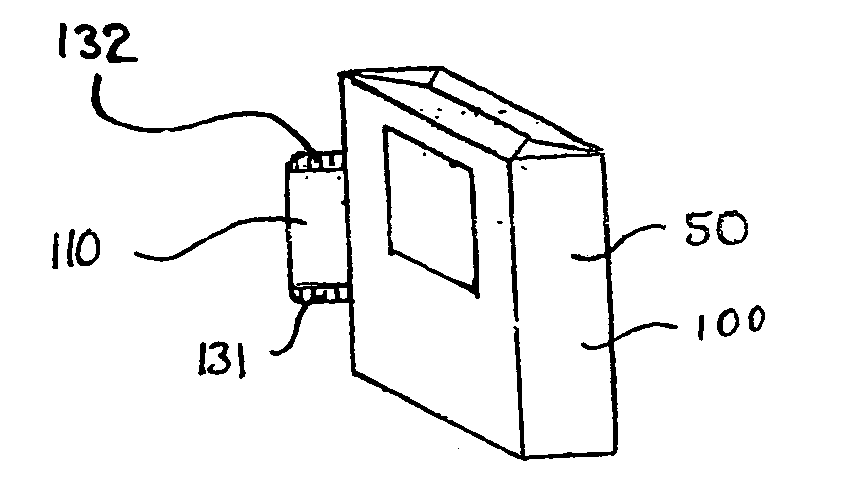

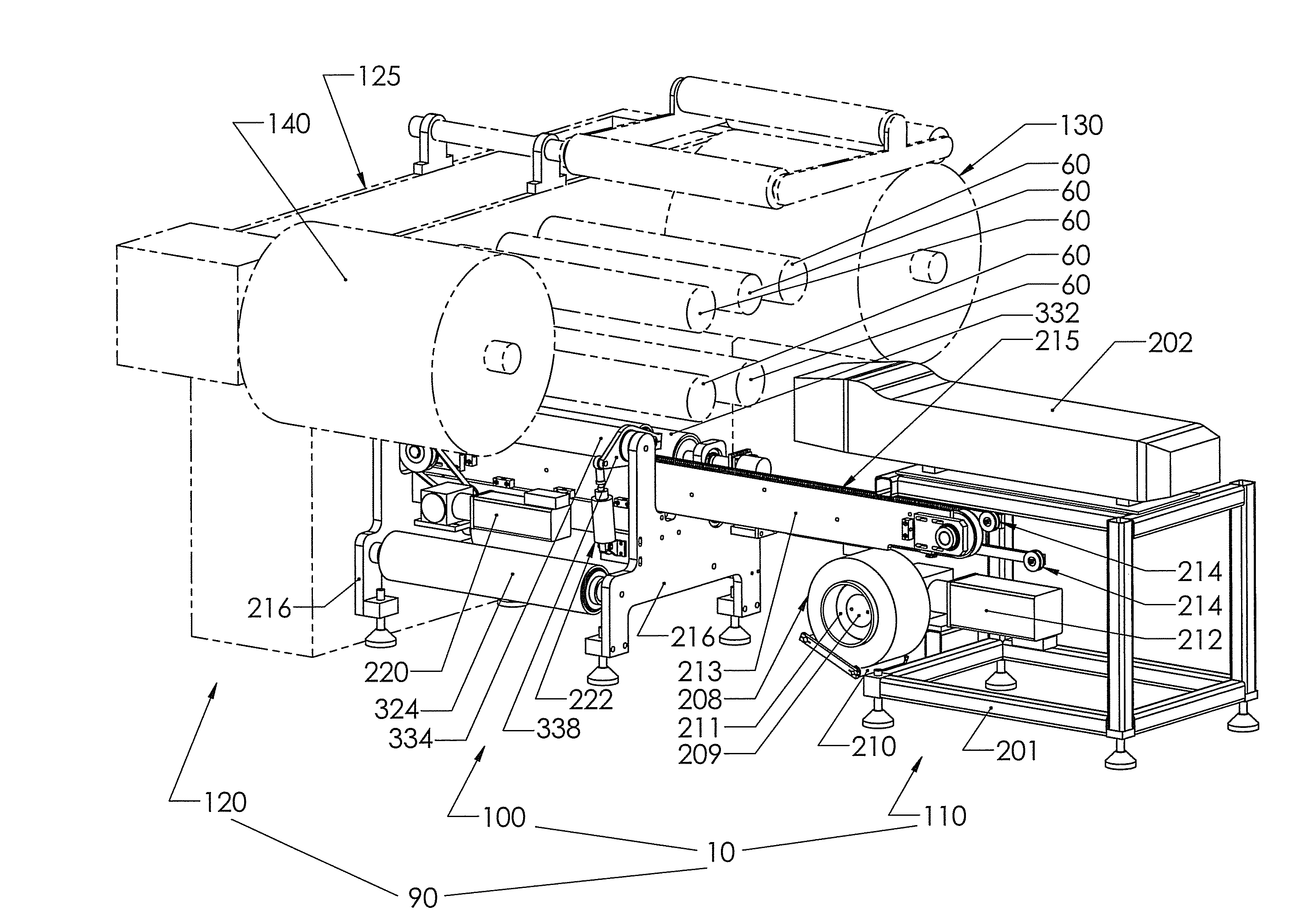

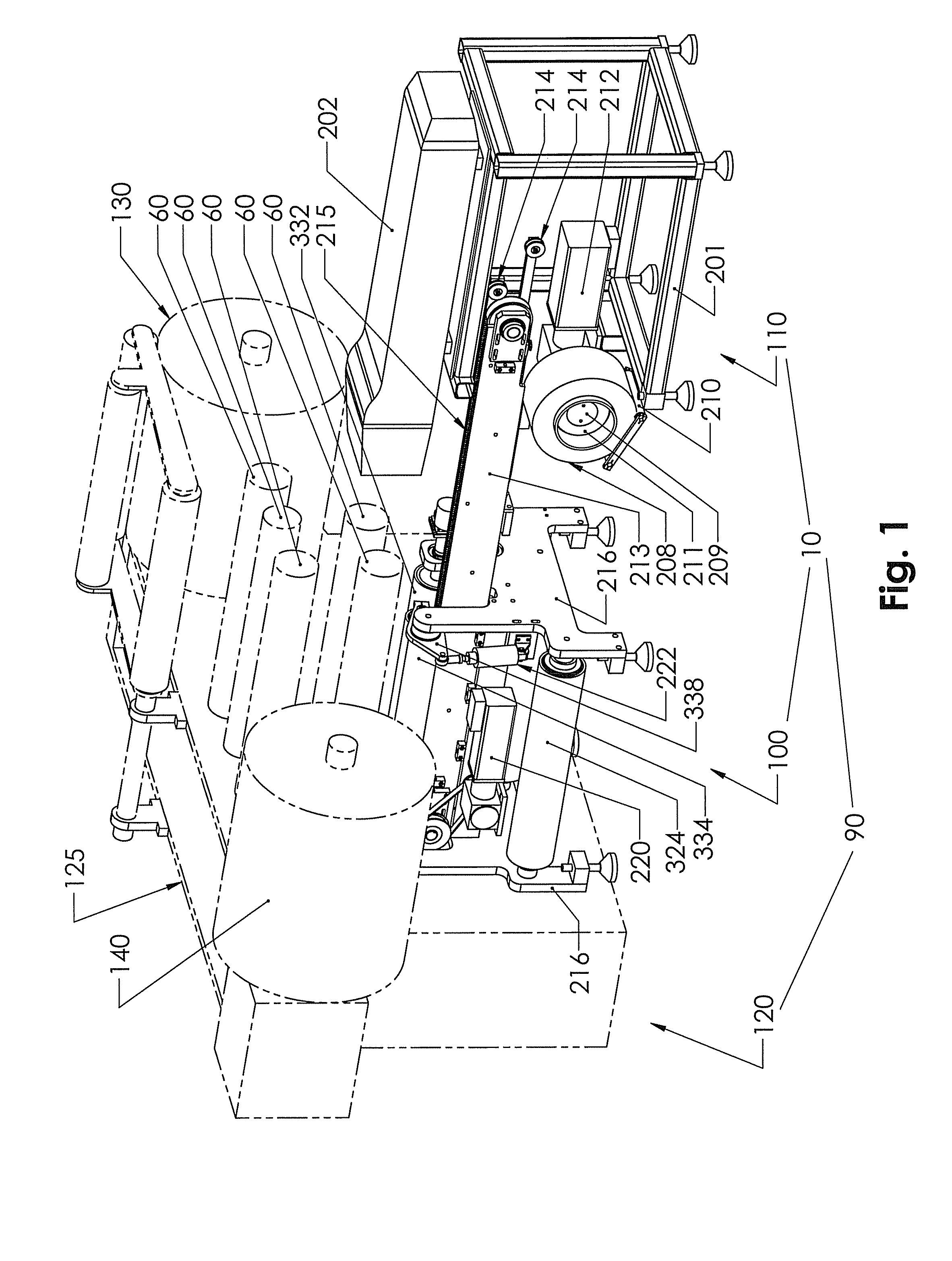

