Plastic film bag with tear tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

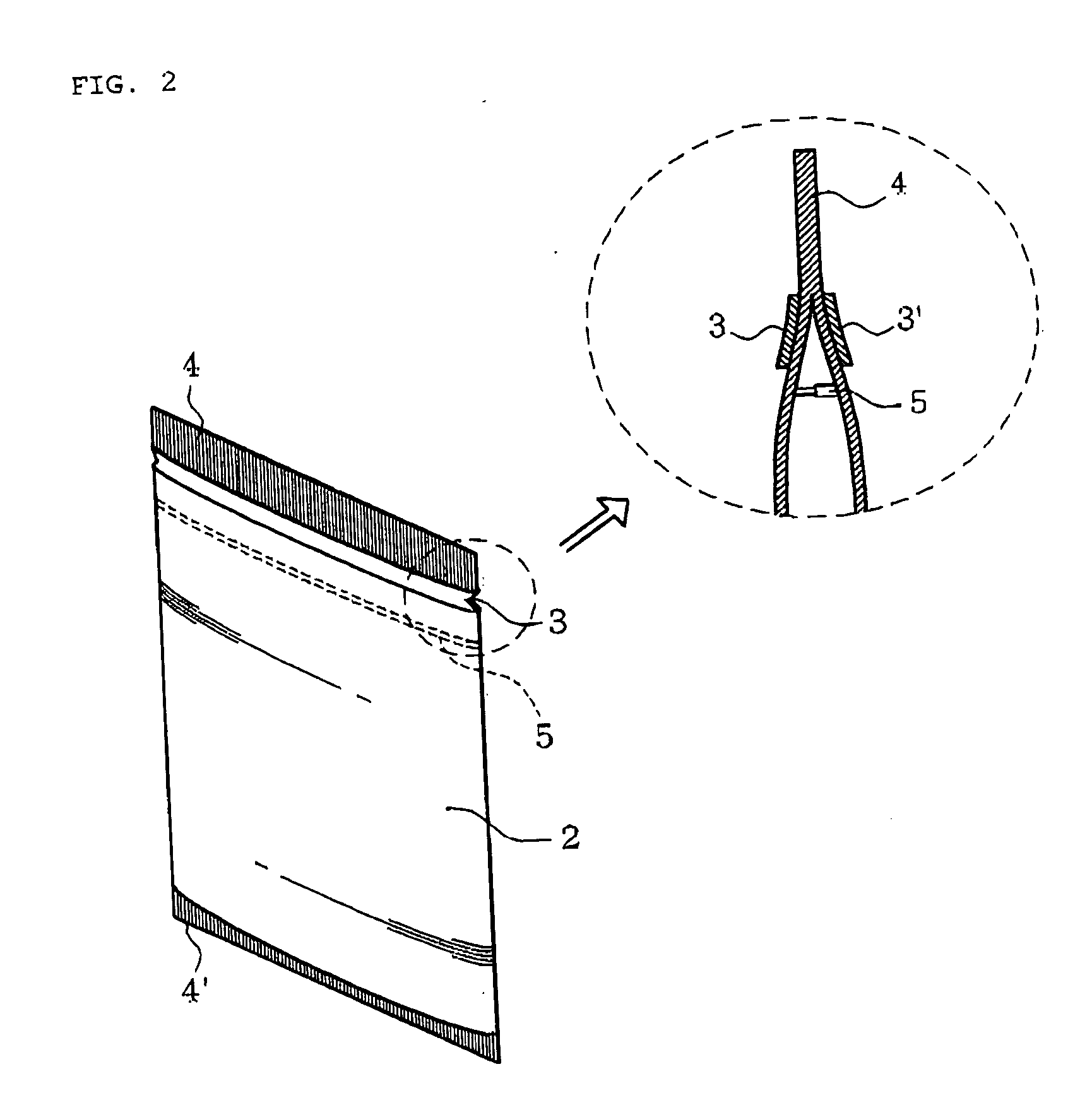

[0021] The present invention provides a plastic film bag which can be opened using tear tapes and can be completely sealed despite the tear tapes being provided on the film bag.

