Ream wrap packaging with tear tapes

a technology of tear tapes and wrapping reams, which is applied in the field of new packaging, can solve the problems of destroying the integrity of the wrapping structure, exposing and scattering loose sheets of paper remaining in the ream, and affecting the storage of unbound papers, so as to prevent physical damage and scatter loose parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

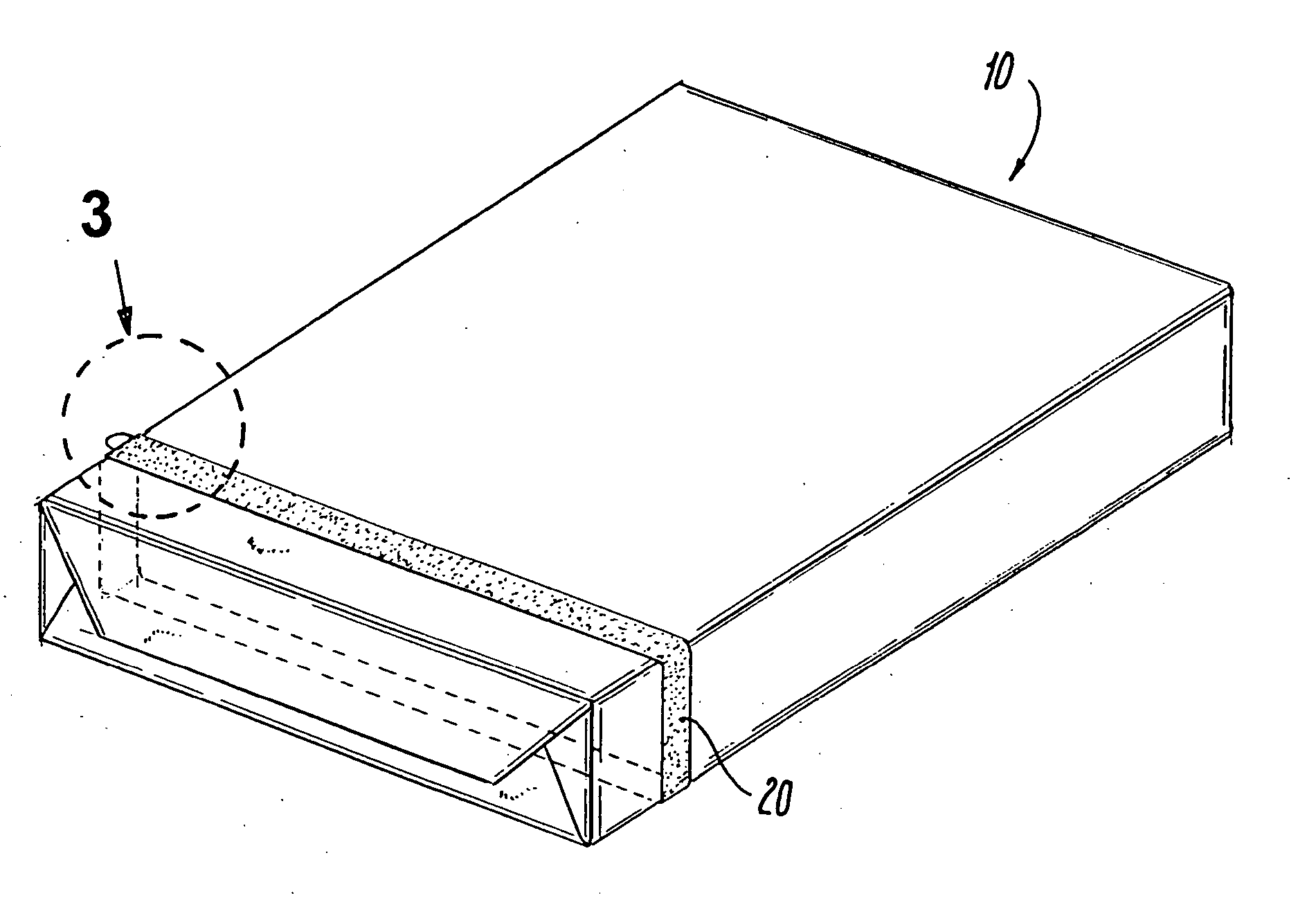

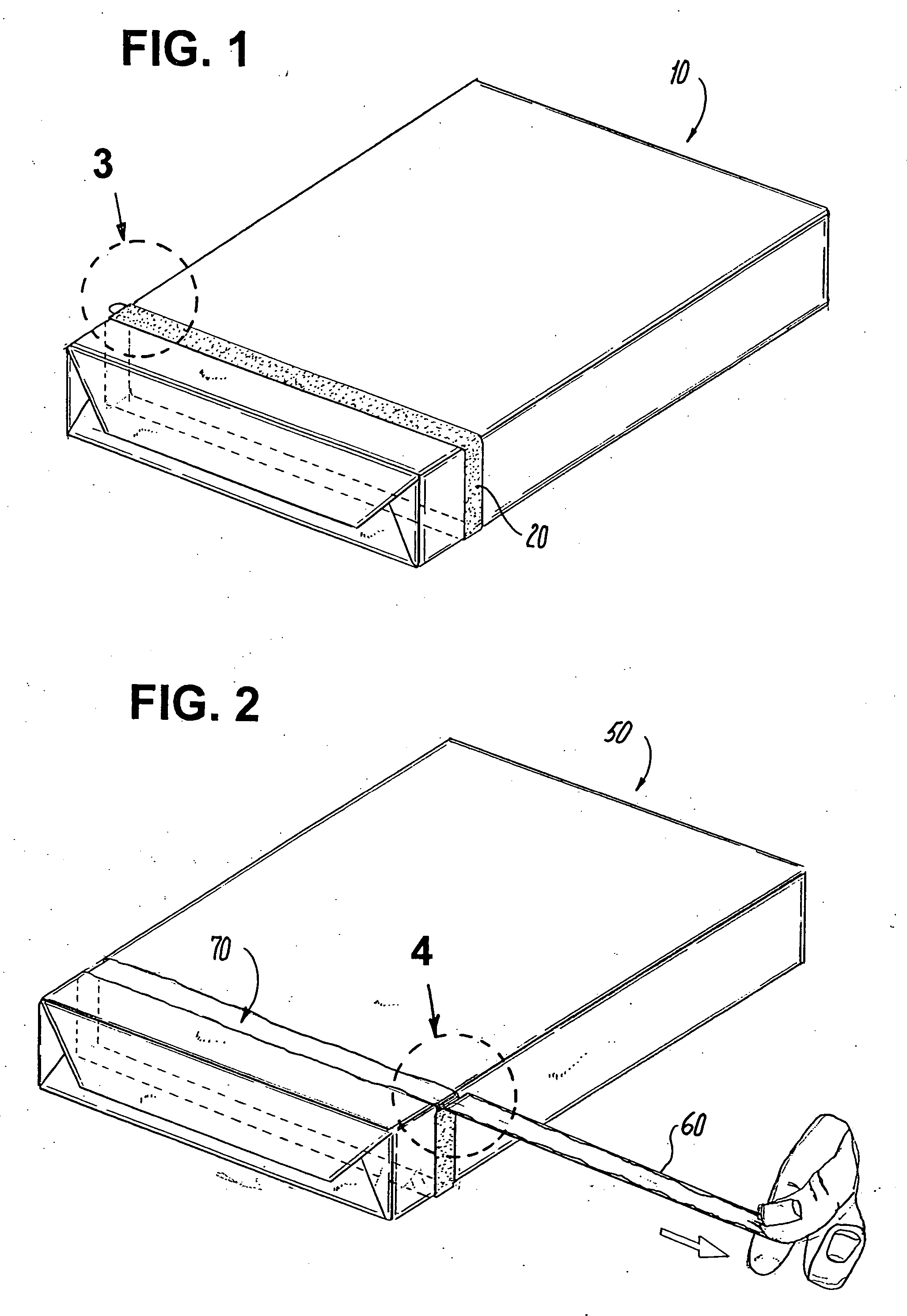

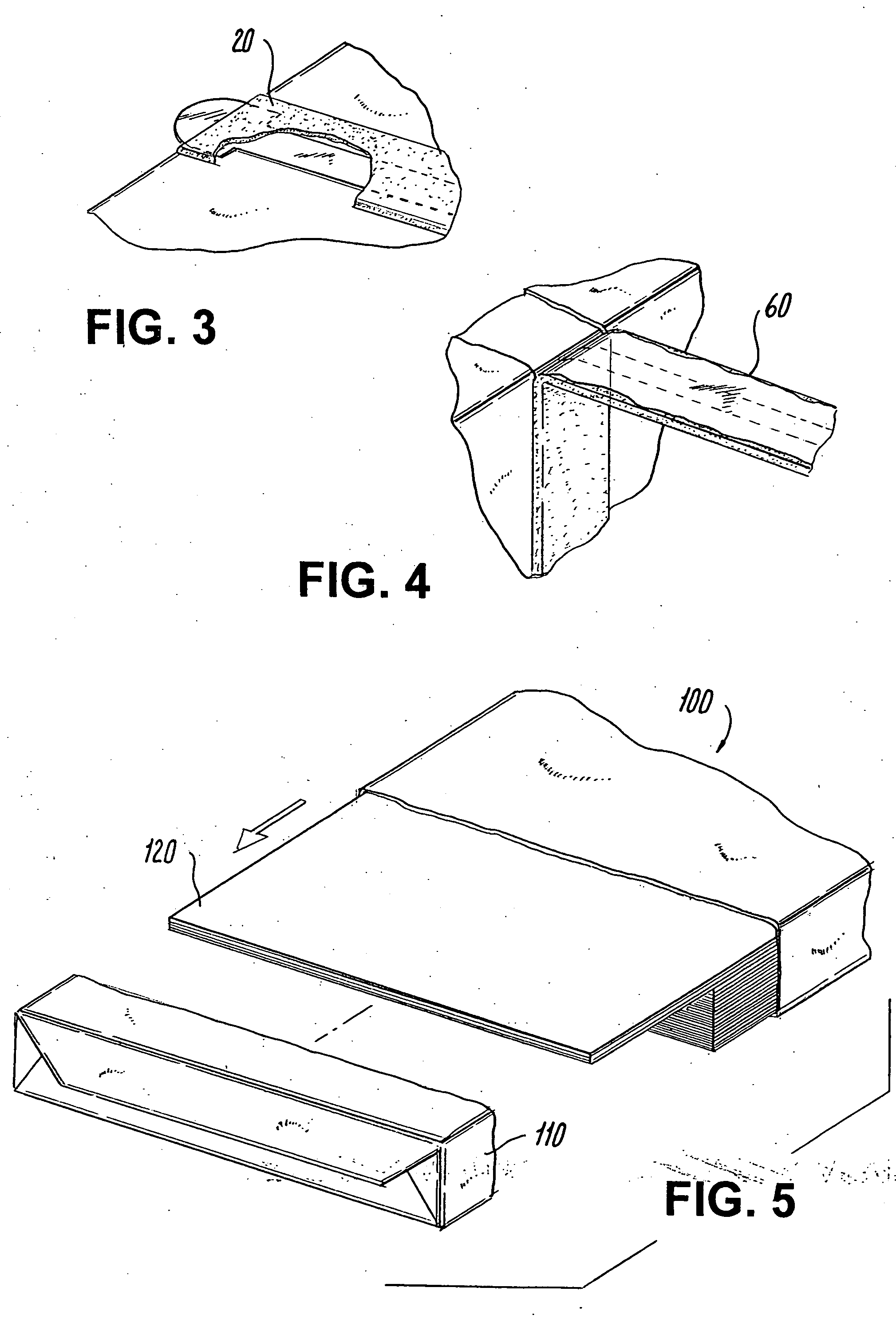

[0029] The present invention relates to a method of wrapping reams of paper involving the insertion of one or more tear tapes into the ream wrap. The tear tape, when pulled, enables the opening and removal of a sealed end of the ream wrap leaving a portion of the wrapper intact to protect, store, and dispense partial reams of paper. The tear tape is inserted in the ream wrap across the web and can be applied to any type of ream wrap packaging, including paper / poly, film, paper / film combination, or shrink wrap.

[0030] In one embodiment, the tear tape comprises a strip of paper or film that is drawn through or coated with wax. The wax is used to adhere the tear tape to the ream wrap. The tear tape is 1 / 32″ to 1½″ in width and is torn lengthwise, not across the width of the strip.

[0031] In another embodiment, the tear tape comprises a non-coated strip of paper or film that is heat-sealed onto the ream wrap. The tear tape is 1 / 32″ to 1½″ in width and is torn lengthwise, not across the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| physical damage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com