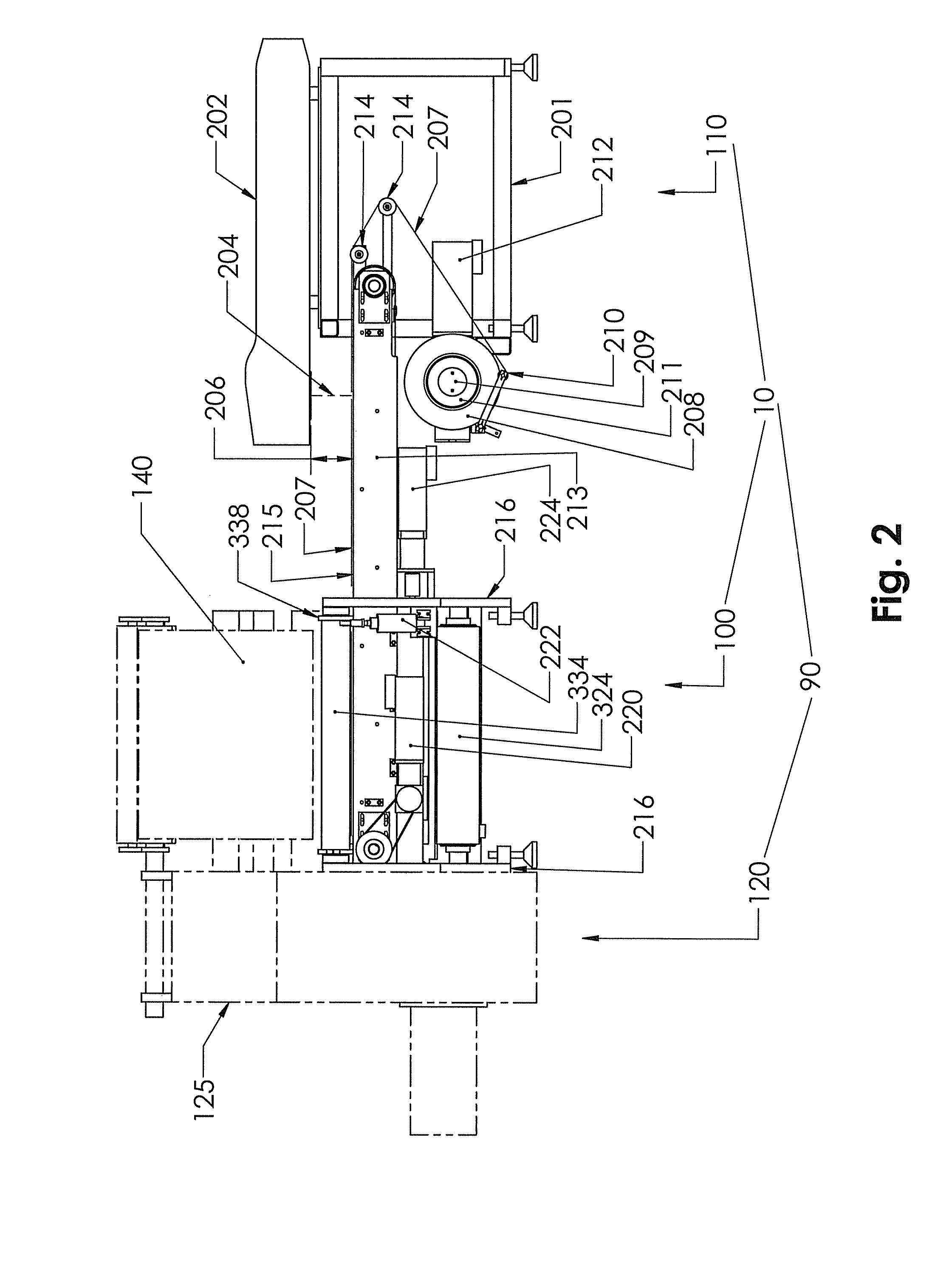

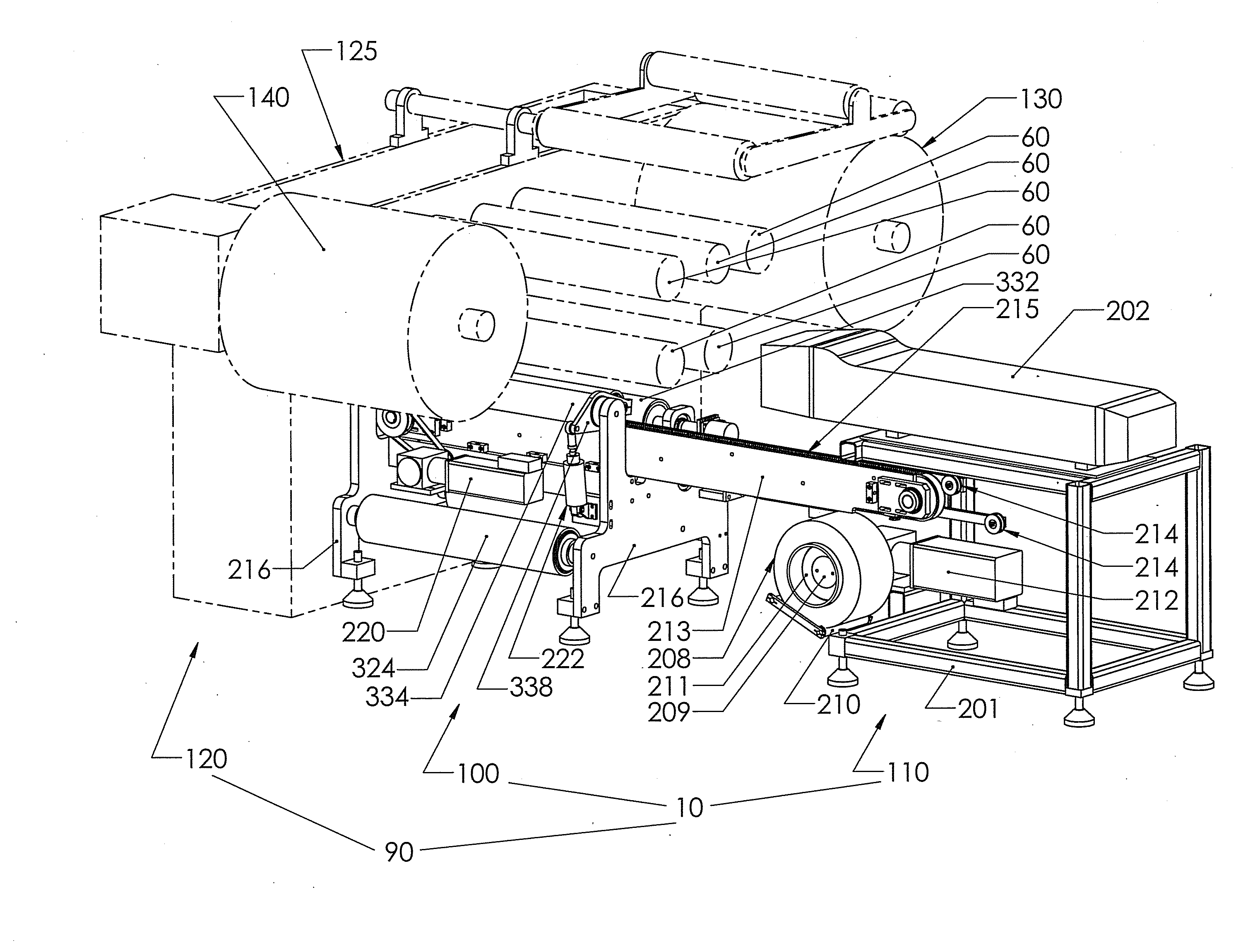

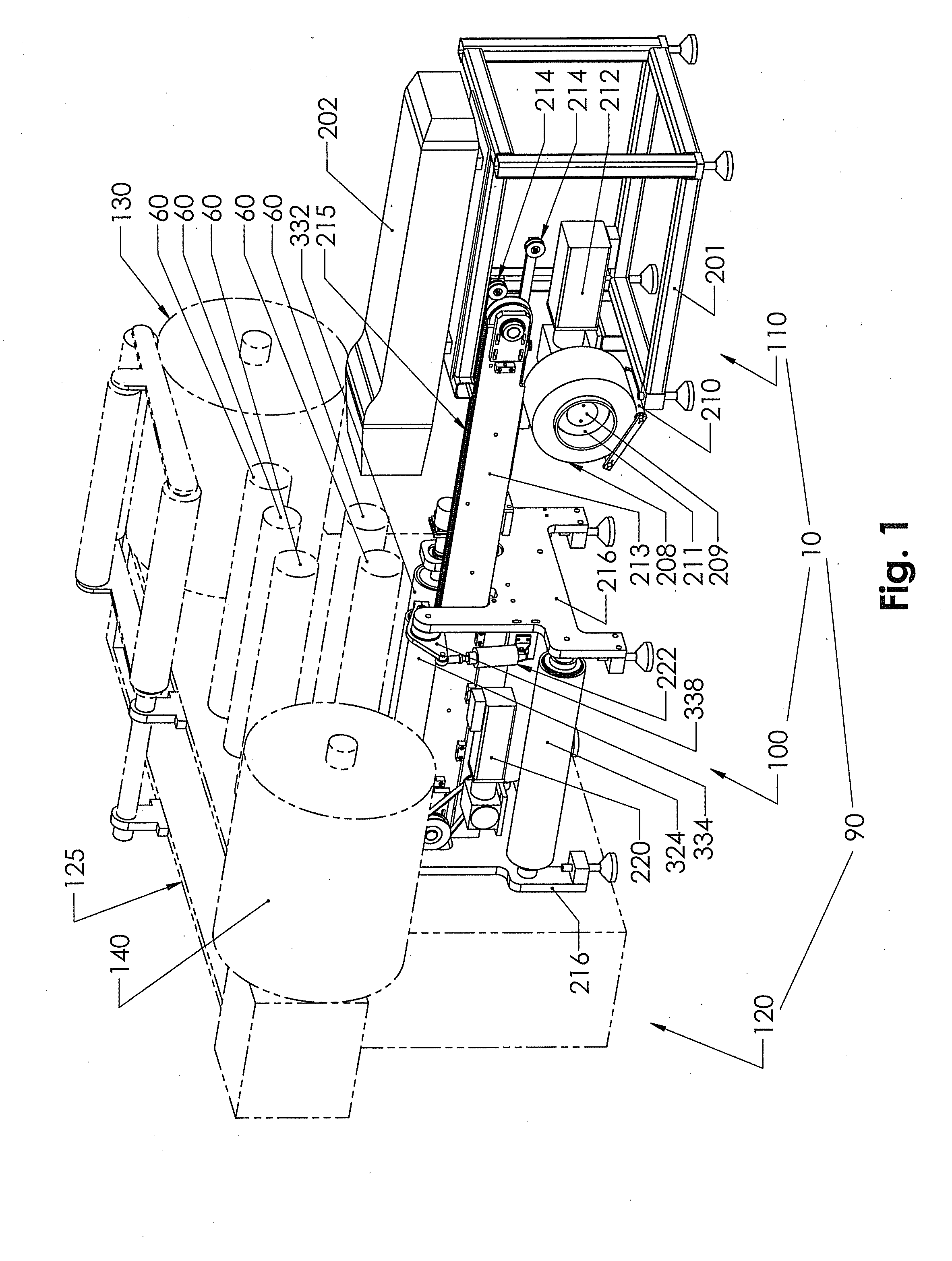