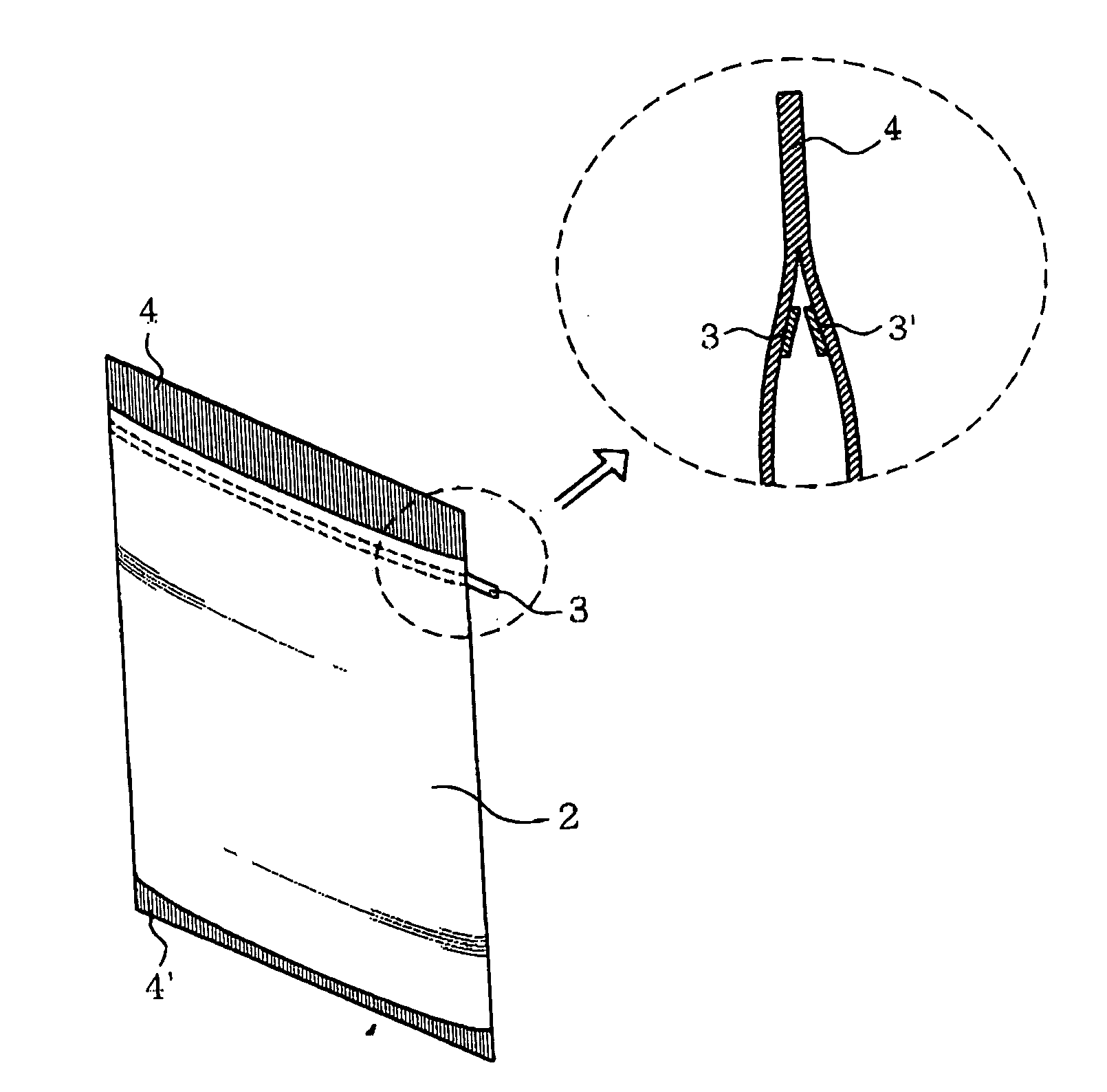

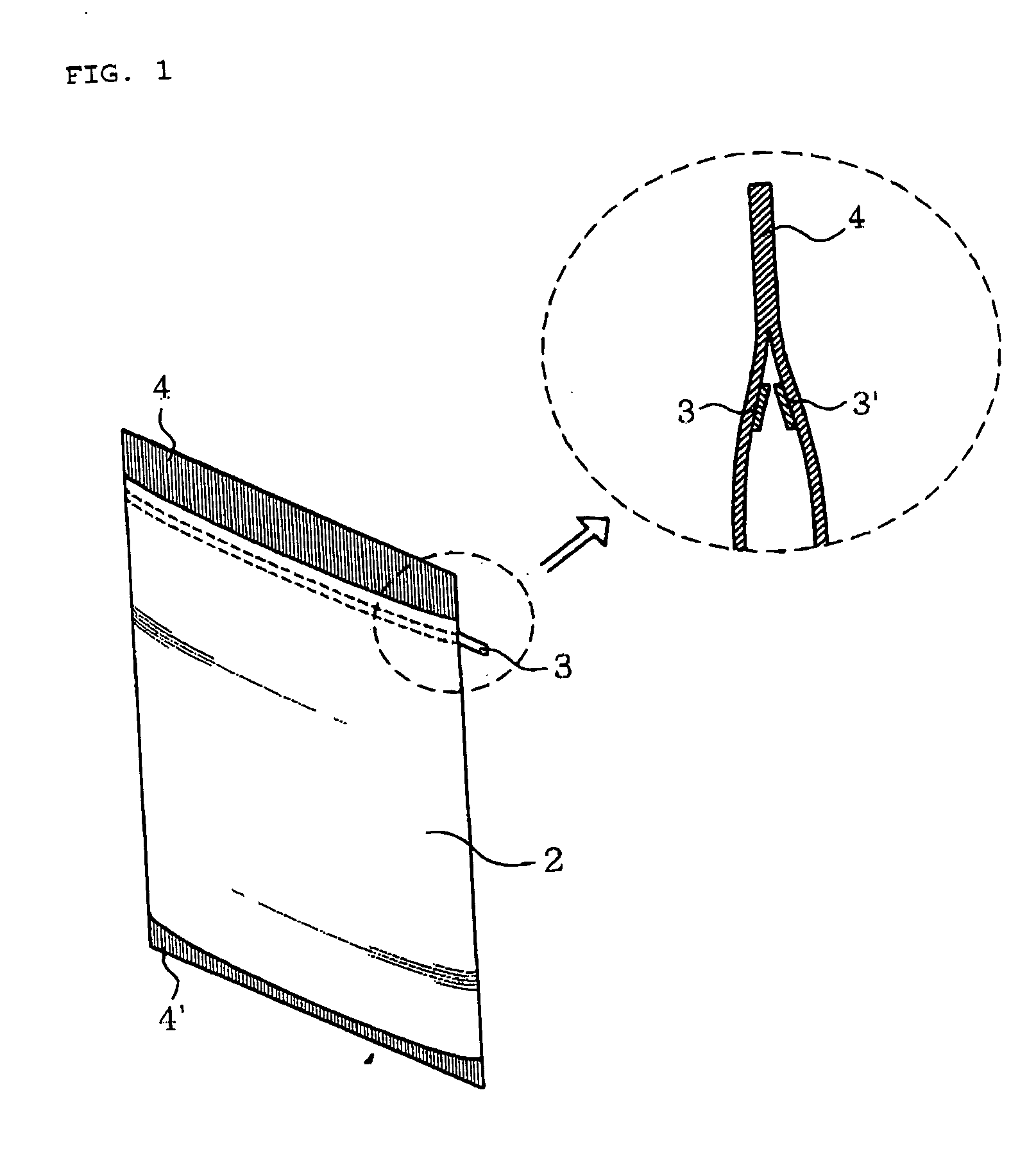

[0022] The plastic film bag according to the present invention will be described in detail with reference to FIG. 2.

[0023] In FIG. 2, the reference numeral 1 denotes a plastic film bag according to the present invention, 2 denotes a film bag body part, 3 and 3′ denote a tear tape, 4 and 4′ denote two seam welded parts, and 5 denotes a plastic fastener. In the present invention, the plastic film bag may be constructed without having the plastic fastener 5, unlike the preferred embodiment.

[0024] In the present invention, the plastic film, used as the material for the plastic film bag 1, may be selected from the group consisting of polyethylene films, polypropylene films, nylon films, polyester films, and papers impregnated with one of the above-mentioned synthetic resins which are polyethylene, polypropylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com