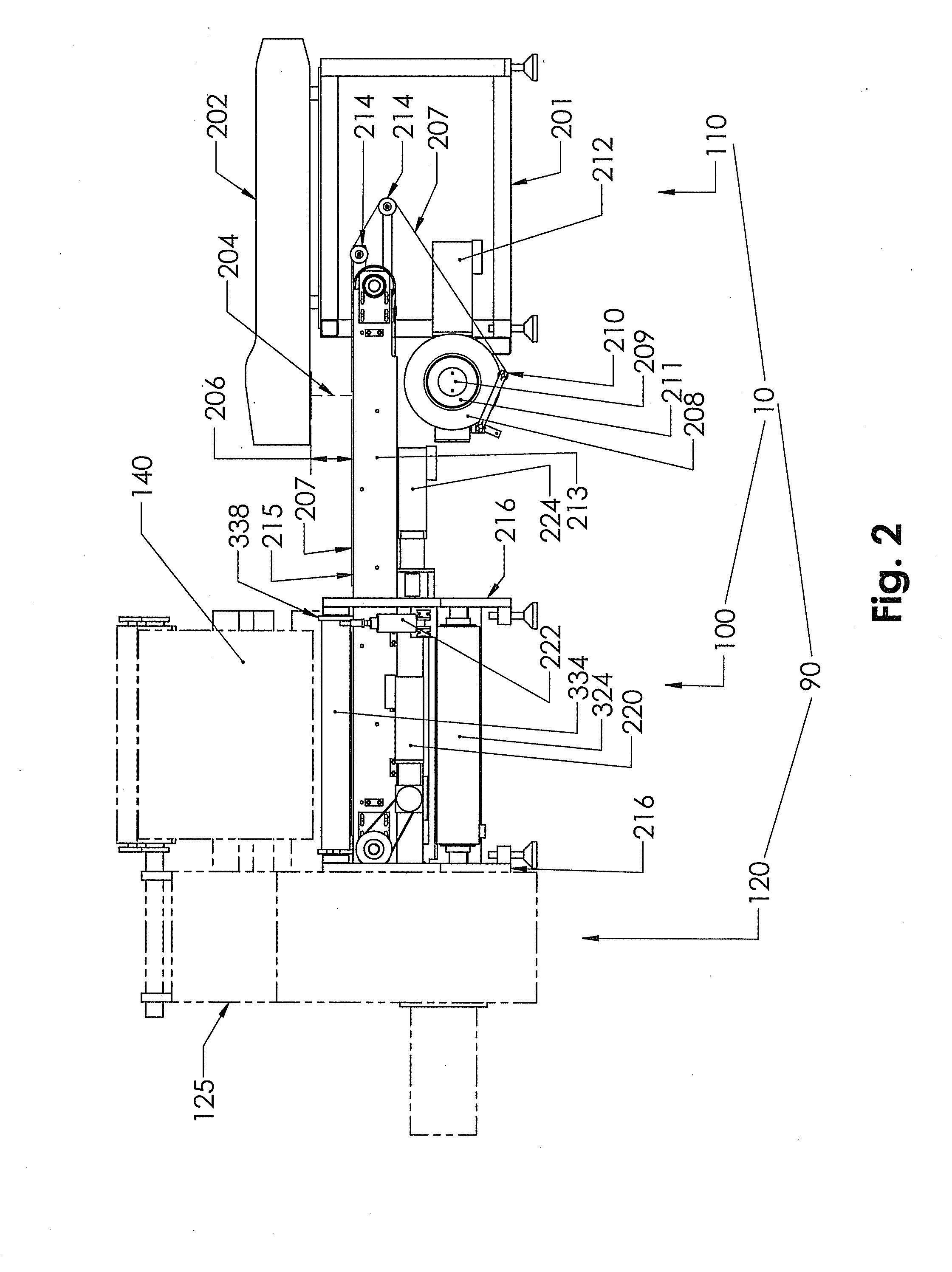

Tear tape applicator for ream wrap and other packaging materials

ActiveUS20080216944A1Easy to openPrevents physical damage and scattering of loose partMechanical working/deformationLamination ancillary operationsAdhesive beltEngineering

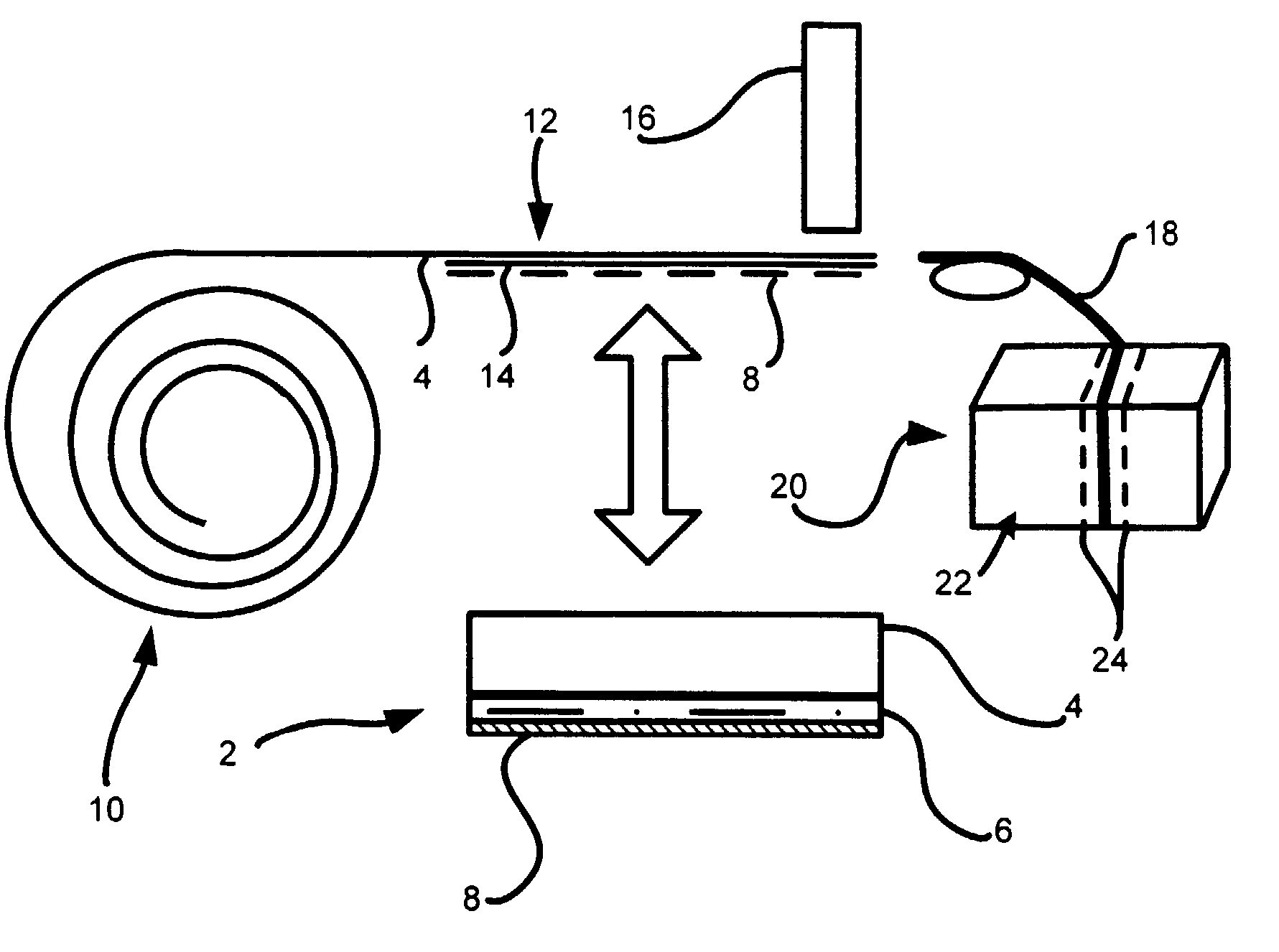

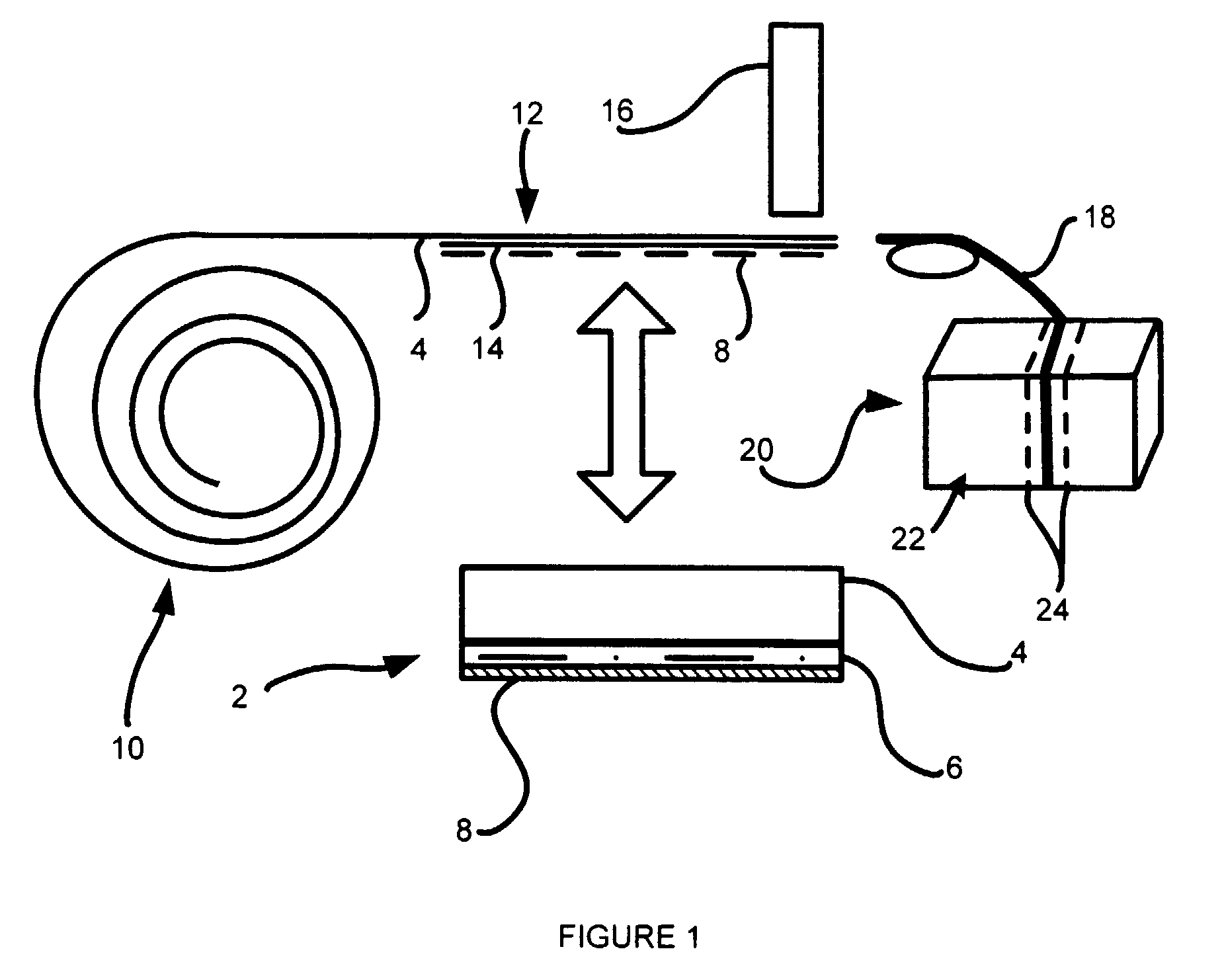

The present invention relates to a system and method for applying tear tape to a packaging substrate. Features of the system include a tear tape applicator unit comprising a laser / tear tape unwind assembly and a tear tape applicator assembly and a winder comprising an unwind roll and a rewind roll. A packaging substrate is advanced from the unwind roll to the rewind roll. The tear tape applicator unit interfaces the winder such that at least one portion of a tear tape is cut by the laser / tear tape unwind assembly and applied to the web of packaging substrate by the tear tape applicator assembly. Features of the method include advancing a web of a packaging substrate along a rewinding line from an unwind end to a rewind end, cutting at least one portion of a tear tape, advancing said at least one portion of said tear tape toward said rewinding line, and applying said at least one portion of said tear tape to said web.

Owner:COATING EXCELLENCE INT

Plastic packaging box

InactiveCN112455873AEffective immobilizationEffective protectionSealingContainers to prevent mechanical damagePlastic packagingStructural engineering

The invention discloses a plastic packaging box. The box comprises a shell and a cover plate, wherein an anti-rolling mechanism is arranged on the shell, and a vertical limiting mechanism is fixedly mounted in the middle of the lower surface of the cover plate. The anti-rolling mechanism comprises an air inlet nozzle, a check valve, a first pipe, a containing cavity, a strip-shaped air bag, sealing tear tape and a connecting mechanism. The air inlet nozzle is formed in the bottom end of the side surface of one end of the shell. The check valve is arranged at the position, close to the air inlet nozzle, of the side wall of the shell. One end of the check valve is fixedly connected with the first pipe. According to the plastic packaging box, by arranging the anti-rolling mechanism, a spherical object can be effectively fixed and protected through the strip-shaped air bag, the fixing stability of the spherical object is improved, the problem that the spherical object breaks away due to vibration in the transportation process is solved, and meanwhile, as the strip-shaped air bag is arranged in the containing cavity when not inflated, the packaging boxes can be stacked and carried conveniently, and use is convenient to carry out.

Owner:淮北悯农生物科技有限公司

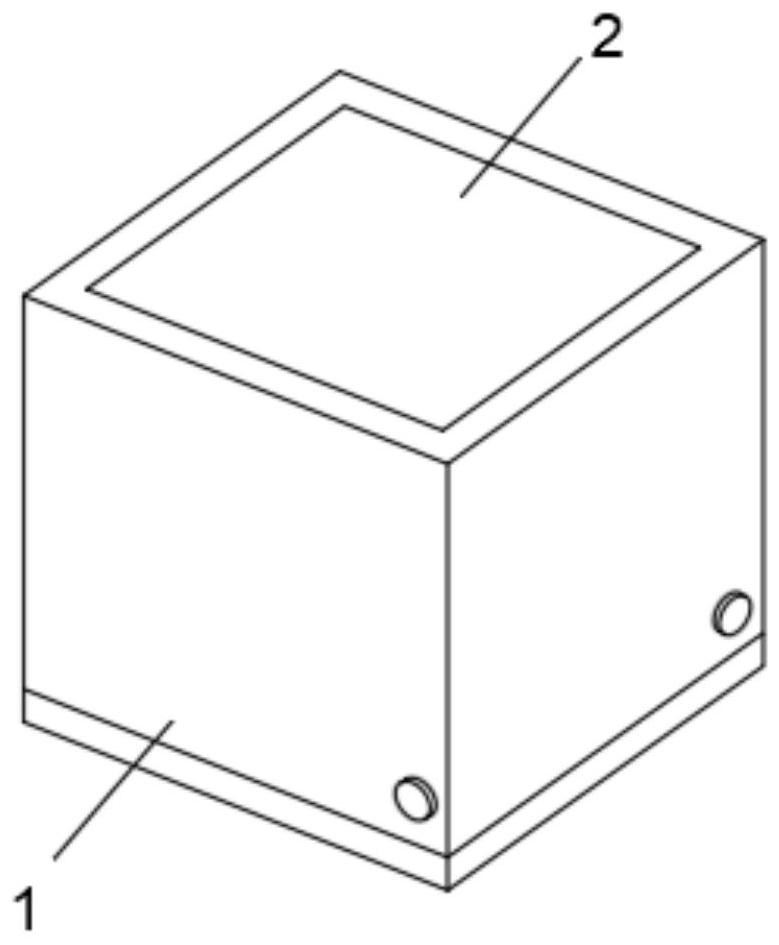

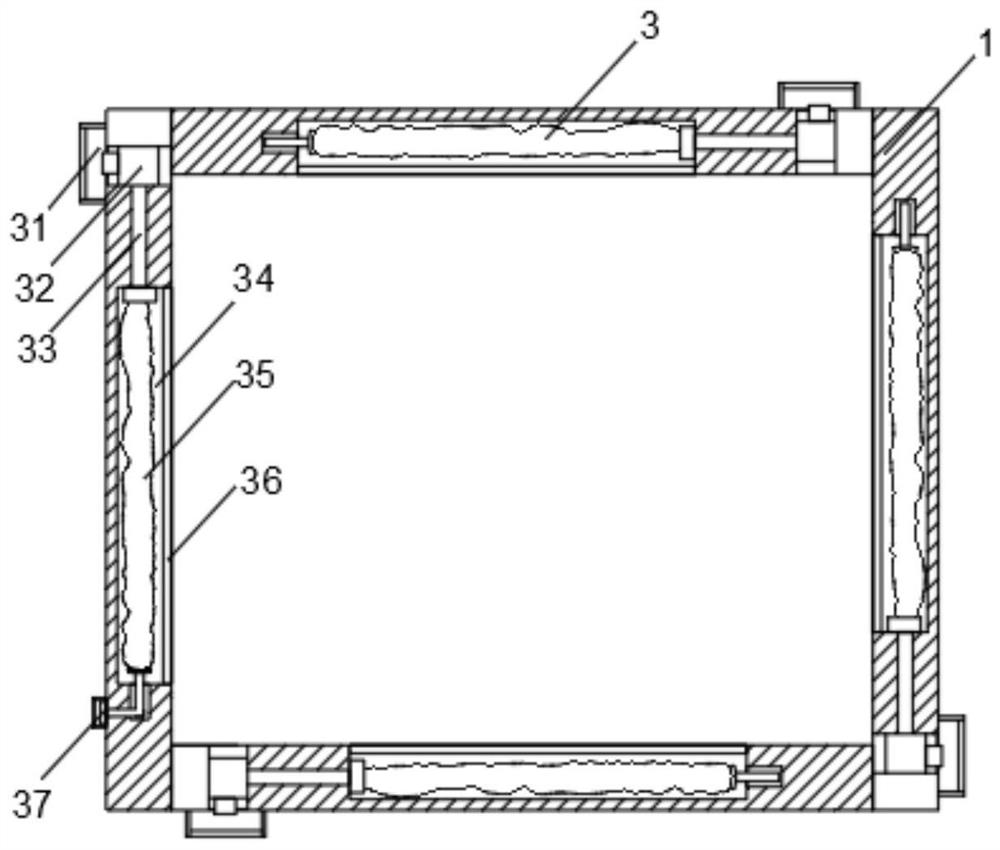

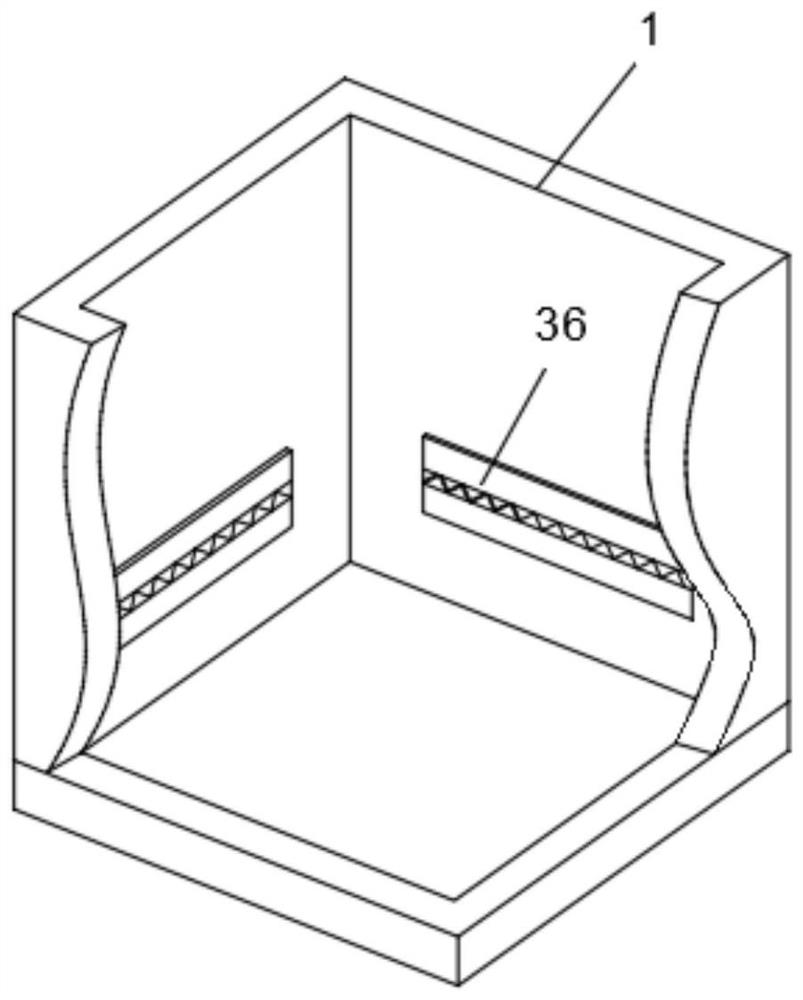

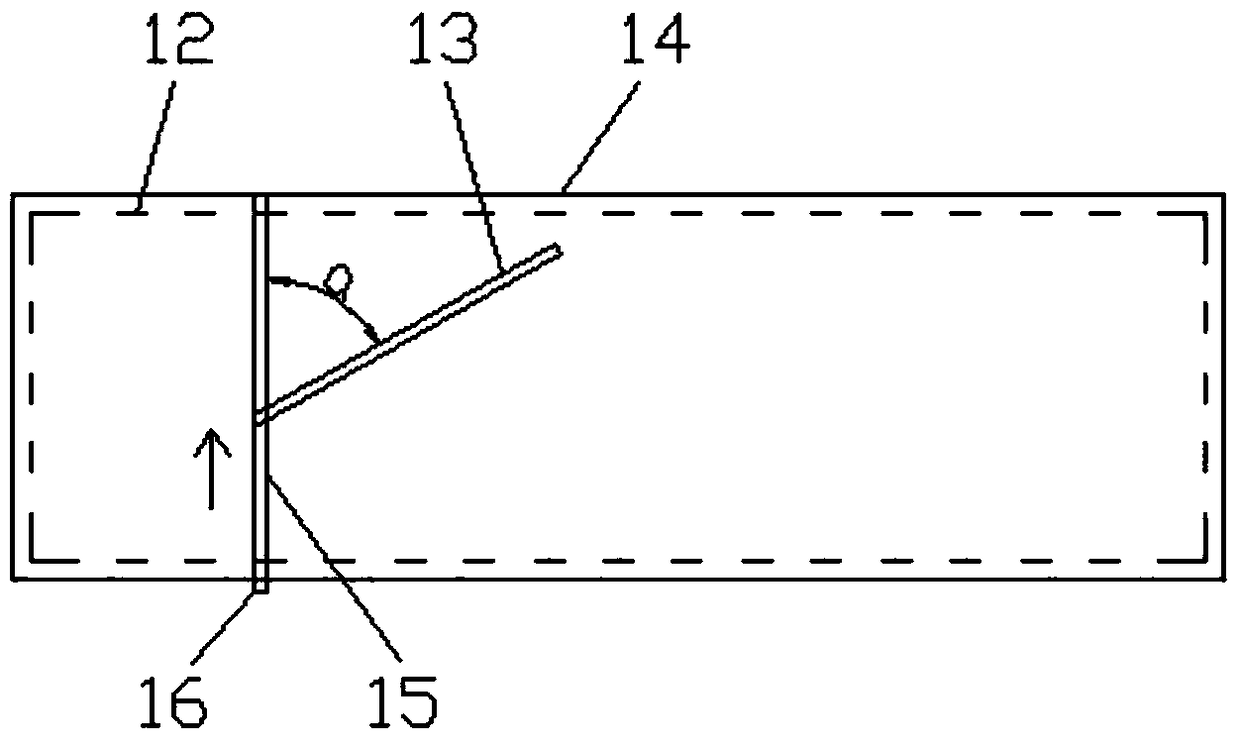

Cigarette packet or cigarette carton tear tape structure and transparent tear tape pasting device

The invention discloses a cigarette packet or cigarette carton tear tape structure and a transparent tear tape pasting device, and belongs to the technical field of cigarette packets and cigarette cartons. The cigarette carton tear tape structure comprises a packaging box and transparent packaging paper wrapping the outside of the packaging box, the transparent packaging paper is provided with a main tear tape, and the main tear tape longitudinally divides the transparent packaging paper into two parts, that is, the left side part and the right side part; the length of the left side part is smaller than that of the right side part, and an oblique tear tape is pasted on the right side part of the transparent packaging paper; the left end of the oblique tear tape extends to the main tear tape and intersects with and adheres to the main tear tape, the main tear tape presses the left end of the oblique tear tape, and an acute angle is formed between the main tear tape and the oblique teartape. The transparent tear tape pasting device comprises a bracket, and the bracket is provided with a tear tape distribution mechanism and a rolling pasting drum wheel. Through the cigarette carton tear tape structure, the cigarette carton transparent paper is convenient to tear, and the corresponding transparent tear tape pasting device is provided.

Owner:江苏瑞驰机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com